#Low-silica quartz

Explore tagged Tumblr posts

Text

Low silica quartz is a type of quartz material made mostly of quartz minerals mixed with resins and pigments. Compared to regular quartz, it has less silicon dioxide. This makes it safer for health and better for the environment when it’s made and used.

0 notes

Text

Lux Quartz Vietnam’s free and low silica quartz are created using advanced technology, combining durability, elegance, and safety for eco-friendly environment.

1 note

·

View note

Text

April 20, Beijing, China, National Museum of China/中国国家博物馆 (Part 2 - Dehua white porcelain exhibition/德化白瓷展 continued):

This was actually the very first piece I encountered at the entrance to the exhibition, a gigantic basket of flowers (probably over 1 meter tall and over 1 meter wide?), the entire thing made of porcelain.

And to reiterate, every part of every piece is porcelain. Though I will say that despite the ultra-realistic shape of the flower petals and leaves, the only detail that hinted at these flowers being made out of porcelain was that the painted colors weren't as vibrant as real flowers. That's it. If you don't examine it up close you really can't tell that it's all porcelain.

This is a good place to roughly introduce the technical side of Dehua white porcelain. The color of Dehua white porcelain mainly comes from the clay it uses, which is a special kaolin clay (gaolingtu/高岭土 in Chinese) found in Dehua. The clay mineral used naturally contains sericite and quartz, both of which are silica minerals and may have contibuted to the almost translucent look of the finished pieces; it also contains comparatively high amounts of potassium oxides, while the amount of iron oxides present is low. Due to the intricate designs of the pieces, the firing success rate may be very low. All those pieces involving super thin parts representing fabric or paper or flower petals? They may bring the success rate down to about 5%. Which means many of these pieces may be the 15th-20th try that finally survived firing. For people who are more interested in the chemistry of Dehua white porcelain, this paper goes into depth about it. There's also a great book in Chinese that goes into depth all about Dehua porcelain. (link goes to the first chapter only)

Continuing on, this is one of many Guanyin/观音 (Avalokiteśvara) statues at the exhibition, again with light clothing made out of porcelain:

More Guanyin statues in various classic depictions/forms, of which there are 33 total. This particular form is called Yulan Guanyin/鱼篮观音 (鱼篮 means fish basket), and comes from a legend where Guanyin transformed into a beautiful female fish vendor in order to guide mortals.

I believe the text here reads 持经观音 (Guanyin holding scripture)? The Guanyin here is holding a vase instead of a scroll though.

This is a classic depiction of Guanyin with a little bit of a modern-ish twist? Guanyin is often depicted with a vase of divine water, but here it forms a circle.

Despite some of the Guanyin statues having the amazing ceramic "clothing", this one remains my favorite, just because of the sense of space and serenity that this simple "frame" design creates:

And this very literal take on "thousand arm Guanyin" (千手观音). It's giving me that "biblically accurate angels" vibe:

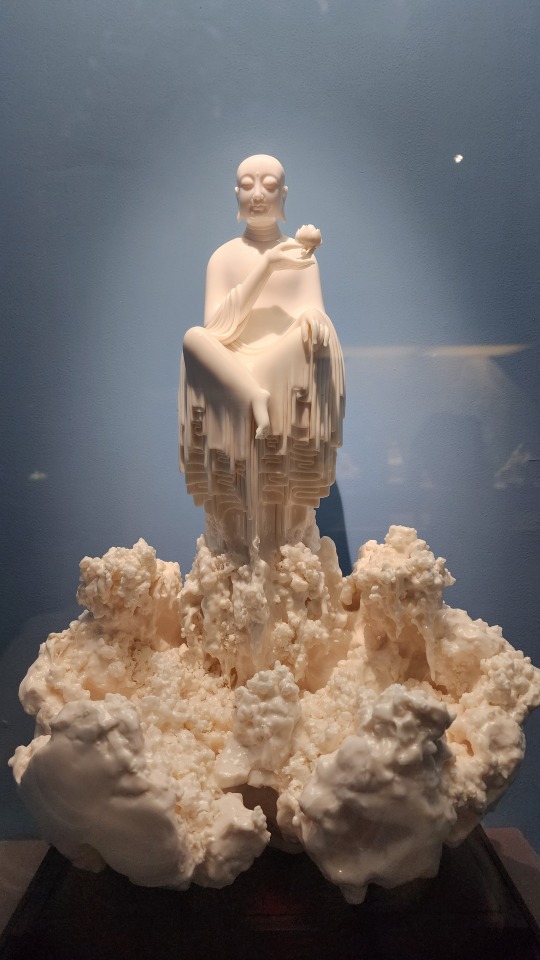

Buddha floating atop.......idk what that is but the texture is amazing:

A fully painted statue of Guanyu/关羽. The gradient and detailed patterns on his robes is amazing:

Two identical (I think?) statues of the daomadan/刀马旦 (female commander archetype) character Mu Guiying/穆桂英 as she would appear in Chinese traditional opera, one painted and one unpainted. The word 巾帼英雄 in the title means "hero in women's headscarf", which is a term used exclusively in reference to female heroes. There's also the phrase "巾帼不让须���", which roughly means "those in women's headscarves aren't inferior to those with beards and thick brows"

Porcelain depiction of Dunhuang's famous feitian/飞天 figures, in the classic pose of playing pipa in reverse (called 反弹琵琶). The clothing on this figure is made of porcelain, but this time also painted:

A porcelain statue of a couple in traditional Lhoba/Luoba/珞巴 clothing. The Lhoba/Luoba people are one of China's 55 少数民族 who mainly live in the south-eastern region of Tibet Autonomous Region, and as of 2019, it is the 少数民族 with the smallest population

A porcelain statue of a woman in traditional Miao/苗 clothing. I love how the artist recreated the traditional Miao silver crown in porcelain.

Painted porcelain bust of a woman wearing the Xunbu/蟳埔 "flower crown", named a zanhuawei/簪花围. The town of Xunbu in Fujian province is known for its tradition of zanhua/簪花, or wearing flowers in one’s hair.

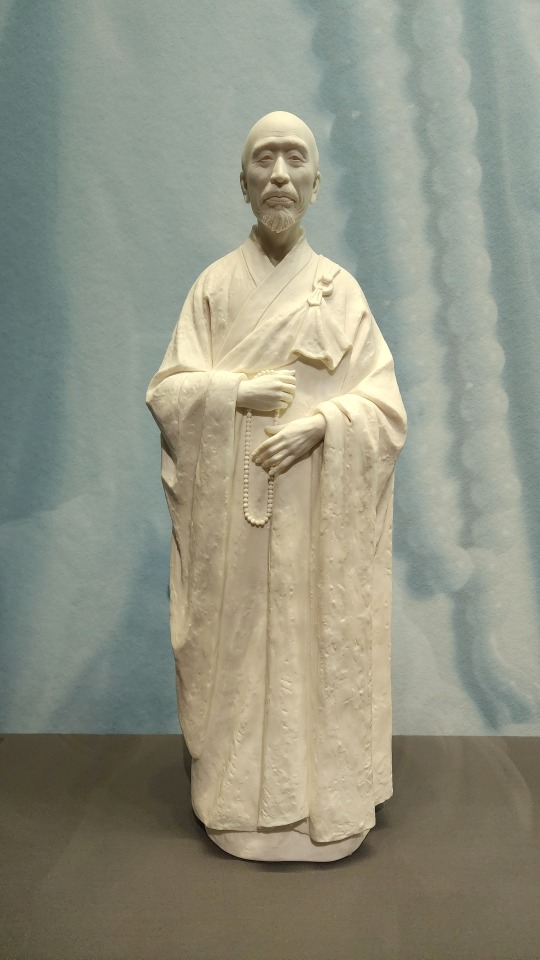

Porcelain statue of a Buddhist monk wearing a zhiduo/直裰 (the robes on the inside) and a jiasha/袈裟 (काषाय/kasaya; the garment on the outside that drapes over the left shoulder). From its looks, one can tell that zhiduo originated from hanfu, but with some minor changes (sidenote, this is not the same as the zhiduo of Ming-era hanfu). Jiasha evolved from the clothing of Indian Buddhist monks, but there appears to be a lot of influence from Central Asia and ancient Greece as well (link goes to pdf; this article is in Chinese).

Some modern-themed pieces. Look at those dresses omg

A porcelain statue of Hua Mulan/花木兰, the character from traditional Chinese literature and opera that inspired the Disney character. I will say though this pose reminds me of someone else.......

#2024 china#beijing#china#national museum of china#dehua porcelain#blanc de chine#porcelain#chinese art#chinese culture#art#culture#buddhism#guanyin

570 notes

·

View notes

Text

https://www.britannica.com/science/nepheline-syenite

What is nepheline syenite used for?

Nepheline syenite from Canada is used to replace feldspar in the manufacture of ceramic and glass products. The feldspar in nepheline syenite may be cryptoperthite or, rarely, a mixture of albite and microcline. Nepheline is sometimes wholly or partly replaced by sodalite or cancrinite.

Is nepheline syenite toxic?

Acute Toxicity Values: No acute toxicity data is available for product. No ecotoxicity data is available. This product is not expected to present an environmental hazard. Waste Disposal Method: Nepheline Syenite is not classified as a hazardous waste under US EPA RCRA regulations.

Does nepheline have cleavage?

Resembles feldspars but nepheline is uniaxial, lacks good cleavage and twinning, and has a low birefringence. Nepheline is softer than quartz and differs in optic sign. Nepheline occurs in alkali-rich, silicon poor igneous rocks (nepeline syenite, foidite and phonolite).

