#Mobile belt conveyor

Explore tagged Tumblr posts

Text

The organic fertilizer pelletizer cannot be separated from the mobile belt conveyor in the pelleting process

In the process of organic fertilizer production line granulation, mobile belt conveyor plays an important role. It can effectively output the material from the pelletizer and evenly disperse it to various places to ensure the smooth progress of the production process.

The conveyor belt of the mobile belt conveyor can quickly transfer the material in the pelletizer, avoiding the cumbersome and time-consuming problem of manual handling. In addition, it can also ensure the uniform dispersion of the material, so that the quality of organic fertilizer granulation is guaranteed. At the same time, the flexibility and mobility of the mobile conveyor enables it to adapt to different production sites and needs, which greatly improves production efficiency.

Secondly, the mobile conveyor can also fine control the material, so as to ensure the quality and uniformity of organic fertilizer. In addition, it has high reliability and can operate stably for a long time, reducing maintenance costs and downtime.

In addition, the use of mobile conveyor also reduces the labor intensity, reducing the tedious work of manual handling and handling. It not only reduces the labor burden of workers, but also improves the safety and reliability of production.

In short, the organic fertilizer granulator is inseparable from the mobile conveyor in the pelleting process. By using mobile conveyors, we can effectively improve production efficiency, ensure product quality, reduce labor intensity and cost, so as to maximize production benefits. Therefore, we should actively promote and apply mobile conveyors to make greater contributions to the development of organic fertilizer granulation industry.

#organic fertilizer equipment#organic fertilizer production line#mobile belt conveyor#organic fertilizer granulator

0 notes

Text

“I’m gonna cycle to work it’s finally not raining YEEHAW”

*intense flare of pain in my wrist causing me to drop my phone*

okay yeah maybe… that’s not a safe idea right now…

#we’ve got the conveyor belt of pain again today friends! ankle#and knee and wrist seem to be the faves but not exclusive!#fibro tag#at least I’m still mobile#tian talks

2 notes

·

View notes

Text

Belt Conveyor Manufacturers In India

A belt conveyor efficiently transports materials over long distances with ease. Its continuous loop of sturdy belts, driven by pulleys, moves items smoothly and swiftly along the conveyor's path. Ideal for industries such as manufacturing, mining, and logistics, belt conveyors offer reliable and versatile material handling solutions. Dhiman Engineering Works (DEWSON) offers a wide range of belt conveyors and portable conveyors. Our equipment is ideal for all regular crushing plants and mobile crushing units.

#Belt Conveyor#Belt Conveyor In India#Belt Conveyor Manufacturers#Mini Mobile Crusher Manufacturer#Mobile Stone Crusher Manufacturer#Stone Crusher Machine Manufacturer

0 notes

Text

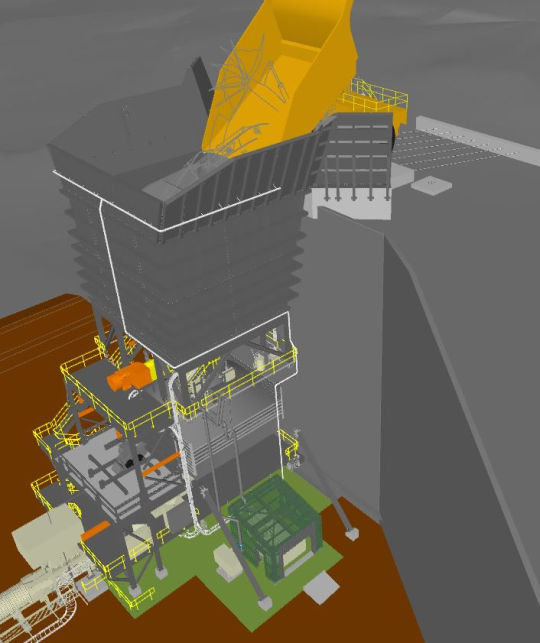

Little P.Eng. Engineering: Leading the Way in Bulk Material Transport Design across North America

In industries where massive volumes of materials are processed, the importance of efficient and safe bulk material transport cannot be overstated. Little P.Eng. Engineering stands as a beacon of excellence in this niche, offering top-tier structural and mechanical designs for a variety of equipment across Canada and the USA.

The Genesis of Bulk Material Transport

Bulk material transport is an integral cog in the machine of large-scale industries. Be it mining, manufacturing, or agriculture, the ability to move vast amounts of raw or processed materials efficiently ensures seamless operations and reduced downtimes. This task's complexity demands innovative solutions tailored to specific needs and geographic conditions.

Decoding Little P.Eng. Engineering's Portfolio

Apron Feeders:

Role: Essential in mining and heavy industry, they deliver a steady feed of materials to other machines.

Little P.Eng. Precision: Custom designs account for rugged conditions, ensuring robustness, minimal wear-tear, and efficient feeding speeds.

Belt Conveyors:

Role: The backbone of many industries, they transport materials over short to long distances.

Little P.Eng.'s Approach: Focus on load-bearing capacity, adaptive designs for different terrains, and durability in varied climatic conditions.

Belt Feeders:

Role: Controlled feeding of bulk materials, often used in coordination with other systems.

