#Miniaturediaphragmpump

Explore tagged Tumblr posts

Text

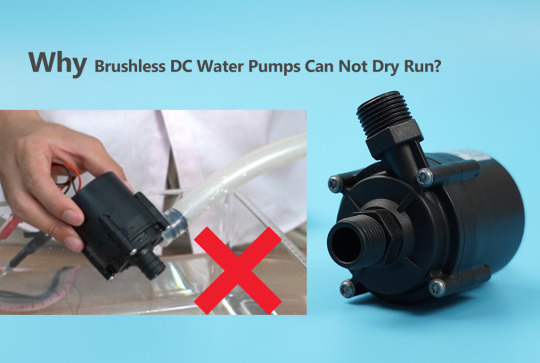

Pump Knowledge: Why Brushless DC Water Pumps Can Not Dry Run?

The dry-running of the brushless DC water pump means there is no water in the pump chamber, or there is an excessive amount of air in the pump chamber when the water pump is running. That is, the water pump runs without water or with poor water flow. When the water pump is working, the water plays an important role in lubrication and cooling, so dry-running is absolutely not allowed. Let's explore the reasons why the brushless DC water pump is strictly prohibited from dry-running, and the factors that may cause this phenomenon. At the same time, we will also discuss what measures can be taken to prevent the water pump from dry-running.

Why Brushless DC Water Pumps can Not Dry Run?

The brushless DC water pump may cause the following problems when dry-running:

Damage to water pump motor: the rotor of the water pump motor rotates at high speed when dry-running, but there is no water cooling, which will cause the motor to overheat, thereby damaging the motor insulation and bearings, and shortening the lifespan of the motor.

Pump stucked: the pump body will generate heat when dry-running. Without the liquid cooling, those narrow gaps are easy to be bitten through due to the long-term thermal expansion and contraction, resulting in the pump being stuck and unable to work normally.

Power consumption Increased: the motor will work without load when dry-running, and the power conversion efficiency will be low, which will cause energy waste and increase power consumption.

Affect the sealing performance of the water pump: dry-running may cause excessive frictional heat at the seal of the water pump, which will affect the sealing performance and cause leakage from the pump body.

Damage to other components: dry-running may lead to overpressure of the pipeline, and even damage to other components, which will have a chain reaction on the system.

Therefore, in order to protect the normal operation of the pump and prolong its service lifetime, it is strictly forbidden to have the brushless DC water pump from dry-running.

Possible Reasons for Dry-running

1. No water supply: Brushless DC water pumps are prone to dry-running when there is no water or insufficient water. For example, the inlet of the water pump is not connected to the water supply or the water supply is suddenly interrupted.

2. Blockage or leakage: If the inlet of the water pump is blocked or leakage occurred, the pump cannot absorb water normally, which may cause dry-running.

3. Failure of the control system: If the control system of the water pump fails, the operation status of the water pump cannot be monitored correctly, which may cause the water pump to continue to run without water and dry-running.

4. Power problem: Unstable power supply or power failure may cause the water pump to fail to operate normally, resulting in dry-running.

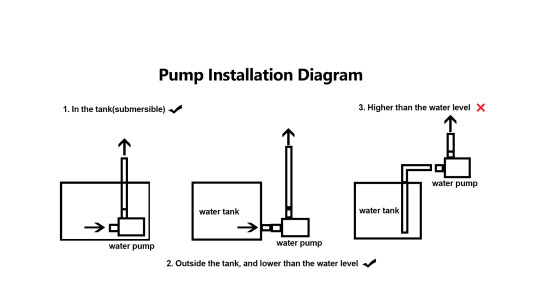

5. Improper installation: Improper installation of the water pump or improper connection of the pipes causes the water pump to fail to pump water normally.

How to Prevent the Water Pump from Dry-running?

The pump inlet must be connected to a pipeline with water source, and being lower than the water source to ensure that water can enter the pump smoothly.

