#Manufacturers list of foaming agent

Explore tagged Tumblr posts

Text

How Chemical Blowing Agents Enhance Polymer Performance

The Significance of Polymer Performance -

Polymer performance is at the core of industrial innovation, influencing the functionality and efficiency of countless products. In this context, chemical blowing agents emerge as pivotal contributors, revolutionizing the landscape of polymer manufacturing. These agents, such as the sought-after azodicarbonamide blowing agent, play a crucial role in achieving lightweight, durable, and environmentally conscious polymer products. The strategic incorporation of chemical blowing agents aligns with the quest for superior polymer performance, ensuring products meet the evolving needs of various industries.

Polymers stand as indispensable players in various industries, forming the backbone of numerous products we interact with daily. The performance of these polymers holds a direct sway over the functionality and efficiency of end-use applications, underscoring the ongoing need for continual improvement and innovation.

Understanding Chemical Blowing Agents -

To enhance polymer performance, manufacturers often turn to chemical blowing agents. These agents are compounds designed to introduce gas and create a cellular structure within the polymer matrix during processing. This controlled expansion leads to several advantageous properties in the final product.

Exploring the Benefits of Chemical Blowing Agents -

Chemical blowing agents offer a range of benefits, including reduced density, improved mechanical properties, enhanced thermal insulation, and sound dampening. In this blog, we'll delve into the fundamental principles behind these agents and how they contribute to elevating polymer performance.

Fundamental Principles of Chemical Blowing Agents -

The Chemistry Behind Chemical Blowing Agents

● Gas Evolution and Expansion Mechanisms:-

Chemical blowing agents release gas upon thermal activation, creating bubbles within the polymer structure. Understanding the chemistry behind this process is crucial for achieving desired performance characteristics.

● Control of Blowing Agent Decomposition:-

Precise control over the blowing agent's decomposition is essential to avoid undesired side effects. Manufacturers must balance decomposition temperature, gas release rate, and other factors to achieve optimal results.

Key Factors Influencing Blowing Agent Selection

● Polymer Type and Processing Conditions:-

Different polymers and processing methods demand specific blowing agents. Compatibility with the base polymer and the processing conditions ensures successful integration and desired performance enhancements.

● Environmental Considerations:-

As sustainability gains prominence, choosing blowing agents with minimal environmental impact becomes crucial. Eco-friendly options contribute to a more responsible and sustainable manufacturing process.

Enhancing Polymer Properties through Chemical Blowing Agents -

Lightweighting and Density Reduction

Enhanced Mechanical Performance:-

By introducing cellular structures, material density is effectively reduced without sacrificing mechanical strength. This results in products that are both lightweight and durable, a particularly advantageous trait in applications within the automotive and aerospace industries.

Improved Fuel Efficiency and Sustainability:-

Reduced weight translates to improved fuel efficiency in transportation, contributing to sustainability goals and aligning with environmental regulations.

Thermal Insulation and Energy Efficiency

Increased Heat Resistance:-

Through the utilization of chemical blowing agents, a polymer's heat resistance is elevated, broadening the spectrum of potential applications in high-temperature environments.

Lower Energy Consumption in Applications:-

Elevated thermal insulation not only curtails energy consumption across diverse applications but also renders products more energy-efficient and cost-effective.

Improved Sound and Vibration Dampening

Noise Reduction Capabilities:-

The cellular structure introduced by blowing agents acts as a sound barrier, contributing to noise reduction in products like automotive components and building materials.

Enhanced Comfort and Safety:-

Reduced vibrations and noise not only enhance comfort but also contribute to safety by minimizing distractions and improving the overall user experience. In conclusion, the strategic use of chemical blowing agents is pivotal in advancing polymer performance across diverse industries. Manufacturers, including the best PVC blowing agent manufacturers in India, continually explore innovative solutions like azodicarbonamide blowing agents to meet evolving demands. As the industry progresses, a focus on sustainable and effective blowing agents will be paramount for achieving optimal polymer performance.

#adcl blowing agent in India#blowing agent manufacturers in india#Best Blowing Agent Supplier in India#blowing agent for artificial leather in india#Best Pvc blowing agent manufacturers in India#best azodicarbonamide blowing agent in india#Foaming agent supplier for Eva in India#Manufacturers list of foaming agent#azodicarbonamide blowing agent#Blowing agent for Roto moulding products in India#Best industrial chemicals manufacturer in India#Thermoplastic elastomer manufacturers in India#Blowing agent for Yoga Mats#Soft Compound Manufacturers in India#Best Filler suppliers for yoga mats in India

0 notes

Text

Ingredients to watch out for or avoid in over the counter skincare products by Cheyanne Mallas

Over-the-counter (OTC) skin care products have become increasingly popular for their convenience and accessibility. However, it is essential for consumers to be aware of the ingredients present in these products as some can potentially harm the skin says Cheyanne Mallas from www.pacheyannemallas.com

This article aims to provide an authoritative guide on the ingredients that should be watched out for or avoided in OTC skin care products.

1. Parabens:

Parabens are commonly used as preservatives in many cosmetic and skin care products. However, studies have shown that parabens can mimic estrogen in the body, leading to potential hormonal disruptions. Research has linked paraben exposure to increased risk of breast cancer and reproductive issues. Therefore, it is advisable to avoid products that contain parabens, such as methylparaben, propylparaben, and butylparaben.

2. Fragrances:

Fragrances are often added to skin care products to enhance their appeal. However, they can cause allergic reactions, skin irritation, and even respiratory problems in some individuals. Manufacturers are not required to disclose the specific ingredients used in fragrances, making it difficult for consumers to identify potential allergens. Opting for fragrance-free or unscented products is recommended to minimize the risk of adverse reactions.

3. Sodium Lauryl Sulfate (SLS) and Sodium Laureth Sulfate (SLES):

SLS and SLES are foaming agents commonly found in cleansers, shampoos, and body washes. While they create a rich lather, they can strip the skin of its natural oils, leading to dryness and irritation. SLS and SLES can also penetrate the skin and potentially interact with other chemicals, causing further damage. It is advisable to choose products that are labeled as SLS/SLES-free or look for alternative surfactants such as coco-glucoside or decyl glucoside.

4. Formaldehyde and Formaldehyde-releasing preservatives:

Formaldehyde and formaldehyde-releasing preservatives, such as quaternium-15 and DMDM hydantoin, are commonly used as preservatives in skin care products. However, they can cause skin irritation, allergic reactions, and have been classified as carcinogenic by the International Agency for Research on Cancer. Checking the ingredient list for these substances and avoiding products containing them is crucial for the safety of the skin.

5. Hydroquinone:

Hydroquinone is a skin lightening ingredient often used to treat hyperpigmentation. However, it has been associated with adverse effects such as skin irritation, redness, and even ochronosis (a skin disorder characterized by darkening and thickening of the skin). Long-term use of hydroquinone can lead to permanent skin damage. It is advisable to consult a dermatologist before using any product containing hydroquinone and only use it under professional guidance.

In conclusion, when selecting OTC skin care products, it is essential to be cautious and knowledgeable about the ingredients they contain. Parabens, fragrances, SLS/SLES, formaldehyde and formaldehyde-releasing preservatives, and hydroquinone are some of the ingredients that should be watched out for or avoided due to their potential harm to the skin says Cheyanne Mallas. By being aware and making informed choices, consumers can ensure the safety and well-being of their skin.

3 notes

·

View notes

Text

Sodium Lauryl Ether Sulphate: What You Need to Know

If you take a look at the ingredients list of your shampoo, body wash, or any other personal care product, there's a high chance that you'll come across the term Sodium Lauryl Ether Sulphate Supplier in USA or SLES. It's a common ingredient found in many household and personal care products, but what exactly is it, and is it safe to use?

What is Sodium Lauryl Ether Sulphate (SLES)?

SLES is a synthetic detergent and surfactant that's used in a wide range of personal care and household cleaning products. It's a white or cream-coloured powder that's highly soluble in water and produces a dense lather. SLES is commonly used in shampoos, body washes, toothpaste, and household cleaners.

