#Magnetic Drive Pump Manufacturer in China

Explore tagged Tumblr posts

Text

Revolutionizing Industrial Fluid Handling: 021pv's High-Pressure Magnetic Drive Pump Solutions

In the dynamic landscape of industrial fluid handling, innovation is key to driving efficiency and reliability. At the forefront of this evolution stands 021pv, a leading Magnetic Drive Pump manufacturer in China, renowned for its cutting-edge solutions and unwavering commitment to quality. In this blog, we delve into 021pv's pioneering High-Pressure Magnetic Drive Pump technology, revolutionizing fluid transfer across diverse industries.

High-pressure applications demand robust and dependable pumping solutions capable of withstanding extreme conditions. Enter 021pv's Magnetic Drive Centrifugal Pump, a testament to precision engineering and technological advancement. Designed to handle high-pressure environments with ease, these pumps offer unparalleled reliability and efficiency, making them indispensable assets across various industrial sectors.

What sets 021pv apart is its dedication to innovation and continuous improvement. Leveraging state-of-the-art manufacturing facilities and a team of skilled engineers, they push the boundaries of pump technology to deliver exceptional performance. From meticulous design to rigorous testing, every aspect of the High-Pressure Magnetic Drive Pump is optimized to meet the stringent demands of modern industrial applications.

Moreover, as a Magnetic Drive Pump manufacturer in China, 021pv benefits from a strategic location that facilitates efficient production and global distribution. With a focus on quality control and compliance with international standards, customers can trust in the reliability and durability of 021pv's products, regardless of their geographical location.

Beyond product excellence, 021pv prioritizes customer satisfaction and long-term partnerships. Their dedicated team provides comprehensive support services, from initial consultation to after-sales support, ensuring seamless integration and optimal performance of High-Pressure Magnetic Drive Pumps in diverse operational environments.

021pv's High-Pressure Magnetic Drive Pump solutions represent a paradigm shift in industrial fluid handling. By combining cutting-edge technology with a commitment to quality and customer satisfaction, they empower industries to achieve new levels of efficiency and reliability. As the go-to Magnetic Drive Pump manufacturer in China, 021pv continues to redefine the standards of excellence in fluid transfer, driving progress and innovation across the global industrial landscape.

#Magnetic drive centrifugal pump china#Magnetic Drive Pump Manufacturer in China#High-Pressure Magnetic Drive Pump

0 notes

Text

Pump Solution Guide for Data Center and Server Liquid Cooling System

The Importance of Liquid Cooling for Data Centers

Liquid cooling is a key method for enhancing energy efficiency in data centers. According to statistics from the White Paper on Liquid Cooling in China's Data Centers, the market size for liquid-cooled data centers in China is expected to exceed 100 billion RMB by 2024.

When the Thermal Design Power (TDP) reaches 200-300W, specialized airflow management, increased fan capacity and speed, as well as larger and thicker heat sinks, are required to dissipate heat fast enough in server thermal designs. However, when the TDP reaches 350-400W, cooling servers with air becomes extremely difficult and costly, with air cooling nearing its limits. (Data source: Application and Development of Liquid Cooling Technology in Data Centers)

In this situation, liquids with higher thermal conductivity become a better option for heat dissipation. Compared to traditional air cooling, liquids can remove 1,000 to 3,000 times more heat per unit volume, not only achieving precise component-level cooling and ensuring the high performance and reliability of components but also facilitating heat recovery, thereby improving energy efficiency.

Liquid cooling refers to the use of liquids instead of air as the coolant to transfer heat away from heat-generating components. By injecting this liquid into servers, the heat can be removed through heat exchange. Generally, the industry classifies liquid cooling into direct and indirect cooling. Currently, indirect cooling mainly involves cold plate liquid cooling technology, while direct cooling primarily focuses on immersion liquid cooling technology, which can be further divided into phase-change and non-phase-change types. Additionally, there is spray-type liquid cooling.

TOPSFLO liquid cooling pump solutions

The rise of Generative AI (AIGC) and the breakthrough applications of large-scale model technologies have significantly increased demands on the computational efficiency of servers and chipsets. Enhancing CPU and GPU processing power is urgently needed to support their vast computational requirements. In response to the challenges of server overheating and the surge in energy consumption due to rapidly increasing computing power, liquid cooling technology has emerged as a cutting-edge solution. TOPSFLO’s liquid cooling pump solutions precisely match the diverse cooling needs of servers, offering broad compatibility with cold plate efficient cooling, cooling distribution unit (CDU) optimization, and innovative immersion cooling methods. These solutions are adaptable to meet the customized design needs of various clients, ensuring that servers maintain cool and efficient performance even under high workloads.

With nearly 20 years of experience in the DC micro pump industry, TOPSFLO possesses extensive expertise in cooling and pressure boosting solutions for pumps. TOPSFLO has made significant strides in developing liquid cooling solutions for the data center industry, successfully creating liquid cooling pumps that are optimally suited for data center applications.

Advantages of TOPSFLO Liquid Cooling Pump Solutions

Leak-proof, Safe, and Reliable: Designed with consideration for data center leakage concerns, the pump's structure and materials have been carefully selected to ensure safety and prevent leaks.

Comprehensive Product Range: Our solutions cater to various data center cooling requirements, supporting different CPU/GPU power ratings (200W-1000W) and various application.

Low Noise: Compared to fan-based solutions, our pump systems reduce noise levels by over 40%.

Long Lifespan: Designed to meet the operational needs of data center equipment for up to 10 years.

Strong Material Compatibility: Our pumps are compatible with a wide range of liquid media to suit different application environments.

Data Center Liquid Cooling Pump Solutions with Different Functions

1. Cold plate liquid cooling pump solution

Cold plate liquid cooling mainly uses cold plates (enclosed cavities made of high thermal conductivity metals such as copper and aluminum) to indirectly transfer the heat of components to the cooling liquid enclosed in the circulation pipe, and then uses the coolant to take away the heat. It transports the intermediate heat to the back end for cooling through the transfer characteristics of the working fluid. The system mainly includes liquid cold plates, liquid cooling water pumps, pipes, joints, etc.

TOPSFLO water pump solution for 1U/2U servers, combined with cold plate liquid cooling solution —TDC

2. Immersion Liquid Cooling Pump Solutions

Immersion liquid cooling involves submerging the heat-generating components of electronic devices directly into a cooling liquid, where heat is dissipated through heat exchange. The key equipment and facilities involved include outdoor cooling sources, cooling subsystems, liquid cooling pumps, liquid cooling pipelines, and immersion chambers (liquid cooling cabinets). Immersion liquid cooling can be categorized into two types based on whether there is a phase change in the cooling medium: single-phase immersion liquid cooling and phase-change immersion liquid cooling. The primary function of the liquid cooling pump is to promote liquid circulation and accelerate heat dissipation. Compared to phase-change immersion liquid cooling, single-phase immersion liquid cooling requires pumps with higher power to achieve effective liquid circulation.

3. Cold distribution unit CDU

CDU is a cooling distribution unit that connects the cold plate liquid cooling internal circulation and external circulation. The cold plate liquid cooling joint is divided into two layout forms: centralized CDU and distributed CDU. CDU components include interfaces, micro water pumps, liquid-liquid or air-liquid heat exchangers, liquid storage tanks, valve control devices, monitoring devices, filters and various sensors, which are mainly used for the measurement and control of cooling capacity, flow, pressure and temperature. In order to ensure that sufficient cooling power can be provided for the equipment, a powerful micro water pump will be used in the CDU to ensure uniform and sufficient distribution of cooling capacity.

