#Micro Molding Materials Market Demand

Explore tagged Tumblr posts

Text

Micro Molding Materials Market Mastery: Unraveling the Dynamics of Material Advancements

The micro molding materials market is estimated to be valued at US$ 1.27 Bn or in 2023 and is expected to exhibit a CAGR of 11.% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market Overview:

Micro molding is a process involves molding of plastic materials into miniature components and parts mostly having dimensions in millimeters or micrometers range. Micro molding materials are plastics like polyamide (nylon), polyester (PET), polycarbonate (PC), polyetherimide (PEI), liquid crystal polymers (LCP), and cyclic olefin copolymer (COC) which are molded into miniature parts using micro-injection molding and micro-transfer molding processes. The miniature plastic components manufactured using micro molding find applications in industries like medical devices, micro-optics, microfluidics, telecommunications and more. Advancements in medical device miniaturization is driving demand for micro molding materials.

Market Dynamics:

The micro molding materials market growth is expected to be driven by rising demand for miniature medical devices. Advancements in micro-fabrication technologies have enabled miniaturization of medical devices used for minimally invasive surgeries, implantable devices and more. Micro components manufactured using micro molding materials are key enablers for developing such miniature medical devices having dimensions in sub-millimeter range. Growing geriatric population and associated rise in chronic diseases is augmenting demand for miniature medical devices thus benefiting micro molding materials market. Another driver is increasing demand for miniature electronics components in industries like communications and consumer electronics. Micro molded plastic components are replacing traditionally used materials like metals to optimize performance in smaller form factors.

SWOT Analysis

Strength: Micro molding materials have high precision and accuracy which allows for miniaturization. They offer complex features and geometries which are not possible through other molding processes. Their use reduces production costs and leads to smaller product sizes.

Weakness: Micro molding requires specialized facilities and equipment which increases initial investment costs. Materials used have limitations regarding maximum part size. Process optimization is challenging.

Opportunity: Growth of industries like medical devices, electronics and automotive provides opportunities for use of micro molding materials. increasing demand for miniaturization of products drives the market.

Threats: Availability of alternative miniaturization techniques like 3D printing poses threat to micro molding materials. Volatility in raw material prices can negatively impact the market.

Key Takeaways

The global Micro Molding Materials market is expected to witness high growth, exhibiting a CAGR of 11% over the forecast period, due to increasing demand for miniaturization of electronic components.

Regional analysis - North America dominates the market currently owing to sizeable electronics industry in the region. Asia Pacific exhibits fastest growth led by countries like China, Taiwan and South Korea.

Key players - Precimold Inc., Accumold, Micromold Inc., Stack Plastics, American Precision Products, ALC Precision, Micro Molding Solutions, Micro Precision Products dominate the market.

#Micro Molding Materials Market Share#Micro Molding Materials Market Growth#Micro Molding Materials Market Demand#Micro Molding Materials Market Trend#Micro Molding Materials Market Analysis

0 notes

Text

Innovative Finishing Solutions in Plastering Works in UAE for Luxury Interiors

Luxury interiors demand precision, creativity, and innovative techniques to achieve a flawless finish. In the UAE, where high-end residential and commercial projects define the skyline, plastering plays a pivotal role in transforming ordinary walls into stunning features that reflect elegance and sophistication. Advanced finishing solutions in plastering have become a key focus for delivering these luxury aesthetics, blending craftsmanship with cutting-edge technology.

Modern Plastering Techniques for Luxury Finishes

Luxury interiors require more than standard plastering; they involve a refined approach that brings out the beauty in every surface. One of the most popular techniques used in high-end projects is Venetian plaster. Known for its smooth, polished finish and marble-like appearance, Venetian plaster adds depth and texture to walls, creating a timeless look. This technique, which has roots in Italian craftsmanship, has gained popularity in the UAE for its ability to elevate interior spaces with a classic yet modern appeal.

Another trend in luxury plastering is the use of micro-cement finishes. Micro-cement is a versatile material that can be applied to walls, ceilings, and even furniture, offering a sleek, industrial look. It provides a seamless, durable surface, ideal for both minimalist and modern designs. This finish is particularly favored in luxury interiors for its clean lines and contemporary style, while also being resistant to moisture, making it suitable for spaces like kitchens and bathrooms.

Textured Plastering for Customized Luxury

Textured plaster finishes are another innovative solution gaining traction in the UAE's luxury interior market. These finishes allow for unique, customized designs, giving homeowners and businesses the chance to create bespoke wall treatments. Techniques like sandblasting, comb plastering, and stucco create a variety of textures that can range from rustic to highly refined, depending on the desired effect. Textured plastering works in UAE luxury homes provide a sense of exclusivity and craftsmanship, transforming walls into works of art.

Moreover, acrylic and gypsum-based plasters are increasingly being used to create intricate designs and patterns on walls and ceilings. Gypsum plaster, known for its smoothness and ease of application, allows for the creation of elaborate moldings and cornices, adding a classical or ornate touch to interiors. These techniques are often used in luxury hotels, villas, and commercial spaces to create a grand ambiance that complements the overall design theme.

Sustainable Luxury: Eco-Friendly Plastering Solutions

In line with global trends, many luxury projects in the UAE are now incorporating sustainable materials and eco-friendly plastering solutions. Clay and lime plasters, for instance, are natural alternatives to conventional materials, offering not only aesthetic appeal but also environmental benefits. These plasters are breathable, reducing moisture buildup and improving indoor air quality, making them ideal for the region's climate.

Eco-friendly plastering solutions are gaining popularity as more architects and designers in the UAE focus on sustainability without compromising luxury. These natural materials offer beautiful, textured finishes while contributing to healthier, more sustainable living environments, aligning with the green building standards now expected in premium construction projects.

Precision and Craftsmanship in Plastering

The true beauty of luxury interiors lies in the attention to detail, and this is especially true in plastering. Companies providing plastering works in UAE understand the importance of precision and craftsmanship in achieving the desired finish. From the initial preparation of surfaces to the final polish, every step must be meticulously executed to ensure a perfect result. High-end projects often require custom solutions, where skilled plasterers collaborate with designers and architects to bring innovative concepts to life.

This dedication to craftsmanship is evident in the fine details, from intricate ceiling moldings to seamless wall finishes that leave no room for imperfections. In luxury interiors, plastering goes beyond functionality, becoming a defining feature that adds character and value to the space.

0 notes

Text

Micro Injection Molding Machine Market Research Insights Shared in Detailed Report

The Micro Injection Molding Machine Market was valued at USD 0.4 billion in 2023-e and will surpass USD 0.8 billion by 2030; growing at a CAGR of 9.4% during 2024 - 2030. The report focuses on estimating the current market potential in terms of the total addressable market for all the segments, sub-segments, and regions. In the process, all the high-growth and upcoming technologies were identified and analyzed to measure their impact on the current and future market.

Micro injection molding is a specialized form of injection molding that focuses on producing very small, highly detailed plastic parts. These parts typically weigh less than 1 gram and have dimensions measured in micrometers. The process involves injecting molten plastic into a mold cavity with extreme precision to achieve the desired shape and features. This technology is essential for manufacturing components that require tight tolerances and intricate geometries.

Read More about Sample Report:

Market Trends and Growth Drivers

Miniaturization in Electronics: The relentless pursuit of smaller, more powerful electronic devices has significantly driven the demand for micro injection molding machines. Components such as connectors, sensors, and micro gears used in smartphones, wearables, and other compact devices require high precision and reliability, which micro injection molding can deliver.

Advancements in Medical Devices: The medical industry is a major contributor to the growth of this market. The production of micro-sized components for minimally invasive surgical instruments, drug delivery systems, and diagnostic equipment necessitates the use of micro injection molding. The ability to produce biocompatible and high-precision parts is critical for medical applications.

