#MakerBot Industries (Business Operation)

Photo

Build Your Very on Robot! French artist Gael Langevin has whipped up a DIY robot design and achieve the plans online for anyone (including you) to download and adapt ... source

#3D Film (Film Genre)#3d printing#Artist (Project Rol...#Build#Crowdsourcing (Industry)#DYI#inmoov#MakerBot Industries (Business Operation)#Robot#Robot (Film Subject)

3 notes

·

View notes

Text

TOP 10 COMPANIES IN 3D PRINTING PLA MARKET

The 3D printing PLA market is expected to grow at a CAGR of 19.8% from 2020 to 2027 to reach $818.0 million by 2027. 3D printing technology has been evolving rapidly and is expected to provide an ideal alternative to manufacturing processes in the coming years. The 3D printing PLA market is witnessing a rise due to the increasing focus on environmental conservation and the growing demand for biodegradable materials. 3D printing PLA is used across applications such as automotive, food & beverage, and artistic goods, emphasizing looks and form rather than strength and durability. In the automotive industry, PLA is frequently used to print tools, jigs, and fixtures, whereas, in food & beverage applications, it is used for customized packaging.

Here are the top 10 companies operating in 3D Printing PLA Market–

Stratasys LTD.

Founded in 1989 and headquartered in Rehovot, Israel, Stratasys is a manufacturer of 3D printers and materials, including FDM and PolyJet3D printers. The company offers prototypes, manufacturing tools, and production parts for industries, including aerospace, automotive, healthcare, consumer products, and education. The company offers PLA materials, which are made up of renewable sources. It not only helps to make the design quickly but also provides a variety of colors in them. The PLA was introduced for the Stratasys F123 series printers due to its tensile strength and high stiffness ratio, making it compatible with 3D printers. Some of the major subsidiaries of the company are MakerBot (New York), GrabCAD (U.S), Stratasys GmBh (U.S), Solid concepts (U.S), and Objet Geometries (Israel).

The company sells its products across the Americas, Europe, and Asia-Pacific, with countries including Brazil, China, Germany, Hong Kong, Israel, Japan, Korea, India, Mexico, the U.K., and the U.S.

ColorFBB B.V.

Founded in 2013 and headquartered in Belfield, Netherlands, colorFBB is engaged in manufacturing PLA/PHA filaments used in the 3D printing industry. The company offers its DPA-100 support material used in the 3D printing filaments. The company also offers color on-demand services to allow customers to choose their preferences and customize their products with 178 different colors of the PLA filament.

Currently, colorFBB is focusing on alliances and partnerships with the fablabs and 3D printing studios to expand its business. The company manufactures Stacker printers and stacker spares, which are widely in 3D printing. The company has expanded its verticals to the logistics department, serving customers in more than 60 countries globally.

Ultimaker B.V.

Founded in 2011 and headquartered in Geldermalsen, Netherlands, Ultimaker manufactures 3D printers, 3D printing materials, and 3D printing software. The company’s major resellers in the 3D printing filaments are MatterHackers, 3D Universe, 3DV Corporation, and Dynamism. The company has offices in the Netherlands, the U.S., Singapore, and production facilities in Europe and the U.S. Its products are widely used in the automotive, architecture, healthcare, and education industries.

Polymaker

Founded in 2012 and headquartered in Suzhou, Jiangsu, Polymaker manufactures polymer filaments and high-quality materials used in the 3D printing industry. The company manufactured the world’s first 3D printable foam-based filament used for designing 3D prototypes. It recently introduced polymaker pc-pbt, PolyMAx PC-FR, and PolyLite PC polycarbonate materials used to print on the METHOD X 3D printer.

Polymaker operates its business activities from the U.S., the Netherlands, and Japan to deliver various products used in the automotive, aerospace, industrial manufacturing, medical, consumer, and other sectors.

Torwell Technologies Co. Ltd.

Founded in 2010 and headquartered in Shenzhen, China, Torwell is a manufacturer and seller of 3D printer filaments. Its product portfolio includes various types of 3D PLA filaments, including PLA, ABS, HIPS, Nylon, PETG, flex filament, wood filament, and conductive filament. The company is a member of the Shenzhen Rapid Prototyping Association. Torwell has also collaborated with the Institute of the High Technology and New Materials and engaged with various polymer materials experts for developing the 3D printing filaments. The company has customers worldwide, including Europe, North America, Japan, and other Asian countries.

A report into the projected growth of the current 3D Printing PLA Market by Meticulous Research® has produced some incredible forecasts for the industry. By 2027, it’s expected to have grown at a CAGR of 19.8%, reaching over $818.0 million.

Evonik Industries AG

Headquartered in Essen, Germany, Evonik is a leading specialty chemicals provider. Evonik Industries combined the business areas of chemicals, energy, and RAG’s real estate, while mining operations continue to be carried out by RAG. Its Specialty Chemicals segment generates around 80% of sales in areas where it holds leading market positions. Evonik is the main sponsor of the German football club Borussia Dortmund. The company operates in the 3D printing materials market through its Performance Materials segment.

The company has its geographic presence in the Middle East & Africa, Asia-Pacific, the Americas, and Europe. Some of the major subsidiaries of the company are Evonik Degussa (Germany), Evonik-Cyro (U.S.), Evonik Tego Chemie GmbH (Germany), Porphyrio NV (Belgium), and Evonik Nutrition & Care GmbH (Germany), among others

BASF SE

Founded in 1865 and headquartered in Emmen, Netherlands, BASF is a manufacturer of various 3D filaments for industrial purposes. In 2017, BASF 3D Printing Solutions was established with the acquisition of Infofill3d. The company offers brands such as BASF Ultrafuse. In November 2019, BASF Forward AM was launched for additive manufacturing. BASF invests heavily in research and development and business development of the industrial and functional application of 3D printing. The company’s R&D laboratories are located in Ludwigshafen (Germany), Lyon (France), Shanghai (China), and Wyandotte (U.S.).

BASF offers a robust portfolio of high-performance 3D printing materials in the chemical industry. The company provides 3D printing solutions along the entire additive manufacturing value chain under the brand Forward AM. The material and solution portfolio offered by the company includes Ultrasint powder bed fusion powders, Ultrafuse metal & plastic filaments, Ultracur3D photopolymers & inks, and additive manufacturing services and solutions.

Zortrax

Founded in 2013 and headquartered in Olsztyn, Poland, Zortrax is a developer of a wide range of 3D printing solutions, including 3D printers, filaments, Z-SUITE software, and other devices. The company offers its products in various industries, such as architecture, medicine, automotive, engineering, industrial prototyping, or fashion. The company uses Z-PLA filament to manufacture the complex 3D models made up of biodegradable materials to keep it eco-friendly. The company also offers cloud-based 3D printing services.

Zortrax offers its products through over 130 partners operating in 90 countries, including Europe, the Americas, Asia, Africa, and Australia.

Fillamentum

Founded in 2011 and headquartered in Hulin, Czech Republic, Fillamentum is engaged in the manufacturing of a wide variety of 3D filaments, including PLA, flex, PETG, ASA, Nylon, ABS, and HIPS in a variety of different colors. The company offers technical materials from simple PLA to Nylon polymers and flexible filaments with high quality and reliability and are mostly used in the 3D printing industry. The company operates its business activities from the U.S., the Netherlands, and Japan, with its product portfolio used in automotive, aerospace, and industrial manufacturing.

FormFutura

Founded in 2012 and headquartered in Amsterdam, Netherlands, FormFutura is engaged in producing 3D filaments, resins, and adhesives. The company offers filaments, such as PLA, ABS, ASA, HIPS, PETG, PP, and PVA, among others. FormFutura supplies its products globally and has a strong presence in the western European market.

Popular Mentions: MatterHackers, Sculpteo, IC3D INC., Protoplant Inc., and Amolen.

Authoritative Research on the 3D Printing PLA Market – Global Opportunity Analysis and Industry Forecast (2020-2027)

Need more information? Meticulous Research®’s new report covers each of these companies in much more detail, providing analysis on the following:

Recent financial performance

Key products

Significant company strategies

Partnerships and acquisitions

The Comprehensive report provides global market size estimates, market share analysis, revenue numbers, and coverage of key issues and trends.