Little P.Eng.'s Vision: Precision-engineered for accurate delivery rates and volumes, ensuring no overloading or wastage.

Mobile Conveyor Bridges:

Role: Vital for large mining operations, they offer flexibility in transporting materials across significant distances.

Little P.Eng.'s Craft: Mobility and stability converge, ensuring these bridges can be relocated effortlessly without compromising safety.

Mobile Transfer Conveyors:

Role: As the name suggests, these conveyors are mobile and are often used in tandem with other stationary equipment.

Little P.Eng. Insight: Prioritizing easy maneuverability, these conveyors also spotlight on energy efficiency and fast material transfer.

Tube Conveyors:

Role: They provide enclosed transport, often used for grains, powders, or any material susceptible to external contamination or spillage.

Little P.Eng.'s Touch: Airtight sealing, efficient transport mechanism, and designs that reduce maintenance downtimes.

In-plant Conveyor Systems:

Role: Within factories or processing plants, they link various stages of production or processing.

Little P.Eng. Expertise: Modular designs that fit seamlessly into existing infrastructures, ensuring no workflow disruption.

Pipe Conveyor Systems:

Role: Offering enclosed transport, they are often used for materials like coal, ensuring no spillage or dust emissions.

Little P.Eng.'s Specialty: Enhanced curvature ability, ensuring a smaller footprint and efficient transport even in space-constrained areas.

Steel Belt Conveyors:

Role: Handling materials at high temperatures or those that might be abrasive or cut regular belts.

Little P.Eng. Mastery: Heat-resilient designs, ensuring prolonged lifespans even under intense conditions.

The North American Landscape: Challenges and Innovations

From the icy terrains of Northern Canada to the industrious heartlands of the USA, each region poses its unique challenges. Whether it's dealing with permafrost or ensuring equipment can withstand desert heat, Little P.Eng. Engineering's designs embody adaptability, ensuring machinery performs at its peak regardless of external conditions.

Moreover, with both countries emphasizing sustainable operations, the engineering firm ensures eco-friendly designs, minimizing energy consumption and environmental impact.

Conclusion

In an age where efficiency can dictate market standings, Little P.Eng. Engineering's contribution to the bulk material transport sector across Canada and the USA is undeniable. Through an intricate understanding of mechanics, topography, and industrial needs, the firm crafts solutions that don't just move materials but advance industries.

Read more:

Transforming the Landscape of Bulk Material Management through Structural and Mechanical Design

Tags:

Little P.Eng. Engineering

Structural design

Mechanical design

Mining equipment

Tailored equipment design

Bulk material transport

Modular design

Apron feeders

Belt conveyors

Belt feeders

Mobile conveyor bridges

Mobile transfer conveyors

Tube conveyor systems

In-plant conveyor systems

Pipe conveyor systems

Steel belt conveyors

North American industry

Sustainable operations

Material movement solutions

Efficient material transport

Custom machinery design

Industrial innovations

Canada industrial machinery

USA industrial machinery

Adaptability in design

Eco-friendly machinery

High-temperature material handling

Enclosed transport systems

Production workflow

Advanced material handling

Bulk Material Handling & Processing

Engineering Services

Structural Engineering Consultancy

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Little P.Eng. Engineering#Structural design#Mechanical design#Mining equipment#Tailored equipment design#Bulk material transport#Modular design#Apron feeders#Belt conveyors#Belt feeders#Mobile conveyor bridges#Mobile transfer conveyors#Tube conveyor systems#In-plant conveyor systems#Pipe conveyor systems#Steel belt conveyors#North American industry#Sustainable operations#Material movement solutions#Efficient material transport#Custom machinery design#Industrial innovations#Canada industrial machinery#USA industrial machinery#Adaptability in design#Eco-friendly machinery#High-temperature material handling#Enclosed transport systems#Production workflow#Advanced material handling

0 notes

Text

youtube

How to Do Belt Installing of Batch Asphalt Mixing Plant?

The asphalt plants or asphalt mixing plant is one plant that is used for mixing the dry warm aggregate, padding and asphalt for homogeneous mixture at the required temperature. And it is widely used to the construction of highway, city road and parking lot.

The major components of a batch asphalt mixing plant are the cold- feed system, asphalt cement supply system, aggregate dryer, mixing tower, and emission-control system.

The main activity of an asphaltbatch type mixing plant is that it heats up aggregates and then mixes them with bitumen and other adhesive substances to generate hot mix asphalt. The quantity and nature of the aggregate are dependent on the specific requirements.