TOPSFLO High-end and Reliable Liquid Cooling Pump Solutions

TOPSFLO has a professional team with reliable capabilities in micro water pumps and liquid cooling technology, and can provide customers with a variety of liquid cooling water pump solutions. These solutions are designed and verified to adapt to the limited cooling space and heat dissipation requirements of each data center, while ensuring excellent cooling efficiency and reliability.

TOPSFLO different series of liquid cooling water pumps are introduced into servers for various application scenarios, and can also be customized according to the cooling needs of different applications, striving to provide our customers with a wider range of liquid water pump solution options.

Wanna to get custom pump service? Feel free to contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Visit our Web: https://www.topstec.com/ http://www.topsflo.com/

youtube

#dcwaterpump#servercoolingpump#serverliquidcooling#coolingpump#liquidcoolingsystem#liquid cooling pump#data center#datacenter#12vdcwaterpump#waterpump#Youtube

0 notes

Text

Common Rail Fuel Injector 0445120044 Common Rail Fuel Injector 0445120048 Common Rail Fuel Injector 0445120049 Common Rail Fuel Injector 0445120054 Common Rail Fuel Injector 0445120057 Common Rail Fuel Injector 0445120059

China Lutong is a manufacturer specialist in diesel injection parts for about 25years. We adjust our step, in draught the advanced producing techniques and high precision equipment to improve our quality with the opportunity and challenge . The quality of us is in the advance in Auto Parts field.

Wha/tsa/pp:+86/133/8690/ 1236 e-m-a-il eric at china-lutong dot net

ELI

Our majored products is VE Pump and the interrelated products (such as Head Rotor, Feed Pump, Cam Plate, Drive Shaft, Magnet Valve, etc. ), Plunger (A, AS, P, PS7100, P8500, MW type, etc. ), Nozzle (DN, DNOPDN, S, SN, PN and so on. ), Delivery Valve, Cat Pencil Nozzle, Head Rotor Lucas… If you have any interested in our products or have any inquiry, Please don′t hesitate to contact us. We will do our best to offer you our high quality products and best service to satisfy you.

0 notes

Text

China offer Pump shaft FA1D56-01-03A for power plant

China offer Pump shaft FA1D56-01-03A for power plant Dongfang Yoyik Engineering Co., Ltd is specialized in producing, manufacturing and selling industrial spare parts, as well as providing products of famous brands. Since 1989, our products have being widely used in various industries from power, oil, chemical, electronic, gas to environmental protection, fire-fighting equipments and nuke industry. Yoyik can offer many spare parts for power plants as below: #DF-Pump shaft FA1D56-01-03A-DF mechanic seal water pump A108-45B/BX1 vane pump parts F3-V10-IS6S-IC-20 rotary piston pump 2.5CY14-1B magnetic coupling centrifugal pump YCZ50-25 vacuum pump P-1931A roots vacuum pump WS-30 piston hydraulic pump A10VS045DR/31R-PPA12N00 Corrosion resistant Single stage centrifugal pump 65-250A Gasket 03506-300/311/415 sealing ring HB4-56J8-79 PRESSURE REDUCING VALVE DB15G-2-L5X/5/2 ,L05-23031-00003, REVISION:2 vacuum pump WSRP-30 transfer pump oil 50AYZ-50 Seal assembly of high pressure accumulator NXQB-40/20-L-A Globe valve IV14MBW316H/416-10-GP-ST-0C manual vacuum pump P-1607 AC lube pump 125LY-35-4 Packing as-stop valve 2-1/2"B09-5076Z-06TS electric transfer oil pump SDH125-100-200C piston plunger pump PV29-2R50-000 pressure joint Z103-01-14.00HD vacuum cleaner P-1964-1 O ring HY.SO.0051.V pumps centrifugal DFB80-50-20 INTEGRATED BLOCK 0508.919T0301.AW001 radial piston pump 5MCY14-1B pump vacuum ZS-185 differential pressure valve 514D098-06 2.5" Lubrication Oil Pump 125LY-36-20 dongfang Nitrogen reducer YQD-II STC shutdown trip AST solenoid valve CCP115D 115VAC 19W pumps parts hydraulic 50YW32-250A dc centrifugal pump YCZ65-250B vacuum cleaner WSRP-30 electric motor centrifugal water pump YNKN300/200-20Y/J solenoid valve AW2110A-220VDC-VITON Pump shaft FA1D56-01-03A mechanical seal FIJ125-100-315 piston vacuum pump PD060PC02SRS5AC00E1200000 vacuum pump rotary vane F3-V10-1S6S-1C20 pressure hose SMS-12/15-610mm-C piston pump PVH074R01AB10A250000002001AB010A Pressure relief valve AR925-20\DN20 level oil thermometer YWZ-500T vickers vane pump F3-V10-1S6S-1C20 oil transfer gear pump SDH65-50-160 OPC Solenoie valve seat OPC G130519 O-ring HZB253-640-03-09 globe valve HY-SHV6.01Z Shaft sleeve Coupling XB08VI-86-1.6-0 globe throttle check valve KJC65C-4.0P AC sealing oil pump KF80KZ/15F4 Shaft end baffle JB/ZQ4724 bellows globe valve core WJ50F1.6P.03 vacum pump air vacuum P-1751 EH oil pump outlet hose 16G2AT-HMP (DN25)-DK025-1600 self-locking pipe joint dn40/q/d9111g-77 vacuum oil pump P-545 mechanical seal in pump CM104-45 vacuum filter YCZ50-250 screw QD9403 fuel pump 80AY-50X10 balanced vane pump F3-SV10-1P5P-00 600MW turbine AC Auxiliary oil pump (TOP)coupling driving pin 125LY-36 piston plunger pump PVH131Q1C.RSF.10.C25 solenoid trip valve F3DG5S2-062A-220VAC-50-DFZK-V/B08 reciprocating piston pump PVHD74R01AA10A250000001ABO1OA PluginsLC25DB20E-7xgasket 03506-300/311/415 part no.:93 solenoid valve 300AA00126A screw pump diagram ACG060N7NVBP vacuum pump price P-1764-1 vacuum cleaner 30-WS Pump shaft FA1D56-01-03A DFYLSYC-2024-4-1-A

0 notes

Text

IE4 Permanent Magnet Synchronous Motors Forecast to 2031 with Key Companies Profile, Supply, Demand and SWOT Analysis

IE4 Permanent Magnet Synchronous Motors Market Outlook — 2025

The global IE4 permanent magnet synchronous motors market size was valued at $85,153 thousand in 2013, and is projected to reach $206,623 thousand by 2025, growing at a CAGR of 9.8% from 2018 to 2025. IE4 permanent magnet synchronous motors is a super-premium efficiency class motor, which is designed and manufactured according to the energy efficiency motors program to encourage end users to use higher efficiency motors. The aim of utilization of IE4 permanent magnet synchronous motors is to reduce energy consumption and minimize CO2 emissions. These motors are further used to drive industrial fans, pumps, compressors, and other mechanical applications, which fuel their adoption.

In addition, IE4 motors find their application in numerous robotic processes. Factors such as speed, acceleration, torque requirements, control, and angular movements make IE4 motors an ideal choice for robotic system manufacturers. Efficiency and performance have increased owing to rising demand for superior machine control, thereby improving the performance of equipment where IE4 motors are installed. Efficiency and performance have increased owing to rising demand for superior machine control.

