#Military Aerospace Coatings Industry Size

Explore tagged Tumblr posts

Text

Data Bridge Market Research analyses the military aerospace coatings market will exhibit a CAGR of 7.00% for the forecast period of 2022-2029.

#Military Aerospace Coatings Market#Military Aerospace Coatings Market Share#Military Aerospace Coatings Market Size#Military Aerospace Coatings Market Growth#Military Aerospace Coatings Market Trends#Military Aerospace Coatings Market Players#Military Aerospace Coatings Market Competitors#Military Aerospace Coatings Industry Size#Military Aerospace Coatings Industry Trends#Military Aerospace Coatings Industry Growth#Military Aerospace Coatings Industry Share#Military Aerospace Coatings Industry Players

0 notes

Text

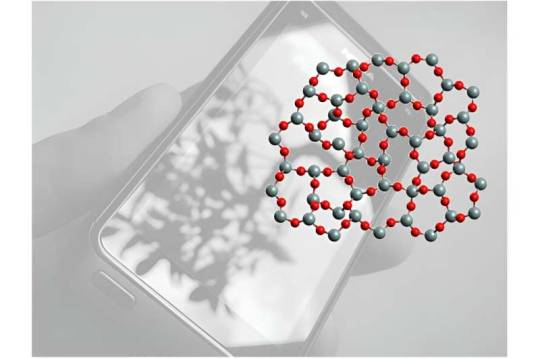

Stability of rings of atoms in glass materials can help predict performance of glass products

Glass is being used in a wider range of high-performance applications, including those for consumers and industry, military and aerospace electronics, coatings and optics. Because of the extreme precision demanded for use in products such as mobile phones and jet aircraft, glass substrates must not change their shape during the manufacturing process. Corning Incorporated, a manufacturer of innovative glass, ceramics and related materials, invests a tremendous amount of resources into studying the stability of different types of glass. Recently, Corning researchers found that understanding the stability of the rings of atoms in glass materials can help them predict the performance of glass products. This capability is important because the most widely used glass is silicate glass, which consists of different sizes of atomic rings connected in three dimensions. Conducting neutron scattering experiments at the Department of Energy's Oak Ridge National Laboratory, ORNL and Corning scientists discovered that as the number of smaller, less-stable atomic rings in a glass increases, the instability, or liquid fragility, of the glass also increases.

Read more.

20 notes

·

View notes

Text

Aluminium Alloy 2014 Sheets & Plates Manufacturers In India

Aluminium Alloy 2014 Sheets & Plates, manufactured and supplied by Siddhgiri Tubes, present a versatile solution for various industrial applications. As leading Manufacturers, Suppliers, Stockists, and Exporters, we offer ASTM B209 specified plates with a wide range of dimensions. These plates come in thicknesses from 0.2mm to 300mm, widths from 500mm to 2500mm, and lengths ranging from 500mm to 10000mm.

India is home to several leading manufacturers of Aluminium Alloy 2014 Sheets & Plates, with a wide range of products catering to diverse industries such as aerospace, defense, automotive, and engineering. Known for its superior strength and heat-treatable properties, Aluminium Alloy 2014 is widely used in high-performance applications that demand strength and durability. Indian manufacturers, like Siddhgiri Tubes, have established themselves as key suppliers in the global market, delivering top-quality products that adhere to international standards.

Product Overview

Aluminium Alloy 2014 is a high-strength, heat-treatable alloy that is often used in critical applications that require excellent mechanical properties and wear resistance. This alloy contains aluminium as its base metal, with copper as the main alloying element, providing the alloy with superior strength and hardness. While it offers moderate corrosion resistance, it is primarily valued for its strength and machinability in demanding structural applications.

Key Features:

High Strength: Alloy 2014 is known for its exceptional tensile strength and fatigue resistance.

Heat Treatable: It can be heat-treated to further enhance its strength, making it suitable for various structural and high-load applications.

Good Machinability: The alloy is easy to machine and fabricate into sheets and plates, making it suitable for various engineering and manufacturing processes.

Moderate Corrosion Resistance: Though not as corrosion-resistant as alloys like 6061, it performs well in environments where corrosion is not the primary concern, provided proper coatings or treatments are applied.

Applications of Aluminium Alloy 2014 Sheets & Plates

Aerospace Industry: Used in aircraft fuselage, wings, and other high-strength structural components.

Defense & Military: Components for military aircraft, missile parts, and other defense-related equipment.

Automotive Industry: High-performance automotive parts that require high strength and minimal weight.

Heavy Engineering: Structural components in bridges, heavy machinery, and load-bearing applications.

Marine Applications: Used in certain marine structures where high strength is required for critical components.

Leading Manufacturers of Aluminium Alloy 2014 Sheets & Plates in India

Siddhgiri Tubes Siddhgiri Tubes is a well-known manufacturer, exporter, and supplier of Aluminium Alloy 2014 Sheets & Plates in India. They offer a wide range of products that are manufactured in compliance with national and international quality standards. With advanced production techniques, they ensure the alloy's strength, dimensional accuracy, and surface finish meet the highest standards required for various applications.Key Products:

Specification Chart of Aluminium Alloy 2014 Sheets & Plates

GradeAluminium 2014 / UNS A92014ASTM SpecificationsASTM B209 / ASME SB209Thickness Chart0.5mm TO 250mmFormPlates, Sheets, Slatting Coils, Coils, Foils, Plain Sheet, Shim Sheet, Strip, Rolls, Perforated Coils, Flats, Blank , RingHardnessQuarter Hard, Soft, Hard, Half Hard, Spring Hard etc.FinishCold rolled sheet (CR), 2D, Hot rolled plate (HR), 2B, BA NO(8), SATIN (Met with Plastic Coated)Size in Milimeter000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm etcLength in MM1000mm TO 6000mmApplications IndustriesGas Processing, Condensers, Sea Water Equipment, Power Generation, Pharmaceuticals, Specialty Chemicals, Pulp, Pharmaceutical Equipment, Chemical Equipment, Petrochemicals, Paper Off-Shore Oil Drilling Companies, Heat Exchangers, Industry

Advantages

Aluminium Alloy 2014 is a high-strength, heat-treatable alloy that offers several key advantages, particularly in applications that require superior mechanical properties. The following are the main advantages of Aluminium Alloy 2014 Sheets & Plates:

1. High Strength-to-Weight Ratio

One of the primary advantages of Aluminium Alloy 2014 is its exceptionally high strength-to-weight ratio. This makes it a preferred choice for applications where strength is critical, but reducing weight is equally important—such as in aerospace, automotive, and defense sectors. The strength of this alloy ensures that it can withstand high-stress conditions without adding unnecessary weight.

2. Excellent Mechanical Properties

Aluminium Alloy 2014 offers outstanding tensile strength, hardness, and fatigue resistance. Its high strength makes it ideal for structural applications where load-bearing capacity is required. When heat-treated, its mechanical properties are further enhanced, making it suitable for demanding conditions, such as aircraft parts and military components.

Tensile Strength: High tensile strength ensures the material can resist forces pulling or stretching it.

Fatigue Resistance: The alloy resists wear and fatigue under repeated stress, which is especially important for aircraft and transportation applications.

3. Heat Treatable for Enhanced Strength

Aluminium Alloy 2014 can be heat-treated to significantly increase its strength and hardness. This heat-treatment process improves the material’s mechanical properties, making it more suitable for specialized applications that require both high strength and durability. The ability to tailor the properties of the alloy through heat treatment adds to its versatility.

4. Good Machinability

Despite its high strength, Aluminium Alloy 2014 is easy to machine and fabricate, which is a key advantage in manufacturing. The alloy’s machinability allows it to be easily cut, drilled, welded, and formed into complex shapes, making it ideal for the production of intricate components. This machinability is especially valuable in industries such as aerospace, where precision and quality control are critical.

