#Medical Polyoxymethylene Market

Explore tagged Tumblr posts

Text

Medical Polyoxymethylene Market Size Estimate, Growing Industry Demands, Current Movements, and Business Opportunities From 2023 to 2030

The Medical Polyoxymethylene (POM) Market refers to the market for polyoxymethylene or polyacetal resins that are specifically designed and used in medical applications. POM is a high-performance engineering plastic known for its excellent mechanical properties, low friction, chemical resistance, and dimensional stability.

Here is some information about the Medical Polyoxymethylene Market:

Market Overview:

The Medical POM Market encompasses the production, distribution, and sales of polyoxymethylene resins and related products for medical applications. These resins are widely used in the medical industry for manufacturing various components and devices.

Key Applications:

Medical POM finds application in a wide range of medical devices and components, including but not limited to:

Surgical instruments Drug delivery systems Orthopedic devices Dental equipment Diagnostic devices Implantable devices Prosthetic devices Disposable medical products

Market Drivers:

Several factors contribute to the growth of the Medical POM Market:

• Increasing demand for high-performance materials in the medical industry • Growing emphasis on patient safety and infection control • Advancements in medical technology and the development of sophisticated medical devices • Rising healthcare expenditure and increasing demand for quality healthcare services • Regulatory standards and guidelines promoting the use of safe and biocompatible materials

Market Trends:

Some notable trends in the Medical POM Market include:

• Shift towards miniaturization and lightweight medical devices • Rising adoption of disposable medical products • Development of antimicrobial POM grades for infection control • Customization of POM materials to meet specific medical device requirements • Increasing use of POM in 3D printing for prototyping and manufacturing

Key Market Players:

The Medical POM Market is highly competitive, with several key players operating globally. Some of the prominent companies in the market include:

Celanese Corporation DuPont de Nemours, Inc. BASF SE Mitsubishi Engineering-Plastics Corporation Ensinger GmbH Polyplastics Co., Ltd. Ticona Engineering Polymers Kolon Plastics, Inc. KEP Europe GmbH PolyOne Corporation

Regional Analysis:

The market for Medical POM is geographically distributed across regions such as North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. North America and Europe have traditionally been significant markets due to the presence of advanced healthcare systems and strong medical device industries. However, the Asia Pacific region is expected to witness substantial growth due to increasing healthcare infrastructure and medical device manufacturing capabilities.

Regulatory Considerations:

Medical POM materials must comply with various regulatory standards and guidelines to ensure their safety and suitability for medical applications. Some common regulations include ISO 10993 for biocompatibility, USP Class VI for material testing, and FDA guidelines for medical devices.

Challenges:

The Medical POM Market faces some challenges, including:

• Stringent regulatory requirements and compliance • Increasing competition from alternative materials • Price fluctuations of raw materials • Environmental concerns related to plastic waste management

1 note

·

View note

Text

Delrin Gear Manufacturer: Superior Solutions for Precision Engineering

Introduction

In the world of engineering, the materials used for components can significantly influence performance, durability, and cost. Delrin, a high-performance acetal resin, has emerged as a popular choice for gear manufacturing due to its exceptional properties. As a leading Delrin gear manufacturer, The Gear Edges is committed to providing top-quality gears that meet the specific needs of various industries. In this article, we will explore the benefits of Delrin gears, their applications, and what sets The Gear Edges apart in this competitive market.

What is Delrin?

Delrin, a brand name for polyoxymethylene (POM), is an engineered thermoplastic known for its excellent mechanical properties and versatility. It exhibits high stiffness, low friction, and good dimensional stability, making it an ideal material for producing gears and other precision components.

Advantages of Delrin Gears

High Strength and Durability Delrin gears are known for their excellent tensile strength and toughness, enabling them to withstand significant mechanical loads without deforming or breaking. This durability extends the lifespan of the gears, making them a cost-effective choice.

Low Friction Coefficient The low friction characteristics of Delrin reduce wear and tear during operation. This feature is particularly beneficial in high-speed applications, as it minimizes energy loss and enhances efficiency.

Corrosion and Chemical Resistance Delrin’s inherent resistance to moisture and chemicals makes it suitable for use in harsh environments. This quality ensures reliable performance in applications exposed to various substances.

Lightweight Compared to metal gears, Delrin gears are significantly lighter, which can lead to overall weight reductions in machinery and equipment. This characteristic is especially important in industries such as automotive and aerospace.

Design Flexibility Delrin can be easily molded into complex shapes, allowing for intricate gear designs that may not be feasible with metal. This design flexibility enables manufacturers to create custom solutions tailored to specific applications.

Applications of Delrin Gears

Delrin gears are utilized in a wide range of industries due to their versatile properties:

Automotive: Used in steering systems, window mechanisms, and powertrain components, Delrin gears help improve performance and reduce noise.

Consumer Electronics: Common in printers, scanners, and various automated devices, Delrin gears provide smooth operation and reliability.

Medical Devices: In medical applications, where precision and reliability are crucial, Delrin gears are used in equipment such as pumps and surgical instruments.

Robotics: Delrin gears enable precise movements in robotic arms and automated guided vehicles (AGVs), enhancing operational efficiency.

The Manufacturing Process at The Gear Edges

At The Gear Edges, our manufacturing process for Delrin gears is designed to ensure the highest quality and precision:

Material Selection We start by sourcing high-quality Delrin resin that meets stringent industry standards. This material selection is crucial for ensuring optimal gear performance.

Precision Molding Using advanced injection molding techniques, we create gears with exact dimensions and tooth profiles. This process guarantees consistency and minimizes the risk of defects.

Machining and Finishing After molding, gears may undergo additional machining to achieve precise specifications and enhance surface finishes, ensuring optimal performance in their intended applications.

Quality Control Each batch of Delrin gears is subjected to rigorous testing and inspection, including dimensional accuracy checks and performance assessments, to ensure they meet our high standards.

Customization We offer customizable solutions, allowing clients to specify unique designs, sizes, and features based on their specific requirements.

Why Choose The Gear Edges?

When selecting a Delrin gear manufacturer, The Gear Edges stands out for several reasons:

Expertise: Our team possesses extensive knowledge and experience in gear manufacturing, allowing us to provide expert guidance and support throughout the process.

Innovation: We continually invest in the latest technologies and manufacturing techniques to ensure our products remain competitive and cutting-edge.

Customer-Centric Approach: We prioritize understanding our clients’ needs, collaborating closely to develop tailored solutions that fit their specifications.

Sustainability: We are committed to environmentally friendly practices, utilizing recyclable materials and implementing waste-reduction strategies in our manufacturing processes.

Conclusion

Delrin gears represent a superior choice for various mechanical applications, offering a combination of strength, durability, and design flexibility. As a leading Delrin gear manufacturer, The Gear Edges is dedicated to delivering high-quality, precision-engineered solutions that meet the unique needs of our clients. With our commitment to innovation, quality, and customer satisfaction, we are well-equipped to be your trusted partner in gear manufacturing. Explore our offerings today and discover how we can help you achieve your engineering goals with reliability and excellence.