0 notes

Text

Polylactic Acid for 3D Printing Market: Opportunities, Insight, Trends, Key Players – Analysis Report to 2027

Polylactic Acid is also referred as polylactide which is semi-crystalline, biodegradable hydrophobic polymer with good mechanical strengths. This is widely used in various packaging applications including food, beverages, household items, healthcare, automotive, and others. The manufacturers of 3D printing are focusing on the development of eco-friendly polylactic acid material due to its bio-degradable nature.

The polylactic acid for 3D printing market has witnessed a significant growth due to various factors like increasing demand for the chemical industry. Furthermore, continuous technological advancements provide a huge market opportunity for the key companies operating in the polylactic acid for 3D printing market. Also, the rise in use of polylactic acid filaments in medical and dental industry is expected to drive the market growth during this forecast timeline. Moreover, polylactic acid is anticipated to grow at a promising rate in the North American market for manufacturing of 3D printing plastics, will positively influence the market growth in this region. Filament produced from polylactic acid is widely used across various application areas as it is available in different colors and blends. Also, easier to use and gives a premium finish to final printed product.

Get Sample Copy of this Report @ https://qualiketresearch.com/request-sample/Polylactic-Acid-for-3D-Printing-Market/request-sample

Strict government rules and regulations are anticipated to hamper the global polylactic acid for 3D printing market growth during this forecast period. Also, the availability of cheaper alternatives will limit the market growth.

Market key Players

Some of the prominent players in the global polylactic acid for 3D printing market are ColorFabb, Ultimake, Torwell Technologies, Shenzhen Esun Industrial, Polymaker, MakerBot Industries, Innofil3D, HATCHBOX 3D, and Fillamentum Manufacturing Czech

Market Taxonomy

By Type

1.75 MM

3 MM or 2.85 MM

By Application

Food Packaging

Household Items

Healthcare

Automotive

Others

By Region

North America

Latin America

Europe

Asia Pacific

Middle East & Africa

Browse Full Research Report @ https://qualiketresearch.com/reports-details/Polylactic-Acid-for-3D-Printing-Market

Read more Report

https://www.mccourier.com/global-computed-tomography-devices-market-future-growth-business-prospects-forthcoming-developments-and-future-investments-by-forecast-2027/

https://www.mccourier.com/massive-growth-of-global-cell-isolation-market-impact-of-covid-19-assessment-opportunities-and-key-players-like-thermo-fisher-scientific-bio-rad-laboratories-ge-healthcare-merck-kgaa-becton-a/

About Us

QualiKet Research is a leading Market Research and Competitive Intelligence partner helping leaders across the world to develop robust strategy and stay ahead for evolution by providing actionable insights about ever changing market scenario, competition and customers. QualiKet Research is dedicated to enhancing the ability of faster decision making by providing timely and scalable intelligence. We use different intelligence tools to come up with evidence that showcases the threats and opportunities which helps our clients outperform their competition.

#Polylactic Acid for 3D Printing Market#Polylactic Acid for 3D Printing Industry#Polylactic Acid for 3D Printing Market Size#Polylactic Acid

0 notes

Text

Dental 3D Printing Market worth $6.5 billion by 2025

The global dental 3D printing market is projected to reach USD 6.5 billion by 2025 from 1.8 billion in 2020, at a CAGR of 28.8% during the forecast period.

The dental 3D printing medical devices market is primarily driven by factors such as the high incidence of dental caries and other dental diseases, rising demand for cosmetic dentistry, the growing adoption of dental 3D printers in hospitals and clinics, and rapid growth in the geriatric population. On the other hand, the rising number of large dental practices is expected to limit market growth to a certain extent.

To know about the assumptions considered for the study, Request for Free Sample Report @ https://www.marketsandmarkets.com/requestsampleNew.asp?id=258228239

The services segment holds the highest market share, by product & service, in the forecast period.

On the basis of product & service, the dental 3D printing market is broadly segmented into services, materials and equipment. The equipment segment is further divided into dental scanners and printers. The large share of the services segment can be attributed to the competitive pricing offered by dental 3D printing service providers and the large-scale outsourcing of dental product design and production by small hospitals, dental clinics, and laboratories.

Based on technology, fused deposition modeling is projected to grow at the highest CAGR in the forecast period

Based on technology, the dental 3D printing market is segmented into VAT photopolymerization, fused deposition modeling, selective laser sintering, PolyJet printing, and other technologies. The fused deposition modeling segment is projected to register the highest growth rate in the dental 3D printing market, by technology during the forecast period. In dentistry, FDM is a widely applied technology due to the availability of a wide range of biocompatible, strong, and sterilizable thermoplastics.

Download a PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=258228239

Based on application, prosthodontics holds the highest market share in the dental 3D printing market

On the basis of application, the 3D printing in dentistry market is segmented into prosthodontics, implantology and orthodontics. Prosthodontics holds the highest share in the dental 3D printing market. The large share of the prosthodontics segment can primarily be attributed to the growing demand for crowns and bridges, rising prevalence of dental caries, increasing incidence of tooth loss, and increasing customer acceptance of advanced dental technologies.

By end user, the dental laboratories segment is growing at the fastest rate in the forecast period

Based on sample type, the dental 3D printing market is segmented into dental laboratories, dental hospitals and clinics and dental academic and research institutes. In this segment, dental laboratories is projected to register the highest growth rate in the dental 3D printing market. The high growth rate of this segment can be attributed to rapid adoption of advanced dental technology by dental laboratories and consolidation of dental laboratories.

North American region holds the highest market share in the dental 3D printing market

North America is expected to account for the largest share of the global dental 3D printing market in 2019. The large share of the North American region is due to the lucrative growth opportunities the region offers due to the high and growing incidence of dental caries and tooth loss (associated with the aging population), high oral care expenditure, the increasing demand for cosmetic dentistry, and the rising popularity of digital dentistry.

Key players in the dental 3D printing market:

Stratasys Ltd. (US), 3D Systems, Inc. (US), EnvisionTEC (Germany), DWS Systems SRL (Italy), Renishaw (UK), Formlabs (US), Prodways Group (France), SLM Solutions Group AG (Germany), Carbon, Inc. (US), Concept Laser (Germany), EOS GmbH Electro Optical Systems (Germany), Rapid Shape (Germany), Asiga (Australia), Roland DG (Japan), DENTSPLY Sirona, Inc. (US), SprintRay (US), Zortrax (Poland), Detax GmbH (Germany), DMG America (US, 3Dresyns (Spain), VOCO GmbH (Germany), Dental Solutions Israel (Israel), TRUMPF (Germany), 3BFab (Turkey), and Keystone Industries (US).

Recent Developments

· In August 2020, Stratasys, Ltd. (US/Israel)’s MakerBot introduced new software to provide a 3D printing workflow for teams to collaborate around the world.

· In October 2020, 3D Systems (US) received US FDA 510(k) clearance for maxillofacial surgical guides 3D-printed using the LaserForm Ti and DuraForm ProX PA materials.

· In November 2020, 3D Systems (US) entered into an agreement with Battery Ventures, a global, technology-focused investment firm, pertained to the sale of Cimatron Ltd. and its related subsidiaries, which operate the Cimatron integrated CAD/CAM software and GibbsCAM CNC programming software businesses.

· In August 2020, EnvisionTEC (Germany) and Keystone Industries (US) brought KeySplint Soft resin through the former company’s Open Material Access Program for use with the Envision One cDLM Dental 3D Printer.

· In October 2020, Formlabs (US) partnered with Braces on Demand (US) to enable Formlabs’ dental users to 3D print braces and orthodontic appliances in-office with Braces on Demand’s proprietary technology.

