#Lubricant Packaging Market Size

Explore tagged Tumblr posts

Text

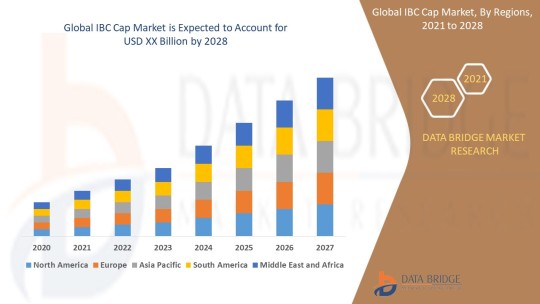

IBC Cap Market Size, Share, Trends, Growth and Competitive Analysis

"IBC Cap Market – Industry Trends and Forecast to 2028

Global IBC Cap Market, By Product Type (Flange, Plugs, Vent-in Plug, Vent-out Plug and Screw closure), Type (Plastic IBC, Metal IBC and Composite IBCs), Material Type (Plastics, Metal, Aluminium and Steel), End Use (Chemicals & Fertilizers, Petroleum & Lubricants, Paints, Inks & Dyes, Food & Beverage, Agriculture, Building & Construction, Healthcare & Pharmaceuticals and Mining), Application (Food And Drinks, Chemical Industry, Oil and Agriculture), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350 Pages PDF Report @

The global IBC cap market is expected to witness significant growth over the forecast period due to the increasing demand for intermediate bulk containers (IBCs) in various industries such as chemicals, food and beverages, pharmaceuticals, and others. The IBC caps play a crucial role in ensuring the safe storage and transportation of liquid products. The market growth is also being driven by technological advancements in IBC cap designs, such as tamper-evident seals and spouts for easy dispensing. Additionally, the growing focus on sustainability and recyclability of packaging materials is further boosting the adoption of IBC caps made from eco-friendly materials.

**Segments**

- Based on material type, the IBC cap market can be segmented into plastic, metal, and others. Plastic caps are widely used due to their lightweight nature and cost-effectiveness. - By cap type, the market can be categorized into screw caps, snap-on caps, and flip-top caps. Screw caps are preferred for their secure sealing properties. - On the basis of end-user industry, the market can be divided into chemicals, food and beverages, pharmaceuticals, and others. The chemicals segment is anticipated to hold a significant market share due to the widespread use of IBCs for storing chemical products.

**Market Players**

- TPS Industrial Srl - Schuetz GmbH & Co. KGaA - Mauser Packaging Solutions - Time Technoplast Ltd - Berry Global Inc. - THIELMANN UCON AG - Precision IBC, Inc. - Peninsula Packaging LLC

These market players are actively involved in strategic initiatives such as product launches, partnerships, and acquisitions to strengthen their market presence and expand their product offerings. The competitive landscape of the IBC cap market is characterized by intense competition, prompting companies to focus on innovation and quality to gain a competitive edge.

The Asia-Pacific region is expected to witness substantial growth in the IBC cap market, driven by the rapid industrialization and the increasing adoption of IBCsThe Asia-Pacific region represents a significant growth opportunity for the global IBC cap market due to several key factors. With rapid industrialization and the expanding manufacturing sector in countries like China, India, and Southeast Asia, there is a growing demand for efficient storage and transportation solutions, including IBCs and their associated caps. The increased focus on chemical production, food processing, and pharmaceutical manufacturing in the region further fuels the need for reliable packaging solutions like IBC caps. As these industries continue to grow, the adoption of IBC caps is expected to rise, driving market expansion in the Asia-Pacific region.

Moreover, the emphasis on enhancing safety standards and ensuring product integrity is a crucial factor contributing to the growth of the IBC cap market in Asia-Pacific. Regulations regarding the safe handling and transportation of hazardous chemicals and pharmaceuticals necessitate the use of high-quality caps that can effectively seal and protect the contents of IBCs. As companies in the region strive to comply with stringent regulatory requirements, the demand for advanced and secure IBC caps is projected to increase significantly.

Additionally, the shift towards sustainability and eco-friendly practices is another trend shaping the IBC cap market in Asia-Pacific. With growing environmental concerns and increasing awareness about plastic pollution, there is a rising preference for IBC caps made from recyclable and biodegradable materials. Market players in the region are focusing on developing sustainable packaging solutions to meet the evolving consumer demands and align with global sustainability goals. This shift towards eco-friendly IBC caps not only addresses environmental concerns but also presents market players with opportunities to differentiate their offerings and attract environmentally conscious customers.

Furthermore, the competitive landscape of the IBC cap market in Asia-Pacific is characterized by the presence of both local manufacturers and international players. Local companies often have a strong understanding of regional market dynamics and customer preferences, giving them a competitive advantage in catering to specific industry needs. On the other hand, multinational companies bring technological expertise and a wide product portfolio, which can appeal to a broader customer base seeking innovative and**Global IBC Cap Market, By Product Type**

- Flange - Plugs - Vent-in Plug - Vent-out Plug - Screw closure

**Type**

- Plastic IBC - Metal IBC - Composite IBCs

**Material Type**

- Plastics - Metal - Aluminium - Steel

**End Use**

- Chemicals & Fertilizers - Petroleum & Lubricants - Paints, Inks & Dyes - Food & Beverage - Agriculture - Building & Construction - Healthcare & Pharmaceuticals - Mining

**Application**

- Food And Drinks - Chemical Industry - Oil and Agriculture

The Global IBC Cap market is experiencing significant growth due to the rising demand for intermediate bulk containers across various industries. Plastic caps are increasingly preferred for their lightweight and cost-effective nature, driving market growth within the material type segment. Screw caps, known for their secure sealing properties, dominate the cap type category. The chemicals segment is anticipated to hold a substantial market share among end-user industries, attributed to the widespread use of IBCs for chemical storage. The market players in the industry are focusing on strategic initiatives like product launches and partnerships to enhance their market presence and offerings. The competitive landscape is intense, spurring companies to innovate and prioritize quality for a competitive advantage.

In Asia-Pacific, the IBC cap market is poised for robust growth fueled by rapid industrialization and the expanding manufacturing sector, particularly in countries like China,

Countries Studied:

North America (Argentina, Brazil, Canada, Chile, Colombia, Mexico, Peru, United States, Rest of Americas)

Europe (Austria, Belgium, Denmark, Finland, France, Germany, Italy, Netherlands, Norway, Poland, Russia, Spain, Sweden, Switzerland, United Kingdom, Rest of Europe)

Middle-East and Africa (Egypt, Israel, Qatar, Saudi Arabia, South Africa, United Arab Emirates, Rest of MEA)

Asia-Pacific (Australia, Bangladesh, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Sri Lanka, Thailand, Taiwan, Rest of Asia-Pacific)

Key Coverage in the IBC Cap Market Report:

Detailed analysis of IBC Cap Market by a thorough assessment of the technology, product type, application, and other key segments of the report

Qualitative and quantitative analysis of the market along with CAGR calculation for the forecast period

Investigative study of the market dynamics including drivers, opportunities, restraints, and limitations that can influence the market growth

Comprehensive analysis of the regions of the IBC Cap industry and their futuristic growth outlook

Competitive landscape benchmarking with key coverage of company profiles, product portfolio, and business expansion strategies

TABLE OF CONTENTS

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Research Methodology

Part 04: Market Landscape

Part 05: Pipeline Analysis

Part 06: Market Sizing

Part 07: Five Forces Analysis

Part 08: Market Segmentation

Part 09: Customer Landscape

Part 10: Regional Landscape

Part 11: Decision Framework

Part 12: Drivers and Challenges

Part 13: Market Trends

Part 14: Vendor Landscape

Part 15: Vendor Analysis

Part 16: Appendix

Browse Trending Reports:

