#Metrology Equipment

Explore tagged Tumblr posts

Text

Coating Thickness Gauge

#Metrology equipment#Metrology tools#Tool maker microscope#Calibration in metrology#Metrology and measuring instruments#Metrology measuring instruments#Optical comparator in metrology#Metrology tools semiconductor#Metrology machines#Metrology and measuring instruments in India#Calibration in metrology in Gurugram#Dimensional Measurement Instruments Suppliers in Gurugram#succession#star wars#super mario

2 notes

·

View notes

Text

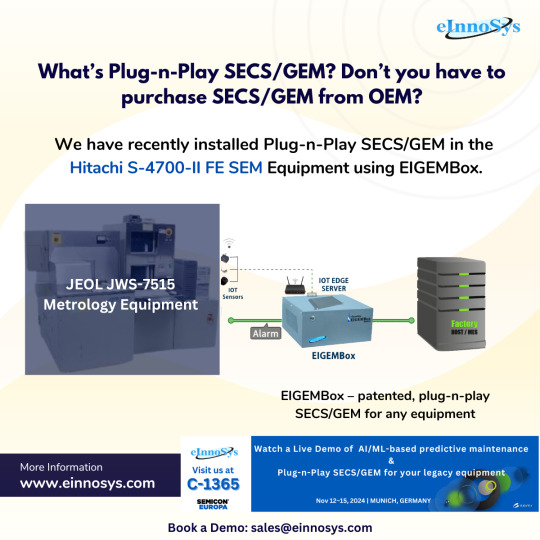

SECS/GEM on JEOL JWS-7515 Metrology Equipment: Enhancing Efficiency with EIGEMBox

In the fast-paced world of semiconductor manufacturing, precision and efficiency are paramount. One key aspect of this process is the metrology equipment used to ensure that every component meets stringent quality standards. The JEOL JWS-7515 is a leading tool in this field, particularly when combined with the EIGEMBox, which facilitates the SECS/GEM protocol. In this blog, we’ll explore the significance of SECS/GEM, the features of the JEOL JWS-7515, and how the EIGEMBox enhances metrology processes.

What is SECS/GEM?

SECS/GEM stands for SEMI Equipment Communication Standard/Generic Equipment Model. It is a widely adopted communication protocol in the semiconductor manufacturing industry that allows for seamless data exchange between manufacturing equipment and host systems. This standard is critical for achieving automation and real-time data acquisition, which helps improve production efficiency and reduce errors.

Why SECS/GEM Matters

Standardization: By providing a uniform communication protocol, SECS/GEM simplifies the integration of various equipment and systems, leading to smoother operations.

Real-time Monitoring: With SECS/GEM, manufacturers can monitor equipment performance in real-time, allowing for quick adjustments and better decision-making.

Data Collection: The protocol facilitates extensive data collection, which is essential for analysis, reporting, and continuous improvement initiatives.

Overview of JEOL JWS-7515

The JEOL JWS-7515 is an advanced metrology tool designed for high-resolution imaging and analysis of semiconductor wafers. Here are some of its standout features:

High-Resolution Imaging

The JWS-7515 utilizes cutting-edge electron beam technology to achieve high-resolution imaging. This capability allows for detailed inspections of wafer surfaces, crucial for identifying defects that could compromise performance.

Versatility

This equipment is versatile enough to handle various materials and applications, making it an invaluable asset in a semiconductor fab. Its ability to analyze different substrates and feature sizes helps manufacturers maintain high standards across diverse product lines.

Automated Functionality

Automation is a key feature of the JWS-7515, which enhances throughput and minimizes human error. The system’s ability to integrate with software tools and other equipment makes it a central hub for metrology operations.

The Role of EIGEMBox

The EIGEMBox is a powerful tool that enhances the capabilities of the JEOL JWS-7515 by facilitating SECS/GEM communication. Here’s how it works:

Seamless Integration

The EIGEMBox acts as a bridge between the JEOL JWS-7515 and the host system, enabling seamless data transfer. This integration is crucial for manufacturers who require real-time insights into their metrology processes.

Enhanced Data Management

With the EIGEMBox, data collected by the JWS-7515 can be efficiently managed and analyzed. The ability to centralize data from multiple sources helps manufacturers streamline operations and improve decision-making.

Flexibility and Scalability

The EIGEMBox is designed to be flexible, accommodating a variety of equipment and systems. As manufacturing needs evolve, the EIGEMBox can be scaled to meet increased demands without significant infrastructure changes.

Benefits of Using SECS/GEM with JEOL JWS-7515 and EIGEMBox

Improved Efficiency

By automating data exchange and analysis, the combination of SECS/GEM, the JEOL JWS-7515, and the EIGEMBox significantly improves operational efficiency. Manufacturers can reduce downtime and optimize workflow, leading to faster production cycles.

Enhanced Quality Control

The ability to conduct real-time monitoring and analysis of wafer conditions ensures that quality control measures are always in place. This capability minimizes the risk of defects reaching the production stage, ultimately enhancing product reliability.

Data-Driven Decision Making

Access to comprehensive, real-time data allows manufacturers to make informed decisions quickly. This responsiveness is critical in a competitive landscape where even minor delays can have significant consequences.

