#Modern Planetary Mixer

Explore tagged Tumblr posts

Text

How Does a Planetary Mixer Work?

A Planetary Mixer operates through a unique mechanism that ensures thorough and efficient mixing of ingredients. Here’s a detailed look at how it works:

1. Planetary Mixing Action

The planetary mixer gets its name from the planetary motion it uses. In this mixing action:

Attachment Rotation: The mixing attachment (such as a paddle, whisk, or dough hook) rotates around its own axis.

Bowl Revolution: Simultaneously, the attachment orbits around the stationary bowl.

This dual movement ensures that every part of the bowl is reached, and ingredients are mixed uniformly. The attachment’s rotation combines with its orbital path to continually fold, beat, and knead the ingredients, providing a comprehensive mixing process.

2. Components of a Planetary Mixer

Several key components work together to create this effective mixing action:

Motor: Powers the mixing mechanism. The motor’s power and speed settings can be adjusted depending on the task.

Attachment Hub: Where different mixing attachments are mounted. The hub is designed to fit securely and allow the attachment to rotate and orbit.

Bowl: The container where ingredients are placed. It is usually made from stainless steel and can be fixed or adjustable, depending on the model.

Speed Control: Allows you to adjust the speed of the mixing attachment to suit various tasks, from slow mixing to high-speed whipping.

3. Different Attachments for Various Tasks

Planetary mixers come with a range of attachments, each designed for specific functions:

Flat Beater: Used for general mixing tasks, such as making batters, cookie dough, and cake mixtures.

Wire Whisk: Ideal for whipping cream, beating eggs, and aerating mixtures.

Dough Hook: Designed for kneading bread and pizza dough, it handles thicker and denser mixtures.

4. Mixing Efficiency

The planetary mixing action is highly efficient due to its ability to:

Ensure Even Mixing: The attachment’s dual movement prevents the formation of lumps or uneven mixtures.

Reduce Manual Intervention: The thorough mixing action means there’s less need to stop and scrape down the sides of the bowl.

Handle Large Quantities: The robust design and powerful motor allow the mixer to handle large volumes of ingredients effectively.

5. Bowl and Attachment Design

The design of the bowl and attachments also contributes to the mixer’s performance:

Bowl Shape: Most bowls are designed with a slight tilt or bowl-lift mechanism to facilitate easy access and mixing. Some models feature a rotating bowl, though most planetary mixers have a stationary bowl.

Attachment Material: Attachments are typically made from durable materials like stainless steel or coated aluminum to withstand heavy use and resist corrosion.

6. Additional Features

Modern planetary mixers may include additional features to enhance functionality and convenience:

Tilt-Head or Bowl-Lift Mechanism: Allows easy access to the bowl and attachment, facilitating ingredient addition and removal.

Splash Guard: Helps to prevent spills and messes during mixing.

Timer and Digital Controls: Some models offer programmable settings and digital displays for precise control over mixing times and speeds.

What is a Planetary Mixer?

A Planetary Mixer is a type of stand mixer known for its robust construction and versatile functionality. Unlike hand mixers, which require constant manual operation, planetary mixers are stationary and powered by an electric motor. Their design is inspired by the way planets orbit the sun, hence the name “planetary.” The mixing attachment rotates around its own axis while orbiting around the bowl, ensuring thorough and even mixing of ingredients.

Conclusion

The planetary mixer’s distinctive action — rotating the attachment while it orbits around the bowl — ensures comprehensive and consistent mixing. This efficient mechanism, combined with various attachments and speed settings, makes the planetary mixer an invaluable tool for both home cooks and professional chefs. Whether you’re whipping up a light meringue or kneading a heavy bread dough, understanding how your planetary mixer works can help you make the most of its capabilities and achieve perfect results every time.

For more details, please contact us!

Website :- https://www.pharmaceutech.com/

Contact No. :- +91–9873069138, +91–8896456000

Email :- [email protected], [email protected]

#Planetary Mixer#Planetary Mixers#Modern Planetary Mixer#Modern Planetary Mixer Manufacturer#Planetary Mixer supplier in India#instech pharma#Pharmaceutech

1 note

·

View note

Text

Bakery Processing Equipment Market Outlook: Opportunities & Challenges Ahead

Executive Summary

The global bakery processing equipment market is entering a pivotal phase marked by accelerated growth, technological advancements, and shifting consumer preferences. Anticipated to grow at a compound annual growth rate (CAGR) of 5.9% between 2023 and 2030, the market is projected to expand significantly from its 2022 valuation, reaching multi-billion-dollar scale by decade’s end.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40325-global-bakery-processing-equipment-market

Bakery Processing Equipment Market Drivers and Challenges

Key Growth Drivers

Robust global demand for baked goods—bread, pastries, cookies—fuels sustained investment in equipment.

Surge in automation: artificial intelligence (AI), Internet of Things (IoT), and energy-efficient systems redefine processing workflows.

Expansion in high-growth regions such as India, China, Brazil, and Southeast Asia, with both industrial and artisanal bakeries scaling operations.

Consumer demand for specialty products—organic, vegan, gluten-free—drives need for adaptable machinery.

Bakery Processing Equipment Market Operational Challenges

High capital expenditure remains a barrier to adoption for small and mid-sized bakeries.

Regulatory scrutiny: compliance with food safety, hygiene, labor, and energy standards increases complexity.

Maintenance demands: industrial-scale equipment requires specialized skills for upkeep, posing cost and training challenges.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40325-global-bakery-processing-equipment-market

Equipment Type Segment Insights

Mixers and Blenders

Batch, spiral, and planetary mixers are key due to their versatility across mixing-intensive bakery processes. Spiral mixers, in particular, are gaining adoption for their superior thermal control during kneading, preserving dough quality at large scale.

Dividers and Rounders

Automated dough dividing and rounding systems boost efficiency, reduce labor dependency, and deliver consistent portion sizes. Next-generation machines featuring servo-driven control boards allow programmable precision and adaptability for multi-SKU output.

Molders and Sheeters

Molders and sheeters are forecast to be the fastest-growing equipment category at a CAGR of approximately 6.8%, due to increasing demand for standardized shaping in bakery offerings. Variable-speed rollers enable seamless transitions between dough types and product formats.

Ovens and Proofers

Accounted for the largest revenue share in 2022 at approximately 33.7%. Modern ovens now include low-energy convection systems with zone-controlled heating and humidity retention, designed to reduce utility consumption and support high output.

End‑Use Application Trends

Bread remains the dominant product segment, accounting for nearly one-third of total revenue. Consumer demand in North America and Europe is driving the segment, with emerging economies like India and China showing rapid growth.

Meanwhile, pizza crusts represent the fastest-growing application, with a projected CAGR of about 6.5%, spurred by the global expansion plans of Western pizza chains.

Regional Bakery Processing Equipment Market Highlights

North America

A mature market where industrial bakeries seek automation, energy efficiency, and compliance. Manufacturers such as The Middleby Corporation and Markel Food Group lead deployments in commercial environments.

Europe

Stricter food safety and sustainability standards dominate. European bakeries prioritize artisanal baking solutions with hygiene certifications and lifecycle sustainability measures, driving frequent equipment upgrades.

Asia‑Pacific

The fastest-growing regional market, propelled by urbanization and rising bakery chains. Key manufacturers including Bühler AG and Anko Food Machine Co., Ltd. are expanding local manufacturing to meet demand.

Middle East & Africa

Investment in hospitality and retail sectors supports market growth. The rise of Western-style bakery chains drives new equipment demand.

South America

Adoption of automated bakery lines is gradually increasing, particularly in Brazil and Argentina, with manufacturers investing to modernize local bakery facilities.

Key Global Bakery Processing Equipment Market Manufacturers

Ali Group S.r.l. (Italy): Full-spectrum bakery solutions spanning mixers to packaging lines.

Baker Perkins Limited (United Kingdom): Renowned for mixers, proofers, and sheeters.

Bühler AG (Switzerland): High-volume production lines, especially for industrial-scale baking.

GEA Group AG (Germany): Precision equipment for high-efficiency bakery operations.

