#M2M device management platform

Explore tagged Tumblr posts

Text

Connect the Dots: Telecom IoT Platform for Smarter Operations

As businesses become more reliant on connected devices, managing networks effectively has never been more important. With the growing Internet of Things (IoT) ecosystem, companies need a reliable and efficient way to handle the increasing number of devices. An advanced telecom IoT platform provides a comprehensive solution that enables businesses to improve operations, enhance control, and make better data-driven decisions.

By leveraging the best IoT connectivity management software, businesses can oversee every device on their network, monitor data flows, and ensure uninterrupted communication. A powerful M2M device management platformin IoT device systems further supports smooth, scalable management, allowing companies to achieve a higher level of operational control. Let’s look at how this technology can drive more efficient operations.

Telecom IoT Platform: Driving Smarter Operations

A reliable telecom IoT platform provides businesses with the ability to monitor and manage connected devices from a single point. With thousands of devices operating simultaneously, maintaining control over each one can be challenging. This is where a centralized platform comes into play. It offers a complete view of the entire IoT network, allowing administrators to monitor device health, track data usage, and manage connectivity effortlessly.

The addition of the best IoT connectivity management software ensures seamless communication between devices. It enables real-time data monitoring, quickly identifying and resolving any connectivity issues. This results in fewer disruptions and more efficient data transfers, helping businesses make timely decisions.

Furthermore, a well-integrated M2M device management platform in IoT device networks helps businesses ensure that all devices work together harmoniously. Machine-to-machine (M2M) communication is vital for industries that rely on multiple interconnected devices, such as smart meters, industrial sensors, and connected vehicles. The platform ensures that these devices function properly, continuously gather data, and stay up-to-date with necessary software upgrades.

Benefits of a Comprehensive IoT Platform

Centralized Device Control A powerful telecom IoT platform provides a unified dashboard for managing all connected devices. With the best IoT connectivity management software, businesses can track device performance, manage configurations, and control data flow with ease. This comprehensive control reduces the risk of system errors and improves overall operational efficiency.

Seamless Connectivity Across Devices Managing connectivity for a growing number of IoT devices requires the right tools. A M2M device management platform in IoT device ecosystems helps keep everything in sync. It ensures reliable, real-time communication between devices, regardless of location or network conditions. This leads to better performance and uninterrupted service, allowing businesses to maintain smooth operations without costly downtime.

Enhanced Security Measures Security is a major concern when dealing with multiple connected devices. A reliable telecom IoT platform includes robust security protocols to protect data and device communication. The best IoT connectivity management software ensures encrypted data transfers and real-time threat detection. Businesses can safeguard their IoT networks from potential cyber risks and comply with industry regulations, reducing the chance of breaches.

Scalable and Flexible Growth As your IoT ecosystem expands, your platform should be able to scale accordingly. A flexible M2M device management platform in IoT device networks makes it easy to add new devices and adjust to changing operational needs. Whether you’re managing a handful of devices or scaling to thousands, a scalable platform ensures that growth is smooth and efficient.

Cost-Effective Operations Implementing the best IoT connectivity management software helps reduce the need for manual monitoring and intervention. By automating many routine tasks and allowing administrators to manage devices remotely, businesses can cut operational costs. The result is a more streamlined process that minimizes the need for on-site visits and troubleshooting, ultimately lowering costs while improving performance.

How to Get the Most from Your IoT Platform

To fully benefit from an IoT platform, businesses must ensure that it integrates smoothly with their existing systems. A telecom IoT platform should support a variety of devices and provide reliable communication between them. The right platform ensures that companies can scale their operations without interruptions, while also optimizing data flow for better decision-making.

A well-implemented M2M device management platform in IoT device networks allows businesses to monitor performance, ensure timely maintenance, and prevent disruptions. With the best IoT connectivity management software, businesses can optimize network usage, reduce latency, and improve data transmission speeds.

By choosing a flexible platform that adapts to future needs, companies can maximize their return on investment. Whether adding new devices or expanding to new regions, the right IoT solution should enable seamless growth and ensure continued operational efficiency.

Conclusion

A well-chosen telecom IoT platform provides businesses with an effective way to manage connected devices, enhance security, and streamline operations. By integrating the best IoT connectivity management software and a reliable M2M device management platform in IoT device systems, businesses can boost performance, reduce costs, and ensure smooth scalability. Investing in the right IoT platform means gaining full control over your device network and ensuring continuous, efficient operations for years to come.Infinity, telecom IoT platform of 6D Technologies has enhanced operational efficiency and improved device management for several telecom companies. Additionally, this solution is built with powerful tools and solutions like connectivity management platform, M2M device management solution, IoT middleware platform, and more. To learn more about this powerful tool, please visit https://www.6dtechnologies.com/products-solutions/internet-of-things/

0 notes

Text

5G Systems Integration Market Driven By Increase Investments In U.S., China, And Japan

The global 5G systems integration market size is estimated to reach USD 62.69 billion by 2030, registering a CAGR of 27.3% from 2022 to 2030, according to a new study by Grand View Research, Inc. Robust increase in the investments to deploy 5G network infrastructures across key countries, such as U.S., China, and Japan, has created the demand for integrating entire fifth generation infrastructure and applications across enterprises. This process will help enterprises to work as a centralized platform that will assist in reducing overall complexity. Thus, robust investments in building fifth-generation infrastructure, coupled with the growing need to set up a 5G-enabled ecosystem, are estimated to propel market growth.

Rapidly building smart cities have surged the adoption of numerous Internet of Things (IoT) devices across the globe. IoT devices require enhanced bandwidth to function appropriately. Thus, in order to provide high-speed broadband by supporting fifth-generation New Radio (NR), such as sub-6GHz and mmWave frequency bands, the entire infrastructure across these smart cities need to be upgraded in line with supporting fifth-generation radio network. Therefore, it is further estimated to boost the market growth from 2022 to 2030.

Gain deeper insights on the market and receive your free copy with TOC now @: 5G Systems Integration Market Report

Moreover, with the evolution of industry 4.0, the adoption of industrial sensors and collaborative robots is gaining popularity in the manufacturing sector across the globe. Therefore, to deliver seamless network connectivity to these above-mentioned devices, it is anticipated to raise the demand for 5G system integration services to make entire manufacturing facilities compatible with supporting next-generation 5G NR.

Rapidly rising digital transformation has disrupted the entire operation of the manufacturing industry. This has increased the trend of the machine-to-machine (M2M) communications to increase overall productivity as well as streamline the whole process. As a result, this has further expanded the need for high broadband to deliver uninterrupted connectivity to industrial sensors and robots. Therefore, the growing need for high broadband connectivity to establish seamless communication between machines is expected to elevate the demand for 5G system integration services in the next few years.

Furthermore, with the emergence of new technologies, such as network slicing and software-defined networking (SDN), the adoption of 5G system integration will witness a rapid surge to reduce overall enterprise infrastructure costs. Moreover, highly trained professionals must implement and manage the fifth-generation system integration services. This is anticipated to hinder market growth over the forecast period.

#5G System Integration Market Size & Share#Global 5G System Integration Market#5G System Integration Market Latest Trends#5G System Integration Market Growth Forecast#COVID-19 Impacts On 5G System Integration Market#5G System Integration Market Revenue Value

2 notes

·

View notes

Text

Decoding IT/OT Convergence: A Guide on Understanding IT and OT

As IoT grows synonymous with digital transformation & advancements in manufacturing, it has also led to a wave of change on the shop floor. This is a significant result of IT/OT Convergence, which led to faster decision-making, better collaboration, and a single source of truth across the organization.

But what does the IT/OT Convergence do with IoT, though? How are IoT, Information Technology (IT), and Operational Technology (OT) connected? For starters, they have the same three letters appearing in some sequence in all three abbreviations, but what more do these three have in common?