Use a suitable pump controller, such as a pressure switch, flow switch or smart controller, to monitor the running status of the pump and avoid dry-running.

Choose a water pump with dry-running protection, so that when the water pump runs without water, it will automatically stop working to avoid damage.

Regularly maintain the water pump, check the running state of the motor, the sealing and the pipeline connection, to ensure that the water pump is running in the best condition.

Dry-running Protection of the Water Pump

When the brushless DC water pump lacks water during running, it may face the risk of burning out. However, the water pump equipped with dry-running protection can realize short-term dry-running when the internal environment is wet, and effectively avoiding the occurrence of burn-in.

All the brushless DC water pumps produced by TOPSFLO are equipped with dry-running protection (either standard or customized). The role of this function should not be underestimated. The electronic control system of the water pump can realize the intelligent monitoring of the current and speed, and accurately triggers the corresponding protection measures according to the set threshold. When the current and speed are lower than the predetermined threshold, the system immediately starts the dry-running protection, so as to ensure that the water pump is not damaged or malfunctioned.

The dry-running protection can monitor the running status of the water pump in real time, accurately identify possible abnormal situations, and respond quickly. Once the system finds that the pump current or speed deviates from the predetermined range, it will immediately take corresponding measures to reduce the pump speed, stop the pump operation or issue an alarm to avoid damage or accidents caused by dry-running.

The excellence of the dry-running protection of TOPSFLO pumps lies not only in the excellent innovation in technology, but also in focusing on providing users with efficient and reliable solutions to ensure the continuous and stable operation of the pump system. Bringing an excellent experience to users in terms of industrial processes and domestic water supply. If you would like to know about the dry-running protection of a specific model of TOPSFLO water pump, please feel free to contact us.

youtube

Key words: 24v dc water pump,24v water pump, 12v dc pump,dc pump, brushless dc pump, dc brushless pump, 12v brushless pump, brushless 12V pump, 12v water pump, small water pump, dc water pump, dc motor pump, bldc water pump, 24v brushless dc pump,mini water pump, 12v mini water pump, 12v dc water pump , micro dc pump, Solar DC Water Pump,Solar DC Pump,hot water dispenser pump,EV charger pump,smart toilet pump,water heater pump,car circulation pump,car water pump,car preheater pump, Server liquid cooling pump

#dcwaterpump#waterpump#brushlessdcpump#topsflopump#solarwaterpump#bldcpump#dc water pump#diaphragm pump#miniaturediaphragmpump#servercoolingpump#12vdcwaterpump#12vwaterpump#12vminipump#24vdcwaterpump#24vwaterpump#24vdcpump#Youtube

0 notes

Text

Mastering the Essential Parameters of Brushless DC Water Pump: What are the Must-Knows?

In the industrial and civil sectors, brushless centrifugal pump are widely used as efficient and reliable fluid transportation equipment in various fields such as industry, agriculture, and healthcare. This article provides a detailed introduction to the main performance parameters of brushless DC centrifugal pumps, as well as an interpretation of the labels of TOPSFLO water pumps, to help you better understand and choose brushless centrifugal pumps.

Flow Rate Parameters

Flowrate is one of the important performance parameters of a brushless centrifugal pump. It represents the amount of liquid that the pump can deliver per unit of time. Flowrate can be measured in terms of volume flowrate or mass flowrate.

The volumetric flow rate (Q) refers to the volume of liquid conveyed by the pump in a unit of time, commonly used measure units are litres/minute (L/min), cubic metres/hour (m³/h) and so on. The volumetric flow rate determines the pumping capacity of the pump. For different application requirements, it is necessary to select an appropriate volumetric flow rate based on the liquid delivery needs.

TOPSFLO pumps are usually labelled with the volumetric flow rate and also the maximum flow capacity (Max water flow / Max air flow / Max flow / Max flow without pressure ), which indicates the maximum flow rate that the pump can achieve without actual load pressure. When the outlet of a brushless centrifugal pump is not connected to any pipework, the flow rate will be at its maximum, but no pressure will be generated.