What are the benefits of Sodium Lauryl Ether Sulphate?

SLES is an effective foaming agent and emulsifier, which means it helps to distribute ingredients evenly in a product. It's also a good degreaser and can effectively remove oil and dirt from the skin and hair. Because of its effectiveness, SLES is commonly used in personal care products to create a rich lather and a smooth texture.

Is Sodium Lauryl Ether Sulphate safe?

There has been some controversy surrounding the safety of Sodium Lauryl Ether Sulphate Exporte in USA. Some studies have suggested that SLES can be a skin irritant and may cause allergic reactions in some people. Additionally, there are concerns that SLES can be absorbed into the bloodstream and accumulate in the body over time.

However, it's important to note that the majority of studies have found SLES to be safe when used in low concentrations. The Cosmetic Ingredient Review (CIR) Expert Panel has concluded that SLES is safe for use in personal care products when formulated to be non-irritating and used at concentrations up to 30%.

It's also worth noting that many personal care products contain other potentially harmful ingredients. If you have concerns about the safety of a product, it's a good idea to read the label carefully and do your research.

Should I avoid products that contain Sodium Lauryl Ether Sulphate?

If you have sensitive skin or are concerned about the safety of Sodium Lauryl Ether Sulphate Distributor in USA, you may want to avoid products that contain it. However, keep in mind that SLES is a common ingredient in many personal care products, so finding products that don't contain it can be difficult.

If you're concerned about the safety of personal care products, there are a few things you can do. First, read the label carefully and look for products that contain natural ingredients. Second, do your research and look for products that have been certified as safe by reputable organizations. Finally, if you're still unsure about the safety of a product, consult a dermatologist or other Healthcare Professional.

In conclusion, Sodium Lauryl Ether Sulphate Manufacturer in India is a common ingredient in many personal care and household cleaning products. While there have been some concerns about its safety, the majority of studies have found it to be safe when used in low concentrations. If you have concerns about the safety of personal care products, it's important to do your research and consult a healthcare professional.

#Sodium Lauryl Ether Sulphate Supplier in USA#Sodium Lauryl Ether Sulphate Exporte in USA#Sodium Lauryl Ether Sulphate Manufacturer in India

3 notes

·

View notes

Text

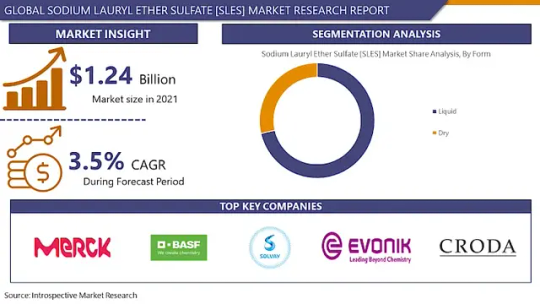

Sodium Lauryl Ether Sulfate Market: Forthcoming Trends and Share Analysis by 2030

The Global Sodium Lauryl Ether Sulfate [SLES] market was estimated at USD 1.24 billion in 2021, and is anticipated to reach USD 1.58 billion by 2028, growing at a CAGR of 3.5%.

sodium lauryl ether sulfate (SLES) was a widely used surfactant in various personal care and household cleaning products due to its excellent foaming and cleaning properties. SLES is primarily used as a surfactant and emulsifying agent in products such as shampoos, body washes, toothpaste, dishwashing detergents, and laundry detergents. Its ability to create foam and its effectiveness in removing dirt and oil make it a popular choice in these applications. The market for SLES has been consistently growing due to increasing demand for personal care and household cleaning products globally. The market size varies depending on factors such as regional consumption patterns, economic conditions, and consumer preferences. Asia-Pacific, particularly China and India, has been a significant market for SLES due to the rapid growth of the personal care and homecare industries in these regions. North America and Europe also have substantial consumption of SLES, driven by the established personal care and household cleaning markets.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

https://introspectivemarketresearch.com/request/15858

Updated Version 2024 is available our Sample Report May Includes the:

Scope For 2024

Brief Introduction to the research report.

Table of Contents (Scope covered as a part of the study)

Top players in the market

Research framework (structure of the report)

Research methodology adopted by Worldwide Market Reports

Leading players involved in the Sodium Lauryl Ether Sulfate Market include:

Godrej Industries, BASF, Taiwan NJC Corporation, Stepan Company, Ultra Group, Kao Corporation, Croda International, Galaxy Surfactants, Ho Tung Chemical, Evonik Industries, Huntsman Corporation, Clariant Corporation, The Dow Chemical Company, Solvay, Zhejiang Zanyu Technology, Merck KGaA, Sasol and other Major Players.

Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years.

If You Have Any Query Sodium Lauryl Ether Sulfate Market Report, Visit:

https://introspectivemarketresearch.com/inquiry/15858

Segmentation of Sodium Lauryl Ether Sulfate Market:

By Type

Cosmetic Grade

Industrial Grade

Pharmaceutical Grade

Others

By Production Method

Inorganic Based

Coco Based

By Form

Liquid

Dry

By Application

Household Detergents & Cleaners

Personal Care Products

Dishwashing Liquids

Medical

Others

By Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

Highlights from the report:

Market Study: It includes key market segments, key manufacturers covered, product range offered in the years considered, Global Sodium Lauryl Ether Sulfate Market, and research objectives. It also covers segmentation study provided in the report based on product type and application.

Market Executive Summary: This section highlights key studies, market growth rates, competitive landscape, market drivers, trends, and issues in addition to macro indicators.

Market Production by Region: The report provides data related to imports and exports, revenue, production and key players of all the studied regional markets are covered in this section.

Sodium Lauryl Ether Sulfate Market Profiles of Top Key Competitors: Analysis of each profiled Roll Hardness Tester market player is detailed in this section. This segment also provides SWOT analysis of individual players, products, production, value, capacity, and other important factors.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=15858

About us:

Introspective Market Research (introspectivemarketresearch.com) is a visionary research consulting firm dedicated to assisting our clients to grow and have a successful impact on the market. Our team at IMR is ready to assist our clients to flourish their business by offering strategies to gain success and monopoly in their respective fields. We are a global market research company, that specializes in using big data and advanced analytics to show the bigger picture of the market trends. We help our clients to think differently and build better tomorrow for all of us. We are a technology-driven research company, we analyse extremely large sets of data to discover deeper insights and provide conclusive consulting. We not only provide intelligence solutions, but we help our clients in how they can achieve their goals.

Contact us:

Introspective Market Research

3001 S King Drive,

Chicago, Illinois

60616 USA

Ph no: +1-773-382-1049

Email: [email protected]

#Sodium Lauryl Ether Sulfate#Sodium Lauryl Ether Sulfate Market#Sodium Lauryl Ether Sulfate Market Size#Sodium Lauryl Ether Sulfate Market Share#Sodium Lauryl Ether Sulfate Market Growth#Sodium Lauryl Ether Sulfate Market Trend#Sodium Lauryl Ether Sulfate Market segment#Sodium Lauryl Ether Sulfate Market Opportunity#Sodium Lauryl Ether Sulfate Market Analysis 2024

0 notes

Text

Aerosol Cans Market: Size, Share, Growth, Top Brands, Research Report 2024-2032

According to IMARC Group latest report titled “Aerosol Cans Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032”, offers a comprehensive analysis of the industry, which comprises insights on aerosol cans market size. The report also includes competitor and regional analysis, and contemporary advancements in the global market.

The global aerosol cans market size reached US$ 12.8 Billion in 2023. Looking forward, IMARC Group expects the market to reach US$ 17.0 Billion by 2032, exhibiting a growth rate (CAGR) of 3.1% during 2024-2032.