Implementation Considerations

While the benefits of integrating SECS/GEM with the JEOL JWS-7515 and EIGEMBox are clear, several implementation considerations should be taken into account:

Training and Support

To fully leverage the capabilities of these technologies, manufacturers should invest in training for their staff. Understanding how to use the equipment and interpret data is essential for maximizing the benefits.

System Compatibility

Ensuring that the EIGEMBox is compatible with existing systems is crucial for a successful integration. Manufacturers should conduct thorough assessments before implementation to identify any potential challenges.

Ongoing Maintenance

Regular maintenance of both the JWS-7515 and the EIGEMBox is essential to maintain optimal performance. A proactive maintenance schedule can help prevent equipment failures and ensure long-term reliability.

Conclusion: Elevate Your Metrology Operations Today

The integration of SECS/GEM with the JEOL JWS-7515 metrology equipment, enhanced by the EIGEMBox, represents a significant advancement in semiconductor manufacturing. By improving efficiency, enhancing quality control, and enabling data-driven decision-making, this combination positions manufacturers for success in a highly competitive market.

If you're looking to elevate your metrology operations and embrace the future of semiconductor manufacturing, now is the time to act! Contact us today to learn more about how SECS/GEM, JEOL JWS-7515, and EIGEMBox can transform your processes. Don’t miss out on the opportunity to enhance your operational efficiency and product quality!

#secs/gem#fab automation#equipment software#secs/gem software#eigembox#secs/gem protocol#semiconductor#secs gem software#JEOL JWS-7515#Metrology Equipment

1 note

·

View note

Text

Bridging the Gap: From Lab to Factory Floor with Metrology Equipment

This is where metrology equipment comes in, acting as the foundation of quality assurance from the lab to the production floor.

Know More: https://www.falcon-geosystems.com/hexagon-metrology/

0 notes

Text

#Brinell Hardness Teter#BHN Hardness Tester#Brinrll#hardness tester#Metallurgy#metrology#metalography#industrial equipment

0 notes

Text

Metrology Lab Equipment Manufacturers in India provide high-quality tools and instruments for accurate measurement and inspection in various industries. Metrology Lab Equipment Manufacturers in Chennai are known for offering reliable and durable equipment, catering to the needs of educational institutions, research labs, and manufacturing units. These manufacturers specialize in products like gauges, micrometers, calipers, and coordinate measuring machines, ensuring precision and performance. Their expertise helps industries maintain quality standards and achieve consistent results.

link:

1 note

·

View note

Text

Gauges and Instruments Manufacturers and Suppliers in Chennai and India

Your Trusted Partner for Precision Measurement and Automation Solutions

Airtronic Gauges & Instruments Pvt. Ltd., headquartered in Chennai, is a leading name in the field of industrial metrology and precision engineering. With over three decades of expertise, we specialize in providing world-class measurement solutions tailored to the needs of industries across India and beyond.

Our commitment to quality, precision, and innovation has established us as a trusted partner for manufacturing and engineering sectors, including automotive, aerospace, electronics, and industrial applications.

Products We Provide

1. Gauges

Our range of gauges is designed for precise and reliable measurements to ensure quality control in manufacturing processes.

Height Gauges: Including Dial Vernier, Digital, and Vernier Height Gauges with advanced features for enhanced accuracy.

Calipers: Digital, Vernier, Dial, and specialized Workshop Calipers for a variety of industrial applications.

Plug Gauges: Accurate and durable, ideal for dimensional inspections.

Ring Gauges: Ensuring compliance with tight tolerances for round components.

2. Coordinate Measuring Machines (CMM)

We supply high-performance CMMs to meet diverse industrial requirements:

Shop Floor CMM: Robust and efficient, designed for rigorous manufacturing environments.

Bridge CMM: Offering unparalleled precision for intricate measurements.

Horizontal Arm CMM: Best suited for large and complex components.

Large CMMs: Optimized for heavy and oversized parts.

3. Torque Solutions

We provide torque wrenches and testers for industries requiring consistent and accurate torque control.

4. Vision-Based Inspection Systems

Advanced systems for automated quality checks, reducing human error and increasing efficiency.

5. Customized Measurement Solutions

Tailor-made gauges and measurement instruments to meet specific industry demands, including the rapidly growing electric vehicle (EV) sector.

Services We Offer

1. Precision Gauging and Calibration

We deliver precision gauging solutions for accurate measurement and reliable quality assurance. Our calibration services ensure that your instruments meet industry standards and maintain their accuracy over time.

2. Industrial Automation

Airtronic provides customized automation solutions to improve production efficiency and consistency in manufacturing processes.

3. Vision Inspection Solutions

Our vision systems utilize advanced image-processing technology to perform detailed inspections and quality checks in real time.

4. Customized Part Development

We specialize in the design and manufacture of custom components and measurement tools, particularly for the electric vehicle (EV) industry.

5. Training and Support

Our team of experts provides comprehensive training programs to ensure optimal usage of our products. We also offer ongoing support to address operational challenges.

Industries We Serve

Automotive Manufacturing: Precision tools and gauges for engine components, chassis, and body parts.

Aerospace: High-accuracy measurement tools for critical aerospace components.

Electronics: Specialized inspection systems for delicate and intricate electronics manufacturing.