Water head Parameters

Water head is a key indicator of the performance of brushless centrifugal pumps. It represents the increase in effective energy per unit mass of liquid from the pump inlet to the pump outlet. The water head determines the pumping capacity of the pump and the height or pressure at which the liquid can be delivered.

The water head is measured in meters (m) and represents the height of the liquid column that can be conveyed. However, the water head does not only represent the height of the liquid, it also includes the energy required to overcome fluid resistance and lift both static pressure and kinetic energy. Therefore, the water head is a key parameter for determining the pump's ability to transport liquid.

TOPSFLO pumps are often labelled with a maximum pressure capacity, i.e. open pressure (Max water head/Max pressure/Open pressure/Open pressure/open pressure without flow), which indicates the maximum pressure that the pump can achieve without actual flow. When a brushless centrifugal pump pumps water to a maximum limit point, no further flow will come out.

Speed Parameters

Speed (n) represents the number of rotations the pump shaft makes per minute, measured in revolutions per minute (r/min). Under constant speed, the flow rate, water head, and power remain unchanged. When the speed changes, the flow rate, water head, and shaft power of the brushless centrifugal pump will also correspondingly change. The selection of speed has an impact on the flow rate, head, and pump efficiency. Different application scenarios require the appropriate speed to be chosen based on specific requirements.

Power Parameters

Power indicates the work done by the pump in a unit of time.

Effective power (Ne) represents the work done by the pump on the conveyed liquid in a unit of time, commonly used unit is watt (W) or kilowatt (kW). It can be calculated through the flow rate, water head and liquid density, this is an important indicator of pump efficiency.

The shaft power (N) represents the pump input power, also indicates the power transferred from the prime mover to the pump shaft. The shaft power is usually less than the effective power because there are various losses within the pump that do not allow the input power to be fully converted into the effective power of the liquid. Shaft power is also expressed in watts (W) or kilowatts (kW).

The mating power (ND) is the power of the prime mover that is mated to the brushless centrifugal pump. Its relation to the shaft power can be calculated by a factor. Mating power is usually used to determine the required prime mover power to ensure proper pump operation.

Input electric power (P) is the input power, also indicates the total electric power that the pump obtains from the power supply. The input power includes the electrical energy required to run the pump as well as the motor's own losses. It is usually expressed in watts (W) or kilowatts (kW).

It should be noted that the power indicated on the nameplate of brushless centrifugal pumps is not the effective power, but rather shaft power, rated power, or input power. For example, the power indicated on the TOPSFLO water pump label is the input power.

Other Parameters

In addition to flow rate, water head, speed, and power, there are other parameters that need to be considered, such as operating temperature, material corrosion resistance, noise level, etc. These parameters should be selected based on specific application scenarios and requirements.

By understanding the performance parameters of the pump, it is possible to accurately match the characteristics of the pump with the application needs. For example, understanding the flow rate can determine the pump's conveying capacity, allowing the selection of an appropriate flow rate to meet the actual requirements. Understanding the head can determine the pump's delivery height or pressure requirements, ensuring that the pump can provide sufficient lift. Understanding the shaft power and effective power can evaluate the pump's energy conversion efficiency, and selecting a high-efficiency pump can provide greater effectiveness. Having a clear understanding of the performance parameters of the pump also helps in selecting suitable supporting equipment such as motors and controllers, while avoiding the risks of overload and damage.