0 notes

Text

Epoxy Resin Market Dynamics, Top Manufacturers Analysis, Trend And Demand, Forecast To 2030

Epoxy Resin Industry Overview

The global epoxy resin market size was estimated at USD 11.25 billion in 2023 and is expected to grow at a CAGR of 6.3% from 2024 to 2030.

Increasing demand for paints and coatings is anticipated to drive market growth significantly during the forecast period. Increasing demand for epoxy resins is attributed to growing spending on construction, particularly residential construction, especially in North America and Western Europe. The rapid growth in global manufacturing activities is expected to fuel the demand for paints & coatings used in the production of motor vehicles and other durable goods, as well as industrial maintenance applications. This is expected to boost the demand for epoxy resins globally.

Gather more insights about the market drivers, restrains and growth of the Epoxy Resin Market

Asia Pacific has been the leading consumer of epoxy resins, fueled by increasing demand from China and India. Infrastructure development, along with increasing automotive production, has fueled paints & coatings demand in the region. Increasing disposable income and willingness to spend are expected to drive the market over the coming years.

In the recent past, global automotive production increased rapidly due to growing demand from middle-class families and rising disposable income across emerging nations such as China, India, Brazil, Vietnam, and others. The rise in automotive demand propelled the consumption of paints & coatings across the automotive industry, thereby fueling the demand for epoxy resins. However, volatile raw material price of epoxy resin is expected to restrain the market growth during the forecast period.

In addition, the outbreak of COVID-19 negatively impacted the demand for epoxy resin in various applications, including paints & coatings, adhesives, wind turbines, and others, owing to the stalled manufacturing activities, restrictions in supply and transportation, and economic slowdown across the globe in 2020. Moreover, the recommencing industrial operation is projected to positively influence the market demand in the coming years.

Browse through Grand View Research's Plastics, Polymers & Resins Industry Research Reports.

• The global medical polyoxymethylene market size was estimated at USD 117.69 million in 2023 and is projected to grow at a CAGR of 6.4% from 2024 to 2030.

• The global multi-med adherence packaging market size was valued at USD 327.73 million in 2023 and is expected to expand at a CAGR of 6.0% from 2024 to 2030.

Market Concentration & Characteristics

The market space is moderately consolidated with the presence of key companies, such as 3M, Aditya Birla Management Corp. Pvt. Ltd, BASF SE, and Sika AG. These companies adopt various strategic initiatives, such as new product launches, partnerships, capacity expansions, and collaborations, to expand their presence in the market. For instance, in March 2024, Safic-Alcan announced its expansion by collaborating with BB Resins Srl. BB Resins Srl is a manufacturer of epoxy resin hardeners, which boasts an extensive range of products specifically designed for the coatings, construction, and adhesives sectors. With this collaboration, Safic-Alcan aims to expand its business across Poland.

The industry is characterized by a high degree of innovation. Technological advancement, upgradation of electronic products, and circuit assembly have propelled PCB fabrication technology toward micro via, fine-trace, high-density tracing, and multi-layers. The usage of epoxy resins enhances thermal dissipation, dimensional stability, and dielectric loss, therefore, propelling the demand for epoxy resins in the manufacture of CCL. In recent years, the electronic industry has grown rapidly, thereby increasing the demand for PCBs across the globe.

In addition, stringent regulations shape the market’s demand and supply dynamics. Stricter regulations on volatile organic compounds (VOCs) and hazardous substances can limit the use of certain raw materials and formulations. This can lead to a shift in market preferences towards eco-friendly and compliant products. For instance, the European Union’s REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation requires comprehensive data on the safety of chemical substances, pushing manufacturers to innovate and produce safer epoxy resin formulations

Key Companies & Market Share Insights

Key companies are adopting several organic and inorganic growth strategies, such as new product development, mergers & acquisitions, and joint ventures, to maintain and expand their market share.

The following are the leading companies in the epoxy resin market. These companies collectively hold the largest market share and dictate industry trends:

3M

Aditya Birla Management Corporation Pvt. Ltd.

Atul Ltd

BASF SE

Solvay

Huntsman International LLC

KUKDO CHEMICAL CO., LTD.

Olin Corporation

Sika AG

NAN YA PLASTICS CORPORATION

Jiangsu Sanmu Group Co., Ltd.

Jubail Chemical Industries LLC

China Petrochemical & Chemical Corporation (SINOPEC)

Hexion

Kolon Industries, Inc.

Techstorm

NAGASE & CO., LTD

Order a free sample PDF of the Epoxy Resin Market Intelligence Study, published by Grand View Research.

0 notes

Text

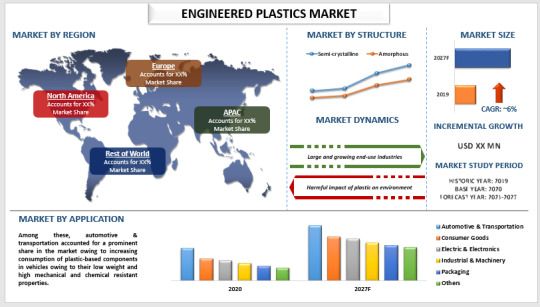

Analyzing the Engineered Plastics Market: Trends and Growth Potential

Engineered plastics, also known as engineering plastics market, are a group of plastic materials that have enhanced mechanical and thermal properties, making them suitable for more demanding applications than standard plastics. These materials are used in a wide range of industries, including automotive, aerospace, electronics, and healthcare. This article explores the current trends, driving forces, challenges, and future prospects of the engineered plastics market.

Understanding Engineered Plastics

Engineered plastics are polymers that exhibit superior strength, heat resistance, and durability compared to commodity plastics. Common types of engineered plastics include polycarbonate (PC), acrylonitrile butadiene styrene (ABS), polyamide (PA or nylon), polyoxymethylene (POM or acetal), and polyphenylene oxide (PPO). These materials are used in applications that require high performance and reliability.

Key Market Drivers

Growth in End-Use Industries: The expansion of industries such as automotive, aerospace, electronics, and healthcare is a major driver for the engineered plastics market. These industries demand materials that can withstand harsh environments, offer high precision, and contribute to lightweighting and energy efficiency.

Technological Advancements: Innovations in polymer science and manufacturing processes are enhancing the properties of engineered plastics. Advances such as reinforced composites, biodegradable polymers, and 3D printing materials are broadening the application scope of engineered plastics.

Environmental Regulations and Sustainability: Stringent environmental regulations and the growing emphasis on sustainability are driving the demand for engineered plastics. These materials are often recyclable, contribute to energy savings through lightweighting, and can replace metal parts, reducing the overall environmental impact.

Market Segmentation

The engineered plastics market can be segmented based on type, application, and region.

By Type:

Polycarbonate (PC): Known for its high impact resistance and transparency, used in automotive parts, electronics, and medical devices.

Acrylonitrile Butadiene Styrene (ABS): Offers good toughness and rigidity, used in automotive components, consumer electronics, and toys.

Polyamide (PA or Nylon): Known for its strength and wear resistance, used in automotive parts, textiles, and industrial applications.

Polyoxymethylene (POM or Acetal): Provides high stiffness and dimensional stability, used in precision parts like gears and bearings.

Polyphenylene Oxide (PPO): Offers high thermal stability and electrical insulation, used in electrical and electronic components.