To speak to our analyst for a discussion on the above findings, click Speak to Analyst @ https://www.marketsandmarkets.com/speaktoanalystNew.asp?id=258228239

0 notes

Text

Additive Manufacturing Market Trends And Analysis By Material Type, By End-use, And Segment Forecasts To 2027

Global Additive Manufacturing Market Report

The ‘Global Additive Manufacturing Market Insights, Forecast to 2027’ offers a comprehensive evaluation of the Additive Manufacturing market on the global scale and sheds light on the growth opportunities and prospects to help readers formulate strategic plans. The report also offers relevant and useful information to help the new entrants and established companies strengthen their market position and formulate strategic approaches to gain a robust footing in the market. The report offers information on the overall market trends and analyzes historical data to offer accurate forecast estimations. The report also provides insightful data about market capacities, technological advancements, R&D developments, and other key features. Market Size – USD 7.97 billion in 2018, Market Growth - CAGR of 14.4%, Market Trends – Development of new and improved 3D Printing technologies and materials

The report is furnished with the latest market scenario and financial condition pertaining to the after-effects of the COVID-19 pandemic. The report assesses the impact of the COVID-19 pandemic on the Additive Manufacturing market and key segments. The report analyses the present and future impact of the pandemic on the Additive Manufacturing market. The report also studies the impact of the COVID-19 pandemic on the global supply chains and economic scenario of the industry. It considers the COVID-19 pandemic as a key factor influencing the growth of the Additive Manufacturing market.

Get a sample of the report @ https://www.reportsanddata.com/sample-enquiry-form/1184

Key Manufacturers in the Global Additive Manufacturing Market:

3D Systems Inc., General Electric, EnvisionTEC, Mcor Technologies Ltd., Optomec Inc., Stratasys Ltd, EOS GmbH, The ExOne Company and MakerBot Industries, LLC

The report offers an in-depth analysis of the value chain, upstream and downstream factors, sales network and distribution channels, growth trends, driving and restraining factors, developments, production and consumption pattern, end-users, and regional bifurcation. The report also provides extensive coverage of the supply chain, key players of the industry, consumer base, company profiles, production and consumption rate, primary applications, and other relevant data.

Request Detailed Table of Content @ https://www.reportsanddata.com/report-detail/additive-manufacturing-market/toc

The report for the Additive Manufacturing market is formulated through the segmentation and sub-segmentation of the market to offer a better understanding of the market. The report also provides an extensive regional segmentation to offer the readers key insights into the spread of the market over key geographical regions. The report also offers a country-wide analysis of the Additive Manufacturing market to gain deeper insights into the business sphere. The regional segmentation also covers the operations of the key players specific to each region.

Material Type (Revenue, USD Million; 2016-2026)

Metal Type (Revenue, USD Million; 2016-2026)

Polymer Type (Revenue, USD Million; 2016-2026)

Ceramics Type (Revenue, USD Million; 2016-2026)

Process (Revenue, USD Million; 2016-2026)

End-use Outlook (Revenue, USD Million; 2016-2026)

Metals

Thermoplastics

Ceramics

Others

Titanium

Stainless Steel

High Performance Alloys

Aluminum

Precious Metals

Others

Acrylonitrile Butadiene Styrene (ABS)

Polylactic Acid (PLA)

Polycarbonate (PC)

Polyvinyl Alcohol (PVA)

Others

Silica/ Glass

Porcelain

Silicon Carbide

Others

Computer-Aided Design

Stereo lithography

Fused Filament Fabrication

Binder Jetting

Material Jetting

Powder Bed Fusion

Material Extrusion

Others

Aerospace

Medical

Manufacturing

Automotive

Construction

Others

To know more about the report, visit @ https://www.reportsanddata.com/report-detail/additive-manufacturing-market

Additive Manufacturing Market Segmentation by Region:

North America, Latin America, Europe, Asia Pacific, and Middle East and Africa.

Scope of the Additive Manufacturing Market Report:

The report offers an extensive assessment of the growth rate and the market size based on the dynamics of the industry and the factors influencing the growth of the market. The report is formulated through authentic sources and verified and validated by industry experts. The report has been formulated through extensive primary and secondary research. It also covers the evaluation of market and competitive landscape along with SWOT analysis and Porter’s Five Forces analysis of the leading companies.

Moreover, the report offers an accurate forecast estimation through a thorough analysis of the historical data (2017-2018) while considering 2019 as the base year. The data offers a panoramic view of the market, assisting the readers to gain valuable insights into the Additive Manufacturing market. To impart better understanding of the market, the key statistical data is organized into pictorial representations such as charts, graphs, tables, diagrams, and figures.

Request customization on the report @ https://www.reportsanddata.com/request-customization-form/1184

Thank you for reading our report. For more inquiry or query on customization, kindly get in touch with us. Our team will ensure you get the best report suited to your needs.

About Us:

Reports and Data is a market research and consulting company that provides syndicated research reports, customized research reports, and consulting services. Our solutions purely focus on your purpose to locate, target and analyze consumer behavior shifts across demographics, across industries and help client’s make a smarter business decision. We offer market intelligence studies ensuring relevant and fact-based research across a multiple industries including Healthcare, Technology, Chemicals, Types, and Energy. We consistently update our research offerings to ensure our clients are aware about the latest trends existent in the market.

Contact Us:

John W

Head of Business Development

Direct Line: +1-212-710-1370

E-mail: [email protected]

Reports and Data | Web: www.reportsanddata.com

News: www.reportsanddata.com/market-news

Connect with us: Facebook | Google+ | LinkedIn | Twitter

0 notes

Text

The Downfall of the Great 3d Printing Monopoly

Kevin Mardirossian

45094953

I have been 3d printing for several years, and have made it a focus of mine. I am a mechanical engineering student and I use my skills and resources in 3d printing to aid several projects which I am a part of, including the aerodynamics subteam of Anteater Racing. I recently designed, manufactured, and programmed an innovative 3d printer meant to increase my capabilities to print unique prototypes and models which contain multiple materials and/or colors, and have to withstand the conditions associated with engineering applications. I have spent countless hours researching all aspects of the past, current, and future 3d printing industry, and have met with several professionals in the field. For these reasons and more, I was inspired to cover this ever-expanding field for this project.

First off, a little background: although most people have only become familiar with 3d printing in the past few years, the technology has been around since the 1980s. One of the first 3d printers was made by Chuck Hull, who saw the potential in his invention and patented the design in 1984. This kind of 3d printer took a UV sensitive resin and selectively cured it layer by layer to build up solid shapes from a vat of liquid resin. This technology is called SLA, which stands for Stereolithography Apparatus. With his patent in hand, Hull founded the company 3D Systems, the first 3d printing company. 4 years after Hull’s filing, S. Scott Crump filed a patent for a new kind of 3d printing, Fused Deposition Modelling, or FDM. FDM printers deposit heated thermoplastics in computer-generated paths one layer at a time to create 3d objects. You can think of this like laying down a layer of hot glue in the shape of a square, then laying down another layer of hot glue on top of that, and so on… S. Scott Crump and his wife Lisa Crump founded Stratasys in 1989. The third and final 3d printing process we will cover was patented in 1994. This method used layers of fine powders and selectively melted them together, it then laid down another layer of powder which was selectively melted on top of the previous. This process, called Selective Laser Melting/Sintering, or SLS/SLM, was the first to be able to print metal objects. Unlike FDM and SLA, SLS machines can be capable of printing virtually anything in a powdered form. This includes metals such as inconel, steel, stainless steel, and aluminum, though SLS machines can also print plastics like nylon. The last part of this story took place in 2002 when 3D Systems acquired the patent for SLS printing, thus cementing 3D Systems and Stratasys as the only two companies allowed to sell 3d printers.

It is clear from the previous paragraph that a massive monopoly had formed. These vastly different manufacturing processes were owned by only two companies. This meant that they could charge whatever they wanted for their machines, and they were not heavily incentivized to put money into innovating their technologies. They could simply continue selling their products for massive profits without losing money to research and development, as long as their customers remained happy. For two decades 3d printers were only used by massive corporations who could afford their tens, or even hundreds, of thousands of dollars price tags.. Advancements were made slowly, and for the most part the technology in the 3d printing space remained stagnant. In spite of this, company profits and stock prices steadily grew, that is, until 2009.