It’s essential to understand these terms before analyzing the IT/OT convergence.

What is Information Technology (IT) and Operational Technology (OT)?

Until IoT became a thing, there were two distinct worlds – traditional OT systems, which have machines, devices, and other industrial equipment, and more digital IT systems that handle everything related to computers, servers, storage, networking, and others. It’s been a while since the two worlds crossed over into one – IoT. To put this in simpler terms using an application of IoT, the smart devices in our homes today that are automated are a perfect example. These devices are part of a network that combines the prowess of both IT and OT systems to automate seemingly mundane human tasks like switching on and off lights. Now that we understand how IT/OT convergence happens, let’s look at IT/OT definitions with some jargon. As the name suggests, Information Technology (IT) includes computers, servers, and networking devices to create, process, store, and exchange all forms of electronic data in a secure manner. For a manufacturing environment, it can be hardware like laptops and servers and software for ERPs, inventory management, and other business-related tools.On the other hand, Operational technology focuses on managing and controlling physical devices operating globally. For manufacturing, it can include systems like MES, SCADA, PLCs, and CNCs that monitor & control the processes on the shop floor.

How does IT/OT Convergence help in Manufacturing?

Converging various aspects of technology is as old as technology itself. Integrating and interoperating different technologies can increase efficiency, cut down costs, and improve the workflows of multiple applications.

Earlier, the OT teams would handle everything that came under the purview of operations, keeping the plant running smoothly. On the other hand, the IT team runs business applications smoothly from the head office. They would only collaborate for one-off tasks like unplanned downtime, an untoward security incident etc., without any real collaboration.

The data for both teams was available in silos with no single source of truth-giving birth to communications issues, blind spots in processes and delayed decision-making. The OT machines, in particular, were only communicating with the world via niche M2M protocols, with data stored at disparate locations, available only in silos. This is where IT/OT convergence came in.

The IT/ OT convergence aimed to bring physical equipment (OT) into the digital world of IT. This was made possible, thanks to many advances in the tech industry, starting from Machine-to-Machine (M2M) communication, not to mention the increasing sophistication of IoT sensors and actuators that can be incorporated into OT equipment. Wireless communication over standard networking protocols allowed the data from each OT system to be communicated to a central server. The IT OT convergence allows for increased autonomy, maintenance, uptime, and accuracy of all the physical systems involved, with instant machine data access to the relevant stakeholders.

This convergence is focused primarily on automatic processes, using connected devices equipped with sensors to gather, send, and receive data. The data then is stored in a central platform, where it can be analyzed, monitored and actioned upon in real-time. This opens up a new realm of possibilities, where anyone with the know-how can develop APIs to analyze different devices and monitor, analyze & control their functioning.

Manufacturers Boon – The IoT Convergence With IoT, IT/OT convergence in manufacturing has become a success story.

The convergence allows businesses and manufacturing entities to be more cost-efficient (or, more precisely, resource-efficient – be it costs, time or supply involved). With the sales and inventory data to optimize manufacturing operations, equipment and energy consumption is more efficient, while maintenance and the quantity of unsold inventory are reduced.

To Know more about Decoding IT/OT Convergence: https://www.infinite-uptime.com/decoding-it-ot-convergence-a-guide-on-understanding-it-and-ot/

0 notes

Text

Industrial Cellular Routers: Encouraging Communication in Isolated and Dangerous Settings

Traditional wired networks are no longer the only way to connect in the modern digital era. Robust, dependable, and secure communication solutions are essential for industries operating in distant or harsh areas in order to connect their vital assets and provide real-time data sharing. The industrial cellular router is a type of customized networking equipment that can be used in industrial environments where cable infrastructure may not be available or is impractical.

An Industrial Cellular Router: What Is It? A ruggedized networking device called an industrial cellular router uses cellular networks to provide wide-area connection for industrial applications. Industrial cellular routers use cellular technology (3G, 4G, and increasingly 5G) to transfer data wirelessly over great distances, in contrast to typical routers that depend on physical connections. They are designed especially to endure the harsh conditions found in industrial settings, such as high humidity, high temperatures, vibration, and electromagnetic interference.

Features and Functionalities: The following are some of the main features and functions of industrial cellular routers:

Wireless Connectivity: Reliable wireless communication is made possible by industrial cellular routers, which enable cellular network communication between industrial systems and equipment. They are compatible with multiple carriers and areas because they support a range of cellular standards and frequencies.

Secure Communication: Security is paramount in industrial applications, especially when transmitting sensitive data over public cellular networks. To secure data and defend against cyber threats, industrial cellular routers use virtual private networks (VPNs), firewalls, and sophisticated encryption techniques.

Remote Management: An administrator may monitor, configure, and troubleshoot devices from a central location with the help of several industrial cellular routers' remote management features. Industrial network implementation, maintenance, and optimization are made easier by this remote management feature.

Redundancy and Failover: Industrial cellular routers may provide redundancy and failover capabilities to guarantee constant connectivity and reduce downtime. In the event of a network outage or disturbance, they can immediately switch between the primary and backup cellular networks or use other communication channels.

Importance in Business Environments: Industrial cellular routers are essential in many different industrial domains, such as:

Oil and Gas: Industrial cellular routers provide for real-time monitoring of production processes, equipment health, and environmental conditions in remote oil and gas fields or offshore platforms. This promotes proactive maintenance and operational efficiency.

Utilities: Industrial cellular routers offer connectivity for remote monitoring, control, and optimization of essential infrastructure in utilities like water treatment plants, electrical substations, and renewable energy installations. This increases dependability and resilience.

Transportation and Logistics: By sending location data, sensor readings, and telemetry information over cellular networks, industrial cellular routers facilitate supply chain visibility, fleet management, and vehicle tracking in transportation and logistics operations.

Manufacturing: Machine-to-machine (M2M) communication in manufacturing facilities is supported by industrial cellular routers, which facilitate the smooth integration of robotic automation, inventory management systems, and production systems.

In summary: For enabling connectivity in remote, difficult, and mission-critical industrial environments, industrial cellular routers are essential equipment. Because of their capacity to deliver dependable, secure, and robust wireless communication, industries are able to maximize operations, maintain a competitive edge in an increasingly interconnected world, and reap the benefits of digital transformation. Organizations in a variety of industrial industries can improve efficiency, spur innovation, and close communication gaps by utilizing industrial cellular routers.