The Middleby Corporation (USA): Automated industrial baking systems with digital controls.

Koenig Maschinen GmbH (Austria): Artisan-focused machinery enabling high-quality bakery output.

Heat and Control Inc. (USA): Equipment that spans baking to sorting, slicing, and packaging.

Bakery Processing Equipment Market Forecast and Opportunities

From 2023 to 2030, the market is forecast to grow steadily at a 5.9% CAGR. The total market value is expected to follow a trajectory from approximately USD 10.2 billion in 2023 to nearly USD 14.9 billion by 2030.

Strategic growth areas include:

IoT-enhanced equipment enabling remote diagnostics, maintenance scheduling, and productivity tracking.

Cloud-connected control panels for real-time oversight and data analytics.

Modular, upgradeable systems suited to evolving production requirements.

AI-powered energy optimization tools that reduce costs and lower carbon footprint.

Regulatory Landscape

Growing alignment with HACCP and global food safety protocols.

Increasing requirements for energy efficiency labeling and certification.

Ergonomic design mandates in North America and the E.U. to support worker safety and productivity.

Competitive Posture

Manufacturers differentiate through digital integration, energy optimization, and modular design. Strategic initiatives include regional facility expansion—especially in Asia-Pacific—and mergers or partnerships to enhance technological capabilities and reach.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40325-global-bakery-processing-equipment-market

Strategic Recommendations

Prioritize R&D investments in smart, flexible equipment capable of meeting emerging bakery formats.

Optimize for energy consumption and connectivity to align with regulatory and sustainability goals.

Expand distribution frameworks in high-growth regions by forging local service partnerships.

Deepen focus on end-use segments such as pizza crusts and artisan breads to align with evolving consumer tastes and market expansion.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] The Brewine 1800W Stand Mixer is an essential kitchen companion for anyone who loves to bake, cook, or prepare food with ease. With its robust 1800-watt motor and a large 6-liter stainless steel bowl, this stand mixer delivers superior mixing power, enabling you to mix, knead, whip, and blend ingredients effortlessly. The sleek silver design complements any kitchen decor while the heavy-duty construction ensures long-lasting durability and reliability. Whether you're an amateur baker or a seasoned chef, the Brewine Stand Mixer will quickly become your go-to appliance for all your food prep needs. With its six adjustable speed settings, you can easily select the right speed for various tasks, whether it's stirring a delicate batter, whipping cream, or kneading thick dough. The mixer’s versatile design allows it to handle a variety of ingredients, giving you the freedom to experiment with different recipes. The included stainless steel bowl has a generous 6-liter capacity, providing ample space for large batches of dough, batter, or other ingredients. The high-quality construction of the bowl ensures it's both durable and easy to clean after use. The robust motor ensures smooth operation, even when mixing dense or heavy ingredients like bread dough. For safety, the Brewine 1800W Stand Mixer features non-slip feet, ensuring the unit remains firmly in place during use, preventing any unwanted movement or instability. The mixer is also equipped with a planetary mixing action, meaning the beaters rotate in multiple directions, ensuring that all ingredients are thoroughly mixed and no part of the bowl is left untouched. The included attachments, such as the dough hook, flat beater, and wire whisk, are all made of high-quality materials and designed to withstand frequent use. Each attachment serves a specific purpose, making this stand mixer versatile enough for a variety of tasks. From baking cakes, cookies, and bread to preparing savory dishes like mashed potatoes or pizza dough, the Brewine Stand Mixer is your ultimate kitchen helper. The Brewine 1800W Stand Mixer not only saves you time and effort but also makes food preparation more enjoyable. Its sleek silver finish, powerful motor, and durable construction make it the perfect addition to any kitchen. Whether you're preparing a family dinner or baking for a special occasion, this stand mixer is built to help you achieve perfect results every time. Powerful 1800W Motor: Delivers optimal mixing performance with ease, ideal for kneading, whipping, and blending. Large 6L Stainless Steel Bowl: Spacious design allows for large batches of dough, batter, and more – perfect for family-sized meals and baking projects. 6 Speed Settings: Customizable speed controls for a variety of tasks, from gentle stirring to high-speed whipping. Planetary Mixing Action: Ensures even mixing by rotating the beaters in multiple directions, ensuring no ingredient is left unmixed. Multiple Attachments: Includes a dough hook, flat beater, and wire whisk for versatile food preparation, perfect for baking, cooking, and more. Non-Slip Feet for Stability: Keeps the stand mixer firmly in place during use, preventing unwanted movement or slipping. Sleek Silver Design: A stylish and modern addition to any kitchen, blending seamlessly with your decor. [ad_2]

0 notes

Text

Concrete Batch Plant

Concrete Batch Plant: The Backbone of Modern Construction

In today’s fast-paced construction environment, the demand for efficiency, precision, and consistency in building materials has never been greater. At the core of this demand lies the concrete batch plant, a crucial facility that plays a central role in ensuring high-quality concrete production. Whether supporting small-scale residential builds or large infrastructure projects, the concrete batch plant is the silent engine powering much of what we see in our built environment. Understanding its function, importance, and various configurations offers valuable insights into the construction industry and how it continues to evolve.

Understanding the Basics of a Concrete Batch Plant

A concrete batch plant is a facility used to combine various ingredients to form concrete. These ingredients typically include water, cement, sand, aggregate (rocks, gravel, etc.), and sometimes admixtures to modify specific properties of the concrete. The goal is to produce a mix that meets project specifications while ensuring uniform quality, whether delivered directly to a job site or precast into structural elements.

There are two main types of concrete batch plants: ready-mix and central mix. Ready-mix plants blend the ingredients and load them into a truck-mounted mixer for final mixing en route to the site. Central mix plants, on the other hand, mix all components on-site before loading them into a truck, often resulting in better control over consistency and performance.

Key Components of a Concrete Batch Plant

A concrete batch plant is more than just a collection of silos and conveyors. It is a sophisticated system designed to handle precise formulations, efficient delivery, and compliance with strict standards. The key components of a concrete batch plant include:

Aggregate Bins and Conveyors These hold and transport sand, gravel, and other aggregates to the mixing unit. The bins are often divided into multiple compartments to accommodate various sizes and types of material, while conveyors or skip hoists move the materials efficiently within the plant.

Cement Silos and Feeders Cement is typically stored in vertical silos to keep it dry and accessible. Feeders measure out the required amount and transfer it to the mixing chamber. A dust collection system is commonly installed to mitigate airborne particles.

Water System Precise water measurement is crucial for concrete strength and workability. Modern plants use flow meters and valves to ensure accuracy, which directly affects the performance of the final product.

Mixing Unit The mixer can be pan, planetary, or twin-shaft in design, each offering different advantages in mixing efficiency and output quality. The choice of mixer depends on production requirements and concrete specifications.

Control System Today’s batch plants are automated with programmable logic controllers (PLCs) and software that ensure exact formulations, quality control, and real-time data tracking. Operators can monitor every stage of production and make immediate adjustments as needed.

Types of Concrete Batch Plants

Not all concrete batch plants are built the same. They can be categorized based on mobility, scale, and mixing process.

Stationary Batch Plants Stationary plants are designed for long-term, high-volume production. These are typically used in infrastructure and commercial developments where consistent output is needed over an extended period. Their robust design allows for larger silos, more storage capacity, and powerful mixers.

Mobile Batch Plants Mobile batch plants offer the flexibility to be transported and set up at or near a construction site. These plants are ideal for remote projects or temporary operations where building a full-scale stationary plant would be impractical.

Dry Batch Plants In dry batch plants, all the ingredients except water are mixed and loaded into the truck. The water is added at the job site, and mixing takes place in transit. While more flexible for longer delivery distances, this method can sometimes result in less consistent concrete if not carefully controlled.

Wet Batch Plants These plants mix all ingredients, including water, at the plant site. This method ensures higher precision and uniformity, making it the preferred choice for projects with strict quality requirements.

