#Mechanical Rubber Products Sales Growth

Explore tagged Tumblr posts

Text

Building and Construction Tapes Market: Regional Growth Trends

The Building and Construction Tapes Market is expanding due to the increasing demand for effective bonding, sealing, and insulation solutions in the construction industry. These tapes play a vital role in enhancing durability, efficiency, and aesthetics across residential, commercial, and industrial projects.

Read Complete Report Details of Building and Construction Tapes Market: https://www.snsinsider.com/reports/building-and-construction-tapes-market-2890

Market Segmentation

By Product

Masking Tapes

Commonly used for temporary protection during painting or finishing.

Features: Easy removal without residue, versatility.

Double-Sided Tapes

Ideal for bonding materials without visible fasteners.

Features: Strong adhesion, aesthetics, durability.

Duct Tapes

Multi-purpose tapes for sealing, repairing, and waterproofing.

Features: High strength, moisture resistance.

Others

Specialty tapes like electrical, reflective, or safety tapes.

By Backing Material

Paper

Lightweight and easy to tear.

Applications: Masking and general-purpose uses.

Foil

Offers high resistance to heat and moisture.

Applications: HVAC and roofing.

Polypropylene (PP)

Flexible, lightweight, and cost-effective.

Applications: Packaging and bonding.

Polyethylene (PE)

High durability and weather resistance.

Applications: Outdoor and heavy-duty tasks.

Foam

Provides cushioning and soundproofing.

Applications: Glazing and insulation.

Polyvinyl Chloride (PVC)

Known for toughness and weather resistance.

Applications: Electrical and plumbing.

PET (Polyethylene Terephthalate)

High tensile strength and thermal stability.

Applications: Specialty bonding.

Others

Includes materials like fabric and rubber-based tapes.

By Application

Building Envelope

Tapes for air sealing and water protection.

Flooring

Used for carpet and tile installation.

Windows and Roofing

Tapes for glazing, sealing, and waterproofing.

Doors, Walls & Ceilings

For bonding, insulation, and soundproofing.

HVAC and Electrical

Tapes used for duct sealing and cable management.

Others

Applications like protection and repair.

By Function

Glazing

Tapes for securing and sealing glass panels.

Bonding

Adhesive tapes replacing mechanical fasteners.

Soundproofing and Insulation

Tapes with acoustic and thermal insulation properties.

Cable Management

Tapes for organizing and securing electrical wiring.

Protection

For surface protection during construction.

By Distribution

Direct Sales

Sales directly to contractors, builders, or end users.

Third-Party

Via distributors, retailers, or e-commerce platforms.

By End Use

Commercial

Office buildings, shopping malls, and institutions.

Industrial

Factories, warehouses, and specialized facilities.

Residential

Houses, apartments, and other living spaces.

By Region

North America

High demand due to renovation and green building trends.

Europe

Focus on energy-efficient and sustainable construction.

Asia-Pacific

Booming construction sector due to urbanization and infrastructure development.

Latin America

Growth driven by increasing investments in housing and commercial projects.

Middle East & Africa

Expansion of commercial and industrial infrastructure.

Market Trends and Opportunities

Sustainability Focus: Growing adoption of eco-friendly tapes using recyclable or biodegradable materials.

Advanced Adhesives: Development of high-strength and weather-resistant adhesive formulations.

Smart Tapes: Incorporation of sensors or functional coatings for advanced applications.

Customization: Tailored tapes to meet specific construction needs.

Market Outlook

The Building and Construction Tapes Market is expected to grow steadily through 2031, driven by urbanization, infrastructure investments, and the push for sustainable construction practices. With innovations in materials and adhesive technologies, the market is poised to offer enhanced performance and versatility across applications.

About Us:

SNS Insider is a global leader in market research and consulting, shaping the future of the industry. Our mission is to empower clients with the insights they need to thrive in dynamic environments. Utilizing advanced methodologies such as surveys, video interviews, and focus groups, we provide up-to-date, accurate market intelligence and consumer insights, ensuring you make confident, informed decisions.

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

0 notes

Text

Vacuum Sucker Market Size, Trends, Forecast to 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Vacuum Sucker Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Vacuum Sucker Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Vacuum Sucker?

The global vacuum sucker market size reached US$ 730.8 million in 2023. Looking forward, Reports and Insights expects the market to reach US$ 1,245.2 million in 2032, exhibiting a growth rate (CAGR) of 6.1% during 2024-2032.

What are Vacuum Sucker Market?

A vacuum sucker, or vacuum suction cup, is a device that utilizes negative air pressure to generate a firm grip on a surface. Constructed from flexible materials such as rubber or silicone, it works by removing air from between the sucker and the surface to create a vacuum seal. This seal enables the vacuum sucker to lift, hold, or move objects securely without the need for mechanical fasteners or adhesives. Widely used across industries like manufacturing, logistics, and automotive, vacuum suckers are crucial for handling delicate or heavy items and for automating material handling tasks.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1901

What are the growth prospects and trends in the Vacuum Sucker Market industry?

The vacuum sucker market growth is driven by various factors and trends and factors. The vacuum sucker market is growing rapidly, driven by its crucial applications in manufacturing, logistics, and automotive industries. The increasing need for automation and efficient material handling solutions fuels this growth, as vacuum suckers provide a reliable method for lifting, moving, and positioning objects without the use of mechanical fasteners or adhesives. Technological advancements, such as more durable and versatile suction cups, are also contributing to market expansion. Furthermore, the focus on enhancing production processes and reducing manual labor is boosting the adoption of vacuum suckers across various sectors. Hence, all these factors contribute to vacuum sucker market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Type:

Electric Vacuum Suckers

Pneumatic Vacuum Suckers

Hybrid Vacuum Suckers

By End-Use Industry:

Automotive

Electronics

Food & Beverage

Packaging

Pharmaceutical

Logistics & Warehousing

Others

By Application:

Material Handling

Assembly & Robotics

Pick & Place

Packaging & Palletizing

Inspection & Testing

Others

By Sales Channel:

Direct Sales

Distributors/Wholesalers

E-commerce

Global Market Segmentation by Region:

North America:

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europ

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Piab AB

Schmalz Inc.

Festo AG & Co. KG

SMC Corporation

Aventics GmbH

VACUUBRAND GMBH + CO KG

Vaccon Company, Inc.

SMC Corporation of America

Pneumadyne, Inc.

Schmalz GmbH

Vuototecnica S.p.A.