Automotive Industry Innovations: As the automotive industry moves towards more sophisticated electronic systems and lightweight materials, the demand for micro-molded parts is increasing. Micro injection molding machines are used to produce connectors, sensors, and other small components that are integral to modern automotive technology.

Sustainability and Material Efficiency: The micro injection molding process is highly efficient in terms of material usage, which aligns with the growing emphasis on sustainability. The ability to produce tiny parts with minimal waste is an attractive feature for industries looking to reduce their environmental footprint.

Challenges in the Micro Injection Molding Machine Market

Despite the promising growth prospects, the micro injection molding machine market faces several challenges:

High Initial Investment: The cost of acquiring micro injection molding machines and the associated tooling can be substantial. This high initial investment may deter small and medium-sized enterprises from entering the market.

Technical Complexity: The process requires a high level of expertise and precision. Maintaining consistent quality and tolerances in micro-molded parts can be challenging, necessitating advanced technology and skilled operators.

Material Selection: Not all materials are suitable for micro injection molding. The selection of appropriate materials that meet the stringent requirements of various applications can be a complex task.

Ask for Customization Report: https://intentmarketresearch.com/ask-for-customization/micro-injection-molding-machine-market-3232.html

Future Prospects

The future of the micro injection molding machine market looks promising, with several factors likely to drive further growth:

Technological Advancements: Ongoing innovations in machine design, process control, and materials will enhance the capabilities of micro injection molding. Developments such as multi-material micro molding and the integration of automation and AI will open new avenues for this technology.

Expansion into New Applications: As industries continue to innovate, new applications for micro-molded parts will emerge. Fields such as aerospace, defense, and biotechnology are expected to adopt micro injection molding for their specialized requirements.

Global Market Expansion: The market is set to expand geographically, with growing demand in regions like Asia-Pacific, driven by the electronics and automotive industries. Increasing industrialization and technological adoption in emerging economies will contribute to market growth.

Customization and Personalization: The trend towards customization in various industries, particularly in medical devices and consumer electronics, will fuel the demand for micro injection molding machines capable of producing tailored parts.

Conclusion

The micro injection molding machine market is poised for significant growth, driven by advancements in technology, increasing demand for miniaturized components, and the pursuit of material efficiency and sustainability. While challenges remain, the industry's future prospects are bright, with ongoing innovations and expanding applications set to propel the market forward

#Micro Injection Molding Machine#Micro Injection Molding Machine Size#Micro Injection Molding Machine Trends#Micro Injection Molding Machine Outlook

0 notes

Text

Transparent and Translucent Concrete Market Size, Share, Forecast [2032]

Transparent and Translucent Concrete Market provides in-depth analysis of the market state of Transparent and Translucent Concrete manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Transparent and Translucent Concrete in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Transparent and Translucent Concrete Market Report:

The report offers a comprehensive and broad perspective on the global Transparent and Translucent Concrete Market.

The market statistics represented in different Transparent and Translucent Concrete segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Transparent and Translucent Concrete are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Transparent and Translucent Concrete.

Major stakeholders, key companies Transparent and Translucent Concrete, investment feasibility and new market entrants study is offered.

Development scope of Transparent and Translucent Concrete in each market segment is covered in this report. The macro and micro-economic factors affecting the Transparent and Translucent Concrete Market

Advancement is elaborated in this report. The upstream and downstream components of Transparent and Translucent Concrete and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/transparent-and-translucent-concrete-market-100590

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Molded Foam Component Market MarketMarket

Rotogravure Printing Machine MarketMarket Share

Museum Software MarketMarket Growth Rate

RFID Smart Cabinets MarketMarket Forecast

Global Vertebroplasty And Kyphoplasty Devices MarketMarket Size

Inkjet Papers and Films MarketMarket Growth

Diabetic Macular Edema Treatment MarketMarket Analysis

Leadframe, Gold Wires and Packaging Materials for Semiconductor MarketMarket Size

Global Dental Plaster MarketMarket Share

Global Mead Beverages MarketMarket Growth

Laser Direct Structuring (LDS) Antenna MarketMarket

Biomass Boiler MarketMarket Share

RF-over-Fiber (RFoF) Solutions MarketMarket Growth Rate

Hydrographic Acquisition Software MarketMarket Forecast

Global Anesthesia Gas Evaporators MarketMarket Size

Industrial Wax MarketMarket Growth

Data Fabric MarketMarket Analysis

Cancer Vaccine MarketMarket Size

Global Tigecycline MarketMarket Share

Global Air Disinfection and Purification Machine MarketMarket Growth

Die-cast aluminum alloy MarketMarket

Automatic Identification and Data Capture MarketMarket Share

Period Panties (Menstrual Underwear) MarketMarket Growth Rate

Assistive Devices for Vulnerable Groups MarketMarket Forecast

Global Portable Gaming Console MarketMarket Size

Chromebook MarketMarket Growth

Infrared Detector MarketMarket Analysis

Demand Side Platforms (DSP) for Programmatic Advertising from the Mobile Side MarketMarket Size

Global Correlative Light Electron Microscopy (CLEM) for materials science (MS) MarketMarket Share

Global Forensic Technology MarketMarket Growth

Security Screening MarketMarket

Artificial Intelligence-Emotion Recognition MarketMarket Share

Bring-your-own-Device (BYOD) MarketMarket Growth Rate

Packaging Metallized Film MarketMarket Forecast

Global Neuromorphic Chip MarketMarket Size

Elliptical Waveguide Tools MarketMarket Growth

Child Backless Booster Seats MarketMarket Analysis

Hairline Powder MarketMarket Size

Global Popcorn Popper MarketMarket Share

Global 10G Laser Chips MarketMarket Growth

1 note

·

View note

Text

Global Rigid Plastic Packaging Market Growth and Challenges Analysis Forecast by 2031

Global Rigid Plastic Packaging Market Scope & Overview

The report's purpose is to provide decision-makers with the market intelligence and strategic insights they require to make sound investment decisions and identify market gaps and expansion opportunities. The Global Rigid Plastic Packaging Market study includes information on industry trends, growth patterns, and corporate strategies to help participants make decisions that will help them maintain a favorable profit trajectory in the next years. The purpose of this research report is to provide readers with a thorough grasp of the industry as well as market segmentation.

Global Rigid Plastic Packaging market research is an in-depth examination of the industry with an emphasis on global market trends. The most recent market study analyses the industry's potential for future growth and provides detailed and useful data on the market's composition and size. The most recent market report analyses the industry's potential for future growth and provides detailed and useful data on the market's composition and size.

Get a Sample Report https://www.snsinsider.com/checkout/2848

Market Key Players:

Silgan Holdings, Berry Plastics Corporation, Amcor Limited, Consolidated Container Company, Pactiv Evergreen Inc, Al Jabri Plastic Factory, Sonoco Products Company, SABIC, Mauser Packaging Solutions, Ball Corporation, and other players.

Market Segmentation Analysis

In today's global economy, the dynamic corporate environment is increasing the demand for business specialists who can keep up with evolving market dynamics. The global Global Rigid Plastic Packaging market is divided into four areas in the report: vertical, service, end use, and geography to gain better understanding of the market.

By Raw Material

Bioplastics

Polyethylene Terephthalate

Polypropylene

Polyethylene

Polystyrene

Polyvinyl Chloride

Expanded Polystyrene

Others

By Product type:

Bottle & Jars

Trays

Rigid Bulk Products

Others

By Production Process:

Thermoforming

Injection Molding

Extrusion

Blow Molding

Others

By Application:

Food & Beverages

Household

Healthcare

Personal Care

Others

COVID-19 Impact Analysis

The emergence of COVID-19 had a tremendous influence on the Global Rigid Plastic Packaging market. Furthermore, future developments have been postponed globally, thus terminating the sector. The COVID-19 lockout compelled the development of new tactics for dealing with oncoming crises while maintaining steady rates of growth.