Aerosol cans are specialized containers designed to release liquid or powdered products in the form of a fine spray or mist. This function is achieved through a propellant under pressure, making the aerosol can a versatile and efficient packaging solution. Common types of aerosol cans include steel, aluminum, and glass, each offering unique benefits in terms of durability, recyclability, and product compatibility. These cans are distinguished by their ease of use, precise dispensing, and ability to maintain product integrity, making them ideal for a wide range of applications. They are predominantly used in industries such as personal care, household cleaning, automotive, and food and beverages. Their design facilitates a controlled and targeted application of products, ranging from deodorants and hairsprays to cleaning agents and cooking oils, thereby enhancing user experience and product efficiency.

Get a Sample Copy of this Report: https://www.imarcgroup.com/aerosol-cans-market/requestsample

Market Trends:

The global market is experiencing significant growth driven by the escalating consumer preference for convenient and efficient packaging solutions, with aerosol cans offering ease of use and consistent product delivery. In the personal care sector, the increasing demand for products such as deodorants, hairsprays, and shaving foams in aerosol packaging is contributing to market expansion. Additionally, the market is benefitting from technological advancements in can manufacturing, leading to lighter, more sustainable, and cost-effective cans. Along with this, the growing awareness of environmental issues is also influencing the market as manufacturers innovate to produce eco-friendlier aerosol cans with improved recyclability and reduced carbon footprint. Apart from this, the expansion of the retail sector and e-commerce platforms is facilitating wider accessibility and distribution of aerosol can-packaged products. Furthermore, the rising disposable incomes and lifestyle changes are creating a positive market outlook.

View Full Report with TOC & List of Figure: https://www.imarcgroup.com/aerosol-cans-market

Competitive Landscape:

The competitive landscape of the market has been studied in the report with the detailed profiles of the key players operating in the market.

Aero-pack Industries Inc.

Ardagh Group S.A.

Arminak & Associates Inc.

Alucon Public Company Limited

Ball Corporation

Bharat Containers

CCL Containers

Colep

Crown Holdings Inc.

DS Containers Inc. Corporation

Jamestrong Packaging Nampak Ltd.

Spray Products

WestRock Group

Aerosol Cans Market Segmentation:

Our report has categorized the market based on region, product type, material, propellant used, capacity and application.

Breakup by Product Type:

Straight Wall Aerosol Cans

Necked-In Aerosol Cans

Shaped Aerosol Cans

Breakup by Material:

Aluminum

Steel

Plastic

Others

Breakup by Propellant Used:

Compressed Gas Propellant

Liquefied Gas Propellant

Breakup by Capacity:

<100ml

100-250 ml

251-500 ml

>500m

Breakup by Application:

Personal Care Products

Household Products

Healthcare Products

Automotive Products

Others

Key highlights of the report:

Market Performance (2018-2023)

Market Outlook (2024-2032)

Porter’s Five Forces Analysis

Market Drivers and Success Factors

SWOT Analysis

Value Chain

Comprehensive Mapping of the Competitive Landscape

About Us

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC’s information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company’s expertise.

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145 | United Kingdom: +44-753-713-2163

0 notes

Text

The Hidden Dangers in Your Shampoo In the quest for luscious, luxurious locks, we often overlook a critical aspect of our hair care routine—shampoo ingredients. Most of us simply grab a bottle of shampoo off the shelf without a second thought. After all, how much harm could a seemingly innocent product do? As it turns out, quite a bit. Welcome to the eye-opening world of toxic shampoo ingredients that could be wreaking havoc on your gorgeous hair! Why Should You Care? Before we delve into the sinister world of toxic shampoo ingredients, it's essential to understand why you should care. Your hair, often referred to as your "crowning glory," deserves the best care possible. Shampoo plays a pivotal role in maintaining its health and appearance. Here are a few reasons why you should be concerned: Hair Health: Your hair reflects your overall health. Shampoo ingredients can impact hair strength, shine, and texture. Scalp Health: A healthy scalp is the foundation for beautiful hair. Some ingredients can irritate the scalp, leading to issues like dandruff and itching. Overall Well-being: Toxic ingredients in shampoo may have broader health implications. Chemicals can be absorbed through the skin and into your bloodstream, potentially affecting your overall well-being. The Alarming Truth: Toxic Shampoo Ingredients Now, let's lift the veil on five toxic shampoo ingredients you should steer clear of: 1. Sodium Lauryl Sulfate (SLS) What is it? SLS is a common foaming agent in shampoos and other personal care products. Harmful Effects: It can strip your hair of its natural oils, leading to dryness and damage. Example Products: Many commercial shampoos contain SLS, so it's crucial to check labels. 2. Parabens What are they? Parabens are synthetic preservatives used to extend a product's shelf life. Health Risks: They have been linked to hormone disruption and potentially even breast cancer. Common Products: Parabens lurk in various cosmetics, including shampoos. 3. Formaldehyde What is it? Formaldehyde is a preservative and a known carcinogen. Health Concerns: Exposure to formaldehyde can lead to scalp irritation and long-term health risks. Hidden Ingredient: It may not be listed explicitly but could be released from other preservatives. 4. Fragrance (Phthalates) What is it? Fragrance is often a blanket term that can hide various chemicals, including phthalates. Concerns: Phthalates have been linked to hormone disruption and may impact fertility. Elusive Yet Present: Manufacturers are not required to disclose the specific chemicals used in fragrance. 5. Propylene Glycol What is it? Propylene glycol is a synthetic substance used to absorb water. Effects: It can cause scalp and skin irritation, especially in those with sensitive skin. Commonly Found: Look out for it in shampoos and other personal care items. Stay Tuned for More Now that you're aware of these alarming shampoo ingredients, the next step is to understand how they affect your hair and overall health. In the upcoming section, we'll explore real-life hair horror stories and the tangible impact of using shampoos containing these ingredients. Your hair deserves better, and we're here to guide you towards healthier alternatives. So, let's dive into the hair-raising tales in Section 2: The Top 5 Toxic Shampoo Ingredients. The Top 5 Toxic Shampoo Ingredients Welcome to the second installment of our journey into the murky world of shampoo ingredients. In this section, we'll unveil the culprits behind the potential harm your shampoo might be causing to your hair and health. Armed with this knowledge, you'll be better equipped to make informed choices and safeguard your gorgeous locks. **1. Sodium Lauryl Sulfate (SLS) What is SLS? SLS, or Sodium Lauryl Sulfate, is a common ingredient found in many shampoos and personal care products. It's the compound responsible for creating that satisfying foaming lather when you wash your hair. Why is it Harmful?

Stripping Natural Oils: SLS is a strong detergent that can strip your hair of its natural oils. This can lead to dryness, frizziness, and overall damage. Irritation: It may cause scalp irritation in some individuals, especially those with sensitive skin. Where Can You Find It? SLS is pervasive in commercial shampoos, so it's crucial to scrutinize product labels. Keep an eye out for it, especially in mainstream brands. 2. Parabens What are Parabens? Parabens are synthetic preservatives used to extend the shelf life of personal care products, including shampoos. Why are They Harmful? Hormone Disruption: Parabens have been associated with hormone disruption, which can lead to various health issues. Breast Cancer Concerns: Some studies have raised concerns about a potential link between parabens and breast cancer. Where Can You Find Them? Parabens are sneakily present in many cosmetics and shampoos. Check labels for any ingredient with "paraben" in its name. 3. Formaldehyde What is Formaldehyde? Formaldehyde is a powerful preservative, but it's also a known carcinogen - a substance capable of causing cancer. Why is it Harmful? Scalp Irritation: Exposure to formaldehyde can cause irritation to your scalp and skin. Long-term Risks: Consistent use may pose long-term health risks due to its carcinogenic properties. How is it Hidden? Formaldehyde may not always be listed explicitly on product labels. It can be released from other preservatives in the shampoo. 4. Fragrance (Phthalates) What is Fragrance? "Fragrance" in shampoo is often a catch-all term for a mixture of various chemicals, including phthalates. What are the Concerns? Hormone Disruption: Phthalates, hiding behind the term "fragrance," can disrupt hormones, potentially affecting fertility. Lack of Transparency: Manufacturers aren't required to disclose the specific chemicals used in their fragrance blends. 5. Propylene Glycol What is Propylene Glycol? Propylene Glycol is a synthetic substance used to absorb water, making products smoother. What are the Effects? Skin and Scalp Irritation: It can lead to irritation of the skin and scalp, particularly in individuals with sensitive skin. Common Usage: You'll find propylene glycol in various personal care items, including shampoos. Stay Informed, Stay Safe Now that you're acquainted with these sinister shampoo ingredients, you're better prepared to protect your hair and health. But our journey doesn't end here. In Section 3: The Impact of Using Shampoos with These Ingredients, we'll delve into real-life hair horror stories and explore the tangible effects of using shampoos that contain these harmful substances. Let's unravel the truth about shampoo safety together! The Impact of Using Shampoos with These Ingredients In our ongoing exploration of the hidden dangers lurking in your shampoo, we've uncovered a trove of unsettling information about five toxic ingredients. But what happens when you use shampoos containing these culprits? It's time to shed light on the real-life impact of these ingredients on your hair and overall well-being. Hair Horror Stories: The Price of Ignorance 1. Sodium Lauryl Sulfate (SLS) Stripped Hair: Users have reported that SLS-containing shampoos leave their hair feeling parched, brittle, and lacking its natural luster. Scalp Sensitivity: For some, the irritation caused by SLS can lead to redness and itching, making hair washing a dreaded ordeal. 2. Parabens Hair Troubles: Parabens may contribute to hair issues such as thinning, excessive dryness, and dullness. Hormonal Imbalance: Concerns about hormonal disruption have left users questioning the long-term effects on their health. 3. Formaldehyde Scalp Agony: Many have experienced discomfort, itching, and even redness when exposed to formaldehyde in their shampoos. Future Fears: The potential risk of cancer looms as a haunting specter for those who regularly use shampoos containing this carcinogen. 4. Fragrance (Phthalates)