General Manufacturing: Gauging solutions to meet diverse industrial needs.

For Business Contact:

Website: https://www.airtronic.in/

Phone: +91 44 4208 8591

Email : https://airtronic.in/

#industry#metrology#gauge#instruments#measuringtools#measuring instruments#precision measurement#manufactures#suppliers#industrial equipment#industrial automation#business

1 note

·

View note

Text

Semiconductor Metrology and Inspection Equipment Market Growth, Analysis, and Industry Insights 2024 to 2032

Semiconductor metrology and inspection equipment play a crucial role in the semiconductor manufacturing process, ensuring that devices meet the highest standards of quality and performance. These tools are employed throughout the fabrication process to measure critical dimensions, assess material properties, and verify the integrity of semiconductor wafers and devices. The increasing complexity of semiconductor designs, driven by the demand for advanced technologies such as AI, 5G, and IoT, necessitates sophisticated metrology solutions that can deliver precise measurements at nanoscale levels.

With the ongoing trend toward miniaturization and integration of semiconductor devices, manufacturers are investing heavily in state-of-the-art metrology and inspection equipment. These systems not only enhance product quality but also help in reducing production costs by minimizing defects and optimizing yield. Advanced metrology tools utilize techniques such as optical measurement, atomic force microscopy (AFM), and X-ray diffraction to provide comprehensive insights into the fabrication process.

The Semiconductor Metrology and Inspection Equipment Market is growing as manufacturers seek precise measurement and quality control solutions to enhance yield and performance in semiconductor fabrication processes.

Future Scope

The future of semiconductor metrology and inspection equipment is bright, with substantial growth expected as the industry continues to evolve. As semiconductor technology advances, there will be a growing need for equipment that can handle increasingly complex structures and smaller feature sizes. Innovations in materials and device architectures, such as 3D NAND and FinFET transistors, will require advanced metrology techniques to ensure that performance specifications are met.

Furthermore, the rise of new applications, including quantum computing and advanced packaging technologies, will create new opportunities for metrology equipment. As these technologies develop, manufacturers will need to adapt their inspection processes to accommodate the unique challenges posed by novel materials and device configurations. This adaptability will be critical for maintaining competitiveness in a rapidly changing market.

Trends

Key trends shaping the semiconductor metrology and inspection equipment market include the increasing emphasis on in-line metrology and automation. Manufacturers are increasingly adopting in-line measurement systems that allow for real-time monitoring of the fabrication process. This capability enables immediate feedback and corrective actions, leading to enhanced yield and efficiency.

Another trend is the integration of artificial intelligence and machine learning into metrology systems. These technologies are being employed to analyze large volumes of data generated during the manufacturing process, providing valuable insights into process optimization and defect detection. As the semiconductor industry embraces smart manufacturing, AI-driven metrology solutions will play a pivotal role in enhancing production efficiency and reducing downtime.

Application

Semiconductor metrology and inspection equipment are utilized across various stages of semiconductor manufacturing, from wafer fabrication to final device testing. In the wafer fabrication process, metrology tools are used to measure critical dimensions, assess film thickness, and evaluate surface characteristics. These measurements are essential for ensuring that the fabrication processes adhere to design specifications.

In addition to wafer fabrication, inspection equipment is crucial during the packaging and assembly stages. These tools verify the integrity of the packaging, ensuring that the devices are free from defects that could impact performance. In the final testing phase, metrology systems are employed to assess the electrical characteristics of semiconductor devices, confirming that they meet performance standards before being shipped to customers.

Key Points

Essential for ensuring quality and performance in semiconductor manufacturing.

Driven by the demand for advanced technologies and complex semiconductor designs.

Promising future with growth opportunities in new applications and materials.

Trends include in-line metrology and AI integration for process optimization.

Applied throughout wafer fabrication, packaging, and final device testing stages.

Read More Details: https://www.snsinsider.com/reports/semiconductor-metrology-and-inspection-equipment-market-4541

Contact Us:

Akash Anand — Head of Business Development & Strategy

Email: [email protected]

Phone: +1–415–230–0044 (US) | +91–7798602273 (IND)

0 notes

Text

#optical measurement equipment#optical measurement system#video measuring machine#Stencil measurement#**Dimensional Metrology System

0 notes

Text

Putting Customers First in the Custom Automation Equipment Development Process

As a leading custom automation equipment solution provider in the semiconductor metrology and inspection, medical devices, and emerging technologies, we have witnessed how the relentless pursuit of technical excellence—prioritizing streamlined processes and criteria fit—can inadvertently overshadow the deeper needs customers.

That is why this article focuses on the importance of understanding customer needs from the beginning. By embracing a holistic approach and redirecting the focus towards customer needs, stronger relationships are developed, exceptional experiences are delivered, and mutual success is achieved.

Exploring Strategic Objectives: The Foundation of Understanding

Steering teams towards a more strategic understanding of our customers, instead of superficial interactions, is an important duty as company leaders. It’s important to inspire teams to learn what customers really need and what is important to them instead of over-focusing on technical specifications. This can be accomplished by, "What do you want to achieve?" or "What would a successful outcome look like?" These answers will reveal a deeper understanding of customer needs, beyond what lies upon the surface.