Is nepheline a rock or mineral?

feldspathoid mineral

Nepheline is an important feldspathoid mineral. It is white, grey or yellow in colour with a vitreous lustre and a poor cleavage. The name Nepheline comes from the Greek word nephele, which means “cloud,” because it becomes strongly clouded when put in strong acid. Nepheline only forms in silica-poor rocks.

3 notes

·

View notes

Text

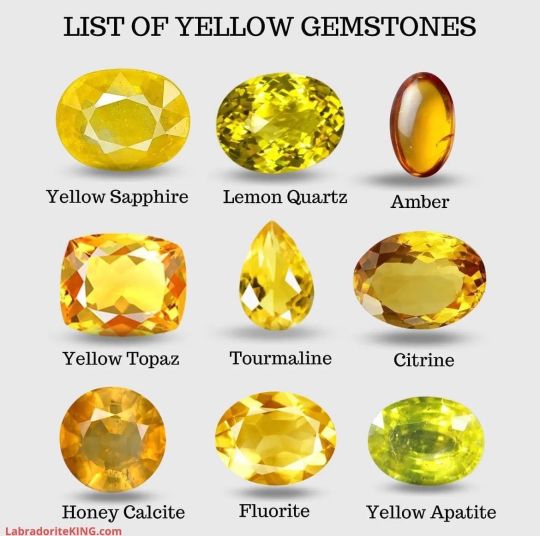

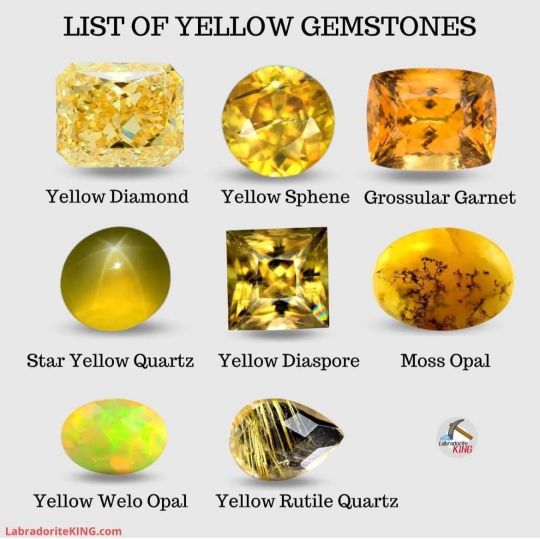

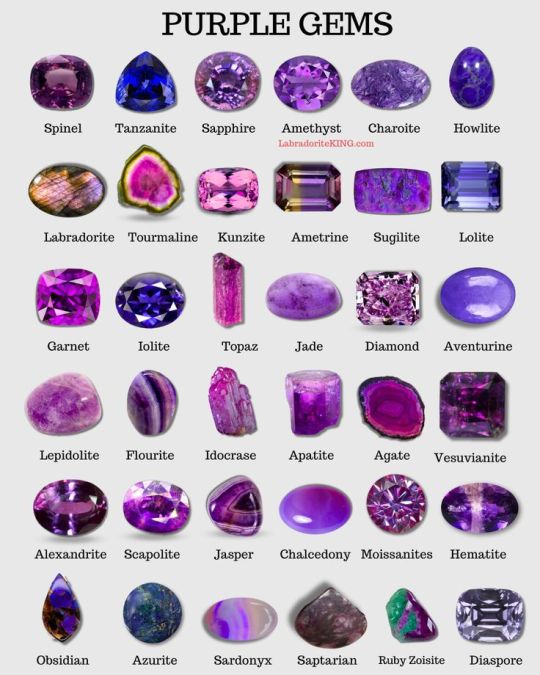

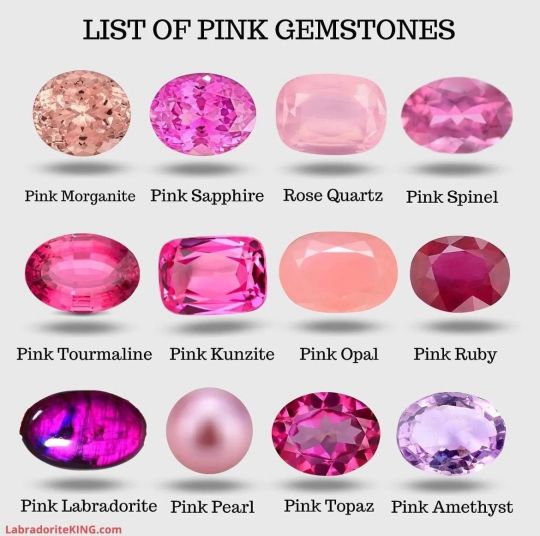

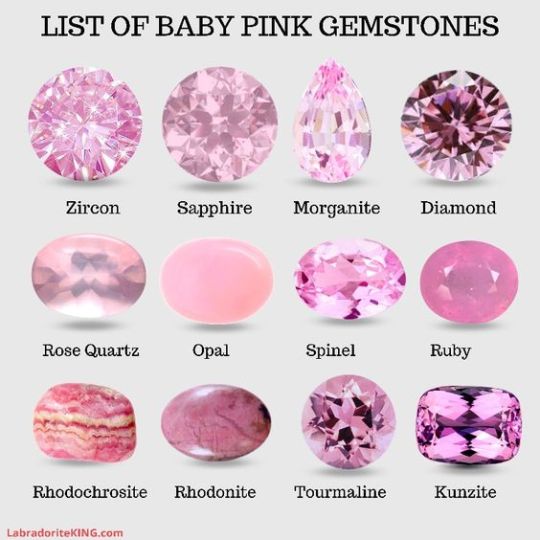

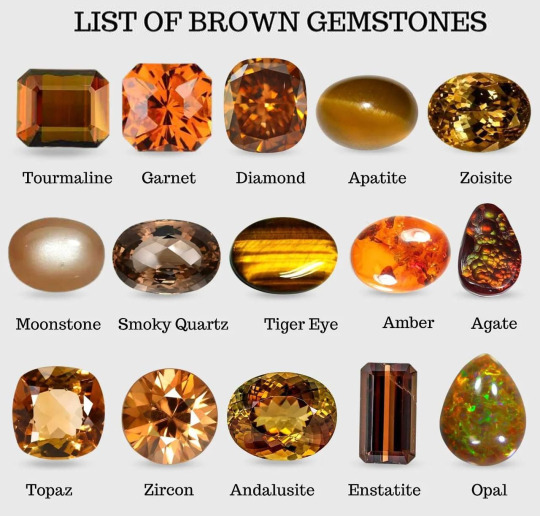

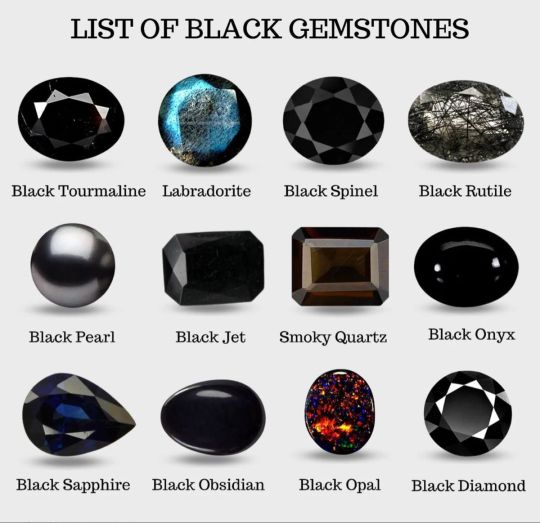

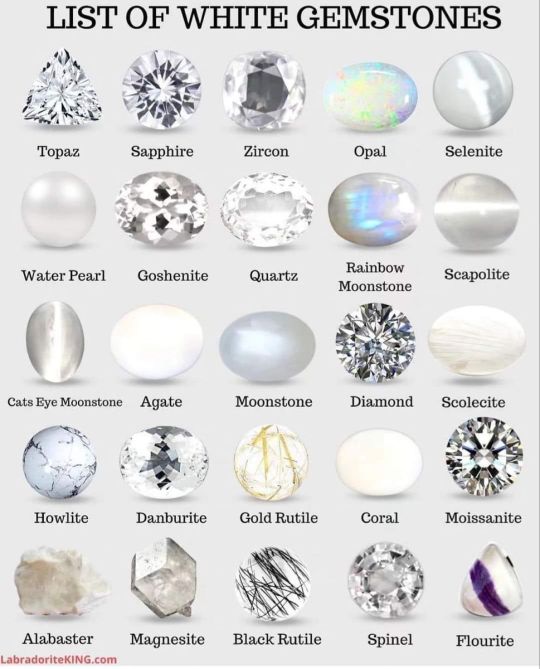

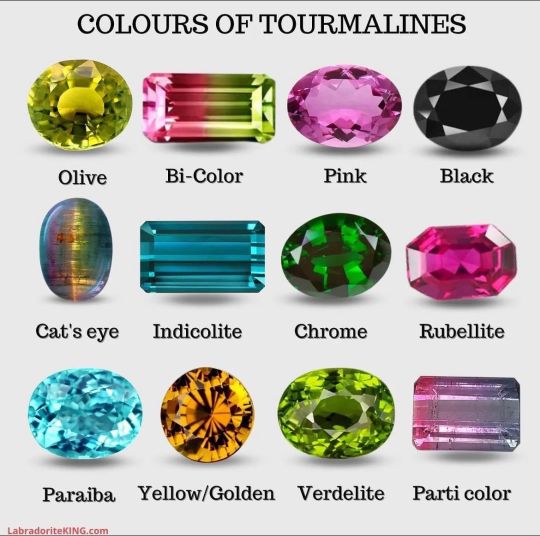

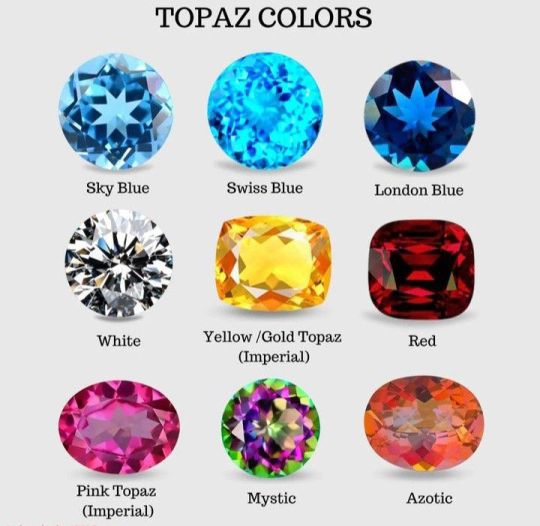

Hi yeah sorry I've seen this a few times on my dash now and let me just say this is like. riddled with inaccuracies. not just when they list the same mineral twice on one graphic (red sapphire is catagorically not sapphire, its ruby. red corundum is ruby) but some of this stuff is just. stupid on first pass.