Regional Outlook

The global Global Rigid Plastic Packaging market study includes geographic analysis for regions such as North America, Latin America, Asia-Pacific, Europe, and the Rest of the World. The market research report includes a regional market analysis, company market shares, and profiles of important revenue sources.

Competitive Analysis

Businesses use a variety of growth and expansion strategies to gain a competitive advantage. Participants in the industry pay close attention to how the various stages of the value chain are connected with business operations. Industry leaders are improving supply chain logistics, increasing their worldwide footprints, and strengthening their company portfolios to get a competitive advantage in the global market, all of which are included in the Global Rigid Plastic Packaging market research report.

Key Reasons to Purchase Global Rigid Plastic PackagingMarket Report

To investigate and investigate micro markets in terms of their market contributions, potential, and distinctive growth tendencies.

The research report goes over the important steps that successful firms take to limit the negative consequences of a pandemic on their operations.

The research includes important industry statistics, major market trends and prospects, and market position data for the leading players in the field.

Conclusion

The latest market research report assesses the current condition of the Global Rigid Plastic Packaging market as well as predicted future changes that may foretell market growth over the projected period.

Buy the Research Report Now https://www.snsinsider.com/checkout/2848

About Us:

SNS Insider is one of the leading Market Size research and consulting agencies that dominates the Market Size research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate Market Size data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

0 notes

Text

Common Injection Molding Processes

Injection molding is a plastic processing technology widely used in the manufacturing industry, and common types of injection molding include the following:

Conventional injection molding: Conventional injection molding refers to the heating and melting of plastic materials into the mold, cooling to obtain a variety of different shapes of plastic products. Conventional injection molding is suitable for the production of various specifications, shapes and materials of plastic products, such as plastic tableware, home appliance shell and so on.

Two-color injection molding: Two-color injection molding refers to the injection molding of two different colors or materials of plastic materials in the same mold, so as to form different colors or materials on the same product. Two-color injection molding is suitable for the production of complex plastic products requiring multi-color or multi-material combinations, such as automotive interiors.

High-speed injection molding: High-speed injection molding refers to the use of high-speed injection, high-pressure injection and other technologies in the injection process, so as to achieve rapid production of plastic products. High-speed injection molding is suitable for the production of large volume, simple structure of plastic products, such as bottle caps.

Precision injection molding: Precision injection molding refers to the use of high-precision molds and high-precision injection machines in the injection process, so as to achieve high-precision, high-quality plastic products production. Precision injection molding is suitable for the production of precision, complex, high-quality plastic products, such as mobile phone shells, optical lenses, etc.

Pneumatic injection molding: Pneumatic injection molding refers to the use of air pressure to drive plastic materials into the mold during the injection process, so as to achieve efficient and high-quality plastic product production. Pneumatic injection molding is suitable for the production of high-volume, thin-wall, high-transparency plastic products, such as plastic cups, plastic glass and so on.

Large injection molding: Large injection molding refers to the production of large size, large weight and large volume plastic products through large injection molding machines and large molds, such as auto parts and engineering plastic products.

Thin-wall injection molding: Thin-wall injection molding refers to the production of thin-wall plastic products with wall thickness below 0.5mm through high-speed injection molding and high-precision molds, such as plastic containers, boxes, etc.

Micro-injection molding: Micro-injection molding refers to the production of micro-size plastic products through micro-injection molding machines and micro-molds, such as micro-parts, micro-devices, etc.

Composite injection molding: Composite injection molding refers to the injection of plastic materials of different materials into the same mold, thereby forming plastic products of composite materials, such as plastic metal composite products, plastic rubber composite products, etc.

Hot runner injection molding: Hot runner injection molding refers to the setting of heating elements in the mold, by controlling the temperature and position of the heating elements, to achieve the precise control of plastic materials into the mold, so as to produce high-quality, high-precision plastic products.

Injection molding is a very flexible and efficient plastic processing technology that is suitable for the production of a wide variety of plastic products. With the continuous progress of technology and the constant change of market demand, injection molding technology is also constantly developing and innovating, and the types and application fields of injection molding are also constantly expanding and deepening.

0 notes

Text

𝐌𝐞𝐭𝐚𝐥 𝐏𝐨𝐰𝐝𝐞𝐫 𝐈𝐧𝐣𝐞𝐜𝐭𝐢𝐨𝐧 𝐌𝐨𝐥𝐝𝐢𝐧𝐠 (𝐌𝐈𝐌) 𝐌𝐚𝐫𝐤𝐞𝐭: 𝐆𝐫𝐨𝐰𝐭𝐡 𝐃𝐫𝐢𝐯𝐞𝐫𝐬, 𝐄𝐦𝐞𝐫𝐠𝐢𝐧𝐠 𝐓𝐫𝐞𝐧𝐝𝐬, 𝐚𝐧𝐝 𝐅𝐮𝐭𝐮𝐫𝐞 𝐎𝐮𝐭𝐥𝐨𝐨𝐤 𝐁𝐲 2024-2030 | 𝐆𝐐 𝐑𝐞𝐬𝐞𝐚𝐫𝐜𝐡

The Metal Powder Injection Molding (MIM) market is set to witness remarkable growth, as indicated by recent market analysis conducted by GQ Research. In 2023, the global Metal Powder Injection Molding (MIM) market showcased a significant presence, boasting a valuation of US$ 4.55 billion. This underscores the substantial demand for Metal Powder Injection Molding (MIM) technology and its widespread adoption across various industries.

Get Sample of this Report at https://gqresearch.com/request-sample/global-metal-powder-injection-molding-mim-market/

Projected Growth: Projections suggest that the Metal Powder Injection Molding (MIM) market will continue its upward trajectory, with a projected value of US$ 10.20 billion by 2030. This growth is expected to be driven by technological advancements, increasing consumer demand, and expanding application areas.

Compound Annual Growth Rate (CAGR): The forecast period anticipates a Compound Annual Growth Rate (CAGR) of 9.76%, reflecting a steady and robust growth rate for the Metal Powder Injection Molding (MIM) market over the coming years.

Technology Adoption:Metal Powder Injection Molding (MIM) has witnessed significant adoption across various industries due to its ability to produce complex metal parts with high precision and cost-effectiveness. The technology has been adopted in industries such as automotive, aerospace, healthcare, electronics, and consumer goods manufacturing. Manufacturers are increasingly leveraging MIM to produce intricate components with tight tolerances, eliminating the need for secondary machining processes and reducing material waste.

Application Diversity:The application diversity of Metal Powder Injection Molding (MIM) is vast, ranging from small, intricate components to larger, more complex parts. MIM is utilized in the production of automotive components like gears, brackets, and connectors, as well as in aerospace for turbine blades, structural components, and fuel system parts. In the healthcare sector, MIM is used to manufacture surgical instruments, orthodontic brackets, and dental implants. Additionally, MIM finds applications in electronics for connectors, sensors, and micro-electro-mechanical systems (MEMS), demonstrating its versatility across industries.

Consumer Preferences:Consumer preferences in the Metal Powder Injection Molding (MIM) market are influenced by factors such as product quality, performance, and cost-effectiveness. End-users prefer MIM-produced components for their high precision, excellent surface finish, and complex geometries, which may be difficult or costly to achieve through traditional manufacturing methods. Moreover, consumers value MIM for its ability to deliver parts with consistent quality and dimensional accuracy, meeting stringent industry standards and regulatory requirements.

Technological Advancements:Technological advancements in Metal Powder Injection Molding (MIM) focus on improving process efficiency, material properties, and part quality. Developments in powder metallurgy, binder formulations, and debinding/sintering processes enhance the production of MIM components with higher density, mechanical strength, and corrosion resistance. Furthermore, advancements in mold design, injection molding equipment, and simulation software optimize tooling performance, reduce cycle times, and minimize defects, leading to increased productivity and cost savings for manufacturers.