#asphalt mixing plant#bitumen#road construction#asphalt drum mix plant#concrete#asphalt plant#asphaltplant#heavy equipment#construction#mobile asphalt drum mix plant#conveyor belts#conveyorsystem#roller conveyor#screw conveyor#conveyorize#belt conveyor#Youtube

1 note

·

View note

Text

We tend to talk about the decline in young adults’ home ownership as if it were a universal phenomenon. This is wrong. The share of 25-to-34-year-olds who own their own home in the US is six percentage points lower today than it was in 1990. In Germany it’s down eight points, in France just three, but in Britain the drop is 22 points. It’s a similar story with incomes, where Britons in their thirties are tracing the same trajectories as their forebears while Americans are leaving theirs in the dust. The conveyor belt of socio-economic progress may have slowed elsewhere in the west, but in Britain it has sheared in two, leaving a generation stranded below. As Rob Ford, professor of political science at the University of Manchester, put it to me, this has completely changed the political calculus for young people. In the old Thatcherite world, young Britons had realistic expectations of upward mobility and home ownership, and their political interests naturally lay with the party of homeowners and low taxes. Today none of these things are true. The sense of betrayal is palpable. Ben Ansell, professor of comparative democratic institutions at Nuffield College, Oxford has shown that young Britons have lost the belief in social mobility that was a given for their parents’ generation. Applying his methodology internationally, I find that just 39 per cent of British under-30s trust that hard work will bring rewards, far below those in the US (60 per cent) and Germany (49), and also far below the 60 per cent of British 70-somethings who believe the same because it was true for them.

John Burn-Murdoch, Why are young people deserting conservatism in Britain but nowhere else?

105 notes

·

View notes

Text

today i had a dream where me and my boy Xavier was messing around in my house but there was a big ass conveyor belt where my mom's bed should've been with psychologists/middle aged philosophers on it and this old lady watching and me and Xavier walk up to her and bro was feeling evil nd devious so he started levitating a few inches off the floor and grabbed something for her but he wasn't ever moving like it was an animation that didn't load and i notice after like 10 seconds and start laughing my ass off but we get bored of messing w/ that lady so we move to my living room where this really really reallyyy pretty person ik was sitting on my couch so me and Xavier sit down a little bit farther along the couch and i tell him i have a crush on her and he goes "i fuckin knew it guess what" and gives me this sticker that says "I HAVE A CRUSH ON (her name) 👍👍👍" and he slaps it on my chest then starts talking to her and brings her over aughghggh i was noticeably uncomfortable for like however long we were talking but eventually she sits back where she was and Xavier STOLE MY SPOT ON THE COUCH 😔😔 (U BITCH XAVIERR) and he's playing some mobile game and i start trying to get him off the couch and now that i think about it that sequence of me trying to reclaim my spot probably looked so gay 😔 especially bc i gave up after failing and js sat on the floor between his legs and then i fell asleep in that spot then woke up irl .crazy but i love these dreams they have my favorite ppl in them !!!

2 notes

·

View notes

Text

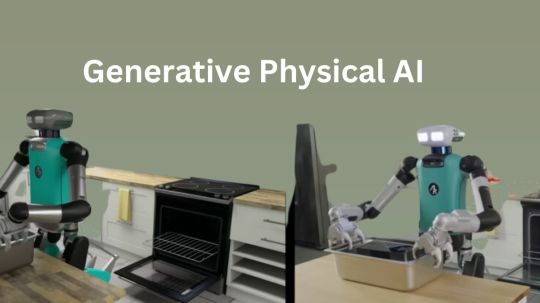

What Is Generative Physical AI? Why It Is Important?

What is Physical AI?

Autonomous robots can see, comprehend, and carry out intricate tasks in the actual (physical) environment with to physical artificial intelligence. Because of its capacity to produce ideas and actions to carry out, it is also sometimes referred to as “Generative physical AI.”

How Does Physical AI Work?

Models of generative AI Massive volumes of text and picture data, mostly from the Internet, are used to train huge language models like GPT and Llama. Although these AIs are very good at creating human language and abstract ideas, their understanding of the physical world and its laws is still somewhat restricted.

Current generative AI is expanded by Generative physical AI, which comprehends the spatial linkages and physical behavior of the three-dimensional environment in which the all inhabit. During the AI training process, this is accomplished by supplying extra data that includes details about the spatial connections and physical laws of the actual world.

Highly realistic computer simulations are used to create the 3D training data, which doubles as an AI training ground and data source.

A digital doppelganger of a location, such a factory, is the first step in physically-based data creation. Sensors and self-governing devices, such as robots, are introduced into this virtual environment. The sensors record different interactions, such as rigid body dynamics like movement and collisions or how light interacts in an environment, and simulations that replicate real-world situations are run.

What Function Does Reinforcement Learning Serve in Physical AI?

Reinforcement learning trains autonomous robots to perform in the real world by teaching them skills in a simulated environment. Through hundreds or even millions of trial-and-error, it enables self-governing robots to acquire abilities in a safe and efficient manner.

By rewarding a physical AI model for doing desirable activities in the simulation, this learning approach helps the model continually adapt and become better. Autonomous robots gradually learn to respond correctly to novel circumstances and unanticipated obstacles via repeated reinforcement learning, readying them for real-world operations.

An autonomous machine may eventually acquire complex fine motor abilities required for practical tasks like packing boxes neatly, assisting in the construction of automobiles, or independently navigating settings.

Why is Physical AI Important?

Autonomous robots used to be unable to detect and comprehend their surroundings. However, Generative physical AI enables the construction and training of robots that can naturally interact with and adapt to their real-world environment.

Teams require strong, physics-based simulations that provide a secure, regulated setting for training autonomous machines in order to develop physical AI. This improves accessibility and utility in real-world applications by facilitating more natural interactions between people and machines, in addition to increasing the efficiency and accuracy of robots in carrying out complicated tasks.