some of these are just not used as gemstones: wulfenite is a lead mineral that is yes, very pretty, but rarely or never used as a gemstone to my knowledge because it is literally one of the major ores of lead (after galena). you really don't want to be touching or having it as jewellry!

calcite is also a terrible mineral to use for jewellry. same with selenite or any evaporite minerals. they dissolve in water or weak acids making their use wherever theres gonna be water (the surface of the earth in its entirety, where humans live) problematic, to say the least.

red diamonds (and pink diamonds) are also both exceedingly rare. like, found in one or two mines in australia and thats it, to my knowledge.

pink tourmaline is mentioned on both pink slides: also pink ruby isnt ruby, its sapphire. at least call it 'pink corundum' if ur gonna mention it twice lmao

the yellow slides also mention quartz four times??? are they really running that low on yellow minerals? god put some more poison ones on there like you did with wulfenite at that point

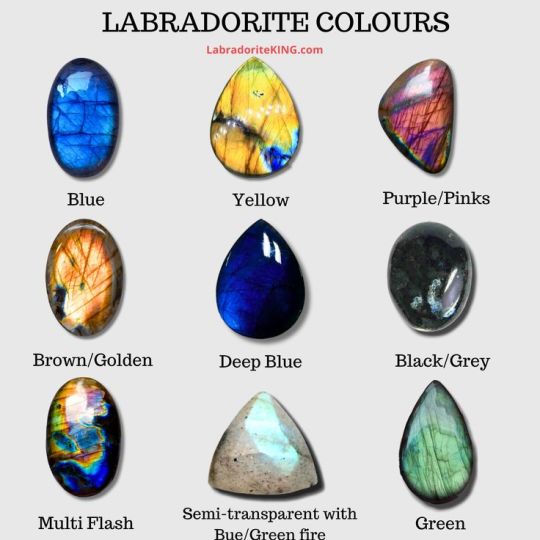

putting opal and labrodorite on practically every slide is just crap too. yeah, opal and labrodorite can be practically any colour, doesnt mean you have to put them on every single slide lmao

malachite is not a gemstone is an ore of copper. it is so brittle and so liable to cracking please god stop using it as a gemstone

moonstone mentioned a grand total of three times on the white gemstones slide!

the 'literally just quartz' count is: 32 by a very quick count, arguably higher because opal is just silica hydrates.

the bi colour slide didnt even include alexandrite, despite it being a) on a previous slide and b) one of the most famous colour changing minerals. fuck my baka life.

overall rating 2/10 just go on geology.com if you want gemstones. or fucking wikipedia. or look at a book on gemology or something please god this sucks more and on different ways every time i look at it.

By LabradoriteKing on Pinterest

#i hate this graphic stop putting it on my dash PLEASE#this is mostly a joke but does really show how little most people know about minerology#and gemology#and geology in general#geology tag

133K notes

·

View notes

Text

Types of Heat Resistant Glass

Heat-resistant glass can withstand high temperatures without cracking or breaking. Therefore, they are suitable for many applications, from making cookware and ovens to fireplace doors. Depending on the application, different types of heat resistant glass may be used, each with its unique properties and applications.

Here are some common types you should know:

Tempered Glass:

It is a type of heat-resistant glass that has been treated at high temperatures to make it extra strong. This makes it safer and more durable than regular glass, as it can withstand impacts and other physical shocks without breaking. It’s also resistant to thermal shock, which means it can handle rapid temperature changes without damage.

Tempered glass usually comes in two varieties: annealed and heat-strengthened. Annealed can withstand temperatures up to 250°C (482°F), while heat-strengthened ones have a maximum temperature rating of 350°C (662°F). This makes it suitable for applications such as fireplace doors, stovetop covers, skylights, and windows in areas with extreme weather.

They are also scratch-resistant and can be designed to be non-reflective, making them a great choice for outdoor applications. Furthermore, since it is four times stronger than regular glass, this type is more resistant to breakage in the event of an accident or impact.

Ceramic Glass:

Ceramic glass is made from silica, boron oxide, alumina, and other materials. It’s known for its high strength and thermal stability; ceramic glass can withstand temperatures up to 1000°C (1832°F). This makes it ideal for use in high-temperature environments such as fireplaces, kilns, and furnaces.

It’s also non-porous, so it won’t absorb liquids or odors. This makes it a great material for use in stoves and cookware where liquids are involved. It’s very scratch resistant as well, making it ideal for applications such as countertops and kitchen surfaces that are exposed to wear and tear.

It also blocks UV radiation, making it great for laboratory applications where UV radiation needs to be blocked.

Ceramic glass is more expensive than tempered or borosilicate glass because of its higher production cost. However, it’s durability and long-life span make up for the expense over time.

Soda-Lime Glass:

Soda-lime is the most common type used in commercial and residential applications. It’s made from a combination of sand, soda ash, calcium carbonate, and other materials. Compared to borosilicate and quartz, soda-lime isn’t as strong or heat resistant; it can withstand temperatures up to 350°C (662°F).

However, its low production cost makes it ideal for use in windows, lighting fixtures, oven doors, cookware, food storage containers, and even art projects. Its ability to be molded into different shapes also makes it a great choice for decorative purposes. Summary Heat-resistant glass is an essential material for many applications due to its ability to withstand extreme temperatures and impacts. Depending on your needs, you can select the right type, such as tempered, ceramic, quartz, or soda-lime. Each type has unique features and benefits, making it suitable for different purposes. With the right selection, you can be sure that your projects will remain safe and secure.

Summary

Heat-resistant glass is an essential material for many applications due to its ability to withstand extreme temperatures and impacts. Depending on your needs, you can select the right type, such as tempered, ceramic, quartz, or soda-lime. Each type has unique features and benefits, making it suitable for different purposes. With the right selection, you can be sure that your projects will remain safe and secure.

0 notes

Text

Ceramic colouring

Part two of my notes from the studio info sheets, which are currently being uploaded at what used to be glacial pace in the 1980s, but is much slower now… Apologies for the length, I get a lot of questions on the differences between various things. Also, my work is definitely not the best examples but because this is done for people buying or learning at my place, it's what gets used a lot for pix.

UNDERSTANDING ADDED CERAMIC COLOURS

Most ceramic pieces have some form of colour decoration applied to them. These vary from quick dips in glaze to complex colouring processes and even precious metals applied in a third firing.

Here are some of the most common colouring techniques.

Glazes

Ceramic glazes are the glassy coating on ceramic pieces that helps to make them tougher and more waterproof, as well as being beautiful. The most basic and traditional glazes are formed with basic materials including salt, quartz, ash and feldspar, with minerals such as copper used as colouring agents.

These days, most potters purchase commercial glazes, which have three major parts: Silica, which melts to create glass; alumina, which ‘stiffens’ the glaze so it holds to the clay rather than melting all over the kiln (usually a fine clay such as bentonite), and flux, which lowers the temperature of the melting point so that the glaze will come glass but the ceramic underneath won’t melt. Glazes can be applied by dipping, pouring, spraying or brushing onto the piece. Some potters also mix up their own, using chemical recipes from glaze specialists or researching their own combinations, which can alter qualities including colour, texture, translucency, how it ‘breaks’ over texture on the clay and how well a glaze will layer with others. You can see some differences in some of these qualities in these leaves.

Glazes are applied to pieces that have previously been ‘bisque’ fired (the first firing that turns ‘greenware’ clay into a solid ceramic piece) and then receive a second firing to turn the glaze into glass and partially or fully vitrify the clay. It’s important that the type of glaze used matches the type of clay body for firing temperature (e.g. Earthenware, Mid-Fire or Stoneware). Additionally, some clays contain minerals that will ‘clash’ with some glazes and cause yellowing or other unwanted effects, so testing is important. Talk with your supplier about glazes that are low in minerals like Zinc, which is a frequent offender in some circumstances.

Underglazes

Unlike glazes, which coat the clay, underglazes become a part of the clay body underneath them. They can be applied to clay that has already been bisque fired, or to greenware, which is clay that has not yet been fired.

They are made up of flux material, which – as in glaze – will lower the melting point of the other materials so they melt and adhere to the clay, colouring agents that are in general made from oxides and stains, water and binders.

Most potters use commercial underglazes, which are extremely predictable in how they will perform. The advantage of this is that you can hand-mix colours and alter textures. For example, in my magpie pin (right), I mixed the orange for the eye from two colours that were nearly but not-quite right. The blacks and greys on the beak are watered down in parts to make them more translucent and add some dimensionality, as is the background blue.