In 2009 the most important patent pertaining to the 3d printing industry expired, opening the door to new competition. Several patents on details about specific 3d printing technologies remained, but the overarching patent preventing any FDM 3d printing technology being sold, had expired. A revolution was about to begin, but the groundwork had been set in 2005. Adrian Bowyer and his team at the University of Bath conceived the idea for a self replicating rapid prototyping machine, or more simply, a 3d printer which could print parts for another 3d printer. This project, dubbed the RepRap project, was completely open source so engineers around the world could try their hand at reinventing rapid prototyping machinery. Because Bowyer did not sell any of his team’s designs they were not infringing on any patents, and as long as nobody profited off their printers. These RepRap machines were about the size of a modern desktop laser printer, much smaller than the industrial, double wide refrigerator size machines produced by Stratasys and 3D Systems. The RepRap movement grew over the coming years and led to the creation of the first commercial 3d printer kit which was available to more than just multi-million dollar corporations. Makerbot was founded in 2009, just as the FDM patent expired. Their first printer sold was a RepRap style kit which could be assembled and operated by makers around the globe. Makerbot grew rapidly and began to manufacture their own pre-built printers for industrial prototyping engineers and teachers who wanted a 3d printer in the classroom. This created a contrast between the cheap self-assembled kits, and the pre-assembled units which were meant to be turn-key for customers who were willing to pay a lot more for a polished product.

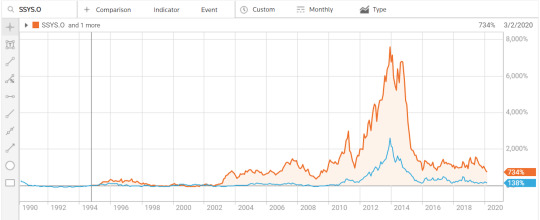

The industry was expanding with the introduction of desktop 3d printers spawned by the expiration of the key patent which kept the technology under the control of a monopoly. We can see this radical change in the market from the graph depicting the stock prices of SSYS (Stratasys) in orange and DDD (3D Systems) in blue.

The graph above is very interesting because Stratasys’s stock increases between late 2008 and 2010, but as more competitors began riding on the backs of the RepRap movement and entered the market, the stock took a steep drop leading into 2011, though it quickly rebounded. Because the market for SLA and SLS printers, which 3D Systems controlled the market in, was more difficult to enter, DDD continued its steady growth as media attention and business interest in 3d printing increased. SLA and SLS 3d printers are far more complex than FDM printers, and require more research and development to create a functioning product, and even more time and money to make those products reliable and easy to use.

More and more 3d printer companies began flooding the market with cheaper printers in the $1000 range, far cheaper than the $10,000-$500,000 machines previously sold by the industry’s behemoths. 3D Systems and Stratasys responded by trying to innovate, leading to lower cost and/or more capable machines in an effort to maintain business interest in their products. For the next few years SSYS and DDD saw tremendous growth because the wide coverage of 3d printing in the media, and their track record for producing proven and trusted products which were worth the increased costs. In an attempt to buy up the desktop 3d printer space, Stratasys acquired Makerbot in 2013. This move soured the reputation of Makerbot for the maker community. A company born out of the liberation of a once locked down industry sold out to become part of the multinational corporation which held the keys which prevented them from existing. Makerbot continued to sell products under their own brand name, though they adopted many business practices and technologies from Stratasys.

Stratasys and many other 3d printer brands have successfully utilized the razor and blade model by selling the 3d printers themselves for reasonable prices, but then selling the plastic required to produce 3d objects at a tremendous mark ups. Kilograms of common plastics normally sold for around $5 are being sold for $50, or even up to $500 in Stratasys’s case. And because these proprietary material cartridges come with embedded microchips, much like an the ink cartridges for an inkjet printer, you can’t simply refill used cartridges or buy third party materials. Once you buy a printer which only accepts proprietary materials, you’re locked in for the lifetime of that printer. So if you’ve paid $100,000 for a printer, it is in your best interest to continue paying $500 for each material cartridge until you can recoup the cost of the printer. This is one reason Stratasys has been able to keep a steady flow of money coming in from customers long after machines have been sold. As competition takes away from their machine sales, they are still making money from their material and customer service sales, both of which are required to keep the machines running.

As more time passes, and more patents once held by the two major 3d printing corporations expire, competition in the market continues to rise. Printers are getting better, cheaper, more reliable, and more cost effective for corporations and individuals alike. The monopoly once entirely controlled by two companies has faded away, and the market is slowly trending toward a lower equilibrium price, a fate made clear by Stratasys’s recently released line of cheaper printers. Because of free market competition the future looks good for consumers as prices go down and quality goes up, but compromises will have to be made if Stratasys and 3D Systems hope to remain afloat.

0 notes

Text

What is 3D Printing and How does it Work?

3D printing or additive manufacturing is a method of creating 3 dimensional solid gadgets from a digital file.

The creation of a 3D printed object is executed the usage of additive processes. In an additive process an object is created by laying down successive layers of material till the item is created. Every of those layers can be seen as a thinly sliced horizontal cross section of the eventual object.

3D printing is the opposite of subtractive production that's slicing out / hollowing out a bit of metal or plastic with for instance a milling machine.

This printing enables you to produce complicated (functional) shapes the use of less material than traditional manufacturing methods.

How Does 3D Printing work?

All of it starts with the creation of a 3D version on your computer. This digital design is for Instance a CAD (Computer Aided Design) file. This version is either constituted of the ground up with 3D modeling software or based on statistics generated with a scanner. With a scanner you are able of create a digital copy of an object.

3DScanners

Presently, costs of 3D scanners variety from costly industrial grade scanners to $30 DIY scanners all of us can make at home. We have created a handy guide to scanning technology proper right here; score them by using cost, velocity, precision and software capabilities.

3D Modeling software

This software is available many forms. There’s commercial grade software that charges lots a year according to license, but additionally free open supply software.

This modeling software is frequently made to suit the functions of the consumer’s industry. This has resulted in the rise of software appropriate to unique niches. As a result, there are software applications available on the market that cater to aerospace or transportation, furniture design or fabrics and style among many others.

For that reason, whilst you are starting out, the amount of picks may be a bit overwhelming, we recommend beginning with Tinkercad. Tinkercad is to be had for free and it works in browsers that support major search engines, as an instance Google Chrome. They provide newbie lessons and have a built in choice to get your object printed via a 3D print service.

From 3D version to 3D Printer

You may have to slice a 3D model so that you can make it printable. Reducing is dividing a 3D model into hundreds or thousands of horizontal layers and is done with slicing software.

Once in a while it’s viable to slice a document inside modeling software or in the 3D printer itself. It's also viable which you are pressured to use a positive slicing device for a sure 3D printer.

When your 3D model is sliced, you are ready to feed it to your printer. This will be accomplished through USB, SD or Wi-Fi. It truly relies upon on what printer brand you work with. Whilst a file is uploaded in a printer, the object is prepared to be printed layer by layer.

MakerBot 3D printers are the industry leaders when it comes desktop printing. MakerBot comes with innovative features like remote mobile app to control printers, MakerBot desktop software to slice files for 3D printing. The 5th generation printers come in three different build sizes.

Jacky’s group of companies one of the leading international traders, shop electronics online UAE, business solutions, general merchandise, Samsung showroom and electronics retail giant in the Middle East, Africa, South Asia and worldwide operations. Provide 3d printers makerbot, maker bot 3d printer, scanner 3d artec spider and 3d printer Dubai.

0 notes

Text

Additive Manufacturing Market Analysis, Top Players, Demand, Industry Challenges and Opportunities to 2027

The market intelligence report on the Additive Manufacturing Market offers the readers a 360° market overview with definitions, market segments, applications, raw material used, product details, cost structures, production processes, and other essential data. The study evaluates the global market landscape, with an in-depth analysis of product pricing, production and consumption volume, cost, value, production capacity, supply and demand dynamics, annual market growth rate, and market estimation till 2027.

This report covers the recent COVID-19 incidence and its impact on Additive Manufacturing Market. The pandemic has widely affected the economic scenario. This study assesses the current landscape of the ever-evolving business sector and the present and future effects of COVID-19 on the market.