Allergic Reactions: Users with sensitivities have reported allergic reactions such as rashes, hives, and swollen scalps. Fertility Worries: The uncertainty surrounding phthalates and fertility has left some individuals anxious about their reproductive health. 5. Propylene Glycol Itchy Reality: Propylene glycol can cause persistent itching and flaking on the scalp, leading to discomfort. Sensitive Scalps Beware: Those with sensitive skin are particularly vulnerable to the adverse effects of this common shampoo ingredient. A Wake-Up Call for Your Hair Care Routine These hair horror stories serve as a stark reminder of the importance of ingredient awareness. Your shampoo choice isn't just about cleanliness; it directly impacts your hair's health and your overall well-being. But fear not, for knowledge is power. In Section 4: How to Identify and Avoid Harmful Ingredients, we will equip you with the tools and insights needed to become a savvy shopper in the world of hair care. We'll guide you through reading labels, choosing safer alternatives, and even provide DIY shampoo recipes for those who prefer a hands-on approach. Together, we'll embark on a journey towards healthier, more radiant hair. Let's continue our exploration into safer hair care practices. How to Identify and Avoid Harmful Ingredients Now that we've journeyed through the murky waters of toxic shampoo ingredients and witnessed their potential impact on your hair and health, it's time to empower you with the knowledge and tools needed to make informed choices. In this section, we'll explore how to identify and avoid these harmful ingredients while navigating the vast landscape of hair care products. Reading Labels: The Art of Ingredient Scrutiny When it comes to safeguarding your hair and health, label reading is your first line of defense. Here's how to decode those shampoo labels like a pro: 1. Check for Ingredient Lists Look for Transparency: Seek products that list all ingredients clearly. Manufacturers should not hide behind vague terms like "fragrance." Scan for Red Flags: Be on the lookout for our infamous five: Sodium Lauryl Sulfate (SLS), parabens, formaldehyde, fragrance (phthalates), and propylene glycol. 2. Understand Terminology Learn the Lingo: Familiarize yourself with chemical names. For example, SLS might be listed as Sodium Lauryl Sulfate. Be Wary of Synonyms: Some harmful ingredients may go by different names. For instance, formaldehyde can be released from other preservatives. Choosing Safer Alternatives: Your Hair's Best Friends Now that you can spot the troublemakers, it's time to embrace safer alternatives. Here are some tips to guide your choices: 1. Go Natural and Organic Nature's Bounty: Natural and organic shampoos often contain fewer synthetic chemicals. Look for certifications like USDA Organic or ECOCERT. Botanical Bliss: Seek ingredients like aloe vera, tea tree oil, and chamomile for gentle cleansing and nourishment. 2. Research Brands Trusted Brands: Research reputable brands known for their commitment to safe, clean ingredients. Read Reviews: Customer reviews can provide insights into a product's performance and safety. DIY Shampoo Recipes: Control in Your Hands For those who prefer a hands-on approach, crafting your own shampoo can be a rewarding endeavor. Here's a simple recipe to get you started: Homemade Nourishing Shampoo Ingredients: 1/4 cup liquid castile soap (unscented) 1/4 cup distilled water 1/2 teaspoon jojoba oil 5-10 drops of essential oil (e.g., lavender, rosemary) Instructions: Mix the castile soap and distilled water in a container. Add jojoba oil and your chosen essential oil for fragrance. Shake well before each use. Note: This DIY recipe ensures you know exactly what's going into your shampoo. Frequently Asked Questions Q1: Are there any natural preservatives I can look for in shampoos? A1: Yes, some natural preservatives include vitamin E (tocopherol), rosemary extract, and grapefruit seed extract. Look for shampoos that use these ingredients.

Q2: Can I trust products labeled 'natural' or 'organic'? A2: While these labels are a good starting point, it's essential to read the ingredient list to ensure the product aligns with your safety standards. Q3: Are there any specific brands you recommend? A3: Some reputable brands known for their commitment to clean ingredients include Avalon Organics, Acure Organics, and SheaMoisture. Your Journey to Healthier Hair Begins Now Armed with the knowledge of how to read labels, select safer alternatives, and even create your own shampoo, you're on your way to healthier, more radiant hair. But our journey doesn't end here. In the upcoming Section 5: Conclusion and Takeaway, we'll wrap up our exploration and provide you with a compelling call to action to kickstart your healthy hair journey. Stay tuned! Conclusion and Takeaway Congratulations on embarking on this enlightening journey through the world of shampoo ingredients! We've covered a lot of ground, from uncovering the toxic ingredients you should avoid to understanding their real-world impact. In this final section, let's recap the key takeaways and chart the course for your future hair care endeavors. Recap of Our Journey The Hidden Dangers in Your Shampoo: We began by introducing you to the critical importance of being aware of the ingredients in your shampoo. Your hair health and overall well-being are closely linked to the products you choose. The Top 5 Toxic Shampoo Ingredients: In the second installment, we unveiled the notorious five culprits: Sodium Lauryl Sulfate (SLS), parabens, formaldehyde, fragrance (phthalates), and propylene glycol. We delved into the harmful effects and where to find them. The Impact of Using Shampoos with These Ingredients: Our third article brought real-life stories to the forefront, showcasing the tangible consequences of using shampoos containing these harmful ingredients. Hair horrors and health concerns came to light. How to Identify and Avoid Harmful Ingredients: Armed with knowledge, the fourth section equipped you with the skills to become a savvy shopper. We explored label reading, safer alternatives, and even provided a DIY shampoo recipe for those eager to take control. Your Healthy Hair Journey Starts Here As we wrap up this series, it's crucial to remember that your hair care journey is ongoing. Armed with knowledge and armed with the power to make informed choices, you're poised for a future of healthier, more vibrant hair. Here's a final takeaway: Read Labels: Always read shampoo labels thoroughly, checking for our infamous five toxic ingredients. Look for transparent, natural, or organic options when possible. Choose Safer Alternatives: Explore trusted brands committed to clean, safe ingredients. Remember that natural and organic options can be gentler on your hair and scalp. Consider DIY: If you're adventurous, try crafting your own shampoo using simple, natural ingredients. By following these guidelines, you can transform your hair care routine into a proactive, health-conscious practice. Your hair will thank you with increased vitality and radiance. Join Our Ongoing Conversation Remember that your hair care journey doesn't end here. Continue to stay informed and share your knowledge with others. Feel free to engage in our ongoing conversation about shampoo safety secrets, and together, we can create a community committed to healthier hair for all. Thank you for joining us on this enlightening journey. Your quest for gorgeous, healthy hair begins now, and we're here to support you every step of the way.