Market Competition:The Metal Powder Injection Molding (MIM) market is characterized by intense competition among MIM manufacturers, material suppliers, and end-users. Key players invest in research and development to expand material choices, refine manufacturing processes, and develop new applications for MIM technology. Strategic partnerships, mergers, and acquisitions enable companies to strengthen their market position, broaden their customer base, and penetrate new geographic regions. Additionally, competition from alternative manufacturing technologies, such as CNC machining and 3D printing, drives innovation and differentiation in the MIM market.

Environmental Considerations:Environmental considerations in the Metal Powder Injection Molding (MIM) market focus on reducing energy consumption, material waste, and environmental impact throughout the production process. MIM manufacturers strive to optimize powder recycling, minimize scrap generation, and implement sustainable practices in powder handling, mixing, and debinding/sintering operations. Moreover, efforts to develop eco-friendly binders, lubricants, and feedstocks contribute to reducing the carbon footprint of MIM production. Additionally, initiatives to improve workplace safety, reduce emissions, and comply with environmental regulations promote sustainability and responsible manufacturing practices in the MIM industry.

Regional Dynamics: Different regions may exhibit varying growth rates and adoption patterns influenced by factors such as consumer preferences, technological infrastructure and regulatory frameworks.

Key players in the industry include:

Indo-MIM Pvt. Ltd

ARC Group Worldwide Inc

CMG Technologies

Parmaco Metal Injection Molding AG

OptiMIM

FloMet LLC

MIM International

FineMIM

PSM Industries Inc

Makuta Technics Inc.

The research report provides a comprehensive analysis of the Metal Powder Injection Molding (MIM) market, offering insights into current trends, market dynamics and future prospects. It explores key factors driving growth, challenges faced by the industry, and potential opportunities for market players.

For more information and to access a complimentary sample report, visit Link to Sample Report: https://gqresearch.com/request-sample/global-metal-powder-injection-molding-mim-market/

About GQ Research:

GQ Research is a company that is creating cutting edge, futuristic and informative reports in many different areas. Some of the most common areas where we generate reports are industry reports, country reports, company reports and everything in between.

Contact:

Jessica Joyal

+1 (614) 602 2897 | +919284395731

Website - https://gqresearch.com/

0 notes

Text

Exploring the frontiers of vibration damping and energy absorption technology: Uncovering the differences and uses of leading material technologies.

The key to industrial progress is the development of material technology, but vibration and noise all the time filled with industrial life, restricting the development of enterprises, affecting industrial progress.

There are some excellent performance vibration absorbing materials on the market, due to good cushioning, abrasion resistance, fatigue resistance or adjustable widely used, where different material properties corresponding to different areas, the following list of common or quite potential vibration absorbing materials in the sports and industrial industries.

Rubber is a natural or synthetic polymer elastomer with good elasticity and fatigue resistance, and is one of the most widely used shock absorbing materials.

01 Characteristics

Good elasticity: able to deform in a wide range and quickly return to its original state.Adjustability: can be customized in various sizes according to demand.

Abrasion resistance: good resistance to friction and abrasion.

02 Advantages

Low cost: natural rubber is widely available and synthetic rubber is easier to prepare.

Easy to process: can be processed into various shapes through injection molding and extrusion

03 Uses

Automotive industry: for shock absorbers, suspension systems, etc.

Sports equipment: such as sports shoes, rackets, etc.

Automotive Suspension Springs

According to statistics, the global revenue of rubber shock pads is approximately $17,010 million in 2021 and is expected to reach $19,550 million in 2028.

Polymer Materials

Polymer materials, also known as polymer materials, is a polymer compound as a substrate, and then equipped with other additives (additives) composed of materials, according to the application of functional classification can be divided into general-purpose polymer materials, special polymer materials and functional polymer materials of three major categories.

01 Characteristics

Fatigue resistance: can be high-speed collision or multiple impact forces, can maintain stable performance.

Adjustability: by changing the molecular structure and crosslinking density, can optimize its performance.

Stability: good resistance to temperature and chemical corrosion.

2 Advantage

Variety of properties: material properties can be customized according to demand.

Good processing performance: it can be processed into complex shapes through a variety of processes.

Lightweight: Lightweight design of structure can be realized.

03 Uses

Aerospace: used in aircraft and spacecraft, the return chamber of the shock absorption system.

Electronic equipment: such as cell phones, laptop computers, anti-vibration protection

Sports: such as extreme sports protective equipment, advanced sports shoes, etc.

Industrial shock absorption: used in large machine tools, mechanical equipment, air conditioning compressors, production equipment and other vibration sources with vibration absorption protection.

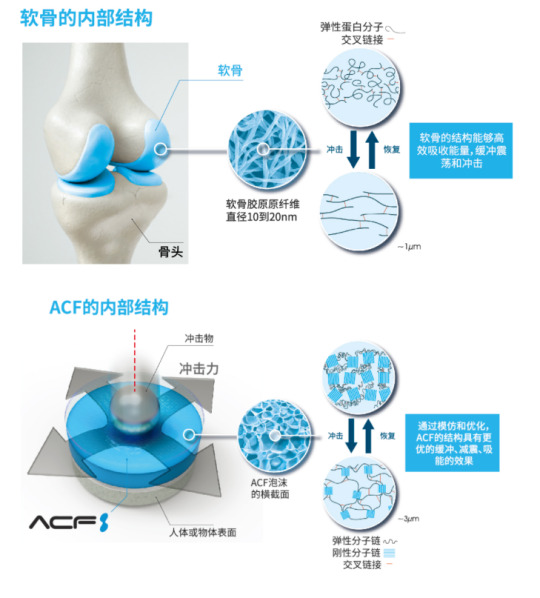

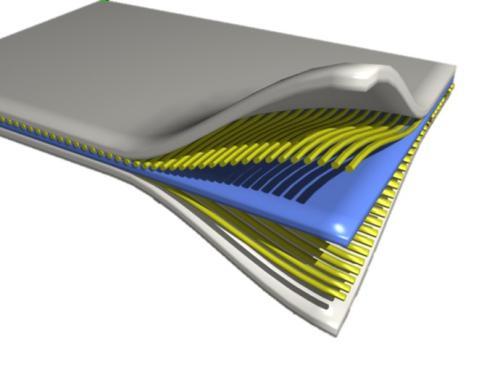

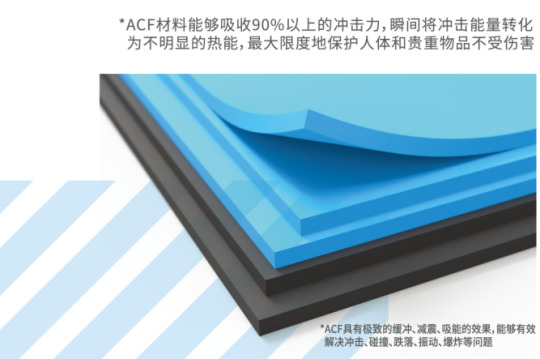

ACF material (full name "ACF artificial cartilage material") is an advanced invention in China in the past 10 years, belonging to the polymer material category of bionic energy-absorbing materials, its technical principle is to adjust and control its micro-nanometer structure by imitating the human articular cartilage, so that it is infinitely close to the articular cartilage structure, with excellent cushioning and energy absorption, and in addition, the ACF material has a good adjustability and stability, and it is the new rising star of the management and control in the scenarios of sports, industry, automobile and other impact protection, vibration, noise, sealing and so on.

Composites are new materials made by combining two or more materials with different properties through physical or chemical methods.