Calcium Glycinate Market Retinal Biologics Market Facial Fat Transfer Market Angio Suites Diagnostic Imaging Market Adoption Of Benelux Power Tools Market De Quervains Tenosynovitis Treatment Market Biodetectors And Accessories Market Colposcope Market Sports Medicine Market Automotive Adhesives Market Infrared Imaging Market Vapour Deposition Market Professional Diagnostics Market Ct Scanner Market Programmable Application Specific Integrated Circuit Asic Market Hospital Operating Room Or Products And Solutions Market Castor Oil Market Zika Virus Infection Drug Market Toluene Diisocynate Market Antibiotic Resistance Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

2 notes

·

View notes

Text

Why Partnering with a Reliable Chemical Manufacturing Company in Chennai Makes Business Sense

Chennai is one of the prominent industrial centers in India, and the capital city of Tamil Nadu is an abuzz city. The city offers a gamut of services to businesses from different sectors. One of the most critical industries thriving in the city is chemical manufacturing. As the need for specialized chemicals continues to increase across sectors like pharmaceuticals, textiles, automobiles, and agriculture, the necessity of collaborating with a chemical manufacturing company in Chennai has never been more evident.

Whether you want bulk chemicals, specialty formulations, or raw materials to be used for the development of products, a supplier can literally be the make or break point of efficiency, quality, and scale for your business. In this blog, we talk about why Chennai is home to some of the best chemical manufacturing companies and what to look for in the right partner for your business.

Importance of Chemical Manufacture to Various Industries

Chemicals form the base of many industries; from industrial purposes to consumer commodities. Pharmaceuticals are impossible without chemicals since these are life-saving drugs. For textiles, it is not possible to manufacture dyes, anti-wrinkle finishes, or water-repellent materials without chemicals. Similarly, chemicals also play an integral role in automotive industries. This is because manufacturing coatings, adhesives, lubricants, and plastics in automotive industries relies entirely on chemicals that ensure the performance, safety, and aesthetics of a vehicle.

The requirement for a good chemical manufacturing company in Chennai is increasing because the industries are becoming more demanding, and more advanced solutions are needed.

Customization, meeting quality standards, and providing on-time delivery will help businesses maintain production schedules without compromising on quality.

Why Chennai is a Hub for Chemical Manufacturing

Being located on the southeaster coast of India, Chennai is an ideal place for domestic as well as international trade. The good transportation network in the city, including the Chennai Port, makes it easy to import raw materials and finished chemicals for exportation. This implies that it is easy for companies to source raw chemicals and distribute their products all over the world.

Several companies in Chennai, including established and new chemical manufacturers, cater to numerous industries. With easy access to skilled labour and robust industrial infrastructure, these cities also offer close proximity to key petrochemical plants, contributing to efficient production of high quality.

Key Selection Factors for Choosing a Chemical Manufacturing Company in Chennai

With so many options, it is sometimes challenging to determine which one is best suited for your business needs. Some of the key factors are described below:

1. Quality Assurance

The quality of chemicals produced by a manufacturing company is paramount. A good company follows the strict standards and certifications within the industry and ensures that all chemicals meet the needed regulatory and safety norms. This ranges from ISO certification, GMP (Good Manufacturing Practice), to environmental standards. Quality assurance is never a compromise.

2. Customization Capabilities

Each business is unique and one-size-fits-all rarely works for the chemical industry. The top-end chemical manufacturer in Chennai is unique because it is capable of manufacturing products according to specific needs; this could be on a unique formulation or packaging.

3. Scalability

As your business grows, your chemical supply needs may change. Choose a manufacturer that can adjust production volumes according to your growth needs, which will ensure continuity and reliability when your business grows. Scalability also means that it can change with new technologies and market trends.

4. Logistics and Delivery

Timely delivery is important in any industry where downtime leads to massive loss of money. An effective chemical manufacturing company in Chennai would be one that provides good logistics and inventory management, ensuring that chemicals get delivered on time and in the right quantities.

5. Sustainability Practices

In today's eco-friendly world, it is of paramount importance to work with a manufacturer who engages in sustainable practices. Seek manufacturers that are engaged in eco-friendly chemical production processes, waste reduction, and follow environmental regulations.

Conclusion

The chemical manufacturing industry in Chennai is booming, and great opportunities are there for businesses from various industries. Partnering with a company that focuses on quality, customization, scalability, and sustainability is sure to meet the chemicals you need for your products while ensuring efficiency in operations.

For large companies or start-ups, the selection of the best manufacturing partner is key in maintaining the competitive advantages in their respective markets. The right chemical supplier contributes to improving the quality of products, reducing associated operational risks, and building a sustainable future for business.

0 notes

Text

Aluminium Caps & Closures Market: Demand for Premium Packaging Solutions

The Aluminium Caps & Closures Market is witnessing robust growth due to its sustainability, versatility, and widespread adoption across various industries. Aluminium closures are recyclable, lightweight, and offer excellent barrier properties, making them ideal for maintaining product integrity in diverse applications.

Read Complete Report Details of Aluminium Caps & Closures Market: https://www.snsinsider.com/reports/aluminium-caps-and-closures-market-2919

Market Segmentation

By Product Type

Easy Open Can Ends

Widely used in the beverage and canned food industries for convenience and consumer ease.

Features: Ease of use, tamper resistance, and durability.

Roll-on Pilfer Proof (ROPP) Caps

Commonly used for sealing bottles in the food, beverage, and pharmaceutical sectors.

Features: Tamper-evidence, resealability, and enhanced product security.

Non-Refillable Caps

Utilized primarily in the spirits and liquor industry to prevent counterfeiting.

Features: Anti-tampering mechanism and regulatory compliance.

Others

Icludes specialized caps and closures designed for niche applications or specific customer requirements.

By Size

Size Range: 17mm to 53mm

Includes standard closures for bottles and containers across industries.

Features: Compatibility with various bottle neck sizes and efficient sealing.

Height Range: 6mm to 12mm

Offers options based on container design and aesthetics.

Features: Customization for brand-specific designs and functional requirements.

By End Use

Food & Beverages

Largest segment driven by the need for safe, tamper-evident, and resealable closures.

Applications: Bottled water, soft drinks, alcoholic beverages, sauces, and canned goods.

Oil & Gas

Used in packaging lubricants and oils, providing spill-proof and secure sealing solutions.

Features: Durable and leak-resistant properties.

Personal Care

Used for packaging shampoos, lotions, and skincare products.

Features: Premium aesthetics and functionality.

Automotive

Utilized in packaging automotive fluids such as coolants, oils, and brake fluids.

Features: Resistance to corrosion and secure sealing.

Others

Includes applications in pharmaceuticals, chemicals, and other specialized industries.

By Region

North America

Growth driven by advancements in packaging technologies and high demand in beverages and personal care products.

Focus on sustainability initiatives boosting aluminium packaging adoption.

Europe

Strong emphasis on recyclable materials and eco-friendly packaging solutions.

Major markets include Germany, France, and the UK.

Asia-Pacific

Largest and fastest-growing market due to rising consumption in the food, beverage, and personal care sectors.

Significant contributions from emerging economies like China, India, and Southeast Asia.

Latin America

Growth influenced by expanding beverage and pharmaceutical industries.

Increasing focus on sustainable packaging solutions.

Middle East & Africa

Rising adoption in the food and beverage industry, coupled with growing demand for premium packaging in personal care.

Market Trends and Opportunities

Sustainability Focus: Aluminium caps and closures are 100% recyclable, aligning with global sustainability goals and increasing consumer preference for eco-friendly packaging.

Product Innovations: Development of lightweight, high-performance closures with improved tamper resistance and resealing capabilities.