Typical goals include:

Commercialization of a product concept

Accelerated time-to-market

Scaling manufacturing

Strategic objectives can be broader and include corporate, user or environmental goals. The more all high-level objectives are known, the stronger the potential partnership.

Empathy Is Key

Nurturing an atmosphere of empathy within our institutions is crucial to be effective leaders. We must prioritize customer concerns and fears with sincerity and understanding. Doing so will lead to a comprehensive knowledge of their expectations, build trust, and open the door for tailored solutions.

Asking "What are your biggest concerns or fears regarding this project?" or "What obstacles do you anticipate?" lead to deeper conversations, trust, and pave the way for a more successful outcome.

Customization as a Competitive Advantage

It’s important to remember that the true value lies in tailoring solutions to meet the unique needs of customers, more so than achieving technical excellence. Encourage teams to consider more than just technical specs, including scheduling, budgeting and more is crucial. This sets the stage for proposing solutions that better align with customer specific needs and can lead to a competitive advantage for them.

For example, during one discussion, a client expressed concerns about project timelines and potential delays that they experienced with vendors in the past. Commitments were made to the customer’s customers, so on-time delivery was critical. After engaging in an open and honest dialogue and listening closely to their worries and discussing options and tradeoffs, led to a better understanding so the project could move forward with both parties having more confidence in it.

By understanding how they felt, we developed a detailed project plan that met their timeline and accounted for potential challenges and risks. This level of proactive engagement addressed their concerns while solidifying our status as a trusted advisor that is invested in their success, which is a higher level relationship than a partnership.

Developing a Customer-Centric Culture

Cultivating a customer-centric culture within our company is critically important as leaders. By encouraging our teams to actively listen, develop a deep understanding of customer needs with empathy, we will be in a much stronger position to serve customers in the way they need and elevate our position to that of an advisor that can be trusted.

6 notes

·

View notes

Text

Precision Unveiled: Exploring the World of Dimensional Measurement Laboratories

Introduction: Unraveling the Secrets of Dimensional Measurement Laboratories

Welcome to the intriguing realm of Dimensional Measurement Laboratories, where precision takes center stage, and the world of measurement is unveiled in all its glory. In this comprehensive exploration, we delve deep into the inner workings of these laboratories, shedding light on their pivotal role in industries ranging from aerospace to manufacturing. Prepare to embark on a journey where precision reigns supreme, and accuracy knows no bounds.

The Essence of Dimensional Measurement Laboratories

At the heart of every Dimensional Measurement Laboratory lies a commitment to precision. These specialized facilities serve as the nerve centers of dimensional analysis, employing state-of-the-art technology and highly skilled personnel to ensure accuracy in measurements that can often be imperceptible to the human eye. Let's break down the key aspects that define these laboratories:

1. Cutting-Edge Equipment: The Pillars of Precision

In the world of Dimensional Measurement Laboratories, equipment is everything. From coordinate measuring machines (CMMs) to laser scanners and optical comparators, these laboratories house an impressive arsenal of tools. These instruments are calibrated to perfection, enabling scientists and engineers to measure dimensions with astonishing accuracy.

2. Metrology Masters: The Art of Measurement

Behind every precise measurement is a metrology master, an expert skilled in the science of measurement. These professionals play a pivotal role in calibration, ensuring that instruments remain accurate and reliable. Their meticulous attention to detail is what sets Dimensional Measurement Laboratories apart.

3. Real-World Applications: Impact Across Industries

The applications of dimensional measurement are far-reaching, touching upon industries that shape our modern world. From ensuring the safety of aerospace components to guaranteeing the precision of medical devices, these laboratories have a hand in it all. In fact, they are indispensable in manufacturing, research, and development.

The Precision Paradox: Why It Matters

Precision may seem like a niche concern, but it has a profound impact on our daily lives. Let's uncover why precision matters, not just in Dimensional Measurement Laboratories but in our broader world:

1. Industry Advancements: Driving Innovation

Precision is the driving force behind innovation in various industries. Imagine the aerospace industry without accurate measurements; the consequences could be catastrophic. Dimensional Measurement Laboratories serve as the guardians of progress, ensuring that groundbreaking advancements can be made safely and reliably.

2. Quality Assurance: The Backbone of Production

In manufacturing, precision is synonymous with quality. A single measurement error can lead to a cascade of problems, resulting in defective products and financial losses. These laboratories act as quality assurance hubs, safeguarding the reputation and profitability of companies worldwide.

3. Scientific Discoveries: Expanding Our Horizons

In the world of scientific research, precision is the key to unlocking new discoveries. From understanding the properties of materials at the nanoscale to deciphering the mysteries of the universe through telescope calibration, Dimensional Measurement Laboratories enable scientists to push the boundaries of knowledge.

Navigating the Dimensions: How It's Done

So, how exactly do Dimensional Measurement Laboratories work their magic? Let's take a closer look at the intricate process of dimensional analysis:

1. Preparation: Setting the Stage

Before any measurement can take place, meticulous preparation is essential. This involves ensuring that the measuring instruments are calibrated to their highest precision and that the environment is controlled to minimize external factors that could affect measurements.