01 Characteristics

Strong comprehensive performance: the advantages of various materials can be utilized comprehensively, such as high strength, good shock absorption, etc.

Strong designability: the proportion and arrangement of each component can be adjusted according to the demand.

02 Advantage

High performance: combines the advantages of various materials.

Lightweight: Lightweight structural design is possible.

03 Uses

Automotive industry: used for lightweighting and vibration damping of body structure, chassis and other components.

Sports equipment: such as golf clubs, bicycle frames, etc.

Automotive Suspension Springs

The share of composites in the automotive industry is increasing year by year, and according to data disclosed by Lucintel, it is expected that the share of lightweight materials used in automobiles will exceed 47% by 2025.

Nanomaterials

Nanomaterials are materials that measure between 1 nanometer and 100 nanometers in at least one dimension.

01 Characteristics

Large specific surface area: nanomaterials have a large ratio of surface atoms to total atoms, giving them unique physical and chemical properties.

High interfacial activity: easy to combine with other materials to form composites with high interfacial activity.

02 Advantages

High performance: excellent performance in vibration damping and energy absorption.

Versatility: nanomaterials are available in a wide variety of types to meet different application needs.

03 Uses

Aerospace: used in shock absorption systems for airplanes and spaceships, return bins.

Sports: such as advanced sports shoes, protective equipment, etc.

The use of nanomaterials in vibration damping, although currently a relatively small percentage of applications, is growing rapidly and is expected to grow significantly over the next few years.

Explore the frontiers in the field of vibration damping and energy absorption technology: these vibration damping and energy absorption materials have their own unique characteristics and are widely used in a number of fields. As a representative of polymer science and technology materials, ACF artificial cartilage materials of Linzhi Technology Group have continuously improved their vibration-damping performance through continuous research and innovation, providing important technical support in the fields of sports, electronics and semiconductors, industrial vibration-damping, automotive, aerospace and rail transportation, and so on. In the future, with the continuous progress of technology, we believe that ACF artificial cartilage material will show its unique advantages in more fields and make greater contribution to the development of society.

400-6543-699

www.acf.com

0 notes

Text

Micro Injection Molding Mastery: Pioneering the Future of Medical Device Manufacturing

Micro Injection Molding Medical Devices Market: Precision in Healthcare

In the ever-evolving landscape of healthcare, precision and miniaturization have become the key drivers of innovation. Micro injection molding has emerged as a critical technology, enabling the production of intricate medical devices that can transform patient care. This burgeoning field, the Micro Injection Molding Medical Devices Market, is poised for significant growth and innovation in the coming years.

What is Micro Injection Molding?

Micro injection molding is a specialized manufacturing process that creates extremely small and precise plastic components with high repeatability. It has found a special place in the production of medical devices, thanks to its ability to create intricate and complex geometries. This technology allows manufacturers to produce components that would be challenging or impossible to achieve through traditional molding methods.

Key Drivers of Growth

1. Miniaturization: The healthcare industry's increasing focus on minimally invasive procedures and wearable devices has driven the demand for smaller, more intricate medical components. Micro injection molding is perfectly suited to meet this need.

2. Advancements in Material Science: The development of new biocompatible and biodegradable materials has opened up new possibilities for medical device design and manufacturing. Micro injection molding facilitates the use of these materials in a precise manner.

3. Cost Efficiency: The scalability and cost-effectiveness of micro injection molding make it an attractive choice for manufacturers. It reduces material wastage, lowers production costs, and enables quicker time-to-market.

4. Customization: The ability to create custom, patient-specific medical devices is a key driver in the market. Micro injection molding allows for the production of personalized components, such as hearing aids, dental implants, and orthodontic devices.

Applications in the Medical Field

Micro injection molding has found applications in various medical fields, including:

1. Diagnostics: The production of tiny, high-precision components for diagnostic devices, such as microfluidic chips, is made possible by micro injection molding. These devices play a crucial role in point-of-care testing and molecular diagnostics.

2. Surgical Instruments: Miniaturized surgical instruments and components, such as clips, connectors, and catheters, benefit from the precision of micro injection molding. These instruments enable less invasive procedures, reducing patient discomfort and recovery time.

3. Drug Delivery: Devices for drug delivery, such as insulin pens and inhalers, are becoming increasingly sophisticated. Micro injection molding allows for the creation of intricate parts that ensure accurate dosing and patient comfort.

4. Implantable Devices: From orthopedic implants to dental prosthetics, the medical field relies on micro injection molding to create customized, biocompatible components that enhance patient outcomes.

Challenges and Opportunities

While the Micro Injection Molding Medical Devices Market shows immense promise, it is not without its challenges. Regulatory compliance, quality control, and the need for highly specialized machinery are all factors that must be considered. However, these challenges also present opportunities for companies that can provide innovative solutions, ensuring the safety and efficacy of medical devices.

Geographical Trends

The micro injection molding medical devices market is not confined to a single region. It is a global market with strong footholds in North America, Europe, and the Asia-Pacific region. The Asia-Pacific market is particularly dynamic, with rising healthcare infrastructure, favorable investment conditions, and a growing demand for medical devices.

Conclusion

The Micro Injection Molding Medical Devices Market is set to play a pivotal role in the healthcare industry's future. The ability to create highly precise, miniaturized components will continue to drive innovation, improving patient outcomes, and expanding the scope of what is possible in medical technology. As the industry evolves and technology advances, it is crucial for manufacturers to stay on the cutting edge of micro injection molding to meet the ever-growing demand for small, complex, and custom medical devices. With the right blend of innovation, regulation, and quality control, this market has the potential to revolutionize healthcare as we know it.

Few Other Promising Reports in Medical Devices Industry

Surgical Sutures Market

Knee Replacement Market

Knee Surgeries and Arthroplasty Pain Management Therapeutics Market

Robotic-assisted Surgery Systems Market

0 notes

Text

Micro-molding Materials Market Odyssey: Navigating the Micro World of Materials

Micro-molding, a specialized form of plastic injection molding, has revolutionized the manufacturing industry by enabling the production of tiny, high-precision components and products. The success of micro-molding processes heavily depends on the choice of materials, as these materials need to exhibit exceptional characteristics to meet the exacting demands of this technology. The micro-molding materials market plays a pivotal role in ensuring the growth and innovation of industries such as medical, electronics, and automotive. In this comprehensive analysis, we delve into the key trends, challenges, and prospects within the Micro-Molding Materials Market.

The Landscape of Micro-Molding Materials Market

Micro-molding is the process of creating small, intricate parts with micrometer-scale features. These applications are diverse and span various industries. Think of microelectromechanical systems (MEMS), micro-optics, microfluidics, and many more. Each of these sectors requires specific material properties to ensure the success of their micro-molding projects. This is where the micro-molding materials market comes into play, as it's crucial for manufacturers to select materials that can withstand the unique pressures and precision required in micro-scale manufacturing.

Key Market Trends

Miniaturization Across Industries One of the prominent trends in the micro-molding materials market is the increasing demand for miniaturization across various industries. The consumer electronics sector, for example, is relentlessly pushing for smaller and more powerful components. In the medical field, micro-molded parts are crucial for minimally invasive procedures and advanced diagnostics. This trend is driving the demand for innovative materials that can meet the stringent size and performance requirements.

Biocompatible Materials In the medical industry, biocompatible materials are a hot topic. Micro-molded components are being used in applications such as drug delivery systems, surgical instruments, and in-vitro diagnostics. Consequently, there's a growing demand for materials that are not only precise but also safe for use within the human body. This trend has led to the development of novel biocompatible materials, widening the scope of the micro-molding materials market.

Advanced Polymers Polymers have always been the go-to materials for micro-molding due to their versatility, ease of processing, and cost-effectiveness. However, with the increasing complexity of micro-molded components, advanced polymers are becoming more popular. These materials offer improved thermal and mechanical properties, making them suitable for applications in extreme environments and industries like aerospace and automotive.