Growing Beverage Industry: Expansion of the alcoholic and non-alcoholic beverage sectors is driving demand for high-quality aluminium closures.

Counterfeit Prevention: Increasing adoption of non-refillable caps to enhance product security and maintain brand integrity.

Premiumization: Growing trend for premium packaging, especially in personal care and alcoholic beverages, creating opportunities for customized designs.

Market Outlook

The Aluminium Caps & Closures Market is poised for substantial growth from 2024 to 2032, driven by increasing demand for sustainable and secure packaging solutions across various industries. Advancements in design and manufacturing technologies, coupled with the global push towards recyclability and reduced carbon footprint, will further enhance the market’s growth trajectory.

About Us:

SNS Insider is a global leader in market research and consulting, shaping the future of the industry. Our mission is to empower clients with the insights they need to thrive in dynamic environments. Utilizing advanced methodologies such as surveys, video interviews, and focus groups, we provide up-to-date, accurate market intelligence and consumer insights, ensuring you make confident, informed decisions. Contact Us: Akash Anand — Head of Business Development & Strategy [email protected] Phone: +1–415–230–0044 (US) | +91–7798602273 (IND)

0 notes

Text

The Solvent Red Market is projected to grow from USD 2,191 million in 2024 to USD 2,975 million by 2032, reflecting a compound annual growth rate (CAGR) of 3.9% over the forecast period. The Solvent Red market has emerged as a pivotal segment within the global chemical and dye industry. This vibrant class of dyes finds extensive applications in a variety of industries, including printing, textiles, plastics, and fuels. Solvent Red dyes are known for their excellent solubility in organic solvents and oils, which make them ideal for non-polar environments. As the global demand for high-quality dyes continues to grow, the Solvent Red market is experiencing significant expansion. This article explores the current dynamics, trends, and future prospects of this market.

Browse the full report https://www.credenceresearch.com/report/solvent-red-market

Market Overview

Solvent Red dyes are a class of synthetic organic compounds that are primarily used to impart color to products such as fuels, lubricants, and inks. These dyes are especially popular in industries where coloration is crucial for branding, identification, or compliance with regulatory requirements. For instance, the use of Solvent Red in fuels is mandated in several countries for taxation and identification purposes.

The market is highly fragmented, with numerous manufacturers and suppliers operating globally. Key regions contributing to the market’s growth include North America, Europe, and the Asia-Pacific. The latter is emerging as a dominant player due to the rapid industrialization in countries like China and India, where the demand for dyes in sectors such as textiles and printing is surging.

Drivers of Market Growth

Rising Demand in End-Use Industries: The expansion of industries such as automotive, packaging, and printing is driving the demand for Solvent Red dyes. In the automotive sector, for example, these dyes are used in lubricants and fuel markers to ensure quality and authenticity.

Technological Advancements: Continuous research and development in dye synthesis have led to the creation of Solvent Red dyes with enhanced stability, higher colorfastness, and environmental compatibility. These advancements are broadening their application scope.

Regulatory Mandates: Governments worldwide have established stringent regulations to ensure the proper identification of fuels and lubricants. Solvent Red dyes play a critical role in meeting these requirements, thereby boosting market demand.

Growing Consumer Awareness: With the increasing emphasis on aesthetics and product differentiation, consumer-driven industries like cosmetics and packaging are increasingly incorporating Solvent Red dyes.

Challenges in the Market

Despite its growth, the Solvent Red market faces several challenges. The production of synthetic dyes involves complex chemical processes that can pose environmental concerns. Stringent regulations around manufacturing emissions and waste disposal are pressuring manufacturers to adopt sustainable practices. Moreover, fluctuating raw material prices and supply chain disruptions can impact the market’s stability.

Emerging Trends

Shift Towards Sustainable Dyes: The industry is witnessing a gradual shift towards eco-friendly and biodegradable dyes. Manufacturers are investing in green chemistry to produce Solvent Red variants that align with global sustainability goals.

Increased Investment in R&D: Companies are focusing on developing innovative dye formulations that cater to the evolving needs of industries such as 3D printing, electronics, and high-performance coatings.

Market Consolidation: Strategic mergers and acquisitions are becoming common as companies aim to strengthen their market position and expand their geographical footprint.

Future Prospects

The future of the Solvent Red market looks promising, with growth projected across multiple industries. According to market analysts, the sector is expected to grow at a compound annual growth rate (CAGR) of approximately 5-7% over the next five years. The increasing demand for advanced dyeing solutions in emerging economies, coupled with the adoption of eco-friendly manufacturing practices, will likely propel market growth.

Additionally, the rise of novel applications, such as in laser printing and electronic displays, is expected to open new avenues for market expansion. Innovations in dye technology and the integration of artificial intelligence in manufacturing processes will further enhance efficiency and product quality.

Key Player Analysis:

Clariant International Ltd.

BASF SE

Huntsman Corporation

Lanxess AG

Dow Chemical Company

Arkema Group

DIC Corporation

Sudarshan Chemical Industries Limited

Asahi Kasei Corporation

Meghmani Organics Limited

Segmentations:

By Demographic:

Consumers

Industrial

Commercial

By Psychographic:

Traditionalists

Modernists

Individualists

By Behavioral:

Heavy users

Medium users

Light users

By Region:

North America

U.S.

Canada

Mexico

Europe

Germany

France

U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

Browse the full report https://www.credenceresearch.com/report/solvent-red-market

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

PVC Additives Market-Industry Forecast, 2024–2030

PVC Additives Market overview

Request Sample Report :

Report Coverage

The report: “PVC Additives Market- Forecast (2024–2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the PVC Additives Industry.

By Type: Stabilizers, Impact Modifiers, Processing Aids, Lubricants, Plasticizers, Fillers, Others.

By Form: Granules, Powder, and Liquid.

By Fabrication Process: Extrusion, Injection Molding, Blow Molding and Others.

By Application: Pipes, Packaging, Furniture’s, Door and Windows, Cables, Medical Devices, Flooring, and Others.

By End Use: Building and Construction, Automotive industry, Textile Industry, Electrical and Electronics, Medical Industry, Food and Beverages, and Others.

By Geography: North America, South America, Europe, APAC, and RoW.

Key Takeaways

Asia Pacific dominates the PVC Additives market owing to rapid increase in building and construction sector.

Certain applications require higher impact strength than PVC would demonstrate normally.

The market drivers and restraints have been assessed to understand their impact over the forecast period.

The report further identifies the key opportunities for growth while also detailing the key challenges and possible threats.

The other key areas of focus include the various applications and end use industry in PVC Additives market and their specific segmented revenue.

Inquiry Before Buying:

PVC Additives Market Segment Analysis — By Type

Stabilizers held the largest share in the PVC Additives market in 2019. This growth is mainly attributed to the increasing demand for stabilizers in varied applications such as pipes & fittings, rigid & semi-rigid films, and others. Due to their superior properties, such as UV resistance, weathering and heat-aging, stabilizers are increasingly favored over other types of additives. To avoid premature degradation, many polymers are vulnerable to environmental degradation and require the addition of a stabilizer such as an antioxidant or UV absorbent. Hampered phenols and obstructed amine light stabilizers (HALS) deactivate emerging radicals, like air-oxidated peroxy compounds. UV absorbers dissipate UV radiation through the material by a method that is non-destructive. Monomers are added to free radical inhibitors as stabilizers to prevent premature polymerization.

PVC Additives Market Segment Analysis — By Forms

Granules held the largest share in the PVC Additives market in 2019. Granules help to increase the density of the freshly synthesized polymer since it lacks the flowing properties required to be processed by an extruder. Due to their plasticity property, they can be molded or shaped by application of heat. Other characteristics of plastic are its low electrical conductivity, low density, transparency and toughness which allowed it to be used for the creation of different products. In addition, plastic’s versatility has led to its use in a wide array of industries. In order to produce normal and high-strength concretes, 10%, 20%, and 30% replacement ratios by volume of PVC granules and powder are used.

