#MdfBoard

Explore tagged Tumblr posts

Text

MDF Board Wholesale Dealers - Bulk Orders Welcome

Experience exceptional quality and service from our MDF board distributors. Reliable, efficient, and cost-effective solutions tailored to your projects, ensuring durability and satisfaction every time.

Visit us:- https://e3groupindia.com/mdf-manufacturer-in-india/

#mdfboard#e3group#mdfmanufacturer#Mdf Board manufacturing Company in India#mdf board supplier#mdf board dealer

0 notes

Text

Top MDF Board Manufacturers and Suppliers in India: Quality Products for Your Projects

Our extensive network comprises trusted MDF board manufacturing companies, dealers, and suppliers across India. We provide seamless connections to reliable sources for high-quality MDF boards, catering to furniture, construction, and interior design projects.

Visit us:- https://e3groupindia.com/

#mdfboard#mdfmanufacturers#mdfsuppliers#indianmdf#qualitymdf#furnitureboards#constructionmaterials#interiordesign#woodalternatives#sustainablematerials#mdfdealer#buildingsupplies#homeimprovement#woodworking#ecofriendlymaterials#indianmanufacturing#mdfproducts#qualityconstruction#furniturematerials#buildingmaterials

0 notes

Text

Decorative Kettle - Exclusively hand-painted in Kerala Mural art. • Material - High-grade Aluminium • Design - Kerala Mural art • Unique Designs made exclusively by our in-house artists.. • Beautify your mantlepiece with this retro look! • Suspend it from the ceiling in a group as a faux-chandelier. • Can be used as a table top accent, flower vase, and plant vase and much more. • An ideal gift for your loved ones of all ages • Note - As each painting is 100% hand-painted, actual paintings may differ slightly in details from the displayed product image. The price of the product is ₹ 999/- Click to buy from our website: https://gifts.penkraft.in/Product-Details/PK-G-16/Decorative-Kettle-1-by-Penkraft---Exclusively-hand-painted-in-Kerala-Mural-art/89 or from Amazon India: https://www.amazon.in/dp/B0B7BBQXQR For queries/assistance: +91 9136024968

#Gifts#Penkraft#Gifting#Giftsforsale#WallDecor#Creativity#Souvenir#handpaintedart#handpaintedgifts#love#instagood#explore#picoftheday#Modernart#becreative#knifepainting#mdf#mdfart#mdfboard#homedecor#keralamural#kettle#keralamuralart#keralamuralpainting#muralart

0 notes

Text

0 notes

Photo

Kabhi kabhi Aditi ko bhi Home Décor mein interest aata hai😉😉 Get MDF Boards jinko endlessly coustomize karke you can get your dream home ready is days! Swipe for some fun suggestions, and visit the site for for! Happy Shopping? Happiest Shopping!😚✌🏼 #homedecor #mdfboard #mdfganeshji #mdfart #mdfproducts #beautifulhomes #customise #homedecorations #mdfproducts #craftbecho (at Bangalore, India) https://www.instagram.com/p/CpxVuIZSE6x/?igshid=NGJjMDIxMWI=

#homedecor#mdfboard#mdfganeshji#mdfart#mdfproducts#beautifulhomes#customise#homedecorations#craftbecho

0 notes

Text

MDF Board– A Convenient Material For Interior Decor

If you follow interior design trends, you’ve likely encountered MDF popping up across decor elements, cabinetry, and furniture projects. MDF (medium-density fiberboard) offers an affordable, versatile material rapidly replacing traditional plywoods and solid woods in fabrication. This article will explore what exactly MDF is, how it’s made, and diverse applications taking the DIY and interiors world by storm. By the end, you’ll see why MDF appeals to everyone from custom furniture workshops to weekend renovation warriors.

What is MDF Board?

MDF stands for medium-density fiberboard, comprised of finely milled wood fibers combined with bonding adhesives and pressed into solid boards. It was initially developed in the 1960s as an affordable alternative to plywood and solid timber boards which were becoming prohibitively expensive.

As a manufactured composite wood product, MDF consistency supercedes the inherent variation found in natural woods subject to knots, grains, and warping. The homogenous texture across MDF boards allows for uniform machining, finishing, and decorative treatments. Meanwhile, density properties provide adequate strength where needed – such as shelving support pieces or furniture frames.

While similarly manufactured like particleboard, MDF contains much finer wood fibers (typically hardwood residual waste) and more powerful resin adhesives. The result is greater durability and stability while maintaining affordability production advantages. These well-balanced performance and cost metrics make MDF today’s preferred furniture building material. It’s also quickly being adopted by contractors and DIY’ers across cabinetry, moulding, and renovation projects.

What is MDF Made Of?