Challenges in the Micro-Molding Materials Market

Material Compatibility Micro-molding is highly sensitive to material properties, and not all materials are suitable for this process. Manufacturers must carefully select materials that offer the right balance of strength, viscosity, and temperature resistance to ensure successful micro-molding. Material compatibility remains a significant challenge, especially when dealing with highly specialized applications.

Cost Considerations The precision required in micro-molding often translates to higher manufacturing costs. Choosing the right materials that meet the desired specifications while staying within budget constraints is a challenging task. Manufacturers must find cost-effective solutions to remain competitive in the micro-molding materials market.

Research and Development As the demand for micro-molded products continues to grow, research and development in the field of micro-molding materials becomes crucial. Companies must invest in developing new materials and improving existing ones to cater to the ever-evolving needs of industries. This requires substantial resources and expertise.

Prospects for the Micro-Molding Materials Market

The prospects for the micro-molding materials market demand are promising. As technology advances, new materials and manufacturing processes are likely to emerge, enabling even greater precision and efficiency in micro-molding. The miniaturization trend across various industries will continue to drive demand for innovative materials that can withstand the challenges posed by micro-molding. Additionally, growing awareness of the environmental impact of materials may lead to the development of more sustainable and eco-friendly options in the micro-molding materials market.

Conclusion

The micro-molding materials market is an integral part of the micro-manufacturing landscape. It serves industries that require miniature, high-precision components, and products. The market is driven by trends such as miniaturization, biocompatibility, and advanced polymers, but it also faces challenges related to material compatibility, cost considerations, and the need for ongoing research and development. Nevertheless, the future of the micro-molding materials market looks promising as it continues to adapt and innovate to meet the evolving demands of various industries.

#Micro-molding Materials Market Share#Micro-molding Materials Market Growth#Micro-molding Materials Market Demand#Micro-molding Materials Market Trend#Micro-molding Materials Market Analysis

0 notes

Text

Polypropylene Injection Molding Market Analysis Demand, Statistics, Top Manufacturers, Revenue by Reports and Insights 2030

The latest market report published by Credence Research, Inc. “Global Polypropylene Injection Molding Market: Growth, Future Prospects, and Competitive Analysis, 2016 – 2028. The global polypropylene injection molding market has witnessed steady growth in recent years and is expected to grow at a CAGR of 3.90% between 2023 and 2030. The market was valued at USD 105.8 billion in 2022 and is expected to reach USD 138.2911858 billion in 2030.

The global polypropylene injection molding market is experiencing a steady growth phase, thanks to the mounting demand for lightweight and resilient materials across various sectors, including packaging, automotive, and consumer goods. Furthermore, the world is witnessing an increasing preference for sustainable and environment-friendly materials, which is expected to augment the market's expansion.

Polypropylene Injection Molding Market Key Growth Trends refer to the significant shifts and developments witnessed in the polypropylene injection molding industry. With increasing demand for lightweight, durable, and cost-effective materials, polypropylene has emerged as a preferred choice among manufacturers across various sectors such as automotive, packaging, electronics, and healthcare. This market segment is experiencing rapid growth due to several key factors. Technological advancements have led to enhanced production capabilities and improved product quality within the industry. Additionally, growing awareness regarding sustainable practices has propelled the adoption of recyclable polypropylene materials that align with environmental regulations.

Future Outlook

The global polypropylene injection molding market is poised for significant growth, particularly in the European region. The rising demand for lightweight, durable, and eco-friendly materials in industries like automotive, packaging, and consumer goods will continue to steer the market's growth trajectory. Despite the challenges, advancements in injection molding technologies such as multi-component molding and micro-injection molding offer significant growth opportunities.

Competitive Landscape

The global polypropylene injection molding market is highly competitive, with major players like ALPLA, Amcor PLC, AptarGroup Inc. (CSP Technologies), BERICAP, and Berry Global Inc. These companies are focusing on product innovation, expanding their applications, and mergers and acquisitions to maintain their market presence.

Browse 190 pages report Polypropylene Injection Molding Market By Applications (Packaging, Building and Construction, Consumer Goods, Electronics, Automotive and Transportation, Healthcare, Other Applications) - Growth, Future Prospects & Competitive Analysis, 2016 – 2030)- https://www.credenceresearch.com/report/polypropylene-injection-molding-market

Applications Driving the Market Growth

Packaging Industry

The packaging sector significantly contributes to the demand for polypropylene injection molding, holding a massive share of the global market. This segment is also projected to exhibit a substantial CAGR during the forecast period. Polypropylene injection molding offers a gamut of advantages for packaging applications, including light weight, durability, and excellent chemical resistance. Furthermore, it is recyclable, which aligns with the global push for sustainable solutions.

Building and Construction Industry

The building and construction industry is expected to demonstrate the highest CAGR during the forecast period. Polypropylene injection molding is gaining traction in this sector owing to its resistance to moisture, chemicals, and decay, making it an ideal choice for various construction applications.

Global Polypropylene Injection Molding Market Segmentation by Region

Europe

In 2022, Europe held nearly three-fifths of the global polypropylene injection molding market, majorly fueling its growth. Europe's robust manufacturing base, supportive government policies, and focus on sustainability are key factors propelling the market in this region.

Asia-Pacific and North America

Asia-Pacific and North America collectively accounted for nearly 55% of the global market share in 2022. Asia-Pacific held over 35% of the market share in the same year, thanks to the strong manufacturing sectors in countries like China, Japan, and India.

Rest of the World

The rest of the world, including Latin America, The Middle East, and Africa, contribute to the remaining demand for polypropylene injection molding. The market growth in these regions is fostered by the expanding manufacturing sectors and increasing environmental consciousness.

Why to Buy This Report-

The report provides a qualitative as well as quantitative analysis of the global Polypropylene Injection Molding Market by segments, current trends, drivers, restraints, opportunities, challenges, and market dynamics with the historical period from 2016-2020, the base year- 2021, and the projection period 2022-2028.

The report includes information on the competitive landscape, such as how the market's top competitors operate at the global, regional, and country levels.

Major nations in each region with their import/export statistics

The global Polypropylene Injection Molding Market report also includes the analysis of the market at a global, regional, and country-level along with key market trends, major players analysis, market growth strategies, and key application areas.

Browse Full Report: https://www.credenceresearch.com/report/polypropylene-injection-molding-market

Visit: https://www.credenceresearch.com/

Related Report: https://www.credenceresearch.com/report/solar-powered-cold-storage-market

Related Report: https://www.credenceresearch.com/report/water-based-barrier-coatings-market

Browse Our Blog: https://www.linkedin.com/pulse/polypropylene-injection-molding-market-2022-growth-strategies-singh

Browse Our Blog: https://medium.com/@priyanshi_97937/polypropylene-injection-molding-market-rising-trends-and-research-outlook-2022-2030-92a6a232420c

About Us -

Credence Research is a viable intelligence and market research platform that provides quantitative B2B research to more than 10,000 clients worldwide and is built on the Give principle. The company is a market research and consulting firm serving governments, non-legislative associations, non-profit organizations, and various organizations worldwide. We help our clients improve their execution in a lasting way and understand their most imperative objectives. For nearly a century, we’ve built a company well-prepared for this task.

Contact Us:

Office No 3 Second Floor, Abhilasha Bhawan, Pinto Park, Gwalior [M.P] 474005 India

0 notes

Text

Metal Injection Molding (MIM) Market –Will Grow At Excellent CAGR of 12.00%, Industry Trends,size,share

The reliable Metal Injection Molding (MIM)market research study presents actionable market insights with which sustainable and money-spinning business strategies can be created. Here, market segmentation is performed in detail based on various parameters that include applications, verticals, deployment model, end user, and geography. All the information, facts, and statistics covered in the report lead to actionable ideas, improved decision-making and better deciding business strategies. The business report assists define, describe and forecast the market by type, application and region. With the complete comprehension of business goals and needs to bridge the gap, Metal Injection Molding (MIM)report is generated which delivers the most suitable solutions.