5. Superior Wear Resistance

The high copper content in Aluminium Alloy 2014 gives it excellent wear resistance, making it ideal for applications subject to abrasion or friction. This wear resistance is important in industries like aerospace, automotive, and heavy machinery, where components must withstand frequent or long-term mechanical stress without degrading.

6. Versatility in Applications

Due to its superior mechanical properties, Aluminium Alloy 2014 is highly versatile and can be used in a wide range of demanding applications:

Aerospace: For high-strength aircraft parts, such as fuselage frames, wing spars, and structural components.

Defense: For military applications, including missile components and armor.

Automotive: Used in high-performance vehicles to reduce weight while maintaining strength.

Heavy Engineering: Ideal for load-bearing components in heavy machinery, bridges, and structural engineering projects.

7. Corrosion Resistance with Proper Coatings

Although Aluminium Alloy 2014 does not have the same level of corrosion resistance as some other aluminium alloys, it can still perform well in most environments when proper coatings or surface treatments are applied. Coating or anodizing the material can protect it from corrosion, particularly in marine or highly humid environments. This makes it adaptable for use in harsh conditions when necessary protective treatments are employed.

8. Cost-Effective for High-Performance Applications

While Aluminium Alloy 2014 may be more expensive than other alloys in some cases, its high strength and durability make it a cost-effective solution for applications where performance is a critical factor. When compared to other high-strength alloys, the long-term benefits of reduced maintenance costs and increased reliability often outweigh the initial cost, making it an excellent value for industries requiring high-performance materials.

9. Global Availability and Easy Sourcing

Aluminium Alloy 2014 Sheets & Plates are widely available from reputable manufacturers in India and around the world. This availability, combined with the ability to source the material in custom sizes and specifications, makes it easy for companies to procure Aluminium Alloy 2014 for their projects, regardless of geographic location.

10. Environmentally Friendly

Aluminium alloys are known for their recyclability. Aluminium Alloy 2014 is no exception, and when it reaches the end of its useful life, it can be recycled with minimal loss of properties. The recycling of aluminium requires less energy than producing new aluminium, making it a more environmentally sustainable option in comparison to many other metals.

Conclusion

Aluminium Alloy 2014 Sheets & Plates offer a range of advantages, from high strength and wear resistance to excellent machinability and heat treatability. These properties make them an ideal choice for high-performance applications across industries like aerospace, automotive, defense, and heavy engineering. The alloy's ability to withstand harsh conditions, coupled with its ease of processing and recyclability, makes it a valuable material in critical applications that demand both durability and precision.

0 notes

Text

Laser Safety Glasses Market Forecast Report, Industry Trends, Size 2024 to 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Laser Safety Glasses Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Laser Safety Glasses Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Laser Safety Glasses Market?

The global laser safety glasses market was valued at US$ 610.1 Mn in 2023 and is expected to register a CAGR of 7.9% over the forecast period and reach US$ 1,209.5 Mn in 2032.

What are Laser Safety Glasses?

Laser safety glasses are protective eyewear designed to shield the eyes from hazardous laser radiation in environments where lasers are used. Constructed with specialized lens materials and coatings, they effectively block or absorb specific laser wavelengths to prevent potential damage to the retina or cornea. Each pair is rated for Optical Density (OD) and specific wavelength ranges, offering tailored protection for various types of lasers commonly found in medical, industrial, scientific, and research applications. Essential for reducing eye injury risks, laser safety glasses provide both safety and comfort for those working with high-intensity laser equipment.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/2479

What are the growth prospects and trends in the Laser Safety Glasses industry?

The laser safety glasses market growth is driven by various factors and trends. The laser safety glasses market is witnessing substantial growth driven by heightened awareness of workplace safety and the increasing adoption of laser technologies across various sectors, including healthcare, manufacturing, research, and entertainment. As laser usage becomes more widespread, the demand for protective eyewear to prevent eye injuries has grown significantly. Advancements in lens technology and materials, along with a stronger focus on compliance with safety regulations, are contributing to market expansion. Furthermore, the rise of e-commerce and online platforms has facilitated access to a broader range of laser safety eyewear options for consumers and businesses. This market is also bolstered by ongoing educational and training initiatives aimed at promoting laser safety in workplaces, ensuring proper usage and adherence to safety standards. Hence, all these factors contribute to laser safety glasses market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Technology

Glass Laser Safety Eyewear

Polycarbonate Safety Glasses

Thin Film Glasses

Laser Protective Face Shields

Intense Pulse Light Safety Glasses

By Application

Automotive

Medical

Chemicals

Military, Aerospace, and Defense

Others

North America

United States

Canada

Europe

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

Benelux

Nordic

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America

Brazil

Mexico

Argentina

Middle East & Africa

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Honeywell International Inc.

3M

VS Eyewear

Thorlabs, Inc.

Univent Optical Technologies

Kentek Corporation

Laser Safety Industries

NoIR Laser Company LLC

uvex group

Phillips Safety Products, Inc.

View Full Report: https://www.reportsandinsights.com/report/Laser Safety Glasses-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Laser Safety Glasses Market share#Laser Safety Glasses Market size#Laser Safety Glasses Market trends

0 notes

Text

Aerogel Market Size, Growth Opportunities Estimated to be Experienced By 2030

The global aerogel market was valued at approximately USD 1.38 billion in 2024, with projections for a compound annual growth rate (CAGR) of 17.0% from 2025 through 2030. Aerogels, renowned for being lightweight, highly porous, and effective insulators, are increasingly applied across various sectors such as construction, aerospace, automotive, and electronics. With a continued rise in global energy consumption, the demand for materials that effectively reduce energy loss is pressing. Aerogels meet this demand with their outstanding thermal insulation qualities, making them particularly valuable for building insulation and providing thermal protection in industrial processes.

Aerogels are low-density materials that retain unique properties in solid form. Traditionally, they are manufactured through supercritical drying technology, although newer technologies have emerged to enhance efficiency. Aerogels are created by removing liquid from a gel in a way that leaves behind a 3D nanoporous structure, typically containing 80 to 99% air. While they can be produced from various materials, silica aerogels are the most common type. Other materials used in aerogel production include polymer and carbon, which are selected based on specific application requirements.

Gather more insights about the market drivers, restrains and growth of the Aerogel Market

The aerospace and defense industries are pivotal segments within the aerogel market, requiring materials that are both lightweight and capable of withstanding extreme temperatures and environmental conditions. Aerogels are increasingly utilized for insulating spacecraft, aircraft, and protective gear for military use. The emphasis on reducing weight to enhance fuel efficiency and overall performance in these sectors drives the demand for aerogels, positioning them as essential for high-performance applications.

Additionally, increased awareness of environmental issues and a move towards sustainable materials are major forces shaping the aerogel market. As industries aim to reduce their ecological impact, aerogels serve as a viable solution due to their low density and high thermal efficiency. Research into bio-based aerogels and eco-friendly production techniques is expected to attract additional investments, accelerating market growth. With sustainability emerging as a priority, aerogels are well-suited to benefit from this shift, solidifying their role as transformative materials across multiple applications.

End-use Segmentation Insights:

In 2024, the oil and gas sector held the largest share of the aerogel market, accounting for 61.0% of total revenue. Aerogels, with their high porosity, low density, exceptional thermal insulation, and strong mechanical properties, are highly valued in oil and gas for efficient thermal management, particularly in drilling, transportation, and refining processes. Their ability to withstand extreme temperatures while providing insulation reduces energy consumption and enhances safety in oil and gas facilities.

