#Manufacturer and supplier of Stainless Steel Tubes and Pipes

Explore tagged Tumblr posts

Text

Steel tubes Manufacturers & Suppliers

Steel pipes, tubes and fitting accessories are essential components in various industrial applications, including construction, oil and gas, infrastructure, and manufacturing. These products are made from high-quality steel materials and are designed to withstand high pressure, corrosion, and extreme temperatures. Fitting accessories for pipes and tubes include a range of components such as elbows, tees, reducers, flanges, valves, and connectors.

#Pipes & fitting accessories#Pipe Suppliers in india#Manufacturer and supplier of Stainless Steel Tubes and Pipes#Seamless pipes#Water tank suppliers#Readymade Toilet Blocks & Accessories#Steel tubes Manufacturers & Suppliers

0 notes

Text

Nickel Alloy Tubes

Nickel Alloy Tubes are widely used in industries that demand exceptional corrosion resistance, high-temperature strength, and durability. These tubes are ideal for applications in chemical processing, aerospace, power generation, marine, and heat exchangers, where exposure to extreme conditions is common. With excellent resistance to oxidation and thermal stress, Nickel Alloy Tubes ensure reliable performance in harsh environments.

#Nickel Alloy Tubes#manufacturer of u tubes#buy seamless tubes and pipes#coil formed tubes manufacturing process#heat exchanger tubes manufacturer#manufacturer of stainless tubes and pipes#seamless tube suppliers#buy coil formed tubes#manufacturer of coil formed tubes#manufacturer of instrumentation tubes#manufacturer of stainless steel pipe

0 notes

Text

Everything You Need to Know About Stainless Steel 317 Sheets and Plates: Properties, Applications, Benefits, and Specifications

Stainless Steel 317 sheets and plates are widely used in various industries due to their superior corrosion resistance, high strength, and excellent durability. This grade of stainless steel is particularly valued in harsh environments where resistance to chemical attack and oxidation is crucial. In this blog, we will explore the properties, applications, benefits, and specifications of Stainless Steel 317 sheets and plates.

What is Stainless Steel 317?

Stainless Steel 317 is an austenitic stainless steel alloy with higher levels of molybdenum and chromium, making it more resistant to corrosion than standard 316 stainless steel. The increased molybdenum content enhances its ability to withstand acidic and chloride-rich environments, making it ideal for use in industries such as chemical processing, marine, and pharmaceuticals.

Properties of Stainless Steel 317 Sheets and Plates

Corrosion Resistance – Superior resistance to pitting, crevice corrosion, and general corrosion, especially in acidic environments.

High Strength and Durability – Provides excellent mechanical properties even at elevated temperatures.

Heat Resistance – Retains its strength and structure in high-temperature applications.

Weldability – Easily weldable using conventional techniques without requiring post-weld heat treatment.

Formability – Can be easily formed and fabricated into different shapes and sizes.

Applications of Stainless Steel 317 Sheets and Plates

Due to its exceptional properties, Stainless Steel 317 is used in various industries, including:

Chemical Processing – Ideal for handling acidic and corrosive substances.

Pharmaceuticals – Used in manufacturing and processing equipment.

Food and Beverage Industry – Safe for food-grade applications due to its non-reactive nature.

Marine Industry – Resistant to saltwater corrosion, making it suitable for marine applications.

Pulp and Paper Industry – Used in bleaching plants where corrosion resistance is essential.

Heat Exchangers and Boilers – Performs well under high temperatures and pressure conditions.

Benefits of Using Stainless Steel 317 Sheets and Plates

Longer Service Life – Enhanced resistance to wear and tear increases its lifespan.

Low Maintenance – Requires minimal upkeep due to its corrosion-resistant nature.

Cost-Effective – Although initially more expensive, it offers long-term savings due to durability.

Versatility – Suitable for various industrial and commercial applications.

Aesthetic Appeal – Provides a sleek and polished appearance for architectural applications.