DESTACO, a Dover Company

ANVER Corporation

AERO-LIFT Vakuumtechnik GmbH

VMECA Co., Ltd.

Discover more: https://www.reportsandinsights.com/report/Vacuum Sucker-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Vacuum Sucker Market Size#Vacuum Sucker Market Share#Vacuum Sucker Market Demand#Vacuum Sucker Market Analysis

0 notes

Text

Enhancing Product Quality with Activated Calcium Carbonate

Activated Calcium Carbonate (ACC) plays a vital role in various industrial applications, ranging from pharmaceuticals to plastics. In India, the manufacturing of ACC has seen a significant upsurge, with several key players contributing to this growth. Among these, Airotech Minerals stands out as one of the leading Activated Calcium Carbonate Manufacturers in India, renowned for its high-quality products and innovative solutions.

Understanding Activated Calcium Carbonate (ACC)

Activated Calcium Carbonate is a refined form of calcium carbonate that has undergone specific processing to enhance its properties. The activation process typically involves the coating of calcium carbonate particles with stearic acid or other compounds, resulting in improved dispersion, better surface properties, and enhanced performance in various applications.

Applications

Plastics and Polymers: ACC is used as a filler and functional additive in plastics to improve mechanical properties, enhance durability, and reduce production costs.

Rubber: In the rubber industry, ACC serves as a reinforcing agent, improving the strength and elasticity of rubber products.

Paints and Coatings: ACC provides improved opacity, brightness, and weather resistance in paints and coatings.

Pharmaceuticals: In the pharmaceutical sector, ACC is utilized as an excipient, ensuring the proper consistency and stability of formulations.

Paper: ACC is used in the paper industry to improve the brightness and opacity of paper products.

Adhesives and Sealants: ACC enhances the properties of adhesives and sealants, providing better adhesion and flexibility.

Why Choose Us?

Advanced Manufacturing Facilities

We boast state-of-the-art manufacturing facilities equipped with the latest technology. These facilities enable the company to produce high-purity ACC with consistent quality. The use of advanced machinery and rigorous quality control processes ensures that every batch of ACC meets stringent industry standards.

Research and Development

Innovation is at the heart of Airotech Minerals' success. The company invests heavily in research and development to continuously improve its products and processes. By staying ahead of industry trends and technological advancements, we can offer cutting-edge solutions that meet the evolving needs of our customers.

Quality Assurance

Quality is a top priority at Airotech Minerals. The company has implemented robust quality assurance measures at every stage of production. From raw material sourcing to final product inspection, stringent quality checks are conducted to ensure the highest standards are maintained. This commitment to quality has earned us certifications from various industry bodies, further validating the excellence of its products.

Sustainable Practices

We are dedicated to sustainable manufacturing practices. The company prioritizes environmental responsibility and strives to minimize its ecological footprint. By adopting eco-friendly processes and reducing waste, Airotech Minerals contributes to global efforts towards sustainability.

Market Presence and Reach

We have a strong presence in both domestic and international markets. The company's products are widely used by leading manufacturers across various industries. By leveraging a robust distribution network, we ensure timely delivery and excellent after-sales support to our customers worldwide.

Conclusion

In the competitive landscape of activated calcium carbonate manufacturing in India, Airotech Minerals has carved a niche for itself through its unwavering commitment to quality, innovation, and customer satisfaction. The company's advanced manufacturing capabilities, focus on research and development, and sustainable practices make it a preferred choice for industries seeking high-performance ACC. We continue to expand our market reach and enhance its product offerings, it remains poised to play a pivotal role in the growth and development of the ACC industry in India and beyond. Discover how our premium Activated Calcium Carbonate can elevate your products. Contact us today to discuss your needs and explore our customized solutions. Reach out now for expert assistance and exceptional customer support.

1 note

·

View note

Text

Tire Recycling Market to Eyewitness Unbelievable Growth (2024-2030)

According to HTF Market Intelligence, theGlobal Tire Recycling market to witness a CAGR of 4.54% during forecast period of 2024-2030. Global Tire Recycling Market Breakdown by Application (Tire-Derived Fuel, Rubberized Asphalt, Tire-Derived Aggregate, Ground Rubber/Crumb Rubber, Others) by Type (Automobile Tire, Rubber Products, Other) by Deployment (Ambient Mechanical Grinding, Cryogenic Grinding, Pyrolysis) and by Geography (North America, South America, Europe, Asia Pacific, MEA). The Tire Recycling market size is estimated to increase by USD Billion at a CAGR of 4.54% from 2024 to 2030.. Currently, market value is pegged at USD Billion.

Get Detailed TOC and Overview of Report @

Tire recycling involves the process of converting used or scrap tires into useful materials.

Some of the key players profiled in the study are Miami Tire Recycling Company (United States), reRubber LLC (United States), L & S Tire (United States), Tire Disposal & Recycling (United States), Ontario Tire Stewardship (Canada), Champlin Tire Recycling (United States), Lakin Tire (United States), New River Tire Recycling (United States), Liberty Tire Recycling (United States), Eldan Recycling A/S (Denmark).

Book Latest Edition of Global Tire Recycling Market Study @ https://www.htfmarketintelligence.com/buy-now?format=1&report=397

About Us:

HTF Market Intelligence is a leading market research company providing end-to-end syndicated and custom market reports, consulting services, and insightful information across the globe. HTF MI integrates History, Trends, and Forecasts to identify the highest value opportunities, cope with the most critical business challenges and transform the businesses. Analysts at HTF MI focuses on comprehending the unique needs of each client to deliver insights that are most suited to his particular requirements.

Contact Us:

Craig Francis (PR & Marketing Manager) HTF Market Intelligence Consulting Private Limited Phone: +15075562445 [email protected]

0 notes

Text

Isoprene Market by End-User | Recent Developments

The European Automobile Manufacturers’ Association noted that approximately 85.4 million motor vehicles were manufactured in 2022 globally. The growth in vehicle production has led to a surge in the adoption of isoprene in tire production. The International Rubber Group reported that global tire production reached around 16.87 million tons in 2021, a 9% increase from 2020. Additionally, isoprene’s resilience, tensile strength, and abrasion resistance have increased its adoption in the rubber and medical industry. As noted by Triton’s report, the global isoprene market will likely register revenue growth at a CAGR of 7.65% over the forecast years 2023-2030.