2. Data Acquisition: Capturing the Essence

Once the stage is set, it's time to collect data. This can involve a variety of methods, from contact measurements using CMMs to non-contact techniques like laser scanning. The goal is to capture the essence of the object being measured with utmost accuracy.

3. Analysis and Interpretation: Deciphering the Numbers

The data collected is then subjected to rigorous analysis. This stage involves complex mathematical algorithms and cutting-edge software to interpret the measurements accurately. Metrology masters play a pivotal role here, ensuring that the data is translated into meaningful insights.

4. Reporting: Precision in Documentation

The final step involves documenting the measurements with precision. Detailed reports are generated, providing clients with a clear understanding of the measurements and their implications. These reports are not just records but also tools for decision-making and quality control.

Beyond the Laboratory: Real-World Applications

Dimensional Measurement Laboratories extend their influence far beyond their physical confines. Let's explore some of the real-world applications where their precision makes a difference:

1. Aerospace Industry: Safeguarding Skies

In the aerospace industry, safety is paramount. Dimensional Measurement Laboratories play a critical role in ensuring the precision and reliability of aircraft components. From engine parts to structural elements, every component undergoes meticulous measurement and inspection.

2. Automotive Sector: Driving Efficiency

Precision in the automotive sector translates to fuel efficiency, safety, and performance. These laboratories are responsible for verifying the accuracy of engine components, ensuring that vehicles meet stringent emission standards, and enhancing overall vehicle quality.

3. Medical Devices: Saving Lives

The medical field relies on precision to save lives. Dimensional Measurement Laboratories verify the accuracy of medical devices, from surgical instruments to diagnostic equipment, guaranteeing that they meet regulatory standards and perform with utmost precision.

4. Research and Development: Innovating the Future

In research and development, every breakthrough begins with accurate measurements. These laboratories support scientific advancements by providing precise measurements for materials, prototypes, and experimental setups, enabling researchers to push the boundaries of knowledge.

Conclusion: The Precision Revolution

In conclusion, Dimensional Measurement Laboratories are the unsung heroes of our modern world. Their unwavering commitment to precision underpins innovation, ensures quality, and drives scientific discovery. From the aerospace industry to medical research, their influence is felt across a myriad of sectors. As we continue to push the boundaries of what's possible, we can rest assured that Dimensional Measurement Laboratories will remain at the forefront of precision, unveiling new dimensions in measurement and advancing our world in ways we can only imagine.

So, the next time you marvel at the precision of a spacecraft, the efficiency of your car, or the accuracy of a medical device, remember that behind it all lies the meticulous work of Dimensional Measurement Laboratories, where precision is not just a goal but a way of life.

2 notes

·

View notes

Text

Imaging Solutions

#Metrology equipment#Metrology tools#Tool maker microscope#Calibration in metrology#Metrology and measuring instruments#Metrology measuring instruments#Optical comparator in metrology#Metrology tools semiconductor#Metrology machines#Metrology and measuring instruments in India#Calibration in metrology in Gurugram#Dimensional Measurement Instruments Suppliers in Gurugram#star wars#succession#super mario

2 notes

·

View notes

Text

North America Semiconductor Manufacturing Equipment Market Size, Growth Status, Analysis and Forecast 2027

North America Semiconductor Manufacturing Equipment Market Semiconductor manufacturing equipment market in North America is expected to grow from US$ 8.45 Bn in 2018 to US$ 13.17 Bn by the year 2027 with a CAGR of 4.7% from the year 2019 to 2027.

North America Semiconductor Manufacturing Equipment Market Significant demand for consumer electronic devices boost the manufacturing prospects, which is further fueling the growth of the semiconductor manufacturing equipment market. North America Semiconductor Manufacturing Equipment Market Moreover, North America Semiconductor Manufacturing Equipment Market the increase in adoption of IoT, artificial intelligence, and connected devices across industry verticals is anticipated to boost semiconductor manufacturing equipment market growth in the forecast period. Today’s smart products contain complex electronic systems that require flawless operation in the real world. North America Semiconductor Manufacturing Equipment Market Device miniaturization, support for multiple wireless technologies, faster data rates, and longer battery life, demand highly sophisticated Integrated Circuits (ICs) incorporated into the devices.

Additionally, North America Semiconductor Manufacturing Equipment Market demand for numerous feature integrations onto a single device has led to complex circuit board designs of these electronics. As an example, a smartphone today includes features such as camera, calling function, torch, storage drives, and connectivity with other devices, compatible ports for connections, a multimedia player, and many other functions, etc. Similarly, other consumer electronic devices have been improving on similar lines propelling the semiconductor manufacturers for more miniaturization of the chips and integration of more functionalities. Smartphones lead the incorporations of semiconductor equipment into the devices.

📚 𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐒𝐚𝐦𝐩𝐥𝐞 𝐏𝐃𝐅 𝐂𝐨𝐩𝐲@ https://www.businessmarketinsights.com/sample/TIPRE00005043

North America Semiconductor Manufacturing Equipment Market The Wafer Manufacturing Equipment segment is the leading equipment type with the highest market share in North America semiconductor manufacturing equipment market. North America Semiconductor Manufacturing Equipment Market It includes single crystal manufacturing equipment, wafer processing equipment, inspection & metrology equipment, and others. The wafer manufacturing equipment is available in different forms and most of which are specific to growing, removing, depositing materials from the wafer. The increase in demand for semiconductor in various applications is expected to have a significant impact on the growth of wafer manufacturing equipment market.