By Application:

Automotive: Engineered plastics are used for components like fuel systems, interior and exterior parts, and under-the-hood applications.

Aerospace: These materials are used in lightweight structural components, interior parts, and insulation.

Electronics: Used in housings, connectors, and circuit boards.

Healthcare: Employed in medical devices, surgical instruments, and diagnostic equipment.

Industrial: Used in machinery parts, gears, bearings, and conveyor systems.

By Region:

North America: Driven by advancements in technology and the presence of key end-use industries.

Europe: Emphasis on sustainability and high-performance materials.

Asia-Pacific: Rapid industrialization and growth in automotive and electronics industries.

Latin America and Middle East & Africa: Emerging markets with increasing demand for high-performance materials.

Challenges in the Market

Despite the positive growth outlook, the engineered plastics market faces several challenges:

High Costs: The production and raw material costs for engineered plastics are higher than for commodity plastics, which can limit their adoption in cost-sensitive applications.

Regulatory Compliance: Meeting stringent environmental and safety regulations requires continuous innovation and investment in research and development.

Market Competition: The market is highly competitive, with numerous players offering a wide range of products. Differentiating based on quality, performance, and sustainability is crucial for gaining a competitive edge.

Request for a sample of the report browse through- https://univdatos.com/get-a-free-sample-form-php/?product_id=23691

Future Prospects

The future of the engineered plastics market is promising, with several growth opportunities on the horizon:

Advancements in Composite Materials: The development of reinforced composites and hybrid materials will enhance the performance characteristics of engineered plastics, expanding their application range.

Growth in Emerging Markets: Emerging economies in Asia-Pacific, Latin America, and Africa present significant growth opportunities. Increasing industrialization and infrastructure development in these regions will drive the demand for engineered plastics.

Sustainability Initiatives: The push for sustainability will continue to drive innovations in biodegradable and recyclable engineered plastics. These materials will play a crucial role in reducing the environmental impact of various industries.

Conclusion

The engineered plastics market is set for robust growth, driven by the expansion of end-use industries, technological advancements, and sustainability trends. While challenges such as high costs and regulatory compliance persist, innovations in composite materials and the growth of emerging markets offer substantial opportunities. As industries evolve, engineered plastics will continue to play a vital role in delivering high-performance, durable, and sustainable solutions.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

0 notes

Text

The Polyoxymethylene (POM) Market is expected to expand from USD 14,418 million in 2024 to USD 24,404.79 million by 2032, with a compound annual growth rate (CAGR) of 6.80%.Polyoxymethylene (POM), also known as acetal, polyacetal, and polyformaldehyde, is a high-performance engineering plastic characterized by its high stiffness, low friction, and excellent dimensional stability. These properties make POM a popular choice in a wide range of applications, from automotive and consumer electronics to industrial machinery and medical devices. This article explores the current trends, growth drivers, challenges, and future prospects of the POM market.

Browse the full report at https://www.credenceresearch.com/report/polyoxymethylene-pom-market

Market Overview

The global POM market has been experiencing steady growth, driven by its increasing application in various end-use industries. In 2023, the market size was valued at approximately USD 3.6 billion, with projections suggesting a compound annual growth rate (CAGR) of around 6% from 2024 to 2030. This growth is primarily attributed to the rising demand for lightweight and durable materials in the automotive and electronics sectors.

Key Growth Drivers

1. Automotive Industry: The automotive industry is one of the largest consumers of POM. The demand for fuel-efficient vehicles has led to the increased use of lightweight materials. POM’s properties make it ideal for manufacturing components such as gears, bearings, and fuel system parts. The push towards electric vehicles (EVs) is further augmenting the demand for POM, as it is used in various electrical components due to its excellent electrical insulation properties.

2. Consumer Electronics: The rapid growth of the consumer electronics market is another significant driver for POM demand. The material’s stability and resistance to wear and tear make it suitable for manufacturing precision parts in electronic devices such as smartphones, laptops, and cameras. The trend towards miniaturization and the need for high-performance materials in electronics are boosting POM consumption.

3. Industrial Machinery: In industrial applications, POM is valued for its mechanical properties and resistance to chemicals. It is used in the production of various machine components that require high precision and durability. The ongoing industrial automation trend is increasing the demand for reliable and efficient materials like POM.

Challenges

Despite its advantageous properties, the POM market faces several challenges:

1. Environmental Concerns: The production of POM involves the use of formaldehyde, a hazardous substance. Environmental regulations regarding the emission of volatile organic compounds (VOCs) and the disposal of plastic waste are becoming stricter. This has prompted manufacturers to invest in research and development to create more sustainable and eco-friendly POM alternatives.

2. Fluctuating Raw Material Prices: The prices of raw materials used in the production of POM, such as methanol, are subject to market fluctuations. This can impact the overall cost of POM production and, consequently, its market price. Manufacturers are looking for ways to mitigate these risks through strategic sourcing and process optimization.

3. Competition from Other Plastics: POM faces competition from other engineering plastics such as polyamide (PA), polycarbonate (PC), and acrylonitrile butadiene styrene (ABS). These materials also offer excellent performance characteristics and are preferred in certain applications. Continuous innovation and differentiation are crucial for POM manufacturers to maintain their market position.

Future Prospects

The future of the POM market looks promising, with several factors contributing to its continued growth:

1. Technological Advancements: Ongoing research and development efforts are focused on enhancing the properties of POM and developing new grades with improved performance characteristics. Innovations such as bio-based POM and recycled POM are gaining traction as sustainable alternatives.

2. Expansion in Emerging Markets: The growing industrialization and urbanization in emerging economies present significant opportunities for POM manufacturers. The increasing demand for consumer goods, automotive, and industrial products in regions like Asia-Pacific and Latin America is expected to drive market growth.

3. Sustainability Initiatives: The global push towards sustainability is encouraging the adoption of eco-friendly materials and processes. POM manufacturers are investing in green technologies and sustainable practices to meet the evolving regulatory requirements and consumer preferences.

Key Player Analysis

Celanese Corporation (US)

Korea Engineering Plastics Co., Ltd. (South Korea)

Daicel Corporation (Japan)

BASF Group (Germany)

Asahi Kasei Corporation (Japan)

LG Chem (South Korea)

SABIC (Saudi Arabia)

Mitsubishi Gas Chemical Company, Inc. (Japan)

LyondellBasell Industries Holdings B.V. (US)

DuPont de Nemours Inc. (US)

China BlueChemical Ltd. (China)

KOLON ENP (South Korea)

Henan Energy Group Co., Ltd. (China)

Segments:

Based on Type

Homopolymer

Copolymer

Based on End-use Industry

Transportation

Consumer

Industrial

Electrical & Electronics

Other End-use Industries

Based on Grade

Low Friction

Low VOC

Conductive

Antistatic

Other Grades

Based on Processing Technique

Injection Molding

Extrusion

Compression Molding

Other Processing Techniques

Based on the Geography

North America

The U.S.

Canada

Mexico

Europe

Germany

France

The U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/polyoxymethylene-pom-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

Polyoxymethylene(POM) Market Report: Trends, Analysis, and Projections

Polyoxymethylene (POM), also known as acetal or polyacetal, is a high-performance engineering thermoplastic known for its excellent mechanical properties, low friction coefficient, and chemical resistance. This blog delves into the dynamics of the global POM market, analyzing key drivers, applications across industries, emerging trends, and future growth prospects.