Every business will undergo a transformation as Generative physical AI opens up new possibilities. For instance:

Robots: With physical AI, robots show notable improvements in their operating skills in a range of environments.

Using direct input from onboard sensors, autonomous mobile robots (AMRs) in warehouses are able to traverse complicated settings and avoid impediments, including people.

Depending on how an item is positioned on a conveyor belt, manipulators may modify their grabbing position and strength, demonstrating both fine and gross motor abilities according to the object type.

This method helps surgical robots learn complex activities like stitching and threading needles, demonstrating the accuracy and versatility of Generative physical AI in teaching robots for particular tasks.

Autonomous Vehicles (AVs): AVs can make wise judgments in a variety of settings, from wide highways to metropolitan cityscapes, by using sensors to sense and comprehend their environment. By exposing AVs to physical AI, they may better identify people, react to traffic or weather, and change lanes on their own, efficiently adjusting to a variety of unforeseen situations.

Smart Spaces: Large interior areas like factories and warehouses, where everyday operations include a constant flow of people, cars, and robots, are becoming safer and more functional with to physical artificial intelligence. By monitoring several things and actions inside these areas, teams may improve dynamic route planning and maximize operational efficiency with the use of fixed cameras and sophisticated computer vision models. Additionally, they effectively see and comprehend large-scale, complicated settings, putting human safety first.

How Can You Get Started With Physical AI?

Using Generative physical AI to create the next generation of autonomous devices requires a coordinated effort from many specialized computers:

Construct a virtual 3D environment: A high-fidelity, physically based virtual environment is needed to reflect the actual world and provide synthetic data essential for training physical AI. In order to create these 3D worlds, developers can simply include RTX rendering and Universal Scene Description (OpenUSD) into their current software tools and simulation processes using the NVIDIA Omniverse platform of APIs, SDKs, and services.

NVIDIA OVX systems support this environment: Large-scale sceneries or data that are required for simulation or model training are also captured in this stage. fVDB, an extension of PyTorch that enables deep learning operations on large-scale 3D data, is a significant technical advancement that has made it possible for effective AI model training and inference with rich 3D datasets. It effectively represents features.

Create synthetic data: Custom synthetic data generation (SDG) pipelines may be constructed using the Omniverse Replicator SDK. Domain randomization is one of Replicator’s built-in features that lets you change a lot of the physical aspects of a 3D simulation, including lighting, position, size, texture, materials, and much more. The resulting pictures may also be further enhanced by using diffusion models with ControlNet.

Train and validate: In addition to pretrained computer vision models available on NVIDIA NGC, the NVIDIA DGX platform, a fully integrated hardware and software AI platform, may be utilized with physically based data to train or fine-tune AI models using frameworks like TensorFlow, PyTorch, or NVIDIA TAO. After training, reference apps such as NVIDIA Isaac Sim may be used to test the model and its software stack in simulation. Additionally, developers may use open-source frameworks like Isaac Lab to use reinforcement learning to improve the robot’s abilities.

In order to power a physical autonomous machine, such a humanoid robot or industrial automation system, the optimized stack may now be installed on the NVIDIA Jetson Orin and, eventually, the next-generation Jetson Thor robotics supercomputer.

Read more on govindhtech.com

#GenerativePhysicalAI#generativeAI#languagemodels#PyTorch#NVIDIAOmniverse#AImodel#artificialintelligence#NVIDIADGX#TensorFlow#AI#technology#technews#news#govindhtech

2 notes

·

View notes

Text

ok gonna delete tumblr mobile again so I'm disappearing (til I'm back w my laptop) but I decided today that I'm probs gonna take a year out after my masters/before doing a PhD (still not 100% sure about the PhD thing which is partially why I'm doing said year out) and I feel like that meme w the dolphins. yayyyyy. weight off my shoulders that I've allowed myself time to explore what I actually wanna do rather than stumble blindly down the conveyor belt of academia

4 notes

·

View notes

Text

Understanding Hydrocarbon Resins: Overview and Applications

What Are Hydrocarbon Resins?

Hydrocarbon resins, commonly referred to as petroleum resins, are synthetic resins derived from unsaturated hydrocarbons. These versatile materials are typically produced from crude oil or natural gas through processes such as thermal or catalytic cracking. They are recognized for their high thermal stability, strong adhesion, and compatibility with various polymers, making them integral to numerous industrial applications.

Types of Hydrocarbon Resins

C5 Resins:

Derived from C5 feedstocks (aliphatic hydrocarbons like pentenes).

Characterized by low molecular weight and tackiness.

Ideal for adhesives and coatings due to their stickiness and flexibility.

C9 Resins:

Made from C9 feedstocks (aromatic hydrocarbons such as indene and styrene).

Known for higher molecular weight, thermal stability, and color stability.

Suitable for rubber compounding and ink formulations.

C5/C9 Copolymer Resins:

A blend of C5 and C9 monomers.

Provides a balanced set of properties, useful in adhesives and sealants.

Hydrogenated Hydrocarbon Resins:

Undergo hydrogenation for enhanced stability, reduced color, and odor.

Suitable for applications requiring high purity, such as hot-melt adhesives and packaging materials.