The US dominated the semiconductor manufacturing equipment market in 2018 and is anticipated to lead the semiconductor manufacturing equipment market across the North American region through the forecast period, followed by Mexico and Canada. North America Semiconductor Manufacturing Equipment Market The figure given below highlights the revenue share of the Mexico in the North American semiconductor manufacturing equipment market in the forecast period:

𝐓𝐡𝐞 𝐋𝐢𝐬𝐭 𝐨𝐟 𝐂𝐨𝐦𝐩𝐚𝐧𝐢𝐞𝐬

Advantest Corporation

Applied Materials, Inc.

ASML Holding N.V.

Hitachi High-Technologies Corporation

KLA Corporation

Lam Research Corporation

Rudolph Technologies, Inc.

Screen Holdings Co., Ltd.

Teradyne Inc.

Tokyo Electron Ltd.

📚𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭 𝐋𝐢𝐧𝐤 @ https://www.businessmarketinsights.com/reports/north-america-semiconductor-manufacturing-equipment-market

NORTH AMERICA SEMICONDUCTOR MANUFACTURING EQUIPMENT MARKET SEGMENTATION

By Equipment Type

Wafer Manufacturing Equipment

Assembly & Packaging Equipment

Test Equipment

Others

By End-Use

Semiconductor Fabrication Plant/Foundry

Semiconductor Electronics Manufacturing

Test Home

By Dimension

2D

2.5D

3D

By Country

U.S.

Canada

Mexico

North America Semiconductor Manufacturing Equipment Market: Overview and Insights

The semiconductor industry forms the backbone of modern technology, providing critical components used in everything from smartphones to electric vehicles. As a result, the semiconductor manufacturing equipment (SME) market plays an essential role in the development and production of semiconductor chips. North America, home to major semiconductor companies and manufacturers, is a key player in the global SME market. The region’s demand for cutting-edge technologies, increasing investments in advanced semiconductor manufacturing processes, and growing reliance on semiconductors across various industries make it a focal point of market activity.

Market Overview

The North American semiconductor manufacturing equipment market encompasses various tools and machinery used to produce semiconductors. These include photolithography equipment, wafer fabrication equipment, assembly and packaging tools, and other supporting technologies. The market is driven by the increasing demand for semiconductors, advancements in process technologies, and the rise of applications such as Artificial Intelligence (AI), 5G networks, automotive electronics, and Internet of Things (IoT).

In recent years, North America has seen significant growth in the semiconductor industry, with both established companies and new entrants investing heavily in manufacturing capabilities. Semiconductor production is capital-intensive, and companies must continuously invest in advanced machinery to stay competitive. Furthermore, geopolitical factors, such as the ongoing U.S.-China trade tensions and the push for reshoring manufacturing, have amplified the region’s focus on building robust semiconductor production capabilities.

Key Players in the Market

The North American semiconductor manufacturing equipment market is characterized by the presence of several established players who supply both equipment and advanced technologies. Some of the major companies in the market include:

Applied Materials: A leading supplier of semiconductor fabrication equipment, Applied Materials offers solutions for wafer fabrication, deposition, etching, and inspection. The company is at the forefront of developing cutting-edge technologies, such as atomic layer deposition (ALD) and EUV lithography.

Lam Research: Lam Research provides equipment used in the wafer fabrication process, specializing in etching, deposition, and clean technology. The company plays a crucial role in enabling advanced semiconductor manufacturing for the most cutting-edge chips.

KLA Corporation: Specializing in process control and yield management solutions, KLA provides tools for inspection, metrology, and patterning. Their technologies are critical in ensuring the reliability and quality of semiconductors produced in fabs.

Tokyo Electron: A global leader in semiconductor manufacturing equipment, Tokyo Electron provides equipment used in both front-end and back-end semiconductor processes. Their tools cover a wide range of activities from lithography to packaging.

ASML: While primarily based in the Netherlands, ASML is a significant player in the North American market, providing the highly specialized EUV lithography equipment needed for the most advanced semiconductor production processes.

Market Trends

Adoption of EUV Lithography: One of the most important technological advancements in semiconductor manufacturing is the adoption of extreme ultraviolet (EUV) lithography. EUV enables the production of smaller and more powerful chips. North American companies are among the first to invest in EUV equipment, and its increasing use is driving growth in the market.

Increased Focus on Sustainability: As environmental concerns continue to grow, semiconductor manufacturers are investing in energy-efficient equipment and adopting more sustainable practices. This trend is expected to continue as companies aim to reduce their carbon footprint and meet regulatory requirements.

Integration of AI and Automation in Manufacturing: Artificial intelligence (AI) and automation are playing a larger role in semiconductor manufacturing. AI is being used to improve yield rates, optimize production processes, and reduce defects. Automation is helping improve efficiency and reduce labor costs.

Diversification of Supply Chain: With the ongoing semiconductor shortages and supply chain disruptions, manufacturers are increasingly diversifying their supply chains to reduce dependence on specific regions or suppliers. This has implications for the distribution of semiconductor manufacturing equipment, which may result in changes in supplier relationships and manufacturing strategies.

