#Medical Grade Stainless Steel Tube Market

Explore tagged Tumblr posts

Text

The Best Stainless Steel Manufacturers in South Africa: What to Know

South Africa is home to a thriving enterprise sector, with stainless-steel being a cornerstone of many industries. From creation to automobile, electricity, and meals processing, stainless steel plays a pivotal position in current infrastructure and manufacturing. In this context, identifying the pleasant stainless steel producers in South Africa becomes important for agencies seeking to deliver outstanding materials. This weblog explores the primary stainless-steel manufacturers in South Africa, their services, and the rate they invest in the corporation.

The Importance of Choosing the Right Stainless Steel Manufacturer

The call for stainless stainless-steel in South Africa has surged due to its sturdiness, corrosion resistance, and versatility. Selecting a dependable manufacturer ensures:

Consistent Quality: Top manufacturers prioritize stringent first-rate management measures to satisfy global requirements.

Customization: Leading vendors provide tailor-made answers to meet enterprise-unique necessities.

Cost-Effectiveness: Reliable producers balance first rate with aggressive pricing.

Timely Deliveries: With sturdy delivery chains, those businesses ensure undertaking remaining dates are met.

Whether you're a small enterprise or a multinational business company enterprise employer, partnering with the great stainless-steel manufacturers can notably enhance your operational overall performance.

Top Stainless Steel Manufacturers in South Africa

Columbus Stainless

Columbus Stainless, primarily based in Middelburg, is one of the fundamental stainless steel manufacturers in South Africa. They produce a brilliant range of stainless-steel products, alongside coils, sheets, and plates. Their current-day facilities and commitment to innovation cause them to be a preferred preference for nearby and worldwide clients.

Macsteel Special Steels

Macsteel is a top notch call among stainless steel companies in South Africa. Known for their massive inventory, they cater to various industries which include mining, production, and automobiles. Their recognition of delivering high-grade substances has earned them recognition as a dependable provider.

NDE Stainless Steel

NDE Stainless Steel stands out for its specialization in corrosion-resistant stainless-steel products. As a trusted stainless-steel dealer in South Africa, they provide a whole range of pipes, tubes, and fittings. Their know-how in catering to the desires of the chemical and marine industries makes them a pacesetter in their place of hobby.

A Global Stainless Steel Leader

While exploring the brilliant producers globally, Vishal Tube Industries deserves a point out. Based in India, we have carved a spot for ourselves by handing over pinnacle-class stainless-steel seamless tubes, welded tubes, and U-tubes. The corporation’s dedication to superb innovation aligns with the desires of industries throughout the globe, consisting of South Africa.

Key highlights of Vishal Tube Industries include:

Advanced Manufacturing Facilities: With modern generation and personnel of over 150 experts, we guarantee unequalled precision and fantastic.

Global Reach: Their stainless steel products cater to industries in Europe, Asia, the Americas, and Africa.

Innovation-Driven Approach: By staying ahead of market trends, they offer top-tier stainless steel pipes and era services to their customers.

Why South Africa Relies on Stainless Steel

The versatility of stainless steel makes it an important cloth within the path of industries in South Africa. Here's why stainless steel is in such excessive demand:

Durability and Longevity: Ideal for creation and infrastructure projects.

Corrosion Resistance: Perfect for coastal regions and marine applications.

Hygiene Standards: Widely used in food processing and medical industries.

Aesthetic Appeal: Adds a current and polished look to architectural duties.

Factors to Consider When Choosing Stainless Steel Suppliers in South Africa

To pick out out the best stainless steel manufacturers, recollect the subsequent:

Product Range: Ensure the dealer gives a big form of stainless steel grades and bureaucracy.

Certifications: Look for compliance with ISO, ASTM, and one in all a kind global necessities.

Technical Support: A dependable manufacturer needs to provide expert guidance on material selection and application.

Sustainability: Leading manufacturers undertake green practices in their manufacturing strategies.

How Vishal Tube Industries Competes Globally

In the worldwide market, we stand out due to its unwavering willpower to best and customer delight. Their philosophy of "imparting worldwide clients with first-ranked stainless-steel pipes and generation offerings" ensures they stay aggressive even in hard markets.

The company’s awareness on maximizing performance, fostering innovation, and handing over advanced products has positioned them as a reliable partner for industries internationally. While they serve customers for the duration of continents, their products moreover resonate with the necessities and necessities of stainless-steel providers in South Africa.

The Future of Stainless Steel in South Africa

With ongoing infrastructure improvement and industrial corporation increase, the decision for stainless steel is poised to upward thrust further. The splendid stainless steel manufacturers in South Africa will maintain to innovate and increase their capabilities to meet this developing name for. Moreover, collaborations with global leaders like Vishal Tube Industries can beautify the super and type of products available within the neighborhood marketplace.

Conclusion

Finding the proper stainless steel companies in South Africa is critical for businesses searching out to advantage prolonged-time period success. By partnering with the incredible stainless steel producers, businesses can make sure everyday remarkable, dependable supply, and fee-effectiveness.

If you’re attempting to find pinnacle-notch stainless steel seamless tubes, welded tubes, or U-tubes, do not forget Vishal Tube Industries for their tremendous understanding and worldwide popularity. Their cutting-edge-day-day centers and customer-centric method reasoned them to have a name within the stainless-steel industry.

In South Africa, producers like Columbus Stainless, Macsteel, and NDE Stainless Steel are important in charge, supplying innovative and reliable solutions for several enterprise desires. As the market evolves, the characteristics of trusted stainless steel providers in South Africa will exceptionally grow greater significantly.

#Stainless Steel Manufacturers in South Africa#Best Stainless Steel Manufacturers#Stainless Steel Suppliers in South Africa

0 notes

Text

Comprehensive Guide to Flanges: Types, Applications, and Standards

Introduction

The biggest stainless steel flanges Manufacturers in India is Shashwat Stainless Inc. Flanges provide a mechanical way for connecting valves, fittings (such as elbows and tees), and pipes. Flanges are a non-permanent type of joint that is easy to prepare and remove, making them a better option than welds for systems that need maintenance. Flanges are the second most common connecting technique after welds, and they can be fitted by screwing, lapping, or welding.

What are Flanges?

A flange is a mechanically joining piece of pipe, either forged or cast, that joins pipe to a pressure vessel, pump, valve, or other piece of devices. Alloy steel, carbon steel, and stainless steel flanges offer simple access for servicing, cleaning, and testing. They typically have different forms, weight charts, force ratings, dimensions, sizes, grades, and specifications that follow ANSI/ASME, EN, BS, and DIN standards.

Types of Flanges

flanges Manufacturers production plants are well outfitted to produce a wide range of flanges, including:

Blind Flange

A blind flange is a ring-shaped used to seal off both ends of pipe systems and pressure vessel openings. It has all the required boltholes on it, but no center hole. It also makes it simple to access pipes or vessels for inspection.

Weld Neck Flange

Glue Neck flanges can be used in high-pressure applications because of their long, tapered hub. Bun welding is the method designed to connect these flanges to a pipe system. Stress concentrations at the flange base are reduced by the neck or hub, which transfers stresses to the pipe.

Slip-on Flange

These fit and weld into various pipes with ease. To give enough strength and stop leaks, a slip-on pipe flange is placed over the pipe and then welded from the inside and outside. Lower pressure applications are a perfect fit for these flanges. Many users prefer it to weld necks because of its lower cost and the fact that cutting pipe to length requires less accuracy.

Socket Weld Flange

The pipe is inserted into the socket end to attach these flanges. It makes the bore smoother and improves the passage of the gas or fluid inside. Smaller high-pressure tubes are typically fitted with socket-weld pipe flanges.

Flanges Application and Uses

Flanges Use in Textile machinery

Flanges Use in the Oil and gas industry

Flanges Use in Medical Gas Pipeline Systems

Flanges Use in Pharmaceutical processing industry

Flanges Use in Fluid piping.

Flanges Use in Modern architecture.

Flanges Use in Water waste projects.