Performance coatings are projected to experience the highest CAGR of 18.4% throughout the forecast period. The drive towards sustainability and energy efficiency is fueling the adoption of aerogel-based performance coatings. As industries seek to reduce their carbon footprint, integrating aerogels into coatings supports these sustainability goals by lowering energy demands for heating and cooling. Additionally, innovations in aerogel production are making these materials more cost-effective and accessible, which encourages their application across an expanding range of industries.

Order a free sample PDF of the Aerogel Market Intelligence Study, published by Grand View Research.

0 notes

Text

Aerogel Industry 2030 Future Scope, Size Estimation, Regional Outlook

The global aerogel market was valued at approximately USD 1.38 billion in 2024, with projections for a compound annual growth rate (CAGR) of 17.0% from 2025 through 2030. Aerogels, renowned for being lightweight, highly porous, and effective insulators, are increasingly applied across various sectors such as construction, aerospace, automotive, and electronics. With a continued rise in global energy consumption, the demand for materials that effectively reduce energy loss is pressing. Aerogels meet this demand with their outstanding thermal insulation qualities, making them particularly valuable for building insulation and providing thermal protection in industrial processes.

Aerogels are low-density materials that retain unique properties in solid form. Traditionally, they are manufactured through supercritical drying technology, although newer technologies have emerged to enhance efficiency. Aerogels are created by removing liquid from a gel in a way that leaves behind a 3D nanoporous structure, typically containing 80 to 99% air. While they can be produced from various materials, silica aerogels are the most common type. Other materials used in aerogel production include polymer and carbon, which are selected based on specific application requirements.

Gather more insights about the market drivers, restrains and growth of the Aerogel Market

The aerospace and defense industries are pivotal segments within the aerogel market, requiring materials that are both lightweight and capable of withstanding extreme temperatures and environmental conditions. Aerogels are increasingly utilized for insulating spacecraft, aircraft, and protective gear for military use. The emphasis on reducing weight to enhance fuel efficiency and overall performance in these sectors drives the demand for aerogels, positioning them as essential for high-performance applications.

Additionally, increased awareness of environmental issues and a move towards sustainable materials are major forces shaping the aerogel market. As industries aim to reduce their ecological impact, aerogels serve as a viable solution due to their low density and high thermal efficiency. Research into bio-based aerogels and eco-friendly production techniques is expected to attract additional investments, accelerating market growth. With sustainability emerging as a priority, aerogels are well-suited to benefit from this shift, solidifying their role as transformative materials across multiple applications.

End-use Segmentation Insights:

In 2024, the oil and gas sector held the largest share of the aerogel market, accounting for 61.0% of total revenue. Aerogels, with their high porosity, low density, exceptional thermal insulation, and strong mechanical properties, are highly valued in oil and gas for efficient thermal management, particularly in drilling, transportation, and refining processes. Their ability to withstand extreme temperatures while providing insulation reduces energy consumption and enhances safety in oil and gas facilities.

Performance coatings are projected to experience the highest CAGR of 18.4% throughout the forecast period. The drive towards sustainability and energy efficiency is fueling the adoption of aerogel-based performance coatings. As industries seek to reduce their carbon footprint, integrating aerogels into coatings supports these sustainability goals by lowering energy demands for heating and cooling. Additionally, innovations in aerogel production are making these materials more cost-effective and accessible, which encourages their application across an expanding range of industries.

Order a free sample PDF of the Aerogel Market Intelligence Study, published by Grand View Research.

0 notes

Text

Biopolymers Market - Forecast(2024 - 2030)

Biopolymers Market Overview

The Biopolymers Market size is projected to reach US$27.5 billion by 2030, after growing at a CAGR of 11.5% over the forecast period 2024–2030. The various benefits associated with the biopolymers such as polyesters, polylactic acid, polyhydroxy butyrate, polybutylene succinate and more include biocompatibility, biodegradability, renewability and more. These benefits make biopolymers a sustainable replacement for petroleum-derived materials. The bolstering food & beverage industry, including poultry products, dried food and more is the primary factor driving the biopolymers market growth. For instance, the FAO’s food outlook published in June 2023 expects global poultry meat production to reach more than 142 million mt, a 1.3% increase compared to 2022’s value. However, The COVID-19 pandemic resulted in restrictions affecting various aspects of the supply chain, including logistics, which had a detrimental impact on production activities in the biopolymers industry. Following the pandemic, government measures aimed at rejuvenating production activities played a crucial role in fueling the recovery and growth of the biopolymers industry. Moreover, the growth of the medical and healthcare industry is fueling the demand for biopolymers. As a result, the biopolymers market size will grow throughout the forecast period.

Request Sample Report:

Report Coverage-The “Biopolymers Market Report — Forecast (2024–2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Biopolymers Market.

By Type: Bio-based Polyesters [Polylactic Acid (PLA), Polyhydroxybutyrate (PHB), Polybutylene Succinate (PBS), Polybutylene Succinate Adipate (PBSA), Polytrimethylene Terephthalate (PTT) and Others], Bio-based Polyolefins, Bio-based Polyamides (Bio-PA) (Homopolyamides, Bio-PA 6, Bio-PA 11, Copolyamides and Others), Polyurethanes, Polysaccharide Polymers (Cellulose-based Polymers and Starch-based Polymers) and Others.

Inquiry Before Buying:

By Molding Process: Extrusion, Injection, Melt compounding and Others.

By Application: Packaging (Rigid Packaging and Flexible Packaging), Fibers, Paper & Cardboard Coatings, Agricultural Seed Coatings, Automotive Interiors & Exteriors, Medical Implants, Circuit Boards, Insulators, Laminates and Others.

By End-use Industry: Food & Beverage (Fresh Food, Bakery, Frozen Food, Dried Food, Poultry Products, Dairy Products, Confectionery, Alcoholic Beverages, Non-alcoholic Beverages and Others), Medical & Healthcare (Pharmaceuticals, Medical Devices and Others), Agriculture, Consumer Electronics (Computers, Smartphones, Refrigerators and Others), Automotive [Passenger Vehicles (PV), Light Commercial Vehicles (LCV) and Heavy Commercial Vehicles (HCV)], Textile, Aerospace (Commercial, Military and Others), Building & Construction (Residential, Commercial, Industrial and Others) and Others

By Geography: North America (the USA, Canada and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium and the Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile and Rest of South America), Rest of the World [Middle East (Saudi Arabia, UAE, Israel and Rest of Middle East) and Africa (South Africa, Nigeria and Rest of Africa)]

Key Takeaways

• Europe dominated the Biopolymers Market, owing to the growth of the fresh food industry in the region. For instance, according to the Federal Statistical Office of Germany,roughly 6,100 agricultural holdings in Germany harvested a total 3.8 million tonnes of vegetables in 2022.

• The government initiatives for green initiatives are fuelling the demand for Biopolymers such as polyesters, polyethylene and more are driving the market growth.

• Moreover, the increasing adoption of Biopolymers in packaging applications is also accelerating market growth.

For More Details on This Report — Request for Sample

Biopolymers Market Segment Analysis — by Application

The packaging segment held the largest Biopolymers Market share in 2023 and is estimated to grow at a CAGR of 10.4% over the forecast period 2024–2030. Biopolymers such as polyesters, polylactic acid, polyhydroxybutyrate and more are frequently deployed in packaging because they enhance the shelf-life of the product and also it reduces the overall carbon footprint related to food packaging. The films composed of biopolymers such as polysaccharides and protein-composed increase mechanical and optical properties. As a result, biopolymers packaging is employed across various end-use industries, including food & beverages, medical & healthcare and more. Thus, owing to the above-mentioned benefits, the adoption of biopolymers is surging in packaging applications, which is accelerating market growth.