Request for FREE Sample Copy of This Research Report at: https://www.reportsanddata.com/sample-enquiry-form/1184

Key participants include 3D Systems Inc., General Electric, EnvisionTEC, Mcor Technologies Ltd., Optomec Inc., Stratasys Ltd, EOS GmbH, The ExOne Company and MakerBot Industries, LLC.

This investigative report on the Additive Manufacturing Market gives a comprehensive overview of the current market development, highlighting key market dynamics. The study also provides a meticulous evaluation of the key threats faced by the pioneers of the market, which allows the participants to comprehend the challenges they may encounter in the future as part of the global market in the forecast duration.

To help gain the business owner further gain business intelligence the study on the Additive Manufacturing market for the forecast period 2020 - 2027 brings to light data on production capability, consumption capacity, spending power, investment feasibility, and technology innovation. A thorough assessment of market performance across different regions is presented through self-explanatory graphic images, charts, and tables that add weight to corporate presentations and marketing materials. The study offers regional profiles of major vendors and extensive country-level break down to empower companies to make a wise investment decision when exploring new regions.

Material Type (Revenue, USD Million; 2016-2026)

Metals

Thermoplastics

Ceramics

Others

Metal Type (Revenue, USD Million; 2016-2026)

Titanium

Stainless Steel

High Performance Alloys

Aluminum

Precious Metals

Others

Polymer Type (Revenue, USD Million; 2016-2026)

Acrylonitrile Butadiene Styrene (ABS)

Polylactic Acid (PLA)

Polycarbonate (PC)

Polyvinyl Alcohol (PVA)

Others

Read Full Report Description at: https://www.reportsanddata.com/report-detail/additive-manufacturing-market

Ceramics Type (Revenue, USD Million; 2016-2026)

Silica/ Glass

Porcelain

Silicon Carbide

Others

Process (Revenue, USD Million; 2016-2026)

Computer-Aided Design

Stereo lithography

Fused Filament Fabrication

Binder Jetting

Material Jetting

Powder Bed Fusion

Material Extrusion

Others

End-use Outlook (Revenue, USD Million; 2016-2026)

Aerospace

Medical

Manufacturing

Automotive

Construction

Others

Regional analysis: Based on geography, the market has been categorized into North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa.

The Market Report Contains The Following Chapters:

Chapter 1: This report on the Additive Manufacturing Market brings in one place all the vital information pertaining to the sector.

Chapter 2: The report comprises of a detailed analysis of players that account for a significant portion of the global market share in the Luxury Car Rental industry, highlighting the company’s latest technological advancement in the market, and the product profile currently available in the market, as well as the regions where they predominantly operate.

Chapter 3: It helps understand the major product segments and the future of the Additive Manufacturing Market. It gives strategic measures in key business segments based on market estimations.

Chapter 4: The report also provides an eight-year forecast survey predicting the growth of the market in the forecast duration.

Read Full Press Release at: https://www.reportsanddata.com/press-release/global-additive-manufacturing-market

The Luxury Car Rental industry research report outlines aspects like production, demand and supply, sales, and the contemporary market scenario exhaustively. Additionally, the report sheds light on production shares and market product sales, as well as production capacity, sales, and revenue. Other market aspects such as import/export dynamics, demand, supply, gross margin, and industry chain structure have also been assessed in the Additive Manufacturing Market report.

Contact Us:

John Watson

Head of Business Development

Direct Line: +1-212-710-1370

E-mail: [email protected]

Reports And Data | Web: www.reportsanddata.com

LinkedIn | Twitter | Blogs | Facebook

0 notes

Text

TOP 10 COMPANIES IN 3D PRINTING PLA MARKET

The 3D printing PLA market is expected to grow at a CAGR of 19.8% from 2020 to 2027 to reach $818.0 million by 2027. 3D printing technology has been evolving rapidly and is expected to provide an ideal alternative to manufacturing processes in the coming years. The 3D printing PLA market is witnessing a rise due to the increasing focus on environmental conservation and the growing demand for biodegradable materials. 3D printing PLA is used across applications such as automotive, food & beverage, and artistic goods, emphasizing looks and form rather than strength and durability. In the automotive industry, PLA is frequently used to print tools, jigs, and fixtures, whereas, in food & beverage applications, it is used for customized packaging.

Here are the top 10 companies operating in 3D Printing PLA Market–

Stratasys LTD.

Founded in 1989 and headquartered in Rehovot, Israel, Stratasys is a manufacturer of 3D printers and materials, including FDM and PolyJet3D printers. The company offers prototypes, manufacturing tools, and production parts for industries, including aerospace, automotive, healthcare, consumer products, and education. The company offers PLA materials, which are made up of renewable sources. It not only helps to make the design quickly but also provides a variety of colors in them. The PLA was introduced for the Stratasys F123 series printers due to its tensile strength and high stiffness ratio, making it compatible with 3D printers. Some of the major subsidiaries of the company are MakerBot (New York), GrabCAD (U.S), Stratasys GmBh (U.S), Solid concepts (U.S), and Objet Geometries (Israel).

The company sells its products across the Americas, Europe, and Asia-Pacific, with countries including Brazil, China, Germany, Hong Kong, Israel, Japan, Korea, India, Mexico, the U.K., and the U.S.

ColorFBB B.V.

Founded in 2013 and headquartered in Belfield, Netherlands, colorFBB is engaged in manufacturing PLA/PHA filaments used in the 3D printing industry. The company offers its DPA-100 support material used in the 3D printing filaments. The company also offers color on-demand services to allow customers to choose their preferences and customize their products with 178 different colors of the PLA filament.

Currently, colorFBB is focusing on alliances and partnerships with the fablabs and 3D printing studios to expand its business. The company manufactures Stacker printers and stacker spares, which are widely in 3D printing. The company has expanded its verticals to the logistics department, serving customers in more than 60 countries globally.

Ultimaker B.V.

Founded in 2011 and headquartered in Geldermalsen, Netherlands, Ultimaker manufactures 3D printers, 3D printing materials, and 3D printing software. The company’s major resellers in the 3D printing filaments are MatterHackers, 3D Universe, 3DV Corporation, and Dynamism. The company has offices in the Netherlands, the U.S., Singapore, and production facilities in Europe and the U.S. Its products are widely used in the automotive, architecture, healthcare, and education industries.

Polymaker

Founded in 2012 and headquartered in Suzhou, Jiangsu, Polymaker manufactures polymer filaments and high-quality materials used in the 3D printing industry. The company manufactured the world’s first 3D printable foam-based filament used for designing 3D prototypes. It recently introduced polymaker pc-pbt, PolyMAx PC-FR, and PolyLite PC polycarbonate materials used to print on the METHOD X 3D printer.

Polymaker operates its business activities from the U.S., the Netherlands, and Japan to deliver various products used in the automotive, aerospace, industrial manufacturing, medical, consumer, and other sectors.

Torwell Technologies Co. Ltd.

Founded in 2010 and headquartered in Shenzhen, China, Torwell is a manufacturer and seller of 3D printer filaments. Its product portfolio includes various types of 3D PLA filaments, including PLA, ABS, HIPS, Nylon, PETG, flex filament, wood filament, and conductive filament. The company is a member of the Shenzhen Rapid Prototyping Association. Torwell has also collaborated with the Institute of the High Technology and New Materials and engaged with various polymer materials experts for developing the 3D printing filaments. The company has customers worldwide, including Europe, North America, Japan, and other Asian countries.

A report into the projected growth of the current 3D Printing PLA Market by Meticulous Research® has produced some incredible forecasts for the industry. By 2027, it’s expected to have grown at a CAGR of 19.8%, reaching over $818.0 million.

Evonik Industries AG

Headquartered in Essen, Germany, Evonik is a leading specialty chemicals provider. Evonik Industries combined the business areas of chemicals, energy, and RAG’s real estate, while mining operations continue to be carried out by RAG. Its Specialty Chemicals segment generates around 80% of sales in areas where it holds leading market positions. Evonik is the main sponsor of the German football club Borussia Dortmund. The company operates in the 3D printing materials market through its Performance Materials segment.