𝐀𝐛𝐨𝐮𝐭 𝐔𝐬:

Business Market Insights is a market research platform that provides subscription service for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductor; Aerospace & Defense; Automotive & Transportation; Energy & Power; Healthcare; Manufacturing & Construction; Food & Beverages; Chemicals & Materials; and Technology, Media, & Telecommunications

You can see this

North America Sleep Apnea Devices Market- https://www.openpr.com/news/3924087/north-america-sleep-apnea-devices-market-size-share

Europe EV Charging Infrastructure Market- https://www.openpr.com/news/3911041/europe-ev-charging-infrastructure-market-analysis-segments

0 notes

Text

Measure Up with Confidence: Falcon Geomatics Unveils Dubai's Premier Metrology Gear

Falcon Geomatics is your premier destination for top-notch metrology equipment in Dubai. With our commitment to excellence and precision, we provide the best-in-class solutions to meet your measurement needs. Whether you're in construction, engineering, or manufacturing, our extensive range of equipment ensures accurate and reliable results every time. Trust Falcon Geomatics for advanced technology and unparalleled service, setting the benchmark for metrology solutions in Dubai.

0 notes

Text

Enhance the performance of your Mitutoyo Micro Vickers Hardness Tester with Multitek's expert repair and upgradation services. Our certified technicians ensure precision and reliability for your testing equipment. Contact us for efficient service and support. https://www.multitek.in/mitutoyo-micro-vicker-hardness-tester-repair-and-machineupgradation-services

Mitutoyo #MicroVickers #HardnessTester #Repair #Upgradation #Metallurgy #Metrology #MechanicalEngineering #Automotive #Industrial #Equipment

#Mtutoyo#Micro Vickers#Hardness Tester#Metallurgy#Metrology#Metalography#industrialengineering#Industrial Equipment#Mechanical Engineering

0 notes

Text

Why International Companies Prefer the Best Testing Labs in Saudi Arabia?

Saudi Arabia is a rapidly growing market for international companies, particularly in industries like oil and gas, construction, pharmaceuticals, food production, and consumer goods. With stringent regulatory requirements and a commitment to high-quality standards, businesses operating in the Kingdom must ensure that their products and services meet compliance criteria. This is where the best testing lab in Saudi Arabia play a crucial role. These labs provide top-notch analytical, chemical, and environmental testing services, helping international businesses maintain quality, safety, and regulatory adherence.

Stringent Regulatory Compliance

One of the primary reasons why international companies choose the best testing labs in Saudi Arabia is the country’s strict regulatory environment. Saudi authorities, including the Saudi Standards, Metrology and Quality Organization (SASO) and the Gulf Standards Organization (GSO), mandate compliance with various testing and certification standards. Companies operating in Saudi Arabia must meet these regulations to gain market access and avoid penalties. The best testing labs help businesses:

Obtain SASO and GSO certifications

Conduct product testing for import approvals

Ensure compliance with ISO, ASTM, and other global standards

Test for chemical, physical, and microbiological safety

Cutting-Edge Technology and Expertise

Top-tier testing labs in Saudi Arabia invest in state-of-the-art equipment and highly trained professionals to ensure the highest accuracy in testing. International companies prefer these labs because they offer:

Advanced testing methodologies including spectroscopy, chromatography, and mass spectrometry

Accredited and ISO 17025-certified facilities

Expert scientists and engineers with deep industry knowledge

Fast turnaround times to meet business deadlines

By leveraging the expertise and advanced technology of these labs, companies can ensure that their products meet Saudi Arabian and international standards.

Support for Multiple Industries

The best testing labs in Saudi Arabia cater to a variety of industries, providing specialized testing services for:

1. Oil and Gas Sector

Saudi Arabia’s oil and gas industry is a major economic driver, and international companies working in this sector require precise testing for:

Petroleum quality control

Gas composition analysis

Corrosion and material testing

Environmental impact assessments

2. Food and Beverage Industry

International food brands and suppliers must adhere to strict halal and food safety standards in Saudi Arabia. The best testing labs help with:

Halal certification testing

Microbiological and chemical contamination analysis

Food packaging safety assessments

3. Pharmaceutical and Healthcare Sector

The healthcare industry relies on laboratory testing for:

Drug efficacy and purity analysis

Medical device compliance testing

Sterility and microbiological testing

4. Construction and Building Materials

With Saudi Arabia's ambitious construction projects like NEOM and Vision 2030 initiatives, testing labs support the industry by providing:

Concrete and steel quality testing

Fire resistance assessments

Structural integrity evaluations

Speed and Efficiency in Testing Services

International companies operate in a fast-paced environment and require quick and efficient testing services. The best testing labs in Saudi Arabia offer:

Expedited testing services to meet tight deadlines

Online result tracking for convenient access

Dedicated customer support teams for seamless communication

This ensures that companies can quickly obtain the necessary approvals and certifications without disrupting their supply chain or product launches.

Competitive Costs and Local Market Expertise

Many international companies find it cost-effective to partner with Saudi-based testing labs rather than outsourcing testing to labs overseas. Benefits include:

Lower logistical costs by testing locally

Faster regulatory approvals due to direct collaboration with authorities

Local market expertise to navigate compliance requirements efficiently

The best testing labs in Saudi Arabia provide an optimal balance of affordability and accuracy, making them the preferred choice for businesses expanding into the region.