Biopolymers Market Segment Analysis — by End-use Industry

The food & beverage segment held a significant Biopolymers Market share in 2023. The key properties of biopolymers are high strength, lightweight and heat resistance. As a result, biopolymers are frequently used in the food and beverage industry. Moreover, due to their superior quality, functionality, affordability and composability, they are an ideal replacement for single-use plastic food & beverage packaging. The surging development of food & beverage facilities, governmental initiatives and others are the crucial variables propelling the food & beverage industry’s growth. For instance, according to Invest India, the food processing sector in India is one of the world’s largest, with output anticipated to reach US$535 billion by 2025–2026. Hence, the growth of the food & beverage industry is expected to fuel the demand for biopolymers. As a result, the market growth will accelerate during the upcoming years.

Schedule a Call:

Biopolymers Market Segment Analysis — by Geography

Europe is the dominating region as it held the largest Biopolymers Market share in 2023. The economic growth of Europe is driven by the growth of the various industries, including food and beverage, medical & healthcare and other similar industries. The food and beverages industry growth are vital for food security in the European region. For instance, according to Food Drink Europe, the food and drink industry in Europe produced a 107.7 production index in the fourth quarter of 2022 and a 109.2 production index in the first quarter of 2023, an increase of 1.4 percent. Also, according to the European Union, in 2022, the production of fruits in the European Union countries was about 35.9 million metric tons and out of this, apples and pears production were the highest at 14.7 million metric tons, which was 40.9% of the total fruit production. Therefore, the booming food & beverage industry in Europe is boosting the demand for biopolymers. This, in turn, is proliferating the biopolymers market size growth.

Biopolymers Market Drivers Government Initiatives for Biopolymers

The transformation of the current linear material system into a circular economy necessitates national and international legislation. This is due to the globalized industry’s complex worldwide supply chains. Governments at the global level are taking initiatives for biopolymers. For instance, In March 2023, the European Commission adopted a policy framework on biobased, biodegradable, and compostable plastics, marking an initiative to drive the biopolymers market. Aligned with the European Green Deal, this non-legislative framework aimed to clarify environmental benefits, set strict standards, and guide future policies on green claims, ecodesign, carbon removal, and microplastics. Thus, the growing government initiatives for biodegradable packaging are driving the demand for biopolymers, which is aiding market growth.

Growth of the Medical Devices Industry

In the production of medical devices such as replacement joints, heart valves, arteries, teeth, tendons, ligaments and eye lenses, biopolymers are used to replace or repair some diseased, damaged, or non-functional pieces of tissue or bone. Factors such as technological improvements in medical equipment and an aging population are accelerating the medical device industry’s growth. For instance, in global comparison, most revenue will be generated in the United States US$182.00bn in 2024. Thus, the growth of the medical device industry is boosting the demand for biopolymers, which, in turn, is driving market growth.

Biopolymers Market Challenge Higher Cost Associated with Biopolymers

Biopolymers such as polyesters, polylactic acid, polyhydroxy butyrate and more have the advantage of easy disposable and regeneration. However, one disadvantage of biopolymers is that they necessitate the use of expensive industrial processors and composters, particularly for those that must be broken down at high industrial temperatures. For instance, according to Plastmart, the major drawback of biopolymers is their higher price tag when compared to traditional polymers. While the typical, conventional polymers cost between US$1000 and US$1500 per metric tonne (MT), biopolymers can cost anywhere from US$4000 to US$15,000 per MT for materials like polyhydroxy butyrate. Therefore, the high price associated with biopolymers may restrict the growth of the biopolymers industry in the coming years.

Buy Now:

Biopolymers Industry Outlook

Technology launches, acquisitions and increased R&D activities are key strategies adopted by players in the Biopolymers Market. The top 10 companies in the Biopolymers market are

Recent Developments:

• In October 2023, Braskem opened a Tokyo office, advancing bio-based solutions in the biopolymers market. With over 15 years in Japan, it reflects their commitment to sustainability. Concurrently expanding in Brazil and Thailand, Braskem focuses on delivering low-carbon alternatives globally.

• In August 2022, DSM Engineering Materials launched StanylB-MB (Bio-based Mass Balanced), a more environmentally friendly version of its mainstay polyamide (PA) product that contains up to 100% bio-based material. It enables DSM Engineering Materials to halve the carbon footprint of this product line.

• In June 2022, a global polymer manufacturer based in Germany launched VerdessenceTM RiceTouch, a new biopolymer used for various personal care products.

Relevant Reports

Polymers Market — Industry Analysis, Market Size, Share, Trends, Application Analysis, Growth and Forecast Analysis

Bio-Based Construction Polymers Market — Industry Analysis, Market Size, Share, Trends, Application Analysis, Growth and Forecast Analysis

Bio-based Polymer Market — Industry Analysis, Market Size, Share, Trends, Application Analysis, Growth and Forecast Analysis

For more Chemicals and Materials Market reports, please click here

0 notes

Text

Biopolymers Market - Forecast(2024 - 2030)

Biopolymers Market Overview

The Biopolymers Market size is projected to reach US$27.5 billion by 2030, after growing at a CAGR of 11.5% over the forecast period 2024-2030. The various benefits associated with the biopolymers such as polyesters, polylactic acid, polyhydroxy butyrate, polybutylene succinate and more include biocompatibility, biodegradability, renewability and more. These benefits make biopolymers a sustainable replacement for petroleum-derived materials. The bolstering food & beverage industry, including poultry products, dried food and more is the primary factor driving the biopolymers market growth. For instance, the FAO’s food outlook published in June 2023 expects global poultry meat production to reach more than 142 million mt, a 1.3% increase compared to 2022’s value. However, The COVID-19 pandemic resulted in restrictions affecting various aspects of the supply chain, including logistics, which had a detrimental impact on production activities in the biopolymers industry. Following the pandemic, government measures aimed at rejuvenating production activities played a crucial role in fueling the recovery and growth of the biopolymers industry. Moreover, the growth of the medical and healthcare industry is fueling the demand for biopolymers. As a result, the biopolymers market size will grow throughout the forecast period.

𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐒𝐚𝐦𝐩𝐥𝐞

Report Coverage

The "Biopolymers Market Report – Forecast (2024-2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Biopolymers Market.

By Type: Bio-based Polyesters [Polylactic Acid (PLA), Polyhydroxybutyrate (PHB), Polybutylene Succinate (PBS), Polybutylene Succinate Adipate (PBSA), Polytrimethylene Terephthalate (PTT) and Others], Bio-based Polyolefins, Bio-based Polyamides (Bio-PA) (Homopolyamides, Bio-PA 6, Bio-PA 11, Copolyamides and Others), Polyurethanes, Polysaccharide Polymers (Cellulose-based Polymers and Starch-based Polymers) and Others.

By Molding Process: Extrusion, Injection, Melt compounding and Others.

By Application: Packaging (Rigid Packaging and Flexible Packaging), Fibers, Paper & Cardboard Coatings, Agricultural Seed Coatings, Automotive Interiors & Exteriors, Medical Implants, Circuit Boards, Insulators, Laminates and Others.

By End-use Industry: Food & Beverage (Fresh Food, Bakery, Frozen Food, Dried Food, Poultry Products, Dairy Products, Confectionery, Alcoholic Beverages, Non-alcoholic Beverages and Others), Medical & Healthcare (Pharmaceuticals, Medical Devices and Others), Agriculture, Consumer Electronics (Computers, Smartphones, Refrigerators and Others), Automotive [Passenger Vehicles (PV), Light Commercial Vehicles (LCV) and Heavy Commercial Vehicles (HCV)], Textile, Aerospace (Commercial, Military and Others), Building & Construction (Residential, Commercial, Industrial and Others) and Others

By Geography: North America (the USA, Canada and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium and the Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile and Rest of South America), Rest of the World [Middle East (Saudi Arabia, UAE, Israel and Rest of Middle East) and Africa (South Africa, Nigeria and Rest of Africa)]

Key Takeaways

• Europe dominated the Biopolymers Market, owing to the growth of the fresh food industry in the region. For instance, according to the Federal Statistical Office of Germany,roughly 6,100 agricultural holdings in Germany harvested a total 3.8 million tonnes of vegetables in 2022.