The demand for eco-friendly tires, synthetic rubber, and footwear has further elevated the deployment of polyisoprene, styrene-isoprene styrene, etc. These factors have also influenced several R&D for effective isoprene applications. For instance, in 2022, researchers at the Leibniz Institute of Plant Biochemistry and Martin Luther University Halle-Wittenberg developed the precise conditions for the enzymatic breakdown of synthetic polyisoprene rubber.

Tire, Adhesive, & Rubber: Expanding Scope of Isoprene Market

Fastest End-user: Tires expected to advance with 7.91% of CAGR during 2023-2030

Tires are essential for vehicles like trucks, tractors, buses, aircraft landing gear, forklifts, etc., as they offer traction and cushioning for wheels. In this regard, polyisoprene tires possess strength, wear resistance, and resilience. Estimates indicate polyisoprene to witness the fastest growth in terms of usability at a CAGR of 8.07% during 2023-2030. While polyisoprene is widely preferred, isobutylene-isoprene’s elastomeric properties are ideal for tire inner and high-pressure tubes. This has prompted various strategic initiatives, including halo butyl rubber manufacturing facilities by Sibur in India, with an annual production target of 60,000 metric tons.

Increased vehicle demand and auto sales benefits have soared the demand for isoprene for tire production globally, especially in the Asia-Pacific. As per estimates, China and Japan contribute around 70% of global tire manufacturing. Therefore, expanding automotive sector creates opportunities for the Asia-Pacific isoprene market.

Revenue Growth: Adhesives expected to register a CAGR of 7.30%

Isoprene adhesives, known for their flexibility, bridge gaps on surfaces in various industries, including aerospace, medical, and electrical. In the medical industry, adhesives find applications in catheters, tapes, etc. In this regard, polyisoprene finds application as a substitute for natural rubber. Isoprene demand in this sector is because it reduces Type I allergies while mitigating nitrosamine synthesis.

As a result, several players have made significant adhesive advancements, significantly boosting the studied market’s growth. For example, in 2020, Henkel inaugurated its largest adhesive production facility in India, supporting nearby regions like the Middle East. Similarly, Arkema established a sizable adhesive factory in Japan, catering to sectors such as hygiene, packaging, labeling, etc.

Due to its outstanding tack and high flexibility, styrene-isoprene styrene (SIS) is also employed to develop adhesives. Estimates suggest SIS is set to expand in volume as it is largely used as a hygiene adhesive in personal care items such as baby diapers, feminine hygiene products, etc. Due to the availability of thermoplastic elastomers in producing these products, the demand for styrene-isoprene styrene is anticipated to increase over the forecast years.

2023-2030: Industrial Rubber Witness Volume Growth at 4.62%

Industrial rubber finds application across diverse sectors such as construction, automotive, and manufacturing. Isoprene in industrial rubber has increased, particularly in construction. It is commonly employed in wall and floor coverings, mechanical rubber goods, geo-membranes, elevators, wiper blades, rubber hoses, etc. Isoprene rubber is well-suited for industrial purposes due to its suspension capacity, rubber reusability, and versatility. The category is projected to expand rapidly due to urbanization, increased disposable income, and population growth.

In addition to the volatile cost of natural rubber, technological advancements in isoprene rubber, including styrene isoprene styrene, polyisoprene, and butyl rubber, fuel the expansion of the isoprene market. For instance, Zeon Corp and Yokohama Rubber Co Ltd co-developed a new technology to produce isoprene from biomass for synthetic rubber production.

Bio-Based Isoprene: A Sustainable Opportunity

The surge in natural gas supply over recent years has shifted ethylene production away from naphtha to ethane cracking. This transition has significantly reduced isoprene production, leading to volatile polyisoprene market prices. Consequently, more sustainable routes for isoprene production involving bio-based products are being explored.

Biomass shows promise as a renewable feedstock for polyisoprene used in the rubber industry. Bio-based isoprene holds potential in various applications, including medical appliances, footwear, rubber tires, fragrances, and polymeric materials. For instance, in 2023, Ginkgo Bioworks collaborated with Visolis to decarbonize tire manufacturing while promoting bio-based isoprene use. Hence, the growing focus on eco-friendly approaches is expected to create affluent opportunities for the isoprene market.

FAQs:

Q1) What is the volume growth of the global isoprene market?

The global isoprene market is expected to witness volume growth at a CAGR of 5.15% during the forecast period 2023-2030.

Q2) Which grades of isoprene are employed across end-user industries?

Polymer and chemical are widely employed grades across end-user industries.

0 notes

Text

Farm Tires

The Farm Tires market is estimated to be valued at over US$ 4,167 million in 2019, with a projected CAGR of 5.3% from 2018 to 2028. Unit sales are expected to reach over 18,676 units in 2019. The global revenue surge in the farm tires market is fueled by the rapid mechanization in the agriculture sector and the increased sales of tractors, a trend expected to persist throughout the forecast period. These tires, known for their large amounts of natural rubber, are designed to handle heavy-duty fieldwork. Additionally, the rising demand for very high flexion tractor tires is anticipated to further drive global sales.

A significant factor boosting global farm tire sales is the potential shift from bias-ply to radial-ply tires, driven by the growing demand for tractors worldwide. The sales of these tires are directly influenced by the increasing market demand for tractors, with over 3.8 million tractors sold between 2017 and 2018. Moreover, technological advancements play a pivotal role in agriculture tire sales, with a surge in demand for very high flexion (VF) and increased flexion (IF) tires due to the growing weight of machinery.

Product development and pricing strategies have a substantial impact on overall sales, with farmers and end-users leaning towards cost-effective tire options. This heightened competition in the sector.

Global Farm Tires Market Size and Forecast: Regional Analysis

Asia Pacific Dominates: Asia Pacific dominated global sales in 2018, driven by substantial sales in China and India, which accounted for over half of the total tractor sales in 2018. The region still holds untapped market potential for farm tire manufacturers and vendors. The aftermarket segment holds a significant market share in Asia Pacific. While OEM presents a substantial revenue opportunity, the limited number of tractor and heavy machinery manufacturers has resulted in fewer farm tire vendors. The region's demand is led by tractors and harvesters, followed by trailers and suits. New entrants and small-scale players often focus on the aftermarket to maintain agility.

North America - A Key Destination: North America is a crucial market for manufacturers, registering a slowdown in net agriculture output in 2017. However, this had a negligible impact on overall farm tire sales, indicating the relatively higher spending capacity in the region. While the industry is experiencing optimistic growth, declining commodity costs could impact farmers' spending capacity, leading to sluggish demand for agriculture tires. Unlike Asia Pacific, North America is expected to witness moderate growth in sales, with market consolidation and leading players holding a major share.