Upsurge in adoption of green technologies is gaining popularity across the world. The benefits energy-efficient IE4 motors offer over standard motors include low fan losses and high-quality insulation & lamination. Such factors have a prominent impact on the demand for energy-efficient IE4 motors across various end-use industries. In addition, implementation of stringent regulations and laws related to the environment, such the EP Act and Minimum Energy Performance Standards (MEPS), drives the demand for these motors across the globe. Industries such as material handling systems, compressed air, HVAC, refrigerators, pumps, and ventilation serve as the key consumers of energy-efficient IE4 motors, thus fueling their demand across the globe. In addition, the blowers and the wind power sectors are anticipated to exhibit high demand for these motors in the coming years.

On the basis of application, the market is classified into material handling, liquid pumps, fans & ventilation, cooling compressors, air compressors & vacuum pumps, blowers, and coolers. In 2017, the air compressors & vacuum pumps segment held the largest share, due to increase in demand for compressors systems in manufacturing and automotive industries.

Region wise, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA. In 2017, Asia-Pacific accounted for the highest share, and is anticipated to secure the leading position during the forecast period. This is attributed to industrial growth in the developing countries such as India and China. China is a pioneer in the IE4 permanent magnet synchronous motors market. Therefore, IE4 permanent magnet synchronous motors market share is highest among the Asia-Pacific countries.

Competition Analysis

The major players operating in the global IE4 permanent magnet synchronous motors market include ABB, Altra Industrial Motion Corp, Anhui Wannan Electric Machine Co., Ltd., Bharat Bijlee, CG global, Danfoss, Fuji Electric Co., Ltd., Hitachi Ltd., Kaeser Kompressoren, Kienle + Spiess GmbH, KSB SE & Co. KGaA, Lafert, Merkes GmbH, Nidec, NORD Drive systems, O.M.E. Motori Elettrici s.r.l., OEMER, Siemens AG, Toshiba Corporation, Weg S.A., and VEM Group. Key players adopted product launch and partnership as its key developmental strategy to sustain the intense competition and improve its product portfolio. For instance, in December 2017, Nord Drivesystems expanded its portfolio of smooth-surface permanent-magnet synchronous motor by launching IE4 or Super Premium Efficiency synchronous motors for applications in food, beverage, and pharmaceutical industries. similarly, in January 2019, WEG S.A, established partnership with Iberian pork producer located in Badajoz, Spain. According to the partnership agreement WEG S.A has provided a W22 Magnet IE4 electric motors for compressors operation of its new refrigeration unit at the Mafresa facilities for cold production.

Many competitors in IE4 permanent magnet synchronous motors market adopted product launch and partnership as its key developmental strategies to sustain the intense competition and improve their product portfolio. For instance, Kaeser established partnership with a renowned motor manufacturer to develop IE4 motors for next-generation compressor packages. Moreover, in December 2017, Nord Drive Systems expanded its portfolio of smooth-surface permanent-magnet synchronous motor by launching IE4 or super-premium efficiency synchronous motors for applications in food, beverage, and pharmaceutical industries.

Full Report With TOC:-https://www.alliedmarketresearch.com/ie4-permanent-magnet-synchronous-motors-market

0 notes

Text

Motors For Negative Pressure Air Fan suppliers

Motors For Negative Pressure Air Fan suppliers Our History 1972: State owned Wenling Micromotor Factory Co., Ltd. 2008: Wenling Nosch Motor Co., Ltd. 2018: Zhejiang Fangyuan Sifu Mechanical and Electrical Co., Ltd. 2019: Establish Shandong Branch 2020: Establish Foreign Trade Department Our Factory Zhejiang Fangyuan Sifu Mechanical and Electrical Co., Ltd. is a high-tech enterprise focusing on motor R&D, manufacturing and sales. It is one of the core enterprises in the manufacturing sector of China's top 500 private enterprises under the Fangyuan Group. The company's main products include iron-shell single three-phase asynchronous motor series, aluminum-shell single three-phase asynchronous motor series, fan special motor series, frequency conversion motor series, permanent magnet DC motor series, etc. Mainly used in water pump power, fan power, machine equipment power, agricultural machinery power, new energy vehicle power, marine equipment power and other fields. The company is located at No. 2479, Haifeng Road, Taizhou Bay New District, Zhejiang (3 kilometers from the east exit of Jiaojiang Coastal Expressway, 10 kilometers from Taizhou Airport, and 20 kilometers from Taizhou High-speed Railway Station).Covering an area of 43 acres, it has a standardized workshop of 35,000 square meters, equipped with more than 50 sets of automatic CNC lathes, CNC grinders, CNC milling machines, machining centers, high-speed punching machines and other metal processing equipment, and equipped with advanced equipment such as automatic wire embedding lines, spraying lines, and automatic assembly lines. There are domestic leading wind tunnel laboratories, test centers, and motor type laboratories. The company has a technical management team with strong professional skills and excellent management capabilities. So far, it has obtained dozens of patent certificates (including 5 invention patents), participated in the formulation of 4 industry standards, and obtained 3C certification, CE Certification, ISO9001 management system certification, ISO45001 occupational health and safety management system certification, ISO14001 environmental management system certification, etc. It has also launched long-term technical cooperation with universities such as China Jiliang University and Zhejiang University of Technology to enhance core power in terms of innovation, stability, high efficiency, and energy saving. Our Product 鈼?IE3 Premium Motor 鈼?IE4 Super Premium Motor 鈼?Single Phase Motor 鈼?FRP Fan Motor 鈼?Negative Pressure Fan Motor 鈼?Cooling Fan Motor 鈼?Exhaust Fan Motor for Cowshed 鈼?Portable Cooler Motor 鈼?Vertical Pump Motor 鈼?Acid and Alkali Resistant Chemical Pump Motor 鈼?Washer Motor 鈼?Special Motor for Woodworking Product Application FRP Fan, Negative Pressure Fan, Cooling Fan, Exhaust Fan, Portable Cooler, Vertical Pump, Acid and Alkali Resistant Chemical Pump, Washer, Woodworking Our Certificate CE, Reach, RoHS, CCC (China Compulsory Certification), IPMS, China Energy Label Production Equipment Automatic wire embedding machine: 10 CNC lathe: 12 CNC grinder : 4 Dynamic balance machine: 4 CNC milling machine: 3 Plastic spraying line: 1 Production line: 9 Paint dipping machine: 2 Multi hole drilling machine: 2 Production Market Annual Output Value: US$20- US$50Million Domestic Market: 55% Eastern Europe: 10% Southeast Asia: 10% Middle East: 5% Africa: 5% South America: 3% Western Europe: 3% Other Areas: 9% Our Service The company takes the spirit of innovation as the guideline, takes high-quality products as the foundation, and takes full-staff entrepreneurship as the core driving force, strongly promotes R&D and innovation, accelerates the adjustment of product structure, optimizes technical processes, improves operational efficiency, and strengthens the spirit of chemical craftsmanship, and uses this as a driving force to build Outstanding enterprise, creating market opportunities, and striding forward to the vanguard of industry segmentation.Motors For Negative Pressure Air Fan suppliers website:http://www.sivomotor.com/

0 notes

Text

What should I pay attention to when using acid and alkali resistant magnetic drive pump?

What should I pay attention to when using acid and alkali resistant magnetic drive pump?