The company has its geographic presence in the Middle East & Africa, Asia-Pacific, the Americas, and Europe. Some of the major subsidiaries of the company are Evonik Degussa (Germany), Evonik-Cyro (U.S.), Evonik Tego Chemie GmbH (Germany), Porphyrio NV (Belgium), and Evonik Nutrition & Care GmbH (Germany), among others

BASF SE

Founded in 1865 and headquartered in Emmen, Netherlands, BASF is a manufacturer of various 3D filaments for industrial purposes. In 2017, BASF 3D Printing Solutions was established with the acquisition of Infofill3d. The company offers brands such as BASF Ultrafuse. In November 2019, BASF Forward AM was launched for additive manufacturing. BASF invests heavily in research and development and business development of the industrial and functional application of 3D printing. The company’s R&D laboratories are located in Ludwigshafen (Germany), Lyon (France), Shanghai (China), and Wyandotte (U.S.).

BASF offers a robust portfolio of high-performance 3D printing materials in the chemical industry. The company provides 3D printing solutions along the entire additive manufacturing value chain under the brand Forward AM. The material and solution portfolio offered by the company includes Ultrasint powder bed fusion powders, Ultrafuse metal & plastic filaments, Ultracur3D photopolymers & inks, and additive manufacturing services and solutions.

Zortrax

Founded in 2013 and headquartered in Olsztyn, Poland, Zortrax is a developer of a wide range of 3D printing solutions, including 3D printers, filaments, Z-SUITE software, and other devices. The company offers its products in various industries, such as architecture, medicine, automotive, engineering, industrial prototyping, or fashion. The company uses Z-PLA filament to manufacture the complex 3D models made up of biodegradable materials to keep it eco-friendly. The company also offers cloud-based 3D printing services.

Zortrax offers its products through over 130 partners operating in 90 countries, including Europe, the Americas, Asia, Africa, and Australia.

Fillamentum

Founded in 2011 and headquartered in Hulin, Czech Republic, Fillamentum is engaged in the manufacturing of a wide variety of 3D filaments, including PLA, flex, PETG, ASA, Nylon, ABS, and HIPS in a variety of different colors. The company offers technical materials from simple PLA to Nylon polymers and flexible filaments with high quality and reliability and are mostly used in the 3D printing industry. The company operates its business activities from the U.S., the Netherlands, and Japan, with its product portfolio used in automotive, aerospace, and industrial manufacturing.

FormFutura

Founded in 2012 and headquartered in Amsterdam, Netherlands, FormFutura is engaged in producing 3D filaments, resins, and adhesives. The company offers filaments, such as PLA, ABS, ASA, HIPS, PETG, PP, and PVA, among others. FormFutura supplies its products globally and has a strong presence in the western European market.

Popular Mentions: MatterHackers, Sculpteo, IC3D INC., Protoplant Inc., and Amolen.

Authoritative Research on the 3D Printing PLA Market – Global Opportunity Analysis and Industry Forecast (2020-2027)

Need more information? Meticulous Research®’s new report covers each of these companies in much more detail, providing analysis on the following:

Recent financial performance

Key products

Significant company strategies

Partnerships and acquisitions

The Comprehensive report provides global market size estimates, market share analysis, revenue numbers, and coverage of key issues and trends.

Please download report pages and learn more:

Download Sample PDF Copy

0 notes

Link

After decades of education, hard labor, planning, and an entire life savings...COVID 19 effectively wiped out our company...virtually overnight!3D Improvements LLC (sole proprietorship) was the lifelong dream of owner, Mr. Dawson. He poured countless hours, days, weeks, (hell, months and years) of his life into his creation. In 2016, he was finally able to see his efforts come to fruition! He built his OWN machine shop, which was really more of a garage, in his driveway and began acquiring used industrial machinery. Mr. Dawson literally depleted his own savings in order to start his company independently and not ask for any handouts or loans. He worked tirelessly rebuilding these old, mostly nonfunctional machines and by the end of 2017, he had a fully functional machine shop! We successfully completed several contracts with local companies, landing two major accounts!The company we received regular orders from closed it's doors temporarily in early March in response to Ohio Covid regulations. Our orders and revenue abruptly ceased! We felt great relief that the US Government was coming to the rescue of small businesses like 3D Improvements. I personally submitted an application for the EIDL loan in March, on the first day it opened on the SBA website. I then had to reapply in April when they changed the application format. After about a month and a half of waiting, we received a mysterious deposit of $2,000. We were hopeful that all businesses would be receiving the full $10,000 grant as some sources speculated. Either way, we were over the moon grateful for the deposit.This afternoon we received a gut wrenching email that stated we had been denied for the EIDL loan portion. There was no reason provided. They hadn't even taken the time or given our company the respect to submit a separate, formal email. The representative/lender simply replied to a previous email we sent to [[email protected]](mailto:[email protected]):"Thank you for contacting the U.S. Small Business Administration Customer Service Center regarding assistance related to the Coronavirus (COVID-19) Pandemic.After a thorough review of your application, we regret we were unable to approve your request for an Economic Injury Disaster Loan (EIDL). If you disagree with the decision made on your loan, you may request reconsideration, subject to the availability of funds."Instant devastation!I have requested to be given a written "reason for denial" as well as an opportunity to appeal the SBA's decision. We offered collateral for any loan awarded to us, even if it is less than $25,000. The company we depended upon for part orders, is still not fully operational and will not yet be purchasing from any outside sources. We have approvals (DLA, JCP, etc.) and staffing capabilities (currently not "employed" but quick access to skilled machinists) to bid on government contracts, however we now do not have the financial reserve to purchase the CNC we need to manufacture products to the quality level required by the U.S. government. We even have a small 3D printer and have considered assembling face masks to aid in PPE relief efforts. However, we can not afford the filament and materials that would be required to do this. We were actually contemplating spending our entire EIDG grant to purchase a Makerbot Replicator Z18 because there was one listed at such a great rate and doing so would allow us to supply at least the local community with face shield/masks and we could still utilize the 3D printer if we were ever able to open back up.Feeling pretty hopeless. Losing hope in the "American Dream" that we've all been sold our whole lives. To me, this proves that hard work and sacrifice does not prevail. Big business prevails. Any words of advice or encouragement would be appreciated.Has anyone heard of an SBA denial being overturned through appeal? Any secret sources of funding out there that we may have missed? We have tried SBA, PTAC, SCORE and SBDC without much luck. These organizations are terrific assets but they only seem to offer assistance with getting started, obtaining registrations and governments "numbers", etc. We have already done all of this on our own. At this point we just need to secure funding in order to jump start the shop, upgrade our machinery, pay a machinist, etc.Thank you for receiving the vent/rant. American small businesses have to stick together through this! I hope others out there are having better luck during this trying time.

0 notes

Text

Dental 3D Printing Market worth $6.5 billion by 2025

The global dental 3D printing market is projected to reach USD 6.5 billion by 2025 from 1.8 billion in 2020, at a CAGR of 28.8% during the forecast period.

The dental 3D printing medical devices market is primarily driven by factors such as the high incidence of dental caries and other dental diseases, rising demand for cosmetic dentistry, the growing adoption of dental 3D printers in hospitals and clinics, and rapid growth in the geriatric population. On the other hand, the rising number of large dental practices is expected to limit market growth to a certain extent.

To know about the assumptions considered for the study, Request for Free Sample Report @ https://www.marketsandmarkets.com/requestsampleNew.asp?id=258228239

The services segment holds the highest market share, by product & service, in the forecast period.

On the basis of product & service, the dental 3D printing market is broadly segmented into services, materials and equipment. The equipment segment is further divided into dental scanners and printers. The large share of the services segment can be attributed to the competitive pricing offered by dental 3D printing service providers and the large-scale outsourcing of dental product design and production by small hospitals, dental clinics, and laboratories.

Based on technology, fused deposition modeling is projected to grow at the highest CAGR in the forecast period

Based on technology, the dental 3D printing market is segmented into VAT photopolymerization, fused deposition modeling, selective laser sintering, PolyJet printing, and other technologies. The fused deposition modeling segment is projected to register the highest growth rate in the dental 3D printing market, by technology during the forecast period. In dentistry, FDM is a widely applied technology due to the availability of a wide range of biocompatible, strong, and sterilizable thermoplastics.