Global Farm Tires Market Size and Forecast: Competition Landscape

The industry is highly competitive, with a significant number of midsize and large-scale enterprises. The majority of manufacturers focus on supplying tires for tractors below 40 HP worldwide. Key players in the Farm Tires market include:

Bridgestone Corp.

Titan Corporation

Balkrishna Industries Limited

Sumitomo Rubber Industries Ltd.

Continental AG

Goodyear Tire & Rubber Company

TBC Corporation

Yokohama Rubber Company

Industry Segmentation

By Vehicle Type:

Tractors

Conventional Tractors

Driverless Tractors

Harvesters

Implements

Others

By Tire Type:

Bias

Radial

By Distribution Channel:

OEM

Aftermarket

0 notes

Text

Global Homogenizers Market Analysis, Top Players, Regions, Market Segments and Forecasts to 2027

The Global HOMOGENIZERS MARKET was valued at USD 1715.15 Million in 2022 and is expected to expand to USD 2018.95 Million in 2030 at a CAGR of 1.78% during the forecast period 2023- 2030.

A part of laboratory or industrial machinery used to mix two non-soluble products into an even consistency that helps to reduce the separation is referred to as Homogenizer.

Homogenizers are industrial equipment used to mix, emulsify, or homogenize various substances, particularly in industries such as food and beverage, pharmaceuticals, cosmetics, and biotechnology. They are essential for achieving a consistent and uniform product quality. Here are some key points about the global homogenizers market

Market Drivers

One of the main factors that drive the market growth is the rising demand for homogenizers in the food and dairy industry as it is used in the food and beverage industry for processing food and manufacturing many dairy products like skimmed milk, and cheese through the blending process.

Additionally, increasing demand for ultrasonic homogenizers is boosting market growth as a few factors like they are normally used for combining several consumer durable products and cosmetics like skin lotions, lubricants, pharmaceutical ointments, and fuels because of their capacity to disperse powders in liquid.

Market Restraints

The main restraining factors that hamper the market growth are several issues related to homogenizers like a heavy capital investment to maintenance and installation of homogenizers, increasing energy and power costs, and growing regulatory approval from organizations.

Market Segmentation

The global Homogenizers market is segmented based on Product, Applications, and region. On the basis of Product, it is segmented into Ultrasonic, Pressure, and Mechanical. Based on Applications, it is segmented into Paper, Ceramics, Fiberglass, Paints and Coatings, Rubber, Plastics, and Others. Based on region, it is segmented into North America, Europe, Asia Pacific, Latin America, Middle East & Africa.

Regional Analysis

Asia Pacific region is likely to dominate the global market owing to the rising demand for processed and packaged food in this region because of the increasing urbanization in countries like India, Taiwan, Japan, China, etc.

North American region is expected to witness substantial growth because of the region’s noteworthy demand for packaged and processed foods from its growing population.

Request A Free Sample: https://qualiketresearch.com/request-sample/Homogenizers-Market/request-sample

𝐌𝐚𝐣𝐨𝐫 M𝐚𝐧𝐮𝐟𝐚𝐜𝐭𝐮𝐫𝐞𝐫𝐬

· GEA Group

· Aktiengesellschaft

· Sonic Corp.

· Avestin Inc.

· PHDTechIntl

· IDEX (U.S.),

· OMA.

· NETZSCH-Feinmahltechnik GmbH

· FBF ITALIA Srl

· SIMES S.A.

· Krones AG

About Us:

QualiKet Research is a leading Market Research and Competitive Intelligence partner helping leaders across the world to develop robust strategy and stay ahead for evolution by providing actionable insights about ever changing market scenario, competition and customers.

QualiKet Research is dedicated to enhancing the ability of faster decision making by providing timely and scalable intelligence.

QualiKet Research strive hard to simplify strategic decisions enabling you to make right choice. We use different intelligence tools to come up with evidence that showcases the threats and opportunities which helps our clients outperform their competition. Our experts provide deep insights which is not available publicly that enables you to take bold steps.

Contact Us:

6060 N Central Expy #500 TX 75204, U.S.A

1 214 660 5449

1201, City Avenue, Shankar Kalat Nagar,

Wakad, Pune 411057, Maharashtra, India

91 9284752585

Sharjah Media City , Al Messaned, Sharjah, UAE.

+91 9284752585

0 notes

Text

Recovered Carbon Black Market: Driving Circular Economy Initiatives

Market Overview:

Recovered carbon black (rCB) is a form of recycled carbon black produced from waste tyres and other rubber products. It is used in the production of various rubber goods and applications such as tires, mechanical rubber goods, and others.

Market Dynamics:

Two major drivers aiding the growth of recovered carbon black market are rising concerns over environmental pollution and stringent regulations regarding carbon emissions. Growing automotive industry worldwide has substantially increased the volume of discarded tires, which serves as a key source for recovered carbon black production. Various countries have implemented regulations banning the use of certain types of carbon black and enforcing the use of recovered carbon black to reduce carbon footprint. Also, recovered carbon black offers comparable quality and performance to that of virgin carbon black at a lower cost. This is encouraging manufacturers to increase reliance on rCB over conventional carbon black.

Major Driver: Increasing demand for carbon black from the tire industry

The tire industry accounts for around 70% of the total recovered carbon black demand globally. With rapid growth in the automotive industry, especially in emerging economies such as China and India, the demand for tires has increased significantly over the past few years. Recovered carbon black finds wide application in tire manufacturing due to its comparable physical and chemical properties to virgin carbon black. It can replace up to 30% of virgin carbon black content in tires. The demand for recovered carbon black from tire manufacturers is expected to continue rising with growing vehicles production and sales around the world.

Major Driver: Stringent environmental regulations regarding carbon emissions

Burning of used tires and other rubber products results in the release of various air pollutants and greenhouse gases into the environment. Many governments and regulatory bodies across major economies have imposed strict regulations targeting reduction of carbon footprint from such uncontrolled burning. Recovered carbon black production involves recycling of carbon content from old tires and rubber goods in an environmentally-controlled process, thereby minimizing air pollution. The end-product, recovered carbon black, also has a lower carbon footprint than virgin carbon black. Such companies are now under legal obligation to use recovered carbon black in their operations where possible. This is a major factor driving its higher demand.