Applications of Hydrocarbon Resins

Adhesives:

Hot Melt Adhesives: Essential for hot-melt formulations due to tackiness and adhesion, used in packaging, bookbinding, and pressure-sensitive adhesives.

Pressure-Sensitive Adhesives: Enhance tack, adhesion, and peel strength for tapes, labels, and hygiene products.

Rubber Compounding:

Serve as tackifiers to improve processing, adhesion, and reinforcement in tires, conveyor belts, and other rubber products.

Provide a balance between tensile strength and elasticity.

Coatings:

Paints and Varnishes: Improve adhesion, gloss, and durability in various paints and varnishes.

Road Markings: Enhance adhesion and weather resistance in traffic paint formulations.

Printing Inks:

Offer excellent adhesion, color stability, and fast drying for flexographic and gravure inks.

Packaging:

Used in films and coatings to improve mechanical properties, adhesion, and sealing.

Tapes and Labels:

Increase tackiness and adhesion in adhesive tapes and labels.

Sealants:

Integral to sealant formulations for construction and automotive uses, providing good adhesion and flexibility.

Advantages of Hydrocarbon Resins

Cost-Effectiveness: Generally more affordable compared to natural resins.

Versatility: Available in various molecular weights and viscosities, allowing for tailored applications.

Chemical Stability: Resistant to chemicals and environmental conditions, suitable for outdoor and industrial uses.

Summary

Hydrocarbon resins are indispensable in many industries, known for their adhesive properties, compatibility with a wide range of materials, and their role in enhancing the performance of adhesives, rubber, coatings, printing inks, and packaging materials. Their cost-effectiveness and adaptability make them a preferred choice for numerous manufacturing processes.

Contact:

Yuen Liang Industrial & Co., Ltd.

Website: www.ylresin.com

Email: [email protected]

Tel: +886-7-6161787 Ext.224

Mobile/WhatsApp/Zalo: +886-952 715 676

Skype: luuman123

#c5 resin#chemicals#hydrocarbon resin#petroleum resin#yuen liang resin#yl resin#taiwan resin#c9 resin

2 notes

·

View notes

Text

I think my mass reporting campaign worked cause I haven't seen one in a while but I will never forget the week I spent on this godforsaken app where it would not stop showing me mobile game ads featuring an ugly animated cow graphically giving birth with the calf going right onto a conveyor belt and there's so much to unpack there but this hellsite will really shove squirting cow pussy in your face while saying trans women's blogs are inappropriate because they post selfies

2 notes

·

View notes

Text

okay i posted photos already but i wanna talk about the weekend so here is a summary: (this is a long post bc am on mobile i am so sorry)

1. FUCK showmasters. money-grabbing, delusional, godawful cunts. i'm glad he only had a 2-event contract with them, but i hope it doesn't put him off future UK cons

2. i got to tell him how much luke's character means to me, that he portrayed an autistic person very sensitively and properly which is tough to get right, that his range is phenomenal and i'm glad he's getting the love he deserves. i don't wanna be That Person and say he wanted to hug me but was ~forbidden~ to, but his arms definitely moved out before he looked at the staff member and then instead reached out to take my hand. he said "thank you, love, your words mean the world to me" and holy SHIT his hands are the SOFTEST THINGS IN THE WORLD!!!!!!! this was also day 1 so he was in the cardigan look and he looked So Ralph i couldn't keep it together lmao

3. when i tell you this man was a CONVEYOR BELT for photo ops. we all joked that you could have put a cardboard cutout in there and it would be exactly the same. same face in all of them and everything. he really seemed done with it all then

4. the panel was. well. about the same as any other. same questions as always were asked. same answers were given. i think bc music as a topic is so opinion based he's been actively deflecting questions about his personal music taste but my GOD did people push that anyway. poor man went into hysterics when someone said to say hi to wes, he was so done with the day. and oh my GOD he hates that panel host guy LMAO his face would be so sweet and gentle when he was talking to the fans and then that guy would open his mouth and jq's face would DROP it was so funny

5. i haven't even mentioned!!!! i made so many friends!!! mostly by wearing my djo hoodie everywhere lol. joe squared supremacy <3 but yeah. i've missed the con experience of just telling someone you like something about them and then spending an entire weekend attached to their hips lol

6. day 2 was SOOOO much calmer. i think bc it was announced super late and also he was only there for half a day. HE HAD A LIL SCRUFF OF BEARD 🥰🥰🥰 and he seemed so much happier. like actual "hello! so nice to see you! how have you been?!" like you see how he is at most cons. he wasn't like that yesterday lmao

7. going off that, when i said "oh you know, just pressing on" he frowned and said "well i hope it gets better!" i said "oh it's great! i've had a good weekend, i hope you have too!" and he went "its been... fucking... lovely!" but the "fucking" was said under his breath in a tone that's usually followed by "mental" or "a shitshow" but yeah. THEN HE WINKED AT ME!!!!!! and said "take care now, won't you?" that's the jq i'd been seeing in videos.