Acid and alkali resistant magnetic drive pump is a new type of pump that uses the working principle of magnetic coupling to transmit torque without contact. When the motor drives the outer magnetic rotor to rotate, the magnetic field drives the inner magnetic rotor and the impeller to rotate synchronously, so as to achieve For the purpose of pumping liquid, since the liquid is enclosed in a…

View On WordPress

#china Magnetic drive pump manufacturers#Magnetic Drive Pump#Magnetic drive pump from china#Magnetic pump manufacturers

0 notes

Text

Control Transformer Market - Forecast(2022 - 2027)

Overview

Control Transformer Market is forecast to reach $9.04 billion by 2025, growing at a CAGR 5.67% from 2020 to 2025. Control transformer provides stepped-down voltages to machine tool control devices to separate control circuits from all lighting and power circuits and allow ungrounded or grounded circuits to be worked. The use of control transformer is important for the control devices to work efficiently and safely. With the concern for safety in electrical equipment, the need for control transformers has increased considerably to prevent the equipment from any accidents. Control transformer is expected to play an important role in helping countries achieve their energy-efficiency goals, as energy saving is the primary feature of these devices. Utilities need to boost the efficiency of electricity and eventually increase the quality of power supplied to customers. Control transformer provides a high degree of secondary voltage stability in less time, which is expected to increase market growth over the forecast period of the control transformer.

Request Sample

Key Takeaways

The need for control transformers has increased with this concern for protection in electrical equipment. These transformers are used to protect the equipment from any incidents. Control transformers are expected to play an important role in helping countries meet their energy efficiency goals, because energy saving is the primary feature of these devices. The three phase dominates the market, due to the need for improved results in different applications. The three-phase Control transformers are used for many general equipment applications in manufacturing, power plants, chemical and other industries. Over 1500 VA transformers are primarily used in heavy-duty industries such as oil & gas, metal & mining, and heavy-duty machinery power generation. Due to industrialization and infrastructural developments in China and India, the Asia Pacific market is projected to hold the largest share of the control transformer market.

By Phase- Segment Analysis

During the forecast period the three phase segment is expected to grow at a CAGR 6.9%. Owing to improved performance in industrial applications compared to the single phase segment, the three-phase segment held the largest share of the control transformer market. The three phase controls the market, owing to the need for better performance in various applications. The three-phase control transformers are used to operate many general equipment in mining, power plants, chemical, and other industries, such as pumps, compressors, crushers, and other mechanical devices.

Inquiry Before Buying

By Power Rating - Segment Analysis

500-1000 VA Segment is expected to grow at a higher CAGR 8.2% during the forecast period. The control transformers are designed specifically for industrial applications where electromagnetic components such as relays, solenoids and magnetic motor starters are used. The 500-100 VA Control Transformers are designed to sustain high voltage inputs with efficiency. Basically, these control transformers are used for electrical devices & systems. With today's growing popularity of cost-saving benefits of high-voltage delivery of modern buildings, 500-1000 VA power transformers are projected to increase and this increase is anticipated to help in growth of control transformer market.

By Geography - Segment Analysis

APAC currently dominates the global Control Transformer market with a share of more than 37.2%. Due to industrialization and infrastructural developments in China and India, the Asia Pacific market is projected to hold the largest share of the control transformer market. Power and distribution infrastructure gradation, aging equipment standby, growing heavy industry development, and renewable energy growth are some of the factors driving demand for control transformers in this region. The increasing need to expand and develop the existing transmission and distribution network to meet rising electricity demand is projected to lead to positive growth of the transformers market during the forecast period. Furthermore, evolving Asia-Pacific markets are expanding many prospects for the introduction of wind power capacity in these nations. Asia's offshore wind capacity is expected to rise 20 times to 43 GW, by 2027. Such factors will eventually fuel the growth of the control transformer market.

Schedule a Call

Drivers – Control Transformer Market

Need to reduce system failures triggered by frequent spikes in voltage

Electricity dependency and the proliferation of highly sensitive electrical equipment make it important to have reliable, high-quality power sources. Transient flickering and voltage instability are significant causes of system failure and operational disruption. Such interruptions can damage critical power equipment including transformers, switchgears, condensers, overhead lines, inductors. Operational losses of USD 80 billion per annum are sustained in the US due to power interruption. High maintenance and manufacturing costs, production delays, loss of revenue, late deliveries, idle workers and increased spoilage and scrap are among the major effects of voltage instability on operations. In addition, uncontrolled voltage stability can cause damage to sensitive electronic equipment by sudden accidents, long-term damage or industrial process interruptions. Control transformers minimize the possibility of voltage instability and ensure safe and reliable performance of the equipment.

Stability for secondary voltage in less time period

Stability for secondary voltage in less time period is a key factor for the growth of the industrial Control Transformer. It helps in keeping the voltage driving system at a steady level when there is high current. It helps prevent issues like short circuiting and technological problems. Targets for electricity generation, increasing the introduction of emerging technology, increasing clean coal, and a share of renewable energy resources provide enormous opportunities for key players as they are significantly driving the need for control transformer for secondary voltage stability.

Buy Now

Challenges – Control Transformer Market

Dependent on other Devices for voltage regulation

During the past few years, voltage regulation has become a major control issue, especially at distribution level and for a twofold reason. Voltage control is a function of voltage magnitude difference between a component's sending and receiving ends. The percentage voltage difference between no load and maximum load voltage distribution lines, transmission lines, and transformers is commonly used in power engineering. Control transformers depend upon other devices for voltage regulation which is a major concern and is anticipated to hinder the market growth of control transformer.

Market Landscape Technology launches, acquisitions, and R&D activities are key strategies adopted by players in Control Transformer Market. Control Transformer Market is expected to be dominated by major companies such as ABB, Siemens, Schneider Electric, Emerson Electric Co., Hammond Power Solutions (HPS), Dongan Electric Manufacturing Co., Eaton, GE, Hubbell, Rockwell Automation, Broadman Transformers, MCI Transformers.

Acquisitions/Technology Launches

In October 2016, ABB introduced a free Total Cost of Ownership (TCO) tool to help customers determine loss capitalization factors, and compare different transformer alternatives from the point of view of total cost and environmental impact. In March 2016, ABB launched a new production facility for transformers in Lodz, Poland. The investment's reach was to support ABB's existing transformer manufacturing facilities in Lodz by providing support workers for machine operators and logistics, buying, efficiency, and engineering.

#control transformer market#control transformer market size#control transformer market shape#control transformer market forecast

0 notes

Text

Magnetic Drive Pumps Market 2021 Global Industry Size, Demand, Growth Analysis, Share, Revenue and Forecast 2028

Magnetic Drive Pumps Market Forecast to 2028 – COVID-19 Impact and Global Analysis – by Flow Rate (Upto 80 m3/hr, 81–200 m3/hr, 201–500 m3/hr, and Above 500 m3/hr), Material (Polypropylene, Polyvinylidene Fluoride, Stainless Steel, Nickel Alloys, PFA, and ETFE), Application (Chemical Processing, Water Treatment, Surface Treatment, Food Processing, Oil & Gas, and Renewable Energies), and Pump Type (Side Channel Pumps, Centrifugal Pumps, and Others)

Get sample PDF Copy of Magnetic Drive Pumps Market at @ https://www.theinsightpartners.com/sample/TIPRE00020289/

The magnetic drive pumps market is expected to reach US$ 1,584.37 million by 2028 from US$ 933.25 million in 2021; it is estimated to grow at a CAGR of 7.9% from 2021 to 2028. The overall market has been segmented into North America, Europe, Asia Pacific (APAC), Middle East and Africa, and South and Central America. In APAC, the magnetic drive pumps market is growing due to the increasing large-scale industrialization. Countries such as China, South Korea, and Thailand have discovered new oil and gas reserves. Further, China and India have a more significant number of chemical industries. Hence, the consumption of magnetic drive pumps is increasing with the growth of industries in the region. Another reason behind the strong growth of the magnetic drive pumps market over the years is the presence of many market players in the region.