Conclusion

The performance parameters of brushless centrifugal pumps are of significant importance for correctly selecting and applying pumps. By fully understanding the performance parameters, it is possible to better select a pump that suits the requirements and ensure that it can achieve the best results in practical applications.

youtube

Key Words: 24v dc water pump,24v water pump, 12v dc pump,dc pump, brushless dc pump, dc brushless pump, 12v brushless pump, brushless 12V pump, 12v water pump, small water pump, dc water pump, dc motor pump, bldc water pump, 24v brushless dc pump,mini water pump, 12v mini water pump, 12v dc water pump, micro dc pump, solar DC water pump,solar DC pump,hot water dispenser pump,EV charger pump,smart toilet pump,water heater pump,car circulation pump,car water pump,car preheater pump, server liquid cooling pump, server electronics cooling pump, server cooling pump, rack server cooling pump,water cooling pump, liquid cooling pump, micro diaphragm liquid pump, micro diaphragm gas pump, inkjet pump, ink printer pump, micro gear pump, DC gear pump, magnetic drive gear pump

#dcwaterpump#waterpump#brushlessdcpump#topsflopump#bldcpump#dc water pump#solarwaterpump#diaphragm pump#miniaturediaphragmpump#servercoolingpump#gearpump#Youtube

0 notes

Photo

Miniature diaphragm liquid pumps and vacuum pumps are essential devices used in a wide range of industries and applications. These compact and versatile pumps play a crucial role in fluid transfer and vacuum generation, offering precise control, reliability, and efficiency.

TOPSFLO Miniature diaphragm liquid pumps are designed to handle the precise dosing, circulation, and dispensing of liquids. They utilize the reciprocating motion of a diaphragm to create pressure differentials for fluid transfer. These pumps are known for their compact size, low power consumption, and excellent reliability. They find applications in various fields, including medical devices, analytical instruments, and industrial automation.

One of the key advantages of TOPSFLO miniature diaphragm liquid pumps is their ability to handle different types of fluids, including corrosive, viscous, and volatile substances. They are constructed with chemically resistant materials such as elastomers, plastics, and stainless steel, ensuring compatibility with a wide range of liquids. The diaphragm design eliminates the need for seals, reducing the risk of leakage and enhancing overall reliability. These pumps are often driven by electric motors or solenoids, offering precise control over flow rates and pressures. This makes them ideal for applications that require accurate fluid handling, such as drug delivery systems, chromatography equipment, and inkjet printers.

Miniature diaphragm vacuum pumps, on the other hand, use the reciprocating motion of a diaphragm to create a vacuum or negative pressure. These pumps are widely used in applications such as sample aspiration, filtration, degassing, and vacuum packaging. They offer several advantages, including efficient operation, low maintenance requirements, and consistent performance.

TOPSFLO Miniature diaphragm vacuum pumps are capable of generating vacuum levels suitable for specific applications, ranging from moderate vacuum to deeper vacuum levels. These pumps are designed to be compact, lightweight, and offer low noise and minimal vibration. This makes them suitable for portable and handheld devices, as well as laboratory equipment.

One of the significant advantages of miniature diaphragm vacuum pumps is that they are oil-free. They do not require lubricants or oil for their operation, making them clean and environmentally friendly. This eliminates the risk of contamination or oil vapor emissions, making them ideal for applications where a clean vacuum environment is essential. Their compact design and compatibility with various fluids allow for easy integration into space-constrained systems.

Both miniature diaphragm liquid pumps and vacuum pumps find applications in a wide range of industries. In the medical field, they are used in diagnostic devices, patient monitoring equipment, and drug delivery systems. Their precise and reliable fluid transfer capabilities ensure accurate dosing and safe operation.

In analytical instruments, such as gas analyzers, spectrometers, and liquid chromatography systems, these pumps enable precise sample handling and fluid control. This enhances the accuracy of measurements and analysis, leading to more reliable results.

Industrial automation also benefits from miniature diaphragm pumps. They are integrated into automated production lines, robotic systems, and manufacturing equipment to ensure precise fluid dispensing, lubrication, and cooling. Their compact size and compatibility with various fluids make them valuable assets in industrial settings.