Understanding the POM Market:

Polyoxymethylene (POM) is a polymer synthesized from formaldehyde, offering high stiffness, strength, dimensional stability, and wear resistance. It finds extensive applications in automotive, electronics, consumer goods, industrial machinery, and healthcare due to its versatile properties.

Market Dynamics:

Automotive Industry: POM is widely used in automotive components such as gears, bushings, clips, fasteners, and fuel system components due to its low friction, wear resistance, and ability to withstand high temperatures and harsh chemicals.

Consumer Goods: In the consumer goods sector, POM is utilized in manufacturing zippers, handles, knobs, toys, and electronic device components due to its excellent surface finish, dimensional stability, and impact resistance.

Electronics and Electrical Applications: POM's electrical insulating properties, dimensional accuracy, and resistance to chemicals make it suitable for connectors, switches, housings, and precision components in electronic devices and electrical systems.

Healthcare and Industrial Machinery: POM's biocompatibility, sterilizability, and mechanical strength make it suitable for medical devices, surgical instruments, pumps, valves, and precision parts in industrial machinery.

Applications Across Industries:

Automotive: Gears, fuel system components, clips, fasteners.

Consumer Goods: Zippers, handles, knobs, toys, electronic components.

Electronics: Connectors, switches, housings, precision components.

Healthcare: Medical devices, surgical instruments, pump parts.

Market Trends:

Focus on Lightweight Solutions: Growing demand for lightweight materials in automotive and aerospace industries drives the adoption of POM and its composites to replace metal components, reducing overall vehicle weight and fuel consumption.

Engineering Innovations: Advances in POM formulations, including reinforced grades, lubricated variants, and impact-modified types, expand application possibilities in demanding environments and specialized applications.

Sustainability Initiatives: Development of bio-based POM and recycling technologies for post-consumer POM waste align with sustainability goals, waste reduction efforts, and regulatory requirements, driving market innovation.

Future Prospects:

The global POM market is poised for steady growth, propelled by expanding applications in key industries, technological advancements, and sustainability initiatives. Investments in R&D, recycling infrastructure, and collaboration across the value chain will shape market evolution and competitiveness.

Conclusion:

Polyoxymethylene (POM) stands out as a high-performance engineering thermoplastic with diverse applications across automotive, consumer goods, electronics, healthcare, and industrial sectors. Understanding market trends, technological innovations, and sustainability imperatives is crucial for stakeholders in the POM market to leverage growth opportunities and address evolving industry needs effectively. With a focus on lightweight design, engineering excellence, and sustainable practices, the POM market presents promising avenues for continued innovation and market expansion globally.

0 notes

Text

Polyoxymethylene (POM) Homopolymer Market would rocket up to USD 1,256.57 million by 2029.

Data Bridge Market Research analyses that the polyoxymethylene (POM) homopolymer market will witness a CAGR of 5.00% for the forecast period of 2022-2029. Growth in the polyoxymethylene (POM) homopolymer especially in the developing economies such as India and China, growing use of polyoxymethylene (POM) homopolymer for a wide range of end user applications such as transportation, medical, food…

View On WordPress

0 notes

Text

Engineering Plastics Market Size, Latest Trends, Regional Insights Dynamics By 2026

The global engineering plastics market is projected to check in a wholesome CAGR of 7.2% in terms of cost and five.7% in phrases of extent all through the forecast duration. Future market Insights offers key insights on the global engineering plastics market in an upcoming studies booklet titled, “Engineering Plastics market: global enterprise analysis and opportunity evaluation, 2016 – 2026”.

Destiny market Insights analyses the market overall performance and affords records on the important thing elements and tendencies impacting market growth over the forecast period 2016–2026. The automobile and transportation section is an increasing number of willing in the direction of adoption of engineering plastics merchandise because of their diverse thermal and mechanical residences.

The fuelling call for for engineering plastics is largely from car components inclusive of fasteners and supports for chassis and power trains and frame panel lens of head lamps as these components require higher energy materials.

Besides mechanical electricity, engineering plastics assist in decreasing the general weight of the cars. Bio-primarily based engineering plastics that assist reduce carbon footprint consisting of polyamides and polycarbonates also are in excessive call for.

Packaging, electric and electronics, and client goods are beneficial segments for bio-based engineering plastics starting from stiff to bendy grades. Robust market increase is probable to be observed throughout high performance plastics such as PEI, PEEK, PSU/PES, PCTF, PVDC, PPSU, LCP, PPS.

Vendor Highlights

The report also profiles leading players dominating the global engineering plastics market. Arkema Group, Asahi Kasei Corporation, BASF SE, Celanese Corporation, Covestro, DSM N.V, DuPont, Lanxess, LG Chem, Mitsubishi Engineering-Plastics Corporation, Saudi Basic Industries Corporation (SABIC), Solvay SA, Teijin Limited, Toray Industries, and Victrex PLC are some of the top companies operating in the global engineering plastics market.

Get a Sample Copy of the Report @ https://www.futuremarketinsights.com/reports/sample/rep-gb-1881

Market segmentation

By Product Type:

Polyamides (PA)

Polycarbonates (PC)

Polyoxymethylene (POM)

Polybutylene terephthalate (PBT)

Acrylonitrile butadiene styrene (ABS) and Styrene Acrylonitrile (SAN)

High Performance Polymers

Fluoropolymers

Polymethyl methacrylate (PMMA)

Others (includes UHMWPE/UHMW, TPI alloys and blends, etc.)

By Application:

Automotive and transportation

Electrical and electronics

Construction

Medical

Industrial and machinery

Packaging

Others (includes furniture and fixtures, sports goods, leisure products, etc.)

Engineering Plastics Market: Region-wise Insights

This report also covers trends driving each segment and offers analysis and insights of the potential of the engineering plastics market in specific regions. The APEJ region is expected to exhibit the highest market growth due to an increase in population, income levels, and rapid urbanisation in the region.

There is plenty of scope in the APEJ region for manufacturing automobiles, consumer appliances, electronic products, medical devices, industrial, and machineries. The APEJ region is anticipated to register a CAGR of 6.8% between 2016 and 2026 in terms of volume.

Browse latest Market Reports@ https://www.futuremarketinsights.com/category/chemicals-and-materials

0 notes

Text

An analysis of the Medical Polyoxymethylene market by 2028, including its size, share, and global outlook

The Medical Polyoxymethylene Market was valued at US$ 61,542.14 thousand in 2019 and is projected to reach US$ 88,482.56 thousand by 2028; it is expected to grow at a CAGR of 4.2% from 2020 to 2028.