The overall magnetic drive pump market size has been derived using both primary and secondary sources. To begin the research process, exhaustive secondary research has been conducted using internal and external sources to obtain qualitative and quantitative information related to the magnetic drive pump market. The process also serves the purpose of obtaining an overview and forecast for the magnetic drive pump market with respect to all the segments pertaining to the region. Also, multiple primary interviews have been conducted with industry participants and commentators to validate the data, as well as to gain more analytical insights into the topic. The participants of this process include industry experts such as VPs, business development managers, market intelligence managers, and national sales managers, along with external consultants, such as valuation experts, research analysts, and key opinion leaders, specializing in the magnetic drive pump market. IWAKI CO., LTD.; Sundyne, Klaus Union GmbH & Co. KG; Flowserve Corporation; Dickow Pump Company; KSB SE & Co. KGaA; ITT Goulds Pumps; Sulzer Ltd; Finish Thompson, Inc.; OPTIMEX; HERMETIC-Pumpen GmbH; CP Pumpen AG; and CDR Pumps are among the key players operating in the global magnetic drive pumps market.

For more details visit here @ https://www.theinsightpartners.com/reports/magnetic-drive-pumps-market/

About Us:

The Insight Partners is a one stop industry research provider of actionable intelligence. We help our clients in getting solutions to their research requirements through our syndicated and consulting research services. We specialize in industries such as Semiconductor and Electronics, Aerospace and Defense, Automotive and Transportation, Biotechnology, Healthcare IT, Manufacturing and Construction, Medical Device, Technology, Media and Telecommunications, Chemicals and Materials.

Contact Us:

If you have any queries about this report or if you would like further information, please contact us:

Contact Person: Sameer Joshi

E-mail: [email protected]

#Magnetic Drive Pumps Market#Magnetic Drive Pumps#Magnetic Drive Pumps Market Size#Magnetic Drive Pumps Market Share#Magnetic Drive Pumps Market Forecast#Magnetic Drive Pumps Market Trends

0 notes

Text

Soft Magnetic Composites (SMCs) Market Share, Future Growth And Forecast 2027

Research Nester has released a report titled “Soft Magnetic Composites (SMCs) Market – Global Demand Analysis & Opportunity Outlook 2027″ which also includes some of the prominent market analyzing parameters such as industry growth drivers, restraints, supply and demand risk, market attractiveness, year-on-year (Y-O-Y) growth comparisons, market share comparisons, BPS analysis, SWOT analysis and Porter’s five force model.

Soft magnetic composites or SMCs are known for its superior chemical properties and thus find amplified utilization across end user industries, specifically, in the automotive and electronics industry. Application of SMCs in traction motors, pumps, AC/DC converters and others helps to reduce the power loss which on the other hand raises the efficiency of the motor. SMCs also find massive application in the production of electric and hybrid vehicles. The rising application across end use industries of SMCs is therefore anticipated to act as the key growth driver for the global SMCs market.

The global SMCs market is anticipated to record a CAGR of 8.2% during the forecast period, i.e. 2020-2027. The market is further slated to reach USD 42,356.6 million from USD 21,375.1 million in-between 2018-2027. The global SMCs market is segmented by application into motors, compressors, transformers, generators and others. Among these segments, motors segment is anticipated to hold the largest market share of around 50.24% in the year 2027. The conversion efficiency of the motor from electrical energy to mechanical energy is highly impacted on account of application of SMCs in electric motors. Further, power loss is a common issue faced by motors, which can be mitigated by applying amorphous alloy and Si-Fe steel material type of SMCs in such motors.

Geographically, the global SMCs market is segmented by five major regions into North America, Europe, Asia-Pacific, Latin America and Middle East & Africa region, out of which, Asia Pacific is anticipated to hold the largest market share of around 43.26% in the year 2027. The region is blessed by nations such as China, India, Japan, Australia and other Southeast Asian countries, where SMCs are wide used across end use industries. Moreover, China is known to be a leader in the production of iron ore, which is a key material for the manufacturing of SMCs. Such factors are anticipated top drive the growth of the market in the region in the upcoming years.

However, concerns for high fluctuations in the price of raw materials used to manufacture SMCs is estimated to act as a barrier to the growth of the global SMCs market.

This report also studies existing competitive scenario of some of the key players of the global SMCs market, which includes profiling of Hitachi Metals, Ltd. (tyo:5486), Hoganas AB, VACUUMSCHMELZE GmbH & Co. KG, PMG Holding GmbH, Horizon Technology Inc., Fluxtrol Inc., Sintex a/s, Shenzhen City Ri Shengchang Magnet Technology Co., Ltd., AMES, and MMG Canada Limited.

The profiling enfolds key information of the companies which comprises of business overview, products and services, key financials and recent news and developments. Conclusively, the report titled “Soft Magnetic Composites (SMCs) Market – Global Demand Analysis & Opportunity Outlook 2027”, analyses the overall global SMCs industry to help new entrants to understand the details of the market. In addition to that, this report also guides existing players looking for expansion and major investors looking for investment in the global SMCs market in the near future.

0 notes

Text

Use of a Safety Valve with a Thermocouple by Safety Relief Valve Manufacturers!

A safety valve to intercept the gas supply in case the flame goes out. Safety valves represent fundamental components within plants and circuits, as they make it possible to reduce the risks of malfunctions and failures that always occur during operation, which can lead to more or less problems for people and the environment nearby. So safety relief valve manufacturers in China make it carefully that give higher values.

One problem that can often arise, especially when in contact with equipment that carries gaseous liquids, is leaks. If the gas does not go through a combustion process during use, it can lead to excessive accumulation in a room, which significantly increases the risk of explosions & accidents.

One solution is the use of safety valves for gas, which can be of different types depending on the function and component to which they are connected:

- Low-pressure safety valves;

- Shut-off valves with thermal safety valves;

- Valves for control units;

- Valves for pressure reducers;

- Safety valves with manual reset;

- Safety valves with thermocouples.

What are thermocouples?

Thermocouples are components for thermal applications that act as temperature converters. They are widely used in the industrial sector because they make it possible to detect the temperature within a process, circuit, or plant and thus verify its correct functioning. For this reason, they are cost-effective components from an economic point of view and are usually standardized based on worldwide regulations. Despite these undoubted advantages, they usually have limitations related to accuracy.

In general, according to safety relief valve suppliers in China, the principle of operation is based on the Seebeck effect, named after the Estonian physicist who theorized it. This principle is based, in short, on two conductors of different types that are brought into contact: it is observed that a temperature difference generates a potential difference that is used as a control signal.

The Use of Thermocouples in Safety Valves

Due to the considerations of safety valves for gas and thermocouples, it is easy to understand that the connection ensures both more effective control of the fluid and an increase in overall plant safety. In particular, the thermocouple detects the absence of a heat source that burns the gas coming out of the duct, causing a reduction or interruption in the flow. This, in turn, avoids excessive gas accumulation, which can have serious consequences from a health point of view. Therefore, thermocouples play the role of "switches" in this type of valve.

To get the best products you can connect with the magnetic drive pump manufacturer in China. Hope you understand the use of safety valves. If you want to know more about safety valves stay tuned with us.