Most underglazes are true to colour (what you see is what you get) in both the bottle and mixes, though some (esp. royal blue and some pinks) change colour between painting and firing and others shift colour or burn out altogether at higher firing temperatures. Some colours can disappear on stoneware or porcelain, as you can see in the two photos below: several colours changed value significantly in these porcelain leaves when they were fired at around 1300°C. Additionally, the glaze had zinc in it, which went cloudy with some of the reds.

Underglazes can be stamped, sponged painted, sprayed, printed and more, delivering effects ranging from solid colour to translucent washes. You can layer underglazes with different techniques, such as the pendant below, which was painted blue then screenprinted with black (which wasn’t actually quite thick enough to screen, hence the shadowing in parts of this print –my bad).

You can also paint a textured piece with underglaze then wipe the surface, leaving the colour in the deeper parts of the texture and either removing it or making it into a soft wash on the surface. This is particularly effective when all or part of the surface will afterwards be glazed, as it can create additional effects. The lizard pin below was underglazed with brushed-on black which was left to dry, then wiped from the surface with swirly motions and a Chux cloth, giving a subtly Goth background, which the clear glaze accentuates.

At very high temperatures, some underglazes will self-glaze, but most require glaze over the top if the item is to be functional (including jewellery) as a piece’s bare or underglazed surface will pick up and hold oils from food, skin, make-up and so on and can be permanently marked by dust and dirt.

Many ceramicists make good use of the attractive effects made possible by using a translucent coloured glaze over an opaque underglaze in a different colour. One danger with glazing over underglaze is that some glazes will react chemically with the underglaze beneath and can either change the colour or create a milky cast in the glaze. I didn’t check that the stoneware glaze I used on the red leaves above was zinc-free and so the red oxide reacted with the zinc in the glaze to create a waxy look that has made several of these pendants imperfect.

Slips and Engobes

Two of the most traditional ways of adding colour and decoration to pottery, slips and engobes are closely related. They contain the same ingredients as glaze, but in different proportions.

Clay is the main ingredient in slip, making up 50-90% of the final product in most commercial slips, with the rest being colour from oxides and stains and flux. Slips can also be made from ‘watered down’ clay of different colour (or with added oxide or stain) that is applied as either a decorative element in itself or to change the colour of the clay body for further decoration. They are applied to clay before it is fired, usually at a leather-hard stage, and can be fluid like paint or thick like toothpaste, which means they can add texture as well as colour.

It’s important that slips ‘fit’ the clay body they are used on, so they need to have similar moisture levels and fire at the same temperatures as the base clay. In my tawny frogmouth chick plaque below, I used a low-fire commercial green slip and home-made white slip from another earthenware clay body to block out the shapes of the chick and leaves and make it easier to get detail in the final decoration on the darker background. I applied the white slip thickly, to get a sense of texture in the feathers.

You can absolutely combine slip with other colouring methods: I added detail and more leaf colour and sticks with underglaze after the bisque firing and then glazed it for effect, though I think next time I won't as the frame should protect the little fellas.

Texture is a common feature in the traditional ways slips have been used, such as in this 17th century charger of Charles II held at LACMA (below, https://collections.lacma.org/node/252241), where the thick lines of slip provide outlines and raised decorative elements to the design.

Engobes have a lower clay content than slips, as around 20-50% (though still higher than glaze) and the clay content is more likely to have been pre-fired. They also contain flux or silica. This means you can use them on bisque-fired pieces as well as greenware. They sit between slips and glazes in their properties and in their ‘glossy’ finish after firing, though some are designed to have a glassier finish.

One important difference between engobes and glazes is that engobes don’t move around as much during firing, so if you have a detailed design, the lines will stay crisp and colours separate. This Iranian bowl (below) from around 1600 CE has a base of white engobe then coloured engobes and stains painted over the top, all of which have stayed crisp. (See https://commons.wikimedia.org/wiki/File:Bowl,_Iran,_Safavid_period,_c._1600_AD,_pottery,_polychrome_on_white_engobe_under_transparent_glaze_-_Montreal_Museum_of_Fine_Arts_-_Montreal,_Canada_-_DSC09729.jpg for more details on this bowl.) You can use engobes with slips or underglaze, or, like the bowl, with glazes on top.

Two slip-related techniques are worth noting. The first is terra sigillata (‘sealed earth’ in modern Italian but ‘clay with little images’ in Latin, referring to the pots it was mostly used on). This is a very fine slip that has had all the coarser particles filtered out (you can buy it commercially or make your own) and is then applied to a smooth, clean and bone-dry surface before bisque firing (it can have texture, but the terra sig will show every mark, so it needs to not have unwanted grooves and scratches). Several coats are used, which are then buffed to create a high-shine finish that glows like a soft clear glaze. It makes pots more waterproof, if not to the level of glaze. It was a popular technique for traditional pots such as this Gaulish one (below) from the Wikipedia page on terra sig and shows up in many countries, including traditional Mexican pots. (Image by AgTigress - Own work, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=11307176)

Finally, sgraffito is a technique where slips, engobes or underglazes are applied to a leather-hard clay surface and then scratched back to create decoration. It’s a very traditional technique for drawing on items in a detailed, monochrome fashion, such as this Mediaeval Tring Parish Church tile held in the British Museum (See https://tringlocalhistory.org.uk/Tiles/index.htm) but it can also be used for more contemporary designs and, with engobes, carve down through different layers of colours for added effects.

Oxides and stains

Several metallic oxides are commonly used as colouring agents, particularly iron, cobalt, chrome, copper and titanium. They can be incorporated into a wide range of techniques including brushing on using water or commercial brushing medium, adding to slips or engobes or to the clay body itself, spraying or printing. Cobalt oxide, for example, gives Delftware its distinctive blue decoration, as in this Japanese style vase, left (from the Wikipedia page on Delftware, By Daderot, CC0, https://commons.wikimedia.org/w/index.php?curid=23743698).

Oxides are naturally occurring and require careful material handling safety in their raw, powder forms. All require PPE and some are extremely toxic. There are good ranges of pre-mixed commercial products available for people who do not have the facilities for safe handling in their workspaces, particularly if that's inside your house. All produce strong colours and there is a wide range of colour that can be achieved using oxides, though some are less stable than others at higher temperatures, particularly reds.

Stains are man-made colourants that are used in most of the other options on this list. They go through a series of processes that make them more stable than some oxides at high temperatures and more predictable, easy to use and often safer than oxides. They can be used in all the same techniques as oxides and are the colouring agents in most commercial glazes, underglazes and commercially made slips and engobes.

Lustres

One of the most expensive techniques, lustres are added in a third firing at a lower temperature than the bisque or glaze firing. They are made of combinations of metals or metallic salts, resins and oils that are painted on over the glaze and deliver a shiny metallic or iridescent finish depending on the ingredients. Cups with bands of gold are a common example, but other colours are common, such as this blue lustre dodo by William de Morgan (below, https://www.demorgan.org.uk/collection/multi-lustre-dodo-tile/).

Lustres require very careful material handling for user safety (including dedicated brushes and a respirator) and for their inherent difficulty and aren’t cheap! Because lustres are metals, you should never put lustreware in the dishwasher or microwave.

But wait, there’s more…

This is a brief overview of ways of colouring ceramics but the full list is vastly longer. It includes enamels and onglazes, effects created by fire and smoke, colours from ash and salts, colours only available with particular types of firing and effects created by draping feathers, hair and metals on items fresh from firing. Hit the internet or library if you’re interested – it’s a fascinating topic and the results are beautiful.

0 notes

Text

Quartz Ceramic Crucible Market, Global Outlook and Forecast 2025-2032

Quartz Ceramic Crucible is a specialized ceramic crucible made from high-purity fused quartz, with a silica content of 99.9% or higher. Known for its fine structure, low thermal conductivity, low coefficient of thermal expansion, excellent thermal shock stability, superior electrical performance, and strong chemical resistance, this crucible is widely used across various industries. Its applications span the glass processing industry, metallurgical industry, electronic industry, chemical industry, and even aerospace. The crucible is typically available in two primary shapes: square and cylindrical.

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/286851/global-quartz-ceramic-crucible-forecast-market-2025-2032-650

Market Size

The global Quartz Ceramic Crucible market was valued at USD 1294.30 million in 2023 and is projected to grow to USD 1785.10 million by 2032, exhibiting a Compound Annual Growth Rate (CAGR) of 4.70% during the forecast period. This growth is driven by increasing demand from key industries such as the photovoltaic and semiconductor sectors.

In North America, the market size was USD 337.26 million in 2023, with a projected CAGR of 4.03% from 2025 to 2032. The market's expansion is fueled by technological advancements and the growing need for high-performance materials in industrial applications.

Market Dynamics

Drivers

Growing Demand in the Photovoltaic Industry: The rise in solar energy adoption has significantly increased the demand for quartz ceramic crucibles, which are essential in the production of solar cells.

Expansion of the Semiconductor Industry: The semiconductor industry's rapid growth, driven by advancements in electronics and IoT, has boosted the need for high-purity quartz ceramic crucibles.

Technological Advancements: Innovations in material science have enhanced the performance and durability of quartz ceramic crucibles, making them more attractive to various industries.

Restraints

High Production Costs: The manufacturing process of high-purity quartz ceramic crucibles is complex and costly, which can limit market growth.

Availability of Alternatives: The presence of alternative materials, such as graphite crucibles, may hinder the market's expansion.

Opportunities

Emerging Markets: Developing regions, particularly in Asia-Pacific, offer significant growth opportunities due to increasing industrialization and investment in renewable energy.

Research and Development: Ongoing R&D activities aimed at improving the properties and reducing the costs of quartz ceramic crucibles can open new avenues for market growth.

Challenges

Supply Chain Disruptions: The global supply chain challenges, exacerbated by geopolitical tensions and the COVID-19 pandemic, can impact the availability of raw materials.