As a composite panel product, MDF consists primarily of:

Wood Fibers – Making up approximately 75-85% of board mass depending on thickness, wood chips and dust comprise the base raw ingredient. Most fiber is sourced from residual hardwood waste streams like oak, maple, birch or poplar dust from lumber production operations. Using waste dramatically reduces input costs and environmental harvesting impacts.

Resin Binders – Around 10% of a board’s weight comes from bonding adhesives like urea formaldehyde or other resin formulations which activate under heat and pressure to cement material. Binders liberate volatile organic compounds (VOCs) during pressing for strict emission controls in modern MDF factories.

Wax – A small MDF ingredient proportion of around 1%, paraffin wax and silicon derivatives aid in smoothing board surfaces from press platens for optimal finesse.

The remaining input mass encompasses process aspects like moisture and press additives to form boards in desired shapes and sizes. Premium MDF brands also integrate background checks that fibers come from certified sustainable forestry stewards.

How is MDF Board Manufactured?

While you won’t likely be making MDF in your backyard anytime soon, understanding the general production process helps appreciate why MDF costs significantly less than solid wood. In a nutshell, processing involves:

Debarked wood reduced to pulp – Timber ends from lumber operations get debarked, chipped, shredded, and milled into fine fibers suspended in water slurry. This pulp gets blended with precise resin adhesive ratios into a viscous furnish.

Furnish de-aired and separated into cake – Before pressing, the thick premix gets de-aired under vacuum. Then it's extruded into cake layers at exact caliper heights to shape boards.

Cake compressed into boards – Blanket cakes move to pressing stations between heated steel platens auto-calibrating to specific densities and sizes. Once resin cures from heat, a continuous panel product emerges rather than individual boards.

Cooled then cut to size – The endless panel gets trimmed to standard building product dimensions as it cools. Edges get machined smooth, and panels are racked for quality checks and curing before orders dispatch.

With the combination of high throughput, low variability, and wood waste feedstock, MDF achieves cost points impossible for solid woods needing sawing, planing, defect removal, edging and custom sizing. Factories balance productivity and air quality via automated, high-tech presses encapsulating emissions.

Where and How to Use MDF Board

MDF was initially manufactured to substitute plywood and timber in industrial furniture and cabinetry fabrication. But user-friendly machining and finishing quickly expanded applications to diverse market segments thanks to MDF’s combination of cost, consistency and capabilities covering both strength and aesthetics.

Some common interior design and construction uses include:

Cabinet Boxes and Shelving – MDF constitutes an ideal hidden substrate for built-in cabinets and closets. It machines precisely for components while resisting warping from humidity over plywood. MDF edging creates perfectly smooth surfaces for hinges, tracks and adjoining trim.

Door Cores – Many hollow and flat interior doors utilize MDF frames underlying veneer, lamination or paint finishes. MDF delivers reliable stability so door slabs don’t distort and bindings remain securely adhered. Strengthened perimeter MDF edges prevent impact dings.

Crown Molding – Intricately shaped trim and decoration depends on smooth, detailable substrates before layering ornamental elements. MDF offers the best starting point for precision routing and retaining the finest detailing from patterns or prototypes with no tear out.

Accent Walls and Backsplashes – MDF serves as an excellent underlayer when applying specialty finishes like textured plasters or tile. Primer-prepped MDF won’t soak up layers unevenly, ensuring color consistency across painted projects.

Furniture Components – Modern casegoods utilize MDF for panels, drawer boxes, rails, frames and commercial-grade products. MDF lasts far longer than particleboard while allowing furniture-quality finishing and on-demand CNC customization.

Signage and Displays - Dimensional lettering, logos, exhibit panels and decorative fixtures shine when machined or printed on MDF. It prevents printed graphics from deteriorating over plywood while providing sturdy, screw-worthy anchoring for mounts and stands.

Arts and Crafts – From children’s hobby projects to professional ready-to-finish craft supply blanks, smooth MDF boards retain precise markings with no tearing while supporting layers like paint, paper mâché or decoupage.

The expansive interior design versatility stems from precision machining/cutting, consistent finishing results and reliable stability surpassing natural wood boards. As manufacturing innovations further improve moisture and emissions properties, expect MDF penetration to keep expanding across both residential and commercial markets.

Conclusion

MDF has cemented itself as a new millennium wonder material – an engineered amalgamation of waste wood fibers and petroleum chemistry delivering fabrication capabilities on par with solid woods at a fraction of the cost. MDF popularity will continue rising thanks to decorator-friendly machinability and finishing behaviors combined with adequate strength properties suiting most furniture or architectural roles.

But MDF is not a standalone solution, as surface protection and edge finishes are still required during use. Nor does MDF match luxury aesthetics and environmental stewardship tenets of solid domestic lumbers. Rather, MDF Boards fills a unique niche benefiting designers needing consistency, precision and value across fabrication and renovation projects. Its mass adoption signals a new norm of hybrid materials synergizing natural and manufactured advantages.