In conclusion, miniature diaphragm liquid pumps and vacuum pumps are crucial components in many industries and applications. Their compact size, efficiency, and versatility make them suitable for diverse fields, ranging from medical and analytical to industrial automation. These pumps offer precise control, reliability, and efficiency, enabling businesses to enhance productivity, improve accuracy, and deliver superior quality in their products and services.

#diaphragm pump#Miniaturediaphragmpump#diaphragm air pump#diaphragmliquidpump#TOPSFLOPUMP#diaphragmgaspump

0 notes

Text

The Application & Superiority of Diaphragm Ink Pump in Digital Direct Inkjet Printing Machines

Diaphragm pump is an indispensable key equipment for digital direct inkjet printing machine. With its unique structure and superior performance, the diaphragm liquid pump provides strong support for the production and manufacturing of digital direct inkjet printing machines.

The working principle of diaphragm liquid pump is to use the energy of air pressure or hydraulic pressure to compress a pair of symmetrical elastic membrane to achieve the transfer of liquid. Its advantages include good sealing, strong suction and discharge capacity, excellent self-priming performance and long service life, which well meet the special requirements of digital direct inkjet printing machines for precision control and stability. We will discuss the detailed application, superiority and trends in digital direct inkjet printing diaphragm pumps below.

I. Application

Digital direct inkjet printing machine is a new traditional printing technology that uses digital inkjet technology to print pictures directly onto the surface of fabrics. It is widely used in textile, garment, shoes and hats industries due to the advantages of various aspects such as printing color, printing effect and cost.

In digital direct inkjet printing machine applications, diaphragm pumps provide positive and negative pressure acting on the ink chamber, thus performing multiple functions such as creating a negative pressure environment, cleaning the printhead, pressure reduction and stabilization, pigment control and fluid transfer within the inkjet printing machine . These applications require the direct inkjet printing pump to be in long-term operation, withstand the high frequency of gas-consuming operations, and maintain a stable pressure. In addition, the ink and volatile gases contain organic volatile and corrosive components, due to the long-term exposure to these substances, micro diaphragm liquid pumps need to have good chemical resistance. Meanwhile, in order to ensure the quality of the finished product inkjet printing, it is essential to control the accuracy and stability of the inkjet fluid at high inkjet speeds.

II. Superiority

1. High precision

Diaphragm Ink Pump are used in digital direct inkjet printing machines to achieve precision control of the inkjet fluid, greatly improving the accuracy and precision of printing. In addition, the diaphragm ink pump can also smoothly control parameters such as inkjet time and pressure without elevating the complexity of the inkjet process, ensuring the stability and accuracy of color and print quality.

2. Good self-priming performance

The self-priming ability of Miniature Diaphragm pump makes it possible to carry out normal suction work even when the liquid is lower than the pump body, which reduces the maintenance difficulty of printing equipment.

3. Easy to operate

Miniature Diaphragm pump is very simple to use, only need to prepare the right amount of printing solution poured into the pump body, easy to operate, and do not need too many workers to operate.

4. Long service life

Due to the excellent corrosion and wear resistance of the diaphragm pump, it has a long service life and can be kept working at a high operating efficiency for a long time.

As mentioned above, the diaphragm pump plays an extremely important role in the digital direct inkjet printing machine, which greatly improves the efficiency and accuracy of traditional printing technology. Through the application of Diaphragm Ink Pump, digital direct inkjet printing machine has become a prominent representative of the industry's performance.

III. Market Trends

Currently, digital direct inkjet printers are facing many new challenges. When printing tasks change, users need fast printing and quick response. Coupled with the industry's recent environmental initiatives (such as the increasing use of water-based inks) also present challenges that require innovative and customized technology solutions.

As one of the leading diaphragm pump manufacturers, TOPSFLO responds to these trends by providing customers with the most appropriate solutions that help meet their challenges and offering a choice of components in different materials, motors, and voltage configurations to ensure long-lasting, efficient operation of the products in any environment.