Advantages of a Concrete Batch Plant

A well-operated concrete batch plant provides numerous advantages to the construction industry:

Improved Quality Control Batch plants allow for controlled and consistent mixing, which is essential for meeting the structural demands of modern buildings and infrastructure. Variability in concrete quality can lead to significant safety risks and structural failures.

Cost Efficiency Producing concrete on-site or nearby reduces the need for long-distance transportation, minimizing fuel costs and delays. Additionally, bulk purchasing and automated systems reduce material wastage.

Environmental Benefits Modern batch plants are designed with environmental considerations in mind. Features such as dust collectors, recycling systems, and water reclamation help reduce the plant’s ecological footprint.

Customization and Versatility A concrete batch plant can be configured to produce a wide range of concrete types, from high-performance to lightweight mixes. This adaptability is critical in meeting the specific needs of diverse construction projects.

Rapid Production and Delivery Automation and high-capacity mixing systems enable batch plants to produce large volumes of concrete quickly. This rapid turnaround supports tight construction timelines and reduces on-site labor downtime.

Safety and Compliance in Concrete Batch Plants

Operating a concrete batch plant involves strict adherence to safety and environmental regulations. Operators must be trained in equipment handling, chemical safety, and emergency response procedures. Regular inspections, proper ventilation, and dust control are essential for maintaining a safe working environment.

In addition to safety protocols, compliance with local, state, and federal regulations is critical. This includes air and water quality standards, noise control, and waste management. Advanced plants may integrate environmental monitoring tools to ensure ongoing compliance and reduce the risk of fines or shutdowns.

Challenges Facing Concrete Batch Plants

Despite their many benefits, concrete batch plants face several challenges. Urban environments, for instance, may limit plant installation due to zoning restrictions or concerns about noise and emissions. Additionally, fluctuating raw material costs and labor shortages can affect operational efficiency.

Technological adaptation is another hurdle. While automation improves productivity, it requires skilled technicians and investments in maintenance. Plants that fail to modernize risk falling behind in efficiency and compliance.

The Future of Concrete Batch Plants

The future of concrete batch plants lies in increased automation, sustainability, and digital integration. Emerging technologies like IoT sensors, AI-based quality prediction, and carbon capture systems are reshaping how batch plants operate. Modular plant designs are also gaining traction, allowing for scalable production that adjusts to project needs.

Sustainability remains a key focus. As the construction industry strives for greener solutions, batch plants are adopting alternative binders, recycled aggregates, and water-saving practices. Innovations in cement alternatives, like fly ash and slag, help reduce the carbon footprint of concrete production without compromising performance.

Additionally, cloud-based control systems and data analytics are empowering plant managers to make data-driven decisions. Real-time insights into mix performance, material usage, and maintenance needs create opportunities for continuous improvement and resource optimization.

Conclusion

A concrete batch plant is far more than a manufacturing facility—it is the heart of modern construction, driving efficiency, consistency, and innovation. As the demand for sustainable, high-quality concrete continues to rise, batch plants will play an increasingly strategic role in delivering the materials that shape our cities and infrastructure. By understanding the components, benefits, challenges, and future trends of a concrete batch plant, stakeholders across the construction sector can make informed decisions that enhance project outcomes and support long-term industry growth.

1 note

·

View note

Text

Mobile Concrete Plant

Mobile Concrete Plant The construction industry is evolving rapidly, and with increasing demand for efficiency and flexibility, traditional stationary methods of producing concrete are being reimagined. At the forefront of this transformation is the mobile concrete plant. Designed to bring production directly to the job site, mobile concrete plants offer a game-changing solution for both small-scale operations and large infrastructure projects. These portable units are reshaping how contractors and builders approach time-sensitive construction challenges, providing agility without sacrificing quality. Understanding What a Mobile Concrete Plant Is A mobile concrete plant is a portable facility that enables on-site mixing and production of concrete. Unlike stationary plants that require a permanent setup and significant space, mobile plants are mounted on trailers or skids, allowing them to be easily transported from one location to another. They consist of all essential components including aggregate bins, cement silos, mixers, conveyors, and control systems, all housed within a compact and mobile design. This flexibility makes the mobile concrete plant a highly efficient option, especially for remote areas or projects that demand rapid setup and movement. Whether it's for road construction, residential builds, bridges, or infrastructure development, having the ability to mix concrete on-demand right where it's needed can significantly cut down on transportation time and material waste. Key Components and Features of a Mobile Concrete Plant Modern mobile concrete plants are engineered with efficiency, automation, and portability in mind. While configurations may vary, most units are composed of several core components:

Aggregate Bins – These bins store different types of aggregates (sand, gravel, crushed stone) used in the concrete mix. They're typically separated by compartments and equipped with weigh belts or batchers for precise measurement.

Cement Silo – A mobile concrete plant usually includes an onboard cement silo for storing powdered cement. This silo is integrated with feeding systems to automatically deliver cement into the mixer.

Mixing Unit – The heart of the plant, the mixer blends all ingredients into a uniform mixture. Mobile plants may use twin shaft, pan, or planetary mixers depending on the desired output and consistency.

Water System – Precise water control is critical to achieving the correct concrete slump. The system includes pumps, tanks, and meters for accurate dosing.

Control Panel – Fully automated systems enable operators to manage batching, mixing, and monitoring operations through a centralized control panel. Advanced models feature programmable logic controllers (PLC) and real-time data feedback.

Chassis and Wheels – Mounted on a strong chassis with road-legal wheels and axles, the entire system can be towed by truck or transported via flatbed. These features make the mobile concrete plant an all-in-one, ready-to-deploy solution ideal for a wide range of field conditions. Benefits of Using a Mobile Concrete Plant The advantages of using a mobile concrete plant extend far beyond just convenience. These plants deliver measurable gains in productivity, cost savings, and project timelines. Here’s how:

Enhanced Flexibility and Portability A mobile concrete plant can be moved to different job sites with minimal effort. This is especially useful for contractors managing multiple projects or working in areas without access to ready-mix suppliers. The ability to produce concrete exactly where it is needed eliminates the delays and costs associated with transporting wet concrete over long distances.

Faster Project Turnaround On-site production of concrete enables immediate pouring and reduces idle time. Crews don’t have to wait for scheduled deliveries or worry about concrete setting during transit. As a result, projects can move forward faster, which is critical for tight deadlines and weather-dependent jobs.

Improved Concrete Quality Because concrete is produced fresh on-site, its properties can be closely controlled. The mix can be adjusted instantly based on environmental conditions or project-specific requirements, improving strength, consistency, and durability. This level of quality control is hard to achieve when relying on third-party suppliers.

Reduced Material Waste A mobile concrete plant allows for precise batching based on actual demand, minimizing leftover material. This not only reduces waste and environmental impact but also cuts down on disposal costs. Additionally, leftover concrete from a pour can often be reused for smaller tasks on the same site.

Cost Savings Over Time Although the upfront investment in a mobile concrete plant may seem significant, the long-term savings are compelling. Contractors save on delivery fees, reduce reliance on suppliers, and mitigate the risk of delays caused by logistical issues. Over time, the plant pays for itself through improved efficiency and cost control.

Ideal for Remote or Rural Projects In areas where access to traditional batching plants is limited or nonexistent, mobile units offer a viable solution. Whether it’s building in mountainous terrain, agricultural zones, or disaster relief areas, the mobile concrete plant provides a reliable method for continuous concrete production. Challenges and Considerations Despite the many benefits, operating a mobile concrete plant does come with its own set of challenges. It’s important to recognize these limitations to ensure optimal performance and ROI.

Operator Training Operating a mobile plant requires skilled personnel who understand both the mechanical and software components of the system. Training is essential to ensure safety and to achieve consistent quality in the mix.

Maintenance Requirements Like any piece of heavy machinery, mobile plants require routine maintenance to keep them operating efficiently. Components such as mixers, conveyors, and pumps must be regularly inspected, cleaned, and serviced to prevent breakdowns.

Permitting and Compliance Even though mobile, these plants still need to comply with local zoning, environmental, and safety regulations. Depending on the jurisdiction, obtaining the necessary permits to operate a mobile concrete plant may take time and require documentation regarding emissions, dust control, and noise levels.