0 notes

Text

Title: Building the Future: A Comprehensive Guide to Smart Factory in Construction Industry 4.0 Today's digital age is catapulting the construction industry into a realm of possibilities and advancements that are as exhilarating as they are essential; a realm termed as Construction Industry 4.0. This transformative era is being shaped by the creation and evolution of smart factories, becoming the harbinger of efficient, innovative, and radically enhanced production processes. The core of Construction Industry 4.0 lies in the integration and optimization of automated construction, additive manufacturing, cloud computing, data analytics, and other IoT-based breakthroughs. This accelerates the transition towards Industry 4.0, where the term 'Smart Factory' is not merely an industry buzzword, but the fulcrum of productive evolution. A smart factory, often synonymous with digital manufacturing, is the quintessence of automation and data exchanges in-built into manufacturing technologies. This choreographed interplay shapeshifts traditional production lines into an interconnected, automated and optimized production environment. Seamless data integration across every aspect of the production chain yields several benefits in a smart construction setup, including reduced costs, waste minimization, accelerated output, enhanced accuracy, and boosted overall efficiency. It sets a platform that merges digital twins with real machines and creates value-adding networks to facilitate human-machine collaboration. As we delve deeper into Construction Industry 4.0, we find the Autonomous Robotic Construction System (ARCS) at its forefront. These sophisticated machines, paired with artificial intelligence and machine learning, streamline the construction process, enabling tasks to be executed much quicker and more precisely than ever. Machine-to-Machine (M2M) communication, a critical feature of smart factories, utilizes real-time data to support decision-making processes and operational efficiency. Internet of Things (IoT) enabled devices, predictive maintenance, augmented reality (AR), compound with M2M communication, forge a robust, responsive, and agile production ecosystem. The advent of the smart factory system holds more than just the promise of techno-driven efficiency. It acts as an imperative tool for sustainability. Aided by green manufacturing and augmented reality, smart factories contribute significantly to the reduction of environmental footprint. Alternatively, the blockchain technology ingrained within such factories contributes to maintaining traceability and accountability, further enhancing transparency within the industry. Beware, though, this digital transformation isn't without challenges. Cybersecurity threats loom larger than ever, with an increasing reliance on connected devices. Workforce adaptation to this rapid digitalization remains an uphill battle too. However, it is encouraging that stakeholders recognize these challenges, ensuring strong countermeasures and risk management strategies are in place. As we move beyond the present to step into the future, the construction sector needs to not just adopt, but adapt to this profound transformation. It is clear that the Smart Factory model, the beacon of Construction Industry 4.0, is here to stay, promising a future of sustainability, efficiency, and technological advancement. In this transformative era, successful enterprises will be those that harness the power of digital evolution, utilizing it to drive growth, innovation and competitiveness in an increasingly global market. All in all, with progressive sophisticated technologies at hand, we can look forward to building the future, today. Title: "Navigating the Construction Industry of Tomorrow: The Rise of the Autonomous Smart Factory" As we march steadfastly into the brave new world of Construction Industry 4.0, we are on the threshold of a revolution that's poised to entirely reshape our built environment.

Inspired by "Building the Future: A Comprehensive Guide to Smart Factory in Construction Industry 4.0," here's a glimpse into a future where the smart factories aren't just an addition to the construction scene, but the heart and soul of this transformative era. The construction industries of the future will be configured around fully automated, intelligent factories. Artificial Intelligence and Machine Learning algorithms will underpin the operations; these digital powerhouses will meticulously ensure enhanced efficiency, extreme precision, and significantly minimized waste. Deeper integration of technologies like 3D printing, robotics, and autonomous vehicles will further refine the construction processes. Tomorrow's smart factories will push the envelope, extending far beyond the manufacturing of materials and components. They will be digital-physical systems capable of self-diagnosis and self-optimization. Pioneering the concept of 'the Internet of Things' (IoT) in construction, these factories will communicate in real-time with every single component involved in construction processes, enabling seamless operations and just-in-time logistics. But it's not just about high-tech equipment and advanced software; the smart factory revolution will also change patterns of employed labor. As automation takes center stage, there will be a palpable shift towards tech-savvy professionals adept at managing and maintaining these advanced systems. The construction site of the future will be a spectacle of synchronized coordination. Autonomous drones and robots will work round the clock, performing tasks ranging from surveying to bricklaying, from transporting materials to performing maintenance checks. This prediction isn't mere speculation anymore; it's a reality taking shape, gradually altering the traditional contours of the construction industry. By adopting smart factories, the construction industry can ensure sustainable growth, with a major emphasis on 'green' practices. The meticulous precision of smart factories guarantees minimal wastage, reducing the industry's environmental footprint. So, what does this mean for you and your venture in the construction industry? Staying ahead of the curve requires embracing this digital transformation. Investing in this golden trove of digitalization means not only surviving but thriving in a future where smart factories are the new norm. The road to the future of the construction industry may seem daunting, but with the integration of smart factories, it promises a journey filled with innovation, efficiency, and sustainability. This is not just the rise of the smart factory; it's the dawn of Construction Industry 4.0 - a new epoch that embodies our collective aspiration for a smarter, greener, and a more efficient tomorrow. "Ready to step into the future of construction? Elevate your business to the next level with a smart factory. Don't get left behind - Start leveraging Industry 4.0 today! Click here to learn how. Your future self will thank you." Start Your Digital Transformation Now! As we continue to unlock the vast potentials of the combination of smart factory and Industry 4.0, the construction industry will inevitably revolutionize in ways we have not imagined. The advent of smart factories will undoubtedly lead to unparalleled efficiency, productivity, and safety levels. Machines will no longer just be tools; they will communicate, analyze, and make decisions. Automation will no longer only be for repetitive tasks, but for complex problem-solving and creative pursuits as well. As a consequence, we may foresee a future where construction sites are largely automated, with data being harnessed for precise planning and execution of projects at an unprecedented scale and pace. This can lead to significant reductions in project timelines and costs, simultaneously increasing the scalability of projects. However, there will also be drastic shifts required in skillsets. Workers

will need to become familiar with AI-driven technologies, robots, and other automation tools. Cybersecurity will become an essential aspect of the construction industry. In this context, perhaps architect and futurist Buckminster Fuller said it best: "We are in an era of comprehensive evolution. The success of the next phase of human development is no longer about the survival of the fittest, but the survival of the most cooperative. This is the future of the construction industry in the age of smart factories and Industry 4.0."

0 notes

Text

Warehouse Management System Market Size, Share, Trends, Growth Opportunities and Competitive Outlook

Warehouse Management System Market Analysis and Size

A warehouse management system is a set of guidelines and procedures designed to organize a distribution center's or warehouse's workload, guarantee its effective operation, and help the facility achieve its goals. Machine-to-Machine (M2M) technology is becoming more popular in warehouse management because it allows machines or devices to exchange information and perform functions on their own. M2M technology allows a warehouse management system to connect to and receive data from instruments such as conveyors, picking equipment, and assembly lines.

Global warehouse management system market which was USD 2,139.96 million in 2022, is expected to reach USD 8,973.50 million by 2030, and is expected to undergo a CAGR of 16.7% during the forecast period of 2023 to 2030. In 2022, software segment is dominating the market because most of the developed as well as developing nations prefer using online software’s as they are feasible in usage. In addition to the market insights such as market value, growth rate, market segments, geographical coverage, market players, and market scenario, the market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, and pestle analysis.

Request access for the sample report: https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-warehouse-management-system-market

Segments Covered

Component (Hardware, Software and Services), Deployment (Cloud-Based and On-Premise), Type of Tier (Advanced, Intermediate and Basic), Distribution Channel (Online and Offline), End-User (Food and Beverage, E-Commerce, Automotive, Third-Party Logistics, Healthcare, Electrical and Electronics, Metals and Machinery, Chemicals, Others)

Countries Covered

U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, Italy, U.K., France, Spain, Netherlands, Belgium, Switzerland, Turkey, Russia, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa

Market Players Covered

Manhattan Associates, (U.S.), Blue Yonder Group, Inc. (U.S.), HighJump (U.S.), Oracle (U.S.), IBM (U.S.), SAP SE (Germany), ACL Digital (U.S.), VMWare Inc. (U.S.), Ericsson Inc (Sweden), Hewlett Packard Enterprise Development LP (U.S.), Softeon (U.S.), Telco Systems (U.S.), NEC Corporation (Japan), Juniper Networks Inc.(U.S.), Infor (U.S.), Versa Networks Inc., (U.S.) and Cisco Systems Inc.(U.S.)