Specifications and Standards

Stainless Steel 317 sheets and plates are available in various thicknesses, widths, and lengths to meet specific industrial requirements. Common standards and specifications include:

ASTM A240 – Standard specification for chromium and chromium-nickel stainless steel plate, sheet, and strip.

UNS S31700 – Unified numbering system designation for Stainless Steel 317.

EN 1.4449 – European standard designation.

Thickness – Ranges from 0.5mm to 100mm.

Width – Varies from 1000mm to 2500mm.

Length – Available in standard and customized lengths.

Conclusion

Stainless Steel 317 sheets and plates are a top choice for industries requiring high corrosion resistance, strength, and durability. Their versatility makes them suitable for various applications, from chemical processing to marine and food industries. Investing in Stainless Steel 317 ensures long-lasting performance, cost savings, and reliability in demanding environments.

For those looking to source high-quality Stainless Steel 317 sheets and plates, it is essential to choose a trusted supplier to guarantee superior material quality and compliance with industry standards.

#heavy metal#metal family#metalcore#pipesupplier#metal sheets#plates#pipes & tubes#industrial metal#metal sonic#metal#Stainless Steel 317 Sheets And Plates Manufacturers#Stainless Steel 317 Sheets And Plates Suppliers#Stainless Steel 317 Sheets And Plates Stockists#Stainless Steel 317 Sheets And Plates Exporters

0 notes

Text

Stainless Steel 316 / 316L Screw Exporters in India

Nascent Pipe & Tubes is one of the prominent traders and stockiest for Stainless Steel 316 / 316L Fasteners (Screws), which would make the grain boundary areas less corrosion resistant. Stainless Steel 316 Hex Head Screws will be less susceptible to sensitization, a condition caused when carbon combines with chromium around the grain boundaries, thereby depleting the grain boundary areas of chromium.

Sensitization occurs with heating into the 800 Degree F to 1300 Degree F region, so Stainless Steel 316L Socket Head Cap Screws is a welding or annealing problem. If you use a Stainless Steel 316 Socket Set Screws with high carbon content the welds may crack spontaneously as they cool down from the welding, where this type of cracking is known as “hot brittleness”. In other words, Stainless Steel 316L Anchore Screws is more resistant to intergranular corrosion.

SS 316-316L Screws Specifications

Specifications

ASTM A 193 ASME SA 193

StandardIS, ASTM, BS and all International Standards

Length3 mm to 200 mm

SizeM3 – M33

TypeHex Head Screw, Socket Head Cap Screw, Socket Set Screws, Anchor Screw, Blind Rivet, Concrete screw, Threaded Screw, Steel Shoulder Screw, Panel Screw, Machine Screw.

0 notes

Text

About Navneet Metal Corporation

In a world of industrial metal supply, it is crucial to find a reliable partner that combines quality, precision and customer -centric values. For over two decades, the Names Metal Corporation has been the partner for many who provide top-tier metal products and unique service.

Navneet Metal Corporation, headquartered in India, has grown from a small local supplier to a well-known name in the metal industry, known for its commitment to quality and comprehensive portfolio of metal products.

What is unique about Navneet Metal Corporation?

Wide range of products

Navneet Metal Corporation offers a wide range of metal products such as coils, sheets, pipes, rods, bars, etc. They offer metals in various grades and sizes to meet various industrial needs, serving industries ranging from engineering and infrastructure to manufacturing and construction.

Unsurpassed quality standards

Quality is the focus of the metal industry.

Navneet Metal Corporation uses only reliable manufacturers who maintain strict quality control throughout the process.

Each product is thoroughly tested to ensure it meets national and international standards, providing durable and reliable materials for all applications.

Why Choose Navneet Metal Corporation?

Partnering with Navneet Metal Corporation means choosing a supplier that prioritizes quality, reliability, and customer satisfaction. Their longstanding relationships with both clients and manufacturers have enabled them to maintain competitive pricing without compromising on quality. From helping clients find the right product to providing efficient logistics and after-sales support, Navneet Metal Corporation is a full-service metal supplier.