Major Restraint: High costs associated with recovered carbon black production

While recovered carbon black yields environmental benefits, its production process entails higher costs compared to virgin carbon black. The expenses involved in collection, sorting, preprocessing and refining of used tires add to its overall manufacturing costs. Also, the capital expenditure required for setting up recovered carbon black plants is significant. These financial challenges pose a restrain to widespread adoption of this material. Many buyers prefer cheaper virgin carbon black if not mandated otherwise by regulations. Cost optimization through economies of scale and technological advancements is critical to overcoming this restraint.

Major Opportunity: Increasing requirement in non-tire rubber goods

Though the tire industry dominates its consumption currently, recovered carbon black holds promising growth opportunities in other rubber product domains as well. Rubber materials find diverse applications across industries like automobile interior & exterior parts, wires & cables, hoses & belts, footwear, flooring, seals & gaskets, and more. With growing preference for green and recycled materials, demand for recovered carbon black is rising from these non-tire sectors. Its novel properties provide functional benefits in products. If large buyers from these industries incorporate recovered carbon black in their materials, itsaddressable market scope will increase multifold in the coming years.

Major Trend: Advancements in carbon black recovery technologies

Continuous innovations are taking place to develop improved and cost-effective methods for recycling carbon content from end-of-life rubber products. New pretreatment and separation techniques enhance recovered carbon black yield and quality. Novel thermal cracking and refining mechanisms optimize energy usage. Adoption of Industry 4.0 technologies like IoT, AI, big data for predictive maintenance and process optimization helps recovered carbon black plants achieve higher efficiencies. Some pioneering companies even utilize carbon dioxide from flue gases to synthesize carbon black, creating a carbon negative footprint. As newer, greener technologies become commercially viable, production costs will reduce, driving the recovered carbon black industry to its next phase of growth.

#Recovered Carbon Black Market Share#Recovered Carbon Black Market Growth#Recovered Carbon Black Market Demand#Recovered Carbon Black Market Trend#Recovered Carbon Black Market Analysis

0 notes

Text

Top 4 players in US Black Carbon market

Buy Now

STORY OUTLINE

Cabot Corporation: A leading contributor of US Black Carbon market since 1882. Their products are known to provide UV protection and conductivity.

Birla Carbon: An Indian flagship business with more than 160 years of experience in the Black Carbon business.

Continental Carbon Company: Providing Black Carbon products in lines of Industrial Rubber Carbon Black, Tire Rubber Carbon Black, and Specialty Carbon Black since 1936.

Orion Engineered Carbons: Providing Black carbon products majorly in two areas, i.e., Rubber Black Carbon and Specialty Black Carbon for more than 160 years.

According to Ken Research, the United States Black Carbon market is anticipated to become a ~USD 3 Bn. industry by 2028 by growing at a CAGR of ~2.5%.

The US Carbon Black market is rapidly growing and is anticipated to attain a significant level of growth in the upcoming years.

There are many reasons behind the growth of US Carbon Black market. Some of these reasons include increasing automotive sales, industrial growth and increase in urbanization rates, along with rise in the demand for rubber goods.

Various companies and players are contributing to their best efforts in the growth of the US Black Carbon market.

This article aims to put light on the contributions done by the major players towards the growth of the US Black Carbon market.

1.Cabot Corporation

Click here know more about this report

Founded in 1882, headquartered in Boston, Massachusetts, having more than 4000 employees worldwide, and presence in more than 20 countries along with a total revenue of USD 4 Bn. in 2022, this chemical company is a leading contributor of US Black Carbon market.

During 1993, their team was successful in developing a method or process of modifying carbon’s surface, which in turn allowed people to be able to change or modify the carbon surface with other chemicals.

This discovery also led to the development of various other technologies such as printer ink and inject colorants.

The products made by this organization has various applications in various fields such as consumer rubber products, adhesives & sealants, construction, digitalization, inject technology, oil, gas & mining, digitalization, fiber, plastics, tires, etc.

When it comes to Black Caron, this chemical company happens to be the largest producer of it. Some of the popular Black Carbon products offered by this organization include VULCAN, BLACK PEARLS, REGAL, MOGUL, ELFTEX, STERLING, MONARCH, etc.

One of the most amazing feature of their specialty carbons is that they are known to provide ultraviolet protection, and conductivity. Furthermore, these carbons are generally used in the areas of coatings, plastics, printing and packaging.

2.Birla Carbon

Click Here to Download a Sample Report

Birla Carbon is one of the flagship business of the parent company Aditya Birla Group. This flagship business is the largest producer of carbon black and is a well-established business not only in the US Carbon Black but in the whole world when it comes to black carbon.

One of the interesting facts about this organization is that it has more than 160 years of experience when it comes to the Carbon industry. Moreover, this organization has 16 manufacturing sites, 2 corporate offices, 2 technology centers, and 8 offices situated in the whole world.

Their manufactured Black Carbon is primarily used in areas of Tires, Specialty Blacks, plastics, electronic products, and mechanical rubber goods.

Last year, they also have opened their remote black carbon showroom which is primarily done to get a knowledge of benefits along with applications of black carbon products.

Their black carbon primarily come in two types, i.e., Industrial and Rubber. Former’s products include COPEBLACK, RAVEN, and CONDUCTEX. While the latter’s products include STATEX and FURNEX.

Recently, they also announced that they aspire to achieve zero carbon emissions by the year 2050.

To achieve this aspiration, they are also following the Green Finance framework. Birla Carbon is also keen to achieve sustainability excellence. In fact, last year the celebrations for their decade of sustainable excellence were also done.

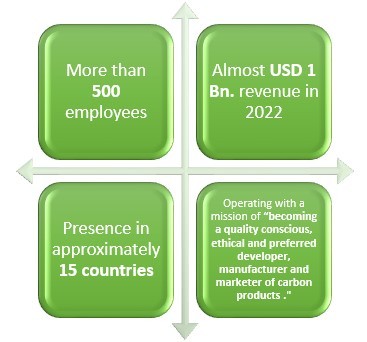

3.Continental Carbon Company

Headquartered in Houston, Texas; with more than 500 employees and presence in almost 15 countries, the Continental Carbon Company is a leading American company in the US Black Carbon market. This company has been in this market since 1936.

They have various lines of work within their Black Carbon range. Industrial Rubber Carbon Black, Tire Rubber Carbon Black, and Specialty Carbon Black are primarily the three of their product lines.