Market Opportunities

Rapid growth in e-commerce

Increased in software advancements

Get full access of the report: https://www.databridgemarketresearch.com/reports/global-warehouse-management-system-market

TABLE OF CONTENTS

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Research Methodology

Part 04: Market Landscape

Part 05: Pipeline Analysis

Part 06: Market Sizing

Part 07: Five Forces Analysis

Part 08: Market Segmentation

Part 09: Customer Landscape

Part 10: Regional Landscape

Part 11: Decision Framework

Part 12: Drivers and Challenges

Part 13: Market Trends

Part 14: Vendor Landscape

Part 15: Vendor Analysis

Part 16: Appendix

Get full access of the toc report: https://www.databridgemarketresearch.com/toc/?dbmr=global-hair-color-products-market

Browse trending report:

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

0 notes

Text

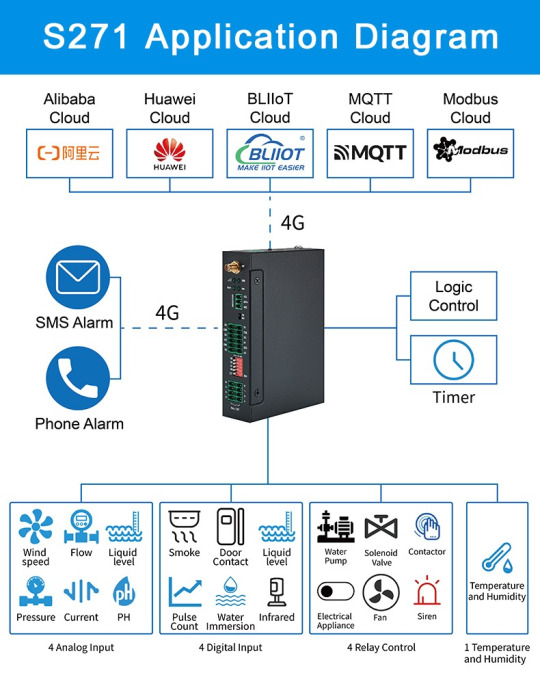

BLIIoT Water Meter Pulse Counting Gateway S271

Background

No matter where you live, water and electric meters are an absolute must. Water meters record how much water you use and how much you pay for it. Water meters help monitor data, conserve water, and lower water bills.

Pulse Counting Gateway

Pulse Counting Gateway S271 is designed to count the number of pulses from electricity meters, water meters or general meters as well as machinery and equipment with pulse outputs. Quickly and cost-effectively transform your traditional water meter into a smart water meter, monitoring data in real time.

Solution

Pulse Counting Gateway S271 can be used in different applications such as agricultural irrigation, smart building meter reading and industrial water use. The device can be connected to a pulse water meter, and then collect water use data and upload the data to the IoT cloud platform via 4G for further visualization. Users can check the status of the water meter and perform monitoring and control at any time. The pulse counter can provide remote monitoring and visual intelligent data management to achieve water conservation.

More information about Water Meter Pulse Counting Gateway S271: https://www.bliiot.com/m2m-rtu-p00175p1.html

0 notes

Text

BLIIoT Water Meter Pulse Counting Gateway S271

Background

No matter where you live, water and electric meters are an absolute must. Water meters record how much water you use and how much you pay for it. Water meters help monitor data, conserve water, and lower water bills.

Pulse Counting Gateway

Pulse Counting Gateway S271 is designed to count the number of pulses from electricity meters, water meters or general meters as well as machinery and equipment with pulse outputs. Quickly and cost-effectively transform your traditional water meter into a smart water meter, monitoring data in real time.

Solution

Pulse Counting Gateway S271 can be used in different applications such as agricultural irrigation, smart building meter reading and industrial water use. The device can be connected to a pulse water meter, and then collect water use data and upload the data to the IoT cloud platform via 4G for further visualization. Users can check the status of the water meter and perform monitoring and control at any time. The pulse counter can provide remote monitoring and visual intelligent data management to achieve water conservation.

More information about Water Meter Pulse Counting Gateway S271: https://www.bliiot.com/m2m-rtu-p00175p1.html

0 notes

Text

IoT Platform Market Look a Witness of Excellent Long-Term Growth – Worldwide Survey by 2028

Latest business intelligence report released on Global IoT Platform Market, covers different industry elements and growth inclinations that helps in predicting market forecast. The report allows complete assessment of current and future scenario scaling top to bottom investigation about the market size, % share of key and emerging segment, major development, and technological advancements. Also, the statistical survey elaborates detailed commentary on changing market dynamics that includes market growth drivers, roadblocks and challenges, future opportunities, and influencing trends to better understand IoT Platform market outlook. List of Key Players Profiled in the study includes market overview, business strategies, financials, Development activities, Market Share and SWOT analysis are PTC Inc. (United States),SAP SE (Germany),International Business Machines Corporation (IBM) (United States),Hitachi, Ltd. (Japan),Accenture plc (United States),Atos (France),Altizon Systems (United States),Flutura Decision Sciences and Analytics (United States),Oracle Corporation (United States),Amazon.com, Inc. (United States) An IoT platform works on a multi-layer technology and manages, processes, and transfers the data to and from connected devices with the help of the Internet. It connects hardware, however diverse, to the cloud by using flexible connectivity options, broad data processing powers, and enterprise-grade security mechanisms. Additionally, it offers connectivity to various IoT-compatible hardware devices including mobiles, laptops, industrial control systems, wearable fitness devices, automotive telematics units, or drone units. Key Market Trends: Growing Adoption of IoT Platform based on Advanced AI Algorithms

Introduction to Industry-Specific Platforms will Lead to Increased Demand

Opportunities: Upsurgin Internet Connectivities and IoT based Infrastructure from Developing Economies

Consumer Shift from Local Data Bases to Cloud-Based Applications Market Growth Drivers: Robustly Increasing Demand for Cloud-Based Data Storages

Upsurging Number of IoT Based Connected Devices across the Globe

Challenges: The Death of Skilled Workforce Across the Globe

Strong Competition and Introduction to Domestic IoT Platform Providers The Global IoT Platform Market segments and Market Data Break Down by Type (Device Management, Application Management, Connectivity Management), Application (Predictive Maintenance, Business Process Optimization, Asset Tracking), Platform (Connectivity Platforms, M2M platforms), End Use Industry (Manufacturing, BFSI, Smart Cities & Homes, Telecommunication, IT, Others), Deployment (Cloud-Based, Hybrid)

Presented By

AMA Research & Media LLP

0 notes

Text

6D Technologies to Exhibit Its Top Products at MWC Barcelona 2024

6D Technologies announced its participation in MWC Barcelona from 26th Feb to 29th Feb, 2024. The company will exhibit its AI-driven technology products for telcos and CSPs.

6D Technologies is a well-known global leader in the telecom and enterprise solution provider industry. The company has delightedly announced its participation as one of the exhibitors at the upcoming Mobile World Congress (MWC) 2024.

As per the shared details, the participation details of 6D Technologies are as below:

Booth No: Stand 2D40 in Hall 2

Venue: Fira Gran Via, Barcelona

Dates: February 26 to February 29, 2024

6D Technologies will showcase its innovative products that are empowered with AI technology to make a difference in the lives of communication service providers, small and large scale telcos, and other companies operating in the telecommunication industry.

The spokesperson of the company announced a brief of all products to be exhibited at MWC Barcelona 2024.

Telecom Digital BSS Platform

Canvas is a complete digital BSS suite that modernizes business support operations and digitizes legacy networks. This platform encompasses advanced modules such as a telecom CRM system, online charging system, billing mediation platform, order management solution, partner management system, unified product catalog management, and more.

Intelligent Customer Value Management Platform

Magik is an AI-powered CVM and big data analytics platform that harnesses the power of AI, ML, and big data to predict customer behavior to devise personalized customer engagement and value management plans. It consists of key modules like campaign management, telecom loyalty programs, gamification software in telecommunication, BI reporting, and more.

Sales and Distribution Platform

Ventas is a full fledged telecom sales and distribution suite that is developed to track and manage the efficiency and accuracy of sales representatives of CSPs. It encompasses futuristic modules like PoS management, inventory management, geo business visibility, telecom channel partner management, field force management, digital onboarding, telecom commission management, and more.