Industries Served by Navneet Metal Corporation

Navneet Metal Corporation caters to a wide range of industries, including:

Construction and Infrastructure – supplying high-strength metals for building and infrastructure projects.

Manufacturing and Engineering – offering raw materials for machinery, automotive parts, and other manufactured goods.

Energy and Power Generation – providing metals that meet the demanding standards for energy applications.

Medical and Pharmaceutical – with metals suitable for equipment and sterile environments.

Conclusion

In an industry where quality, reliability, and precision are paramount, Navneet Metal Corporation stands out as a leader. Their commitment to excellence, combined with a focus on innovation and sustainability, makes them a preferred partner for companies across various sectors. As Navneet Metal Corporation continues to expand, they remain dedicated to providing exceptional products and solutions that meet the evolving needs of the metal industry.

For more information on products, services, or to discuss a custom order, reach out to Navneet Metal Corporation’s team of experts. Discover a supplier that not only understands your needs but is committed to exceeding your expectations.

#Stainless Steel Suppliers#Industrial Metal Supplier#Navneet Metal Corporation#Quality Metal Distributor#Stainless Steel Coil Supplier#Precision Metal Manufacturing#High-Quality Steel Distributor#Metal Sheets and Plates Supplier#Stainless Steel Bar Supplier#Alloy Steel Supplier#Navneet Metal Steel Products#Metal Tubing and Pipes Supplier#Metal Stockist and Distributor#Metal Fabrication Services#Steel and Metal Distributor#Stainless Steel for Industrial Use#Metal Sheets and Coils Supplier#Stainless Steel Strip Supplier#Industrial Metal Manufacturer#Quality Metal Supply India#Wholesale Stainless Steel Supplier#Stainless Steel Sheets and Plates#Stainless Steel Pipe Manufacturer#Leading Metal Corporation India#Metal Product Exporter#Stainless Steel Bars and Rods#Metal Supply for Construction#Metal Industry Supplier#Premium Stainless Steel Products#Industrial Metal Stockists

0 notes

Text

Leading Stainless Steel Tubes Manufacturer for Industrial Needs - MPJ tubing is the industry leader in tubing, piping, and stainless steel tube manufacturing. Contact now

Leading Stainless Steel Tubes Manufacturer for Industrial Needs - MPJ tubing is the industry leader in tubing, piping, and stainless steel tube manufacturing. Contact now

MPJ Tubing is the go-to choice for all your stainless steel tubing and pipes needs. As a leading manufacturer in the industry, we pride ourselves on our top-quality products and exceptional customer service. Our stainless steel tubes are perfect for a variety of industrial applications and are sure to meet your needs. Whether you are a buyer, exporter, or importer, MPJ Tubing has the products you need to get the job done right. Contact us today to learn more about how we can assist you with all of your stainless steel tubing needs.In addition to our wide range of stainless steel tubing options, MPJ Tubing also offers customization services to ensure that you get the perfect product for your specific application. Our team of expert engineers and designers will work with you to create a customized solution that meets your exact specifications and requirements. Furthermore, MPJ Tubing is committed to sustainability and environmental responsibility. We strive to minimize waste and emissions throughout our manufacturing process and are constantly looking for ways to reduce our carbon footprint. By choosing MPJ Tubing for your stainless steel tubing needs, you can feel confident that you are supporting a company that values environmental stewardship. In conclusion, when it comes to stainless steel tubing, MPJ Tubing is the clear choice. With top-quality products, exceptional customer service, customization options, and a commitment to sustainability, you can trust MPJ Tubing to meet all of your industrial tubing needs. Contact us today to learn more about how we can help you with your next project.

HEAD OFFICE

101, Shreepati Castle C-Wing, 1st Floor, Khetwadi Main Road, Opp Union High School, Mumbai, India

LET'S TALK

+91 22 23870230 +91 22 66362484

MAIL US

FACTORY UNIT 1

Survey No 120, Unit No 3 At Chadasna, Ambavpura Road Nr GIDC, Phase 3, Chhatral, Kadi, Mehsana, Gujarat, India.