Environmental Regulations: Stricter environmental regulations regarding the production and disposal of ceramic materials may pose challenges for manufacturers.

Regional Analysis

North America

North America is a significant market for quartz ceramic crucibles, driven by the presence of major semiconductor and photovoltaic industries. The region's market size was USD 337.26 million in 2023, with a projected CAGR of 4.03% from 2025 to 2032.

Europe

Europe is another key market, with countries like Germany, France, and the UK leading the demand. The region's focus on renewable energy and advanced manufacturing technologies supports market growth.

Asia-Pacific

Asia-Pacific is expected to witness the highest growth rate, fueled by rapid industrialization, increasing investments in renewable energy, and the presence of major semiconductor manufacturers in countries like China, Japan, and South Korea.

South America

South America's market is growing steadily, with Brazil and Argentina being the primary contributors. The region's expanding industrial base and increasing focus on renewable energy are driving demand.

Middle East and Africa

The Middle East and Africa region is also experiencing growth, particularly in countries like Saudi Arabia and South Africa, where industrial diversification and investment in new technologies are on the rise.

Competitor Analysis

The global Quartz Ceramic Crucible market is highly competitive, with several key players dominating the landscape. Major companies include:

FerroTec

Saint Gobain

Shin-Etsu Quartz

Momentive Performance Materials

Xuzhou Fenggu Mining

Shengyuan Optical Glass

Nantong Juyi Refractory Technology

Zibo Longtai Cave Industry Technology

Sun Light Quartz Ceramics

Inner Mongolia OJing Science & Technology

Jinzhou Youxin Quartz Technology

Jiangxi Zhongyu New Material Technology

These companies are focusing on strategic initiatives such as mergers and acquisitions, product innovation, and expanding their geographic presence to strengthen their market position.

Global Quartz Ceramic Crucible: Market Segmentation Analysis

This report provides a deep insight into the global Quartz Ceramic Crucible market, covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market size, competitive landscape, development trend, niche market, key market drivers and challenges, SWOT analysis, value chain analysis, etc.

The analysis helps the reader to shape the competition within the industries and strategies for the competitive environment to enhance the potential profit. Furthermore, it provides a simple framework for evaluating and assessing the position of the business organization. The report structure also focuses on the competitive landscape of the Global Quartz Ceramic Crucible market. This report introduces in detail the market share, market performance, product situation, operation situation, etc., of the main players, which helps the readers in the industry to identify the main competitors and deeply understand the competition pattern of the market.

In a word, this report is a must-read for industry players, investors, researchers, consultants, business strategists, and all those who have any kind of stake or are planning to foray into the Quartz Ceramic Crucible market in any manner.

Market Segmentation (by Application)

Photovoltaic Industry

Semiconductor Industry

Others

Market Segmentation (by Type)

SiO2 Content 99.5%

SiO2 Content >99.5%

Key Company

FerroTec

Saint Gobain

Shin-Etsu Quartz

Momentive Performance Materials

Xuzhou Fenggu Mining

Shengyuan Optical Glass

Nantong Juyi Refractory Technology

Zibo Longtai Cave Industry Technology

Sun Light Quartz Ceramics

Inner Mongolia OJing Science & Technology

Jinzhou Youxin Quartz Technology

Jiangxi Zhongyu New Material Technology

Geographic Segmentation

North America (USA, Canada, Mexico)

Europe (Germany, UK, France, Russia, Italy, Rest of Europe)

Asia-Pacific (China, Japan, South Korea, India, Southeast Asia, Rest of Asia-Pacific)

South America (Brazil, Argentina, Columbia, Rest of South America)

The Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, South Africa, Rest of MEA)

FAQ

What is the current market size of Quartz Ceramic Crucible?

The global Quartz Ceramic Crucible market was valued at USD 1294.30 million in 2023 and is projected to reach USD 1785.10 million by 2032.

Which are the key companies operating in the Quartz Ceramic Crucible market?

Key companies include FerroTec, Saint Gobain, Shin-Etsu Quartz, Momentive Performance Materials, and Xuzhou Fenggu Mining, among others.

What are the key growth drivers in the Quartz Ceramic Crucible market?

The key growth drivers include the increasing demand from the photovoltaic and semiconductor industries, technological advancements, and the expansion of emerging markets.

Which regions dominate the Quartz Ceramic Crucible market?

North America, Europe, and Asia-Pacific are the dominant regions, with Asia-Pacific expected to witness the highest growth rate.

What are the emerging trends in the Quartz Ceramic Crucible market?

Emerging trends include the development of high-performance materials, increasing investments in renewable energy, and the expansion of the semiconductor industry.

Key Benefits of This Market Research: • Industry drivers, restraints, and opportunities covered in the study • Neutral perspective on the market performance • Recent industry trends and developments • Competitive landscape & strategies of key players • Potential & niche segments and regions exhibiting promising growth covered • Historical, current, and projected market size, in terms of value • In-depth analysis of the Quartz Ceramic Crucible Market • Overview of the regional outlook of the Quartz Ceramic Crucible Market:

Key Reasons to Buy this Report: • Access to date statistics compiled by our researchers. These provide you with historical and forecast data, which is analyzed to tell you why your market is set to change • This enables you to anticipate market changes to remain ahead of your competitors • You will be able to copy data from the Excel spreadsheet straight into your marketing plans, business presentations, or other strategic documents • The concise analysis, clear graph, and table format will enable you to pinpoint the information you require quickly • Provision of market value (USD Billion) data for each segment and sub-segment • Indicates the region and segment that is expected to witness the fastest growth as well as to dominate the market • Analysis by geography highlighting the consumption of the product/service in the region as well as indicating the factors that are affecting the market within each region • Competitive landscape which incorporates the market ranking of the major players, along with new service/product launches, partnerships, business expansions, and acquisitions in the past five years of companies profiled • Extensive company profiles comprising of company overview, company insights, product benchmarking, and SWOT analysis for the major market players • The current as well as the future market outlook of the industry concerning recent developments which involve growth opportunities and drivers as well as challenges and restraints of both emerging as well as developed regions • Includes in-depth analysis of the market from various perspectives through Porter’s five forces analysis • Provides insight into the market through Value Chain • Market dynamics scenario, along with growth opportunities of the market in the years to come • 6-month post-sales analyst support Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/286851/global-quartz-ceramic-crucible-forecast-market-2025-2032-650

0 notes

Text

3D First Week Videos Notes

Kurt Schwitters popularized collage, he used this technique as an extension of painting. His works are a German approach to the cubist and expressionist movement. However, Schwitters’ never became a direct follower of any movement. His ideals remain on his own experimental use and free to constantly change and be a radical figure in the art world.

Joseph’s Cornell’s work created scenes, narratives, mysteries stories, characters as well as having touches of music and movement. His works would create curiosity among the meaning of art in correlation to life directions. What are these objects speaking to you? What’s the symbolism to a greater, unspoken statements.

Louise Nevelson collected scraps of wood in the streets of NY, which she created large scale sculptures assembling these pieces together. Her sculptures are called assemblages. “A life that surpasses the life which they were originally created.”

A relief refers to a type of sculpture where a figure elevates/ elevates from a flat background/ surface . Low relief, stick out less from the surface and high relief sand out so well it looks torn out of the background.

Clay comes from eroded and weathered granite for millions of years, they are broken down into fine particles that slide into one another, wherefore, forming cay. If clay is compressed for years, it becomes a new stone named “shale” which can be grinned and formed clay again. Clay is composed of layers of alumina, silica and chemically bonded water. Despite all possession these layers, different clays can vary in dosage, which affects the plastic. Other rocks with similar compositions can also be eroded into clay: Gabbro and Basalt. They are all igneous or volcanic rocks, when magma from a volcano cools. In the wild, granite can be composed of quartz and mica, a shiny, flaky rock, which is historically used to create cookware because it can handle rough temperatures.

0 notes

Text

The Versatility of Industrial Fused Quartz Glass in Modern Industries

Industrial fused quartz glass is a highly versatile material that plays a critical role in various industrial applications. Known for its exceptional thermal, mechanical, and chemical properties, this glass is manufactured by melting high-purity silica. Companies like Apex Quartz specialize in delivering premium-quality fused quartz glass tailored to the needs of different industries.

Key Properties of Industrial Fused Quartz Glass

Thermal Stability: Fused quartz glass can withstand extreme temperatures without deforming, making it ideal for high-temperature environments.

Optical Clarity: It offers excellent transparency in ultraviolet, visible, and infrared wavelengths, which is essential for optical and scientific applications.

High Purity: Made from nearly pure silica, fused quartz glass is highly resistant to chemical corrosion and contamination.

Low Thermal Expansion: Its minimal expansion ensures dimensional stability during temperature fluctuations.

Applications of Industrial Fused Quartz Glass

Semiconductor Manufacturing: Used in wafer production, etching, and chemical vapor deposition processes due to its heat resistance and purity.

Lighting and Optics: Ideal for high-intensity lamps, UV sterilizers, and optical lenses.

Laboratory Equipment: Perfect for labware like crucibles, beakers, and reactors that require durability under high temperatures.

Aerospace and Defense: Used in heat shields, radar domes, and high-precision components due to its thermal and mechanical properties.

Why Choose Fused Quartz Glass?

Industrial fused quartz glass is a long-lasting and efficient solution for demanding environments. Its unique properties ensure superior performance, making it indispensable for industries that prioritize quality and reliability.

For tailored solutions and expert guidance on industrial fused quartz glass, visit Apex Quartz and explore their range of innovative products.

0 notes

Text

CFlo Shines at The Mining Show 2024 in Dubai

02 December 2024

We are proud to have participated as Gold Sponsors of The Mining Show 2024, held at the Festival Arena, Dubai, on November 26-27. This premier event, focused on mining in the Middle East, Africa, and South Asia, brought together industry leaders and innovators to explore advancements in mineral exploration, beneficiation, and operational excellence.