Telecom IoT Platform

Infinity is a popular IoT solution for telcos that blends the perfect power of the Internet of Things and AI to increase advantages for CSPs and telcos. Certainly, it helps in increasing monetization options for telcos with its cutting-edge technologies and efficient modules like M2M device management, URL filtering, IoT connectivity management, IoT middleware, and more.

Telecom Digital Financial Platform

Aureus is an all-inclusive AI packed digital financial suite for companies operating in the telecommunication industry. It is developed on multichannel principles and it provides access to some really powerful tools like a mobile wallet, merchant management, agency banking solution, conversational banking system, voucher management solution, automated chargeback management solution, and more.

Unified VAS platform

Lynx is a renowned unified VAS consolidation and network management platform that blends an array of functionalities and apps within a single platform for telcos. It provides a robust platform and a range of empowering solutions such as SMS and signaling firewall, network solutions, SMSC, SMS gateway, USSD gateway, CRBT, SDP, WSMS, and many more.

About MWC Barcelona 2024

Mobile World Congress (MWC) is renowned as the ultimate event for global mobile connectivity and telecommunication professionals. MWC Barcelona 2024 will spotlight six key themes: 5G and Beyond, Connecting Everything, Humanising AI, Manufacturing DX, Game Changers, and Our Digital DNA. This event will showcase leading brands amidst cutting-edge technologies, compelling content, and influential keynotes. It claims to promise insightful keynote sessions, inspiration, and impactful business deals, bringing decision-makers and keynotes to the forefront of the global mobile industry.

About 6D Technologies

6D Technologies secures the top place as one of the leading providers of the best technology products to the mobile and telecommunication industry. It specializes in telecommunications solutions, digital transformation, and AI driven products that bring revolutionary changes for telcos, network operators, CSPs, and more. The representatives of 6D Technologies will participate in the upcoming event, MWC Barcelona 2024 to exhibit their flagship products. To learn more about participation of 6D Technologies at MWC 2024, please visit https://www.6dtechnologies.com/press-release/mobile-world-congress/

1 note

·

View note

Text

Recent Trends in Android App Development You Should Know

The market for Android app development is expanding quickly. Naturally, as 5G technology and the Internet of Things gain popularity, it is anticipated to grow even more.

Latest Trends in Android App Development:-

The Google Assistant and chatbots

In the upcoming year, chatbots will be in great demand. In the end, chatbots are revolutionizing how companies interact with their clients and address their issues. Chatbots are being used by several sectors, including retail, eCommerce, and food delivery.

Voice-activated chatbots use text-to-speech and speech-to-text conversion tools. The ability to differentiate yourself from rivals has emerged as a new trend. Because chatbots are built using cutting-edge ML algorithms, they are appropriate for strategic use. It implies that massive amounts of data may be analyzed automatically, and chatbots can assist users by giving them pertinent information without human involvement.

5G Technology

5G technology promises exponential speed and performance compared to 4G networks. Having a data transfer speed of 100 GBPS, 5G technology enables the development of high-performance, feature-rich apps that boost company performance.

Utilizing On-Demand Software

One of the key trends in Android app development is the focus on customer service. There are numerous on-demand apps accessible now, such as Postmate and Uber.

Following the pandemic, people have grown even more accustomed to using on-demand services. To reach their target customers, a number of businesses, including healthcare, travel, retail, hotels, and grocery shops, now use on-demand apps.

The practice of developing Android applications on-demand will keep expanding in the upcoming year. These programs speed up and simplify routine operations.

IoT (Internet of Things)

Android app development will significantly increase as linked gadgets like smartwatches, home assistants, and security systems become more commonplace.

IoT integration is made possible by the Google IoT platform using Android Studio and its APIs. Programmers must take into account logical connectors and APIs to communicate with devices made by various manufacturers.

Machine-to-machine (M2M) app development is another term for Internet of Things (IoT) apps. Before integrating hardware and networking components, IoT software developers should create a fully functional dashboard in the cloud using either a web browser or a mobile device.

MotionLayout

By bridging the gap between complicated motions and layout transitions, MotionLayout expands the functionality of Android development. The MotionLayout assists you in controlling widget motion and animation in your app. This framework incorporates TransitionManager, CoordinatorLayout, and the property animation framework.

The ConstraintLayout library includes MotionLayout, which is backward compatible with API level 14. Regardless of their complexity or size, transitions are always described in XML via MotionLayout, which is intrinsically declarative.

One of the trends in Android app development that you can anticipate seeing more of in the future is MotionLayout.

EMM & APM

Application Performance Management (APM) and Enterprise Mobile Management (EMM) have progressively advanced in the IT/Software industry over the past few years.

The streamlined procedure of people and technology engaged in mobile computing is known as an EMM. To realize a common vision, it combines wrapping, containerization, mobile device management, and business synchronization.

Applications Performance Management keeps track of how quickly and precisely people, computers, and the underlying network infrastructure carry out transactions.

It's critical to have a thorough understanding of your applications from start to finish. Data is gathered whenever an app is not functioning as intended in order to determine the cause and offer remedies.

Technology behind blockchain

Blockchain technology has finally been used after several years after its creation. Blockchain-based decentralized apps allow developers improved access control and transparency, preventing illegal access to the app.

By 2026, it is predicted that the market for blockchain technology would generate $52.5 billion, with a CAGR of 62.73%. Decentralized applications (Dapps) on the blockchain are open-source software programs based on smart contracts. These applications operate without the capacity to change or remove data thanks to a decentralized blockchain.

These apps offer speedy payments, trustworthy data recordings, and universal use in addition to being tamper-proof. A company that creates Android apps can use blockchain technology to maintain strong security procedures. Particularly in the financial industry, which includes banks, currency exchange, and other financial institutions, this approach is quickly becoming a typical component of Android development.

Conclusion

Before committing, take the time to carefully assess your technical knowledge, financial situation, business needs, and infrastructure.

It is critical that we comprehend the processes involved in creating Android apps and the effects they have on the Android ecosystem. Partner with a mobile app development company to maximize their potential rather than simply copying modifications.

It could appear difficult to locate a business that adheres to all notable developments in Android app development. However, it's worthwhile because a reliable Android app development company may take your company to the next level. Original Source:-http://bit.ly/3CpB4uG

#Android App Development#Android App Development Company#Android App Development Dubai#Android App Developer

0 notes

Text

Decoding IT/OT Convergence: A Guide on Understanding IT and OT

As IoT grows synonymous with digital transformation & advancements in manufacturing, it has also led to a wave of change on the shop floor. This is a significant result of IT/OT Convergence, which led to faster decision-making, better collaboration, and a single source of truth across the organization.

But what does the IT/OT Convergence do with IoT, though? How are IoT, Information Technology (IT), and Operational Technology (OT) connected? For starters, they have the same three letters appearing in some sequence in all three abbreviations, but what more do these three have in common?

It’s essential to understand these terms before analyzing the IT/OT convergence.

What is Information Technology (IT) and Operational Technology (OT)?

Until IoT became a thing, there were two distinct worlds – traditional OT systems, which have machines, devices, and other industrial equipment, and more digital IT systems that handle everything related to computers, servers, storage, networking, and others. It’s been a while since the two worlds crossed over into one – IoT. To put this in simpler terms using an application of IoT, the smart devices in our homes today that are automated are a perfect example. These devices are part of a network that combines the prowess of both IT and OT systems to automate seemingly mundane human tasks like switching on and off lights. Now that we understand how IT/OT convergence happens, let’s look at IT/OT definitions with some jargon. As the name suggests, Information Technology (IT) includes computers, servers, and networking devices to create, process, store, and exchange all forms of electronic data in a secure manner. For a manufacturing environment, it can be hardware like laptops and servers and software for ERPs, inventory management, and other business-related tools.On the other hand, Operational technology focuses on managing and controlling physical devices operating globally. For manufacturing, it can include systems like MES, SCADA, PLCs, and CNCs that monitor & control the processes on the shop floor.