• The government initiatives for green initiatives are fuelling the demand for Biopolymers such as polyesters, polyethylene and more are driving the market growth.

• Moreover, the increasing adoption of Biopolymers in packaging applications is also accelerating market growth.

• However, the high cost of the Biopolymers is expected to create a retrain for the market growth during the projected forecast period.

Biopolymers Market Segment Analysis – by Application

The packaging segment held the largest Biopolymers Market share in 2023 and is estimated to grow at a CAGR of 10.4% over the forecast period 2024-2030. Biopolymers such as polyesters, polylactic acid, polyhydroxybutyrate and more are frequently deployed in packaging because they enhance the shelf-life of the product and also it reduces the overall carbon footprint related to food packaging. The films composed of biopolymers such as polysaccharides and protein-composed increase mechanical and optical properties. As a result, biopolymers packaging is employed across various end-use industries, including food & beverages, medical & healthcare and more. Thus, owing to the above-mentioned benefits, the adoption of biopolymers is surging in packaging applications, which is accelerating market growth.

Biopolymers Market Segment Analysis – by End-use Industry

The food & beverage segment held a significant Biopolymers Market share in 2023. The key properties of biopolymers are high strength, lightweight and heat resistance. As a result, biopolymers are frequently used in the food and beverage industry. Moreover, due to their superior quality, functionality, affordability and composability, they are an ideal replacement for single-use plastic food & beverage packaging. The surging development of food & beverage facilities, governmental initiatives and others are the crucial variables propelling the food & beverage industry's growth. For instance, according to Invest India, the food processing sector in India is one of the world’s largest, with output anticipated to reach US$535 billion by 2025-2026. Hence, the growth of the food & beverage industry is expected to fuel the demand for biopolymers. As a result, the market growth will accelerate during the upcoming years.

Biopolymers Market Segment Analysis – by Geography

Europe is the dominating region as it held the largest Biopolymers Market share in 2023. The economic growth of Europe is driven by the growth of the various industries, including food and beverage, medical & healthcare and other similar industries. The food and beverages industry growth are vital for food security in the European region. For instance, according to Food Drink Europe, the food and drink industry in Europe produced a 107.7 production index in the fourth quarter of 2022 and a 109.2 production index in the first quarter of 2023, an increase of 1.4 percent. Also, according to the European Union, in 2022, the production of fruits in the European Union countries was about 35.9 million metric tons and out of this, apples and pears production were the highest at 14.7 million metric tons, which was 40.9% of the total fruit production. Therefore, the booming food & beverage industry in Europe is boosting the demand for biopolymers. This, in turn, is proliferating the biopolymers market size growth.

0 notes

Text

Thermal Spray Coatings Materials Market Insights and Global Outlook 2024-2030

"Thermal Spray Coatings Materials" 2024 Breakdown, Data Source, Secondary Sources, Primary Sources, Research Report delivers leading competitors strategic analysis, with micro and macro-economic factors, market trends, future growth scenarios, with pricing analysis. This report provides a holistic overview on Market Current Situations, Key Collaborations, Merger & Acquisitions along with Trending Innovations and New Business Development Policies. A detailed professional report focusing on primary and secondary growth drivers, regional segments, growth share, and geographical analysis of top key players. Thermal Spray Coatings Materials trend analysis with historical data, estimates to 2024 and Compound Annual Growth Rate (CAGR) forecast to 2030.

Top Key Players Covered in Market Report 2024-2030:FUJIMI INCORPORATED、Entegris、Hansol IONES、SEWON HARDFACING CO.,LTD、Saint-Gobain、Oerlikon Balzers、APS Materials, Inc.、NGK (NTK CERATE)、Hansol IONES、FEMVIX CORP.、Coorstek、CINOS、Yeedex、YMC Co., Ltd.、Treibacher Industrie AG、Shin-Etsu Rare Earths

Short Description of the Thermal Spray Coatings Materials 2024-2030: Market Overview of Global Thermal Spray Coatings Materials: According to our latest research, the global Thermal Spray Coatings Materials looks promising in the next 6 years. As of 2024, the global Thermal Spray Coatings Materials was estimated at USD Million, and it’s anticipated to reach USD Million in 2030, with a CAGR during the forecast years. This report covers a research time span from 2019 to 2029, and presents a deep and comprehensive analysis of the global Thermal Spray Coatings Materials, with a systematical description of the status quo and trends of the whole market, a close look into the competitive landscape of the major players, and a detailed elaboration on segment markets by type, by application and by region. Global and Regional Analysis: North America (United States, Canada and Mexico) Europe (Germany, France, United Kingdom, Russia, Italy, and Rest of Europe) Asia-Pacific (China, Japan, Korea, India, Southeast Asia, and Australia) South America (Brazil, Argentina, Colombia, and Rest of South America) Middle East & Africa (Saudi Arabia, UAE, Egypt, South Africa, and Rest of Middle East & Africa)

Market Segmentation Thermal Spray Coatings Materials report provides an exhaustive 360-degree analysis, by utilizing both primary and secondary research techniques. The research gained comprehensive insights into current market dynamics, pricing trends, developments, supply-demand and evolving consumer behaviors.

On the basis of product type, this report displays the production, revenue, price, market Yttrium Oxide Thermal Spray Powder Alumina-based Thermal Spray Powder Others

On the basis of the end users/applications, this report focuses on the status and outlook for major applications/end users, consumption (sales), market share and growth rate for each Semiconductor Manufacturing Equipment Automotive Military & Aerospace Other

Inquire or Share Your Questions If Any before Purchasing This Report https://www.globalinforesearch.com/contact-us Our method for estimating market size is holistic and multifaceted. We assess vital industry trends, regulatory landscapes, and segment-specific dynamics, evaluating their potential influence on demand projections. Key macroeconomic factors, including price fluctuations, demographic shifts, and changes in demand patterns, are integrated into our calculations. To discover market value, we not only delve deep into the profiles of prominent players and their global market shares but also rely on our frequently updated internal database, enriched with insights and announcements from pivotal market stakeholders.

Some of the Key Questions Answered in this Report:

What is the Thermal Spray Coatings Materials size at the regional and country level

What are the key drivers, restraints, opportunities, and challenges of the Thermal Spray Coatings Materials, and how they are expected to impact the market

What is the global (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa) sales value, production value, consumption value, import and export of Thermal Spray Coatings Materials

Who are the global key manufacturers of the Thermal Spray Coatings Materials? How is their operating situation (capacity, production, sales, price, cost, gross, and revenue)

What are the Thermal Spray Coatings Materials opportunities and threats faced by the vendors in the Thermal Spray Coatings Materials?

Which application/end-user or product type may seek incremental growth prospects? What is the market share of each type and application?

What focused approach and constraints are holding the Thermal Spray Coatings Materials?

What are the different sales, marketing, and distribution channels in the global industry?

What are the key market trends impacting the growth of the Thermal Spray Coatings Materials?