PVC Additives Market Segment Analysis — By Fabrication Process

Extrusion held the largest share in the PVC Additives market in 2019. Extrusion is used mainly for handling large plastic volumes. The pellets, granules, chips, or powders are fed into the extruder and melted under high temperatures. PVC compounding is a process where additives are mixed with the base resin in order to obtain a homogenous mix. The additives are used either to enhance process capabilities or to improve product efficiency. The use of sizing parts will generate any length of profiles to the desired length. Co-extrusion allows the manufacture of semi-finished multi-layer products with special barrier properties.

PVC Additives Market Segment Analysis — By Application

Pipes is projected to witness highest share in PVC Additives market in 2019. This rise is mainly due to the growing demand for pipes & fittings in piping and plumbing, gas pipeline laying, and telecommunication and electrical cable sheathing. Due to the replacement of traditional concrete, iron, and steel-based pipes & fittings with PVC pipes in the building & construction industry, the market for PVC additives in the pipes & fittings segment is expected to witness significant development. The market for building materials is on high demand, with the continually growing population. The prerequisite for housing is pipes and fittings, which are a critical necessity. Urbanization with a large network of connections has contributed to an increase in drainage requirements. There is a growing demand for pipes and fittings to cope with advanced piping links, which in turn drives market growth. Globally, there has been a rising demand for rainwater harvesting system that has helped to heat up the pipe and fit market. In 2019, recently the commercial sector has slowed as the risk for a downturn in global construction increases due to COVID-19 pandemic which led to temporary lockdown of all economic activities across globe.

PVC Additives Market Segment Analysis — By End Use

Building and construction dominates the PVC Additives market growing at a CAGR of 6.00%. With the growing construction industry and its demand for PVC Additives particularly in the regions of Asia-Pacific, North America and Europe, the demand of PVC Additives for all kinds of buildings is expected to see an upsurge. Residential application segment is witnessing growth due to the rising penetration from untapped markets. First-mover advantage in untapped regions and relatively low acquisition costs remain key driving forces in this application market. Furthermore, R&D in PVC Additives will support the growth of the PVC Additives market.

Schedule A Call :

PVC Additives Market Segment Analysis — Geography

Asia-Pacific (APAC) dominated the PVC Additives market growing at CAGR of 41% followed by North America and Europe. APAC as a whole is set to continue to be one of the largest and fastest growing construction markets globally. Large and more developed markets such China, India, Japan, and South Korea are expected to grow more in the coming years. China is driving much of the PVC Additives market demand in Asia-Pacific region followed by India and Japan. Of the five fastest growing regions in construction sector, other than U.S. all are Asian countries including China and India who majorly drive the demand for construction investment in this regions. The strong and healthy growth in construction sector is associated with growing population and middle class economy, which tend to drive APAC residential construction market further and hence the PVC Additives market. The number of buildings that have illuminated PVC Additives is growing sharply in APAC region. The increasing number of new building constructions, along with the rise in the number of renovation projects has further propelled the market. Currently the construction industry has been affected due to COVID-19 pandemic where most of the industrial activity has been temporarily shut down. In in turn has affected the demand and supply chain as well which has been restricting the growth in year 2020.

PVC Additives Market Drivers

Replacement of conventional material with PVC will drive the market

PVC is replacing traditional building materials such as wood, metal, concrete and clay in many applications. Versatility, cost-effectiveness and excellent use record make it the most important polymer in the construction sector, accounting for 60%. These products are often lighter, less expensive and offer many performance advantages. Making it prominent material than conventional.

Rapid industrialization and infrastructure activity will augment the growth of PVC Additives

Improvement in economic climate along with boom in industrialization and infrastructure activity across the globe is leading the growth of PVC Additives. Oxford Economics has estimated global infrastructure investment needs to be $94 trillion between 2016 and 2040. This is 19 percent higher than would be delivered under current trends. With the increasing rate of industrialization and infrastructure activity, as a result of which PVC Additives growth is augmenting.

PVC Additives Market Challenges

Low R&D expenditure in the emerging markets and high maintenance cost will hamper the market to growth

Innovation is the key to developing new products, but most manufacturers are not investing much into R&D. Rather than cutting-edge technology, they invest in creating relevant technology. These factors are hampering the growth of the market. Because most of the pipes and fittings are located underground in the event of any malfunction or failure, the cost of repairs can be even greater.

Buy Now :

Market Landscape

Technology launches, acquisitions and R&D activities are key strategies adopted by players in the PVC Additives market. In 2019 the PVC Additives market has been consolidated by the top five players accounting for xx% of the share. Major players in the PVC Additives market are BASF SE, Arkema SA, Akzo Nobel N.V, Adeka Corporation, Clariant AG and Others.

Acquisitions/Technology Launches/ Product Launches

In April 2017, Lanxess Corporation has completed acquisition of Chemtura. With this acquisition, Lanxess significantly expands its market position for PVC additives. A notable sampling includes: the sale of its proprietary OBS (organic-based heat stabilizers) for rigid PVC applications to Baerlocher; the sale of the rest of its PVC additives business to Galata Chemicals.

Key Market Players

The Top 5 companies in the PVC Additives Market are:

BASF SE

Arkema SA

Akzo Nobel N.V

Adeka Corporation

Clariant AG

For more Chemicals and Materials Market reports — Please click here

0 notes

Text

Precision Biscuit Machines for Confectionery Manufacturing

Biscuit making machine is an art and science, requiring the perfect blend of precision, efficiency, and innovation. In today’s fast-paced confectionery industry, manufacturers depend heavily on advanced machinery to maintain consistent quality and meet increasing consumer demands. Precision biscuit machines have become the backbone of modern biscuit production, offering a seamless blend of technology and craftsmanship.

Why Are Precision Biscuit Machines Important?

Precision biscuit making machine are designed to handle various stages of biscuit production, such as dough mixing, forming, baking, and packaging. These machines ensure:

Consistency: Uniform size, shape, and texture for every biscuit.

Efficiency: High-speed production while maintaining quality.

Customization: Flexibility to produce a wide variety of biscuits, from cream-filled to digestive.

Cost-effectiveness: Reduced labor costs and minimized wastage.

Key Features of Precision Biscuit Machines

Automated Dough Processing: Ensures consistent mixing and hydration for uniform dough quality.

Customizable Molds and Dies: Create unique shapes and designs to match brand identity.

High-Speed Ovens: Provide even baking with precise temperature control.

Integrated Quality Checks: Detect imperfections, ensuring only the best products reach consumers.

Energy Efficiency: Modern machines are designed to consume less power, lowering production costs.

Benefits of Using Precision Biscuit Machines

Improved Productivity: Faster production cycles meet high market demand.

Enhanced Product Quality: Uniformity in size, taste, and appearance boosts consumer satisfaction.

Hygienic Production: Complies with food safety standards, maintaining hygiene.

Reduced Operational Costs: Automated systems minimize human errors and material wastage.

Frequently Asked Questions (FAQ)

What types of biscuits can be made with precision machines?

Precision biscuit machines are versatile and can produce a wide range of biscuits, including:

Hard biscuits

Soft biscuits

Sandwich biscuits

Cream-filled biscuits

Decorative biscuits with embossed designs

How do precision biscuit machines enhance efficiency?

These machines automate repetitive tasks such as dough sheeting, cutting, and baking. With built-in sensors and quality checks, they ensure fewer errors and reduce downtime, leading to faster and more efficient production.

Are these machines suitable for small-scale manufacturers?

Yes, precision biscuit machines come in various sizes and capacities, making them ideal for both small and large-scale manufacturers. Smaller models are affordable and perfect for startups, while larger ones cater to mass production.