Download a PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=258228239

Based on application, prosthodontics holds the highest market share in the dental 3D printing market

On the basis of application, the 3D printing in dentistry market is segmented into prosthodontics, implantology and orthodontics. Prosthodontics holds the highest share in the dental 3D printing market. The large share of the prosthodontics segment can primarily be attributed to the growing demand for crowns and bridges, rising prevalence of dental caries, increasing incidence of tooth loss, and increasing customer acceptance of advanced dental technologies.

By end user, the dental laboratories segment is growing at the fastest rate in the forecast period

Based on sample type, the dental 3D printing market is segmented into dental laboratories, dental hospitals and clinics and dental academic and research institutes. In this segment, dental laboratories is projected to register the highest growth rate in the dental 3D printing market. The high growth rate of this segment can be attributed to rapid adoption of advanced dental technology by dental laboratories and consolidation of dental laboratories.

North American region holds the highest market share in the dental 3D printing market

North America is expected to account for the largest share of the global dental 3D printing market in 2019. The large share of the North American region is due to the lucrative growth opportunities the region offers due to the high and growing incidence of dental caries and tooth loss (associated with the aging population), high oral care expenditure, the increasing demand for cosmetic dentistry, and the rising popularity of digital dentistry.

Key players in the dental 3D printing market:

Stratasys Ltd. (US), 3D Systems, Inc. (US), EnvisionTEC (Germany), DWS Systems SRL (Italy), Renishaw (UK), Formlabs (US), Prodways Group (France), SLM Solutions Group AG (Germany), Carbon, Inc. (US), Concept Laser (Germany), EOS GmbH Electro Optical Systems (Germany), Rapid Shape (Germany), Asiga (Australia), Roland DG (Japan), DENTSPLY Sirona, Inc. (US), SprintRay (US), Zortrax (Poland), Detax GmbH (Germany), DMG America (US, 3Dresyns (Spain), VOCO GmbH (Germany), Dental Solutions Israel (Israel), TRUMPF (Germany), 3BFab (Turkey), and Keystone Industries (US).

Recent Developments

In August 2020, Stratasys, Ltd. (US/Israel)’s MakerBot introduced new software to provide a 3D printing workflow for teams to collaborate around the world.

In October 2020, 3D Systems (US) received US FDA 510(k) clearance for maxillofacial surgical guides 3D-printed using the LaserForm Ti and DuraForm ProX PA materials.

In November 2020, 3D Systems (US) entered into an agreement with Battery Ventures, a global, technology-focused investment firm, pertained to the sale of Cimatron Ltd. and its related subsidiaries, which operate the Cimatron integrated CAD/CAM software and GibbsCAM CNC programming software businesses.

In August 2020, EnvisionTEC (Germany) and Keystone Industries (US) brought KeySplint Soft resin through the former company’s Open Material Access Program for use with the Envision One cDLM Dental 3D Printer.

In October 2020, Formlabs (US) partnered with Braces on Demand (US) to enable Formlabs’ dental users to 3D print braces and orthodontic appliances in-office with Braces on Demand’s proprietary technology.

To speak to our analyst for a discussion on the above findings, click Speak to Analyst @ https://www.marketsandmarkets.com/speaktoanalystNew.asp?id=258228239

0 notes

Link

Alice Lloyd George Contributor

Alice Lloyd George is an investor at RRE Ventures and the host of Flux, a series of podcast conversations with leaders in frontier technology.

More posts by this contributor

Solving the mystery of sleep

A conversation with Dean Kamen on the myth of “Eureka!”

From Elon’s Neuralink to Bryan Johnson’s Kernel, a new wave of businesses are specifically focusing on ways to access, read and write from the brain.

The holy grail lies in how to do that without invasive implants, and how to do it for a mass market.

One company aiming to do just that is New York-based CTRL-labs, who recently closed a $28 million Series B. The team, comprising over 12 PHDs, is decoding individual neurons and developing an electromyography-based armband that reads the nervous signals travelling from the brain to the fingers. These signals are then translated into desired intentions, enabling anything from thought-to-text to moving objects.

Scientists have known about electrical activity in the brain since Hans Berger first recorded it using an EEG in 1924, and the term “brain computer interface” (BCI) was coined as early as the 1970s by Jacques Vidal at UCLA. Since then most BCI applications have been tested in the military or medical realm. Although it’s still the early innings of neurotech commercialization, in recent years the pace of capital going in and company formation has picked up.

For a conversation with Flux I sat down with Thomas Reardon the CEO of CTRL-labs and discussed his journey to founding the company. Reardon explained why New York is the best place to build a machine learning based business right now and how he recruits top talent. He shares what developers can expect when the CTRL-kit ships in Q1 and explains how a brain control interface may well make the smartphone redundant.

An excerpt is published below. Full transcript on Medium.

AMLG: I’m excited to have Thomas Reardon on the show today. He is the co-founder and CEO of CTRL-labs a company building the next generation of non-invasive neural computing here in Manhattan. He’s just cycled from uptown — thanks for coming down here to Chinatown. Reardon was previously the founder of a startup called Avegadro, which was acquired by Openwave. He also spent time at Microsoft where he was project lead on Internet Explorer. He’s one of the founders of the Worldwide Web Consortium, a body that has established many of the standards that still govern the Web, and he’s one of the architects of XML and CSS. Why don’t we get into your background, how you got to where you are today and why you’re the most excited to be doing what you’re doing right now.

W3 is an international standards organization founded and led by Tim Berners Lee.

TR: My background — well I’m a bit of an old man so this is a longer story. I have a commercial software background. I didn’t go to college when I was younger. I started a company at 19 years old and ended up at Microsoft back in 1990, so this was before the Windows revolution stormed the world. I spent 10 years at Microsoft. The biggest part of that was starting up the Internet Explorer project and then leading the internet architecture effort at Microsoft so that’s how I ended up working on things like CSS and XML, some of the web nerds out there should be deeply familiar with those terms. Then after doing another company that focused on the mobile Internet, Phone.com and Openwave, where I served as CTO, I got a bit tired of the Web. I got fatigued at the sense that the Web was growing up not to introduce any new technology experience or any new computer science to the world. It was just transferring bones from one grave to another. We were reinventing everything that had been invented in the 80s and early 90s and webifying it but we weren’t creating new experiences. I got profoundly turned off by the evolution of the Web and what we were doing to put it on mobile devices. We weren’t creating new value for people. We weren’t solving new human problems. We were solving corporate problems. We were trying to create new leverage for the entrenched companies.

So I left tech in 2003. Effectively retired. I decided to go and get a proper college education. I went and studied Greek and Latin and got a degree in classics. Along the way I started studying neuroscience and was fascinated by the biology of neurons. This led me to grad school and doing a Ph.D. which I split across Duke and Columbia. I’d woken up some time in like 2005 2006 and was reading an article in The New York Times. It was something about a cell and I scratched my head and said, we all hear that term we all talk about cells and cells in the body, but I have no idea what a cell really is. To the point where a New York Times article was too deep for me, and that almost embarrassed me and shocked me and led me down this path of studying biology in a deeper almost molecular way.

AMLG: So you were really in the heart of it all when you were working at Microsoft and building your startup. Now you are building this company in New York — we’ve got Columbia and NYU and there’s a lot of commercial industries — does that feel different for you, building a company here?

TR: Well let’s look at the kind of company we’re building. We’re building a company which is at its heart about machine learning. We’re in an era in which every startup tries to have a slide in their deck that says something about ML, but most of them are a joke in comparison. This is the place in the world to build a company that has machine learning at its core. Between Columbia and NYU and now Cornell Tech, and the unbelievably deep bench of machine learning talent embedded in the finance industry, we have more ML people at an elite level in New York than any place on earth. It’s dramatic. Our ability to recruit here is unparalleled. We beat the big five all the time. We’re now 42 people and half of them are Ph.D. scientists. For every single one of them we were competing against Google, Facebook, Apple.