Economic Impact on the Thermal Spray Coatings Materials and development trend of the Thermal Spray Coatings Materials

What are the Thermal Spray Coatings Materials opportunities, market risk, and market overview of the Thermal Spray Coatings Materials

The content of the study subjects, includes a total of 15 chapters: Chapter 1, to describe Hydrogen Bromide product scope, market overview, market estimation caveats and base year. Chapter 2, to profile the top manufacturers of Hydrogen Bromide, with price, sales, revenue and global market share of Hydrogen Bromide from 2019 to 2024. Chapter 3, the Hydrogen Bromide competitive situation, sales quantity, revenue and global market share of top manufacturers are analyzed emphatically by landscape contrast. Chapter 4, the Hydrogen Bromide breakdown data are shown at the regional level, to show the sales quantity, consumption value and growth by regions, from 2019 to 2030. Chapter 5 and 6, to segment the sales by Type and application, with sales market share and growth rate by type, application, from 2019 to 2030. Chapter 7, 8, 9, 10 and 11, to break the sales data at the country level, with sales quantity, consumption value and market share for key countries in the world, from 2017 to 2022.and Thermal Spray Coatings Materials forecast, by regions, type and application, with sales and revenue, from 2025 to 2030. Chapter 12, market dynamics, drivers, restraints, trends and Porters Five Forces analysis. Chapter 13, the key raw materials and key suppliers, and industry chain of Hydrogen Bromide. Chapter 14 and 15, to describe Hydrogen Bromide sales channel, distributors, customers, research findings and conclusion. Global Info Research is a company that digs deep into global industry information to support enterprises with market strategies and in-depth market development analysis reports. We provides market information consulting services in the global region to support enterprise strategic planning and official information reporting, and focuses on customized research, management consulting, IPO consulting, industry chain research, database and top industry services. At the same time, Global Info Research is also a report publisher, a customer and an interest-based suppliers, and is trusted by more than 30,000 companies around the world. We will always carry out all aspects of our business with excellent expertise and experience.

0 notes

Text

Fasteners in Focus: Trends and Innovations in the Fastener Industry

Fasteners Introduction

Fasteners are inevitable in many industries, such as automotive, aerospace, construction, and electronics. Examples of fasteners are bolts, nuts, screws, washers, and rivets; all these are used to either join or hold materials together. Their importance lies in the fact that they mechanically stabilize and strengthen structures and machinery.

Trends in the Fastener Industry

1. Advanced Materials

Another significant trend in the fastener industry is the high-grade materials being used. What used to be the run-of-a-mill for producing fasteners is being combined with alloys and composite materials. These are conventionally classified by high strength, high corrosion resistance, low weight, and various other attributes, hence doing them good for critical applications in the aerospace, automotive, and construction industries.

2. Coatings and Finishes

Offerings have expanded to include better characteristics, coatings, and finishes on the fasteners for better performance and endurance. These coatings provide resistance to corrosion, wear, and longevity under extreme temperatures, among other detriments. The most common coating finishes are zinc plating, anodizing, and organic coatings. Nascent Pipe & Tubes guarantees all our fasteners are available in strict quality, with a variety of finishes to meet the exclusive requirements of the industries.

3. Smart Fasteners

Connected smart fasteners are rapidly growing in demand, called forth by Industry 4.0, wherein the company fits the sensors and IoT on the fasteners to enhance real-time monitoring for tension, vibration, and environmental conditions, in a move to assure peak performance and service maintenance of critical structures; to prevent failure and associated downtime by mitigating failures.

4. Sustainable Manufacturing

Sustainability is gaining more prominence as a focus area in the fastener industry. Makers have started accepting processes as well as materials that are friendly to the eco-system to reduce the carbon footprint. Initiatives for recycling and using easily degradable materials are inclusive strategies adopted by the makers. Here, at Nascent Pipe & Tubes, we are committed to practicing green manufacturing for a wonderful sustainable future.

Fastener Technology Innovations

1. High-Performance Fasteners

Much fastener technology development nowadays is in the production of high-performance fasteners for use under aggressive or extreme ambient conditions. Among those are improved strength and fatigue resistance. Fastener designs with long lives. Much development applies to the toughest cases of aerospace, military, or industrial machinery.

2. Customized Solutions

One of the emerging trends in fasteners is towards customization, or the manufacture of products according to specific applications, along with tailor-made shapes, sizes, and materials to cater to all engineering requirements. Located in Mumbai, Nascent Pipe & Tubes lays its sole emphasis on providing its customers with specifically made-to-order solutions in fasteners so that they can assure themselves of getting what they want for their end products.

3. 3D Printing

3D printing technology is a game changer for fastener production. It allows fast prototyping and enables complex geometries that, otherwise, cannot be achieved by conventional manufacturing methods. This innovation not only reduces lead times but also enables the making of lightweight, high-precision fasteners.

Nascent Pipe & Tubes: Your Partner in Fastener Solution Ends

Nascent Pipe & Tubes is one of the largest manufacturers and fabricators of high-grade bolts, and its wide range of contents serves all kinds of industries, which helps us fulfill large and diverse requirements. Our dedication to innovation, quality, and customer satisfaction has led us to deliver only those fasteners that stand out in unparalleled performance and reliability.

Why Us?

Quality Control: We test our fasteners for international quality standards.

Wide Variety: We engage in the distribution of a wide array of fasteners which vary from bolts and nuts to screws and washers.

Customization: We cater to the specific needs of industries in a customized solution.

Innovation: We ensure to be up to date with the trends and technologies to deliver cutting-edge products.

Sustainability: Manufacturing processes are environment-friendly and sustainable.

Conclusion

Fastener companies are fast-paced and driven by innovation and sustainability. As one of the most reliable companies in the fastener industry, Nascent Pipe & Tubes appreciates this fact, and we devote our relentless efforts to the acquisition of superior fastener solutions that will enable the diversifying needs of a myriad of business sectors. Enabled with new materials, intelligent technologies, and sustainable practices, we continuously set examples to the stakeholders of our peers and responded to challenges with guarantees and promises of reliability in high-performance fasteners. For more information on our products and services, visit our website or contact us today.

0 notes

Text

Waterborne Coatings Market Overview

The Waterborne Coatings Market size is projected to reach US$112.8 billion by 2027, after growing at a CAGR of 5.9% during the forecast period 2022-2027. Waterborne Coatings are generally preferred over other conventional ones since these contain close to 80% water content, which makes them environmentally friendly. Waterborne coatings are often employed in the building & construction and automotive industry, which is supporting the Waterborne Coatings industry's growth. According to the International Organization of Motor Vehicle Manufacturers (OICA), global automotive production increased from 77,621,582 units in 2020 to 80,145,988 units in 2021. The rapid growth of the building & construction and automotive industry has increased the demand for environmentally friendly waterborne coatings, which fuels the market growth. Several end-use industries in the Waterborne Coatings industry suffered negative effects as a result of the novel coronavirus pandemic, which had a direct impact on the Waterborne Coatings Market size in the year 2020.

👉 𝗗𝗼𝘄𝗻𝗹𝗼𝗮𝗱 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 @ https://tinyurl.com/bx4ks9ej

Waterborne Coatings Market Report Coverage

The “Waterborne Coatings Market Report – Forecast (2022-2027)” by IndustryARC, covers an in-depth analysis of the following segments in the Waterborne Coatings industry.