FACTORY UNIT 2

Survey No.:860, Near Kamla Amrut Industrial Park Rajpur-Indrad Approach Road, Vill. Irana, Tal, Kadi, Gujarat, India.

WAREHOUSE

Plot No #14, 11th lane Khetwadi, Mumbai, Maharashtra, India.

#mpj tubing#stainless steel tube manufacturer#stainless steel#tubes manufacturers#pipe manufacturer#supplier#exporters#manufacturers#supplements#manufacturer

1 note

·

View note

Text

Discover the versatility of steel tubes in construction, including stainless steel options. Learn about their benefits, sizes, and the role of steel tubes manufacturers and suppliers.

#Steel tubes#stainless steel tubes#steel tubes and pipes#steel tubes manufacturers#steel tubes suppliers#steel tubes for construction#steel tubes sizes

0 notes

Text

Stainless Steel 316 Pipes/Tubes Manufacturer, Supplier in Oman | Bhagya laxmi industrial

A leading Stainless Steel 316 Pipes/Tubes Manufacturer, Supplier in Oman, offering high-quality products designed for various industrial applications. These pipes and tubes are known for their excellent corrosion resistance, durability, and strength, making them ideal for use in harsh environments. The extensive range of sizes and specifications ensures compatibility with diverse project requirements. Committed to delivering exceptional service and reliable solutions, this supplier meets the highest industry standards for quality and performance.

0 notes

Text

Stainless Steel 347H Pipes & Tubes Suppliers In India

Introduction: In the realm of industrial infrastructure, Stainless Steel 347H pipes and tubes are integral components, essential for fluid conveyance and structural integrity, particularly in high-temperature and corrosive environments. As industries in India endeavor for excellence and reliability in their operations, securing dependable suppliers for Stainless Steel 347H pipes and tubes becomes imperative. This article delves into the significance of Stainless Steel 347H pipes and tubes, elucidating why they are indispensable and highlighting the countries that rely on imports of these products.

Why you should use Stainless Steel 347H pipes and tubes:

Elevated Temperature Resistance: Stainless Steel 347H is specifically engineered for high-temperature applications, offering superior resistance to oxidation and corrosion at elevated temperatures. This property makes it ideal for use in environments where exposure to high heat and thermal cycling is prevalent, such as heat exchangers, furnace components, and exhaust systems.

Corrosion Resistance: Stainless Steel 347H pipes and tubes exhibit excellent resistance to corrosion, particularly in environments containing chlorides and other corrosive substances. This resistance ensures longevity and reliability, even in harsh operating conditions encountered in chemical processing, petrochemical, and aerospace industries.

High Strength and Durability: Stainless Steel 347H pipes and tubes possess high tensile strength and durability, providing structural integrity and withstanding high-pressure conditions at elevated temperatures. This characteristic ensures the safe and efficient transport of fluids and gases in demanding industrial processes.

Creep Resistance: Stainless Steel 347H demonstrates excellent creep resistance, maintaining dimensional stability and mechanical properties under prolonged exposure to elevated temperatures. This property ensures long-term performance and reliability in applications where thermal expansion and contraction occur.

Weldability and Formability: Stainless Steel 347H is readily weldable and formable, allowing for easy fabrication into various shapes and sizes. This versatility in fabrication makes it adaptable to a wide range of industrial applications, providing customized solutions to meet specific requirements.

Countries which import Stainless Steel 347H pipes and tubes from India:

United States: The United States imports Stainless Steel 347H pipes and tubes from India for various industrial applications, including chemical processing, oil and gas industries, and power generation.

United Kingdom: The United Kingdom relies on imports of Stainless Steel 347H pipes and tubes from India for use in architectural structures, automotive exhaust systems, and aerospace components.

Germany: Germany imports Stainless Steel 347H pipes and tubes from India for applications in automotive manufacturing, machinery construction, and industrial furnace components, where elevated temperature performance and corrosion resistance are crucial.