AMLG: Presumably this is a more interesting problem for them to work on. If they want to go work at Goldman in AI they can do that for a couple of years, make some dollars and then come back and do the interesting stuff.

TR: They can make a bigger salary but they will work on something that nobody in the rest of the world will ever get to hear about. The reason why people don’t talk about all this ML talent here is when it’s embedded in finance you never get to hear about it. It’s all secret. Underneath the waters. The work we’re doing and this new generation of companies that have ML at their core — even a company like Spotify is, on the one hand fundamentally a licensing and copyright arbitrage company, but on the other hand what broke out for Spotify was their ML work. It was fundamental to the offer. That’s the kind of thing that’s happening in New York again and again now. There’s lots of companies — like a hardware company — that would be scary to build in New York. We have a significant hardware component to what we’re doing. It is hard to recruit A team world-class hardware folks in New York but we can get them. We recently hired the head of product from Peloton who formerly ran Makerbot.

AMLG: We support that and believe there’s a budding pool here. And I guess the third bench is neuro, which Columbia is very strong in.

Larry Abbott helped found the Center of Theoretical Neuroscience at Columbia

TR: Yes as is NYU. Neuroscience is in some sense the signature department at Columbia. The field breaks across two domains — the biological and the computational. Computational neuroscience is machine learning for real neurons, building operating computational models of how real neurons do their work. It’s the field that drives a lot of the breakthroughs in machine learning. We have these biologically inspired concepts in machine learning that come from computational neuroscience. Colombia has by far the top computational neuroscience group in the world and probably the top biological neuroscience group in the world. There are five Nobel Prize winners in the program and Larry Abbott the legend of theoretical neuroscience. It’s its an unbelievably deep bench.

AMLG: How do you recruit people that are smarter than you? This is a question that everyone listening wants to know.

Patrick Kaifosh, Thomas Reardon, Tim Machado the co-founders of CTRL-labs

TR: I’m not dumb but I’m not as smart as my co-founder and I’m not as smart as half of the scientific staff inside the company. I affectionately refer to my co-founder as a mutant. Patrick Kaifosh, who’s chief scientist. He is one of the smartest human beings I’ve ever known. Patrick is one of those generational people that can change our concept of what’s possible, and he does that in a first principles way. The recruiting part is to engage people in a way that lets them know that you’re going to take all the crap away that allows them to work on the hardest problems with the best people.

AMLG: I believe it and I’ve met some of them. So what was the conversation with Kaifosh and Tim when when you first sat down and decided to pursue the idea?

TR: So we were wrapping up our graduate studies, the three of us. We were looking at what it would be like to stay in academia and the bureaucracy involved in trying to be a working scientist in academia and writing grants. We were looking around at the young faculty members we saw at Columbia and thought, that doesn’t look like they’re having fun.

AMLG: When you were leaving Columbia it sounds like there wasn’t another company idea. Was it clear that this was the idea that you wanted to pursue at that time?

TR: What we knew is we wanted to do something collaborative. We did not think, let’s go build a brain machine interface. We don’t actually like that phrase, we like to call them neural interfaces. We didn’t think about neural interfaces at all. The second idea we had, an ingredient we put into the stew and started mixing up was, was that we wanted to leverage experimental technologies from neuroscience that hadn’t yet been commercialized. In some sense this was like when Genentech was starting in the mid 70s. We had found the crystal structure of DNA back in the late 40s, there had been 30 years of molecular biology, we figured out DNA then RNA then protein synthesis then ribosome. Thirty years of molecular biology but nobody had commercialized it yet. Then Genentech came along with this idea that we could make synthetic protein, that we could start to commercialize some of these core experimental techniques and do translation work and bring value back to humanity. It was all just sitting there on the shelf ready to be exploited.

We thought OK what are the technologies in neuroscience that we use at the bench that could be exploited? For instance spike sorting, the ability to listen with a single electrode to lots of neurons at the same time and see all the different electrical impulses and de-convolve them. You get this big noisy signal and you can see the individual neurons activity. So we started playing with that idea, lets harvest the last 30 or 40 years of bench experimental neuroscience. What are the techniques that were invented that we could harvest?

AMLG: We’ve been reading about these things and there’s been so much excitement about BMI but you haven’t really seen things in market things that people can hack around with. I don’t know why that gap hasn’t been filled. Does no one have the balls to go take these off the shelf and try and turn them into something or is it a timing question?

The brain has upper motor neurons in the cortex which map to lower motor neurons in the spinal cord, which send long axons down to contact the muscles. They release neurotransmitters that turn individual muscle fibres on and off. Motor units have 1:1 correspondence with motor neurons. When motor neurons fire in the spinal cord, an output signal from the brain, you get a direct response in the muscle. If those EMG signals can be decoded, then you can decode the zeros and ones of the nervous system — action potential

TR: Some of this is chutzpah and some of it is timing. The technologies that we are leveraging weren’t fully developed for how we’re using them. We had to do some invention since we started the company three years ago. But they were far enough along that you could imagine the gap and come up with a way to cross the gap. How could we, for instance, decode an individual neuron using a technology called electromyography. Electromyography has been around for probably over a century and that’s the ability to —

AMLG: Thats what we call EMG.

TR: EMG. Yes you can record the electrical activity of a muscle. EKG electrocardiography is basically EMG for the heart alone. You’re looking at the electrical activity of the heart muscles. We thought if you improve this legacy technology of EMG sufficiently, if you improve the signal to noise, you ought to be able to see the individual fibers of a muscle. If you know some neuroanatomy what you figure out is that the individual fibers correspond to individual neurons. And by listening to individual fibers we can now reconstruct the activity of individual neurons. That’s the root of a neural interface. The ability to listen to an individual neuron.

EEG toy “the Force Trainer”

AMLG: My family are Star Wars fans and we had a device one Christmas that we sat around playing with, the force trainer. If you put the device around your head and stare long enough the thing is supposed to move. Everything I’ve ever tried has been like that has been like that Force Trainer, a little frustrating —

TR: Thats EEG, electroencephalography. That’s when you put something on your skull and record the electrical activity. The waves of activity that happen in the cortex, in the outer part of your brain.

AMLG: And it doesn’t work well because the skull is too thick?

TR: There’s a bunch of reasons why it doesn’t work that well. The unfortunate thing is that when most people hear about it that’s one of the first things they think about like, oh well all my thinking is up here in the cortex right underneath my skull and that’s what you’re interfacing with. That is actually —

AMLG: A myth?

TR: Both a myth and the wrong approach. I’m going have to go deep on this one because it’s subtle but important. The first thing is let’s just talk about the signal qualities of EEG versus what we’re doing where we listen to individual neurons and do it without having to drill into your body or place an electrode inside of you. EEG is trying to listen to the activity of lots of neurons all at the same time tens of thousands hundreds of thousands of neurons and kind of get a sense of what the roar of those neurons is. I liken it to sitting outside of Giant Stadium with a microphone trying to listen to a conversation in Section 23 Row 4 seat 9. You can’t do it. At best you can tell is that one of the teams scored you hear the roar of the entire stadium. That’s basically what we have with EEG today. The ability to hear the roar. So for instance we say the easiest thing to decode with EMG is surprise. I could put a headset on you and tell if you’re surprised.

AMLG: That doesn’t seem too handy.

TR: Yup not much more than that. Turns out surprise is this global brain state and your entire brain lights up. In every animal that we do this in surprise looks the same — it’s a big global Christmas tree that lights up across the entire brain. But you can’t use that for control. And this cuts to the name of our company, CTRL-labs. I don’t just want to decode your state. I want to give you the ability to control things in the world in a way that feels magical. It feels like Star Wars. I want you to feel like the Star Wars Emperor. What we’re trying to do is give you control and a kind of control you’ve never experienced before.

The MYO armband by Canadian startup Thalmic Labs

AMLG: This is control over motion right? Maybe you can clarify — where I’ve seen other companies like MYO, which was an armband, it was really motion capture where people were capturing how you intended to gesture, rather than what you were thinking about?

TR: Yeah. In some sense we’re a successor to MYO (Thalmic Labs) — if Thalmic had been built by neuroscientists you would have ended up on the path that we’re on now.