0 notes

Text

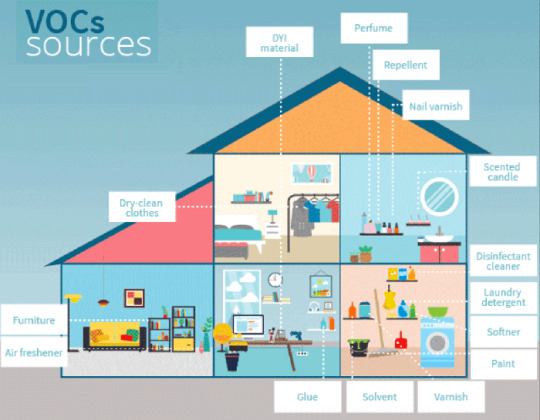

A HEALTHY HOME DETOX

The benefits of eating clean, nutritious, whole foods are clear – the less toxins, chemicals, and junk you feed your body, the more vibrant you’ll feel. While the phrase “you are what you eat” is true, your environment also greatly impacts your health.

CLEANING PRODUCTS

Toxic chemicals are a given in generic cleaning products. Begin your healthy home detox by switching

to natural alternatives. Not all cleaning products list their ingredients, so a little extra know-how may be required – anything with a danger, hazard, or poison label should be avoided along with ingredients

(in the rare event they are listed) like ammonia, DEA, APEs, and TEA. Although even the most natural cleaners contain small amounts of hard-to-pronounce ingredients, choose cleaning products like you would food. Opt for short ingredient lists (five or less) and as always, plant-based ingredients are the best choices, followed by solvent and phosphate-free labels. Avoid labels that promote vague terms like natural and ecologically-friendly. Alternatively, you may make your own products. Baking soda, lemon, vinegar, and cornstarch are pantry staples that double as cleaning products. Combined with hot water and elbow grease, you may never need to use a chemical cleaner again.

FURNITURE AND TEXTILES

Mattress manufacturers often add flame retardants to comply with fire regulations. Regardless of the chemical concoction used (there are more than a few), retardants are known to cause poor brain development as well as learning, behavior, and memory problems in children. Carpets also contain their own chemical cocktail – stain resistance treatments, antimicrobial properties, antistatic agents, etc. They’re all toxic.

Be a conscious consumer and choose a mattress made from natural materials like untreated cotton

or wool. Also ensure they’re free of synthetic materials like foam, glue, and moth-proofing chemicals. Use the same standards when choosing bedding, curtains, and rugs. Clean carpets with a plant-based detergent, or if you’re moving homes or renovating, opt for hardwood floors instead.

PAINT AND DECORATION

Be sure to use no-VOC (volatile organic compounds) paints. Many companies advertise no-VOC, but this is only the base white paint. Once color is added, it’s no longer no-VOC. If you prefer using wallpaper, avoid vinyl, which can trap mold and fungus and cause respiratory problems. Creating a home that’s healthy for you and the environment requires a lot less than you might think.

Natural wood, simple white (no-VOC!) walls, and toxin-free carpets and furniture go a long way. You can also use other natural fabrics like hemp, bamboo, silk, and linen. A truly clean, green home can’t be achieved overnight – so if you can’t incorporate these suggestions right now, that’s okay. Start small and work your way to a 100% healthy home.

HERE ARE SOME WAYS TO KICK OFF YOUR HEALTHY HOME:

• Grow plants indoors

• Open windows and allow fresh air to flow through rooms

• Switch to energy-saving light bulbs

• Open the blinds and allow sunshine to filter in

• Compost kitchen scraps

• Use appliances efficiently and don’t leave lights and other electrics turned on • Recycle trash

• Buy recycled goods

Are you a woman looking to improve your health and well-being? Do you want to cleanse your body and mind from the inside out? If so, we invite you to join our online detox group.

Our group is a supportive community of women just like you, who are committed to their health and wellness journey. We share tips, recipes, and encouragement to help each other succeed in our detox goals.

Don’t miss out on this opportunity to connect with like-minded women and start your detox journey today. Click the button below to join us now!

Join Now

#detoxhome#detoxyourhouse#detoxcasa#eliminatetoxins#eliminateillness#holistic approach#holisticwellness#tampa#fitness#holistic medicine