How does IT/OT Convergence help in Manufacturing?

Converging various aspects of technology is as old as technology itself. Integrating and interoperating different technologies can increase efficiency, cut down costs, and improve the workflows of multiple applications.

Earlier, the OT teams would handle everything that came under the purview of operations, keeping the plant running smoothly. On the other hand, the IT team runs business applications smoothly from the head office. They would only collaborate for one-off tasks like unplanned downtime, an untoward security incident etc., without any real collaboration.

The data for both teams was available in silos with no single source of truth-giving birth to communications issues, blind spots in processes and delayed decision-making. The OT machines, in particular, were only communicating with the world via niche M2M protocols, with data stored at disparate locations, available only in silos. This is where IT/OT convergence came in. The IT/ OT convergence aimed to bring physical equipment (OT) into the digital world of IT. This was made possible, thanks to many advances in the tech industry, starting from Machine-to-Machine (M2M) communication, not to mention the increasing sophistication of IoT sensors and actuators that can be incorporated into OT equipment. Wireless communication over standard networking protocols allowed the data from each OT system to be communicated to a central server. The IT OT convergence allows for increased autonomy, maintenance, uptime, and accuracy of all the physical systems involved, with instant machine data access to the relevant stakeholders. This convergence is focused primarily on automatic processes, using connected devices equipped with sensors to gather, send, and receive data. The data then is stored in a central platform, where it can be analyzed, monitored and actioned upon in real-time. This opens up a new realm of possibilities, where anyone with the know-how can develop APIs to analyze different devices and monitor, analyze & control their functioning.

Manufacturers Boon – The IoT Convergence

With IoT, IT/OT convergence in manufacturing has become a success story.

The convergence allows businesses and manufacturing entities to be more cost-efficient (or, more precisely, resource-efficient – be it costs, time or supply involved). With the sales and inventory data to optimize manufacturing operations, equipment and energy consumption is more efficient, while maintenance and the quantity of unsold inventory are reduced.

Here are some notable key benefits of switching to an IoT-enabled manufacturing environment.

Real-time decision making:IIoT (Industrial Internet of Things) allows manufacturers to collect all the data they would ever need and analyze it in real-time. Sensitive data can be analyzed directly at the source, which significantly reduces the bandwidth required, not to mention the increased levels of security.

Predictive Maintenance: One of the most significant benefits of IIoT is the revolution of predictive maintenance. Unplanned downtime can cause manufacturing entities to lose a substantial amount of money, while the traditional preventive maintenance method proves to be highly costly. The IT/OT convergence makes it possible for manufacturers to predict when the machines need maintenance and plan accordingly without unnecessary downtime or repair costs.

Increased Efficiency: Whether your manufacturing entity is looking to decrease annual energy costs, increase inventory turns, reduce the time to introduce a new PLC, decrease defect rates, or improve the overall effectiveness of the physical machinery involved – IT/OT convergence can help your business do it all.

Phases of IT/OT Convergence

There are three primary phases of IT/OT Convergence.

Process convergence – Deals with the intersection of workflows, ensuring that important projects and data are communicated to relevant stakeholders.

Software and Data Convergence – Deals with procuring the necessary software and data from the front office for the IT/OT needs. This is a technology-based convergence that deals with the network architecture of the enterprise.

Physical Convergence – Deals with the hardware – old hardware is either replaced or retrofitted with new sensors and actuators to accommodate the incorporation of IT into traditional OT.

Final Word

IT/OT convergence has been a significant milestone in the IoT journey and a win-win for both OT & IT Teams.

The OT teams can now access the machine data whenever they need it for proactive decision making to create value in their machines, processes & workforce. They can align better with overall business systems like ERP etc., creating unparalleled insights.

The IT teams can fulfil their smart factory vision with a healthy understanding of the ground reality and collaborate with the operations team to evolve together.

We’ve covered many of such stories in detail

in our Case Studies section

– where we showcase just how much businesses in your industry can gain through process digitization and using the Internet of Things.

Want to know how IT/OT convergence can revolutionize your manufacturing processes? Please

get in touch

with us – and our domain experts would be happy to explain over a quick call.

Click here to schedule a demo with our team of experts.

This blog is referenced from : https://www.infinite-uptime.com/decoding-it-ot-convergence-a-guide-on-understanding-it-and-ot/

0 notes

Text

MG HECTOR: Do You Really Need It? This Will Help You Decide!

In India, the brand-new "connected" SUV MG Hector has been gaining popularity despite being sold at affordable costs. MG Hector Car offers a wide range of features across its rigorous technology connecting vehicles. In terms of comfort & performance, the MG Hector distinguishes itself in the market by providing luxury and a hybrid powertrain respectively. The connectivity characteristics boast a real cause for its purchase and stand as a first preference in the segment. For sales questions, get in touch with the PPS MG Dealers in Hyderabad to learn more about the cutting-edge technology of the MG Hector.

MG Hector is equipped with FANTASTIC FOUR FEATURES (FFF) apart from the routine aspects of an SUV. The FFF are AI-powered voice assist, a 48V mild hybrid system, pre-loaded apps for a 10.4-inch touchscreen infotainment system, iSmart technology, and the ability to receive over-the-air updates. Below are the details of 4 features.

AI-powered Voice Assist

Voice Assist is the most alluring connectivity feature on the MG Hector and MG Hector Plus. Nuance incorporated artificial intelligence and machine learning with the collaboration and this allows synchronization with Indian accents easily. The voice assistant on MG Hector is easy to start and responds when you say "Hello MG." Over 100 tasks are easy to carry including opening and closing the windows and sunroof, navigation control, and climate control systems.

Pre-loaded Apps For the Infotainment System

In response to the growing popularity of touchscreen devices today, MG foresees the need and offers a 10.4-inch HD touch display on the Hector. Hector's infotainment system comes with many pre-installed apps. An intuitive interface replaces the conventional buttons making the touchscreen technology enablement with the centre console easier to access the majority of capabilities.

iSmart Telematics Smartphone App

Owners of MG Hector cars can access real-time data on their smartphones. This is possible with the next-generation connected car technology app from MG iSmart. The function on the MG Hector allows geo-fencing, location tracking, and tyre pressure monitoring. The app provides significant access to turn on the ignition, lock/unlock the doors, and start the air conditioning.

Over-the-air Updates and 5G Capability

The Hector is equipped with an M2M (Machine to Machine) SIM card to connect with the Internet Protocol Version 6 interface (IPv6). With the help of Airtel's telecom network and Cisco's IoT Connectivity Management platform Jasper, the telematics suite is able to enable 5G technology. With the same technology, 5G connectivity is easier as the owners purchase this technology-integrated vehicle.

What is special about MG Hector?

The MG Hector effortlessly downloads new software updates when available via Over-The-Air (OTA). This makes it possible for owners to get live software updates, entertainment material, and app updates. Additionally, this increases the reputation of Hector's Internet access which matches the faster connectivity on a smartphone.

Are MG cars long lasting?

MG Hector has longer durability while making the host information about the business, service centres, and dealers easier to access. For MG Service Hyderabad, visit renowned PPS and thanks to the MDMS (Magnet Dealer Management System) in MG Hector. According to the top auto manufacturer MG, this will make it possible to identify clients and give them access to services at the business' service centres and dealerships.

Hector alerts MG's customer management centre via an eCall emergency response system in the event of an accident (named Pulse Hub). Furthermore, when an airbag opens, Pulse Hub, messages are sent to registered phone numbers, and a number of emergency response steps are triggered.

Is MG Hector good for long drive?