Initial Investment While cost-effective over the long term, acquiring a mobile concrete plant is a capital-intensive decision. Small or emerging contractors need to carefully assess their project pipeline and operational capacity before committing to the purchase.

Site Preparation Even though the plant is mobile, it still needs a stable base to operate from. The site must be level, have access to water and power (or generators), and be configured to safely receive raw materials and dispatch the finished product. Applications of Mobile Concrete Plants The versatility of mobile concrete plants makes them suitable for a wide variety of projects. Some common applications include: • Highway and Road Construction – Eliminates the need for long hauls and provides fresh concrete for paving and repair. • Bridge and Infrastructure Projects – Produces customized mixes on-site for piers, beams, and foundations. • Residential and Commercial Development – Enables small batch pours for footings, slabs, and driveways without depending on external suppliers. • Remote Mining or Energy Operations – Supplies concrete in isolated locations where traditional logistics are impractical. • Emergency Relief and Disaster Response – Allows quick setup to restore infrastructure in crisis-affected regions. Conclusion A mobile concrete plant offers an intelligent, agile alternative to traditional batching facilities, empowering construction teams to produce high-quality concrete on demand, wherever it’s needed. Its combination of portability, precision, and productivity makes it a powerful tool in today’s competitive and fast-paced construction landscape. For contractors who value speed, control, and reliability, the mobile concrete plant stands out as a vital asset that can transform the way concrete is delivered and applied on-site.

concreteplanters #concrete #concreteplanter #concretepots #concretedesign #plants #concreteart #interiordesign #planters #cement #concretedecor #parkercolorado #denver #castlerockcolorado #denvercolorado #littletoncolorado #lonetreecolorado #colorado #highlandsranchcolorado

1 note

·

View note

Text

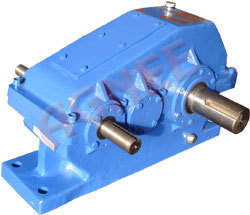

Reduction Gearboxes in Food Processing: Benefits + Best Practices

In food processing, precision, reliability, and hygiene are non-negotiable. Every component in a food production system must be designed to meet high standards, and reduction gearboxes are no exception. These vital components ensure that machinery operates at the correct speed and torque, enabling smooth and efficient processing. This article explores how reduction gearboxes support food industry operations, key benefits, and best practices for selection and maintenance.

Reduction Gearboxes Overview

What is a Reduction Gearbox?

A reduction gearbox is a mechanical device that reduces the speed of an input shaft while increasing the torque. This change in speed and torque is essential for applications that require controlled movement and power efficiency—common requirements in food processing operations. By lowering the RPM (revolutions per minute), gearboxes allow machines to perform more delicate or precise tasks without compromising power.

How it Works in Food Processing Machinery

In food processing, machines like mixers, conveyors, slicers, grinders, and packaging equipment all rely on consistent and accurate motion. A reduction gearbox connects to the motor and adjusts its output to suit the application's needs. For instance, a dough mixer requires slower, high-torque movements to knead properly—something that a gearbox enables by moderating the speed from the electric motor.

Moreover, food processing involves start-stop cycles, variable speeds, and continuous duty operations. Reduction gearboxes help maintain machine stability and protect motors from unnecessary stress or overload, extending the lifespan of the entire system.

Common Types Used in the Food Industry

Several types of gearboxes are used across food processing environments. Common ones include:

Helical Gearboxes: Known for their smooth and quiet operation, ideal for continuous food production lines.

Worm Gearboxes: Compact and suitable for applications requiring high torque at low speeds.

Planetary Gearboxes: Offer high efficiency and are perfect for heavy-duty tasks requiring a compact footprint.

Bevel Gearboxes: Used where right-angle motion is needed in limited space.

When paired with a reliable industrial gearbox, these types are instrumental in improving operational output while maintaining hygienic standards.

Key Benefits of Reduction Gearboxes in Food Processing

Reduction gearboxes offer multiple benefits in food processing, which include:

1. Enhanced Precision

Food processing requires accurate dosing, cutting, mixing, and packaging. Gearboxes enable the machinery to perform these operations with precision by providing the right speed and torque, reducing product waste and improving quality consistency.

2. Improved Hygiene Standards

Modern reduction gearboxes are designed for environments where cleanliness is paramount. Stainless steel housings, smooth surfaces, and sealed designs prevent bacterial contamination and support CIP (clean-in-place) protocols. This is crucial in ensuring compliance with food safety regulations.

3. Energy Efficiency

By regulating speed and reducing mechanical load, gearboxes significantly lower energy consumption. Machines run more efficiently, and motors operate under less strain, resulting in long-term energy savings—an important factor in reducing operational costs.

4. Noise and Vibration Reduction

Reduction gearboxes minimize noise and vibration, which not only makes the environment more comfortable for workers but also reduces wear and tear on machinery, leading to fewer breakdowns and longer equipment life.

5. High Torque Output

In tasks like grinding meat or mixing dough, high torque is essential. Gearboxes step down motor speed while multiplying torque, enabling machines to handle demanding tasks more effectively.

Best Practices for Selecting the Right Reduction Gearbox

Choosing the appropriate gearbox is critical to achieving optimum performance and reliability. Here are some best practices to follow:

1. Assess Application Requirements

Determine the specific load, torque, and speed requirements of the machinery. Consider duty cycles, environmental conditions, and whether continuous or intermittent operation is needed.

2. Material and Build Quality

Food-grade materials such as stainless steel are non-negotiable. Ensure the gearbox has appropriate ingress protection (IP ratings) and corrosion resistance, especially in washdown environments.

3. Compatibility with Motor and System

The gearbox should integrate smoothly with existing systems. Check for alignment, shaft size, mounting options, and gear ratio compatibility.

4. Hygienic Design Standards

Look for gearboxes that are certified or designed to meet industry standards such as FDA, USDA, or EHEDG guidelines. These ensure that the unit can be cleaned easily and doesn’t harbor contaminants.

5. Supplier Reliability and Support

Work with trusted manufacturers or suppliers who provide technical support, after-sales service, and customization options if needed.

Maintenance Tips to Maximise Gearbox Performance

Proper maintenance not only prolongs the life of a gearbox but also safeguards your food processing operations from unplanned downtimes.

1. Regular Inspection

Inspect gearboxes periodically for unusual noise, leaks, temperature spikes, and vibrations. Early detection of issues helps prevent major failures.

2. Lubrication Checks

Use food-grade lubricants approved for your equipment. Monitor levels and contamination, and adhere to the manufacturer’s lubrication schedule.

3. Seal and Gasket Integrity

Seals and gaskets should be checked regularly for wear or damage. In hygienic environments, even small leaks can lead to contamination or mechanical failure.

4. Monitor Load Conditions

Avoid operating gearboxes under load conditions beyond their rated capacity. Overloading can cause overheating, misalignment, and accelerated wear.

5. Clean Carefully

When cleaning, ensure water or chemical sprays do not enter the gearbox. Use CIP-compatible gearboxes where possible to maintain internal integrity.

Why Partner with Santram Engineers

Choosing the right partner can make a significant difference in the performance and reliability of your food processing systems. Santram Engineers is a leading name in industrial power transmission, offering robust and hygienically designed gearboxes ideal for food industry applications.

Why Santram?

Expertise in Food-Grade Gearboxes: Our products are designed to meet strict hygiene standards while delivering top-tier performance.

Trusted Brands: We work with global gearbox brands to provide reliable solutions with a proven track record.

After-Sales Support: From installation guidance to preventive maintenance programs, we ensure your systems run without interruption.

Customization Options: We understand that each processing line is unique, so we offer tailored solutions to meet your exact needs.

Whether you're upgrading your existing setup or designing a new production line, Santram Engineers is committed to delivering the best reduction gearbox solutions tailored for the food industry.