#safety relief valve manufacturers in China#safety relief valve suppliers in China#magnetic drive pump manufacturer in China

0 notes

Text

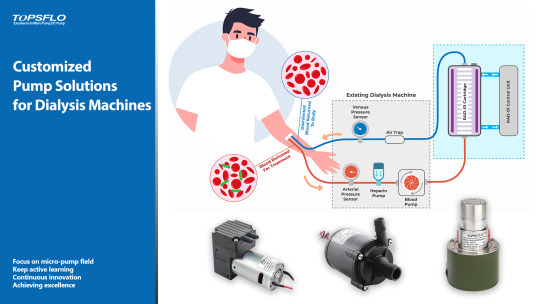

𝗠𝗶𝗰𝗿𝗼 𝗣𝘂𝗺𝗽 𝗮𝗻𝗱 𝗙𝗹𝘂𝗶𝗱𝗶𝗰 𝗦𝗼𝗹𝘂𝘁𝗶𝗼𝗻𝘀 𝗳𝗼𝗿 𝗠𝗲𝗱𝗶𝗰𝗮𝗹 𝗜𝗻𝗱𝘂𝘀𝘁𝗿𝘆 - 𝗛𝗲𝗺𝗼𝗱𝗶𝗮𝗹𝘆𝘀𝗶𝘀 𝗣𝘂𝗺𝗽

Overview

Hemodialysis serves as a vital renal replacement therapy for individuals battling chronic renal failure. Over the years, the prevalence of chronic renal failure has risen steadily, particularly due to factors like diabetic nephropathy, hypertensive nephropathy, and renal artery stenosis. This surge in patients necessitates hemodialysis treatment to sustain life.

Dialysis is a life-sustaining treatment for patients with end-stage kidney failure whose kidneys can no longer function. The dialysis machines removing water, solutes, and toxins from the blood. Dialysis works on the principles of diffusion across a semipermeable membrane. Blood flows by one side of a semipermeable membrane and a dialysate on the opposite side. The two main types of dialysis are hemodialysis and peritoneal dialysis.

In peritoneal dialysis, wastes and water are removed from the blood inside the body using the peritoneum as a natural semipermeable membrane.

However, in hemodialysis, the patient’s blood is pumped through a dialyzer. Blood flows through fibers, while dialysis solution flows around the outside of the fibers. The patient’s blood is cleaned in a dialyzer machine from waste products such as urea, creatinine, potassium, and extra fluid pass through the membrane, while the blood cells, protein, etc. remain in the blood.

Choosing the Right Dialysis Pumps

In hemodialysis machines, two circuits are crucial: the blood circuit for extracorporeal circulation lines and the hydraulic circuit for managing dialysis fluid. The hydraulic circuit involves various pumps, TOPSFLO offers a range of pumps engineered to meet OEM specifications for dialysis devices (Model recommendations are as follows):

1. Centrifugal Pumps

2. Diaphragm Gas Pump

3. Magnetic Drive Gear Pumps

External gear pumps are widely acclaimed for their pivotal role in powering dialysis machines, particularly in the medical sector. These pumps operate through the synchronization of two identical gears, commonly referred to as the "motor" and "driven" gears. The motor gear, propelled by a motor, in turn, drives the other gear, facilitating fluid transport by trapping small volumes between the gear teeth and the outer housing wall. This mechanism efficiently moves fluid from the inlet side to the outlet side, making external gear pumps a preferred choice for applications requiring precise fluid pressurization and minimal pressure fluctuations.

The distinctive advantages of external gear pumps contribute to their suitability for health technology applications, notably in hemodialysis machines. These advantages include exceptional priming capacity, ensuring swift initiation of fluid movement. Moreover, these pumps exhibit compatibility with wide temperature variations, a critical feature considering the temperature fluctuations experienced during post-treatment washing. Additionally, the compact size of external gear pumps further enhances their appeal for medical applications, offering an efficient and space-saving solution for fluid management in hemodialysis machines.

Pumps can operate at a temperature of 38°C throughout the dialysis cycle to prevent thermal shock to the patient. Their quiet operation is crucial for patient comfort. Stable performance, vacuum maintenance, and differential pressure are critical factors for the machine's operation, especially biocompatibility. The disinfectants in dialysis equipment pack strength, yet their corrosiveness poses challenges. Enter TOPSFLO pumps, crafted from materials demonstrated to endure numerous chemical heat clean cycles, ensuring unwavering performance. The outcome? A durable pump boasting biocompatibility, minimal noise, and significant reductions in long-term maintenance costs. Choose us for a pump solution where materials make the difference, offering reliability and longevity.

TOPSFLO pumps precisely and safely manage fluids within dialysis systems. As one of leaders in micro pump and fluidic solutions for the medical industry, TOPSFLO collaborates with customers to provide technical solutions, ensuring critical parameters for safety and performance are met.

Conclusion

TOPSFLO's commitment to innovation and collaboration makes it a reliable partner in the development of medical devices. For more information or to discuss a new project, welcome to have a consultation.

Wanna to get pump solution or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Find more pumps: http://www.topsflo.com/

youtube

#hemodialysis#dialysis machine#hemodialysis machine#centrifugal pumps#gear pumps#diaphragmairpump#medical pump#Youtube

0 notes

Text

Rare earth metals can be recycled from broken hard drives

Billions of electronic devices are thrown away every year. These almost all contain rare earth metals. Most of it is now lost. Researchers have developed a method to recover rare earth metals from discarded hard drives.

Telephones, LED lamps, hard drives and wind turbines: they wouldn't work without rare earth elements[1]. For example, powerful magnets are made from the element neodymium[2] that, among other things, make the motor of the Tesla Model 3 run. But these rare earths are rarely reused: only 1 to 5 percent is recycled.

Scientists at the US Oak Ridge National Laboratory[3] have developed a method to very efficiently recover rare-earth metals from magnets in hard drives. More than 95 percent of the rare earths present could be extracted from the hard disks, with almost complete purity.

The method used has been around for some time, but recent research[4] shows that it is possible to recycle rare earths at low cost and on a large scale. Until now, this was too expensive to be of commercial interest. "The system is modular and scalable, with low emissions and minimal residual waste," researcher Ramesh Bhave said in a press release[5]. The technology is expected to be used by wind turbine builders and electric vehicle manufacturers.

Dependence on China

Recycling rare earths is not an unnecessary luxury: according to the International Energy Agency (IEA) [6], the demand for rare earths will triple in the next twenty years. Electric cars and wind turbines use far more of these minerals than their fossil counterparts.

The world market is currently almost completely dependent on China for the extraction of rare earth metals. About 80 percent of all rare earths are mined there. Chinese companies also have major interests in rare earth mines on the African continent. Experts point to possible problems with security of supply, as the Chinese industry is a major consumer. Recycling can offer a solution for Western companies.

Environmental damage

The name 'rare earth metals' is a bit misleading. It is a group of seventeen chemical elements, the majority of which can be found in the Earth's crust. They are only slightly concentrated and are packed in other minerals. This makes them difficult to win.

Mines mainly use two methods to extract the metals - both of which cause major environmental damage. In one method, the top layer of the bottom is scraped off to create a water basin. Adding chemicals to the water separates the rare earths from other minerals in the soil. In the other method, water and chemicals are injected deep into the ground and then pumped back up.

Every tonne of rare earths produces 2,000 tonnes of toxic, and sometimes even radioactive waste. This can make groundwater undrinkable. Agriculture is therefore no longer even possible in the vicinity of some mines. For this reason alone, it is important to recycle rare earth metals as much as possible.