Their Industrial Rubber Carbon Black is suitable for many things such as flex strength for belts & hoses, weather stripping, abrasion resistance for footwear, and commercial roofing. The products in this line include N550, N650, N660, N683, N762 and N774.

Their Tire Rubber Carbon Black is primarily provides fuel mileage, abrasion resistance, treadwear, hysteresis. The products in this category include N234, N326, N330, N351, LH30, N550, N650 and N660.

Their Specialty Carbon Black typically provides conductivity, UV protection, and pigmentation. The products in this category primarily include SBX152, SBX252, SBX352, SBX452, SBX552, SBX652, SBX256, SBX656, SBX 251, and SBX351.

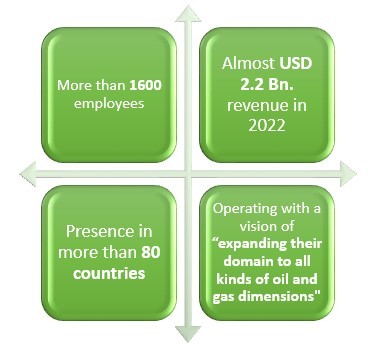

4.Orion Engineered Carbons

Click here Request for custom report

Operating in the Black Carbon market for more than 160 years, this German company is a well-established company in the US Black Carbon market. It has its headquarters situated in Luxembourg, Europe. On the other hand, its executive offices are situated in Houston, Texas, US.

This company was formed in the year 2011 when the Evonik Industries decided to sell off their Black Carbon business. Now this chemical company is known to be the pigment black’s largest producer, and rubber blacks’ third largest producer in the world.

Their product lines can be broadly divided into two categories: Rubber Black Carbon and Specialty Black Carbon. The former is primarily used in the tire industry while the latter is typically used paints, coatings, and lithium-ion batteries.

Footwear, Wiper Blades, Gaskets, Seals, Extruded Profiles, Tubes, Rubber flooring, Anti-vibration engine mounts, Seals, Belts, etc. are the primary applications of their Black Carbon products.

Their Black Carbon products primarily include Thermal Blacks, Furnace Blacks, Specialty Gas Blacks, Lamp Blacks, Acetylene Blacks, etc.

#US Carbon Black market#US Carbon Black market forecast#US Carbon Black market share#US Carbon Black market size#US Carbon Black market growth#US Carbon Black market analysis#US Carbon Black Industry#United States Carbon Black market#US Carbon Black market trends#US Carbon Black industry challenges#Leading Service providers US Carbon Black Market#Leading players in US furnace black market#Competitors in US thermal black market#Emerging players US Carbon Black industry#Major players in US Carbon black sector#Top 5 Carbon black manufacturers US#Automobile companies in Carbon Black market US#Top players US lamp black market#Investment US Carbon Black Market#Funds raised startups furnace black market#Thermal Black in US Carbon Black market#Furnace Black in US Carbon Black market#Tires and Rubber products in Carbon Black market US#Investors in US Carbon Black market#Venture Capitalists in US Carbon Black market#US Soot Carbon Black market#US Carbon Black particles market#US residual Carbon Black market#US amorphous carbon black market#US Carbon black sector

0 notes

Text

Isoprene Market by End-User | Recent Developments

The European Automobile Manufacturers’ Association noted that approximately 85.4 million motor vehicles were manufactured in 2022 globally. The growth in vehicle production has led to a surge in the adoption of isoprene in tire production. The International Rubber Group reported that global tire production reached around 16.87 million tons in 2021, a 9% increase from 2020. Additionally, isoprene’s resilience, tensile strength, and abrasion resistance have increased its adoption in the rubber and medical industry. As noted by Triton’s report, the global isoprene market will likely register revenue growth at a CAGR of 7.65% over the forecast years 2023-2030.

The demand for eco-friendly tires, synthetic rubber, and footwear has further elevated the deployment of polyisoprene, styrene-isoprene styrene, etc. These factors have also influenced several R&D for effective isoprene applications. For instance, in 2022, researchers at the Leibniz Institute of Plant Biochemistry and Martin Luther University Halle-Wittenberg developed the precise conditions for the enzymatic breakdown of synthetic polyisoprene rubber.

Tire, Adhesive, & Rubber: Expanding Scope of Isoprene Market

Fastest End-user: Tires expected to advance with 7.91% of CAGR during 2023-2030

Tires are essential for vehicles like trucks, tractors, buses, aircraft landing gear, forklifts, etc., as they offer traction and cushioning for wheels. In this regard, polyisoprene tires possess strength, wear resistance, and resilience. Estimates indicate polyisoprene to witness the fastest growth in terms of usability at a CAGR of 8.07% during 2023-2030. While polyisoprene is widely preferred, isobutylene-isoprene’s elastomeric properties are ideal for tire inner and high-pressure tubes. This has prompted various strategic initiatives, including halo butyl rubber manufacturing facilities by Sibur in India, with an annual production target of 60,000 metric tons.

Increased vehicle demand and auto sales benefits have soared the demand for isoprene for tire production globally, especially in the Asia-Pacific. As per estimates, China and Japan contribute around 70% of global tire manufacturing. Therefore, expanding automotive sector creates opportunities for the Asia-Pacific isoprene market.

Revenue Growth: Adhesives expected to register a CAGR of 7.30%

Isoprene adhesives, known for their flexibility, bridge gaps on surfaces in various industries, including aerospace, medical, and electrical. In the medical industry, adhesives find applications in catheters, tapes, etc. In this regard, polyisoprene finds application as a substitute for natural rubber. Isoprene demand in this sector is because it reduces Type I allergies while mitigating nitrosamine synthesis.

As a result, several players have made significant adhesive advancements, significantly boosting the studied market’s growth. For example, in 2020, Henkel inaugurated its largest adhesive production facility in India, supporting nearby regions like the Middle East. Similarly, Arkema established a sizable adhesive factory in Japan, catering to sectors such as hygiene, packaging, labeling, etc.

Due to its outstanding tack and high flexibility, styrene-isoprene styrene (SIS) is also employed to develop adhesives. Estimates suggest SIS is set to expand in volume as it is largely used as a hygiene adhesive in personal care items such as baby diapers, feminine hygiene products, etc. Due to the availability of thermoplastic elastomers in producing these products, the demand for styrene-isoprene styrene is anticipated to increase over the forecast years.