1 note

·

View note

Text

Complete List of Products With PFAS Chemicals to Avoid

Now that the dangers of PFAS chemicals are well-known, we don't blame you if you want to do everything you can to limit your exposure to these forever chemicals. Here, we've shared a list of products that are often made with PFAS, so you can choose safer, healthier alternatives whenever possible. 📌 Key Takeaways: - PFAS, or polyfluoroalkyl substances, are a group of chemicals that have been linked to health problems including cancer, high blood pressure, high cholesterol, weight gain, immune system effects, thyroid disease, and more. - Products that may contain PFAS include drinking water, food packaging, water-resistant textiles and outdoor gear, stain-repellent carpets and upholsteries, firefighting foam, non-stick cookware, and many more household products. 🤔 Are PFAS Still Used In The US? You might assume that, now we're more aware of the potential health effects of toxic PFAS chemicals, our use of these chemicals would be banned or illegal. However, while the use of PFAS has largely been phased out in the US, manufacturers have simply replaced these chemicals with shorter-chain substitutes, which are thought to be similarly toxic to humans. Plus, you may own many products at home that were made before the PFAS phase-out and are therefore potentially unsafe. Additionally, the problem still remains that PFAS are classed as "forever chemicals" because they linger in the environment for decades. So, we're still being exposed to these chemicals even if they're not commonly used today. ☢️ Products That Contain PFAS Here is a list of some of the products that may contain PFAS: - Non-stick cookware, such as Teflon and other PTFE-based coatings. - Stain-resistant carpets and upholstery, including furniture and curtains. - Water-resistant clothing and outdoor gear, such as rain jackets and tents. - Food packaging materials, such as pizza boxes, microwave popcorn bags, and fast food wrappers. - Firefighting foam and other firefighting equipment. - Dental floss and stain-resistant dental coatings. - Personal care products, such as waterproof mascara, sunscreen, and shaving cream. - Lubricants and hydraulic fluids used in industrial equipment. - Electrical wires and cables, especially those used in aerospace and military applications. - Building materials, such as sealants, adhesives, and insulation. It's important to note that not all products containing PFAS are labeled as such, so it can be challenging to determine if a product contains these chemicals. Now let's explore a bit more in depth the products which are most likely to expose you to PFAs substances. Drinking Water Drinking water is one of the main sources of PFAS exposure in the US. PFAS chemicals enter surface water supplies through wastewater discharge, runoff from industrial sites, airfields, and fire training sites, and landfills. Leaks and spills can also cause PFAS to run into natural bodies of water. The problem arises when these water sources are used as drinking water supplies. Most water treatment plants are ill-equipped to remove PFAS using existing treatment methods, and the EPA doesn't currently regulate these chemicals (although it is in the process of proposing a drinking water standard), so water utilities don't legally have to remove them. How can you find out whether your tap water contains PFAS? We recommend checking your Water Quality Report, which lists all the contaminants detected in your public water supply. You could also test your water with a private laboratory test if you wanted the most accurate results. Greaseproof Bags and Containers PFAS chemicals are still authorized to be used as grease-proofing agents in grease-resistant paper and bags, microwave popcorn bags, fast-food wrappers, take-out containers, pizza boxes, any other kind of grease-resistant packaging, and bags of pet food. The purpose of PFAS is to prevent grease and oil from leaking through the container or food packaging. You may be exposed to PFAS from products that use these chemicals as greaseproofing agents because the PFAS could contaminate the foods stored inside the packaging. Non-Stick Cookware Non-stick cookware is another common source of PFAS exposure today. PFAS are used to prevent foods and ingredients from sticking to frying pans, pots, and other items of cookware. Again, this comes with a likelihood that traces of the PFAS used to coat the cookware surfaces will leach into your food as you cook it, so you end up ingesting PFAS chemicals in your food. If you want to avoid PFAS in your cooking equipment, look for ceramic pots and pans, which are non-stick and shouldn't contain these dangerous chemicals. Read the manufacturer's marketing materials to look for mentions of PFAS, PFOA, or PTFE, and contact the manufacturer if you're unsure. Water-Repelling Textiles Certain textiles, especially those used to make ponchos and raincoats, are still made using PFAS and similar toxic chemicals today. PFAS continue to be favored for this use because of their unparalleled ability to repel water, dirt, and oil. A recent study found that 72% of textile products with water- or stain-resistant coatings, including bedding, tablecloths, raincoats and yoga pants, contained PFAS. Many of these items were sourced from big name retailers, like Walmart, Target, and REI. It's highly unlikely that PFAS will be absorbed through your skin from a textile containing these forever chemicals. However, the big issue with PFAS still being used so widely in textiles is that it increases the likelihood of PFAS contamination in the environment due to an increase of PFAS products in landfills. Once in the environment, PFAS can contaminate our water, soils, and soil-grown foods. Cleaning Products Cleaning products, including dishwasher detergent, stain removers, and laundry detergent, often contain PFAS to improve their effectiveness. Cleaners and stain-removers used in dry-cleaners may also contain PFAS. One Florida-based study of seven dry cleaning facilities found that two of these facilities used cleaning products containing PFAS. So, while PFAS chemicals aren't guaranteed to be used at dry cleaners, it's worth checking in advance before you send your items to be laundered. Personal Care Products PFAS are also still widely present in a number of personal care products, including shampoos, nail polish, hand sanitizer, dental floss, and eye makeup. There are a few reasons why PFAS might be used for this purpose, depending on the product type. In cosmetics, PFAS are favored because they smooth and condition the skin, giving a shiny appearance. In other products, PFAS are simply used to improve texture and consistency. The water-repelling abilities of PFAS make them useful in products that are used alongside water but need to maintain their form long enough to take effect, like shampoos and conditioners. The particularly worrying fact about PFAS in personal care products is that early studies suggest PFAS can be absorbed through the skin, and can cause the same harm as ingestion of these chemicals. Carpets, Furniture, & Upholstery Clothing items aren't the only fabrics to contain PFAS compounds. Stain-resistant coatings are also used on carpets, upholstery, leathers, and other fabrics. PFAS might be found in any item of stain-resistant furniture in your home. The good news is that most carpet manufacturers have now phased out the use of PFAS chemicals in their consumer products, but there's still a risk of PFAS exposure from contact with older carpets and furniture items. One 2018 study of the carpets in 18 different California-based childhood centers found that samples of carpets and dust contained high levels of more than 40 different PFAS. The study predicted that children at these centers were at risk of an estimated PFAS intake of 0.023-1.9 ng/kg body weight per day via dust ingestion. Firefighting Foam PFAS are still used in Aqueous Film Forming Foams (AFFF), which are used to tackle flammable liquid fires, (or Class B fires). These foams are highly effective, but they're also a major cause of PFAS water contamination and contaminated soil in the environment across the world. The problem with the use of AFFF foams is that it's very difficult to prevent these foams from contaminating local areas due to runoff and seepage. Several states have begun restricting the use of AFFF foams in some use cases (such as in training exercises), but as of yet, there is no federal ruling that prohibits firefighting entities from using these foams in their line of work. Foods You might also be exposed to PFAS in the foods you eat. We already know that PFAS is used in the packaging for certain types of food. PFAS could enter these foods through contact with their packaging. Contamination on farms is another source of PFAS food contamination. Eggs, dairy products, shellfish, fish, and certain types of meat, especially organ meats, have been found to contain larger concentrations of longer-chain PFAS. Essentially, any food source that has been grown or raised using water, soil, or biosolids contaminated with PFAS is at risk of being exposed to these toxic chemicals. Related Articles: - The Top 6 Water Filters for PFAs “Forever Chemicals” in - Effective Ways to Remove PFAS from Drinking Water - Exploring the Effectiveness of Reverse Osmosis for Removing PFAS from Water 📑 Final Word If you're not ingesting PFAS compounds in contaminated drinking water, there's a high likelihood that you're still exposed to these chemicals in other consumer products, like food packaging, stain resistant sprays and cleaners, carpets, nonstick cookware, fast food containers, and cosmetics. The Environmental Protection Agency is yet to make an official regulation for PFAS in drinking water, which is one of the reasons why we think this chemical is still so widely used in manufacturing today. What can you do to reduce your PFAS exposure? We recommend that you start reading labels closely and know what your products contain before you buy them. This especially applies when you're buying cookware, stain-resistant carpeting, cleaning products, and personal care products. You can also lobby for companies to ban PFAS in their products, whether by contacting the manufacturers directly, making your voice known on social media, or speaking to your local policymakers. Hopefully, there will come a time in the near future when the health risks of PFAS are taken seriously and they're no longer used in our products - but until that day comes, it's important to try to reduce your PFAS exposure as much as possible. Read the full article

0 notes

Text

What are the benefits of using natural soap Your Skin will Observe the Change

Soap isn't as it was once. Many soaps sold on shelves in supermarkets have more common than soaps that contain washing powder. Disagree? We don't agree? There are currently very few true soaps on the market. Most body cleanser products, liquid and solid, are synthetic detergent products. We were surprised by this. If you're in agreement we'll take a closer review of the differences between these two is, and why it is important.

Two very different soaps

Mixing oils, fats, and lye makes soap. Saponification is the process of mixing fats or oils with the lye. The end result is whipped Body Butter + Glycerin. The use of olive oil leaves elements of olives. Using coconut oil leaves components of coconut, and it goes on. There are other natural ingredients, like Shea butter to nourish the skin or oatmeal to provide exfoliating properties. Nothing should be removed and there is no need for synthetic chemicals to be added. This pure soap is fine in its current form.

On the other hand, we have detergents that are mass-produced, let's call them synthetic soaps. Following the process of saponification the products are stripped of their most important ingredient, glycerin. Glycerin is a natural humectant that helps to draw moisture to your skin and is known as an emollient that soothes. Some soap makers are not cautious enough to separate the glycerin out of the soap they sell or in their higher-end soaps. They often then include synthetic ingredients, detergents foaming agents, chemical fragrances to the glycerin lacking soap to mimic the properties of the ingredients that were taken out.

From trash to traditional

There was once an era when soap was handmade. The traditional way to create it was, and is, called the cold process. Once the soap is prepared, it's poured into molds that will saponify over one day, then taken out to dry for a few days before being cut into bars of soap and left to cure for up to a month. It's as natural as soap gets and that's the way we make our soap here at All Natural Body butter. In the 19th century, when it was realized that glycerin could be extracted from soap everything changed.

Due to the rapid growth of industrial manufacturing, the smaller soapmakers who were hand-crafted were forced out by larger companies that capitalized on being able extract valuable glycerin that could later be sold off or used in other profitable products. Glycerin for instance is a key ingredient in nitroglycerin (the explosive that is used in the making of dynamite) and there was plenty of demand for it in the early 20th century. Glycerin-free soap was offered as a byproduct, and then mixed with synthetic ingredients to resemble the real soap. It was cheaper than soap made by hand makers.

The things you don't require

Check out what ingredients are in a typical bar of soap you can purchase from your local store. It may be made up of sodium lauryl Sulfate (SLS) an anionic surfactant that is used in laundry detergents, which can dry out and irritate your skin. It could also contain sodium laureth-sulfate (SLS), a low-cost foaming agent that can be contaminated with Dioxane.

If it's listed as antibacterial, it's likely to contain triclosan. It is classified as a pesticide by Environmental Protection Agency. The majority of antibacterial liquid soaps and the third of bar soaps contain triclosan believed to be contributing to increasing resistance of bacterial strains across the globe. This chemical can get into our waterways, and can disrupt the photosynthesis of algae. It accumulates in the fat tissues of fish, and carries it up the food chain.