8. photos were much the same but i liked my second one better AND he rubbed my back, said "thank you so much for coming, get home safe!" AND HE WINKED AGAIN

9. day 2 panel was fuckin. EMPTY. i asked him a question about how he said in the wonderland interview that he'd love to pursue a music career, i was like "was that for real or were you just saying it to get to the next question" and he was like "i'm just so lazy, it takes a lot of work to be a musician and i'm not one now, but someday i might start a band" aw. also he is a VERY sarcastic man who i think people take way too seriously lol. also x2 his bitchface towards the host was even less subtle LMAO

10. we saw him leaving and the poor man had his cap on and his head down, he REALLY wanted to leave and i don't blame him in the slightest

11. FUCK. showmasters. they deliberately oversold jq and didn't honour refunds, autographs were either included in diamond passes or bought on the day for £75 IN CASH??? and one of my new friends was the only one left when they cut for time from photo ops, she asked if she could just get one, JOE SAID YES BUT THE STAFF SAID NO. we had one staff member talking to us DIRECTLY about what time jq was paid to stay until, said "but it would be nice if he chooses to stay longer" and then started talking about how last year's summer event was so unfairly criticised?? and was like "even joe said he wasn't stressed" ofc he isn't gonna talk shit about a company he was still legally under contract for??? and one tried to tell us not to sit on the floor, 30ft away from the first aid room door, bc there was NO OTHER SEATING, saying that it's our own fault if we got mauled by a stretcher in an emergency. there was no emergency.

12. i have practically bankrupt myself at artist booths and i'm tempted to do it all again in liverpool in a few weeks lmfao

11 notes

·

View notes

Text

5 ways to make your fulfillment center run more efficiently

Running a fulfillment center can be extremely challenging in today’s complex and challenging business environment. As an online seller, it's important to ensure that your fulfillment center runs efficiently to meet the demands of your customers. In this blog, we will explore the best five ways to make your fulfillment center run more efficiently.

Optimize your inventory management system

Managing your inventory is one of the most important aspects of running a fulfillment center efficiently. An effective inventory management system can help you track your stock levels and ensure that you have enough products on hand to meet customer demand. Use inventory management software that integrates with your order management system to help you track inventory in real time and avoid stockouts. Utilize demand forecasting to make sure you have enough inventory to fulfill orders during peak demand periods.

Implement efficient picking and packing processes

Picking and packing are the two most critical processes in the order fulfillment cycle. Optimize your picking and packing processes by grouping orders by proximity, picking in batches, and using barcode scanning to avoid errors. Use automation and packing materials that are appropriate for the product being shipped to ensure that items arrive in good condition. You can also implement a quality control process to ensure accuracy and minimize errors.

Invest in automation

Automation can help you improve efficiency and reduce labor costs. Consider investing in automation tools such as conveyor belts, sortation systems, and robots to streamline your fulfillment process. Automation can also help you increase throughput and accuracy, reduce manual labor, and minimize errors. On the other hand, instead of installing all these tools, you can simply partner with NimbusPost, a tech-enabled shipping aggregator that already has 540 fully-equipped facilities and several types of warehouses to provide easy order fulfillment.

Streamline your shipping process

Shipping is a crucial aspect of fulfillment. To make your shipping process more efficient, use shipping software that integrates with your order management system. This can help you automate shipping label generation and reduce manual data entry. Choose a reliable courier service in India or a global shipping partner to ensure timely delivery and track your shipments in real time.

Train and empower your staff

Your employees are the backbone of your fulfillment center. To improve efficiency, provide regular training to ensure that they understand their roles and responsibilities. Empower your staff by giving them the tools and resources they need to succeed, such as mobile devices for picking and packing or access to real-time inventory information. Encourage open communication and solicit feedback to identify opportunities for improvement.

Conclusion

There are several ways to make your fulfillment center run more efficiently. You can follow the mentioned ways to improve your fulfillment center’s efficiency or just hire a solid shipping aggregator to get everything handled without stress at the best rates

2 notes

·

View notes

Text

What are the latest warehouse automation technologies?

Gone are the days of manual labour and static, inefficient operations. Today, we stand at the forefront of a revolution driven by the latest warehouse automation technologies. These innovations reshape how businesses handle inventory, fulfil orders, and optimize supply chains.

From autonomous robots and artificial intelligence to the Internet of Things (IoT) and advanced data analytics, we'll explore how these technologies enhance efficiency, reduce costs, and ensure seamless operations in modern warehouses.

1-Robotic Process Automation (RPA): RPA involves using software robots to automate repetitive tasks like data entry, order processing, and inventory tracking. The robots interact with various systems and applications to streamline workflows.

2-Autonomous Mobile Robots (AMRs): Robotic vehicles called AMRs navigate and operate in warehouses without fixed infrastructure, such as conveyor belts or tracks. They perform tasks like picking, packing, and transporting goods.

3-Automated Guided Vehicles (AGVs): AGVs are similar to AMRs but typically follow fixed paths or routes guided by physical markers or magnetic tape. They are commonly used for material transport in warehouses and distribution centres.

4-Goods-to-Person Systems: This approach involves bringing the items to the workers rather than having workers travel throughout the warehouse to pick items. Automated systems retrieve and deliver goods to a workstation, reducing walking time and improving efficiency.