Flanges Standards

The following standards apply to stainless steel flanges: ISO, ANSI, ASME, DIN, JIS, and custom standards. The following standards are followed by Viraj Profile Private Limited: ASME/ANSI, EN, DIN, AFNOR, AWWA, GOST, BS, JIS, AS, MSS, SA, UNI, and more. There are over 50,000 SKUs in the stainless steel flange market, available in a variety of sizes and shapes. We are also a Pipe and Tubes Manufacturers in India

Best Stainless Steel Flanges Manufacturer in India

The ASME B16.47 201 Stainless Steel Flanges is one of our most popular items in the metal market. These products can be adjusted to our customers' specifications and come in a range of shapes, sizes, and dimensions. stainless steel flanges Manufacturers offer these things in the right amount and with all customized options to satisfy the demands of different industry sectors.

We produce these Stainless Steel ANSI B16.5 Flanges with extra benefits and functionality to satisfy industry demands. They carry out harmful and non-destructive checks in order to keep similarity and verify every situation.

Also, Stainless Steel Flanges Suppliers In India have a reputation for being the biggest suppliers of flanges, involving SMO 254 flanges, Super Duplex Steel F55, F53, and 2507 flanges, Super Duplex Steel 32760 flanges, Super Duplex Steel 32750 flanges, Duplex Steel 31803 flanges for and so forth.

For More Details

Website: shashwatstainless.com

Product: Stainless Steel Flanges SuppliersOther Product: Sheet and Plate Weight Chart in kg, mm

#stainless steel flanges Manufacturers in India#stainless steel flanges Manufacturers#stainless steel flanges#Stainless Steel Flanges Suppliers

0 notes

Text

Steel Market — Forecast (2024–2030)

Steel market is analyzed to be $1,746.35 billion in 2023 and is projected to reach $2,105 billion in 2030. The market is estimated to grow with a CAGR of 4.13% during 2024-2030. Steel is an alloy that is made up of iron ore or scrap steel and carbon. In general, steels have various unique properties including being non-corrosive, rust-resistant and heavier than other metals such as aluminum. Therefore, steel is extensively used in various end-use industry verticals, including the manufacturing various transportation and automobile components, medical equipment, metal surgical implants, structural components and more, which in turn is boosting its market growth. In recent years, the steel market has experienced fluctuations driven by several factors. One significant trend in the steel market is the impact of trade policies and tariffs. Trade tensions between major steel-producing nations, such as the United States, China, and the European Union, have led to shifts in supply chains and pricing dynamics. Tariffs imposed on steel imports have affected the competitiveness of domestic producers and influenced global trade patterns. Additionally, sustainability concerns and environmental regulations have influenced market dynamics. Increasing awareness of carbon emissions and the environmental footprint of steel production has led to a growing demand for greener steel products. This has prompted investments in cleaner production technologies such as electric arc furnaces and the development of recycled steel. Moreover, technological advancements and innovations in steel manufacturing processes have enhanced efficiency and product quality. As a result, the steel market is poised for sustained growth as global economic recovery accelerates, with innovations in technology and sustainability shaping future trends.

Steel Market Report Coverage

The report: “Steel Industry – Forecast (2024-2030)”, by IndustryARC covers an in-depth analysis of the following segments of the Steel Market Report. By Type: Carbon Steel, (Low Carbon Steel, Medium Carbon Steel, High Carbon Steel), Stainless Steel (Austenitic Stainless Steels, Ferritic Stainless Steels, Martensitic Stainless Steels, Precipitation Hardening Grade Stainless Steels, Duplex Stainless Steels), Alloy Steel (Chromium Molybdenum Steel, Nickel-Chromium-Molybdenum Steel, Chromium Vanadium Steel, HSLA -Nickel-Chromium-Molybdenum Steel), Tool Steel (Water-hardening tool steels, Shock-resisting tool steels, Cold-work tool steels, Hot-work steels, High-speed tool steels, Others), Others By Form: Bar, Rod, Tube, Pipe, Plate, Sheet, Structural, Others By Application: Transportation (Road, Bridges, Barriers, Rail, Tracks, Rail Cars), Construction (Cool Metal (infrared reflecting) Roofing, Purlins, Beams, Pipe, Recyclable steel framing (studs), Desks/Furniture), Packaging (Canes, Bottles, Others), Water Projects (Levees/Dams/Locks), Energy (Renewable, Nuclear, Bio-fuels, Fossil, Electric Grid), Others By Industry: Construction (Steel Skeletons, Concrete Walls, Pillars, Nails, Bolts, Screws, Others), Machinery (Bulldozers, Backhoe Leaders, Pipelayers, Others), Automotive and Transportation (Exhaust, Trim/Decorative, Engine, Chassis, Fasteners, Tubing For Fuel Lines), Kitchenware and Domestic Appliances (Small Household Appliances, Black Home Appliances, White Home Appliances), Electrical and Electronics (Motor Mount Brackets, Adapter Plates, Electronic Frames and Chassis, Brackets, Others), Healthcare (Orthopaedic Implants, Artificial Heart Valves, Bone Fixation, Catheters, Others), Energy (Scrubbers, Heat Exchangers, Others) By Region: North America, South America, Europe, Asia-Pacific and Rest of the World

Request Sample

Key Takeaways

Steel Market Segment Analysis – By Type In terms of type, the Steel Market is segmented into carbon steel, stainless steel, alloy steel, tool steel and others. In 2023, the Stainless-steel segment generated the greatest revenue of $361.94 billion and is projected to reach a revenue of $482.28 billion by 2030. Owing to the various benefits posed by stainless steel such as corrosion resistance, high and low temperature resistance, the ease of fabrication, strength, aesthetic appeal is one of the key factors for its adoption among various end-use industries, which in turn is boosting its market growth. The stainless-steel segment can be further classified as Austenitic stainless steels, Ferritic stainless steels, Martensitic stainless steels, Precipitation hardening grade stainless steel and Duplex stainless steels.

Steel Market Segment Analysis – By Form By form, the steel market is segmented into bar, rod, tube, pipe, plate, sheet, structural and others. The bar segment accounted for the major market share in 2023, with a revenue of $554.58 billion, and is forecast to grow at a CAGR of 4.68% by 2030. The increasing demand for steel bar from various end-user industries such as building and construction, bridges, and many others, are driving the growth of the segment during the forecast period of 2024-2030.

Steel Market Segment Analysis – By Application Steel Market is segmented by its application that includes transportation, construction, packaging, water projects, energy and others. The energy segment held the dominant market share, 31% of the whole market, in 2023, and is expected to maintain its dominance by 2030 with a CAGR of 4.69%. One of the major factors for the segment growth is the increasing awareness and focus towards renewable energy sources. Steel plays a crucial role in producing and distributing energy as well as improving energy efficiency. Renewable energy is further classified as Wind Towers and Foundation, Wind Turbines and Solar Parabolic Mirror Supports & Collectors.

Steel Market Segment Analysis – By Industry The Steel finds its application across the industries such as construction, machinery, automotive and transportation, kitchenware and domestic appliance, electrical and electronics, healthcare, energy and others. Among them, the construction segment is the largest consumer of steel, as bearable structures can be manufactured easily at a low cost. The property of steel in its various forms and alloys makes it more flexible to cater the exclusive projects integrated with infrastructure. Moreover, the rapid industrialization and urbanization in various developing countries are fueling the segment growth in strengthening its dominant market position during the forecast period.

Buy Now

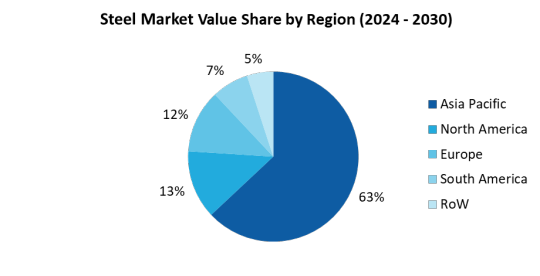

Steel Market Segment Analysis - By Geography/Country The report comprises of the region wise study of the global market including North America, South America, Europe, Asia-Pacific and Rest of the World. Above all, Asia-Pacific region held the biggest share in 2023, up to 63% of the whole steel market owing to the rapidly expanding defense, machinery, automotive, and shipbuilding industries in the countries such as India, China, South Korea, and Japan. Foreign direct investment in energy and infrastructure is likely to provide opportunities for the market vendors. Coupled with favorable government regulations, growing infrastructure and construction activities in developing economies of the Asia-Pacific region are boosting the demand for the market.