Read More: https://www.santramengineers.com/reduction-gearboxes-food-processing-benefits-best-practices/

0 notes

Text

Understanding the Essential Components of a Stationary Concrete Batching Plant

A stationary concrete batching plant is a cornerstone of high-volume concrete production, ensuring efficiency, consistency, and quality in construction projects. Unlike mobile batching plants, stationary models are designed for long-term operations, making them ideal for infrastructure developments, commercial buildings, and industrial applications. Let's explore the key components that contribute to their seamless functionality. 1. Aggregate Storage and Handling System Aggregates, such as sand, gravel, and crushed stone, are stored in bins or silos. The plant uses conveyors or skip hoists to transfer these materials to the mixing unit. Precision in handling aggregates ensures a well-balanced concrete mix. 2. Cement Storage and Feeding System Cement is stored in silos, which protect it from moisture contamination. The screw conveyor system transports cement from the silo to the mixing unit, maintaining accuracy in proportioning. 3. Water Dosing System A carefully calibrated water metering system guarantees the correct water-to-cement ratio, affecting concrete strength and workability. Some advanced plants integrate automated moisture sensors to adjust water input based on aggregate conditions. 4. Admixture System Chemical admixtures enhance specific concrete properties such as strength, durability, and setting time. The batching plant features an admixture dosing unit, which ensures precise and uniform dispersion in the mix. 5. Mixing Unit The heart of the batching plant, the mixing unit, typically consists of either a twin-shaft mixer, planetary mixer, or drum mixer, depending on the required output and application. It ensures homogeneity and consistency by thoroughly blending materials. 6. Control System Modern plants integrate a fully automated control panel, allowing operators to monitor and adjust parameters efficiently. Advanced systems incorporate PLC-based technology with user-friendly interfaces for seamless operation. 7. Discharge and Delivery System Once mixed, the concrete is discharged into transit mixers, dump trucks, or directly onto site molds. A well-designed discharge system minimizes waste and ensures smooth workflow. Advantages of a Stationary Concrete Batching Plant - High Production Capacity – Ideal for large-scale projects requiring consistent concrete output. - Precision in Mix Designs – Automated systems enhance accuracy in material batching. - Durability & Longevity – Designed for continuous operation with minimal maintenance. - Environmental Efficiency – Dust collection systems reduce emissions, promoting sustainability. Stationary batching plants are indispensable for construction firms demanding superior concrete quality with reliable output. Whether for roadways, bridges, or industrial complexes, investing in a high-performance batching plant optimizes production and efficiency. Discover GAJJAR make extensive range of ready-mix concrete batching plants, designed to maximize productivity while maintaining strict environmental and safety compliance. Get in touch at +91-92270 22899 or email us at [email protected] for expert guidance, competitive pricing, and tailor-made solutions. Build with confidence—build smarter, faster, and stronger! Read the full article

0 notes

Text

Best Gearbox Manufacturer in Ahmedabad

A gearbox is a mechanical device used to increase torque and reduce speed or vice versa, depending on the application. It plays a crucial role in various machines and equipment, particularly in industries such as automotive, manufacturing, mining, agriculture, and power transmission. Gearboxes work by using a combination of gears to transmit mechanical power from a driving shaft to a driven shaft. These gears can be configured in several ways—spur, helical, bevel, or worm—based on torque requirements, speed, and direction of rotation. With advancements in engineering, modern gearboxes now offer higher efficiency, reduced noise levels, and compact designs. There are several types of gearboxes available in the market, including worm gearboxes, helical gearboxes, bevel gearboxes, planetary gearboxes, and inline gearboxes. Each type is tailored for specific load capacities and mechanical advantages. For instance, worm gearboxes are preferred for applications that require high torque output and minimal speed, while planetary gearboxes are known for their high efficiency and compact design in high-speed, high-load applications. Gearboxes are commonly made from durable materials like cast iron, aluminum, or stainless steel, ensuring they withstand harsh working environments and prolonged operational hours. Choosing the right gearbox depends on factors such as input speed, output torque, load characteristics, space constraints, and environmental conditions. Manufacturers listed on platforms like Indian Trade Bird offer a wide variety of gearboxes suitable for both heavy-duty industrial use and precision-based mechanical systems. Whether for conveyors, mixers, crushers, or power tools, gearboxes ensure smooth power transmission, reliability, and energy efficiency. Investing in a high-quality gearbox leads to reduced maintenance, longer machine life, and enhanced overall productivity.

For More Details Click Here: https://www.indiantradebird.com/product/gearbox

0 notes

Text

Trusted Bakery Equipment Manufacturer in Bangalore – Your Partner in Baking Excellence

In the fast-growing food industry of Bangalore, owning a bakery isn’t just about good recipes—it's about the right tools. To bake efficiently, maintain hygiene, and deliver consistent quality, you need top-class bakery equipment. If you're looking for a reliable bakery equipment manufacturer in Bangalore, you’re in the right place.

At Mountain Kitchen Equipment, we design and manufacture premium bakery machinery that makes baking easier, faster, and better. Our machines are built with modern technology, durable materials, and user-friendly designs to help you grow your bakery business with confidence.

Why Mountain Kitchen Equipment is the Leading Bakery Equipment Manufacturer in Bangalore

We are not just another equipment provider—we are your trusted baking partner. Mountain Kitchen Equipment has been serving bakeries, hotels, restaurants, and cloud kitchens across Bangalore and India. Our expertise in manufacturing customized, high-performance machines makes us a preferred choice for anyone setting up or upgrading a bakery.

Here’s why customers trust us:

✅ Custom-made equipment to suit your baking needs

✅ Strong stainless-steel body and long-lasting performance

✅ Modern design with energy-saving technology

✅ Efficient service and timely delivery

✅ Complete bakery setup and kitchen planning solutions

Whether you’re starting a small home bakery or a large-scale commercial unit, we have the perfect solutions for you.

Our Wide Range of Bakery Equipment

As a professional bakery equipment manufacturer in Bangalore, we offer a complete range of machines to support every stage of the baking process. All our equipment is designed to meet food safety standards, improve efficiency, and reduce manual labor.

1. Bakery Ovens

We offer a wide selection of ovens built for different types of baking:

Deck Ovens: Ideal for cakes, bread, and pizzas.

Rotary Rack Ovens: Designed for bulk baking with even heat distribution.

Convection Ovens: Faster and more uniform baking—perfect for bakeries with high demand.

All ovens are equipped with digital temperature control, timer settings, and energy-efficient operation.

2. Dough Kneaders & Mixers

Preparing dough by hand can be tiring and time-consuming. Our powerful dough mixers and kneaders are designed for smooth, lump-free mixing:

Spiral Mixers: Great for bread, buns, and pizza dough.

Planetary Mixers: Ideal for whipping cream, mixing batter, or kneading cake dough.

3. Dough Sheeters & Dividers

Speed up your production with machines that roll, divide, and portion your dough accurately and effortlessly. Perfect for puff pastries, pizza bases, and layered bakery items.

4. Bread Slicers

Get uniform slices every time. Our bread slicers are easy to operate, safe, and perfect for commercial bakeries and shops.

5. Proving Chambers (Fermentation Units)

Let your dough rise perfectly. Our proving chambers maintain ideal temperature and humidity, giving you soft, airy, and tasty results every time.

6. Bakery Display Showcases

Not just baking, but also displaying matters. We manufacture stylish display counters that keep your cakes, pastries, and desserts fresh and appealing.

Why Investing in Quality Bakery Equipment Matters

Working with a trusted bakery equipment manufacturer in Bangalore gives you more than just machines. It’s an investment in quality, speed, hygiene, and customer satisfaction. Here’s how:

✔ Increased Efficiency: Machines handle larger batches, saving time and manpower.

✔ Better Product Quality: Consistent baking leads to better taste, texture, and presentation.

✔ Energy Savings: Modern machines use less power, reducing electricity bills.

✔ Hygienic Operations: Stainless-steel and food-grade materials ensure safety and cleanliness.

✔ Long-Term Profitability: Durable equipment reduces maintenance and replacement costs.

Customized Solutions for Your Bakery Needs

No two bakeries are the same. That’s why we don’t believe in one-size-fits-all. As a leading bakery equipment manufacturer in Bangalore, we provide equipment tailored to your menu, space, and budget.