Polyoxymethylene (POM) is a high-performance engineered thermoplastic, which is traditionally produced through ring opening polymerization of formaldehyde and is mainly supplied in the form of pellets. POM resins are produced by the process of polymerization of formaldehyde so as to provide the homopolymers and copolymers by deploying the other monomers. They are known for its several constructive and mechanical properties which makes them a suitable material to replace metal in production of several medical devices. POM is known to provide metal-like machining properties along with thermal and dimensional stability, ultra-high modulus, enhanced strength, hardness and rigidness, minimal friction coefficient and gas/vapor permeability, dielectric strength, and better retention characteristics at elevated temperature. All such properties make it an ideal material to be used in production of several medical devices and equipment such as dialysis machines, handles for instrument, pharmaceutical closure, inhalers, insulin pens and other such application areas. The growth of the market is strongly driven by advancements in technology along with growth of medical device industry. Rapid urbanization, coupled with economic growth and rise in incidence of chronic ailments and diseases, is further stimulating the demand for medical polyoxymethylene.

Request for sample copy @ https://www.theinsightpartners.com/sample/TIPRE00004877/

The report segmentation of Medical Polyoxymethylene Market as follows:

Based on application, the medical polyoxymethylene market is segmented into dialysis machine, handles for surgical instruments, inhalers, insulin pen, and others. The insulin pen segment held the largest share in the global medical polyoxymethylene market in 2019. The insulin pen segment is considered to be one of the lucrative segments in the medical polyoxymethylene market. Insulin pens are categorized under drug delivery devices, which are easy to use, effective, and quite affordable. These factors have positively impacted the demand for insulin pens across developed and developing economies as many people with diabetes are preferring these pens to administer insulin. The rising number of aging patients, coupled with increasing incidence of diabetes and surging adoption of advance drug delivery methods, is expected to positively affect the demand for insulin pens in the market. Several manufacturers of drug delivery devices are focused on creating complex products by using high-performance materials with better physical and mechanical features, along with advanced functionality and better aesthetics and ergonomics, which could align with the objective of meeting complexity and cost effectiveness. Hence, to cater to the growing demand, manufacturers have come up with the use of polyoxymethylene (POM) in drug delivery devices.

The global medical polyoxymethylene market is segmented into five main regions—North America, Europe, Asia Pacific (APAC), Middle East & Africa (MEA), and South America (SAM). In 2019, Asia Pacific contributed to the largest share in the global medical polyoxymethylene market. The growth of the medical polyoxymethylene market in this region is primarily attributed to the presence of strong industrial base along with presence of prominent manufactures significantly contributing to the market growth. Growth of medical sector in the developing countries such as China, South Korea, and India provide lucrative opportunities for the growth of the medical polyoxymethylene market in Asia Pacific. Further, rapid urbanization, along with rise in incidence of chronic diseases, is also favoring the market growth in the region. The easy accessibility and availability of raw materials, coupled with cheap labor and low production cost, is yet another factor driving the market in the region.

About Us:

The Insight Partners is a one stop industry research provider of actionable intelligence. We help our clients in getting solutions to their research requirements through our syndicated and consulting research services. We specialize in industries such as Semiconductor and Electronics, Aerospace and Defense, Automotive and Transportation, Biotechnology, Healthcare IT, Manufacturing and Construction, Medical Device, Technology, Media and Telecommunications, Chemicals and Materials.

Contact Us:

If you have any queries about this report or if you would like further information, please contact us:

Contact Person: Sameer Joshi

Phone: +1-646-491-9876

Press Release: https://www.theinsightpartners.com/pr/polyoxymethylene-pom-market

#Medical Polyoxymethylene Market#Medical Polyoxymethylene Industry#Medical Polyoxymethylene Market Share

0 notes

Text

Plastic Products Injection Molding

Among one of the most important facets of any type of product advancement task utilizing plastic injection molding is choosing the right material, as it straight impacts the molding operation as well as also the component efficiency. There are countless plastic materials available out there. So, exactly how do you make sure you choose the best one? What product would certainly be finest matched for the component's application? To aid you much better understand this process, right here is a checklist of some of the most typical plastic molding materials and their applications.

Plastic Molding Materials

Nylon (Polyamide). Nylon is often utilized for quick-release clasps. Nylon is typically used to create strong mechanical parts. Bushings, gears and also bearings are some common automobile parts created making use of nylon. Acrylic. Polymer tubes can be tinted for numerous impacts. We make use of acrylic to produce clear parts such as home windows, clear wall surfaces and also various illumination equipment. It is typically made use of as a choice to glass due to its high tensile strength and climate as well as scrape immune nature. Polycarbonate. Polycarbonate compact discs are really resilient. When molding with this amorphous polycarbonate material, accurate dimensional control can be kept as it has predictable as well as uniform mold contraction. We use polycarbonate when we require something significantly stronger than acrylic. Polyoxymethylene (POM). POM is warm steady for this cooking area blade deal with. Polyoxymethylene is a sort of acetal material made use of for generating mechanical and auto parts that would typically be made with steel. This design polycarbonate material is very strong, challenging and also inflexible. It is typically made use of to create gears, fasteners, knife deals with as well as sphere bearings. Although polyoxymethylene has high resistance in the direction of solvents such as alcohols, fuel, cleaning agents and also electric motor oils, it ought to not be revealed to hydrochloric acid as well as nitric acid. Polystyrene (PS). Polystyrene is difficult enough to be used for tool boxes. When it comes to injection molding, there are two types of polystyrene that are typically made use of. Hard situations for tool kits as well as bodies of power devices are also made using High Influence Polystyrene. Acrylonitrile Butadiene Styrene (ABS). ABS plastic utilized in computer tricks. ABS takes a pounding on this computer system key-board. There are many advantages to utilizing Acrylonitrile Butadiene Styrene. It is generally used to produce electronic components such as phone adaptors, keyboard keys and also wall surface outlet plastic guards. Polypropylene (PP). Polypropylene is used to make living hinges such as in this cap. This polycarbonate product is commonly made use of in the food storage and packaging market, as it does not allow chemicals combine with foodstuff. Polypropylene can be cleaned in hot water without derogatory, and it has high chemical and wetness resistance. It has amazing effect toughness, flexibility and also toughness. Polyethylene (PE). Polyethylene is adaptable and will not soak up water. Polyethylene is a light-weight polycarbonate material that has high chemical resistance, flexibility and electric insulating residential properties. It is not especially strong or hard, but still, this material is made use of in wide variety of customer plastic parts, such as milk containers, medication as well as cleaning agent containers, plastic bags and wastebasket. Polyethylene is also the most usual injection molding plastic type to be utilized in the manufacturing of children's playthings. Thermoplastic Polyurethane (TPU). TPU creates excellent phone shield. Thermoplastic polyurethane, because of its soft and also flexible nature as well as wonderful tensile and also tear stamina, is often made use of to produce parts that demand a rubber- like elasticity. TPU does well at heats and is commonly made use of in power devices, wire insulations as well as showing off items. Thermoplastic Rubber (TPR). TPR is made use of in clinical catheters. This material is generally a mix of plastic and rubber, and also is simple to utilize in the injection molding process. TPR exhibits residential or commercial properties of both rubber and also plastic products.

Full Injection Molding Product Checklist.

We hope this brief introduction aided you to understand a few of the most prominent injection molding plastic types, their residential properties as well as applications. Please note that we can collaborate with you to customize all of these materials with lubes, glass fibers and also UV stabilizers to suit your distinct task requirements.

1 note

·

View note

Text

Various Material Selection for Plastic Moulding in China

Material selection for plastic moulding in China is one of the initial tasks that is for experts to handle. The thermoplastic materials are synthetic polymers that molds at a specific temperature and becomes sold on cooling. These materials are based for the moulds that have further used to create plastic products.