Yes. A hybrid powertrain is made more widely available on the MG Hector, making it easier and comfortable for driving in long jouneys. Also, this technology marks an important step in MG's effort to incorporate current requirements with the hybrid mode. The technology sync's with a 1.5-liter turbocharged gasoline engine alongside a 48-volt system that allows good MG Hector Mileage. MG Hector's fuel economy elevates by 12% and CO2 emissions are cut by 11% with such a sizable battery-powered system. Also, there are more features such as the E-boost, idle start-stop, and regenerative braking.

Are MG cars good quality?

The design, performance, and price going hand-by-hand and driving buyers attention in MG Hector. It's the finest advice with absolute quality when choosing an SUV in the sub-Rs 20 lakh pricing range. MG Hector Price ranges from Rs. 12.18 Lakhs* to Rs. 16.88 Lakhs (ex-showroom price in India). There are 3 options- 1.5-liter turbo-petrol, 1.5-liter turbo-petrol with 48-volt mild hybrid, and 2.0-liter diesel engines. In particular, MG states that the hybrid model with an ARAI certification has a fuel efficiency rating of 15.81 km per liter.

Conclusion

It is without a doubt a YES to choose the MG Hector because of the FFF formula that was described in the opening sections, which has a powerful influence on drawing attention from potential automobile buyers to this model. Purchase the MG Hector at a low price and enjoy a smooth driving experience. To learn more about the technical specifications or features of the MG Hector, schedule a test drive online or browse and visit MG Showrooms in Hyderabad.

0 notes

Text

Leveling up the game of IoT using AI

The past decade has realized that the way manufacturers view their machines can be transformed if they use artificial intelligence coupled with real-time data analytics and communication. When artificial intelligence is combined with the power of IoT, the generation of smart manufacturing can be unlocked as these technologies have been creating waves in the sector individually. By combining all these powers, the advantages become manifold. According to Nick Bostrom, a Swedish philosopher, "machine intelligence is the last invention that humanity will ever need to make." For such machines, AI can act as its brain, which collects, processes, and uses vital information retrieved from devices connected through IoT, which acts as the nervous system for sending and receiving signals. By using both technologies, the system becomes intelligent enough to make decisions for itself on its own, which also forms the AIoT or Artificial Intelligence of Things. By 2026, the global AIoT sector is expected to grow by more than 78.3 billion US dollars, accounting for approximately 40% compound annual growth rate, as reported by Research and Markets. Integration of AI with IoT IoT includes technologies such as enhanced connectivity, cloud computing, machine-tomachine (M2M) communication, and various others that enable the connectivity of the machines, provide storage for data, and convert it into meaningful insights. On the other hand, AIoT is used to enhance the capabilities of IoT, which offers numerous benefits to the markets that make use of technologies. Previously, manufacturers were satisfied with their machines' ability to perform optimally and make their own decisions upon the data stored and processed. But with the integration of AI into these machines, the manufacturers can close the loop as the devices can spontaneously take action on their learned processes to perform in the best manner. But to make AIoT more comprehendible and viable, data management systems need to be added along with the machines so that they can support speedy decision-making. Storing data on the cloud seems feasible as data is analyzed near its source, but AIoT can up this game as the data analysis would be done at the edge itself, the point where the data is collected. Reaping the Benefits of AIoT To be able to make use of AIoT at the edge, the development of its offline model needs to be done, along with training it using the existing stored datasets. This training would help ensure that the model meets the requirements and expectations. Once the offline model passes the conditions, the sector leaders can implement it by exporting it online and using live data fed on a real-time basis. But easier said than done, testing the model based on stored data could produce different results from testing it on live data. This is because live data may not be categorized or filtered and may lead to a chaos of knowledge as each data set may arrive at different time intervals. For this purpose, data filtration needs to be done before AIoT ultimately uses it. At this point, edge analytics is presented by Brabo Edge Platform, manufacturing connectivity and intelligence platform developed by Solulever, a Dutch technology startup. The Industry 4.0 platform helps collect the data in real-time from the connected IoT devices or edge devices and prepares them before being fed to AIoT. The data is made scalable after being received in different formats from multiple sources and then analyzed. By harmonizing the data, the devices become more intelligent to make their own decisions and even act upon them on their own, which results in maximum output and reduced wastage. Even though individually, all of these technologies render great power to the manufacturing industry, when combined, they become indomitable. Suppose enterprises start integrating AIoT and Edge technologies from companies like Solulever. In that case, they can uncover these technologies' full potential and benefits to make the processes optimized, fast and efficient

0 notes

Text

IOT in security & surveillance

Abstract: Security and surveillance has become a common facet of business. There are dangers in the world: some are personal dangers, others are dangers or risks associated with assets. While there has been much recent debate about the appropriate use and amount of surveillance, it is fair to say that some amount of security and surveillance is necessary in today’s world.

INTRODUCTION

Security and surveillance solutions include everything from the most simple home monitoring systems and burglar alarms, to high-definition, motion-detecting cameras and retina scanning security solutions. Various forms of connectivity – both fixed-line and wireless – enable a basic type of M2M security solutions. However, when data from the solutions are aggregated and analyzed to predict behavior or thwart crimes, and we are able to access these data on common platforms and devices – including mobile devices – we have entered the world of the Internet of Things (IoT).

In 2012 there were 28 million security and surveillance IoT device connections worldwide growing to 170 million in 2021 at a compound-annual-growth-rate of 22%. See Figure 1. These include device connections in homes and businesses. Today, quite a large percentage of security and surveillance systems – especially those in homes – are unconnected. We anticipate an increase over the next ten years of the percentage of these kind of home systems that are connected

WORKING

To function as intended, IoT devices need to be managed both internally, (e.g., software maintenance) and externally (i.e., their communication with other devices).

This is accomplished by connecting every IoT device to a management unit, known as a command and control (C&C) center. Centers are responsible for software maintenance, configurations, firmware updates to patch bugs and vulnerabilities, as well as the provisioning and authentication of tasks, such as device enrollment.

Communication between devices is enabled via application program interface (API). Once a device’s manufacturer exposes its API, other devices or applications can use it to gather data and communicate. Some APIs even allow control over devices. For example, a building manager can use an API to remotely lock doors inside a specific office.

C&C centers and APIs effectively manage day-to-day IoT operations. That said, their centralized nature creates a number of exploitable weak spots, including:

Unpatched vulnerabilities – Connectivity issues or the need for end-users to manually download updates directly from a C&C center often result in devices running on outdated software, leaving them open to newly discovered security vulnerabilities.

Weak authentication – Manufacturers often release IoT devices (e.g., home routers) containing easily decipherable passwords, which might be left in place by vendors and end-users. When left open to remote access, these devices become easy prey for attackers running automated scripts for bulk exploitation.

Vulnerable APIs – As a gateway to a C&C center, APIs are commonly targeted by a variety of threats, including Man in the Middle (MITM), code injections (e.g., SQLI), and distributed denial of service (DDoS) assaults. More information about the implications of API-targeting attacks can be found here.

Data Theft

An IoT device contains vast amounts of data, much of which is unique to its individual users, including online browsing/purchase records, credit card details and personal health information.

An improperly secured device leaves this data vulnerable to theft. What’s more, vulnerable devices can be used as gateways to other areas of the network they are deployed on, allowing for more sensitive data to be extracted.

Physical Harm

IoT devices are now commonplace in the medical industry, with examples including pacemakers, heart monitors and defibrillators. While convenient (e.g., a doctor can fine-tune a patient’s pacemaker remotely), these devices are also vulnerable to security threats.

An improperly secured device can be exploited to interfere with a patient’s medical care. It’s an exceedingly rare occurrence, albeit one to be considered when developing a strategy for securing IoT devices.