What maintenance do precision biscuit machines require?

Regular maintenance includes:

Cleaning to prevent dough buildup.

Lubricating moving parts to ensure smooth operation.

Inspecting electrical components for wear and tear.

Following the manufacturer’s maintenance schedule for optimal performance.

Can these machines adapt to new recipes?

Absolutely! Modern precision biscuit machines are highly adaptable. With adjustable settings and customizable molds, they can handle new recipes and unique ingredient combinations effortlessly.

Are precision biscuit machines environmentally friendly?

Many modern machines are designed with energy efficiency in mind. They use advanced technologies to minimize energy consumption and reduce waste, making them eco-friendly.

How can I choose the right machine for my business?

Consider the following factors:

Production capacity needed

Types of biscuits to be produced

Available space in your facility

Budget and expected ROI

After-sales service and support offered by the manufacturer

Conclusion

Precision biscuit making machine are a game-changer in the confectionery industry. Their ability to deliver consistent quality, high efficiency, and customization makes them indispensable for biscuit manufacturers. Whether you are starting small or running a large-scale operation, investing in the right precision machinery ensures your products stand out in a competitive market.

0 notes

Text

0 notes

Text

Cosmetic Chemicals Market: What is It for?

The term cosmetic encompasses various beauty and self-care items that many people use every day. This includes makeup and perfume. All generally produced from a mix of the cosmetic chemicals market sourced from natural and synthetic origins.

The cosmetic chemicals market serves various purposes. That includes preserving the item and enhancing fragrance. It can also create a smooth along with silky texture.

What is It for?

The cosmetic chemicals market size is expanding as it delivers numerous benefits for personal care goods and the users.

Ensure safety and cleanliness

Preservatives serve to avoid contamination and inhibit harmful bacteria growth. Parabens are generally utilized in cosmetics along with personal hygiene items. They work effectively to prevent the yeast and bacteria growth which can cause spoilage thus extending the product’s shelf life.

Formaldehyde is most commonly associated with its properties as a preservative along with antibacterial agent. All living organisms basically generate it through cellular metabolism. This chemical is essential in producing numerous consumer and personal care goods. Plastics are also utilized in cosmetic packaging to safeguard and extend the product shelf life.

Improve scent

Fragrances consist of intricate blends of natural and synthetic ingredients incorporated into various consumer products to impart a unique scent. As one of the oldest cosmetics, it basically combines these scent ingredients with a person’s natural attributes to amplify their body odor. Products such as shampoos and body lotions include fragrances designed to enhance the user experience.

Enhance color

Titanium dioxide is a naturally occurring metal in animals and plants. It has been in use for a century across various consumer and industrial products. That includes soap, cosmetics, or sunscreen.

Soften the skin

Emollients help cosmetics glide on smoothly. It also contributes to a smoother and softer feel on the skin. These are often employed to alleviate dry and itchy skin issues. That includes psoriasis and eczema. These barrier creams work by filling in the spaces within skin cells. They create a film on the outer layer of the skin to lock in moisture and prevent dryness. These substances can be found in creams and sprays.

Mineral oil is popular for being clear and odorless. It is a widely popular ingredient in numerous personal care and cosmetics items. Its lightweight properties especially allow it for applications in baby lotions and ointments. It effectively reduces water loss and ensures skin stays moisturized.

Sun protector

Sunscreens particularly help guard the skin against dangerous UV rays. Benzophenone is a common ingredient in many skincare products including lip balm and soap. It generally helps to protect other ingredients from breaking down due to UV exposure. This further preserves the product’s color and aroma.

Skin cleanser

Another importance of the cosmetic chemicals market is serving as a skin cleanser. Surfactants enable soap to blend with water by reducing the surface tension. We can also find them in lubricants like shaving cream. It is because they facilitate easy razor movement over stubble and concurrently minimize irritation.

Toluene is a transparent and colorless liquid popular for its recognizable sweet odor. Its application is common as a solvent in industrial environment. It serves as an important component in nail enamel removers because of its ability to dissolve various substances. Additionally, toluene is valuable in nail products to ensure smooth application of polishes and lacquers.

1 note

·

View note

Text

Global Industrial Degreaser Market Analysis 2024: Size Forecast and Growth Prospects

The industrial degreaser global market report 2024 from The Business Research Company provides comprehensive market statistics, including global market size, regional shares, competitor market share, detailed segments, trends, and opportunities. This report offers an in-depth analysis of current and future industry scenarios, delivering a complete perspective for thriving in the industrial automation software market.

Industrial Degreaser Market, 2024 report by The Business Research Company offers comprehensive insights into the current state of the market and highlights future growth opportunities.

Market Size - The industrial degreaser market size has grown strongly in recent years. It will grow from $20.17 billion in 2023 to $21.43 billion in 2024 at a compound annual growth rate (CAGR) of 6.2%. The growth in the historic period can be attributed to industry-specific customization, market demand for water-based solutions, focus on regulatory compliance, bio-based and solvent-free solutions, environmental regulations.

The industrial degreaser market size is expected to see strong growth in the next few years. It will grow to $26.12 billion in 2028 at a compound annual growth rate (CAGR) of 5.1%. The growth in the forecast period can be attributed to continued regulatory emphasis, growing sustainability awareness, enhanced packaging sustainability, market expansion of water-based solutions, increasing demand for customized solutions. Major trends in the forecast period include bio-based and solvent-free solutions, advanced technology integration, water-based degreasers, packaging innovations, technological advancements.

Order your report now for swift delivery @ https://www.thebusinessresearchcompany.com/report/industrial-degreaser-global-market-report

Scope Of Industrial Degreaser Market The Business Research Company's reports encompass a wide range of information, including:

1. Market Size (Historic and Forecast): Analysis of the market's historical performance and projections for future growth.

2. Drivers: Examination of the key factors propelling market growth.

3. Trends: Identification of emerging trends and patterns shaping the market landscape.

4. Key Segments: Breakdown of the market into its primary segments and their respective performance.

5. Focus Regions and Geographies: Insight into the most critical regions and geographical areas influencing the market.

6. Macro Economic Factors: Assessment of broader economic elements impacting the market.

Industrial Degreaser Market Overview

Market Drivers - The rising automotive production is expected to propel the growth of the industrial degreaser market going forward. Automotive production refers to manufacturing motor vehicles, including passenger automobiles, light trucks, and commercial vehicles. This involves creating the vehicle's concept, design, and specifications, including its appearance, performance, and safety features. Industrial degreasers in the automotive industry facilitate the cleaning and maintenance of vehicle parts. The automotive sector widely adopts degreasers for cleaning and maintaining various components of vehicles. For instance, in May 2023, according to the European Automobile Manufacturers' Association (ACEA) a lobbying and standards group of the automobile industry, in 2022, 85.4 million motor vehicles were produced worldwide, an increase of 5.7% compared to 2021. Therefore, the rising automotive production is driving the growth of the industrial degreaser market.

Market Trends - Major companies operating in the industrial degreaser market are developing innovative products such as, high-purity hydrocarbons and alcohol degreasers to better serve customer needs. High-purity hydrocarbons and alcohol degreaser refers to using highly purified solvents for vital cleaning applications. These solvents are frequently used in degreasers to remove grease, lubricants, cutting fluids, corrosion inhibitors, and other pollutants commonly found in industrial applications. For instance, in July 2023, Molyslip, a UK-based manufacturer of specialist lubricants, launched SLIPCLEAN RD. This unique cleaner and degreaser is formulated to remove various industrial soils and impurities, including oil, grease, carbon deposits, inks, and semi-cured adhesives. SLIPCLEAN RD is created with high-quality hydrocarbons and alcohol to ensure maximum cleaning power while leaving no residue. The product's rapid evaporation rate ensures quick drying, resulting in immaculate surfaces.