United Arab Emirates: The UAE imports Stainless Steel 347H pipes and tubes from India for use in construction, oil and gas refineries, and desalination plants, where they provide reliable performance in corrosive and high-temperature environments.

Conclusion: Stainless Steel 347H pipes and tubes play a crucial role in various industries, offering superior high-temperature resistance, corrosion resistance, strength, and weldability. Their versatility and reliability make them essential for fluid transport and structural applications in challenging environments. Industries in India and worldwide must prioritize sourcing Stainless Steel 347H pipes and tubes from trusted suppliers to ensure the integrity and efficiency of their operations, particularly in high-temperature and corrosive environments.

#Stainless Steel 347/347H Pipes & Tubes Manufacturers#Stainless Steel 347/347H Pipes & Tubes Suppliers#Stainless Steel 347/347H Pipes & Tubes Stockists#Stainless Steel 347/347H Pipes & Tubes Exporters#Stainless Steel 347/347H Pipes & Tubes Manufacturers In India#Stainless Steel 347/347H Pipes & Tubes Suppliers In India#Stainless Steel 347/347H Pipes & Tubes Stockists In India#Stainless Steel 347/347H Pipes & Tubes Exporters In India

0 notes

Text

We are a leader in Indian markets for many years in the field of manufacturing & exporting of Stainless Steel 310H Pipes & tubes. SS 310H Pipes and SS 310H Tubes are being used in the most significant engineering purposes and as well in certain functions in the automotive segment. Our SS 310H Pipes and Tubes are quite appropriate for flanging, bending, and parallel forming processes, and also for fusion welding.

#Stainless Steel 310H Pipes & Tubes Manufacturers#Stainless Steel 310H Pipes & Tubes Suppliers#Stainless Steel 310H Pipes & Tubes Stockists

0 notes

Text

Nickel Alloy Tubes

Nickel Alloy Tubes

KRYSTAL GLOBAL ENGINEERING LIMITED (Formally Known as Krystal Steel Manufacturing Private Limited) is a Stainless Steel company with the vision to be the Leader from INDIA in Stainless and Nickel Alloy Tubes with success based on Operational Excellence and Superlative Services.

We are dedicated to help our customers gain a competitive advantage by supplying a wide range of products such as Tubes, Pipes, U Tubes, Coil Formed Tubes.

KRYSTAL has well established “State of Art” facilitates with continuous enhancement of the product and services to serve the customers across the globe.

Tap here to know more about: https://krystalgeltd.com

#Bright Annealed tubes#Buy Seamless Tubes and Pipes#capillary tubes#Heat Exchanger Tubes Manufacturer#Inconel alloy#Instrumentation Tube#Seamless Tube Suppliers#Seamless Heat Exchanger Tube#Hydraulic Tubes Manufacturer#Manufacturer of Instrumentation Tubes#Manufacturer of Seamless tubes & Pipes#Manufacturer Heat Exchanger Tubes#Manufacturer of Stainless Steel Pipe#Manufacturer of Stainless Steel Tube and Pipe#Manufacturer of Stainless Steel Tubes#Monel alloy#Nickel Alloy Tubes#seamless pipe manufacturer#stainless steel bright annealed tubes manufacturers#stainless steel manufacturer in india#Stainless Steel Pipe manufacturers in India#Stainless Steel Pipe Manufacturing Company In Vadodara#Stainless Steel Seamless Pipes#stainless steel seamless tubes

0 notes

Text

Seamless Pipe Manufacturer

A Seamless Pipe Manufacturer specializes in producing high-quality, durable pipes without any welded joints, ensuring superior strength and resistance to pressure. These manufacturers use advanced techniques like hot rolling, cold drawing, and extrusion to create seamless pipes for industries such as oil & gas, construction, automotive, and power generation.