Steel Market - Drivers

Growing Demand for Steel Across the Various Regions Several factors have a significant impact on the overall development of the steel market. The major growth factor driving the Steel Market is the growing demand for steel across a variety of developing regions. For instance, Global crude steel production in January-November 2023 reached 1715.12 million metric tons, marking a marginal 0.5% year-on-year growth, per provisional data from the World Steel Association. November 2023 saw a production of 145.5 million metric tons, up by 3.3% from the previous year. China led the production with 952.14 million metric tons, followed by India and Japan, USA, Russia, South Korea, and Germany.

Construction and Infrastructure Development: Construction activities, including residential, commercial, and infrastructure projects such as roads, bridges, and railways, are major drivers of steel demand. Urbanization and industrialization also contribute to the growth of the construction sector, thereby increasing the demand for steel products. For instance, as per Green Finance & Development Center, China Belt and Road Initiative (BRI) Investment Report 2023, engagement totalled about USD88.3 billion, with USD44.6 billion from investment and USD43.7 billion from construction contracts. Also, The US Department of Transportation allocates $3.2 billion in extra funding, alongside $4.3 billion from the Bipartisan Infrastructure Law for 2023. The Budget prioritizes $4.5 billion for the Capital Investment Grant program, aiming to bolster transit infrastructure for economic growth. As a result, the steel market is anticipated to thrive, propelled by heightened construction activities and the need for durable materials, reflecting a promising outlook for the industry.

Steel Market -Challenges

Environmental Regulations and Sustainability The steel industry is facing mounting pressure to tackle environmental issues by cutting carbon emissions and enhancing sustainability efforts. Meeting stringent environmental regulations demands substantial investments in technology and infrastructure, presenting a formidable challenge for many companies. Despite the financial hurdles, embracing these changes can pave the way for a more sustainable and eco-friendly future for the industry.

Steel Market - Competitive Landscape The companies referred in the study include Baosteel Co., Ltd., Posco Holding Inc, Nippon Steel Corporation, JFE Holdings, Tata Steel Limited, United States Steel Corporation, Anshan Iron and Steel Group Corporation, Hyundai Steel Co., Ltd., ThyssenKrupp AG, ArcelorMittal S.A., among others. Technology launches, acquisitions, and R&D activities are key strategies adopted by the key players in the Steel Market.

0 notes

Text

Everything You Need to Know About Stainless Steel Tube

Stainless steel tubing is becoming increasingly popular in various industries due to its durability, corrosion-resistant properties, and wide range of uses. From medical equipment to industrial piping, this material offers numerous benefits that make it an attractive option. Stainless Steel Tube Suppliers offer a wide range of stainless steel tubing, serving diverse industries with various grades, sizes, and finishes. They provide materials for construction, manufacturing, and industrial applications, ensuring access to quality stainless steel tubes.

Properties of Stainless Steel Tube

Stainless steel tubing is a type of steel that is made from a combination of both chromium and steel. It is an alloy with high corrosion resistance, making it a preferred choice in various applications. Another notable property of stainless steel is its strength and durability; it can withstand exposure to high temperatures and harsh environments. Finally, it is very easy to clean and maintain, which makes it ideal for applications where hygiene is important.

Applications of Stainless Steel Tube

One of the main applications of stainless steel tubes is in the medical industry. It is used to produce surgical instruments such as needles, scalpels, and more. The material's biocompatibility and sterilization capabilities make it a preferred choice for medical applications. Additionally, it is also widely used in the chemical, food processing, and oil and gas industries.

Types of Stainless Steel Tube

There are several types of stainless steel tubing available in the market. The three most commonly used are austenitic, ferritic, and martensitic. Austenitic is the most commonly used because it is easy to weld, form, and fabricate. Ferritic is less pliable and easier to weld than austenitic, while martensitic is known for its hardness.

Benefits of Using Stainless Steel Tube

Stainless steel tubing offers several benefits, making it a preferred choice for many applications. It is durable, corrosion-resistant, and easy to clean and maintain. It can be made in various sizes and shapes to suit different applications, making it versatile. Additionally, it is recyclable, making it eco-friendly.

Conclusion

Stainless steel tubing is becoming increasingly popular in various industries due to its exceptional properties and benefits. The material's durability, corrosion-resistant properties, and ease of maintenance make it an ideal choice for many applications. Whether you are in the medical, food processing, or oil and gas industry, stainless steel tubing can help ensure your equipment is strong, long-lasting, and operates efficiently. We hope this guide has given you the knowledge to make an informed decision when choosing stainless steel tubing for your next project.

1 note

·

View note

Text

BEST SS TUBE MILL MACHINE MANUFACTURERS IN AHMEDABAD

Are you searching for a top-notch tube mill manufacturer for your production requirements?

You need to go no farther than Ahmedabad, which is home to some of the greatest tube mill manufacturers in Ahmedabad in the business. So how can you pick the best choice for your company when there are so many to select from?

To take the load off your shoulders we “Ashapura Industries” have come up with all the questions you need to know before choosing the best ss tube mill machine manufacturers in Ahmedabad.

What is the SS Tube?

SS Tube is an abbreviation for stainless steel tube. It is a hollow cylindrical construction composed of corrosion-resistant stainless steel, which is a strong material. Several industries, including building, transportation, industry, and decoration employ stainless steel tubes.

There are several grades of stainless-steel tubes, including 304 and 316, each with unique characteristics and uses. To fulfil the unique requirements of diverse industries and applications, they are offered in a variety of diameters, wall thicknesses, and lengths.

Stainless steel tubes are frequently used in heat exchangers, medical devices, food and beverage processing equipment, structural elements, and architectural elements, among other applications. They are widely used in fields that need great strength, resistance to corrosion, and aesthetic appeal.

What is the SS Tube mill?

Stainless steel tubes are made using a machine called a "SS tube mill" from steel coils or strips. Many steps are involved in the process, including cutting, sizing, welding, and forming.

Forming is the initial step in the procedure when a set of rollers is used to shape the steel strip into a cylindrical shape. Afterward, a high-frequency induction welding procedure is used to join the strip's edges together. After being welded, the tube is sent through a series of sizing rolls to get the proper ovality, wall thickness, and outside diameter.

Once the tube is sized, it may be cut to the desired length using a flying saw or a rotary cutting machine. The cut tube is then inspected for defects and may be further processed to achieve specific surface finishes, such as polishing or bead blasting.

Stainless steel tube mills come in different sizes and configurations, depending on the specific requirements of the application. Some mills can produce tubes with a diameter as small as a few millimetres, while others can produce large-diameter tubes used in industrial and structural applications.

Why do we need ss tube mill machine manufacturers in Ahmedabad?

There are several reasons why we need SS tube mill machine manufacturers in Ahmedabad:

Manufacturing Capability:

Ahmedabad has a well-developed industrial infrastructure and a skilled workforce, which makes it an ideal location for SS tube mill machine manufacturing. The manufacturers in Ahmedabad can produce high-quality stainless-steel tubes in various sizes, shapes, and grades to meet the specific needs of different industries.

Meeting the demand for high-quality tube mills:

Tube mills are an essential piece of machinery used in various industries, such as construction, automotive, and aerospace. To meet the growing demand for these machines, we need reliable and efficient manufacturers who can design and manufacture high-quality tube mills.

Customized solutions:

Every business has unique requirements when it comes to tube mills. By working with SS tube mill machine manufacturers in Ahmedabad, businesses can get customized solutions that meet their specific needs. This ensures that they have the right equipment for their operations, which can lead to improved efficiency and productivity.

Local manufacturing:

By working with local manufacturers in Ahmedabad, businesses can benefit from reduced lead times, faster delivery, and better communication. This can help them to better manage their supply chain and respond more quickly to changing market demands.

Cost-effective solutions:

Working with SS tube mill machine manufacturers in Ahmedabad can also be cost-effective compared to importing machines from other countries. This can help businesses to reduce their costs and improve their bottom line.

What is the use of an SS tube mill machine?

An SS tube mill machine produces stainless steel tubes of various sizes and shapes.

It is used in industries such as construction, automotive, and aerospace.