APPLICATIONS

The Opportunity - Smart Surveillance

Everyone is talking about the Iot, a trendy area of tech that is fairly new and growing exponentially. According to some estimates, the Internet of Things will connect 50 billion devices (not including PCs, smartphones and tablets) by 2020 – 250 of which will get connected every second. Also, the global economic value of IoT will reach $19 trillion by 2020. These figures have gotten everyone interested, including big players like IBM, which has recently invested $3 billion in its IoT division. So what is the significance for the video surveillance and security sector? The Internet of Things is likely to have a tremendous impact, as all types of organizations will look to connect their devices, enhance security and create ‘smart surveillance’ solutions.

Approach Reformulated With IoT

For many years, the focus within the video surveillance industry has been to connect most systems to Internet Protocol (IP) based networks. The next phase, Machine-to-Machine (M2M) as we call it, managed to create a connected device-based industry, and IP video surveillance systems perfectly integrated into that. Typical M2M successful examples would be GPS tracking solutions and remote asset (fixed or mobile) monitoring, to name a few. The result of these migrations was a huge amount of data that businesses had to manage.

With the recent improvements in mobile network (like LTE high speed connections), cloud technology and readily available fiber optics backbone, the Internet of Things (IoT) came into play. IoT brings a holistic approach to the table where connected systems and generated data are analyzed locally, or in the cloud, returning to decision makers the information they need, when they need it and in a fully customisable and easy-to-read interface.

Applications – IoT In Mining Industry

For example, in the mining industry, the technology can optimize operations and reduce risk. It can be used to monitor operations and videos, estimate the traffic going underground in the mines, and help with sub-systems management. Advanced video surveillance solutions, powered by the Internet of Things, can be used to read sensors and integrate with them. Thus, IoT can provide an array of connected sensors to businesses, which will help reduce the points of failure. With the deployment of IoT, 10-25% of operating costs can be reduced, like those associated with people and vehicle counting, and temperature and gas sensing.IoT can also help in the reduction of costs involved in the special care that has to be taken with monitoring and managing operations around inflammable gases. With smart surveillance and sensing systems, cameras can be programmed to trigger notifications. This can help businesses be better prepared and allocate resources strategically. Another direct application would be to help with managing the airflow in mines. There is also a risk of loss of lives, when it comes to mining operations, and this can be prevented with smart sensor systems. Connected sensing systems and smart video surveillance support with a predictive analytics component can help businesses predict hazards and take corrective actions in real time.

Smart Surveillance In Aviation Industry

Another industry that can benefit greatly from IoT is aviation. An airbus A380-1000, expected to be ready in 2020, will have 10,000 sensors per wing. An aircraft of this size is estimated to generate 8 Terabytes of data per day, which can be gathered and analyzed. Also, the aviation sector sees 35 million departures per year and, while there is surveillance data, nobody is analyzing these sensors. So, the opportunity in the aviation industry is huge. Security vulnerabilities are a major cause of concern for this industry, and this is where a smart video surveillance and sensory system can be helpful. By analyzing connected sensors and learning from the vast amounts of data generated, air travel can be made safer.

DISCUSSION

This survey intended to give an overview of the current trends in IoT security research. At the same time, this survey presented some attack vectors and challenges to IoT security. High quality papers from Web of Knowledge were reviewed and categorized into by their objectives, methods used in the research, and the simulation tools used in order to simulate or validate the results. It was found that other than the simulation tools and modeller, the availability of the platform to validate the security protocol will help in producing a novel IoT security protocol. Hence, there is no doubt that the rapid progress of research in IoT security is supported by the availability of simulation tools and IoT modellers. There have been real catastrophic events resulting from attackers using insecure devices as “thingbots” to attack the IoT network. This is strong evidence that the security of the IoT is of pressing concern. It is also assumed that the IoT will remain a target and attack vector for years to come. This is due to the increasing number of IoT devices, the heterogeneity of the protocols used in the IoT, and the minimal or default security measures embedded in the devices by the manufacturers. Clearly, cyber (IT) security, such as authentication, encryption, and firewalls, should be implemented as security measures in the IoT. But this is not sufficient. The interaction and integration between physical and cyber systems make the IoT different from the traditional network.

FUTURE SCOPE

Internet of Things (IoT) is an escalating trend in today's world, and has proved to be a game changer in the field of technology. More and more sensors and devices are being connected together to develop new systems to solve real world problems. With the increase in technology and automation, security has become a major concern. The first line of defense for any property is always a security system, which alerts the owners regarding intrusion in real time. Currently, there exist multiple security systems, which make use of various motion sensors to detect any motion and notify the owner about the intrusion. However, most of these systems do not provide the features of zone barriers, facial recognition, remote camera surveillance and power failure detection, combined with ease of use, economic viability and power efficiency. The main objective of the proposed architecture is to overcome all these problems by developing a smart security and surveillance system which makes use of multiple ultrasonic sensors to detect intrusion attempts on the property of the owner, in order to notify them of the presence of an unauthorized person. Also, the system provides a warning to the person who has intentionally or unintentionally entered the property, so that they can step back in time, without triggering any alarm. With the help of a remote camera surveillance feature, the owner can monitor the surroundings of their property remotely. This system will issue an alert to the owner in case of a power failure as well. This system provides face recognition as an authentication procedure, in order to allow the valid entrants to enter into their property. All these features combined, create a flexible and reliable security system, which can be used in various properties, such as homes, offices, museums and so on.

CONCLUSION

By harnessing the power of IoT for your security and surveillance solutions, you enable building owners, organization managers, and security professionals to:

Manage and control surveillance devices remotely to monitor all aspects of a facility.

Make smarter decisions about the best course of action to take based on real-time security conditions.

Determine when there is a false alarm without having to physically inspect the location or unnecessarily dispatch law enforcement.

Collect and analyze data to make important improvements to security processes and systems.

Perhaps the greatest benefit of using IoT solutions for your security system is the ability to prevent the loss of critical assets. IoT security solutions allow organizations to

Gain greater visibility over who enters and leaves a facility in real-time.

Consistently and securely monitor facility conditions from any location with Wi-Fi access.

Act quickly on important security alerts delivered right to their mobile device.

IoT makes it possible to gain greater visibility over your assets to improve security and prevent critical loss through real-time surveillance. Telit enables integrated wireless IoT security and surveillance solutions for security service providers, building owners, public organizations, and cities that want to build effective and secure security systems.

Author:

Jai Vardhan Singh Rathore, Anjali kale, Prathmesh Jadhav, Vaishnavi Jadhav

5 notes

·

View notes

Text

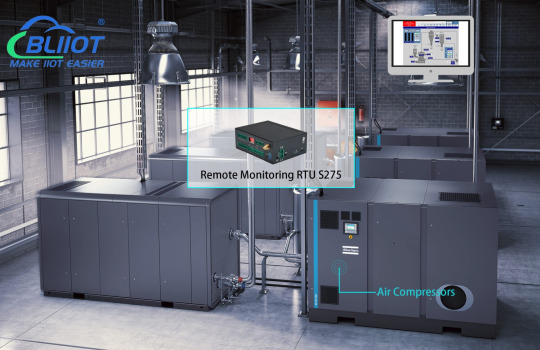

BLIIoT Air Compressor Remote Monitoring Solution

Background

As a large mechanical equipment, air compressors will generate a lot of after-sales maintenance and troubleshooting needs during long-term use. High power consumption and maintenance costs amplify the impact of failures, which can result in significant losses through delayed repairs and extended downtime.

By making air compressors IoT-enabled, maintenance personnel can remotely monitor compressor operation, detect abnormalities in a timely manner and proactively solve problems. This strategy minimizes downtime-related losses, enriches customer service, and enhances the overall value proposition.

Air compressor monitoring requirements

Real-Time Monitoring and Remote Control