Conclusion

For international companies looking to enter or expand in Saudi Arabia, partnering with the best testing lab is essential for compliance, product quality, and market success. These labs offer advanced technology, regulatory expertise, industry-specific testing, and efficient services that ensure businesses meet Saudi and global standards. By choosing a reputable testing lab, companies can streamline their operations, reduce risks, and establish a strong presence in one of the world’s most dynamic markets.

#best testing lab#best testing lab saudi#best testing lab saudi arabia#testing lab near me#best testing labs

0 notes

Text

Local Regulations on Water Hardness: What You Need to Know

Water hardness is an essential factor in determining water quality, affecting household plumbing, appliances, and even industrial operations. Understanding local regulations on water hardness can help homeowners and businesses ensure compliance with safety standards. If you’re searching for a "Water Hardness Test near me," it’s important to be aware of relevant regulations and testing methods.

What is Water Hardness?

Water hardness refers to the concentration of dissolved minerals, primarily calcium and magnesium, in water. It is typically measured in parts per million (ppm) or grains per gallon (gpg). Hard water can lead to limescale buildup in pipes, reduced efficiency of soap and detergents, and damage to appliances over time.

Hardness Levels Classification

Soft Water: 0-60 ppm (0-3.5 gpg)

Moderately Hard Water: 61-120 ppm (3.6-7 gpg)

Hard Water: 121-180 ppm (7.1-10.5 gpg)

Very Hard Water: 181+ ppm (10.6+ gpg)

Local Regulations on Water Hardness

Water hardness regulations vary by region and country. Some local water authorities set limits or provide recommendations to ensure water quality for residential and industrial use.

1. EPA Guidelines (United States)

The Environmental Protection Agency (EPA) does not regulate water hardness as a health concern but provides recommendations for optimal water quality. The U.S. Geological Survey (USGS) classifies water hardness and encourages regular testing to prevent infrastructure damage.

2. EU Water Quality Standards

The European Union (EU) sets guidelines for water quality under the Drinking Water Directive (98/83/EC). While no specific hardness limits exist, member states may enforce their own standards to protect household plumbing and industrial machinery.

3. UK Water Hardness Standards

In the UK, water hardness varies by region, and local water suppliers provide hardness information. The Water Supply (Water Quality) Regulations require testing for minerals like calcium and magnesium to ensure efficient water usage.

4. GCC and UAE Water Standards

The UAE follows stringent guidelines for potable water quality under the Emirates Authority for Standardization and Metrology (ESMA). Businesses and residents are encouraged to conduct regular "Water Hardness Test near me" searches to stay compliant with these standards.

Why Local Water Hardness Regulations Matter

1. Protecting Infrastructure

Hard water can cause scale buildup in plumbing systems, leading to higher maintenance costs. Regulations help ensure that water supplies remain within safe hardness limits to prevent these issues.

2. Ensuring Safe Drinking Water

Although hard water is not harmful to health, excessive mineral content can affect taste and cause water to appear cloudy. Compliance with local regulations ensures that drinking water remains palatable and safe.

3. Preserving Appliance Efficiency

Water hardness impacts appliances such as water heaters, dishwashers, and boilers. Regulations help maintain energy efficiency and prolong the lifespan of household and industrial equipment.

4. Supporting Industrial Compliance

Industries relying on water for manufacturing, food processing, and pharmaceuticals must adhere to strict hardness regulations to ensure product quality and equipment longevity.

How to Conduct a Water Hardness Test

If you need to determine whether your water meets local regulations, conducting a test is essential. Searching for a "Water Hardness Test near me" will help you find nearby labs or DIY test kits.

1. Using a Test Kit

Home water hardness test kits are available at hardware stores and online. These kits include test strips or liquid reagents that change color based on mineral concentration.

2. Professional Laboratory Testing

A certified lab can provide accurate and detailed water hardness analysis. Lab testing is ideal for businesses, industrial facilities, and homeowners seeking precise data.

3. Contacting Your Water Supplier

Many local water authorities provide hardness level reports. Checking with your supplier can be a quick way to determine the hardness of your water supply.

Steps to Reduce Water Hardness

If testing indicates that your water is too hard, consider the following solutions:

1. Install a Water Softener

A water softener removes excess calcium and magnesium through ion exchange, improving water quality and protecting appliances.

2. Use Chemical Treatments

Some households use water conditioning agents or phosphates to reduce hardness in specific applications, such as laundry or dishwashing.

3. Reverse Osmosis Filtration

A reverse osmosis (RO) system can remove minerals from water, ensuring compliance with regulations for drinking and industrial use.

Conclusion

Understanding local regulations on water hardness is crucial for maintaining compliance, protecting infrastructure, and ensuring safe drinking water. Whether you’re a homeowner or business owner, regular testing is essential. By searching for a "Water Hardness Test near me," you can find professional labs or test kits to monitor your water quality effectively. Staying informed about water hardness regulations helps improve water usage efficiency and safeguards your appliances and plumbing systems.

#water hardness test near me#water hardness test#water testing#testing lab near me#testing lab delhi

0 notes