The machine shapes flat strips of stainless steel into seamless tubes through a series of rollers and welders.

The resulting tubes are high-quality and can be used for structural support, fluid transport, and heat exchange.

In summary, the use of an SS tube mill machine is to produce high-quality stainless-steel tubes for various industrial applications.

Benefits of having the Best SS Tube Mill Machine Manufacturers in Ahmedabad:

High-quality production: Advanced technology for durable and reliable stainless steel tubes.

Customized solutions: Tailored solutions for different industries.

Cost-effective production: Affordable tubes from high-quality raw materials.

Timely delivery: Strategically located for reduced transportation costs and faster delivery.

Skilled workforce: Ahmedabad's industrial infrastructure and skilled workforce produce various sizes, shapes, and grades of stainless-steel tubes.

Why choose only the best SS Tube Mill Machine Manufacturer in Ahmedabad?

Quality: The best SS tube mill machine manufacturers in Ahmedabad produce high-quality tubes that meet industry standards.

Customization: They provide customized solutions to meet the specific needs of different industries.

Cost-effective: They have access to high-quality raw materials at competitive prices, which helps in producing cost-effective tubes.

Timely delivery: They are located in a strategically advantageous location, which helps in the timely delivery of the tubes.

Reputation: They have a proven track record of delivering high-quality products and excellent customer service.

Looking for high-quality and reliable stainless-steel tubes? Ashapura Industries use advanced technology and skilled workforce to make us the best tube mill manufacturer in Ahmedabad. With customized solutions, cost-effective production, and timely delivery, we offer a one-stop solution for all your stainless-steel tube needs.

Trust us for durable and dependable stainless-steel tubes that meet industry standards. Contact us now to learn more about our products and services.

#Tube Mill Manufacturer in Ahmedabad#SS Tube Mill Machine Manufacturer in Ahmedabad#SS Tube Mill Machine Manufacturers

0 notes

Text

Medical Grade Stainless Steel Tube Market - Global Industry Outlook Research Report 2021-2026 Added By DecisionDatabases

The global Medical Grade Stainless Steel Tube Market report offers a comprehensive assessment of the market for the forecast years. The report contains several segments and an analysis of the market trends and growth factors that are playing a vital role in the market. These factors encompass the drivers, restraints, and opportunities. This global industry offers an outlook on the strategic development of the market in terms of revenue profits over the forecast period 2021-2026.

The key market players for the global Medical Grade Stainless Steel Tube market are listed below:

AMETEK

Sandvik

Teshima

Om Steel Tubes

Tech Tube

Bison Stainless Tube

K-Tube Technologies (Cook Group)

Vita Needle Company

M&M International

Fuji Seiko

Minitubes

Others

Click here to get a FREE Sample Copy of the Medical Grade Stainless Steel Tube Market Research Report @ https://www.decisiondatabases.com/contact/download-sample-15885

The Global Medical Grade Stainless Steel Tube Market Report is equipped with market data from 2016 to 2026. The report gives a market overview covering key drivers and risk factors. The report is bifurcated by top global manufactures mentioning sales, revenue, and prices as applicable. It also evaluates the competitive scenario of the leading players. The report expands to cover regional market data along with type and application. The report forecasts sales and revenue from 2021 to 2026. The detailed sales channel is also covered in the study.

COVID-19 Impact Analysis on Medical Grade Stainless Steel Tube Market

The global pandemic COVID-19 has affected the Medical Grade Stainless Steel Tube market directly or indirectly. This study covers a separate section giving an explicitly clear understanding of the aftereffects of this pandemic. The detailed study highlights the probable outcomes of this global crisis on the Medical Grade Stainless Steel Tube industry. The impact study on production, supply-demand, and sales provides a holistic approach to the future.

Do You Have Any Query Or Report Customization? Ask Our Market Expert @ https://www.decisiondatabases.com/contact/ask-questions-15885

Why Purchase this Report?

A robust research methodology has been followed to collect data for the report. Data, thus collected passes through multiple quality checks to ensure the best quality is served.

The report gives a holistic view of the competitive scenario of the Medical Grade Stainless Steel Tube market

The latest product launches along with technological changes and development are covered in the report.

The data analysis in the report helps in understanding the anticipated Medical Grade Stainless Steel Tube market dynamics from 2021 to 2026.

DecisionDatabases has a vast repository of data, therefore, we can accommodate customized requirements also.

The graphs, tables and pie charts, and info-graphics covered in the report will help in a better understanding of the report.

The market drivers, restraints, upcoming opportunities, and anticipated restraints cited in the report will assist in making an informed decision.

To better understand the market scenario, the Medical Grade Stainless Steel Tube market is segmented as below:

By Types:

304

316

Others

By Applications:

Medical Equipment

Medical Supplies

Others

By Regions:

North America (U.S., Canada, Mexico)

Europe (U.K., France, Germany, Spain, Italy, Central & Eastern Europe)

Asia Pacific (China, Japan, South Korea, ASEAN, India, Rest of Asia Pacific)

Latin America (Brazil, Rest of L.A.)

The Middle East and Africa (Turkey, GCC, Rest of Middle East)

The content of the study subjects includes a total of 14 chapters:

Chapter 1: To describe Medical Grade Stainless Steel Tube product scope, market overview, market opportunities, market driving force, and market risks. Chapter 2: To profile the top manufacturers of Medical Grade Stainless Steel Tube, with price, sales, revenue, and global market share of Medical Grade Stainless Steel Tube in 2018 and 2019. Chapter 3: The Medical Grade Stainless Steel Tube competitive situation, sales, revenue, and global market share of top manufacturers are analyzed emphatically by landscape contrast. Chapter 4: The Medical Grade Stainless Steel Tube breakdown data are shown at the regional level, to show the sales, revenue, and growth by region, from 2015 to 2020. Chapter 5 and 6: To segment the sales by type and application, with sales market share and growth rate by type, application, from 2015 to 2020. Chapter 7, 8, 9, 10 & 11: To break the sales data at the country level, with sales, revenue, and market share for key countries in the world, from 2016 to 2021 and Medical Grade Stainless Steel Tube market forecast, by regions, type, and application, with sales and revenue, from 2021 to 2026. Chapter 12, 13 & 14: To describe Medical Grade Stainless Steel Tube sales channel, distributors, customers, research findings and conclusion, appendix, and data source.

Directly Purchase the Complete Global Medical Grade Stainless Steel Tube Market Research Report @ https://www.decisiondatabases.com/contact/buy-now-15885

About Us:

DecisionDatabases.com is a global business research report provider, enriching decision-makers, and strategists with qualitative statistics. DecisionDatabases.com is proficient in providing syndicated research reports, customized research reports, company profiles, and industry databases across multiple domains. Our expert research analysts have been trained to map client’s research requirements to the correct research resource leading to a distinctive edge over its competitors. We provide intellectual, precise, and meaningful data at a lightning speed.

For more details: DecisionDatabases.com E-Mail: [email protected] Phone: +91 90 28 057900 Web: https://www.decisiondatabases.com/

Reference Source:

https://view.publitas.com/decisiondatabases-com-_vzxge7jabyb/medical-grade-stainless-steel-tube-market-research-report-from-2021-to-2026/

#Medical Grade Stainless Steel Tube Market#Medical Grade Stainless Steel Tube Market Report#Medical Grade Stainless Steel Tube Market Size#Medical Grade Stainless Steel Tube Market Share

0 notes

Text

Titanium Plate Details

Titanium is a steel utilized in numerous things. It belongs in stainless-steel, nickel alloys, aluminum, very alloys, alloy steel as well as, certainly, titanium. Titanium is available in differing qualities, such as readily pure or aerospace grades. The aerospace market, petroleum-chemical sector as well as the medical sector are just a few who depend upon titanium. It is provided and also made use of globally as a raw material. The raw material types titanium comes in are sheet, pole, plate, bar, tubes, coil, extrusions as well as titanium ingot. Titanium forgings as well as spreadings are also taken into consideration resources. One of the most requiring markets rely on high honesty titanium product needs.