Managed by Mayank Arora, Associate Director of Sustainable Initiatives and Ilya Bochkarev, Business Development Manager (Russia), our booth was a vibrant showcase of CFlo’s latest breakthroughs in mineral beneficiation technology, featuring innovative solutions for upgrading low-grade ores of iron, bauxite, phosphate, quartz, limestone, manganese, and chromite. The strong interest from visitors and industry experts highlighted the region’s growing focus on sustainable resource management - an area where CFlo continues to lead.

We were honored to welcome Mr. Nirmal Bathwal, Chairman of Bathwal Corporation, and Mr. Nikunj Bathwal, Managing Director of Power International, to our booth. Engaging discussions around their Combo Mega E5 wash plant - a cutting-edge facility designed for processing silica limestone ore - emphasized the shared vision of maximizing resource recovery and setting new benchmarks in efficiency.

Additionally, we had the privilege of hosting our esteemed customers from Pakistan, Mr. Anwaar Ghani, Managing Director, and Mr. Obaid Ghani, during the event. Their visit underscored the strong partnership we share, and we encourage everyone to check out the Ghani Glass case study on our website to learn more about their success story with CFlo solutions.

A standout moment was the insightful presentation by our Co-Founder and Director of Global Sales, Enda Ivanoff, on “Optimizing Mineral Processing Efficiency through Modular Technology.” His session underscored our commitment to enhancing productivity, scalability, and sustainability, and it resonated strongly with the audience.

Reflecting on CFlo’s participation and growing presence in the Middle East, Manish Bhartia, Promoter and Managing Director, remarked:

"At CFlo, our mission has always been to drive sustainable innovation in resource management. The Mining Show provided a fantastic platform to demonstrate our capabilities, foster collaboration, and reinforce our commitment to helping industries achieve efficiency and sustainability. We’re thrilled by the positive response and look forward to building on these connections to expand our impact globally."

We extend our sincere gratitude to the organizers for creating an exceptional platform for collaboration and knowledge exchange.

Events like these are vital in fostering partnerships and driving progress in the mining sector.

As we look ahead, CFlo remains dedicated to pioneering transformative technologies that shape a sustainable future for the industry.

Thank you, Dubai! We look forward to continuing our journey of innovation and leadership in the region and beyond.

For more information please visit us : https://cfloworld.com/news-events/news/2024/dec/cflo-shines-at-the-mining-show-2024-in-dubai/ .

=========================================

Company Name : CFlo World

Address : Ecospace Business Park Block 4A/Floor 6, Action Area II New Town, Rajarhat Kolkata 700 160, India

Phone: +91 33 3029 3800

Fax: +91 33 3029 3802

Official Email Address: [email protected]

Url : https://cfloworld.com/

0 notes

Text

Sandstone Walling, Slabs, and Steps: A Guide to Using Sandstone in Construction and Landscaping

Sandstone is a material that has been used for construction for centuries. It’s not just a timeless stone; it’s also one of the most durable and versatile materials available for various outdoor and indoor applications. Whether you’re looking to construct a beautiful feature wall, create a functional set of steps, or lay down some paving slabs, sandstone provides a natural, lasting solution. This guide will walk you through the benefits and applications of sandstone walling, slabs, and steps, giving you the information needed to use this stone effectively in your projects.

What is Sandstone?

Before diving into the specific applications of sandstone, it's important to understand what sandstone is. Sandstone is a sedimentary rock primarily made up of sand-sized particles. These particles can be composed of minerals like quartz or feldspar and are bonded together by a variety of natural cementing agents like silica, calcite, or iron oxide. The result is a durable material with a natural, textured appearance that’s perfect for both decorative and structural uses.

Sandstone is widely available in many regions, offering a range of colors from creamy beige to reddish-brown, making it an appealing choice for different design aesthetics.

Why Choose Sandstone for Walling, Slabs, and Steps?

Durability and Strength

One of the main reasons sandstone is so popular for construction is its durability. Sandstone can endure extreme weather conditions, including harsh sunlight, heavy rainfall, and freezing temperatures, without degrading or losing its aesthetic appeal. This makes it an excellent choice for both structural and decorative outdoor applications, from retaining walls to garden steps.

Natural Aesthetic

Sandstone’s naturally occurring colors and textures are another reason why it’s widely used in construction. The warm hues and irregular surfaces create a rustic yet elegant finish that can complement a variety of settings. Whether you are working on a traditional garden wall or a modern landscape design, sandstone can fit in perfectly, bringing a natural beauty to the project.

Low Maintenance

Unlike some materials that require constant cleaning, sealing, or repainting, sandstone is relatively low-maintenance. It doesn’t easily stain or develop moss or algae, making it a good choice for outdoor spaces where you want minimal upkeep. Over time, it develops a natural patina, further enhancing its rustic charm.

Versatility

Sandstone is incredibly versatile, used for everything from walls and steps to slabs and cladding. It can be cut into various shapes and sizes to suit specific needs, whether you’re constructing a retaining wall, creating pathways, or adding steps to your garden.

Sandstone Walling: Strength and Aesthetic Appeal

Benefits of Sandstone Walling

Sandstone walling offers a perfect blend of beauty and functionality. It can be used to build garden walls, retaining walls, or boundary walls, and it offers several key benefits:

Visual Appeal: Sandstone brings warmth and character to any space. Its natural color variations create a dynamic and textured surface that can complement any outdoor design, from contemporary to rustic.

Structural Integrity: Sandstone is a strong material that can withstand significant pressure, which makes it ideal for retaining walls or other structures that need to support weight. It can also be used to create dry-stone walls for landscaping.

Eco-Friendly: As a natural stone, sandstone is an environmentally friendly choice. It’s sourced directly from the earth without the need for complex processing, making it a sustainable building material.

Types of Sandstone Walling

There are a few different ways that you can incorporate sandstone into walling:

Dry-Stone Walling: This technique involves stacking stones without mortar. The stones interlock naturally, and over time, the weight and pressure make the structure more stable. Dry-stone walls are commonly used in gardens and rural landscapes to define boundaries or create terraces.

Mortared Sandstone Walling: For more structural stability, mortared walling involves using a cement-based mortar to bond the stones together. This is typically used for retaining walls or walls that need to bear significant weight. Mortared sandstone walls are also often used in building foundations or in high-traffic areas where extra strength is required.

Cladding: Sandstone can also be used as cladding for buildings, creating a natural stone finish on the exterior. This gives your home or structure a beautiful, rustic appearance while maintaining modern strength and durability.

How to Build Sandstone Walls

Building a sandstone wall requires careful planning and execution to ensure that it is both functional and aesthetically pleasing. Here are some steps to follow when building your own sandstone wall:

Prepare the Site: Clear the area where the wall will be built, removing any debris and ensuring that the ground is level. This is particularly important for dry-stone walls, which rely on stability from the ground.

Foundation: For dry-stone walls, you can lay a foundation of compacted gravel to provide a stable base. For mortared walls, you will need to dig a trench for a concrete foundation, which will ensure the wall has a solid structure.

Placement of Stones: Start by placing the largest stones at the bottom of the wall and gradually work upwards. Make sure that each stone is level and properly aligned with the adjacent stones. If you’re using mortar, apply it between each stone, but avoid excess mortar that could affect the appearance of the wall.

Backfilling: For retaining walls, you will need to backfill the space behind the wall with gravel to allow for proper drainage and reduce pressure on the wall. This is important for maintaining the wall’s integrity over time.

Capping: Once the wall is complete, you can finish the top by placing larger, flatter stones to give it a finished look.

Sandstone Slabs: The Perfect Solution for Paving

Benefits of Sandstone Slabs

Sandstone slabs are an excellent choice for creating pathways, patios, and driveways. Their durability, slip resistance, and natural appearance make them an ideal material for these surfaces.

Durability: Sandstone slabs are highly durable and can withstand the pressure of foot traffic, vehicles, and weathering. They will maintain their integrity over time and provide a long-lasting solution for your outdoor paving needs.

Slip Resistance: The natural texture of sandstone makes it slip-resistant, which is especially important for outdoor areas like walkways, pool decks, or patios where wet conditions may be common.

Natural Look: The variety of colors and textures in sandstone slabs allows them to blend beautifully with natural surroundings. Whether you're designing a formal garden or a casual outdoor space, sandstone slabs can enhance the overall aesthetic of the area.

How to Lay Sandstone Slabs

Laying sandstone slabs is a relatively simple process that requires proper preparation to ensure the finished surface is level, stable, and durable. Here’s how to lay your own sandstone slabs:

Prepare the Site: Excavate the area where the slabs will be laid. Remove any weeds, grass, or debris, and level the ground. For larger areas, it’s recommended to use a compactor to compact the soil and prevent settling.

Create a Base: Lay down a layer of sand or gravel as the base for the slabs. This layer provides drainage and ensures that the slabs are stable and level.

Place the Slabs: Begin laying the slabs, starting from one end and working your way across. Make sure the slabs are level and flush with each other, leaving enough space between each one for jointing material.

Fill the Joints: Once all the slabs are in place, fill the joints with fine sand or a mortar mixture. Sweep the sand into the joints to help lock the slabs into place and prevent weeds from growing.

Sandstone Steps: Enhancing Your Landscape

Benefits of Sandstone Steps

In addition to its use in walls and slabs, sandstone is also an ideal material for steps. Whether you're creating garden steps, a staircase for a pathway, or steps leading to a raised terrace, sandstone steps offer several benefits:

Aesthetic Appeal: Sandstone steps provide a natural and elegant look. The warm tones and smooth surfaces of sandstone make it an attractive choice for landscaping and garden design.