Whether you're running:

A retail bakery shop

A hotel kitchen

A cloud bakery

A café

A confectionery outlet

…we’ll help you choose the right machines and design the perfect kitchen layout.

We also provide kitchen planning services, including:

Site visit and space survey

BOQ and budgeting

Electrical & plumbing layouts

Ventilation and exhaust planning

Serving Bakeries Across Bangalore and Beyond

Mountain Kitchen Equipment has delivered bakery equipment to hundreds of clients across Bangalore and Karnataka. From Koramangala to Rajajinagar, Whitefield to Jayanagar, our machines are trusted by new entrepreneurs, experienced chefs, and bakery chains.

We have worked with:

Cloud kitchens

Hotel bakeries

Pastry shops

College canteens

Supermarket bakeries

Our commitment to quality and service makes us a dependable bakery equipment manufacturer in Bangalore for businesses of all sizes.

Frequently Asked Questions (FAQs)

Q1: What is the price of bakery equipment in Bangalore? Prices vary based on machine size and function. We offer competitive rates and value-for-money solutions. Get in touch for a custom quote.

Q2: Do you provide warranty and after-sales support? Yes, we provide warranty on all bakery machines along with complete service support, installation, and guidance.

Q3: Can I get custom-designed machines for my bakery space? Absolutely! We offer customized bakery solutions based on your kitchen size and production requirements.

Q4: How long will delivery take? Delivery times vary based on product type and customization. Standard equipment can be delivered in 7–10 working days.

Conclusion: Let’s Build Your Dream Bakery Together

Starting or expanding your bakery is a big step—and we’re here to make it easier. As a reliable bakery equipment manufacturer in Bangalore, Mountain Kitchen Equipment delivers high-quality machines, expert support, and tailor-made solutions to help you bake better and grow faster.

Our equipment is trusted by top bakeries across the city for its quality, performance, and lasting value. With our complete bakery setup services, you get everything you need from start to finish—under one roof.

📞 Contact us today to get started. Let’s create a kitchen that helps you bake with passion and serve with pride.

0 notes

Text

Boost Your Bakery’s Efficiency with the Dual Whisk Planetary Mixer

In the world of commercial baking, consistency, speed, and quality are non-negotiables. Whether you're whipping up airy meringues, mixing thick batters, or crafting fluffy whipped cream, having the right equipment makes all the difference. That’s where the Dual Whisk Planetary Mixer steps in as a game-changer for professional kitchens and bakeries alike.

What is a Dual Whisk Planetary Mixer?

At its core, a planetary mixer is named for its unique motion — the mixing attachments rotate on their own axes while simultaneously orbiting the bowl, much like the planets move around the sun. This movement ensures uniform mixing, reaching all areas of the bowl without needing manual intervention.

Now, take that powerful concept and double it — that's the magic of the Dual Whisk Planetary Mixer. Instead of one whisk or beater, this model comes with two synchronized whisks operating in tandem, significantly increasing the aeration and speed of your mixing process.

Key Benefits of the Dual Whisk System

Superior Mixing Efficiency The dual whisk setup means you can mix ingredients faster and more thoroughly. Whether you're preparing mousse, sponge cake batter, or egg whites, the increased contact and movement of two whisks make for quicker and more effective results.

Perfect for High-Volume Production Designed for medium to large-scale operations, the Dual Whisk Planetary Mixer is ideal for commercial bakeries, hotels, and food manufacturing units. Its powerful motor and high-capacity bowl allow continuous, heavy-duty use without compromising on performance.

Consistent Texture and Volume For recipes that require precise aeration — like soufflés or whipped creams — the dual whisk action ensures consistent volume and texture every time. Say goodbye to over-whipped or under-aerated batches.

Versatility with Attachments Many models offer interchangeable tools beyond whisks, such as dough hooks and flat beaters, turning your mixer into a multifunctional powerhouse. From kneading pizza dough to mixing cookie batter, it’s equipped for a variety of tasks.

User-Friendly Controls Most Dual Whisk Planetary Mixers come with intuitive digital or mechanical controls, allowing for variable speed settings, timers, and safety features — giving operators greater control and reducing fatigue.

Ideal Applications

This mixer isn’t just for sweets. It’s a versatile tool that can be used across multiple food prep categories:

Whipping large batches of cream or egg whites

Mixing batters for cakes and muffins

Preparing emulsions like mayonnaise or mousse

Even handling light doughs

Final Thoughts

The Dual Whisk Planetary Mixer is more than just a piece of equipment — it's an investment in your kitchen's productivity and quality control. For businesses looking to scale up without sacrificing consistency, this mixer delivers the power, precision, and performance that modern food production demands.

If you’re in the market for a robust, efficient, and versatile mixing solution, the dual whisk planetary mixer should be at the top of your list. Your recipes — and your bottom line — will thank you.

Let me know if you want it tailored for a specific brand, product model, or audience (like small bakeries or industrial use).

0 notes

Text

Precast Concrete Production Made Easy with a Reliable Concrete Batch Plant for Sale

Precast concrete has become an essential element in modern construction due to its durability, versatility, and efficiency. However, achieving high-quality precast elements requires a dependable and well-designed concrete batch plant for sale. These plants ensure precise material proportions, consistent mixing, and streamlined production, making them indispensable for large-scale and specialized projects. Investing in a reliable batch plant not only enhances production speed but also minimizes material wastage and operational inefficiencies.

When selecting a concrete batch plant for precast production, several factors must be considered. The right plant should provide accurate batching, high mixing efficiency, and automation features that optimize workflow. Additionally, it should be adaptable to different concrete formulations and project specifications. By choosing a robust and advanced batching solution, precast manufacturers can maintain high output quality while reducing costs and project delays.

Ensuring Precision and Consistency in Concrete Mixing

Automated Batching for Accurate Material Proportioning

One of the most critical aspects of precast concrete production is achieving precise material ratios. A high-quality batch plant integrates automated weighing and dosing systems that ensure every batch maintains uniform composition. This level of precision reduces variability in concrete properties, leading to structurally sound and aesthetically consistent precast components.

High-Performance Mixers for Uniform Blending

Mixing quality directly impacts the strength and durability of precast elements. Modern ready mix concrete plants are equipped with planetary or twin-shaft mixers, designed to create a homogeneous blend in minimal time. These mixers ensure even distribution of cement, aggregates, and admixtures, eliminating inconsistencies that could compromise the integrity of the final product.

Streamlining Production for Maximum Efficiency

Automated Control Systems for Seamless Operations

State-of-the-art concrete batch plants feature fully automated control systems that regulate mixing time, material flow, and moisture content. Operators can monitor and adjust settings in real-time, ensuring continuous production with minimal interruptions. This automation significantly reduces labor requirements and enhances overall productivity.

Optimized Material Handling and Storage

Efficient precast production depends on well-organized material management. Reliable batch plants incorporate silo storage, conveyor systems, and aggregate bins that facilitate smooth material flow. Properly designed material handling systems prevent contamination, segregation, and delays, resulting in a more efficient and cost-effective workflow.

Long-Term Cost Savings and Sustainable Production

Reducing Waste and Optimizing Resource Utilization

Investing in a high-quality portable concrete batch plant leads to substantial long-term savings by minimizing raw material waste and enhancing production efficiency. Advanced batching technology ensures that each batch meets project specifications, reducing the need for costly rework or material disposal.

Eco-Friendly Solutions for Sustainable Construction

Modern concrete batch plants are designed with sustainability in mind. Features such as recycled water systems, energy-efficient motors, and dust suppression units help reduce environmental impact. By adopting a reliable and eco-conscious batching solution, precast manufacturers can meet stringent industry regulations while contributing to greener construction practices.

0 notes

Text

Top 10 Bakery Equipment Manufacturer in Bangalore – High-Quality Solutions for Your Business

If you are planning to start or upgrade a bakery business, having the right equipment is crucial for efficiency and quality. Bangalore is home to several manufacturers that provide top-notch bakery equipment to meet the needs of both small and large-scale bakeries. Choosing the best manufacturer ensures durability, efficiency, and improved productivity. If you are searching for the Top 10 Bakery Equipment Manufacturer in Bangalore, Mountain Kitchen Equipment is a leading provider of high-quality, customized solutions tailored to your bakery’s needs.