1 note

·

View note

Link

FEATURES OF TUBULAR CHIPBOARD

Our Tubular Chipboard Sizes are as below:

Thickness: 30.mm, 33mm, 35mm, 38mm, 60mm

Width: 1250mm (Width is stable and can not change)

Length: Between 1800mm to 2500mm

FEATURES OF SOLID CHIPBOARD

Our Solid Chipboard Sizes are as below:

Thickness: 30mm, 33mm, 35mm, 38mm, 60mm

Width: 1250mm (Width is stable and can not change)

Length: Between 1800mm to 2500mm

#tubularparticleboard#tubularchipboard#hollowcoreboard#particleboard#MdfBoard#particleboardsuppliers#hollowparticleboard#chipboardsheetssuppliers#chipboardmanufacturers#chipboardsupplier#solidchipboard

1 note

·

View note

Photo

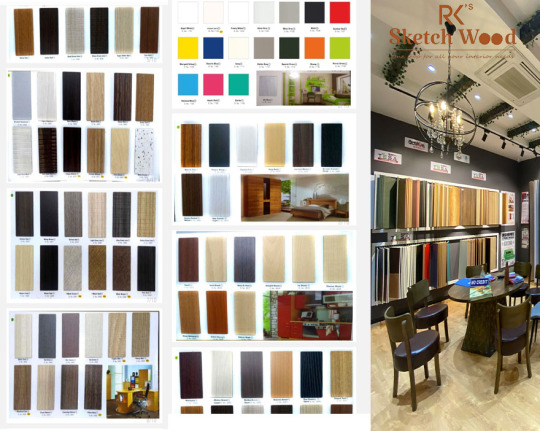

MDF, Particle, HDHMR & Boilo boards in Hyderabad

When it comes to choosing for the MDF & Particle, HDHMR & Boilo boards in Hyderabad... 💥 RK's Sketch Wood is the Trusted name here We deal all kinds of boards 100+ shades such as #mdfboard, #hdfboard, #glossyboard, products are extremely hygienic Reach Us for more details: +91 7330611515

#actiontesamdf#RKSketchWood#plywood#plywoodsupplier#actiontesaboards#mdfboardthickness#mdfboardhyderabad#mdfboarddistribuotor#mdfboardprice#mdfboardnearme#mdfboardmanufacturer#mdf#mdfboard#hdmr#prelammdf#particleboard#furnituredesign#kitchenfurniture#kitchen furniture#homedecor#mdfsheets#furniture#XDHMR#InteriorGradeMDF#ExteriorGradeMDF

2 notes

·

View notes

Text

ولادت حضرت امام حسین علیه السلام مبارک باد

1 note

·

View note

Text

MDF Boards: Environmental Benefits of Using Eco-Friendly Products

The manufacturing of MDF board generates little waste compared to its counterpart, which is wood. This way of reducing less wood waste ensures that we safeguard the environment and the trees of a fully grown forest while maintaining the ecological balance of Earth.

Read more:- https://bit.ly/45InBf4

#mdfboard#mdfboardmanufacturer#mdfboardmanufacturerinindia#mdfboardmanufacturingcompanyinindia#mdfboardsupplier#mdfboarddealer

0 notes

Text

Best MDF Board Suppliers in India - Affordable Prices

Find affordable MDF boards from top suppliers in India. We offer fast delivery and excellent customer service. Get high-quality MDF boards in various thicknesses and sizes, perfect for furniture making, interior design, and more. Trust us for reliable MDF board supplies and timely delivery across India.

Read More:- https://e3groupindia.com/mdf-manufacturer-in-india/

#mdfboard#mdfboardmanufacturers#mdfboardsuppliers#mdfboarddealers#mdfboardmanufacturing#mdfboardexporter#quality#affordable#reliable#trusted

0 notes

Text

Decorative Kettle - Exclusively hand-painted in Kerala Mural art. • Material - High-grade Aluminium • Design - Kerala Mural art • Unique Designs made exclusively by our in-house artists.. • Beautify your mantlepiece with this retro look! • Suspend it from the ceiling in a group as a faux-chandelier. • Can be used as a table top accent, flower vase, and plant vase and much more. • An ideal gift for your loved ones of all ages • Note - As each painting is 100% hand-painted, actual paintings may differ slightly in details from the displayed product image. The price of the product is ₹ 999/- Click to buy from our website: https://gifts.penkraft.in/Product-Details/PK-G-16/Decorative-Kettle-1-by-Penkraft---Exclusively-hand-painted-in-Kerala-Mural-art/89 or from Amazon India: https://www.amazon.in/dp/B0B7BBQXQR For queries/assistance: +91 9136024968