Durability: Sandstone is strong enough to withstand the weight of foot traffic without cracking or wearing down over time. Its ability to endure different weather conditions makes it perfect for outdoor use.

Slip Resistance: Like sandstone slabs, steps made from sandstone offer excellent traction, reducing the risk of slipping, particularly when wet.

How to Build Sandstone Steps

To create durable and beautiful sandstone steps, follow these steps:

Design the Layout: Plan the number of steps and the dimensions based on the height you need to cover. Mark out the area where the steps will be placed.

Excavation: Dig out the area where the steps will go, ensuring that each step has a stable base.

Create a Solid Base: For each step, add a layer of compacted gravel or concrete to provide stability. This foundation will prevent the steps from shifting or settling over time.

Place the Steps: Begin placing the sandstone blocks or slabs one by one. Check each for levelness and adjust as necessary to ensure the steps are evenly spaced and stable.

Finishing Touches: Once the steps are in place, fill in any gaps with sand or mortar to secure the stones and prevent weed growth.

Conclusion

Sandstone is a timeless and durable material that can enhance your landscape with its natural beauty and strength. Whether you’re building a garden wall, laying down slabs for a pathway, or installing steps, sandstone offers a reliable and aesthetic solution. By choosing sandstone, you are not only selecting a material that will stand the test of time

0 notes

Text

Unlocking Industrial Potential with Premium Quartz Granules

The excellent physical and chemical characteristics of quartz granules make them an essential part of many industrial applications. The natural quartz used to make these granules is known for its hardness, durability, and ability to withstand heat and chemicals. Quartz granules are used as a basic raw material in a variety of sectors, including construction, paint, electronics, glassmaking, and ceramics, demonstrating its significance and adaptability.

Comprehending the features, uses, and quality requirements of Supplier of Quartz Granules is crucial if you're looking for a trustworthy source. Reliable quartz granules contribute to cost-effectiveness, durability, and efficiency in industrial processes by guaranteeing the intended performance.

Describe the Quartz Granules.

Granules of quartz are quartz particles that have been graded and treated into different sizes. These granules are extracted from naturally existing quartz deposits and then refined to guarantee uniformity and purity. They are usually divided into different sizes based on the use, such as coarse, medium, and fine granules.

The main component of quartz, silicon dioxide (SiO₂), is what gives it its special qualities. Quartz is an excellent material for industrial usage because of its remarkable durability and abrasion resistance, as evidenced by its Mohs hardness of 7. Its performance in high-temperature environments is further improved by its low coefficient of thermal expansion and high melting point.

Utilizing Quartz Granules

Glass Production

Granules of quartz are a key component used in the making of glass. The creation of transparent and long-lasting glass for windows, bottles, and optical instruments is guaranteed by their high silica content and chemical purity.

Ceramics Sector

Quartz grains serve as a flux in the production of ceramics, assisting in the regulation of the melting point and enhancing the durability and polish of finished goods. They are also utilized in the manufacturing of porcelain, sanitary ware, and tiles.

coatings and paints

Paints and coatings are enhanced with quartz granules because of their superior binding qualities and resilience to weathering and abrasion. Because they improve the coatings' quality and longevity, they can be used both indoors and outdoors.

Electronics Quartz is an important material in the electronics industry because of its piezoelectric qualities. The production of semiconductors, oscillators, and other electronic components uses quartz granules.

Construction Supplies

Quartz grains are utilized in the manufacturing of ornamental aggregates, concrete, and engineered stone. Their strength and beauty make them the perfect material for architectural facades, floors, and countertops.

Properties of Superior Quartz Granules

Authenticity: Because premium quartz granules contain more than 99% silica, they are suitable for a range of industrial procedures.

In applications such as glass and ceramics, uniform particle size and distribution are crucial for obtaining consistent outcomes.

Thermal Stability: When used in applications such as refractory materials, quartz granules should be stable at high temperatures.

Chemical Resistance: The ability of quartz to withstand acids and chemicals guarantees that it will function well in harsh conditions.

Why Opt for a Trustworthy Provider?

To guarantee constant supply and high-quality products, choosing a reliable provider of quartz granules is essential. Reputable suppliers offer tailored solutions and are aware of the unique needs of various industries. Their capacity to deliver quartz grains in large quantities while keeping consistent quality and strict adherence to quality control procedures are essential.

Known for supplying quartz, Pratibha Refractory Minerals

In the market for high-quality quartz granules, Pratibha Refractory Minerals is a reliable source. The company is renowned for its dedication to quality, producing quartz granules that satisfy the most exacting industry standards. Prioritizing client pleasure, Pratibha Refractory Minerals guarantees prompt delivery, affordable prices, and reliable product quality, which makes it a popular option for businesses all over the world.

Final Thoughts

The unparalleled durability, chemical resistance, and thermal stability of quartz granules make them an essential resource for a wide range of industries. Their importance in contemporary industrial processes is highlighted by their applications, which range from electronics to glass making.

0 notes

Text

Examine the Top Powder Choices for Commercial Uses

It's critical to collaborate with suppliers who can provide consistent, superior products that are suited to the requirements of diverse industries when looking for trustworthy quartz powder manufacturers. Because of its exceptional physical qualities, including high hardness, low chemical reactivity, and durability, quartz powder—which is derived from the mineral quartz—is a material that finds extensive use. Consequently, quartz powder finds use in a wide range of industries, such as construction, electronics, glass manufacturing, and ceramics. Because of its many uses, quartz powder is an essential component of many industrial processes.

The naturally occurring mineral quartz is ground into fine particles to make quartz powder. Because these particles are available in a range of sizes, they can be used in a variety of applications. One of the most important ingredients in the ceramics industry is quartz powder, which is used to make porcelain and ceramics. Because of its high hardness, ceramic products are stronger and last longer. Quartz powder is a key ingredient in the glassmaking process that helps create transparent, premium glass. For glass products used in windows, containers, and other applications, it offers the strength, transparency, and smoothness that are necessary.

Concrete, mortar, and grout are all made with quartz powder in the construction sector. These materials are perfect for construction projects that call for strong, long-lasting solutions because of their high silica content, which increases their strength and durability. Additionally, quartz powder is used to enhance the final product's opacity, finish, and surface texture in paint and coating manufacturing. The powder is perfect for a variety of industrial coatings because of its inert nature, which prevents it from reacting chemically with other materials.

Manufacturers of quartz powder are required to make sure their product satisfies industry standards, which frequently entail stringent quality control procedures to ensure consistency and purity. The manufacturing process involves carefully selecting raw materials and using advanced grinding techniques to achieve the desired particle size. Additionally, some producers might provide specially made quartz powder solutions to satisfy particular requirements, like changing the particle size or adding surface treatments to improve functionality.

The consistency of product quality is one of the most crucial factors to consider when selecting a quartz powder manufacturer. Even small variations in quartz powder composition or particle size can affect the performance of the final product in various applications. For businesses that rely on quartz powder in high-performance industries, selecting a manufacturer with a track record of delivering high-quality, consistent products is essential to maintaining operational efficiency and ensuring the durability and quality of the end products.

Reliability in delivery is also crucial for companies that require bulk quantities of quartz powder. Supply delays can affect company operations and cause schedule disruptions for production. Businesses can therefore feel more at ease by working with a manufacturer who is renowned for prompt deliveries and first-rate customer support. Furthermore, maintaining low production costs and guaranteeing the overall profitability of operations depend heavily on competitive pricing.

One of the top brands in the production of quartz powder, Sudarshan Group is renowned for supplying top-notch quartz powder to businesses worldwide. The Sudarshan Group, which places a high priority on innovation and quality, uses cutting-edge facilities and technology to create quartz powder that is tailored to the individual needs of its clients. Their reputation as a reliable supplier for a range of industries, including glass manufacturing, construction, and ceramics, stems from their dedication to quality and customer satisfaction. Sudarshan Group provides products that guarantee the smooth and effective operation of your production processes, regardless of your need for bulk quantities or customised solutions.

In conclusion, it's critical to pick a supplier that provides premium, pure, and finely processed products when looking for quartz powder manufacturers. Choosing a trustworthy manufacturer is essential to guaranteeing consistent performance and product quality, whether you need quartz powder for ceramics, construction, or other industries. Businesses can obtain the best quartz powder available, supported by outstanding customer service and industry knowledge, by collaborating with a respectable manufacturer such as Sudarshan Group. Sudarshan Group's dedication to producing high-quality goods guarantees that your company will prosper in a market that is becoming more and more competitive.

0 notes

Text

Fused Silica Prices Trend | Pricing | News | Database | Chart

Fused silica, a non-crystalline form of silicon dioxide, plays a critical role in a wide range of industries due to its remarkable properties, including high purity, superior thermal stability, low thermal expansion, and excellent transparency in the ultraviolet (UV) to infrared (IR) spectrum. These characteristics make it indispensable in applications such as semiconductor manufacturing, optics, telecommunications, and scientific instrumentation. Over recent years, the prices of fused silica have experienced notable fluctuations, driven by a mix of supply and demand dynamics, raw material costs, geopolitical factors, and advancements in manufacturing technologies. Understanding these market forces provides crucial insights for businesses and investors navigating this complex market landscape.

One of the key factors influencing the pricing of fused silica is its production process, which demands high-purity raw materials and precise manufacturing techniques. Unlike standard glass, fused silica requires a meticulous melting process that minimizes impurities to achieve its exceptional properties. As a result, even minor variations in the cost of high-grade silicon dioxide feedstock can significantly impact the final price of fused silica. Additionally, energy costs play a crucial role, as the high-temperature processes involved in the production of fused silica consume substantial energy. Any increase in energy prices or disruptions in energy supply chains can lead to a direct rise in the cost of production, ultimately reflected in market prices.