The industrial degreaser market covered in this report is segmented –

1) By Type : Water-Based, Solvent BasedBy Grade 2) By Liquid-Based, Petroleum-Based, Bio-Based, Other Grades 3) By Application: Automative, Manufacturing, Pharmaceutical, Aviation, Other Applications

Get an inside scoop of the industrial degreaser market, Request now for Sample Report @ https://www.thebusinessresearchcompany.com/sample.aspx?id=13680&type=smp

Regional Insights - North America was the largest region in the industrial degreaser market in 2023. The regions covered in the industrial degreaser market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

Key Companies - Major companies operating in the industrial degreaser market report are BASF SE, The Dow Chemical Company, 3M, Henkel AG & Co. KGaA, The Sherwin-Williams Company, Evonik Industries, Emerson Industrial Automation, Ecolab Inc., DuPont de Nemours, Inc., Akzo Nobel N.V., Eastman Chemical Company, Clariant AG, Diversey, Inc., Stepan Company, Quaker Chemical Corporation, Superior Industries Inc., Valvoline Inc., RUST-OLEUM, A.W. Chesterton Company, Castrol, Aervoe Industries, Inc., Sunburst Chemicals, Inc., NCH Corporation, QualiChem, Inc., PETROFER Chemie H. R. Fischer GmbH + Co. KG

Table of Contents 1. Executive Summary 2. Industrial Degreaser Market Report Structure 3. Industrial Degreaser Market Trends And Strategies 4. Industrial Degreaser Market – Macro Economic Scenario 5. Industrial Degreaser Market Size And Growth ….. 27. Industrial Degreaser Market Competitor Landscape And Company Profiles 28. Key Mergers And Acquisitions 29. Future Outlook and Potential Analysis 30. Appendix

Contact Us: The Business Research Company Europe: +44 207 1930 708 Asia: +91 88972 63534 Americas: +1 315 623 0293 Email: [email protected]

Follow Us On: LinkedIn: https://in.linkedin.com/company/the-business-research-company Twitter: https://twitter.com/tbrc_info Facebook: https://www.facebook.com/TheBusinessResearchCompany YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ Blog: https://blog.tbrc.info/ Healthcare Blog: https://healthcareresearchreports.com/ Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Fluid Dispensing Equipment Market Growth Strategic Market Overview and Growth Projections

The global fluid dispensing equipment market size was valued at USD 9.11 billion in 2021 and is projected to reach USD 14.76 billion by 2030 at a CAGR of 5.51% from 2022 to 2030.

The latest Global Fluid Dispensing Equipment Market by straits research provides an in-depth analysis of the Fluid Dispensing Equipment Market, including its future growth potential and key factors influencing its trajectory. This comprehensive report explores crucial elements driving market expansion, current challenges, competitive landscapes, and emerging opportunities. It delves into significant trends, competitive strategies, and the role of key industry players shaping the global Fluid Dispensing Equipment Market. Additionally, it provides insight into the regulatory environment, market dynamics, and regional performance, offering a holistic view of the global market’s landscape through 2032.

Competitive Landscape

Some of the prominent key players operating in the Fluid Dispensing Equipment Market are

Speedline Technologies

Musashi

ITW Dynatec

Valco

Dymax

GPD Global

Fisnar

Henline Adhesive Equipment

IVEK Corp.

Sulzer Mixpac.

Get Free Request Sample Report @ https://straitsresearch.com/report/fluid-dispensing-equipment-market/request-sample

The Fluid Dispensing Equipment Market Research report delivers comprehensive annual revenue forecasts alongside detailed analysis of sales growth within the market. These projections, developed by seasoned analysts, are grounded in a deep exploration of the latest industry trends. The forecasts offer valuable insights for investors, highlighting key growth opportunities and industry potential. Additionally, the report provides a concise dashboard overview of leading organizations, showcasing their effective marketing strategies, market share, and the most recent advancements in both historical and current market landscapes.Global Fluid Dispensing Equipment Market: Segmentation

The Fluid Dispensing Equipment Market segmentation divides the market into multiple sub-segments based on product type, application, and geographical region. This segmentation approach enables more precise regional and country-level forecasts, providing deeper insights into market dynamics and potential growth opportunities within each segment.

On the Basis of Products

Flux

Lubricant

Solder Paste

Adhesives and Sealants

Epoxy Adhesives

Epoxy Underfill

Conformal Coatings

Others

On the Basis of Types

Manual System

Automated Robotics System

On the Basis of Forms

Liquid Fluid

Gaseous Fluid

On the Basis of Application

Bonding

Filling

Lubricating

Sealing

On the Basis of End-Users

Medical Devices

Transportation

Construction

Electrical and Electronics

Semiconductor Packaging

Printed Circuit Boards

Food and Beverages

Others

Stay ahead of the competition with our in-depth analysis of the market trends!

Buy Now @ https://straitsresearch.com/buy-now/fluid-dispensing-equipment-market

Market Highlights:

A company's revenue and the applications market are used by market analysts, data analysts, and others in connected industries to assess product values and regional markets.

But not limited to: reports from corporations, international Organization, and governments; market surveys; relevant industry news.

Examining historical market patterns, making predictions for the year 2022, as well as looking forward to 2032, using CAGRs (compound annual growth rates)

Historical and anticipated data on demand, application, pricing, and market share by country are all included in the study, which focuses on major markets such the United States, Europe, and China.

Apart from that, it sheds light on the primary market forces at work as well as the obstacles, opportunities, and threats that suppliers face. In addition, the worldwide market's leading players are profiled, together with their respective market shares.

Goals of the Study

What is the overall size and scope of the Fluid Dispensing Equipment Market market?

What are the key trends currently influencing the market landscape?

Who are the primary competitors operating within the Fluid Dispensing Equipment Market market?

What are the potential growth opportunities for companies in this market?

What are the major challenges or obstacles the market is currently facing?

What demographic segments are primarily targeted in the Fluid Dispensing Equipment Market market?

What are the prevailing consumer preferences and behaviors within this market?

What are the key market segments, and how do they contribute to the overall market share?

What are the future growth projections for the Fluid Dispensing Equipment Market market over the next several years?

How do regulatory and legal frameworks influence the market?

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

0 notes

Text

Textile Chemicals Market Is Experiencing Healthy Growth Worldwide

Textile Chemicals Industry Overview

The global textile chemicals market size is expected to reach USD 36.14 billion by 2030, registering a CAGR of 4.5% from 2024 to 2030, according to a new report by Grand View Research, Inc. The growth is majorly driven by increasing demand for textile products from major applications including apparel, home furnishing, technical textiles, and others.

Rapidly growing demand from the apparel industry is anticipated to propel the demand for the product during the forecast period. Home furnishing, specifically in developing economies, demanding modern and attractive furniture products is expected to have a positive impact on the growth of the market.

Numerous chemicals are used in the fabric manufacturing industry to offer a wide range of performance features during the production process, which are known as process chemicals. These end products include biopolishing enzymes, desizing enzymes, flame retardants, antiviral/antimicrobial agents, lubricating/anti-crease agents, water and oil repellents, printing auxiliaries, and softening agents.

Gather more insights about the market drivers, restrains and growth of the Textile Chemicals Market

Based on existing operations and technologies, new application areas for textile chemicals are being developed, wherein these products can help improve efficiency, promote cost reduction, reduce environmental impacts, and ensure the performance of formulations. Application sectors for the product include apparel, home furnishing, technical textiles, and others. STYLUS APPAREL; HYAK DESIGN GROUP; Suuchi Inc.; TechniTextile Québec; and Stafford Textiles Limited are some of the major end-users in the market.