By selecting a particular material early in the design process helps customers to avoid high costs. The plastic materials balance the blend of stiffness, toughness, and durability to produce needed functionality.

There are key differences in each polymer resin to use, and on these characteristics, the materials are selected for moulds. The various materials are in the division of molecular weight, high-density, and low density. Below are the five materials, common in use, for moulds:

ABS

ABS is Acrylonitrile Butadiene Styrene, a terpolymer engineered from styrene and acrylonitrile with sparkle of polybutadiene. It can be produced easily and at an affordable price. It has the strong, sturdy characteristics that even meets the aesthetic requirements.

Polycarbonates

You may need the high-class thermoplastic, and you shall have it. It has increased shatter resistance and is naturally transparent. The ideal material for safety goggles, medical applications, and kitchenware. Other uses include aircraft parts, sockets in prosthetics, and data storage devices for its high-strength ability.

Glass-filled Nylon

Nylon shares its class with polyamides. It is the material for cords, vests, and musical strings moulds. The glass fibers give it extra strength, heat resistance, and nonconductive to electricity. However, it has a high-melting-point.

Polypropylene

Polypropylene or PP is the material for reusable plastic food containers, diaper lining, and plastic moldings. Although it is sensitive and offers resistance to ultraviolet light and direct sunlight when blended with other resin for different uses.

Acetal

Acetal or Polyoxymethylene (POM) is another engineered thermoplastic known for its stiffness, dimensional stability, and low friction. The different formulas in the market sold under names as Delrin, Ramtal, and Hostaform.

Last, to say, get yourself the best material from best plastic mold manufacturer China, Deep Mould. The company offers other services like Research and Development, Injection Molding, and Quality Control.

1 note

·

View note

Text

Engineering Plastics Market Trends: 2023, Growth Prospects, Future Demand, Size and Forecast Estimation by 2030

The engineering plastics market is a segment of the overall plastics industry that focuses on the production and utilization of high-performance plastics with enhanced mechanical, thermal, chemical, and electrical properties. Engineering plastics are designed to withstand demanding applications and provide superior performance compared to traditional plastics.

Here is a comprehensive overview of the engineering plastics market:

Types of Engineering Plastics:

Polyamide (PA, Nylon) Polycarbonate (PC) Polyoxymethylene (POM, Acetal) Polybutylene Terephthalate (PBT) Polyethylene Terephthalate (PET) Polyphenylene Sulfide (PPS) Polyether Ether Ketone (PEEK) Polyimide (PI) Polysulfone (PSU) Polyetherimide (PEI)

Properties and Applications:

•Polyamide (PA): Excellent strength, toughness, and chemical resistance. Used in automotive, electrical, and consumer goods industries. • Polycarbonate (PC): High impact resistance, transparency, and heat resistance. Applications include automotive components, electronic devices, and construction. • Polyoxymethylene (POM): Low friction, high stiffness, and dimensional stability. Used in gears, bearings, and electrical connectors. • Polybutylene Terephthalate (PBT): Good electrical insulation and resistance to chemicals. Commonly found in automotive parts, electrical connectors, and appliances. • Polyethylene Terephthalate (PET): High strength, chemical resistance, and clarity. Used in beverage bottles, food packaging, and textiles. • Polyphenylene Sulfide (PPS): Excellent thermal and chemical resistance. Applications include electrical components, automotive parts, and filters. • Polyether Ether Ketone (PEEK): Exceptional mechanical and thermal properties. Used in aerospace, medical, and electrical industries. • Polyimide (PI): Excellent heat resistance, electrical insulation, and chemical stability. Commonly used in electronics, aerospace, and automotive applications. • Polysulfone (PSU): High temperature resistance, transparency, and chemical resistance. Used in medical equipment, plumbing, and automotive parts. • Polyetherimide (PEI): Good heat resistance, flame retardancy, and electrical properties. Applications include electrical connectors, aerospace components, and automotive parts.

Market Drivers:

Increasing demand from automotive, electrical and electronics, and aerospace industries for lightweight and high-performance materials. Growing focus on sustainable and environmentally friendly plastics. Advancements in technology leading to improved engineering plastic formulations. Expansion of end-use industries in emerging economies.

Market Challenges:

High material costs compared to traditional plastics. Limited recycling options for certain engineering plastics. Stringent regulations on plastic waste management and disposal.

Market Trends:

Increasing research and development activities to develop new engineering plastic materials with enhanced properties. Rising adoption of engineering plastics in 3D printing applications. Growing demand for bio-based and biodegradable engineering plastics. Shift towards lightweight materials to improve fuel efficiency in automotive and aerospace sectors.

Regional Analysis:

Asia-Pacific: Dominates the engineering plastics market due to rapid industrialization, urbanization, and manufacturing activities in countries like China, India, and Japan.

North America: Significant market share, driven by the automotive, aerospace, and electrical industries.

Europe: Strong presence of automotive and electrical manufacturers contributing to the market growth.

Rest of the World: Increasing demand for engineering plastics in developing regions like Latin America and the Middle East.

Key Players:

BASF SE DowDuPont Inc. Covestro AG Solvay SA Mitsubishi Engineering-Plastics Corporation SABIC Evonik Industries AG Celanese Corporation LANXESS AG Arkema SA

The engineering plastics market is expected to continue growing as industries seek materials that offer superior performance, durability, and sustainability. Technological advancements and increasing investment in research and development activities will likely drive the development of innovative engineering plastic materials in the future.

0 notes

Text

Engineering Plastic Market Opportunities, Challenges, Forecast and Strategies to 2026

The recent research, Engineering Plastic market enables stakeholders, field marketing executives and business owners get one step ahead by giving them a better understanding of their immediate competitors for the forecast period, 2019 to 2026. Most importantly, the study empowers product owners to recognize the primary market they are expected to serve. To help companies and individuals operating in the Engineering Plastic market ensure they have access to commensurate resources in a particular location the research, assess the size that they can realistically target and tap.

Request For Free PDF Sample Of This Research Report At: https://www.reportsanddata.com/sample-enquiry-form/1851

The global engineering plastics market is forecast to reach USD 138.59 Billion by 2026, according to a new report by Reports and Data. The market is rising rapidly in the global market due to the increase in high demand for engineering plastics in various highly productive applications. These plastics offer transparency, self-lubrication, and economy in fabricating and decorating with almost the same durability and toughness when compared to metals.

Key participants include BASF SE, Dowdupont, LG Chem Ltd., Asahi Kasei Corporation, Mitsubishi Engineering-Plastics Corporation, Polyplastics Co. Ltd, Royal DSM, Trinseo, Evonik Industries AG, LANXESS.