By Resin Type: Acrylic, Epoxy, Polyester, Polyurethane, Vinyl Acetate, Alkyd, Polytetrafluoroethylene, Polyvinylidene Fluoride, Polyvinylidene Chloride and Others. By End-use Industry: Aerospace (Commercial Aircrafts, Military Aircrafts and Others), Automotive [Passenger Vehicles (PVs), Light Commercial Vehicles (LCVs) and Heavy Commercial Vehicles (HCVs)], Marine (Cargo, Passenger and Others), Locomotive (Electric and Diesel), Building and Construction (Residential, Commercial, Industrial and Infrastructural), Paper & Pulp, Packaging, Wood & Furniture and Others. By Geography: North America (the USA, Canada and Mexico), Europe (the UK, Germany, France, Italy, the Netherlands, Spain, Belgium and the Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia and the Rest of APAC), South America (Brazil, Argentina, Colombia, Chile and the Rest of South America) and the Rest of the World (the Middle East and Africa)

#Waterborne Coatings Market Share#Waterborne Coatings Market Size#Waterborne Coatings Market Forecast#Waterborne Coatings Market Research#Waterborne Coatings Market Treads#Waterborne Coatings Market Application#Waterborne Coatings Market Growth#Waterborne Coatings Market Price

0 notes

Text

Asia Pacific Metal Coated Fibers Market Analysis, Scope, Report 2023-2030

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated the Asia Pacific Metal Coated Fibers Market size by value at USD 864.22 million in 2023. During the forecast period between 2024 and 2030, BlueWeave expects the Asia Pacific Metal Coated Fibers Market size to expand at a CAGR of 4.86% reaching a value of USD 1,037.18 million by 2030. The Asia Pacific Metal Coated Fibers Market is driven by several key factors. Firstly, the rising demand for lightweight and high-strength materials across various industries such as aerospace, automotive, and electronics is propelling the market growth. Metal-coated fibers offer enhanced mechanical properties while maintaining a lightweight profile, making them ideal for applications requiring strength without added weight. Additionally, the growing focus on technological advancements and innovation in materials is driving the adoption of metal-coated fibers for diverse applications, further fueling market expansion.

By volume, BlueWeave estimated the Asia Pacific Metal Coated Fibers Market size at 9.36 million tons in 2023. During the forecast period between 2024 and 2030, BlueWeave expects the Asia Pacific Metal Coated Fibers Market size to expand at a CAGR of 4.18% reaching a volume of 11.65 million tons by 2030. Moreover, the increasing investments in infrastructure development and construction projects across the Asia Pacific region are contributing to the growth of the metal coated fibers market. The fibers find extensive applications in reinforced concrete structures, offering improved durability and strength. With governments and private sectors investing significantly in infrastructure projects, there is a heightened demand for construction materials that enhance structural integrity and longevity, thereby boosting the adoption of metal-coated fibers. The trend is expected to continue driving market growth in the coming years.

Opportunity – Surging demand for metal coated fibers from emerging technology sectors

The adoption of emerging technologies like 5G, the Internet of Things (IoT), and advanced manufacturing processes is propelling the growth of the Asia Pacific Metal Coated Fibers market. These fibers find extensive applications in sectors, such as telecommunications, aerospace, and automotive industries, where high-performance materials are essential. The increasing need for high-speed data transmission, lightweight materials for aircraft, and durable components in automotive manufacturing is fueling the demand for metal-coated fibers across the Asia Pacific region. The trend is expected to continue driving market expansion in the foreseeable future.

Sample Request @ https://www.blueweaveconsulting.com/report/asia-pacific-metal-coated-fibers-market/report-sample

Impact of Escalating Geopolitical Tensions on Asia Pacific Metal Coated Fibers Market

Escalating geopolitical tensions in the Asia Pacific Metal Coated Fibers Market have been fueled by various factors. The region's strategic importance in global supply chains, particularly in the electronics and aerospace industries, has heightened competition and territorial disputes. Recent events, such as increased military presence in the South China Sea and border conflicts between India and China, have raised concerns over supply chain disruptions and access to critical resources. Additionally, economic sanctions and trade disputes between major players like China and the United States have further strained relations, impacting market dynamics. These tensions have led to increased uncertainty, affecting investment decisions and supply chain strategies in the metal-coated fibers market across the Asia Pacific region.

Asia Pacific Metal Coated Fibers Market

Segmental Coverage

Asia Pacific Metal Coated Fibers Market – By Material

Based on material, Asia Pacific Metal Coated Fibers Market is divided into Aluminum, Copper, Nickel, Gold, and Silver segments. The aluminum segment is the leading material in the Asia Pacific Metal Coated Fibers Market. Aluminum-coated fibers are widely utilized across various industries due to their lightweight nature, corrosion resistance, and conductivity properties. Industries such as aerospace, automotive, and electronics extensively use aluminum-coated fibers for applications ranging from lightweight structural components to electromagnetic shielding. The demand for aluminum-coated fibers continues to grow owing to their versatility and effectiveness in diverse applications, making it the leading segment in the Asia Pacific Metal Coated Fibers Market.

Asia Pacific Metal Coated Fibers Market – By Fiber

Based on fiber, Asia Pacific Metal Coated Fibers Market is bifurcated into Single-Mode Fibers and Multimode Fibers segments. The multimode fibers segment typically dominates in terms of market share and revenue. Multimode fibers are known for their ability to carry multiple light rays simultaneously, making them suitable for various applications, such as data transmission over short distances. The segment's larger market share signifies its widespread adoption across industries in the Asia Pacific region, reflecting the demand for high-capacity data transmission solutions and the versatility offered by multimode fiber technology.

Competitive Landscape

Asia Pacific Metal Coated Fibers Market is fiercely competitive. Major companies in the market include Fujikura, Furukawa Electric, Sumitomo Electric Industries, Corning, and Yangtze Optical Fibre and Cable. These companies use various strategies, including increasing investments in their R&D activities, mergers, and acquisitions, joint ventures, collaborations, licensing agreements, and new product and service releases to further strengthen their position in the Asia Pacific Metal Coated Fibers Market.

Contact Us:

BlueWeave Consulting & Research Pvt Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

Aerospace Industry Paint Spray Guns, Global Market Size Forecast, Top 7 Players Rank and Market Share

Aerospace Industry Paint Spray Guns Market Summary

Paint Spray Gun is a device sprays coating material through the air onto a surface. This report only covers Paint Spray Gun used for Aerospace Industry.

According to the new market research report “Global Aerospace Industry Paint Spray Guns Market Report 2023-2029”, published by QYResearch, the global Aerospace Industry Paint Spray Guns market size is projected to reach USD 269.35 million by 2029, at a CAGR of 3.9% during the forecast period.

Figure. Global Aerospace Industry Paint Spray Guns Market Size (US$ Million), 2018-2029

Based on or includes research from QYResearch: Global Aerospace Industry Paint Spray Guns Market Report 2023-2029.

Market Drivers:

Increasing aircraft production: The global aerospace industry is experiencing steady growth, with increasing demand for commercial and military aircraft. As aircraft production ramps up, the demand for paint spray guns used in the aerospace industry also increases. These guns are essential for painting aircraft exteriors, interiors, and components.

Growing maintenance, repair, and overhaul (MRO) activities: Airlines and aircraft operators conduct regular maintenance and repaint aircraft to maintain their appearance and ensure corrosion protection. MRO activities involve painting, refinishing, and repainting aircraft surfaces, which drives the demand for efficient and high-quality paint spray guns.

Restraint:

One potential restraint in the aerospace industry paint spray guns market is the high cost of advanced paint spray gun systems. The aerospace sector demands sophisticated and high-performance paint spray guns that meet stringent quality and safety requirements. These advanced systems often come with a higher price tag due to their specialized design, materials, and compliance with industry standards. The high cost of these paint spray guns can pose a challenge, especially for small and medium-sized aerospace companies or operators with limited budgets.

Another restraint is the complexity of the aerospace painting process. Aerospace painting involves meticulous surface preparation, stringent environmental controls, and precise application techniques. This complexity requires skilled and trained personnel to handle paint spray guns effectively. The limited availability of trained professionals and the need for specialized knowledge can be a hindrance to the widespread adoption and efficient use of paint spray guns in the aerospace industry.