The manufacturing of textile chemicals is highly dependent on abundant availability and favorable costs of raw materials. In this market, successful commercialization of products such as yarn lubricants, finishing agents, coating & sizing agents, and others and investments in production capacity are some of the key strategies of the market players.

The market is highly competitive owing to the presence of a large number of manufacturers with a global presence. The leading product manufacturers include Dow, Huntsman International LLC, The Lubrizol Corporation, Archroma, Evonik Industries AG, and Solvay S.A.

Browse through Grand View Research's Specialty Polymers Industry Research Reports.

The global aseptic packaging market size was valued at USD 77.1 million in 2024 and is projected to grow at a CAGR of 10.8% from 2025 to 2030.

The global fluoropolymer films market size was valued at USD 1.09 billion in 2023 and is projected to grow at a CAGR of 12.9% from 2024 to 2030.

Textile Chemicals Market Segmentation

Grand View Research has segmented the global textile chemicals market based on process, product, application, and region:

Textile Chemicals Process Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Pretreatment

Bleaching Agents

Desizing Agents

Scouring Agents

Others

Coating

Anti-Piling

Protection

Water Proofing

Water Repellant

Others

Treatment Of Finished Products

Softening

Stiffening

Others

Textile Chemicals Product Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Coating & Sizing Chemicals

Colorants & Auxiliaries

Dispersants/levelant

Fixative

UV absorber

Others

Finishing Agents

Antimicrobial or anti-inflammatory

Flame retardants

Repellent and release

Others

Surfactants

Detergents & Dispersing Agents

Emulsifying Agents

Lubricating Agents

Wetting Agents

Denim Finishing Agents

Anti-back Staining Agents

Bleaching Agents

Crush Resistant Agents

Defoamers

Enzymes

Resins

Softeners

Others

Textile Chemicals Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Apparel

Innerwear

Outerwear

Sportswear

Others

Home Furnishing

Carpet

Drapery

Furniture

Others

Technical Textiles

Agrotech

Buildtech

Geotech

Indutech

Medtech

Mobiltech

Packtech

Protech

Others

Other Applications

Textile Chemicals Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

North America

US

Canada

Mexico

Europe

Germany

Turkey

Italy

UK

France

Russia

Spain

Poland

Asia Pacific

China

India

Japan

South Korea

Vietnam

Indonesia

Central & South America

Brazil

Argentina

Middle East and Africa

Saudi Arabia

South Africa

Morocco

Tunisia

UAE

Kenya

Key Companies profiled:

AB Enzymes

Archroma

BASF SE

BioTex Malaysia

Dow

Ethox Chemicals, LLC

Evonik Industries AG

Fibro Chem, LLC

German Chemicals Ltd.

Govi N.V.

Huntsman International LLC

Kemira Oyj

Kiri Industries Ltd.

LANXESS

OMNOVA Solutions Inc.

Omya United Chemicals

Organic Dyes and Pigments

Resil Chemicals Pvt. Ltd.

Solvay S.A

The Lubrizol Corporation

Key Textile Chemicals Company Insights

Some of the key players operating in the global textile chemicals market include Kiri Industries Ltd., AB Enzymes, Dow, BASF SE, The Lubrizol Corporation, Kemira Oyj, and Evonik Industries AG, among others.

AB Enzymes is a biotech company that develops and manufactures enzyme preparations for a wide range of applications such as baking, fruit juice processing, grains processing, animal feed, paper, textiles, and laundry.

BASF SE operates through six business segments, including chemicals, industrial solutions, materials, surface technologies, nutrition and care, and agricultural solutions. The chemical segment's product portfolio includes intermediates, monomers, petrochemicals, and catalysts. The company provides non-halogenated flame-retardants for several end-use industries, including the textile market.

Evonik Industries AG is a global manufacturer of specialty chemicals. It operates through four business segments: Specialty Additives, Nutrition and care, Smart Materials, and Performance Materials. Under the Performance Materials segment, the company offers performance intermediates such as large-volume additives and intermediates, along with functional solutions such as polymer additives, potassium derivatives, cyanuric chloride, alkyl chlorides, and alkoxides.

Kemira Oyj is a global chemical manufacturer with business operations in pulp & paper, water, oil & gas, metals & mining, food, and energy industries. For textile processing, the company offers oil-based foam control products and dry powder flocculants. Oil-based foam control products (defoamers) are active dispersions in mineral oil that can be used for persistent foam reduction applications. They are cost-efficient and well-suited for high temperatures. Their primary applications include textiles and wastewater treatment. Dry powder flocculants, such as nonionic polyacrylamides, offered by the company are effective in textile processing applications such as the flocculation of negatively charged particles.

Recent Developments

In January 2024, Devan Chemicals, a provider of sustainable textile finishes, is excited to announce its upcoming participation in Heimtextil 2024. Devan invites attendees to visit their booth in Hall 11.0, booth A21, to experience firsthand the latest sustainable textile finishes they have developed.

In April 2024, BASF SE announced its portfolio of polyamides for the textile industry. The company’s sustainable polyamide PA6 and PA6.6 product range have been certified under the Recycled Claim Standard (RCS) for textile applications. This certification allows BASF SE to market textiles produced using recycled raw materials.

In May 2023, Dystar announced its eco-advanced indigo dyeing, which aims to reduce energy consumption by up to 30% and water usage by up to 90% during the production process.

In November 2023, Solvay introduced a textile fiber that decomposes rapidly in the oceans, minimizing the environmental impact of microplastics. The new textile polyamide, set to be manufactured at the company's industrial facility in Brazil, will decrease oceanic impact by roughly 40 times compared to traditional fibers. This product development aligns with the global trend of rising demand and market shifts toward more sustainable textile solutions.

Order a free sample PDF of the Textile Chemicals Market Intelligence Study, published by Grand View Research.

0 notes

Text

Exploring India’s Excellence in Talc Powder Export Industry

Talc, a naturally occurring mineral, is a versatile material widely used across various industries. Its unique physical and chemical properties make it a key component in products ranging from cosmetics to industrial applications. Among the global suppliers of talc powder, India has emerged as a significant exporter, offering high-quality products to meet international demands. This article explores the growing prominence of India as a talc powder exporter in India and the reasons behind its success in the global market.

Understanding Talc and Its Properties

Talc is a hydrous magnesium silicate mineral that is soft, absorbs moisture well, and is chemically inert. It is appropriate for a variety of applications due to its greasy feel and resistance to heat, electricity, and acids. Its softness, which makes it the softest mineral on the Mohs scale, is its most famous characteristic.

Talc ore is ground and pulverized into fine particles to create talc powder. The resultant white or off-white powder is essential in many industries because of its exceptional qualities, which include high lubricity, chemical resistance, and opacity.

Applications of Talc Powder

Cosmetics and Personal Care ProductsTalc powder is widely used in cosmetics for its smooth texture and absorbent properties. It is a vital ingredient in products such as face powders, foundations, and baby powders, offering a silky finish and reducing moisture.

Pharmaceutical IndustryIn the pharmaceutical sector, talc powder is used as a filler and a lubricant in tablet manufacturing. Its chemical inertness ensures that it does not react with active ingredients.

Paints and CoatingsTalc serves as a functional additive in paints and coatings, enhancing their durability, coverage, and anti-corrosive properties. It is also responsible for improving the dispersion of pigments.

Paper IndustryTalc is a filler material in the paper industry, providing smoothness, opacity, and a glossy finish to paper products. It also improves the printability of paper.

Plastic and Rubber IndustriesIn plastics, talc improves rigidity and impact resistance. In the rubber industry, it enhances the properties of rubber compounds, contributing to better performance and durability.

CeramicsTalc is a key ingredient in the production of ceramics, aiding in the process of vitrification and improving the strength and finish of ceramic products.