Titanium is so famously made use of in important functions due to its resilient, yet light characteristic. It is nearly fifty percent lighter than steel, yet is thirty percent more powerful. Although titanium is sixty percent heavier than light weight aluminum, it is additionally twice as solid. Together with this, the remarkable strength retention for titanium is an additional very popular facet. It has stamina retention is to one thousand levels Fahrenheit. As soon as titanium is alloyed with various other metals, its toughness rises. In addition to this, the alloys can stand up to high temperatures. A steel alloyed with titanium likewise acts to brighten the resultant alloy. Some popular steels titanium is alloyed with are light weight aluminum, iron, manganese, molybdenum, as well as others.

Titanium Tube

One more trait that makes this aspect an useful item to make use of is its high resistance to deterioration. Therefore, as it is exposed to the ambience, a tight consistent oxide film is developed. This film is resistant to lots of harsh materials such as salt water.

Titanium Sheet

The titanium metal industry was developed in the 1950s. This was initially and also foremost in reaction to the promising aerospace market. Within this sector, titanium was used in making airframe architectural parts and skin, air engine elements, airplane hydraulic systems, missiles, area craft as well as rockets. The homes of titanium are priceless in this industry.

The military is an additional industry which utilizes titanium for weapons and assisted missiles. The price of titanium plate dropped as the 1970s approached. This made the item much more available for extra sensible applications, like shipbuilding. Titanium is made use of mainly in ship props, submarines, rigging, shafts and also other components which often tend to be extremely destructive. Progressively, titanium has actually been utilized in medical applications as a result of its lightweight strength in addition to its hypoallergenic features, being that it is nickel free. This beneficial metal is being located useful is a growing number of sectors also, from showing off products to petrochemical applications.

0 notes

Text

Complete Guide of Stainless Steel Pipe and Tubes

Highly corrosive materials often need to be transported, and Stainless Steel Pipe suppliers in UAE are the ideal choice. Because it contains more than 8% of these elements, Stainless Steel 304 Pipe suppliers in UAE is considered an alloy manufacturer of the highest quality. An external layer of chromium protects an alloy metal pipe. Thus, the internal environment is unaffected by its external setting. These pipes have a high market value because of their high quality and wide range of available sizes. The wide varieties of pipes include:

316L Stainless Steel Sheet

One of the most adaptable forms of steel is produced by 316L Stainless Steel Sheet suppliers. It resists rust, pitting, and soil and water stains in any environment. Because of its high corrosion resistance can be used in various settings, including digesters, space jet engine parts, mining equipment, and medical machinery.

Mild Steel Plate

They are also in high demand because of the harmony between their toughness, strength, and flexibility. Low-carbon steel, medium-carbon steel, high-carbon steel, etc., are all types of MS.

IS 2062 Grade B Plate

Indian National Standards certify IS 2062 Grade B steel. Indian-standard IS 2062 Grade B Plate is structural steel. These plates are made of carbon, manganese, sulphur, phosphorus, and silicon. The 2062 gr b substance makes them resistant to oxidative and corrosive environments. This material produces micro-alloyed sheets, plates, coils, and other sections. Is 2062 Gr B usually utilised? This grade's parts are ductile and resistant to temperature variations.

A36 Steel Plate

A36 Steel Plate is a mild, hot-rolled carbon structural steel that is widely used. A36 is the best steel for welding and can be easily machined using standard tools for punching, grinding, drilling, tapping, and other similar tasks. In contrast to those of higher-performance alloys, these structural steel plate properties make the valuable steel in various contexts.

Alloy Steel Plate

Steel with between 1% and 50% of the weight of another element added to it to improve its mechanical properties is called Alloy Steel Plate. Both low-alloy and high-alloy steels exist, and both have their uses.

SS ERW Pipe

SS ERW Pipe suppliers in UAE produced steel using a method called electric resistance welding, and it is made from a variety of stainless-steel materials. Electric resistance joins the ends of the sheets, plates, or strips that make up the pipes.

Stainless Steel tube

Stainless Steel tube suppliers in UAE is responsible formade of stainless steel can be considered "seamless" if they lack any welds or other welded connections. Due to its resistance to both high temperatures and intense pressure, metal is a great choice. It finds widespread use in the oil and gas industry and the mechanical and engineering sectors. On top of that, its mechanical properties produced by Alloy Steel Plate suppliers in UAE are excellent in cold and hot conditions.

Conclusion

Aerospace, electronics, railroad machinery, chemical tanks, food vats, and marine applications are just some of the many fields that use stainless steel pipes and tubes. You can also find pipes and tubes like these in resistor jackets and other furnace accessories and in high-temperature heating systems.

0 notes

Text

Cold Drawn Stainless Steel Welded Tube

Cold Drawn Stainless Steel Welded Tube

Cold Drawn Stainless Steel Welded Tubes is one of main products in Jaway metal co,.ltd.it has large stock of stainless steel,in accordance with GB standard,ASTM,JIS,BS.To provide customers with super fast delivery of a variety of steel products. For Cold Drawn Stainless Steel Welded Tubes,we make sure high quality conctrol policy and fast delivery.Also for welded pipe we have grade for 304, 316,304L,316l,310S,310H,410,430,etc,and outside diameter from OD10.3 to OD508mm,and thickness from 1.65-50.01mm,or according to customer request.we sell very well for this welded pipe and always export to Europe, America South Asia, Korea and jordan,etc.can meet any requirments and with comepertive price.welcome to make an inquiry. Application for cold drawn stainless steel welded tubes,our customer alway buy this type pipe usd for Furniture, petroleum, chemical industry, boiler gas, plumbing equipment, aerospace, papermaking, automobile, food, packaging machinery, medical treatment, decoration, furniture, railings and other projects, hardware processing, ships, power plants and other industries. Many people on the market are used to make stair handrails, window guards, railings, furniture, etc. So if u are interested in this material, pls send an inquiry to us for compertive price.

https://eastasiametal.com/index.html

1 note

·

View note

Text

How to Select Stainless Steel plate

The construction industry is inseparable from stainless steel plates. Stainless steel plate has good corrosion resistance performance, so now many steel plate manufacturers are increasing the production of stainless steel plate. But there are also some illegal vendors, and they only pursue benefits but ignore the quality of stainless steel plates. Below we will introduce several stainless steel plate selection methods.

1. When selecting stainless steel plate, we should consider its uses and application environment. For example, the welded pipe is generally used for decoration; seamless pipe is usually used for fluid transport; for medical or kitchen, we often use sanitary grade stainless steel plates. Generally, 200 series stainless steel materials are used indoors, 304 materials are used outdoors, however, 316 materials and others are generally used in acidic, alkaline places or coastal areas.

2. Make sure the material is qualified. Take 304 as an example

a. From the price analysis, if 304 stainless steel plate is even lower than the prevailing price of 301 material on the market, you should be careful to identify it, and it is probably some other materials.

b. Identify whether the pipe surface is stamped with steel seal 304, and ask for qualifications and certifications as proof;

c. Run acid reagent test; After 30 seconds, material 304 will not change color, and 201 will turn black

d. For bulk purchase, you can take samples to the national authority testing center for composition testing.

3. Check whether the color of the outer surface and the inner wall of the tube is bright and smooth and whether the thickness is uniform or rough.

4. It is inevitable that the hot galvanized pipe sometimes has a pitting surface, but it basically does not affect the use, but it is better to check carefully and choose the less one, especially check the inner surface.

5. Be sure to choose a famous brand or visit the factory.

0 notes

Text

Steel Market - Forecast(2024 - 2030)

Steel Market - Overview

The Steel market is analyzed to be $1,746.35 billion in 2023 and is projected to reach $2,105 billion in 2030. The market is estimated to grow with a CAGR of 4.13% during 2024-2030. Steel is an alloy that is made up of iron ore or scrap steel and carbon. In general, steels have various unique properties including being non-corrosive, rust-resistant and heavier than other metals such as aluminum. Therefore, steel is extensively used in various end-use industry verticals, including the manufacturing various transportation and automobile components, medical equipment, metal surgical implants, structural components and more, which in turn is boosting its market growth. In recent years, the steel market has experienced fluctuations driven by several factors. One significant trend in the steel market is the impact of trade policies and tariffs. Trade tensions between major steel-producing nations, such as the United States, China, and the European Union, have led to shifts in supply chains and pricing dynamics. Tariffs imposed on steel imports have affected the competitiveness of domestic producers and influenced global trade patterns. Additionally, sustainability concerns and environmental regulations have influenced market dynamics. Increasing awareness of carbon emissions and the environmental footprint of steel production has led to a growing demand for greener steel products. This has prompted investments in cleaner production technologies such as electric arc furnaces and the development of recycled steel. Moreover, technological advancements and innovations in steel manufacturing processes have enhanced efficiency and product quality. As a result, the steel market is poised for sustained growth as global economic recovery accelerates, with innovations in technology and sustainability shaping future trends.