Furthermore, Metal Injection Molding (MIM)market report provides superior market perspective in terms of product trends, marketing strategy, future products, new geographical markets, future events, sales strategies, customer actions or behaviours. The report comprises of estimations of CAGR values which are quite significant and aids businesses to decide upon the investment value over the time period. The market study in this reliable market report also analyzes the market status, growth rate, future trends, market drivers, opportunities and challenges, risks and entry barriers, sales channels, and distributors by keeping SWOT analysis and Porter's Five Forces Analysis as a base. An insightful Metal Injection Molding (MIM)market report assists clients to stay ahead of the time and competition.

Request For Sample Report@ https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-metal-injection-molding-mim-market

Global metal injection molding (MIM) market was valued at USD 3.96 billion in 2021 and is expected to reach USD 9.80 billion by 2029, registering a CAGR of 12.00% during the forecast period of 2022-2029. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand.

Market Definition

Metal Injection molding, also known as MIM technology, is a metalworking manufacturing technology. It is a process that is done by mixing the binder material to create a feedstock which is used to produce the final product. It can eliminate several product finishing steps and make it possible to produce different parts of complex shapes with high precision at minimal costs. It is used in various applications such as electronics, power tools and others.

Recent Developments

· In 2021, metal powder products announced that it had completed the acquisition of Proform Powdered Metals, based in U.S. It is a leading provider of high-quality sintered bronze bearings and spacers.

Global Metal Injection Molding (MIM) Market Scope

The metal injection molding (MIM) market is segmented on the basis of material and end users. The growth amongst these segments will help you analyze meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Material

· Stainless Steel

· Low Alloy Steel

· Carbon Steel

· Soft Magnetic Alloy

· Cobalt Alloy

· Tool Steel

· Tungsten Steel

· Titanium

· Controlled Expansion Alloys

· High-Temperature Alloys

· Carbonyl Iron Powder

· Others

End Users

· Electrical & Electronics

· Fiber Optic Connectors

· Filter Components

· Heat Sinks

· Micro-Switches

· Connectors

· Others

· Automotive

· Electrical Systems

· Fuel System

· Interiors

· Powertrain

· Safety System

· Others

· Medical

· Surgical Instruments

· Orthopedic

· Implants

· Others

· Aerospace

· Fasteners

· Screws

· Seatbelt Components

· Bushings

· Rotors

· Others

· Firearms & Defense

· Fire Suppression

· Cam Block

· Sensor Housings

· Others

Metal Injection Molding (MIM) Market Share Analysis

The metal injection molding (MIM) market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to metal injection molding (MIM) market.

Some of the major players operating in the metal injection molding (MIM) market are

· ASH Industries (U.S.)

· Rockleigh Industries. (U.S.)

· Molex Group LLC (U.S.)

· Schunk Sintermetalltechnik GmbH (Germany)

· Medicines Patent Pool (Switzerland)

· Sandvik AB (Sweden)

· TEKNA. (China)

· PSM Industries, Inc. (U.S.)

· GKN Powder Metallurgy (India)

· Advanced Powder Products, Inc. (U.S.)

· Alpha Precision Group (U.S.)

· CMG Technologies (U.K.)

· Epson Atmix Corporation (Japan)

· Hitachi Metals, Ltd. (Japan)

· Smith Metal Products. (U.S.)

· Parmaco Metal Injection Molding AG (Switzerland)

· INDO-MIM (India)

Read Detailed Report@ https://www.databridgemarketresearch.com/reports/global-metal-injection-molding-mim-market

Metal Injection Molding (MIM) Market Regional Analysis/Insights

The metal injection molding (MIM) market is analyzed and market size insights and trends are provided by material and end users as referenced above.

The countries covered in the metal injection molding (MIM) market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, Israel, Egypt, South Africa, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

Asia-Pacific dominates the market in terms of market share and market revenue and will continue to flourish its dominance during the forecast period of 2022-2029. The market growth over this region is attributed to the increasing population and rising industrialization.

North America on the other hand, is estimated to show lucrative growth over the forecast period of 2022-2029, due to the rapid economic development and rising demands from various end user industries in the region.

Key questions answered in the report:

· What will the market development pace of Metal Injection Molding (MIM)market?

· What are the key factors driving the Global Metal Injection Molding (MIM)market?

· Who are the key manufacturers in market space?

· What are the market openings, market hazard and market outline of the market?

· What are sales, revenue, and price analysis of top manufacturers of Metal Injection Molding (MIM)market?

· Who are the distributors, traders, and dealers of Metal Injection Molding (MIM)market?

· What are the Metal Injection Molding (MIM)market opportunities and threats faced by the vendors in the Global Metal Injection Molding (MIM)industries?

· What are deals, income, and value examination by types and utilizations of the market?

· What are deals, income, and value examination by areas of enterprises?

Explore More Reports@

https://www.databridgemarketresearch.com/reports/global-extruded-nets-market

https://www.databridgemarketresearch.com/reports/global-glassware-market

https://www.databridgemarketresearch.com/reports/nigeria-home-appliances-market

https://www.databridgemarketresearch.com/reports/south-africa-home-appliances-market

https://www.databridgemarketresearch.com/reports/global-metal-injection-molding-mim-market

https://www.databridgemarketresearch.com/reports/global-aquaculture-equipment-market

https://www.databridgemarketresearch.com/reports/global-benzalkonium-chloride-market

https://www.databridgemarketresearch.com/reports/global-crustacean-farming-market

About Data Bridge Market Research (DBMR):

Data Bridge Market Research Pvt Ltd is a multinational management consulting firm with offices in India and Canada. As an innovative and neoteric market analysis and advisory company with unmatched durability level and advanced approaches. We are committed to uncover the best consumer prospects and to foster useful knowledge for your company to succeed in the market.

Data Bridge Market Research is a result of sheer wisdom and practice that was conceived and built-in Pune in the year 2015. The company came into existence from the healthcare department with far fewer employees intending to cover the whole market while providing the best class analysis. Later, the company widened its departments, as well as expands their reach by opening a new office in Gurugram location in the year 2018, where a team of highly qualified personnel joins hands for the growth of the company. “Even in the tough times of COVID-19 where the Virus slowed down everything around the world, the dedicated Team of Data Bridge Market Research worked round the clock to provide quality and support to our client base, which also tells about the excellence in our sleeve.”

Data Bridge Market Research has over 500 analysts working in different industries. We have catered more than 40% of the fortune 500 companies globally and have a network of more than 5000+ clientele around the globe.

Contact Us

US: +1 888 387 2818 UK: +44 208 089 1725 Hong Kong: +852 8192 7475 Email – [email protected]

0 notes

Text

North America Ceramic Injection Molding Market Scope, Trends and Growth Forecasts to 2027

“The ceramic injection molding market in North America was valued at US$ 108.49 Mn in 2019 and is projected to reach US$ 203.73 Mn by 2027; it is expected to grow at a CAGR of 8.3% during the forecast period.”

The report titled “North America Ceramic Injection Molding Market” has recently been added by Business Market Insights to induce a stronger and more effective business outlook. It provides associate in-depth analysis of the various attributes of the industry, like trends, policies, and customers operational in several geographies. Research analysts use quantitative as well as qualitative analytical techniques to supply users, business owners, and industry professionals with accurate and actionable data. The North America Ceramic Injection Molding Market study provides comprehensive data which enhances the understanding, scope, and application during the forecast period.