India as a Leading Exporter of Talc Powder

India is one of the largest exporters of talc powder, with abundant reserves and advanced processing facilities. The country is known for producing talc of superior quality with high purity levels, making it suitable for demanding applications. States like Rajasthan, Uttarakhand, and Andhra Pradesh are rich in talc deposits, supporting a robust mining and processing industry.

Indian talc exporters have gained a reputation for their consistent supply, competitive pricing, and adherence to international quality standards. They serve industries in regions like the Middle East, Europe, North America, and Southeast Asia. The growing demand for talc powder in cosmetics, pharmaceuticals, and industrial sectors has further solidified India's position as a reliable supplier.

The Role of Talc Powder Exporters

Talc powder exporters in India play a crucial role in connecting domestic producers with global markets. They ensure the supply chain is seamless, from sourcing raw talc ore to processing it into powder and packaging it for shipment. Exporters also invest in advanced technologies to maintain the quality of the talc powder, meeting specific requirements such as particle size, brightness, and chemical composition.

Moreover, Indian exporters are increasingly adopting sustainable practices to minimize environmental impact. These include efficient mining techniques, recycling water in processing plants, and adhering to stringent environmental regulations.

Why Choose India for Talc Powder Exports?

High-Quality ReservesIndia has access to some of the purest talc deposits globally, ensuring high-grade products.

Advanced Processing TechniquesIndian exporters utilize state-of-the-art processing facilities to meet global standards.

Competitive PricingFavorable labor costs and efficient logistics make Indian talc powder competitively priced.

Adherence to StandardsExporters comply with international quality certifications and safety guidelines, ensuring reliability.

Customized SolutionsExporters offer tailored talc products to suit the specific needs of diverse industries.

Pratibha Refractory Minerals: A Trusted Name

Pratibha Refractory Minerals is a well-known name in the talc powder export industry. With a commitment to quality and customer satisfaction, the company provides high-grade talc products to various international markets, ensuring excellence in every shipment.

Conclusion

India's rise as a talc powder exporter is a testament to its resource richness, technological advancements, and dedication to quality. The country's ability to cater to diverse industry needs while maintaining sustainability makes it a preferred destination for talc powder imports. With companies like Pratibha Refractory Minerals leading the way, India continues to strengthen its position in the global talc industry.

0 notes

Text

The Best Oil Filling Machines for Accurate and Efficient Packaging

As businesses in the food, cosmetic, and industrial sectors seek to optimize their operations, selecting the right filling equipment becomes crucial. The article provides detailed insights into the unique features, advantages, and applications of these machines, guiding manufacturers to make informed decisions tailored to their needs.

Automatic Oil Filling Machine The automatic oil filling machine is a versatile and highly adaptable piece of equipment designed to handle a wide variety of oil products. Its impressive capacity, ranging from 90ml to 140ml, allows manufacturers to fill different container sizes seamlessly. With fully automated settings, it simplifies the entire filling process, reducing manual labor and increasing productivity. The universal design makes it suitable for diverse oil applications, from food-grade oils to industrial lubricants. For large-scale manufacturers looking to streamline operations and ensure precision, this machine delivers unmatched efficiency and reliability.

Avocado Oil Filling Machine The avocado oil filling machine is specifically engineered to handle the luxurious and high-value nature of avocado oil. Known for its thick and nutrient-rich consistency, avocado oil requires precise volume measurement, and this machine delivers just that. It’s constructed with materials that resist wear and tear from natural oil properties, ensuring long-lasting performance. Whether for boutique health brands or mass production, the scalable design meets a wide range of production needs. Additionally, it operates efficiently with minimal manual input, enhancing overall productivity while keeping quality at the forefront.

Peanut Oil Filling Machine The peanut oil filling machine is designed to manage the specific challenges posed by the dense and rich properties of peanut oil. It features advanced volumetric technology that provides precise dosing, ensuring uniform filling and minimal waste. Built for both small-scale and large-scale operations, the machine is versatile and easy to maintain, thanks to its stainless-steel construction. This setup is ideal for food manufacturing businesses looking to improve output while maintaining high-quality standards. Furthermore, it’s designed to work under demanding conditions, providing consistent results and long-term reliability.

Corn Oil Filling Machine With a focus on efficiency and accuracy, the corn oil filling machine is built to handle the high-volume production needs of corn oil manufacturers. Its automated design minimizes human error, ensuring every container is filled to exact specifications. This machine excels in large production environments where speed and consistency are critical, allowing manufacturers to meet high market demand. Constructed from durable, food-safe materials, it ensures that the corn oil maintains its quality and purity throughout the filling process. Simple to operate and maintain, it’s a cost-effective solution for manufacturers aiming to optimize their operations.

Cottonseed Oil Filling Machine The cottonseed oil filling machine is engineered to manage the unique viscosity and properties of cottonseed oil. It comes equipped with sophisticated measurement and filling technology, allowing for accurate and efficient filling operations. The machine’s sturdy construction and corrosion-resistant materials make it ideal for long-term use in harsh production environments. It can be customized to handle different container sizes, offering flexibility for various packaging requirements. For manufacturers of cottonseed oil, this equipment ensures a seamless production process, maintaining product quality while increasing output.

Safflower Oil Filling Machine This safflower oil filling machine is designed to deliver high-precision filling for safflower oil, known for its thin and delicate nature. The equipment utilizes advanced technology to measure and dispense oil accurately, reducing wastage and maximizing efficiency. Its design ensures that the oil maintains its quality and nutritional value throughout the process. Ideal for health and wellness brands, the machine handles both small and bulk quantities with ease. Its streamlined operation and minimal maintenance needs make it an essential tool for businesses seeking reliable and consistent performance.

Flaxseed Oil Filling Machine Engineered to meet the needs of flaxseed oil producers, the flaxseed oil filling machine offers precision and efficiency for delicate oil products. The machine ensures accurate filling while protecting the sensitive nature of flaxseed oil, which is prone to oxidation. Constructed from high-quality, corrosion-resistant materials, it ensures a hygienic and safe production process. Its adaptability makes it suitable for various packaging formats, from small bottles for retail sales to large containers for bulk distribution. By minimizing waste and maximizing accuracy, this equipment significantly boosts production efficiency.

Rice Bran Oil Filling Machine The rice bran oil filling machine is built to handle the unique characteristics of rice bran oil, which is highly valued for its health benefits. With advanced automation features, the machine ensures consistent filling and reduces the risk of contamination. Its durable construction supports high-speed operations, making it perfect for large-scale production environments. The equipment is designed to be user-friendly, with simple controls that minimize operator training time. By maintaining product integrity and optimizing filling efficiency, it serves as a critical component in the manufacturing process for rice bran oil producers.

Brazil Nut Oil Filling Machine Designed specifically for the rich and luxurious texture of Brazil nut oil, Brazil nut oil filling machine ensures precision and quality with every use. It features cutting-edge volumetric filling technology that guarantees consistent and accurate fills, whether for small retail bottles or larger wholesale containers. The machine's robust build ensures durability, even under heavy use, while the easy-to-clean components maintain hygiene standards. This equipment is particularly beneficial for niche oil producers looking to maintain the high quality of their products. With its reliable performance, it streamlines production, making it a valuable investment for any oil processing business.

Best Oils Filling Machine The best oils filling machine is a versatile and efficient solution that can handle a wide variety of oil products. It is designed with state-of-the-art automation technology that ensures accurate and consistent filling for different types of oils, from edible oils to specialty oils. The machine's flexibility makes it suitable for both small businesses and large-scale manufacturing operations. It features user-friendly controls and is constructed from high-quality materials to ensure long-lasting performance. This equipment stands out for its adaptability, precision, and ability to boost productivity across multiple oil packaging applications.

Summary