Steel Market Report Coverage

The report: “Steel Industry – Forecast (2024-2030)”, by IndustryARC covers an in-depth analysis of the following segments of the Steel Market Report.

By Type: Carbon Steel, (Low Carbon Steel, Medium Carbon Steel, High Carbon Steel), Stainless Steel (Austenitic Stainless Steels, Ferritic Stainless Steels, Martensitic Stainless Steels, Precipitation Hardening Grade Stainless Steels, Duplex Stainless Steels), Alloy Steel (Chromium Molybdenum Steel, Nickel-Chromium-Molybdenum Steel, Chromium Vanadium Steel, HSLA -Nickel-Chromium-Molybdenum Steel), Tool Steel (Water-hardening tool steels, Shock-resisting tool steels, Cold-work tool steels, Hot-work steels, High-speed tool steels, Others), Others

By Form: Bar, Rod, Tube, Pipe, Plate, Sheet, Structural, Others

By Application: Transportation (Road, Bridges, Barriers, Rail, Tracks, Rail Cars), Construction (Cool Metal (infrared reflecting) Roofing, Purlins, Beams, Pipe, Recyclable steel framing (studs), Desks/Furniture), Packaging (Canes, Bottles, Others), Water Projects (Levees/Dams/Locks), Energy (Renewable, Nuclear, Bio-fuels, Fossil, Electric Grid), Others

By Industry: Construction (Steel Skeletons, Concrete Walls, Pillars, Nails, Bolts, Screws, Others), Machinery (Bulldozers, Backhoe Leaders, Pipelayers, Others), Automotive and Transportation (Exhaust, Trim/Decorative, Engine, Chassis, Fasteners, Tubing For Fuel Lines), Kitchenware and Domestic Appliances (Small Household Appliances, Black Home Appliances, White Home Appliances), Electrical and Electronics (Motor Mount Brackets, Adapter Plates, Electronic Frames and Chassis, Brackets, Others), Healthcare (Orthopaedic Implants, Artificial Heart Valves, Bone Fixation, Catheters, Others), Energy (Scrubbers, Heat Exchangers, Others)

By Region: North America, South America, Europe, Asia-Pacific and Rest of the World

Request Sample

Key Takeaways

• The Asia-Pacific region, particularly China, has been a dominant force in the global steel market with a share of 63% in 2023, owing to China's rapid industrialization and urbanization have driven substantial demand for steel in the construction, infrastructure, and manufacturing sectors.

• Government infrastructure spending, particularly in major economies, plays a significant role in driving steel demand. Large-scale infrastructure projects, such as bridges, railways, and urban development initiatives, can create substantial demand for steel products.

• The automotive sector is a significant consumer of steel, particularly in the production of vehicles. Changes in consumer demand for automobiles, as well as shifts towards electric vehicles which may use different materials, can impact steel demand in this sector.

Steel Market Segment Analysis – By Type

In terms of type, the Steel Market is segmented into carbon steel, stainless steel, alloy steel, tool steel and others. In 2023, the Stainless-steel segment generated the greatest revenue of $361.94 billion and is projected to reach a revenue of $482.28 billion by 2030. Owing to the various benefits posed by stainless steel such as corrosion resistance, high and low temperature resistance, the ease of fabrication, strength, aesthetic appeal is one of the key factors for its adoption among various end-use industries, which in turn is boosting its market growth. The stainless-steel segment can be further classified as Austenitic stainless steels, Ferritic stainless steels, Martensitic stainless steels, Precipitation hardening grade stainless steel and Duplex stainless steels.

Inquiry Before Buying

Steel Market Segment Analysis – By Form

By form, the steel market is segmented into bar, rod, tube, pipe, plate, sheet, structural and others. The bar segment accounted for the major market share in 2023, with a revenue of $554.58 billion, and is forecast to grow at a CAGR of 4.68% by 2030. The increasing demand for steel bar from various end-user industries such as building and construction, bridges, and many others, are driving the growth of the segment during the forecast period of 2024-2030.

Steel Market Segment Analysis – By Application

Steel Market is segmented by its application that includes transportation, construction, packaging, water projects, energy and others. The energy segment held the dominant market share, 31% of the whole market, in 2023, and is expected to maintain its dominance by 2030 with a CAGR of 4.69%. One of the major factors for the segment growth is the increasing awareness and focus towards renewable energy sources. Steel plays a crucial role in producing and distributing energy as well as improving energy efficiency. Renewable energy is further classified as Wind Towers and Foundation, Wind Turbines and Solar Parabolic Mirror Supports & Collectors.

Steel Market Segment Analysis – By Industry

The Steel finds its application across the industries such as construction, machinery, automotive and transportation, kitchenware and domestic appliance, electrical and electronics, healthcare, energy and others. Among them, the construction segment is the largest consumer of steel, as bearable structures can be manufactured easily at a low cost. The property of steel in its various forms and alloys makes it more flexible to cater the exclusive projects integrated with infrastructure. Moreover, the rapid industrialization and urbanization in various developing countries are fueling the segment growth in strengthening its dominant market position during the forecast period.

Steel Market Segment Analysis - By Geography/Country

The report comprises of the region wise study of the global market including North America, South America, Europe, Asia-Pacific and Rest of the World. Above all, Asia-Pacific region held the biggest share in 2023, up to 63% of the whole steel market owing to the rapidly expanding defense, machinery, automotive, and shipbuilding industries in the countries such as India, China, South Korea, and Japan. Foreign direct investment in energy and infrastructure is likely to provide opportunities for the market vendors. Coupled with favorable government regulations, growing infrastructure and construction activities in developing economies of the Asia-Pacific region are boosting the demand for the market.

Schedule a Call

Steel Market - Drivers

Growing Demand for Steel Across the Various Regions

Several factors have a significant impact on the overall development of the steel market. The major growth factor driving the Steel Market is the growing demand for steel across a variety of developing regions. For instance, Global crude steel production in January-November 2023 reached 1715.12 million metric tons, marking a marginal 0.5% year-on-year growth, per provisional data from the World Steel Association. November 2023 saw a production of 145.5 million metric tons, up by 3.3% from the previous year. China led the production with 952.14 million metric tons, followed by India and Japan, USA, Russia, South Korea, and Germany.

Construction and Infrastructure Development:

Construction activities, including residential, commercial, and infrastructure projects such as roads, bridges, and railways, are major drivers of steel demand. Urbanization and industrialization also contribute to the growth of the construction sector, thereby increasing the demand for steel products. For instance, as per Green Finance & Development Center, China Belt and Road Initiative (BRI) Investment Report 2023, engagement totalled about USD88.3 billion, with USD44.6 billion from investment and USD43.7 billion from construction contracts. Also, The US Department of Transportation allocates $3.2 billion in extra funding, alongside $4.3 billion from the Bipartisan Infrastructure Law for 2023. The Budget prioritizes $4.5 billion for the Capital Investment Grant program, aiming to bolster transit infrastructure for economic growth. As a result, the steel market is anticipated to thrive, propelled by heightened construction activities and the need for durable materials, reflecting a promising outlook for the industry.

Steel Market -Challenges

Environmental Regulations and Sustainability

The steel industry is facing mounting pressure to tackle environmental issues by cutting carbon emissions and enhancing sustainability efforts. Meeting stringent environmental regulations demands substantial investments in technology and infrastructure, presenting a formidable challenge for many companies. Despite the financial hurdles, embracing these changes can pave the way for a more sustainable and eco-friendly future for the industry.