2023-2030: Industrial Rubber Witness Volume Growth at 4.62%

Industrial rubber finds application across diverse sectors such as construction, automotive, and manufacturing. Isoprene in industrial rubber has increased, particularly in construction. It is commonly employed in wall and floor coverings, mechanical rubber goods, geo-membranes, elevators, wiper blades, rubber hoses, etc. Isoprene rubber is well-suited for industrial purposes due to its suspension capacity, rubber reusability, and versatility. The category is projected to expand rapidly due to urbanization, increased disposable income, and population growth.

In addition to the volatile cost of natural rubber, technological advancements in isoprene rubber, including styrene isoprene styrene, polyisoprene, and butyl rubber, fuel the expansion of the isoprene market. For instance, Zeon Corp and Yokohama Rubber Co Ltd co-developed a new technology to produce isoprene from biomass for synthetic rubber production.

Bio-Based Isoprene: A Sustainable Opportunity

The surge in natural gas supply over recent years has shifted ethylene production away from naphtha to ethane cracking. This transition has significantly reduced isoprene production, leading to volatile polyisoprene market prices. Consequently, more sustainable routes for isoprene production involving bio-based products are being explored.

Biomass shows promise as a renewable feedstock for polyisoprene used in the rubber industry. Bio-based isoprene holds potential in various applications, including medical appliances, footwear, rubber tires, fragrances, and polymeric materials. For instance, in 2023, Ginkgo Bioworks collaborated with Visolis to decarbonize tire manufacturing while promoting bio-based isoprene use. Hence, the growing focus on eco-friendly approaches is expected to create affluent opportunities for the isoprene market.

FAQs:

Q1) What is the volume growth of the global isoprene market?

The global isoprene market is expected to witness volume growth at a CAGR of 5.15% during the forecast period 2023-2030.

Q2) Which grades of isoprene are employed across end-user industries?

Polymer and chemical are widely employed grades across end-user industries.

#isoprene market#isoprene#chemicals & materials#polymers & resins#triton market research#market research reports

0 notes

Text

Viscose Staple Fibre Market Size, Share, Growth, Major Players, Industry Analysis by Forecast

According to ChemAnalyst report, “Global Viscose Staple Fibre (VSF) Market: Plant Capacity, Production, Operating Efficiency, Demand & Supply, End Use, Distribution Channel, Region, Competition, Trade, Customer & Price Intelligence Market Analysis, 2015-2030”, global Viscose Staple Fibre (VSF) market has shown considerable growth in historic period and is projected to achieve a healthy CAGR of 4.78% during the forecast period. Due to continuous growing demand for bio-degradable, eco-friendly, and sustainable products from consumers, there is expected an increase in the demand of VSF for its lightweight and heat absorbing properties from Industries such as apparel and textiles. As VSF possess the ability to be light, breathable, and highly absorbent of heat and moisture, they are highly used in the manufacturing of soft, smooth, and durable fabrics for various sectors.

Viscose Staple Fibre Overview:

Viscose Staple Fibre (VSF) also known as artificial cotton Fibre is a versatile natural and biodegradable Fibre which is similar to cotton in texture. Due to its versatility as it is breathable, flexible, easy to blend and have excellent color retention, VSF makes an incredible choice for many textile factories to manufacture fabrics for chiffon, crepe, lace, outerwear, and others. VSF is a natural fibre that is made of cellulose from the pulp that dissolves including cotton pulp and wood pulp. The demand of viscose fibres in woven and non-woven textiles industry is expected to drive the VSF market in upcoming years. The production of the VSF increased rapidly up to 2.8 million tonnes due to the high demand in non-woven textiles applications. The insufficient availability and supply of Fibres including cotton leading to its multiple increase in prices worldwide would further propel the demand for Viscose Staple Fibres.

Read Full Report Here: https://www.chemanalyst.com/industry-report/viscose-staple-fibre-market-607

Viscose Staple Fibre Applications:

VSF has numerous applications such as Yarns: VSF are highly used in the making of viscose embroidery threads, cord, novelty Yarns, chenille etc; Fabrics: As VSF blends easily with other fibres, it is widely used in making crepes, lace, outerwear etc; Apparels: women’s, men’s and kid’s clothing are made using VSF; Domestic textiles: Viscose fibres are used in blankets, curtains, hosiery, tablecloth and others; Industrial textiles: VSF are also used in the manufacturing of mechanical rubber, goods such as tires, belts, hoses, agriculture and other textile industries.

Environmental Impact:

Chemicals that are being used in the production of Viscose such as Carbon disulphide, are toxic and can lead to adverse health effects. However, VSF is a natural fibre and have a cotton like structure, which is not considered hazardous or polluting. When it comes to biodegradation, the viscose staple fibre is highly accessible to water and microorganisms which makes them completely biodegradable. The new method that has been Introduced lately for the manufacturing of VSF is known as Lyocell Process in which N-Methlymorpholine N-oxide is used as a solvent which produces a very little waste product making it more sustainable and environmentally friendly.

Due to the onset of the Covid-19, The production, and sales of VSF were highly impacted due to the fall in textile sector. Due to government’s restrictions and nationwide lockdowns, the manufacturers halted their operations, which affected the global supply chain and distribution. However, there is expected an Improvement in the upcoming year as the economy is reopening and operations are resuming by the companies. Rising demand from woven and non-woven textile industry is driving an uprise in global VSF market. As cases due to COVID increased, the manufacturers also started focusing on the production of mask which further increased the overall market of non-woven Fibres, that is used for production of masks for example Lenzing AG, which is a leading company based in Austria which started the safety masks production in 2020 following numerous increases in the demand.

Viscose Staple Fibre Regional Outlook:

Region wise, Asia-Pacific region dominates the VSF market followed by Europe and North America. The dominance of the APAC region is highly impacted by the continuous growth of textile industry across Asian countries leading a huge demand for VSF for various applications. The Asian countries including China, Japan, India and South Korea accounts for the largest world mill consumption of Viscose Staple Fibre for textile applications, whereas for non-woven applications, Western Europe dominates the VSF mill consumption. China has become the largest exporter of grey Viscose Staple fabrics followed by Indonesia. The production and demand of VSF has declined over the last few years worldwide. However, former Soviet Union countries and Eastern European countries has shown an increase in the production and demand of VSF over the last several years. The market price and expenditure pattern of Australia’s textile and yarn industry similar to that of the U.S. industry.