5-Automated Storage and Retrieval Systems (AS/RS): AS/RS systems use robotics to store and retrieve items from racks or shelves automatically. These systems can significantly increase storage density and optimize space utilization.

6-Collaborative Robots (Cobots): Cobots are designed to work alongside human workers. They can assist with tasks like picking, packing and sorting, enhancing efficiency and safety.

7-Warehouse Management Systems (WMS): While not a physical automation technology, modern WMS software uses advanced algorithms and AI to optimize inventory management, order fulfilment, and warehouse processes.

8-Vision Systems and Machine Learning: Computer vision technology combined with machine learning can be utilized for tasks such as object recognition, inventory movement tracking, and quality control.

9-IoT and Sensor Networks: Internet of Things (IoT) devices and sensors collect real-time data on inventory levels, environmental conditions, equipment health, and more, enabling better decision-making and predictive maintenance.

10-Voice and Wearable Technologies: Wearable devices and voice-guided picking systems can provide workers with real-time information and instructions, improving accuracy and efficiency.11-Automated Packaging Solutions: These systems automate the packaging process by selecting the appropriate box size, sealing packages, and applying labels, reducing manual labour and ensuring consistent packaging quality.

1 note

·

View note

Text

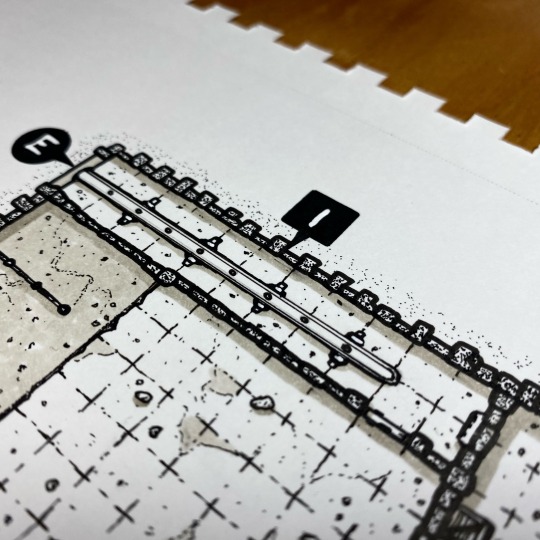

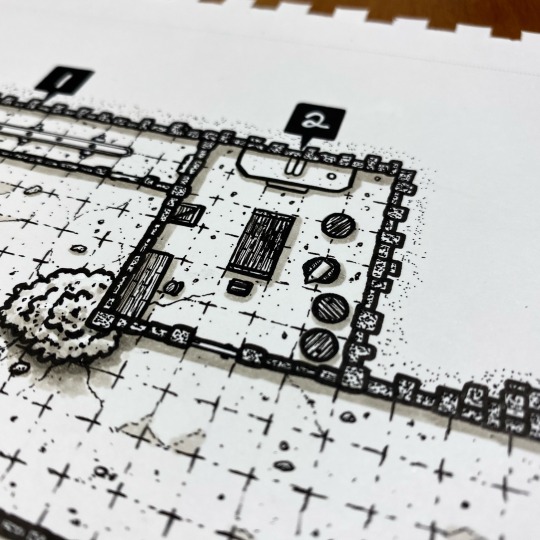

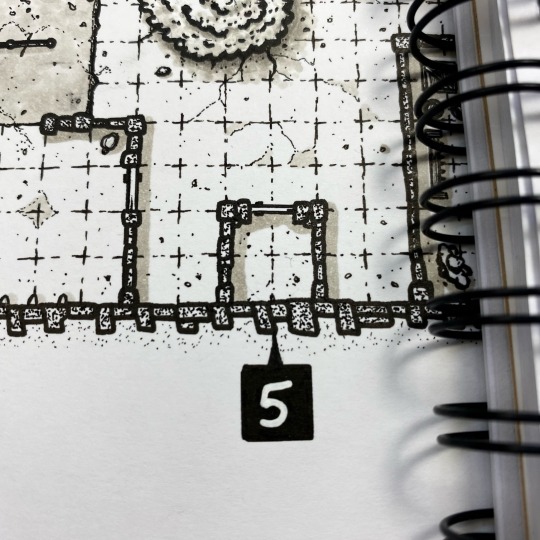

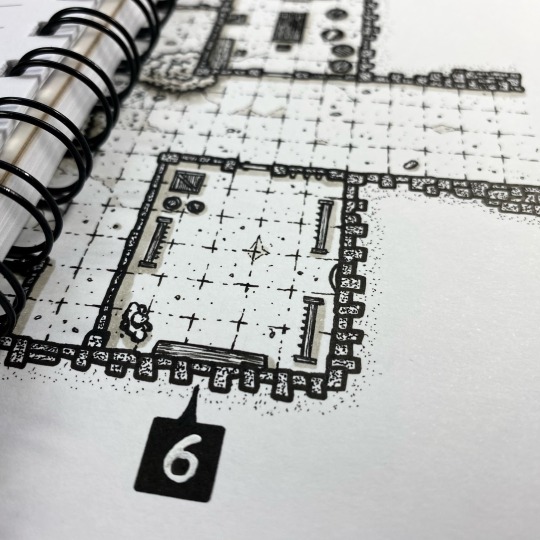

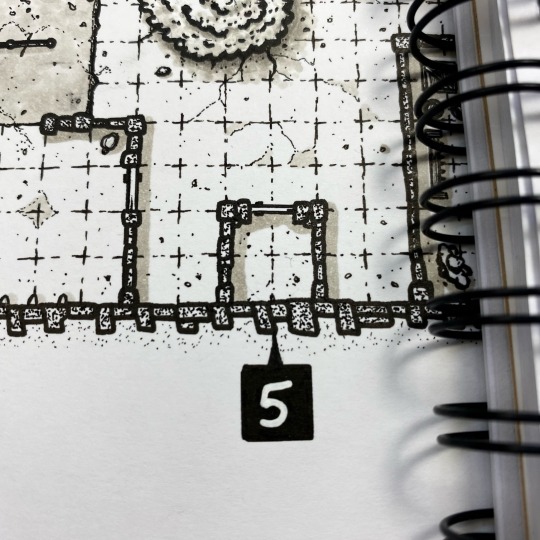

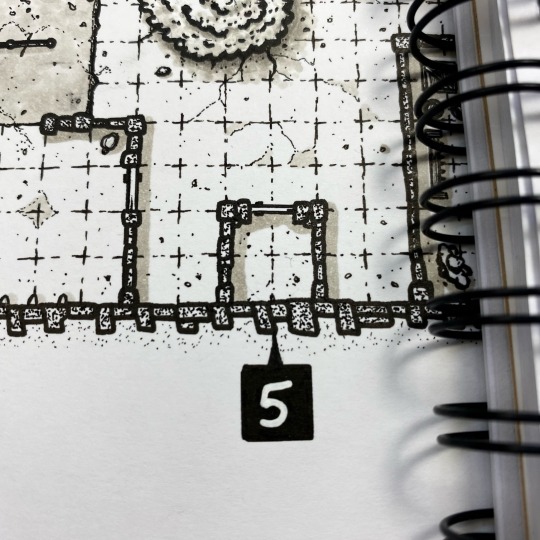

March - The Gatehouse, Area 1A

#dungeon23

3.1. Kennels

A wooden door, locked. On the lower-half of the door, a smaller door, about knee-height, unlocked.

Inside, a peculiar conveyor belt runs towards the back of the narrow room. On the west wall, a sealed hatch. On the east wall, a simple control panel, featuring three prominent, unlabeled buttons.

If the conveyor is activated, the hatch will open and begin churning out Mech-Canis units. 1D10 quadrupedal mechanoids will be produced, one every minute, before it runs out of components. The Mech-Canis are programmed to relentlessly attack any intruder.

E: Exits to The Keep, South

3.2. Smithy

A wooden door, ajar. Inside, the room smells of soot and steel. A large workbench rests prominently in the middle of the room. A mounted anvil is placed nearby. Barrels and crates filled with the remnants of coal and water are placed around the perimeter of the room.