Buy Now

Steel Market - Competitive Landscape

The companies referred in the study include Baosteel Co., Ltd., Posco Holding Inc, Nippon Steel Corporation, JFE Holdings, Tata Steel Limited, United States Steel Corporation, Anshan Iron and Steel Group Corporation, Hyundai Steel Co., Ltd., ThyssenKrupp AG, ArcelorMittal S.A., among others. Technology launches, acquisitions, and R&D activities are key strategies adopted by the key players in the Steel Market.

Steel Market - Recent Developments

November 2022, Tata Steel launched the fourth edition of MaterialNEXT, focusing on 'Materials to Wonder.' This open innovation event aims to gather ideas on emerging materials and their applications. The program spans five months across Idea Selection, Development, and Evaluation stages, fostering collaboration among scientists, researchers, and startups.

May 2022, Kobe Steel introduced "Kobenable Steel," Japan's pioneering low CO2 blast furnace steel, aiming to curtail emissions during ironmaking. Utilizing innovative CO2 Reduction Solution technology, it plans to roll out the product this fiscal year, marking a milestone in sustainable steel production.

In June 2023, Nippon Steel introduces ZEXEED™ Checkered Sheet, a new addition to its high corrosion resistant coated steel series

#steel market#steel market size#steel market shape#steel market forecast#steel market analysis#steel market report#steel market growth

0 notes

Text

New Technology and System Solution for Silicone Oil Spraying for Prefilled Syringe

The pre-filled syringe, or pre-filling syringe, has the function of both storing drugs and traditional syringe. Compared with the traditional "bottle + syringe" method, the pre-filled syringe brings many advantages to pharmaceutical enterprises and clinical use. Prefilled syringe is very convenient and easy to use, more safe and reliable, and can simplify clinical operation. Hospitals and patients benefit from the faster and safer use of prefilled syringes. Prefilled syringe market grows rapidly in Europe, the United States and China. Its early stage applications were mainly focused on delivery of insulin, tumor drug and vaccine. With continuous technology development, prefilled has started to enter applications of new biotech reagent, genetic drugs, and other medium and high-end medicines.

A prefilled syringe includes a syringe, a push rod, an injection needle and a protective cap.

In order to ensure that the rubber piston on the push rod of the assembly can slide freely in the syringe tube, the inner wall of the syringe tube should be lubricated by spraying silicone oil in the production process of prefilled syringe assembly. If the amount of sprayed silicone oil is too small, it affects rubber piston’s smooth movement in the syringe during usage. If the silicone oil spraying volume is too much, the residual silicone oil inside the syringe may affect the quality of drug inside the syringe. Therefore, spraying minimum silicone oil with desired lubrication performance, is a common technical requirement for prefilled syringe manufacturers.

An old traditional lubrication treatment method is to dip and soak syringe needle and rubber piston into a tank of silicone oil that has been diluted with solvent. Then take the syringe out and dry it in an oven. The drying process can cause silicone oil to fall off unevenly, which causes uneven lubrication coating and poor performance. Another method is to use spraying gun to spray silicone oil into syringe. This method has thick edges, uneven coating, large particles and other issues.

In order to address the old technology’s spraying issue, Guangzhou Ascend Precision Machinery Company Limited (www.ascendgz.com) has worked with multinational corporations and components partners to develop better spraying technology and system. Through serving major medical device companies such as BD and Weigao, Guangzhou Ascend has continued to introduce high precision micro-liter level and nano-liter level silicone oil spraying systems for prefilled syringe and other medical devices.

FSH-DS128 series is Guangzhou Ascend’s latest automatic silicone oil amortization and spraying system. The system includes a high precision ceramic pump module, a set of XYZ table, and a set of precision spraying nozzle. The complete system can spray silicone oil down to 5-50 micron droplet size. Spraying volume can go down to sub micro-liter level. FSH-DS128 system can do custom design for successful spraying high viscosity silicone oil such as Dow Corning 360. Our custom nozzle has successfully atomized silicones ranging up to 100,000cps in volumes below 1mg per spray dose.

FSH-DS128 system uses AP micro pump for fluid dispensing and volume control. The AP micro pump is based on sapphire grade ceramic pump technology with high efficiency, high precision, corrosion resistance and contamination free. AP micro pump has been widely used for dispensing, filling, and spraying applications for pharmaceutical, biotech, and medical device industries. Low maintenance, extremely high reliability, and high efficiency, has made AP micro pump a top choice for fluid dispensing and spraying applications.

FSH-DS128 system uses Sonicair nozzle for applications requiring a consistent and precise coating method. The Sonicair nozzle is manufactured from 316 stainless steel and there are no moving parts or valves that can compromise the effectiveness of the spray. Unlike many air nozzles that depend on time and pressure to atomize fluids, AP ceramic micro pump feeds the Sonicair nozzle. This delivers a precise volume of fluid to the nozzle, injecting it into an air stream creates an atomized field that exits the nozzle through a precision orifice. The outcome is a uniform and consistent conical or beam spray pattern. The airflow exiting the nozzle also helps to expand the spray pattern by nebulizing the spray as it travels further away from the orifice. The cone shape spraying is proved to be the most effective method of spraying the inside of a syringe.

System Features and Benefits:

• Sapphire grade high precision ceramic pump.

• Corrosion resistant. Contamination free.

• Special precision nozzle

• Micro spray. From micro-liter to nano-liter.

• Fine uniform atomization. 5-50 micron droplet size.

• High precision. CV up to 0.5%

• Low maintenance. Extremely stable and reliable.

• Track record of success, such as BD and Weigao

• Top choice for refilled syringe spraying.

Guangzhou Ascend Precision Machinery Co.,Ltd. (www.ascendgz.com) is a high-tech company that specializes in fluid control equipment and system solutions. Our company has rich experience in the design and manufacturing of precision equipment for low volume fluid dispensing, refilling, glue dispensing, and spraying applications. Our product’s high quality, high efficiency, and best value, have helped us bring more value to customers in the world.

0 notes

Text

Medical Plastics Market Outlook, 2019-2027

Global Medical Plastics Market: Overview

The medical industry world over has been benefitting from the wide range of devices, equipment, and implants made with high performance plastics. Sellers and manufacturers in the global medical plastics market are reaping revenue gains by leveraging the versatility, safety, and cost-effectiveness of medical-grade plastics in these applications. In addition, the freedom that medical grade plastics offer to fabricators has helped bolster their application, underpinning the evolution of the medical grade plastics market, notes Transparency Market Research (TMR).

Manufacturers over the recent decade have been increasingly adopting high technology polymers in making devices that will be used for various stages in disease management and surgeries. Unique set of characteristics of plastics have enabled manufacturers in medical plastics market replace titanium/stainless steel metals with plastics, such as in medical tubing.

The global medical plastics market is projected to clock a CAGR of 7.2% from 2019 to 2027 and reach valuation of US$15.4 bn by the end of the period.

The competitive landscape in the global medical plastics market is characterized by the presence of several small- and medium-scale players. Further, the shares are fairly distributed among numerous players. Well-entrenched manufacturers in the medical plastics market are forking out money for constant capacity expansion and are engaging in mergers to consolidate their position globally. Some of them are The Lubrizol Corporation, Solvay, Covestro AG, Arkema S.A., and Evonik Industries AG.

Request for Covid-19 Impact Analysis :https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=1115

The range of medical-grade plastics available for application are vast. Major of them are PVC, PE, PP, PS, engineering plastics, and silicone. Though the use of conventional plastics still rules the roost, engineered thermoplastics are gathering steam among manufacturers in the medical plastics market.

Request A Sample – https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=11150

Application of 3D Printing Underpin Abundant Opportunities for Manufacturers

The environmentally friendliness of medical grade plastics along with their cost-effectiveness is one of the compelling propositions for the demands in the medical plastics market. Advent of 3D printing and their rising applications in polymer manufacturing have expanded the prospects in the medical plastics market.

Enquiry before buying :https://www.transparencymarketresearch.com/sample/sample.php?flag=EB&rep_id=1115

Among all medical devices, braces and prosthetics made with medical plastics are witnessing huge demands in the healthcare industries in various developing and developed nations. The application of 3D printing has also helped spur the use of medical plastics in making personalized implants, broadening the scope of therapeutics possible with plastic materials. A case in point is patient-specific prosthetic arms. Thus, the potential of medical plastics in making customized implants has catalyzed revenue generation in the medical plastics market market.