Each diaphragm pump product from TOPSFLO is tested before shipment to ensure extremely high quality and reliability for years of continuous operation. Moreover, its self-priming performance and simple operation can improve the efficiency and stability of the production line and reduce breakdowns in the production process.

At present, TOPSFLO Diaphragm Ink Pump have been affirmed by well-known customers in a wide range of markets such as Japan, Israel, USA, UK, India and China.

Customer Case: A digital direct inkjet printing equipment manufacturer in Shenzhen uses TOPSFLO diaphragm pump

The manufacturer uses TOPSFLO diaphragm pump product TF30 for color control and liquid transfer, and has achieved good results. TF30 has a reasonable and compact overall design, high performance, low power consumption, low noise, and also has a long life, maintenance-free characteristics. Especially its excellent self-priming performance, high pressure, suction force >30kpa, pressure >1bar, reduces the failure in the production process. Its excellent structural design and convenient operation provide long-term guarantee for the stability and efficiency of the production line, which greatly improves the product quality and market reputation of customers.

In the field of digital direct printing machine manufacturing, as the core component of printing equipment, TOPSFLO digital direct printing pump makes the production and manufacturing process more efficient, stable and reliable, and is worthy of consideration and selection by the R&D and purchasing personnel of the majority of professional printer manufacturers.

More details can be found: http://www.topsflo.com/

https://www.youtube.com/watch?v=fDCEXH_jZFY

1 note

·

View note

Link

TOPSFLO 소형 다이어프램 펌프가 국제적으로 유명��� 회사에서 선택한 이유는 무엇입니까?

Skype:topsflo ✉E-Mail:[email protected]

0 notes

Photo

Successfully replaced famous American brands! TOPSFLO ultra-low noise diaphragm pump helps customers solve the problems of new medical system

After careful and rigorous evaluation of the customer's project, TOPSFLO recommended the TF30A-C #DCbrushlessdiaphragmliquidpump to match the customer's heating equipment according to its low noise and long life requirements. This miniature diaphragm pump offers advantages over industry standards:

1. Noise as low as 50dB: TOPSFLO adopts double ball imported bearings, high-precision molds, and eccentric silent design to ensure long-term silent operation of the pump (ordinary pumps use single bearing or oil-impregnated bearing, which is not wear-resistant, has a short life, and has a noise of about 60dB).

2. The service life is more than 15,000 hours: self-developed and designed high-grade hollow cup brushless slotless motors, imported molds and raw materials, metal balance blocks, longer pump life, stable and reliable long-term operation (greatly exceeding the domestic general manufacturers brushless 5,000 hours of life).

3. The patented design balance block has good balance performance and low vibration, which is much better than ordinary products.

4. Good airtightness: Reasonable structure, innovatively designed diaphragm & valve, configured pump head & complete sealing system, the overall airtightness of the pump has reached an excellent level.

5. The product structure design is based on the international brands KNF and Parker pumps. The overall design is reasonable, compact, high performance, low noise and low vibration.

Click to read the full text

http://www.topsflo.com/news/micro-diaphragm-liquid-pump.html

Contact us:

Skype:topsflo

Email:[email protected]

0 notes

Photo

How to Choose a #microdiaphragmpump? As the core component of the equipment, many clients are not very familiar with micro-diaphragm pump and do not know how to choose it for the first time. TOPSFLO has been focusing on micro-diaphragm pumps for 17 years, providing high-quality micro diaphragm pumps for many internationally renowned companies, providing solutions, and reaching long-term and stable cooperation.Why? Click to read the full text👇👇 http://www.topsflo.com/news/micro-diaphragm-pump.html Contact us: 📱Skype:topsflo ✉Email:[email protected] 🔗www.topsflo.com #Miniaturediaphragmpump #microdiaphragmpump #diaphragmvacuumpump #diaphragmliquidpump #airpump

0 notes