Get a Sample Copy of the Report, Click Here:

https://www.businessmarketinsights.com/sample/TIPRE00018232

The Key Players in this market are:

· ARBURG GmbH + Co KG

· Ceramco, Inc.

· CoorsTek Inc.

· INDO-MIM

· Micro

· Morgan Advanced Materials

· OECHSLER AG

In this report, the market has been segmented on the basis of:

Based on types, the North America Ceramic Injection Molding market is primarily split into:

· Alumina

· Zirconia

· Others

Based on Applications the North America Ceramic Injection Molding market covers:

· Industrial Machinery

· Automotive

· Healthcare

· Electrical and Electronics

· Consumer Goods

· Others

Scope of North America Ceramic Injection Molding Market:

North America Ceramic Injection Molding Market report evaluates the growth rate and the market value based on market dynamics, growth inducing factors. Complete knowledge is based on the latest industry news, opportunities, and trends. The report contains a comprehensive market research and vendor landscape in additionally to a SWOT analysis of the key vendors.

Key Highlights of the North America Ceramic Injection Molding Market Research Report:

-The report summarizes the North America Ceramic Injection Molding Market by stating the basic product definition, applications, product scope, product price and value, supply and demand ratio, and market summery.

Competitive landscape of all leading key players together with their business strategies, approaches, and latest North America Ceramic Injection Molding market movements.

-It elements market feasibility investment, opportunities, growth factors, restraints, market risks, and North America Ceramic Injection Molding business driving forces.

-It performs a comprehensive study of emerging players within the North America Ceramic Injection Molding business together with the present ones.

-It accomplishes primary and secondary analysis and resources to estimate top products, market size, and industrial partnerships of North America Ceramic Injection Molding business.

-North America Ceramic Injection Molding market report ends by articulating research findings, data sources, and results, list of dealers, sales channels, businesses, and distributors along with an appendix.

We offer clients specialized report services that take into consideration the most variables influencing the development of the worldwide Market. Feel free to call or drop your requirement to get the get customized research report.

Click Here to Buy Now:

https://www.businessmarketinsights.com/buy/single/TIPRE00018232

About Us:

Business Market Insights is a market research platform that provides subscription service for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductor; Aerospace & Defense; Automotive & Transportation; Energy & Power; Healthcare; Manufacturing & Construction; Food & Beverages; Chemicals & Materials; and Technology, Media, & Telecommunications.

Contact Us:

If you have any questions about this report or would like further information, please contact us:

Contact person: Sameer Joshi

Email: [email protected]

Phone: +16467917070

0 notes

Text

Hey there! If you're curious about the future of injection molding, you've come to the right place. In this blog, we'll dive into the latest trends and innovations shaping this ever-evolving industry. We'll touch on plastic materials, molds, machines, automation, and surface treatments, all while highlighting some fascinating data. So, let's jump right in, shall we? Plastic materials - Sustainability & bioplastics: The future of injection molding is looking greener than ever, with a growing focus on sustainable materials. According to a study by Grand View Research, the global bioplastics market is expected to reach $35.47 billion by 2027, growing at a CAGR of 16.2% from 2020 to 2027. Manufacturers are increasingly turning to biodegradable and bio-based plastics, such as PLA, PHA, and bio-PET, to reduce their environmental footprint and meet consumer demands for eco-friendly products. Transparent polypropylene balls on a coral colored background. In addition to bioplastics, material development in injection molding is also focused on bio-composites and advanced polymers. Bio-composites, which combine natural fibers (like flax, hemp, or bamboo) with biodegradable resins, are gaining traction for their lightweight, high-strength, and eco-friendly properties. According to a report by MarketsandMarkets, the global natural fiber composites market is expected to reach $10.89 billion by 2024, at a CAGR of 11.0% from 2019 to 2024. Advanced polymers, such as high-performance thermoplastics like PEEK, PEI, and PPSU, are being used in more demanding applications due to their exceptional mechanical, thermal, and chemical resistance properties. These advanced materials are particularly valuable in industries such as aerospace, automotive, and medical devices, where performance and durability are critical. Molds - Additive manufacturing & micro-molding: The mold-making process is undergoing a paradigm shift, with additive manufacturing (AM) technologies, like 3D printing, gaining traction. AM enables rapid prototyping and shorter lead times, allowing for more flexible and cost-effective mold production. Furthermore, micro-molding - the production of intricate, high-precision parts - is gaining popularity, especially in industries like medical devices and electronics. In fact, the global micro injection molding market is estimated to reach $1.58 billion by 2027, growing at a CAGR of 11.4% from 2020. Machines - Energy efficiency & all-electric machines: As the industry moves toward greener practices, energy-efficient injection molding machines are becoming more widespread. All-electric machines, known for their precision and energy savings of up to 50% compared to hydraulic machines, are becoming the go-to choice for manufacturers. According to a report by Fortune Business Insights, the global electric injection molding machines market is projected to grow at a CAGR of 4.6% between 2021 and 2028. In addition to all-electric machines, multi-material injection molding machines are also making waves in the industry. These machines enable the production of complex, multi-component parts by injecting different materials in a single cycle. This capability not only enhances design flexibility but also reduces assembly costs and simplifies supply chains. In-mold sensors are another innovation in injection molding machines, providing real-time feedback on process parameters like temperature, pressure, and flow rate. These sensors allow for better process control, ensuring consistent part quality and reducing the risk of defects. Moreover, the data collected by these sensors can be analyzed to identify trends and optimize the molding process further. Automation - Robotics & Industry 4.0: The future of injection molding is all about automation. Collaborative robots (cobots) and advanced automation systems are becoming increasingly prevalent, streamlining production and reducing labor costs. Embracing Industry 4.

0, injection molding facilities are integrating smart technologies, such as IoT, AI, and Big Data analytics, to optimize processes and drive efficiency. One study by McKinsey & Company suggests that adopting Industry 4.0 technologies could increase productivity in the plastics sector by 15-20%. In the realm of automation, vision systems are playing an increasingly important role in the injection molding process. These systems utilize cameras and sensors to inspect parts for defects, ensuring quality control and reducing waste. By integrating AI and machine learning, vision systems can adapt and improve over time, further enhancing their accuracy and efficiency. Digital twin technology is another trend that's revolutionizing the injection molding industry. A digital twin is a virtual replica of a physical asset, such as an injection molding machine or an entire production line. By simulating and optimizing the molding process in a digital environment, manufacturers can identify potential issues, test various scenarios, and implement improvements before making changes to the actual production process. According to Gartner, 75% of organizations implementing IoT will have adopted digital twin technology by 2023. Surface treatments - Multi-functional coatings & nano-technology: Last but not least, innovative surface treatments are revolutionizing injection molded parts. Multi-functional coatings, such as hydrophobic, and self-healing coatings, are enhancing the performance and durability of plastic parts. Additionally, nano-technology is enabling the development of new materials with unique properties, like superior strength and thermal conductivity, opening up a world of possibilities for injection molding. There you have it! The future of injection molding is shaping up to be an exciting blend of sustainability, technological advancements, and innovative materials. As we continue to push the boundaries of what's possible, one thing's for sure - this industry is not slowing down anytime soon. So, stay tuned for more cutting-edge developments in the world of injection molding!

0 notes

Text

Polyaspartic floor coating | Duomit.com

Epoxy flooring consists of two main ingredients: resin and hardener. Resin is a liquid mixture of polymers, while hardener is a solid material that reacts with the resin when mixed. Once the two are combined, the epoxy becomes a solid substance. Like most people, you no doubt have never dealt with epoxy paints before and consider it just another type of paint like a varnish or semi-gloss. However, placing epoxy coating in the same class as ordinary garage floor paints is like saying a Dodge Ram is the same as a Bugatti Chiron because they are both cars.

What You Want To Know About Epoxy Floors