Type Outlook (Revenue, USD Billion; 2016-2026)

Acrylonitrile Butadiene Styrene (ABS)

Nylons

Polyamides (PA)

Polybutylene Terephthalate (PBT)

Polycarbonates (PC)

Polyethers

Polyethylene Terephthalate (PET)

Polyimides (PI)

Polyoxymethylene (POM)

Polyphenylenes

Polysulphone (PSU)

Polytetrafluoroethylene (PTFE)

Performance Parameter Outlook (Revenue, USD Billion; 2016-2026)

High Performance

Low Performance

Applications of Plastic Outlook (Revenue, USD Billion; 2016-2026)

Packaging

Automotive

Electronics & Electrical Components

Construction

Machinery

Consumer Goods

Medical Products

Others

Read Full Press Release:

The report charts the future of the Engineering Plastic market for the forecast period, 2019 to 2026. The perfect balance of information on various topics including the sudden upswing in spending power, end-use, distribution channels and others add great value to this literature. A collaboration of charts, graphics images and tables offers more clarity on the overall study. Researchers behind the report explore why customers are purchasing products and services from immediate competitors.

There are chapters to cover the vital aspects of the Global Engineering Plastic Market.

· Chapter 1 covers the Engineering Plastic Introduction, product scope, market overview, market opportunities, market risk, market driving force;

· Chapter 2 talks about the top manufacturers and analyses their sales, revenue and pricing decisions for the duration 2018 and 2019;

· Chapter 3 displays the competitive nature of the market by discussing the competition among the top manufacturers. It dissects the market using sales, revenue and market share data for 2016 and 2017;

· Chapter 4, shows the global market by regions and the proportionate size of each market region based on sales, revenue and market share of Engineering Plastic, for the period 2019- 2026;

· Continue...

To identify the key trends in the industry, click on the link below: https://www.reportsanddata.com/press-release/global-engineering-plastics-market

About Reports and Data

Reports and Data is a market research and consulting company that provides syndicated research reports, customized research reports, and consulting services. Our solutions purely focus on your purpose to locate, target and analyze consumer behavior shifts across demographics, across industries and help client’s make a smarter business decision. We offer market intelligence studies ensuring relevant and fact-based research across a multiple industries including Healthcare, Technology, Chemicals, Power, and Energy. We consistently update our research offerings to ensure our clients are aware about the latest trends existent in the market. Reports and Data has a strong base of experienced analysts from varied areas of expertise.

Contact Us:

John Watson

Head of Business Development

Reports And Data | Web: www.reportsanddata.com

Direct Line: +1-800-819-3052

E-mail: [email protected]

1 note

·

View note

Text

Engineering Plastics Market Trends | Segmentation, Outlook, Industry Report to 2026

Future Market Insights delivers key insights on the global engineering plastics market in an upcoming research publication titled, “Engineering Plastics Market: Global Industry Analysis and Opportunity Assessment, 2016 – 2026”.

The global engineering plastics market is projected to register a healthy CAGR of 7.2% in terms of value and 5.7% in terms of volume during the forecast period. Future Market Insights analyses the market performance and provides information on the key factors and trends impacting market growth over the forecast period 2016–2026.

The report segments the global engineering plastics market on the basis of Product Type into Polyamides (PA), Polycarbonates (PC), Polyoxymethylene (POM), Polybutylene terephthalate (PBT), Acrylonitrile butadiene styrene (ABS) and Styrene Acrylonitrile (SAN), High Performance Polymers, Fluoropolymers, Polymethyl methacrylate (PMMA), and Others (includes UHMWPE/UHMW, TPI alloys and blends, etc.); and on the basis of Application into Automotive and transportation, Electrical and electronics, Construction, Medical, Industrial and machinery, Packaging, and Others (includes furniture and fixtures, sports goods, leisure products, etc.).

The Automotive and transportation segment is increasingly inclined towards adoption of engineering plastics products due to their various thermal and mechanical properties. The fuelling demand for engineering plastics is largely from automotive components such as fasteners and supports for chassis and power trains and body panel lens of head lamps as these parts require higher strength materials.

Besides mechanical strength, engineering plastics help in reducing the overall weight of the vehicles. Bio-based engineering plastics that help reduce carbon footprint such as polyamides and polycarbonates are also in high demand. Packaging, electrical and electronics, and consumer goods are lucrative segments for bio-based engineering plastics ranging from stiff to flexible grades. Strong market growth is likely to be observed across high performance plastics such as PEI, PEEK, PSU/PES, PCTF, PVDC, PPSU, LCP, PPS.

A growing use of engineering plastics by end user industries, especially automotive, transportation, and medical industries is expected to drive global demand over the forecast period. Rapid urbanisation, infrastructure development, and increased income levels across various end-user segments are other factors likely to boost the growth of the global engineering plastics market. However, high costs of engineering plastics, increasing use of alternative substitutes, and fluctuations in the cost of raw materials are expected to hamper the growth of the global engineering plastics market over the forecast period.

Global sales revenue of engineering plastics is expected to witness steady incremental growth during the forecast period. In the product type category, the high performance plastics segment is anticipated to register a healthy CAGR of 9.6% between 2016 and 2026, attributed to an increasing application in the medical industry. In the application category, the electrical and electronics segment is estimated to account for 36% value share of the global engineering plastics market by 2016, followed by the automotive and transportation segment (32.1%) and the construction segment (11.1%).

Engineering Plastics Market: Region-wise Insights

This report also covers trends driving each segment and offers analysis and insights of the potential of the engineering plastics market in specific regions. The APEJ region is expected to exhibit the highest market growth due to an increase in population, income levels, and rapid urbanisation in the region. There is plenty of scope in the APEJ region for manufacturing automobiles, consumer appliances, electronic products, medical devices, industrial, and machineries.

The APEJ region is anticipated to register a CAGR of 6.8% between 2016 and 2026 in terms of volume. APEJ is expected to gain substantial market share owing to high demand from India and China, especially in the automotive and electrical and electronics industries. The North America market is expected to register a CAGR of 7.3% during the forecast period, owing to an increasing consumption of engineering plastics in the automotive and transportation industry in the region. In terms of volume, the market share of Western Europe and Japan is expected to decrease substantially over the forecast period, as they are mature markets for engineering plastics.

Vendor Highlights

The report also profiles leading players dominating the global engineering plastics market. Arkema Group, Asahi Kasei Corporation, BASF SE, Celanese Corporation, Covestro, DSM N.V, DuPont, Lanxess, LG Chem, Mitsubishi Engineering-Plastics Corporation, Saudi Basic Industries Corporation (SABIC), Solvay SA, Teijin Limited, Toray Industries, and Victrex PLC are some of the top companies operating in the global engineering plastics market.

For More Info - https://www.futuremarketinsights.com/reports/engineering-plastics-market

0 notes

Text

Global Medical Plastics Market Study 2015-2030

Analysis of the MEDICAL PLASTICS MARKET

A comprehensive market study on the MEDICAL PLASTICS MARKET Market provides an overview of the demand-supply and consumption patterns of Medical Plastics Market across six different regions. This market study describes the Medical Plastics Market Market, with focus on major countries and their subsequent demand for different segments. This report on the global Medical Plastics Market market offers a complete overview of various factors impacting positively or negatively on the overall growth of the Keyword market.