In the southwest corner of the room, a simple desk, covered with blacksmithing tools. Tacked to the wall, the remnants of drawings, only their scrap corners remain.

On the north side of the room, a large forge covers the wall. It’s been cold for a long time.

3.3. Stables

Five stalls line the west wall. The floor is well trampled, made up of compacted earth and hay. Embedded into the floor, the bones of a horse, scattered across several stalls.

The Recla-Mare: The phantom of a deceased horse haunts this area. An incorporeal form of grey mist, followed by a flowing, silver mane. Passing through the mist chills you to your core, exposing you to heartless thoughts of betrayal for 1D3 hours. The mare has no love for humankind, not any more.

3.4. Tack Room

A wooden door to the east, unlocked. A wide opening to the north.

Filled with equipment used for horse riding. Hanging from the walls are an assortment of bridles and stirrups. A well-used saddle is propped up in one corner. On the workbench, spanning the west wall, hammers, nails, and horseshoes can be found, along with other tools for hoof maintenance.

3.5. Shed

A simple shed, unlocked. Inside, a broom, bucket, shovel, and pitchfork.

3.6. Armoury

A wooden door, unlocked. Inside, weapon racks line the walls, though there are no weapons in them. A small collection of crates and barrels fill one corner of the room, they too, are empty.

A partial suit of armour sits propped up in the southwest corner of the room, tethered to a display pole. The suit is antiquated, but could offer some basic protection at the cost of mobility and stealth. It clatters loudly if worn.

—-

What’s up with Tumblr not adding images sometimes?

-

3 notes

·

View notes

Text

Porto Flavia, Sardinia, Italy.

Porto Flavia is a Sardinian public works built between 1922 and 1924 in Masua in the province of Iglesias in southern Sardinia. A 600 meter long tunnel overlooking the sea in front of Sugar Loaf.

Ships stopped to load the minerals destined for the foundries of Northern Europe below the point, reducing transport costs and times.

The system was and is made up of 2 superimposed tunnels separated vertically by 9 silos. In the upper gallery the silos were loaded from the surrounding island, in the lower one equipped with a conveyor belt they then loaded the ships using a lead and zinc mobile arm.

Flavia is the name of the daughter of Cesare Vercelli, designer and construction manager for the construction of the work.

Italy

1K notes

·

View notes