#manufacturer of u tubes#buy seamless tubes and pipes#coil formed tubes manufacturing process#heat exchanger tubes manufacturer#manufacturer of stainless tubes and pipes#seamless tube suppliers#buy coil formed tubes#manufacturer of coil formed tubes#manufacturer of instrumentation tubes#manufacturer of stainless steel pipe

0 notes

Text

#heavy metal#metal#pipes & tubes#plates#industrial metal#metal sheets#pipesupplier#metal family#metalcore#metal sonic#Stainless Steel 316L Sheets And Plates Manufacturers#Stainless Steel 316L Sheets And Plates Suppliers#Stainless Steel 316L Sheets And Plates Stockists#Stainless Steel 316L Sheets And Plates Exporters

0 notes

Text

Stainless Steel 304 Pipes & Tubes Exporters In India

#Stainless Steel 304 Pipes & Tubes Suppliers#Stainless Steel 304 Pipes & Tubes Stockists#Stainless Steel 304 Pipes & Tubes Exporters#Stainless Steel 304 Pipes & Tubes Manufacturers In India#Stainless Steel 304 Pipes & Tubes Suppliers In India#Stainless Steel 304 Pipes & Tubes Stockists In India

0 notes

Text

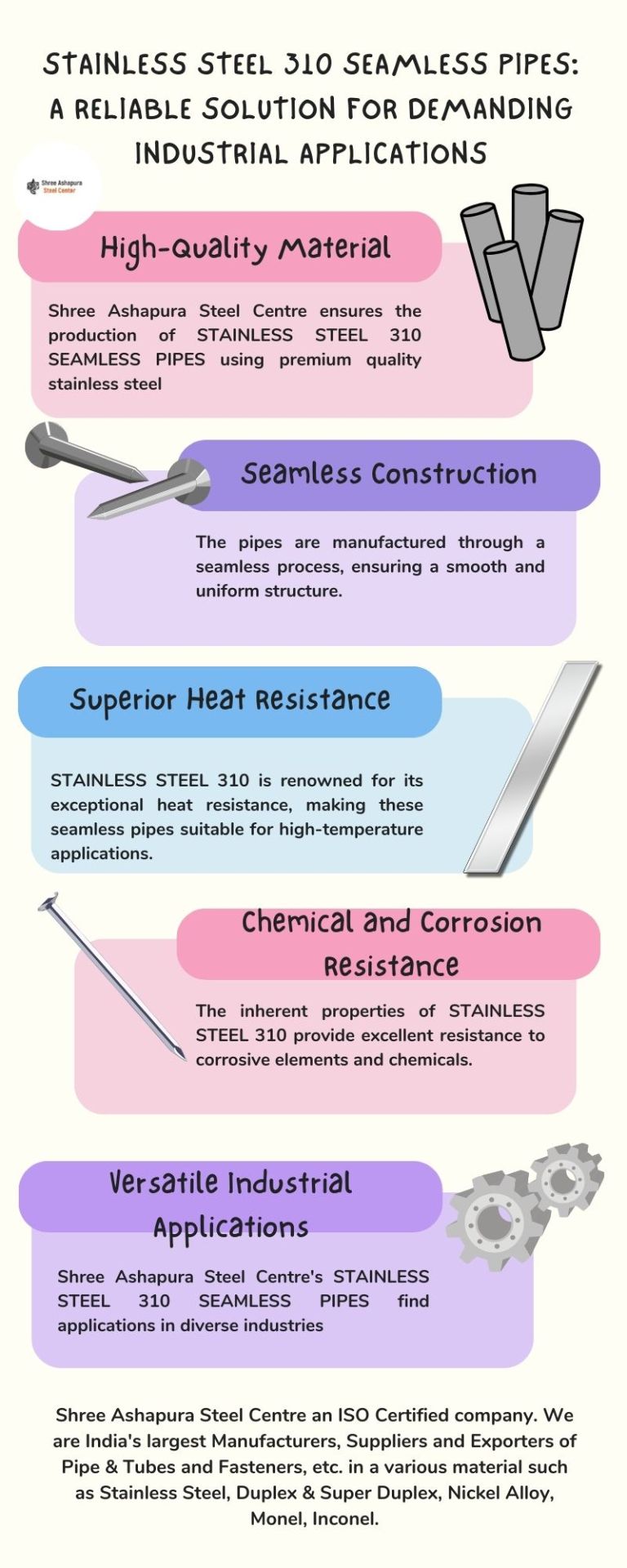

Shree Ashapura Steel Centre an ISO Certified company. We are India's largest Manufacturers, Suppliers and Exporters of Pipe & Tubes and Fasteners, etc. in a various material such as Stainless Steel, Duplex & Super Duplex, Nickel Alloy, Monel, Inconel.