The Only Thing You Really Need, Naturally

There are many natural oils, butters, plant extracts and exfoliants that can be used in real natural soap, ingredients that are truly beneficial for your overall health and skin. Take coconut oil, with its moisturizing and disinfectant properties, and vitamin E, essential for healthy and glowing skin. There's also Shea butter, with its skin-healing properties which have been considered to be highly valued from the time of the Pharaohs in Ancient Egypt. Eucalyptus contains natural antibacterial and antifungal properties. Peppermint leaves can also be used as a decongestant and create an invigorating and fresh scent. Soaps that are effective don't need to clean you only, they can help you feel healthier and feel much better too.

2 notes

·

View notes

Text

6 Factors to Consider When Buying a Lotion Pump Dispenser

Lotion pumps are used in a wide variety of liquid products – we’re talking about soaps, body wash, hand creams, and the likes. Products with lotion pump dispensers are more noticeable and preferable by consumers, and why wouldn’t they? Lotion pumps are incredibly convenient to use, plus they last long.

If you are thinking of buying a lotion pump dispenser but doesn’t know how to check which is better and which is not, then you bumped in the right article. We’re going to list down six factors that you have to look at to land on the ideal pump closure for your containers. More than that, we made an additional list of six lotion pumps from YEHPAK that you have to check out. So, let’s go!

See our checklist that you need to weigh in when deciding which variety of lotion pump to buy.

Material Composition

The material composition of the lotion pump will determine the durability of the equipment. Aside from the commonly used polypropylene (PP) plastic, there are quite a lot of varieties you can select from, such as ceramic, steel, and glass materials.

Before you opt for a lotion pump dispenser, you must first evaluate where do you plan to use it. Will it be for personal use? For commercial use? Or for business consumption? If it is for private or household access, then ceramic or steel type would be excellent for aesthetics and longevity. If it is for commercial use, steel is preferable for durability. Last but not least, if it is for business, then plastic and glass type is your best option since they are lightweight and cost-efficient.

Neck Size

It is essential to know what is the precision of the neck size you are looking for. Some variables include 20/410, 20/415, 24/410, and 24/415 – and these sizes can almost match to various bottleneck sizes. Through this, you can create a perfect bottle–dispenser match, while trying your selected pump into different bottles of your product.

Tube Length

You also have to check the tube length. Note that the plastic tube used inside the container can be cut to the ideal size of the chamber. Besides, the diameter of the tube will depend on the thickness of the liquid inside the bottle. So choose wisely.

Pump Dosage

0.5ml,0.12ml, 0.28ml, 1.4ml, and 2.0ml are just some of the popular dosing amount variables. Choosing your airless pump bottles dose will rely on product specifications, expected usage, cost of the product, or bottle capacity.

Color

Since dispensing pumps are typically made of plastic in the manufacturing process, it would be effortless to add color along the process. This can be arranged easily if a client prefers dispensing pump customization in bulk. Frequently, they can also be colored with an aluminum sheath, which gives a compelling look and defines a luxury edge of a particular product.

Price

Every person in business knows that quality is essential, so if you opt for a good quality product, then you better be prepared to pay more. However, if the type of quality is none of your concern, then you can always choose for an economical pump dispenser – as long as it provides its purpose, then you won’t have a problem.

We have good news! If you are looking for a durable and excellent quality lotion pump, then you have to see YEHPAK’s bestsellers. What’s more, is that they’re offered at reasonable prices. Check them all out!

This white lotion pump has a 24/410 neck size, a discharge rate of 2cc, and a tube length of 90mm. This selection is ideal for liquid soap products and other house cleaning materials for ease of access

This lotion pump is open for product customization, depending on your style and color preference. You can choose from 24/410, 28/400, 28/410, and 28/415 neck sizes. This selection is best used for liquid soap, body wash, and lotions.

This lotion pump is available at 4 neck sizes – 24/410, 28/400, 28/410, and 28/415. You can opt for nail polish remover push pump dispenser customization with a discharge rate of 2cc. Also, you can select metallic colors, which is best for cosmetic items.

This smooth black lotion pump is available in a wide range of neck sizes. You may choose from 20/410, 24/410, 24/415, 28/400, 28/410, and 28/415. Note that the dispenser is accessible for a discharge rate of 2cc – applicable to any bottled items.

Our smooth lotion pump dispenser is available at any color and ready for brand customization. You may select from 24/410, 28/400, 28/410, and 28/415 neck sizes. This selection has a discharge rate of 2cc and can be used for body wash, liquid soap, cleaning agents, cosmetics, and more.

Our nail polish pump dispenser is available in a wide range of neck sizes. You may choose from 20/410, 24/410, 24/415, 28/400, 28/410, and 28/415. Note that the dispenser is accessible for a discharge rate of 2cc, and is best used for body wash, liquid soap, and shampoo packaging

Plastic lotion pumps, one of the most popular dispensing methods for viscous (thick liquid) products in the personal care and beauty industry, come in all shapes and sizes. When used as designed, pumps dispense the right amount of product time after time. But have you ever wondered what goes in a lotion pump to makes it work? While there are hundreds of different designs in the market today, the basic principle is the same, and Packaging Crash Course took apart one of these lotion pumps to give you an overview of these components, and how they contribute to the overall functionality of pumping the product from the bottle to your hand.

Generally speaking, a lotion pump consists of the following components :

Actuator : An actuator, or the pump head, is what the consumer presses down to pump the product out of the container. The actuator is often made of PP plastic and can have many different designs - and often come with a up-lock or down-lock features to prevent accidental output,. This is one of the component designs that can set one pump apart from another when it comes to the exterior design, it is also the part where ergonomics play a role in consumer satisfaction.

Closure : The component that screws the entire assembly onto the neck finish of the bottle. It is identified with the common neck finish destination such as 28-410, 33-400. Often made of PP plastic, it is often designed with a rib side or smooth side surface. In certain cases a shiny metal overshell can be installed to give the lotion pump a high-end, elegant look.

A lotion pump acts much like a air suction device that draws the product from the bottle to the consumer's hand despite the law of gravity telling it do the opposite. When the consumer presses down on the actuator, the piston moves to compress the spring and the upward air pressure draws the ball upwards, along with the product inside, into the dip tube and subsequently the chamber. As the user releases the actuator, the spring returns the piston and actuator into it's up position, and the ball is returned to it's resting position, sealing the chamber and preventing the liquid product from flowing back down into the bottle. This initial cycle is called "priming". When the user presses down on the actuator again, the product that is already in the chamber will be drawn from the chamber, through the stem and actuator, and dispense out of the pump and onto the consumer's hand. If the pump has a bigger chamber (common for high output pumps), it may require additional priming before the product will be dispensed through the actuator.

Lotion Pump Output

The output of a plastic foam pump is often measured in cc (or ml). Commonly in the range of 0.5 to 4cc, with some larger pumps with bigger chambers and longer piston / spring components having output up to 8cc. Many manufacturers have multiple output options for each of their lotion pump offerings, giving the product marketer full control of dosage. For more information about pump output, please see our other Quick Question Monday article here.

To see a catalog list of the lotion pumps that O.Berk has to offer, please feel free to click here. If you have more questions about lotion pumps in general, please don't hesitate to contact us directly here.

Choosing the right fluid dispensing pump for a given application is critical. Whether it’s accuracy and precision or the need to perform for millions of cycles, understanding the most suitable types of pumps available is the first step. This article describes several pumps commonly used for medical manufacturing applications. It examines their advantages and disadvantages. In addition, it discusses how to maximize accuracy by minimizing fluid slip, an important factor in the design of any positive displacement pump. It also looks at the importance of testing the fluid prior to determining what pump is best for the application.

There are essentially two types of drive systems that control fluid delivery using positive displacement. Linear drive systems and rotary drive systems. Positive displacement pumping refers to a pump that retracts in a cavity to generate volume on the suction side and extends into the cavity displacing the fluid on the discharge. This is a constant for each cycle. Both linear and rotary positive displacement pumps provide exceptional accuracy and precision. However, each method has its’ advantages and disadvantages.