Source

Kaz Schonebeek, Zeldzame aardmetalen kunnen gerecycled worden uit kapotte harde schijven, in: Change Inc, 02-08-2022, https://www.change.inc/industrie/zeldzame-aarde-uit-kapotte-harde-schijven-38713

[1] The rare-earth elements (REE), also called the rare-earth metals or (in context) rare-earth oxides, or the lanthanides (though yttrium and scandium are usually included as rare-earths) are a set of 17 nearly-indistinguishable lustrous silvery-white soft heavy metals. Scandium and yttrium are considered rare-earth elements because they tend to occur in the same ore deposits as the lanthanides and exhibit similar chemical properties, but have different electronic and magnetic properties.

[2] Neodymium is a chemical element with the symbol Nd and atomic number 60. It is the fourth member of the lanthanide series and is considered to be one of the rare-earth metals. It is a hard, slightly malleable, silvery metal that quickly tarnishes in air and moisture. When oxidized, neodymium reacts quickly to produce pink, purple/blue and yellow compounds in the +2, +3 and +4 oxidation states. It is generally regarded as having one of the most complex spectra of the elements.

[3] Oak Ridge National Laboratory delivers scientific discoveries and technical breakthroughs needed to realize solutions in energy and national security and provide economic benefit to the nation. It addresses national needs through impactful research and world-leading research centres. Its wide range of partnerships with other US Department of Energy laboratories and programs, universities, and industry allows us to pair our strengths with others for outstanding contributions to science.https://www.ornl.gov/?_ga=2.1476401.1824697948.1659515937-1868561651.1654358647

[4] Syed Z. Islam, Priyesh Wagh,James Eli Jenkins, Christopher Zarzana, Mac Foster, Ramesh Bhave, Process Scale-Up of an Energy-Efficient Membrane Solvent Extraction Process for Rare Earth Recycling from Electronic Wastes, in: Advanced Engineering Materials, First published: 25 June 2022; https://onlinelibrary.wiley.com/doi/abs/10.1002/adem.202200390?_ga=2.5735219.1824697948.1659515937-1868561651.1654358647

[5] Oak Ridge National Laboratory’s Ramesh Bhave and team partnered with Momentum Technologies to develop a modular, scalable system for recycling scrap permanent magnets in e-waste. https://www.ornl.gov/news/saving-e-waste-scraps?_ga=2.29117116.1824697948.1659515937-1868561651.1654358647

[6] The International Energy Agency (IEA; French: Agence internationale de l'énergie) is a Paris-based autonomous intergovernmental organisation established in the framework of the Organisation for Economic Co-operation and Development (OECD) in 1974 in the wake of the 1973 oil crisis. The IEA was initially dedicated to responding to physical disruptions in the supply of oil, as well as serving as an information source on statistics about the international oil market and other energy sectors. It is best known for the publication of its annual World Energy Outlook. https://www.iea.org/about

0 notes

Text

Research Report to Understand Demographical Landscape of Magnetometer Market

Transparency Market Research delivers key insights into the global magnetometer market. In terms of revenue, the global magnetometer market is estimated to expand at a CAGR of ~ 6% during the forecast period, owing to numerous factors, regarding which, TMR offers thorough insights and forecasts in its report on the global magnetometer market.

A magnetometer is a device used to measure the direction and strength of the magnetic field at a particular location. Magnetometers are employed across several sectors such as energy, healthcare, aerospace & defense, consumer electronics, surveys, and industrial.

Get sample copy of at: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=23462

Increasing usage of magnetometers for the detection of archaeological sites is also one of the major factors likely to drive the global magnetometer market in the near future. Archaeologists are using magnetometer-based devices to discover archaeological sites. These sites may consist of minerals that can be detected with the help of magnetometers. Magnetometers in geophysical surveys conducted for mineral exploration are largely used to search for elements such as gold, silver, iron, and copper.

To get glimpse of what our report offers, ask for a report brochure here

Archaeologists use satellite global positioning systems (GPSs) to rapidly and precisely map the location of archaeological sites on the ground. Magnetometers are incorporated into GPS devices that receive signals from numerous satellites orbiting around the Earth, and measure the distance from each satellite on the basis of how quickly the magnetic signal travels. Then, by means of the geometric principle of trilateration, the device calculates the location of the site on the ground. Thus, magnetometers are increasingly being used for the detection of archaeological sites, due to their better detection capability. This factor is anticipated to fuel the global magnetometer market during the forecast period.

Global Magnetometer Market: Prominent Regions

North America accounted for a key share of the global magnetometer market in 2018. The region is expected to dominate the global market between 2019 and 2027, owing to the increasing adoption of smartphones, tablets, and consumer electronics products in the region. Among the countries/sub-regions, the U.S constituted a significant share of the market in North America in 2018. The U.S. makes high investments in R&D activities aimed at innovating new technologies, and is the most technologically-advanced country.

Europe has emerged as the second-largest market for magnetometers across the world. The region is anticipated to hold a considerable share of the global magnetometer market during the forecast period, owing to the increasing penetration of magnetometers in countries of Western Europe and Central Europe, and increased spending on semiconductor manufacturing. The rising use of magnetometers in aerospace and automotive industries is also expected to augment the adoption of magnetometers in Europe in the next few years.

Asia Pacific is anticipated to be a highly lucrative market for magnetometers throughout the forecast period, owing to the increasing adoption of magnetometers in developing economies in the region, such as China. The lucrativeness of the APAC market is anticipated to increase in the next few years, owing to extensive research and development activities taking place in the field of optical pumped magnetometers in the region.

Key players operating in the global magnetometer market are sharpening their competitive edges to display synergies through close cooperation and collaboration in the areas of sales, marketing, and production. Manufacturers are also expanding through organic methods, such as increasing production capacity, in order to meet the rising demand.

Global Magnetometer Market: Key Players

Key players operating in the global magnetometer market are Bartington Instruments Ltd, Cryogenic Limited, Gem Systems Advanced Magnetometers, Geometrics, FOERSTER Holding GmbH, Honeywell International Inc., Infineon Technology, Lake Shore Cryotronics, Inc., Lockheed Martin Corporation, NXP Semiconductors N.V, Scintrex Limited, Marine Magnetics Corp, Tristan Technologies, Inc., and VectorNav Technologies.

Global Magnetometer Market: Segmentation

Magnetometer Market by Technology

Scalar Magnetometers

Vector Magnetometers

Magnetometer Market by Product

Single Axis

Three Axis

Magnetometer Market by Form Factor

Portable

Fixed

Magnetometer Market by End-use Industry

Energy

Healthcare

Aerospace & Defence

Consumer Electronics

Surveyors

Industrial

Others

Have any query? Inquiry about report at: https://www.transparencymarketresearch.com/sample/sample.php?flag=EB&rep_id=23462

About Us

Transparency Market Research is a global market intelligence company, providing global business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insight for thousands of decision makers. Our experienced team of analysts, researchers, and consultants use proprietary data sources and various tools and techniques to gather and analyze information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact

Transparency Market Research, 90 Sate Street, Suite 700, Albany, NY 12207 Tel: +1-518-618-1030 USA – Canada Toll Free: 866-552-3453 Email: [email protected] Website: https://www.transparencymarketresearch.com

0 notes

Text

Soft Magnetic Material Market Is Expected To Grow Swiftly By 2027

The global soft magnetic material market size is anticipated to reach USD 26.12 billion by 2027, according to a new report by Grand View Research, Inc. The market is expected to expand at a revenue-based CAGR of 3.9% from 2020 to 2027. The rapid expansion in electricity grids and power distribution is anticipated to boost the demand in the market.