#Stainless Steel 310 Seamless Pipe Manufacturer#DIN 1.4841 Seamless Tube#ASME SA312 SS 310 Polished Pipe#UNS S31000 Seamless Pipe Supplier#ASTM A312 TP310 Pipe#Stainless Steel 310 ERW pipe Stockiest#ss 310 tube#310 stainless steel square tubing#DIN 1.4539 Seamless Tube#ASME SA673 SS 904L Polished Pipe Manufacturer#UNS N08904 Seamless Pipe Supplier#ASTM A312 tp 904L Welded Pipe#DIN 1.4539 Rectangular Pipe#Stainless Steel 904L Seamless Tube Stockiest

0 notes

Text

Stainless steel square tube manufacturer in Uttarpradesh

Welcome to Nav Bharat Tubes, your go-to destination for top-quality stainless steel pipes, square tubes, and coils in Uttar Pradesh. As a leading stainless steel solutions provider, we take pride in offering a diverse range of products to meet the varied needs of industries across the region.

Jindal Stainless Steel Pipe Supplier in Uttar Pradesh:

Nav Bharat Tubes is your trusted partner as a Jindal stainless steel pipe supplier in Uttar Pradesh. Our commitment to excellence ensures that you receive premium quality stainless steel pipes manufactured by Jindal, a name synonymous with reliability and durability.

Stainless Steel Square Tube Manufacturer in Uttar Pradesh:

Explore the versatility and strength of stainless steel square tubes from Nav Bharat Tubes, a prominent manufacturer in Uttar Pradesh. Our state-of-the-art manufacturing facility ensures precision and quality, making our stainless steel square tubes the ideal choice for various applications.

Stainless Steel Coil Manufacturer in Uttar Pradesh:

Nav Bharat Tubes stands out as a premier stainless steel coil manufacturer in Uttar Pradesh. Our coils are crafted with precision and care, using the finest stainless steel materials. Whether you need coils for industrial, construction, or architectural purposes, we have you covered.

Comprehensive Stainless Steel Solutions:

At Nav Bharat Tubes, we offer a comprehensive range of stainless steel products to cater to the diverse needs of our clients. Our commitment to quality, coupled with a customer-centric approach, makes us the preferred choice for businesses seeking reliable stainless steel solutions in Uttar Pradesh.

Unrivaled Quality Assurance:

Quality is at the forefront of our operations. Nav Bharat Tubes adheres to stringent quality control measures, ensuring that each stainless steel product meets the highest industry standards. Our dedication to quality assurance reflects our commitment to delivering excellence to our valued customers.

Timely Delivery and Customer Satisfaction:

We understand the importance of timely deliveries in your projects. Nav Bharat Tubes takes pride in its efficient supply chain management, ensuring that you receive your stainless steel pipes, square tubes, and coils on time. Our customer-centric approach guarantees your satisfaction at every step.

Conclusion:

Choose Nav Bharat Tubes as your trusted partner for high-quality stainless steel pipes, square tubes, and coils in Uttar Pradesh. With our commitment to excellence, unrivaled quality assurance, and comprehensive product range, we stand as the preferred choice for industries seeking top-tier stainless steel solutions. Elevate your projects with Nav Bharat Tubes – where quality meets reliability.

https://navbharattubes.com/

9602233334

#Stainless steel coil manufacturer in Uttarpradesh#Stainless steel square tube manufacturer in Uttarpradesh#Jindal Stainless steel pipe supplier in Uttarpradesh

0 notes