Opportunity:

Increasing aircraft fleet size: The global aerospace industry is witnessing steady growth in aircraft fleet size, driven by rising air travel demand and fleet modernization efforts. This provides an opportunity for the aerospace paint spray guns market, as more aircraft will require painting during manufacturing, maintenance, and repainting processes.

Advancements in paint application technology: Technological advancements in paint spray gun systems, such as improved atomization, reduced overspray, and advanced control systems, offer opportunities for more efficient and precise painting processes. Manufacturers that can provide innovative paint spray gun solutions with enhanced features, such as digital controls and integrated sensors, will be well-positioned to capitalize on these opportunities.

Figure. Global Aerospace Industry Paint Spray Guns Top 7 Players Ranking and Market Share(Continually updated)

Based on or includes research from QYResearch: Global Aerospace Industry Paint Spray Guns Market Report 2023-2029.

This report profiles key players of Aerospace Industry Paint Spray Guns such as Carlisle Fluid Technologies (CFT), EXEL Industries, Graco, Nordson, Anest Iwata, 3M, Wagner.

In 2022, the global top five Aerospace Industry Paint Spray Guns players account for 70% of market share in terms of revenue. Above figure shows the key players ranked by revenue in Aerospace Industry Paint Spray Guns.

Figure. Aerospace Industry Paint Spray Guns, Global Market Size, Split by Product Segment

Based on or includes research from QYResearch: Global Aerospace Industry Paint Spray Guns Market Report 2023-2029.

In terms of product type, Manual is the largest segment, hold a share of 65%.

Figure. Aerospace Industry Paint Spray Guns, Global Market Size, Split by Application Segment

Based on or includes research from QYResearch: Global Aerospace Industry Paint Spray Guns Market Report 2023-2029.

In terms of product application, Commercial Aircraft is the largest application, hold a share of 69%.

Figure. Aerospace Industry Paint Spray Guns, Global Market Size, Split by Region

Based on or includes research from QYResearch: Global Aerospace Industry Paint Spray Guns Market Report 2023-2029.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Ananka

Q1) Fasteners in the Defense and Military Industry

Ans) Fasteners are essential components in the defense and military industry, playing a critical role in providing support and security for a wide range of applications. From equipment and vehicles to aircraft and infrastructure, durable and reliable fasteners are crucial for ensuring the safety, functionality, and effectiveness of military operations. Here are some key aspects of fasteners in the defense and military sector:

1. High-Strength and Reliability: Military operations demand fasteners with exceptional strength and reliability to withstand extreme conditions and high loads. These fasteners are designed to hold together heavy machinery, armored vehicles, aircraft structures, and critical components operating in harsh environments.

2. Corrosion Resistance: Military equipment and infrastructure often face exposure to corrosive elements, such as saltwater, humidity, and chemicals. Fasteners with corrosion-resistant coatings, such as zinc-nickel or other specialized treatments, ensure long-term performance and prevent degradation in challenging conditions.

3. Aerospace Applications: The aerospace industry within the defense sector requires fasteners that meet strict specifications and standards due to the critical nature of aircraft components. High-strength fasteners with precision engineering are used in assembling aircraft structures, engines, and various systems.

4. Military Vehicles: Fasteners are extensively used in military vehicles, including tanks, armored personnel carriers, and trucks. These vehicles require secure fastening solutions to maintain structural integrity and protect personnel and equipment during combat situations.

5. Ammunition and Ordnance: Fasteners are used in the assembly of ammunition and ordnance to ensure proper containment and functioning during deployment. The reliability and precision of these fasteners are crucial to the safety and effectiveness of military operations.

6. Modular and Portable Solutions: The military often requires fasteners that facilitate modular construction and portability for temporary structures, shelters, and field operations. Fasteners with quick assembly and disassembly capabilities are preferred for rapid deployment.

7. Electronic Systems: Fasteners secure sensitive electronic equipment, communication devices, and surveillance systems in military applications. These fasteners must provide both physical security and electrical conductivity for reliable operation.

8. Cybersecurity: In an increasingly digitized military environment, fasteners can play a role in cybersecurity by ensuring that critical electronic components are tamper-proof and protected against cyber-attacks.

9. Stealth Technology: Fasteners may be designed to minimize radar signatures and reduce the chances of detection by adversaries, supporting stealth technology in military applications.

10. Specialized Fasteners: The defense industry often relies on specialized fasteners, such as tamper-resistant or tamper-evident fasteners, to protect sensitive information, equipment, and assets from unauthorized access or tampering.

In conclusion, fasteners are indispensable components in the defense and military industry. They provide the necessary strength, reliability, and security required for various military applications, contributing to the success and safety of military operations worldwide.

High Tensile Fasteners

Q2) How Fasteners Support Sustainable Packaging Solutions

Ans) Fasteners play a significant role in supporting sustainable packaging solutions by facilitating efficient and eco-friendly packaging practices. Sustainable packaging aims to minimize the environmental impact of packaging materials, reduce waste, and promote recycling and reuse. Here are some ways in which fasteners contribute to sustainable packaging solutions:

1. Reduced Material Waste: Fasteners enable the creation of custom-sized and fitted packaging, reducing the need for excessive packaging materials. By securely fastening packaging components together, such as corrugated boxes or cartons, the packaging can be tailored to fit the product snugly, reducing empty space and material waste.

2. Reusability: Fasteners that allow for easy disassembly and reassembly of packaging encourage reuse. For example, reusable plastic or metal fasteners in retail packaging allow consumers to open and close the packaging multiple times without damaging it. This reduces the need for additional packaging and promotes a more sustainable product lifecycle.

3. Recycling Facilitation: Fasteners that are easy to remove during recycling help streamline the recycling process. Separating fasteners from packaging materials simplifies the recycling of different materials, ensuring that packaging components are properly recycled or disposed of in an environmentally friendly manner.

4. Eco-Friendly Fastener Materials: Sustainable fastener materials, such as biodegradable or recyclable plastics, can be used in packaging applications. These materials break down naturally over time or can be recycled, reducing the environmental impact of the packaging.

5. Reduced Packaging Weight: Lightweight fasteners, such as plastic clips or straps, contribute to lightweight packaging. Lighter packaging materials require less energy during transportation, resulting in reduced fuel consumption and greenhouse gas emissions.

6. Modular Packaging Design: Fasteners enable the design of modular packaging solutions, where packaging components can be assembled and disassembled easily. This modularity allows for more efficient storage and transportation of packaging materials, reducing the need for oversized packaging and optimizing space utilization.

7. Biodegradable or Compostable Fasteners: In certain applications, biodegradable or compostable fasteners can be used in conjunction with sustainable packaging materials. These fasteners break down naturally, contributing to overall packaging sustainability.

8. Sustainable Materials Bonding: In some cases, fasteners can replace adhesives or tapes that may contain harmful chemicals. Using fasteners instead of adhesives simplifies the recycling process and reduces the risk of contamination in recycling streams.

9. Minimizing Packaging Waste: By choosing appropriate fastening methods and materials, packaging can be designed to minimize waste during both production and end-of-life disposal. Fasteners contribute to the overall efficiency of packaging solutions, reducing waste generation.

10. Eco-Friendly Packaging Designs: Innovative fastener designs can lead to more sustainable packaging concepts. For instance, reusable fastening systems in returnable packaging can promote circular economy principles.

In conclusion, fasteners support sustainable packaging solutions by enabling efficient, reusable, and recyclable packaging practices. By using the right fasteners and materials, packaging can be optimized for reduced waste, improved recyclability, and minimized environmental impact. Manufacturers and designers play a crucial role in incorporating sustainable fastening solutions to support environmentally responsible packaging practices.

ASME Fastener Standards

Q3) Fastening Techniques in Art and Sculpture: From Classic to Contemporary