The demand for soft magnetic materials is driven by the phenomenal character of getting magnetized and demagnetized with ease. This characteristic is quite essential in electrical and electronic circuits as the magnetic energy is converted back to electrical energy easily before being reintroduced in the circuit. This is not possible in case of hard or permanent magnetic materials, as their magnetization and demagnetization require a large amount of energy. As a result, soft magnetic materials find applications in motors, transformers, generators, and others.

Motors held the largest volume share of the market in 2019. Soft magnetic materials are used in motors where they enhance the field produced by motor windings and channel the flux in permanent magnet motors. Electric motors have ample applications in machine tools, pumps, power tools, turbines, ships, mills, vehicles, home appliances, HVAC equipment, and medical equipment, among others. The use of motors in various industries is boosting its demand.

Electric vehicles are a prominent end-use segment of motors. The growing production of electric vehicles owing to environmental concerns related to conventional vehicles and government initiatives is anticipated to positively influence the demand for motors. Due to the growing demand, manufacturers are compelled to expand their motor production capacities.

For example, in February 2020, Nidec announced its intention to invest a sum of ¥200 billion (USD 1.8 billion) in EV powertrains rush. The investment of the company shall be split into three new plants in China, Poland, and Mexico. Together the three facilities are expected to produce 8.4 electric motors annually.

Electrical steel or silicon steel is the most prominent type of soft magnetic material and is used in transformers, motors, and generators. Owing to its high silicon content, it helps increase electrical resistivity thus, reducing eddy current losses. Grain-oriented silicon steel is preferred in transformers because of its orientation, which helps minimize magnetic losses.

Electrical steel has high demand in its end-use segments, which has propelled its production. For example, in January 2019, U. S. Steel Košice announced about building a new non-grain oriented electrical steel line in Kosice worth an investment of USD 130 million and an annual production capacity of 100 kilotons. The plant was expected to be operational by the fourth quarter of 2020. However, on account of the outbreak of COVID-19 virus across the world, the U.S. Steel Corporation had to take certain actions in order to preserve long-term growth, under which the above-mentioned investment remains delayed, as of March 2020.

Asia Pacific held the largest share of the market in 2019 and this trend shall continue over the forecast period, owing to increasing emphasis on power distribution, electric vehicle production, and growth in consumer goods and medical equipment in developing economies. Countries such as India have huge potential for investment as the electricity demand in the country is expected to reach over 15,000 TWh by 2040. The gradual shift towards renewable energy sources is another driving factor for the power sector, thus, a positive sign for market growth.

The competitive scenario of the market is high with the presence of various players, who are engaged in developing strategies in order to gain a competitive edge in the market. For example, in July 2019, Carpenter Technology announced that it shall help provide soft magnetic alloys for electric aircraft engine demonstrators. The company had made an investment of USD 100 million in a precision strip mill for expanding its soft magnetic capabilities for catering to the aerospace and other industries.

Request a free sample copy or view report summary: Soft Magnetic Material Market Report

Soft Magnetic Materials Market Report Highlights

Middle East & Africa expected to register the fastest growth rate of 5.0% in terms of revenue over the forecast period, owing to the huge potential for the power sector to flourish in the region

Asia Pacific constituted a volume share of over 46.0% in 2019 of the global market, which is attributable to the increasing manufacturing activities in terms of automotive, medical equipment, consumer goods, and infrastructure in developing economies of the region

Motors is anticipated to witness the fastest growth rate of 4.1% in terms of revenue across the forecast period, considering its wide range of applications which is accelerating in electric vehicles and power distribution sectors

Ferrites held a revenue share of over 12.0% in 2019 of the global market owing to their high cost than electrical steel

The market growth is sluggish as of 2020 owing to the covid-19 pandemic, which has disrupted the manufacturing sector, where demand for soft magnetic materials exists. However, the demand in the healthcare sector persists, owing to increasing patients and their rising need for medical equipment such as ventilators.

Soft Magnetic Materials Market Segmentation

Grand View Research has segmented the global soft magnetic materials market report on the basis of application, product, and region:

Soft Magnetic Materials Application Outlook (Volume, Kilotons; Revenue, USD Million, 2016 - 2027)

Motors

Transformers

Alternators

Others

Soft Magnetic Materials Product Outlook (Volume, Kilotons; Revenue, USD Million, 2016 - 2027)

Electrical Steel

Ferrite

Permalloys

Others

Soft Magnetic Materials Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2016 - 2027)

North America

Europe

Asia Pacific

Central & South America

The Middle East & Africa

The U.S.

Canada

Mexico

Germany

Italy

Turkey

China

Japan

South Korea

Brazil

List of Key Players of Soft Magnetic Materials Market

Arnold Magnetic Technologies

GKN Sinter Metals Engineering GmbH

Hitachi Metals Group

JFE Steel Group

Mahindra CIE

MATE CO., LTD

Meyer Sintermetall AG

Sintered Specialties, LLC

Steward Advanced Materials LLC

VACUUMSCHMELZE GmbH & Co. KG

About Grand View Research

Grand View Research, Inc. is a U.S. based market research and consulting company, registered in the State of California and headquartered in San Francisco. The company provides syndicated research reports, customized research reports, and consulting services. To help clients make informed business decisions, we offer market intelligence studies ensuring relevant and fact-based research across a range of industries, from technology to chemicals, materials and healthcare.

0 notes

Text

Choose Right Pump

Life water pumps should be low-noise, energy-saving water pumps. The obsolete water pumps may still exist in the market, but they must not be used, so pay attention when buying them.

How to choose pump

If you are buying lifting pumps for water tanks and water towers, try to reduce the number of pumps, and use one for one. When one can meet the requirements, it is not advisable to use multiple pumps in parallel; if multiple pumps must be used When running in parallel or collocation of large and small pumps, the model and number of pumps should not be too much. Generally, there should be no more than two models. The pump head range should be similar; each pump should still run in the high-efficiency area when running in parallel.

About our campany

Taicang Magnetic Pump Co., Ltd is the first ever specialized manufacturer designing and producing magnetic-driving pumps in China who started to research and develop magnetic pumps with Shanghai Chemical Industry Design Institute (SCIDI) in 1979.

The company is located at No. 11, South Chengxi Road, Taicang City, Jiangsu Province, China. It has a land area of 20,500 square meters, a construction area of 14,200 square meters and 110 employees. The company has a magnetic pump R & D center and a college student workstation, which has close cooperation with many domestic colleges and universities.

The factory has 4 CNC vertical machining centers, 8 CNC lathes, 2 CNC grinding machines, 3 CNC wire cutting machines, 1 laser welding machine, 1 robot welding machine, 1 CNC scribing machine, 50HZ, 60HZ available 1 set of conversion pump test equipment, 1 set of far infrared metal element detector, 1 set of material chemical analyzer and other advanced equipment.

Our Service

Pre-sale service

When customers haven't decided which magnetic pump to buy, we'll give them different ways to promote our company's products and introduce the product structure and features according to the customer's specific situation. We'll focus on introducing the products' safety, reliability, energy efficiency, etc. So that customers could understand the difference between our products and other companies'. Knowing the value of use, they'll be determined to use the company's products and create a desire to buy it.

In-sale service

a) Patiently help customers to choose products;

b) Introduce and display products for customers

c) Explain details about how to use products and precautions

d) Answer questions raised by customers

After-sales service

We'll do all the service work after the products are sold. For example, installation and commissioning, repair, maintenance, etc. This is meant to guide the corporate brand awareness, and interpretation of the brand corporate image. We'll have excellent quality and perfect after-sales service, will maximize the brand appeal and maintain brand credibility, will win the trust of customers and establish opportunities for long-term cooperation.

0 notes