Calibration. In a rotary application, the volume of displacement is a factor of the pump angle relative to the motor axis. Once the volume is calibrated, the pump module can be locked into position. The displacement is adjustable so it should be checked to confirm that calibration is still within specification. In a linear application, mechanical calibration is not required. The pump module is set in a static location, and volume is determined by how far the piston retracts in the cavity. There is no mechanical set point to change volume; only software is used to adjust this parameter.

Cycle Time. Rotary pumps can produce faster dispenses because the rotary valving motion and linear displacement motion are performed simultaneously. A single cycle is controlled by one revolution of the motor. Multiple revolutions will produce larger volumes based on the pumps fixed volume. Cycle time and the ability to produce a more constant flow rate (based on pump revolutions) are the rotary pumps’ strengths. The dispense profile of a rotary pump includes pulsations which are due to the sinusoidal waveform. This offers the unique advantage of firing off small volumes of fluid very quickly. An example of a rotary application would be dispensing microliter range dots of fluid onto a substrate passing through a high-speed automation system.

By contrast, a linear pump must retract from the suction port to draw fluid into the chamber valve to the discharge port, and then eject the fluid. In general, larger volumes require more time, depending on pump size. The linear dispense creates a flat dispense profile with no pulsation throughout the entire chamber capacity of the pump module. If more volume or a longer dispense is required, two pumps may be run out of phase so that one pump is discharging while the other is on the intake stroke. An example of a linear application would be dispensing a constant line over a distance, such as a diagnostic reagent, or precisely filling a substrate with slow absorption rates. Continuous web applications are ideal for this tandem approach.

1 note

·

View note

Text

Sodium Lauryl Ether Sulfate Market: Forthcoming Trends and Share Analysis by 2030

The Global Sodium Lauryl Ether Sulfate [SLES] market was estimated at USD 1.24 billion in 2021, and is anticipated to reach USD 1.58 billion by 2028, growing at a CAGR of 3.5%.

Sodium Lauryl Ether Sulfate (SLES) is a widely used surfactant and foaming agent in various personal care and household products. It is derived from ethoxylated lauryl alcohol and is known for its excellent cleaning and foaming properties. The market for SLES has experienced steady growth over the years, driven by the increasing demand for personal care products, including shampoos, body washes, soaps, and detergents. The versatility and effectiveness of SLES in cleaning applications make it a popular choice among manufacturers across the globe.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

https://introspectivemarketresearch.com/request/15858

Updated Version 2024 is available our Sample Report May Includes the:

Scope For 2024

Brief Introduction to the research report.

Table of Contents (Scope covered as a part of the study)

Top players in the market

Research framework (structure of the report)

Research methodology adopted by Worldwide Market Reports

Leading players involved in the Sodium Lauryl Ether Sulfate Market include:

Godrej Industries, BASF, Taiwan NJC Corporation, Stepan Company, Ultra Group, Kao Corporation, Croda International, Galaxy Surfactants, Ho Tung Chemical, Evonik Industries, Huntsman Corporation, Clariant Corporation, The Dow Chemical Company, Solvay, Zhejiang Zanyu Technology, Merck KGaA, Sasol and other Major Players.

Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years.

If You Have Any Query Sodium Lauryl Ether Sulfate Market Report, Visit:

https://introspectivemarketresearch.com/inquiry/15858

Segmentation of Sodium Lauryl Ether Sulfate Market:

By Type

Cosmetic Grade

Industrial Grade

Pharmaceutical Grade

Others

By Production Method

Inorganic Based

Coco Based

By Form

Liquid

Dry

By Application

Household Detergents & Cleaners

Personal Care Products

Dishwashing Liquids

Medical

Others

By Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

Highlights from the report:

Market Study: It includes key market segments, key manufacturers covered, product range offered in the years considered, Global Sodium Lauryl Ether Sulfate Market, and research objectives. It also covers segmentation study provided in the report based on product type and application.

Market Executive Summary: This section highlights key studies, market growth rates, competitive landscape, market drivers, trends, and issues in addition to macro indicators.

Market Production by Region: The report provides data related to imports and exports, revenue, production and key players of all the studied regional markets are covered in this section.

Sodium Lauryl Ether Sulfate Market Profiles of Top Key Competitors: Analysis of each profiled Roll Hardness Tester market player is detailed in this section. This segment also provides SWOT analysis of individual players, products, production, value, capacity, and other important factors.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=15858

About us:

Introspective Market Research (introspectivemarketresearch.com) is a visionary research consulting firm dedicated to assisting our clients to grow and have a successful impact on the market. Our team at IMR is ready to assist our clients to flourish their business by offering strategies to gain success and monopoly in their respective fields. We are a global market research company, that specializes in using big data and advanced analytics to show the bigger picture of the market trends. We help our clients to think differently and build better tomorrow for all of us. We are a technology-driven research company, we analyse extremely large sets of data to discover deeper insights and provide conclusive consulting. We not only provide intelligence solutions, but we help our clients in how they can achieve their goals.

Contact us:

Introspective Market Research

3001 S King Drive,

Chicago, Illinois

60616 USA

Ph no: +1-773-382-1049

Email: [email protected]

#Sodium Lauryl Ether Sulfate#Sodium Lauryl Ether Sulfate Market#Sodium Lauryl Ether Sulfate Market Size#Sodium Lauryl Ether Sulfate Market Share#Sodium Lauryl Ether Sulfate Market Growth#Sodium Lauryl Ether Sulfate Market Trend#Sodium Lauryl Ether Sulfate Market segment#Sodium Lauryl Ether Sulfate Market Opportunity#Sodium Lauryl Ether Sulfate Market Analysis 2024

0 notes

Text

How to Make Mold Release Agent: Complete Guide and Tips

To produce large quantities of similar products, manufacturing companies use molds. This process is very efficient and doesn’t take plenty of time, which is another reason why brands use it. Some of the final products which were made using molds include glass, metal, rubber, plastic, and similar. What’s more, molds are also implemented in compression, blow molding, injection, and more, to name just a few. But when producers use mold, they need a chemical component that separates the materials from the mold. And that chemical has a name – mold release agent.

That’s why we compiled a thorough and detailed guide about everything there is to know about the mold release oil or agent. We’ll define the term, see its various types and where it can be applied. After that, we’ll move on to the production process and end with factors to consider when buying mold release agents. Read on and take notes!

What Is a Release Agent?

For all those who aren’t familiar with the term, a release agent is a chemical that stops the materials from bonding with the surface of the mold. You can even find it under different names such as a de-molding agent. Its main role is to create an effect of slipping so that the substance easily separates from the mold. Metaphorically speaking, it’s like putting a bit of butter in the pan before you plan to bake something with the idea to effortlessly remove the food from the pan’s bottom after you’re done with the cooking.

Thus, the answer to the question ‘What's mold release agent?’ is that it’s considered to be a crucial barrier that prevents the substance from blending with the mold. If that happens and a release agent isn’t used, manufacturers have to perform elaborate processes of cleaning up. All of that may result in losing plenty of time as well as productivity. That’s why companies who implement mold release oils look towards them as an investment rather than a cost once they find the oil that suits their needs and production.

It’s common for mistakes to happen even while using this type of chemical. For instance, an agent that isn’t right for the product or its wrongful usage can have huge negative consequences. That may impact the whole overall quality and performance of the finished product. But we’ll get to that very quickly.

The Functionality of the Release Agent

As we previously stated, the main function of the release agent is to act as a barrier. However, more very useful functions can be attributed to it. We’ll cover some of the most important ones now.

Having said that, these chemicals have the ability to minimize the production period. That’s why manufacturing firms can work with exceptionally tight and rigorous schedules. The release agents will help them increase the volume of materials during the process of molding. If that isn’t enough, the whole cycle time of the process is significantly reduced. In return, that translates to saving time as well as money for the brand.