Why High-Quality Bakery Equipment is Essential?

Investing in professional bakery equipment can enhance production efficiency, maintain food hygiene, and ensure consistent product quality. The right equipment allows bakers to work smoothly, minimize waste, and increase output while maintaining high standards.

Key Benefits of Using Professional Bakery Equipment

Efficiency & Speed Commercial-grade bakery equipment speeds up the baking process, ensuring timely production without compromising quality.

Durability & Longevity High-quality bakery machines are designed for long-term use and can withstand daily production demands.

Consistent Quality The right equipment helps maintain uniform texture, taste, and appearance in bakery products.

Energy Efficiency Modern bakery equipment is designed to consume less energy, reducing operational costs and increasing profitability.

Customization Options Leading Top 10 Bakery Equipment Manufacturer in Bangalore offer tailored solutions to fit your specific business requirements.

Top 10 Bakery Equipment Every Bakery Needs

At Mountain Kitchen Equipment, we manufacture and supply a wide range of essential bakery equipment, ensuring top performance and efficiency.

1. Planetary & Spiral Mixers

These are essential for mixing dough efficiently, ensuring the right texture and consistency.

2. Dough Sheeters

Used for rolling dough evenly, making it easier to prepare pastries and layered baked goods.

3. Rotary & Convection Ovens

Designed for even baking, these ovens ensure that products are cooked uniformly, reducing wastage and enhancing flavor.

4. Bread Slicers

Perfect for slicing loaves quickly and uniformly, making them ready for packaging and sale.

5. Proofing Chambers

These chambers provide the ideal temperature and humidity for dough fermentation, ensuring better texture and taste.

6. Baking Trays & Racks

Essential for efficient baking and cooling, these racks and trays help in organizing large-scale production.

7. Cake Depositors & Fillers

Ideal for efficiently portioning batter and fillings, making cake production seamless.

8. Dough Dividers & Rounders

Used for portioning and shaping dough into uniform sizes, ensuring consistent product quality.

9. Refrigeration & Freezing Units

Used to store perishable ingredients and finished products, maintaining freshness and extending shelf life.

10. Display & Showcases

A well-designed display unit enhances product visibility, attracting customers and boosting sales.

Why Choose Mountain Kitchen Equipment?

Finding the right Top 10 Bakery Equipment Manufacturer in Bangalore is essential for your bakery’s success. Here’s why Mountain Kitchen Equipment is the best choice:

✅ Years of Industry Experience

We have extensive experience in designing and manufacturing high-performance bakery equipment tailored to different business needs.

✅ Superior Build Quality

Our equipment is made from high-quality stainless steel and food-grade materials, ensuring durability and hygiene.

✅ Customization Options

We offer bakery equipment solutions designed to fit your specific production capacity and kitchen space.

✅ Energy-Efficient Technology

Our equipment is designed with modern technology that minimizes power consumption, reducing operational costs.

✅ Excellent After-Sales Support

From installation to maintenance, we provide top-notch after-sales support to ensure smooth operations.

How to Choose the Right Bakery Equipment?

1. Assess Your Bakery’s Needs

Consider your menu, production volume, and available space before selecting equipment.

2. Focus on Quality & Durability

Invest in reliable equipment that ensures long-term performance and minimal downtime.

3. Ensure Energy Efficiency

Opt for machines that consume less energy to reduce your operational expenses.

4. Work with a Trusted Manufacturer

Partnering with a reputed Top 10 Bakery Equipment Manufacturer in Bangalore ensures that you get premium-quality products and excellent service.

Why Bangalore Businesses Trust Mountain Kitchen Equipment?

Bangalore’s growing bakery industry demands top-quality equipment for seamless operations. From small bakeries to large-scale production facilities, efficient equipment is crucial for success. Mountain Kitchen Equipment has been a trusted partner for bakeries across Bangalore, delivering high-performance and durable solutions.

Our Satisfied Clients Include:

Bakery Chains & Cafés

Hotels & Restaurants

Industrial Bakeries

Cloud Kitchens & Catering Services

Home Bakers Scaling Up to Commercial Production

Success Stories from Our Clients

Many of our clients have transformed their bakery operations with our top-notch equipment. Our customized solutions and excellent service have helped businesses increase productivity, maintain quality, and enhance profitability.

Conclusion

The right bakery equipment is essential for the success of your business. Mountain Kitchen Equipment is among the Top 10 Bakery Equipment Manufacturer in Bangalore, offering reliable, durable, and customized solutions for all bakery businesses.

If you’re looking to upgrade or set up a new bakery, contact Mountain Kitchen Equipment today. Let us help you build a kitchen that enhances efficiency and success!

0 notes

Text

Best Hotel Kitchen Equipment Manufacturer in Delhi

Best Hotel Kitchen Equipment Manufacturer in Delhi

A well-equipped kitchen is the backbone of any successful hotel. From preparing delicious meals to ensuring smooth kitchen operations, high-quality kitchen equipment is essential for maintaining efficiency and hygiene. If you are looking for the Best Hotel Kitchen Equipment Manufacturer in Delhi, BS Kitchen Equipment is the trusted name in the industry. With years of experience, top-notch products, and excellent customer service, BS Kitchen Equipment is the go-to choice for hotels in Delhi and beyond.

Why Choosing the Right Kitchen Equipment Manufacturer is Important?

Choosing the right manufacturer for your hotel kitchen equipment is crucial for several reasons:

Efficiency: Well-designed kitchen equipment enhances speed and productivity.

Durability: High-quality materials ensure longevity and reduce maintenance costs.

Hygiene: Stainless steel and food-grade materials maintain cleanliness and safety.

Customization: Every hotel kitchen has unique needs, requiring tailored solutions.

Cost-effectiveness: Investing in premium equipment reduces long-term expenses.

BS Kitchen Equipment – Leading Manufacturer in Delhi

BS Kitchen Equipment is a reputed company offering a complete range of hotel kitchen equipment. Their products are designed to meet the needs of hotels, restaurants, and catering businesses.

Key Features of BS Kitchen Equipment:

High-Quality Materials: Use of stainless steel and durable components.

Custom Designs: Tailored equipment to fit different kitchen layouts.

Energy-Efficient Solutions: Equipment that helps reduce energy consumption.

Advanced Technology: Integration of modern technology for better performance.

Competitive Pricing: Affordable solutions without compromising quality.

Products Offered by BS Kitchen Equipment

BS Kitchen Equipment provides a wide range of products, making it the Best Hotel Kitchen Equipment Manufacturer in Delhi. Their product range includes:

1. Cooking Equipment

Gas & electric burners

Commercial ovens

Grills & tandoors

Fryers

Steamers

2. Refrigeration Equipment

Deep freezers

Walk-in coolers

Visi coolers

Under-counter refrigerators

Display fridges

3. Food Preparation Equipment

Dough kneaders

Vegetable cutters

Meat mincers

Planetary & spiral mixers

4. Storage & Shelving Solutions

Stainless steel racks

Cabinets

Worktables

Dishwashing stations

5. Serving & Display Counters

Bain-marie counters

Hot & cold display counters

Buffet stations

Salad counters

Why BS Kitchen Equipment is the Best Choice?

With numerous kitchen equipment manufacturers in Delhi, BS Kitchen Equipment stands out due to its:

Unmatched Experience: Years of industry expertise and knowledge.

Quality Assurance: All equipment undergoes rigorous quality checks.

Customization Options: Solutions tailored to fit any kitchen size and requirement.

Reliable After-Sales Service: Prompt maintenance and support services.

Timely Delivery: Fast manufacturing and delivery process.

Customization Services for Hotels

One of the standout features of BS Kitchen Equipment is its ability to provide customized solutions. Every hotel kitchen is different, and their team works closely with clients to design and manufacture equipment that fits specific needs.

Customization services include:

Modifying sizes and designs to fit the available space.

Integrating energy-efficient solutions.

Offering personalized branding on equipment.