Request Sample Report: Viscose Staple Fibre (VSF) Market Analysis Report

Some of the major players operating in global Viscose Staple Fibre market are Aditya Birla Chemicals, Glanzstoff, Jilin Chemical Fibre Group co., Ltd, Kelheim Fibres GmbH, Nanjing Chemical Fibre Co. Ltd, Xingda Chemical Fibre Co. Ltd, Lenzing AG, Tangshan Sanyou Group Xingda Chemical Fibre Co., Ltd, Xinjiang Zhongtai Chemical Co. Ltd, Sateri Holding Ltd. and Others.

“Being linked to the downstream application such as Clothing, Auto Industries and home textiles etc, the global Viscose Staple Fibre Industry has shown a significant growth along with the growing population and shifting in the consumer preference. It is projected that in the upcoming years, India is going to become the world's fifth biggest consumer market. In addition, growing per capita income worldwide poised a stronger outlook to the country’s VSF demand. The nationwide lockdown and government’s restrictions affected the global supply chain logistics and caused immediate shortage of raw materials hence increased the prices of VSF in textile industry. Meanwhile, China serves as the major region for growth as well as with sufficiently installed capacities. With new competitors emerging across the Asian acetone market, it is extremely important to keep an eye which region will grab the biggest market share during the forecast period .” said Mr. Karan Chechi, Research Director with TechSci Research, a research-based management consulting firm promoting ChemAnalyst worldwide.

About Us:

ChemAnalyst is a subsidiary of Techsci Research, which was established in 2008, and has been providing exceptional management consulting to its clients across the globe for over a decade now. For the past four years, ChemAnalyst has been a prominent provider of Chemical commodity prices in more than 15 countries. We are a team of more than 100 Chemical Analysts who are committed to provide in-depth market insights and real-time price movement for 300+ chemical and petrochemical products. ChemAnalyst has reverberated as a preferred pricing supplier among Procurement managers and Strategy professionals worldwide. On our platform, we provide an algorithm-based subscription where users can track and compare years of historical data and prices based on grades and incoterms (CIF, CFR, FOB, & EX-Works) in just one go.

The ChemAnalyst team also assists clients with Market Analysis for over 1200 chemicals including assessing demand & supply gaps, locating verified suppliers, choosing whether to trade or manufacture, developing Procurement Strategies, monitoring imports and exports of Chemicals, and much more. The users will not only be able to analyze historical data for past years but will also get to inspect detailed forecasts for the upcoming years. With access to local field teams, the company provides high-quality, reliable market analysis data for more than 40 countries.

ChemAnalyst is your one-stop solution for all data-related needs. We at ChemAnalyst are dedicated to accommodate all of our world-class clients with their data and insights needs via our comprehensive online platform.

Contact Us:

ChemAnalyst

B-44 Sector-57 Noida,

National Capital Region

Tel: 0120-4523990

Mob: +91-8882805349

Email: [email protected]

Website: https://www.chemanalyst.com/

0 notes

Text

Genesis Gas Solutions Pvt Ltd, a subsidiary of Vikas Lifecare, has received its first-ever orders for Ultrasonic Gas Meters valued at INR 30 Million.

Vikas Lifecare Limited has announced that its subsidiary, Genesis Gas Solutions Pvt. Ltd (Genesis), has received orders for Ultrasonic Gas Meters valued at INR 30 Million. These meters are highly accurate and reliable as they measure the gas volume flow by analyzing the transit times of high-frequency sound waves. They are particularly useful for Large Diameter Gas Pipe Lines, where mechanical drive meters can result in commercial losses.

The Ultrasonic meters supplied by Genesis will be used by various City Gas Distribution companies as part of their Field Regulating Skid (FRS). Genesis had previously signed an agreement with SICK AG, Germany to provide Ultrasonic Gas Meters (FlowSic 500) for Industrial and Commercial gas customers. Genesis has also integrated its own MDM solution, EnerDash, with the Ultrasonic meters (FlowSic 500) to enhance their functionality.

About Genesis Gas Solutions Pvt Ltd: Genesis Gas Solutions Pvt Ltd was established in 2017 by a team of technopreneurs and finance professionals with a focus on the City Gas Distribution sector in India. The company is a pioneer in Smart Gas and Water Metering and currently holds about 20% of the Domestic Gas Metering market share in India.

Genesis has achieved several notable accomplishments in the industry, including:

Supplying Gas meters to various CGDs of India and providing after-sales services under an exclusive supply arrangement, having supplied over 4 lakh meters of Hangzhou Beta Meter Co. Ltd.

Providing Smart Meter Interface Unit (MIU) and associated services to Indraprastha Gas Ltd, a JV of GAIL, BPCL, and the Government of NCT of Delhi.

Offering smart metering solutions (AMR & Prepaid) with RF-based Lora WAN technology in partnership with Tata Communications.

Developing India’s first Meter Data Management (MDM) and Head end system for Gas utilities, which operates over 150,000 smart meters in India.

Creating its own network solution to complement its field devices, which is being recognized by global companies such as Honeywell and Hitachi, who are testing these products for their projects worldwide.

About Vikas Lifecare Ltd: Vikas Lifecare Ltd. (VLL) is a certified ISO 9001:2015 company that trades and manufactures polymer, rubber compounds, and additives for plastics, synthetic, and natural rubber. The company operates in various business segments, including Polymer & Rubber Commodity Compounds and MasterBatches. VLL contributes to the Environment Protection initiatives of the Government of India by manufacturing up-cycled compounds from industrial and post-consumer waste materials like EVA, PVC, PP, PE, etc., and fulfilling the mandated EPR obligations for conglomerates consuming large amounts of plastic products and packaging materials.

VLL is a Del-Credere agent of ONGC Petro Additions Limited, a public sector undertaking producing a wide range of base polymers and commodity plastic raw materials.

Recently, VLL has diversified its business interests beyond raw materials and entered the B2C segment with a range of consumer products, including FMCG, Agro, and Infrastructure Products. The company plans to expand its business growth through intricately planned and selected product portfolios via acquisitions, joint ventures, and tie-ups.

VLL’s subsidiary, Genesis Gas Solutions Pvt. Ltd., is a major supplier of Smart Gas Meters to all major Gas Distribution Companies in India for domestic and commercial consumers. Genesis is a pioneer in Smart Gas and Water Metering and currently holds about 20% of the Domestic Gas Metering business share in India.

The company’s securities are listed on both the Stock Exchanges, BSE (Scrip Code: 542655) and NSE (Symbol: VIKASLIFE).

1 note

·

View note