Rising Use in Making in Disposable Medical Devices Underscore Vast Potential

One of the most prominent applications of medical plastics has been disposable medical devices, mainly due to the fact that plastics is cost-effective and light. Further, the medical plastics market is seeing new demands in the use of medical-grade plastic containers and boxes for disposing of surgical sharps and biohazards.

More Trending Report by Transparency Market Research –https://www.globenewswire.com/news-release/2022/03/21/2406705/0/en/Industrial-Gases-Market-to-Expand-at-CAGR-of-6-1-during-Forecast-Period-Observes-TMR-Study.html

Growing role of devices made with medical plastics in chronic disease management has catalyzed prospects in the medical plastics market. Favorable insurance regulations in some regions are offering large momentum to the global market. North America and Europe have been at the forefront, and the growth in the markets are driven by widespread uptake of medical-grade plastics.

About Us:

Transparency Market Research is a global market intelligence company, providing global business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insight for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants, use proprietary data sources and various tools and techniques to gather, and analyse information. Now avail flexible Research Subscriptions, and access Research multi-format through downloadable databooks, infographics, charts, interactive playbook for data visualization and full reports through MarketNgage, the unified market intelligence engine. Sign Up for a 7 day free trial!

Contact

Rohit Bhisey Transparency Market Research, 90 State Street, Suite 700, Albany, NY 12207 Tel: +1-518-618-1030 USA – Canada Toll Free: 866-552-3453 Email: [email protected] Website: https://www.transparencymarketresearch.com

0 notes

Text

Vases Nz

Water pipes or glass vases are great tools for every smoker. These sets use water to filter out any heavy particles and water-soluble molecules from the burnt herbs and concentrate; Thus creating smoother vapor for the smokers. At Vases, we have a large collection of water pipes for sale in NZ that can satisfy both beginners and connoisseurs. We have a variety of smoking accessories.

Shake well and drink the entire contents of this bottle at a comfortable yet consistent pace. If you desire, drinking an additional 500ml of water can be helpful.

As part of the toxin elimination process, be sure to urinate frequently. This is important for a successful cleanse.

Sit back and relax, you have purchased the best cleansing product on the market.

Important tips:

When cleansing the system, it is important to drink as much water as possible in the lead up to using this product.

Avoid unwanted toxins.

Best when taken on an empty stomach; however if you have a sensitive stomach, you may eat something light (like toast).

This product is not intended for regular or daily use.

Cleansing is beneficial prior to any diet or exercise program.

Do not use this product if you are pregnant, breast-feeding, have kidney or gallbladder disorder or disease. This product is not recommended for prolonged use. When using this product you may experience minor nausea, diarrhea, dizziness or cramping. If you experience any of these symptoms, discontinue use of product. If symptoms persist, seek medical assistance. Not intended for daily use.

This Smoking glass pipe is made from heat resistant and clear borosilicate glass material, giving it a sleek and clean look.

Our glass pipe is non-reactive which will provide you with smooth and pure flavour with no chemical aftertaste.

Smoking Glass Pipes Collection

Anodized for smooth finish; this means no wear or smudge marks.

Made from Aircraft Grade Aluminum Rod using the newest in CNC machining technology.

Razor sharp Diamond Cutting Blades for extreme efficiency.

Powerful Neodymium Magnets for incredible closure.

Stainless steel pollen screen allows for only the finest pollen to fall to the bottom catch.

Thin polly ring around top grinding section, for smooth grinding and no friction.

Comes with protective pouch and pollen scraper!

Glow in the Dark Smoking Glass water pipe with ice catcher

Glass Material

This water pipe is made from heat resistant and clear borosilicate glass material, giving it a sleek and clean look that allows you to watch the bubbles stack as your vapor percolate. Our glass material is also non-reactive, providing you pure tastes with no nasty addition chemical taste.

Beaker Base Shape

The beaker base shape gives the water pipe a scientific look and great stability. The shape is also very easy to clean.

Ice Catcher

The ice catcher allows the water pipe hold multiple ice cubes at the top of the tube. This help the water pipe produce extra-cool vapour. Visit here = https://www.vases.co.nz/

0 notes

Text

TURP Loop and Electrodes by Nikotech

Transurethral resection of prostate is a kind of surgery which is performed in order to treat urine related problems which occurs due to a large prostate. A mix of visual and surgical instruments is therefore inserted with the help of the tip of the genital which goes into the tube that carries urine from your bladder (urethra). Turp electrodes are the most highly required surgical instrument as it helps to treat the genitals of a human body. The right quality and highly advanced material should be used while manufacturing the Turp Electrodes as impacts the most on the positive side of the treatment if the best quality is used for manufacturing. Turp electrodes are also known as cutting loop as it is used for coagulation of soft tissues. It is a one-sided and single dimensional electrode that is generally designed with an objective to deliver frequencies of moderate level.

They provide the best and high quality medical types of equipment that is made of stainless steel and high quality elements. Nikotech has a wide range of collection in almost all its products which are showcased. These products are delivered with safety and secured way in order to prevent any sort of damage or harm to human beings. In order to maintain hygiene a fresh pack of such electrodes are used in patients. All the services and products of Nikotech strive to meet the international standards set

Nikotech is always known for bringing in innovation and not to follow the same routine stuff. Nikotech always works in a way that is customer-centric and bound to today world’s problems. It is located in Bangalore but the services are available worldwide and this is one of the reasons they strive providing high-end services that meet globally set standards. Quality products is said to be Nikotech’s Reputation as they directly link it with the same. They strive in order to achieve premier services at a cost-effective price to its customer base as these factors play an important role.

Creativity and Innovations with a touch of excellence is the heart and soul of the product life cycle at Nikotech and therefore they always strive to welcome changes and such related and also implement the same in order to achieve a highly enhanced and most satisfied product collection. Why go elsewhere when you have the best here. Nikotech is an ISO certified company which explains the raw materials used for manufacturing are high graded one’s

Nikotech has taken an oath to serve the medical industry and always ensure the best is served. They often use “Made in India” tag as their whole end to end production is taken place using Indian materials and machinery only. Also, Nikotech wants to bring in change globally in terms of brand and class with a pride of being an Indian Company. The suppliers of the company are also Highly certified and trustworthy. That being said, all their services are reliable, cost effective and best in range. One such company which has always provided high quality hassle-free Turp Electrodes is Nikotech.

Companies in the medical sector often end up with issues in terms of quality and this prones at reducing their value in the society but when we talk about Nikotech we can see changes drastically because of their highly skilled team of good amount of experience and their strategic approach towards sustaining in the market.

They have a wide range of best in class top-notch products that are like Double j Stent, Urology Products, Urethral Stent, Facial Dilator, Suprapubic Catheter, Endopylotomy Stent, Nottingham Catheter, PCN Catheter, PCN Catheter Set, Ureteral Catheter, Urethral Dilator set, Ureteral Dilator.

For more information visit website:- https://nikotech.in/

0 notes

Text

The Only Guide To A Drill Rod You’ll Ever Need

A drill rod is a common term in the machinery and manufacturing industries. You can use drill rods to manufacture various tools such as cutters, hot-work tools, machine parts, punches, files, and more. But, do we know how to choose the right drill rod for our needs?

Drill rods differentiate in regards to toughness, durability, temperature resistance, and applications. With so many different material grades and types to choose from, how do we ensure we choose the correct drill rod?

That’s where we come in – this is the only guide you’ll ever need to drill rods, their uses, and applications. This guide is suitable for complete beginners as well as professionals in the industry.

Let’s see some of the most frequently asked questions on the subject of drill rods!

What Is a Drill Rod?

Simply put, a drill rod is a lengthier steel piece of easy-to-mold tool steel that you can use for machining to produce different tools and parts.

Typically, drill rods are round. However, there are some square ones, such as the square kellys you’ll see below. Drill rods are generally soft enough to be machined into their final form.

Drill rods need to have a clean and smooth surface. To manufacture them in this way, we usually use precision grinding.

What Is a Drill Rod Used For?

Drill rods have many different applications. Producers usually use drill rods for manufacturing drilling bits, shafts, dowel pins, reamers, punches, taps, hammers, files, cutting tools, hot-work tools, etc.