#Gifts#Penkraft#Gifting#Giftsforsale#WallDecor#Creativity#Souvenir#handpaintedart#handpaintedgifts#love#instagood#explore#picoftheday#Modernart#becreative#knifepainting#mdf#mdfart#mdfboard#homedecor#keralamural#kettle#keralamuralart#keralamuralpainting#muralart

0 notes

Text

Embrace the Radiance: Positive MDF Board, Illuminating Spaces with Style and Strength

Positive Chipboard India Private Limited is a renowned manufacturer and supplier based in India that places customer satisfaction as its top priority. They provide outstanding products, including particle boards and MDF, which are versatile building materials belonging to the composite board and fiberboard product family. MDF, similar in application to plywood, finds widespread use in various home and professional projects for furniture and interior works. Positive MDF offers two grades: Plain and Pre-Laminated MDF (Medium Density Fiberboard).

The notable characteristic of MDF lies in its homogeneous construction, free from layers. By employing advanced technology that ensures the application of compression pressure throughout the boards, even reaching the core, we achieve a densified core essential for superior routing capabilities. As a result, our boards exhibit exceptional routing features.

MDF stands for Medium Density Fiberboard. It is a type of engineered wood product that is commonly used in construction, furniture manufacturing, and other applications. MDF is made by breaking down hardwood or softwood fibers into small particles, which are then combined with a resin binder and compressed under high pressure and heat to form panels.

· Plain Exterior MDF Board Manufacturers and Suppliers

The boards exhibit remarkable water resistance and can be customized to improve their resistance to fungus and termites, according to the customer’s preferences. They offer several benefits such as a consistent and uniform structure that provides equal strength in every direction. Additionally, they maintain their dimensional stability even when exposed to different atmospheric conditions.

· Plain Interior MDF Board Manufacturers and Suppliers

If you’re seeking the highest quality MDF Board. This remarkable material possesses a homogeneous structure and uniform properties, ensuring a consistent strength that is evenly distributed in all directions. It is free from knots or grains, resulting in a reliable strength throughout. Notably, it excels in screw retention strength, both on its face and edges, without any splintering or flaking. Similar to natural wood, it is easy to cut, staple, turn, and join. Moreover, it offers the versatility to be laminated, veneered, lacquered, painted, printed, or coated with PVC.

Here are some key characteristics and features of MDF:

Density: MDF has a higher density compared to other types of fiberboard, such as particle board. The density of MDF typically ranges from 600 to 800 kg/m³, which gives it good strength and stability.

Composition: MDF is composed of small wood fibers that are bound together with synthetic resins or binders. This composition provides MDF with a smooth and uniform surface, making it suitable for painting, veneering, or laminating.

Strength and Durability: MDF is known for its high strength and durability. It’s homogeneous structure and dense composition make it resistant to warping, cracking, and splitting.

Versatility: MDF is a highly versatile material. It can be easily machined, cut, drilled, and shaped using standard woodworking tools. Its uniform composition allows for precise and intricate detailing. MDF is also compatible with a variety of finishes, such as paint, laminate, or veneer, giving it a wide range of decorative possibilities.

Affordability: MDF is generally more affordable than solid wood or plywood, making it a cost-effective choice for many applications. It provides a balance between quality and price, making it popular in both commercial and residential projects.

Applications: MDF has a wide range of applications in various industries. It is commonly used in furniture manufacturing for items such as cabinets, shelves, and tabletops. MDF is also used for interior trim work, wall panels, doors, and flooring underlayment. Its smooth surface and stability make it an ideal choice for painting or adding decorative finishes.

Overall, MDF is a versatile and cost-effective engineered wood product that offers strength, durability, and a smooth surface for various applications in construction and furniture manufacturing.

0 notes

Photo

"You're a wizard, Harish." We can't promise you an owl with a letter, but we can get you some fire Harry Potter Coasters of the 4 houses of Hogwarts, and that's just the start! Photo frames, Nameplates, Table Top Decor and Wall Hangings! Glory to MDF, there's something for everyone🛐🛐🛐 Search for MDF on Craftbecho.com now💃🏻💃🏻💃🏻 #craft #crafts #mdfboard #mdf #mdfart #mdfganeshji #mdfcoasters #harrypotter #harrypotterfan #homedecor #hanuman #bajrangbali #bholenath #nameplates #wallhanging #tabledecoration (at Mumbai - मुंबई) https://www.instagram.com/p/Cphxe6kyaWY/?igshid=NGJjMDIxMWI=

#craft#crafts#mdfboard#mdf#mdfart#mdfganeshji#mdfcoasters#harrypotter#harrypotterfan#homedecor#hanuman#bajrangbali#bholenath#nameplates#wallhanging#tabledecoration

0 notes