Get Real Time Prices for Fused silica: https://www.chemanalyst.com/Pricing-data/fused-silica-1591

Demand for fused silica is largely shaped by the performance of its key end-use sectors. The semiconductor industry, for instance, is a major consumer of high-purity fused silica due to its use in photomasks, lenses, and other critical components of chip manufacturing. With the global semiconductor market experiencing both rapid growth and periods of cyclical demand, any shifts in this sector can lead to corresponding changes in the demand for fused silica. When semiconductor production booms, so does the demand for high-purity materials, often driving up prices. Conversely, a slowdown or inventory correction in the semiconductor sector may exert downward pressure on fused silica prices.

The optics and photonics industries also contribute significantly to the demand for fused silica, as it is used in a wide range of optical components, including lenses, windows, and mirrors. These sectors are driven by technological advancements in laser systems, medical devices, and other optical technologies. As innovations in these fields accelerate, the demand for high-performance materials like fused silica rises, leading to potential price increases. Additionally, fused silica is essential in fiber optic communications, a key enabler of modern telecommunications and high-speed data transfer. The growing deployment of 5G networks and expansion of data centers globally are expected to continue supporting robust demand for fused silica, affecting its price trajectory.

Geopolitical factors and international trade dynamics can also significantly impact fused silica prices. Many countries that produce high-purity silica materials are subject to export controls, tariffs, and trade restrictions. For example, trade tensions between major economies can disrupt supply chains, limiting access to raw materials or driving up production costs due to tariffs and other trade barriers. Any political instability or regulatory changes in key producing regions can lead to market uncertainty and price volatility, influencing the cost and availability of fused silica for global buyers.

On the supply side, the availability of high-quality silicon dioxide feedstock is critical for fused silica production. Natural quartz, the primary source of silicon dioxide, must meet stringent purity requirements to be suitable for high-end applications. Variability in mining conditions, extraction costs, and environmental regulations can all affect the supply of high-purity quartz. In recent years, increased attention to environmental sustainability has prompted stricter regulations on mining practices, potentially raising costs for producers and impacting the price of fused silica in the market. Furthermore, environmental concerns have led to investments in cleaner and more sustainable production methods, which may carry higher initial costs but ultimately contribute to long-term stability and innovation within the industry.

Technological advancements also play a role in shaping fused silica prices. Improvements in production processes, such as precision melting techniques and automated quality control systems, can enhance efficiency and reduce waste, potentially lowering production costs. However, implementing new technologies often requires significant capital investment, which can initially drive prices higher. Over time, as these technologies become more widely adopted, they may contribute to price stabilization and greater consistency in product quality, benefiting both producers and consumers.

In recent years, the global market for fused silica has also been affected by supply chain disruptions, particularly during the COVID-19 pandemic. Lockdowns, labor shortages, and logistical challenges led to delays and increased costs in the production and distribution of high-purity silica materials. Even as economies gradually recover, lingering supply chain issues and fluctuations in demand across various sectors continue to influence market dynamics. Companies have increasingly sought to diversify their supply chains and invest in localized production capabilities to mitigate future risks, which could have long-term implications for pricing trends.

In conclusion, fused silica prices are shaped by a complex interplay of factors, including production costs, demand from key industries, geopolitical influences, and technological advancements. Understanding these dynamics is essential for stakeholders navigating the market, whether as producers, buyers, or investors. As the global economy continues to evolve and new technologies emerge, the fused silica market will likely experience further changes in pricing trends, requiring continuous monitoring and adaptation to stay ahead in this critical sector.

Welcome to ChemAnalyst App: https://www.chemanalyst.com/ChemAnalyst/ChemAnalystApp

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Fused Silica#Fused Silica Prices#Fused Silica Price#Fused Silica News#Fused Silica Monitor#Fused Silica Market

0 notes

Text

Additive Manufacturing Market, Industry Forecast, 2024–2030.

Additive Manufacturing Market Overview:

Sample Report :

Additionally, Increasing focus on metal additive manufacturing technologies. Researchers and companies have been actively working on expanding the range of metals and alloys available for AM. This includes not only traditional metals like titanium, aluminum, and stainless steel but also high-performance alloys for specialized applications. The development of new metal powders suitable for various AM processes has been a focus area. The integration of Additive Manufacturing with traditional manufacturing processes in companies were exploring hybrid manufacturing approaches that combine the strengths of additive and subtractive methods. This integration aimed to leverage the design flexibility of Additive Manufacturing and the efficiency of traditional methods to optimize production workflows. These factors impact the growth in Additive Manufacturing Market.

Market Snapshot:

Additive Manufacturing Market — Report Coverage:

The “Additive Manufacturing Market Report — Forecast (2024–2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Additive Manufacturing Market.

AttributeSegment

By Type

● Materials

● Systems

● Services & Parts

By Material

● Plastics

○ Acrylonitrile Butadiene Styrene (ABS)

○ Polylactic Acid (PLA)

○ Polyethylene (PE)

▪ High-Density Polyethylene (HDPE)

▪ Low-Density Polyethylene (LDPE)

▪ Linear Low-Density Polyethylene (LLDPE)

▪ Others

○ Polycarbonate (PC)

○ Polypropylene (PP)

○ Polyethylene Terephthalate (PETE)

○ Nylon

○ Others

● Metals

○ Iron

○ Steel

○ Silver

○ Aluminum

○ Copper

○ Titanium

○ Gold

○ Zinc

○ Others

● Ceramics

○ Glass

○ Silica

○ Quartz

○ Others

● Others

By Technology

● Powder Bed Fusion

○ Direct Metal Laser Sintering (DMLS)

○ Selective Laser Sintering (SLS)

○ Selective Laser Melting (SLM)

○ Electron Beam Melting (EBM)

○ Others

● Binder Jetting

● Directed Energy Deposition

○ Laser Deposition Technology (LDT) excluding LCT

○ Laser Additive Manufacturing (LAM)

○ Laser Metal Deposition (LMD)

○ Laser Engineering Net Shape (LENS)

○ Laser Cladding Technology (LCT)

○ Electron Beam Additive Manufacturing (EBAM)

○ Wire Arc Additive Manufacturing (WAAM)

○ Laser Deposition Welding (LDW)

○ Others

● Material Extrusion

● Material Jetting

○ Drop On Demand (DOD)

○ Polyjet by Object

○ Others

● Vat Polymerization

○ Stereolithography (SLA)

○ Digital Light Processing (DLP)

○ Continuous Liquid Interface Production (CLIP)

○ Others

● Others

By End-Use Industry

● Industrial

● Aerospace

○ Commercial

○ Military

○ Others

● Consumer Goods

○ Furniture

○ Watches and Jewelry

○ Shoes and Soles

○ Others

● Oil & Gas

● Automotive

○ Passenger Cars

○ Light Commercial Vehicles (LCV)

○ Heavy Commercial Vehicles (HCV)

○ Others

● Medical & Healthcare

● Electrical & Electronics

○ Conductors

○ Resistors

○ Sensors

○ Semiconductors

○ Others

● Building and Construction

○ Residential

○ Commercial

○ Industrial

○ Infrastructure

The COVID-19 pandemic had a mixed impact on the Additive Manufacturing (AM) market. While disruptions in global supply chains initially posed challenges for material sourcing, the flexibility of AM processes proved beneficial in addressing urgent needs for medical equipment and components. The demand for 3D printing surged during the pandemic, with AM technologies being utilized for the rapid production of ventilator parts, face shields, and other critical supplies. The crisis highlighted the agility of AM in responding to unforeseen challenges and increased awareness of its potential across various industries.

Inquiry Before Buying :

The situation in Ukraine had indirect effects on the Additive Manufacturing (AM) market, primarily through broader geopolitical and economic repercussions. Disruptions in supply chains, especially for metals and other raw materials used in AM processes, were potential concerns. Additionally, uncertainties in global markets may have influenced investment decisions and R&D activities in the AM sector. However, the impact varied depending on the resilience of individual companies and their exposure to the geopolitical developments.

Key Takeaways:

North America Dominated the Market

Geographically, in the Additive Manufacturing market share, the North America region has held a dominant market share of 41% in 2023, Rising government investments and projects in the United States for additive manufacturing have also raised the growth of the market. For instance, to address the challenges in single laser melting (SLM), America Makes awarded GE Global $2.6 million to build an open-source, multi-laser production machine and AM platform. Additionally, in Canada, the rising partnership between research universities in the field of additive manufacturing is also influencing the growth of the market. U.S. is anticipated to lead the global additive manufacturing market with the largest installed base for 3d printer in the world. With such a dominant presence of the 3d printers in the country U.S. is likely to contribute more than one third in the revenue generated by additive manufacturing worldwide.

Metal is the Fastest Growing Segment

In the Additive Manufacturing Market forecast, the Metal segment is estimated to grow with a CAGR of 23.5% during the forecast period. Metals are a better option for 3D printing compared to plastics, as they have more industrial usage. Often the 3D metal printing shows itself to be unique as the new technologies can readily surpass what was offered by traditional processes. In AM of metals a powder feedstock or more rarely a wire is fully melted by the energy input of a laser or electron beam and transformed layer by layer into a solid part of nearly any geometry. The most popular processes for AM of metals are Laser Beam Melting (LBM), Electron Beam Melting (EBM) and Laser Metal. In a survey conducted across the globe, about 23% of the 3D printing materials used are metals. The 3D printing metals segment is also poised to grow as it has a competitive edge over other plastic materials used in 3D Printing. Metal 3D printing is too expensive, furthermore other companies, like Desktop Metal and Markforged, are developing approaches to manufacture affordable metal 3D printers.

Schedule A Call :

Aerospace to Hold Largest Market Share