Distinct market estimations and forecasts are presented in this comprehensive Medical Plastics Market market study. Various secondary sources such as encyclopedia, directories, technical handbooks, company annual reports, industry association publications, magazine articles, world economic outlook, and databases have been referred to identify and collect information useful for this extensive commercial study of Medical Plastics Market. Moreover, both micro-economic and macro-economic factors have been considered to arrive at growth rate and size estimation in the short and long-term forecast. Prismane Consulting supplements this with primary research. The primary sources are experts from related industries and suppliers. For market forecast, and production / plant operating rates, we assume numerous reasons that drive production including new production capacity is brought on-stream, Planned, and unplanned outages of existing capacities and Subdued demand from end-use applications.

Request Sample Report-

https://prismaneconsulting.com/report_request_sample?_token=AtOR24a5a5RESAa3MlwksGpYOtlOq2YkD0lImEc4&report_id=349

The current COVID-19 pandemic is causing high and rising human costs worldwide. Isolation, nationwide lockdowns, and widespread closures to stop the spread of the virus have severely impacted the economy. As a result, the global economy declined by an around of -3.5% in 2020, much worse and below the 2008-2009 subprime mortgage crisis. The global economy has grown between 5% and 6% in 2021 and 2022 due to the normalization brought in the regional economic activities on back of the fading COVID-19 pandemic and stability in the crude oil prices. The economic activities have been aided by the new policies surrounding financial, agricultural, industrial, and manufacturing sector. The report on Medical Plastics Market Market studies and outlines the impact of COVID-19 and presents the forecasts for the short, mid and long-term. The report also covers Macro-economic factors like GDP, Population and World Economic integration, Economic & Energy Outlook, Industry & Policy Developments, End-use Industry / Applications Market, Reasoning & Analysis, Insightful Commentary, Market Review, Comparative Analysis, Latest Trends and market developments, Key players, Strategic Issues and Recommendations, Business Opportunity Assessment and much more.

Global Global Medical Plastics Demand Analysis By Type, By Application,

(Volume, Value) (2015–2030)

Strategic Issues

Demand Analysis and Forecast (2015 – 2030)

Demand

Demand Growth Rate (%)

Driving Force Analysis

Global Medical Plastics Market, By Type

Polypropylene (PP)

Polyvinyl Chloride (PVC)

Polyamides (PA)

Acrylonitrile Butadiene Styrene (ABS)

Polystyrene (PS)

Polyethylene (PE)

Polyethylene Terephthalate (PET)

Polyacetal/Polyoxymethylene (POM)

Polycarbonate (PC)

Polymethyl Methacrylate (PMMA)

Liquid Crystalline Polymer (LCP)

Polytetrafluoroethylene (Teflon)

Polyetheretherketone (PEEK)

Polysulfone (PSU)

Silicone

Others

Global Medical Plastics Market, By Application

Drug Delivery

Surgical Equipments

Injection Systems

Medical Instruments

Wearable

Others

Why Prismane Consulting?

Chemical Sciences, Engineering, Oil & Gas, Finance, Economics and Business backgrounds

Real-world industry, consulting, and market research experience

Average work experience of 10+ years

Get Full Access of the Report @

https://prismaneconsulting.com/checkout?_token=AtOR24a5a5RESAa3MlwksGpYOtlOq2YkD0lImEc4&report_id=349&single_user_license=Single

About Prismane Consulting

Prismane Consulting is a unique global boutique consulting firm with an Indian origin. We present ourselves to the world outside providing management, economic and technical expertise to improve customer engagement, boost operational efficiency, reduce costs, and achieve superior business results. Prismane Consulting serves leading businesses in the field of Chemicals, Petrochemicals, Polymers, Materials, Environment and Energy. We have been advising clients on their key strategic issues solving their toughest and most critical business problems. To know more write to us on [email protected]

Contact Us

Prismane Consulting

Office #519, Amanora Chambers, Amanora Park Town,

Hadapsar-Magarpatta Road,

Pune 411028

India

0 notes

Text

High-Tech Plastics Streamline Innovative Expansion in Automotive Industry

Automotive plastics are materials used to produce automobile components like electrical, glazing, interior & exterior furnishings. The automotive Original Equipment Manufacturers (OEMs) utilize plastics owing to several benefits particularly, lightweight property, corrosion resistance, and scope for flexible innovations. The rising usages and technological developments in the material led to the growth of the automotive plastics market, flourishing with a CAGR of 9.78% from 2019 to 2027.

As a result of the growing environmental concerns, stringent carbon emissions norms and demand for lightweight & fuel-efficient vehicles, the high-performance plastics are highly adopted in the automotive industry as it meets higher requirements than standard plastics.

Applications of High-Performance Polymers in the Automobile Sectors:

1. Acrylonitrile Butadiene Styrene (ABS)

ABS is chemical & impact-resistant plastic manufactured using suspension, emulsion, and mass processes. It is used in automotive bumper cars, electric components, dashboards, and wheel covers. Also, due to its high insulation property, it is utilized in other sectors like electronics, aerospace, and medical sectors.

2. Polyvinyl Chloride (PVC)

PVC has rigid and flexible variants and is flame retardant with excellent thermal stability and less lead content. Its major automotive applications are underbody coatings, sealants & floor modules, wire harnesses, and exterior parts. Other sectors utilizing the polymer are construction, electrical, and plumbing.

3. Polymethyl Methacrylate (PMMA)

PMMA is a transparent, rigid thermoplastic and a cheaper alternative for Polycarbonate. As it is lightweight and shatter-proof, it is used as a substitute for glass. PMMA has varied applications in automotive parts such as windows, screens, and displays. Also, it has utilization in sectors, namely construction, sanitary ware, and lighting fixtures.

4. Polypropylene (PP)

PP is a semi-rigid, translucent polymer with good chemical & electrical resistance at high temperatures. Its automotive applications include bumpers, cable insulation, and carpet fibers. Along with the automotive industry, it has applications in packaging, consumer products, and electronics owing to its lightweight.

5. Polyethylene (PE)

PE is a rigid, high-impact strength plastic with excellent chemical resistance. It is widely used in the automobile sector for car bodies and electrical insulation.

6. Polyamides (PA)

PA occurs both naturally as well as artificially, and the synthetic PA is known as Nylon. It has high impact strength and abrasion resistance with high durability. Its applications range from gears, bearings to weatherproof coatings.

7. Polyurethane (PU)

PU product has high tensile strength, hardness, and abrasive resistance. It is lightweight and used in interior furnishing, foams, seat cushioning, and hard plastic parts.

8. Polycarbonate (PC)

PC is a polymer that offers a combination of stiffness, toughness, and hardness with high impact strength. It is used in automotive bumpers, bulletproof substitutes, and helmets.

9. Polyoxymethylene (POM)

POM has properties like stiffness, rigidity, chemical resistance, and yield strength. It has applications in gears, fuel systems, and interior & exterior trims. Also, it is highly utilized in electrical and electronic components due to its high insulation properties.

10. Polyethylene Terephthalate (PET)

PET is the most common thermoplastic polymer resin of the polyester family. It is mostly used in the production of synthetic fibers. Its automotive applications are wiper arm, engine cover, headlamp retainer, and gear housing.

Thus, the high adoption and applications of high-performance plastics elevate the growth of the automotive plastics market, despite the challenges of geopolitical turmoil, volatility of raw materials, and environmental concerns.

#Plastics#Automotive Industry#Automotive#Plastics Streamline#inkwood#inkwood research#market research report#market research reports

0 notes