Adapting equipment features to meet the chef’s preferences.

Installation & After-Sales Support

Purchasing high-quality equipment is just the first step. Proper installation and regular maintenance are essential for longevity and performance. BS Kitchen Equipment provides:

Professional Installation: Expert technicians ensure proper setup.

Training & Guidance: Assistance for staff to use the equipment efficiently.

Regular Maintenance: Scheduled servicing to keep equipment in top condition.

Quick Repairs: Fast and reliable repair services.

Industries Served

BS Kitchen Equipment caters to a wide range of businesses, including:

Luxury & budget hotels

Restaurants & cafés

Catering services

Bakeries & confectioneries

Food courts & cloud kitchens

Conclusion

For hotels looking to enhance their kitchen operations, BS Kitchen Equipment is the Best Hotel Kitchen Equipment Manufacturer in Delhi. Their commitment to quality, innovation, and customer satisfaction makes them the ideal choice for all commercial kitchen needs. Investing in their high-quality kitchen solutions ensures efficiency, safety, and long-term savings.

If you are planning to upgrade or set up a new hotel kitchen, explore BS Kitchen Equipment’s range of products and services. Visit their website for more details: BS Kitchen Equipment.

#Best Hotel Kitchen Equipment Manufacturer in Delhi#Hotel Kitchen#Hotel Kitchen Equipment#Hotel Kitchen Equipment Manufacturer

0 notes

Text

The Best Hotel Kitchen Equipment in Chennai – Kalam Kitchen Equipments

A well-equipped kitchen is the backbone of any successful hotel. From cooking appliances to storage units, high-quality hotel kitchen equipment in Chennai is essential for smooth operations. Investing in the right equipment ensures efficiency, safety, and customer satisfaction. Kalam Kitchen Equipments is a trusted name in the industry, offering premium-quality kitchen solutions tailored to the needs of hotels, restaurants, and catering businesses.

Why Choose Kalam Kitchen Equipments?

Kalam Kitchen Equipments is a leading supplier of hotel kitchen equipment in Chennai, providing state-of-the-art solutions designed to improve efficiency and streamline kitchen operations. These are the ideal option for the following reasons:

High-Quality Materials: All equipment is made using durable stainless steel for hygiene and longevity.

Customized Solutions: They provide equipment tailored to the unique requirements of each hotel kitchen.

Reasonably priced: competitive prices without sacrificing quality.

Reliable After-Sales Support: Professional service and maintenance for long-term efficiency.

Wide Range of Equipment: From cooking appliances to refrigeration and storage solutions.

Essential Hotel Kitchen Equipment

A commercial kitchen in a hotel requires a range of specialized equipment to meet industry standards. Kalam Kitchen Equipments provides all the essentials, including:

1. Cooking Equipment

Commercial Gas Ranges

Induction Cooktops

Deep Fryers

Griddles & Grillers

Ovens (Convection, Deck, Combi)

2. Food Preparation Equipment

Vegetable Cutters

Dough Kneaders

Meat Slicers

Mixers & Blenders

Planetary & Spiral Mixers

3. Refrigeration & Storage Equipment

Commercial Refrigerators

Deep Freezers

Cold Storage Units

Walk-in Chillers

Stainless Steel Shelving Units

4. Serving & Display Equipment

Bain Marie Counters

Buffet Display Units

Hot & Cold Food Displays

Kitchen Trolleys

SS Service Counters

5. Dishwashing & Cleaning Equipment

Commercial Dishwashers

Sink Units

Waste Disposal Systems

High-Pressure Cleaning Systems

Benefits of Investing in Quality Hotel Kitchen Equipment

Investing in premium hotel kitchen equipment in Chennai can make a huge difference in kitchen efficiency and overall operations. Here’s how:

Improved Workflow: Professional-grade equipment ensures faster food preparation and smooth service.

Cost-Effective: Durable and energy-efficient equipment lowers maintenance costs.

Better Food Quality: Precision cooking and high-performance appliances enhance the quality of dishes.

Safety & Hygiene: Stainless steel equipment ensures food safety and meets industry standards.

Energy Efficiency: Modern appliances reduce power consumption and operational costs.

How to Choose the Right Hotel Kitchen Equipment?

When selecting hotel kitchen equipment in Chennai, consider the following factors:

Space & Layout: Ensure the equipment fits well within the available kitchen space.

Business Needs: Choose equipment based on the type and scale of food production.

Budget Considerations: Balance affordability with quality and durability.

Maintenance & Support: Opt for a supplier that provides after-sales service.

Ease of Cleaning: Select equipment that is easy to clean and maintain.

Maintenance Tips for Hotel Kitchen Equipment

Proper maintenance of kitchen equipment extends its lifespan and ensures uninterrupted operations. Follow these tips:

Regular Cleaning: Prevent grease buildup and food contamination.

Scheduled Inspections: Identify and fix issues before they escalate.

Proper Usage: Train staff to use equipment correctly to avoid damage.

Timely Repairs: Replace worn-out parts to ensure smooth operations.

Lubrication & Calibration: Keep machines running efficiently with regular servicing.

Why Hotels Trust Kalam Kitchen Equipments?

Kalam Kitchen Equipments has built a reputation as a trusted supplier of hotel kitchen equipment in Chennai. Here’s what makes them the preferred choice:

Proven Track Record: Years of work experience in the field.

Customer Satisfaction: Positive testimonials from top hotels and restaurants.

Latest Technology: Advanced kitchen solutions for modern commercial kitchens.

Expert Consultation: Guidance in selecting the right equipment based on business needs.

Quick Delivery: Fast shipping and installation for a hassle-free experience.

Customer Testimonials

Many hotels and restaurants in Chennai rely on Kalam Kitchen Equipments for their kitchen needs. What some of them have to say is as follows:

“Our hotel kitchen is now more efficient thanks to Kalam Kitchen Equipments. The quality of their products is unmatched.” – Hotel Owner, Chennai.

“We purchased a complete kitchen setup from them, and everything works perfectly. Highly recommended!” – Restaurant Manager, Chennai.

“Excellent customer service and high-quality kitchen equipment. Our chefs are very satisfied with the performance.” – Catering Business, Tamil Nadu.

Expanding Your Hotel Kitchen? Contact Kalam Kitchen Equipments!

As hotels grow, their kitchen needs evolve. Upgrading to high-performance hotel kitchen equipment in Chennai ensures that your business stays ahead of the competition. Whether you’re opening a new hotel or upgrading your existing kitchen, Kalam Kitchen Equipments has the right solutions for you.

Our Commitment to Quality

At Kalam Kitchen Equipments, we take pride in offering reliable and durable kitchen equipment that meets international standards. Our team ensures every product is tested for performance and durability before delivery.

Get in Touch Today!

For the best hotel kitchen equipment in Chennai, contact Kalam Kitchen Equipments today:

Phone: +91 82483 21081

Website: kalamkitchenequipments.com

Address: MIG 6046, TNHB, Ayapakkam, Chennai-600047

Equip your hotel kitchen with the best-in-class solutions from Kalam Kitchen Equipments and ensure seamless operations with top-quality appliances. Get in touch today to find the perfect kitchen equipment for your business!

#kitchenequipmentsuppliersintamilnadu#hotelkitchenequipmentmanufacturersinchennai#bestcommercialkitchenequipmentmanufacturersinindia

0 notes

Text

The Ultimate Guide to Choosing Bord Og Stoler and Eltemaskin for Your Commercial Kitchen

When it comes to setting up a commercial kitchen, two essential elements that often get overlooked are Bord Og Stoler (tables and chairs) and Eltemaskin (dough mixer). These components play a significant role in ensuring efficiency, comfort, and overall functionality in any restaurant, café, or bakery. Whether you are opening a new food establishment or upgrading your current kitchen, investing in high-quality furniture and equipment is crucial for a seamless operation.

Bord Og Stoler: Creating the Perfect Dining Atmosphere

The choice of Bord Og Stoler is vital for any restaurant or café, as it directly impacts customer experience. Here are some factors to consider when selecting tables and chairs for your establishment:

1. Material and Durability