#Liquid Silicone Rubber Market Growth

Explore tagged Tumblr posts

Text

#Liquid Silicone Rubber Market#Liquid Silicone Rubber Market Trends#Liquid Silicone Rubber Market Growth#Liquid Silicone Rubber Market Industry#Liquid Silicone Rubber Market Research#Liquid Silicone Rubber Market Report

0 notes

Text

Data Bridge Market Research analyses that the liquid silicone rubber market will witness a CAGR of 7.81% for the forecast period of 2021-2028. Growing focus of the manufacturers towards new product development, growing use of liquid silicone rubber for a wide range of end use applications such as electrical and electronics, automotive, medical, consumer goods, building and construction, cosmetic applications, aerospace and aeronautics and industrial components and surge in industrialization especially in the developing countries are the major factors attributable to the growth of the liquid silicone rubber market.

#Liquid Silicone Rubber Market#Liquid Silicone Rubber Market Share#Liquid Silicone Rubber Market Size#Liquid Silicone Rubber Market Growth#Liquid Silicone Rubber Market Trends#Liquid Silicone Rubber Market Players#Liquid Silicone Rubber Market Competitors#Liquid Silicone Rubber Industry Size#Liquid Silicone Rubber Industry Trends#Liquid Silicone Rubber Industry Growth#Liquid Silicone Rubber Industry Share#Liquid Silicone Rubber Industry Players

0 notes

Text

0 notes

Text

0 notes

Text

Silicone Elastomers Market Top Manufacturing Industry Revenue Size & Share Outlook

The silicone elastomers market is estimated to grow from USD 8.6 billion in 2024 to USD 12.3 billion by 2029, at a CAGR of 7.4% in terms of value. The rising infrastructure development in developing economies, and aesthetically appealing healthcare devices in the medical industry serve as a significant driver for silicone elastomers market. This scenario presents a unique opportunity for the industry to focus on the development of silicone elastomers, which not only meets consumer demands but also aligns with sustainability goals. However, complex maufacturing process act as restraint, emphasizing the urgent need for eco-friendly alternatives in the silicone elastomers market.

Download PDF Brochure at https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=6310524

Based on type, the silicone elastomers market is segmented as high temperature vulcanized, room temperature vulcanized, and liquid silicone rubber. High temperature vulcanization stands out as the largest segment in terms of value, globally. The dominance of the high-temperature vulcanized (HTV) segment in the silicone elastomers market is attributed to its exceptional heat resistance, rendering it optimal for challenging environments like automotive & transportation, and industrial sectors. High-temperature vulcanized silicone elastomers offer superior thermal stability, flexibility, and durability, driving extensive adoption in high-performance and extreme-temperature applications, thereby consolidating their leadership position in the market. Furthermore, the liquid silicone rubber segment is forecasted to exhibit the highest CAGR in terms of value during the forecast year 2024 and 2029.

Based on process, the silicone elastomers market is segmented as extrusion, liquid injection molding, injection molding, compression molding, and others. Liquid injection molding stands out as the largest segment in terms of value, globally. The Liquid Injection Molding (LIM) process has secured dominance in the silicone elastomers market by offering unparalleled precision and efficiency in manufacturing intricate components. Its capability to produce high-quality, customized products consistently aligns with the stringent demands of industries like healthcare, electrical & electronics, and automotive & transportation, reinforcing its position as the preferred choice and market leader.

Based on end-use industry, the silicone elastomers market has been categorized into various segments including building & construction, foams, automotive & transportation, electrical & electronics, healthcare, consumer goods, and others. Notably, the electrical & electronics segment emerged as the market leader in 2023. The rapid advancements in technology, driving increased demand for smart devices and sustainable energy solutions. The sector's innovation, such as 5G integration, AI applications, and electric vehicles, played a pivotal role. Growing consumer preferences for smart homes and IoT-connected devices further fueled the industry's dominance. Furthermore, the healthcare segment is forecasted to exhibit the highest CAGR in terms of value during the forecast year 2024 and 2029.

Based on region, the silicone elastomers market has been categorized into five regions including North America, Europe, Asia Pacific, Middle East & Africa, and South America. Asia Pacific stands out as the fastest growing market for silicone elastomers in terms of value during the forecast year 2024 and 2029. Asia Pacific 's dominance in the silicone elastomers market has been largely driven by technological innovation. The region is home to research and development centers as well as a bustling startup and innovation community that is concentrated on sustainable solutions. The market for silicone elastomers grew due to the growth in manufacturing industries in the region, leading to a substantial expansion of the silicone elastomers market in the Asia Pacific.

Request For FREE Sample of Report at https://www.marketsandmarkets.com/requestsampleNew.asp?id=6310524

The key players in this market are Dow Inc. (US), Wacker Chemie AG (Germany), Momentive Performance Materials Inc. (US), Shin-Etsu Chemical Co., Ltd. (Japan), China National Bluestar (Group) co. Ltd. (China), Reiss Manufacturing Inc. (US), Mesgo S.p.A (Germany), Cabot Corporation (US), Rogers Corporation (US), and DuPont de Nemours, Inc. (US). They have implemented strategies such as new product launches and acquisitions to enhance their competitors.

#Silicone Elastomers Market#Silicone Elastomers#Silicone Elastomer#Silicone#Elastomers Market#Elastomer#Elastomers

0 notes

Text

Silicone Elastomers Market Innovations in High-Temperature and Flexible Materials

Silicone Elastomers Market Growth Strategic Market Overview and Growth Projections

The global silicone elastomers market size was valued at USD 9.1 billion in 2022 and is projected to reach USD 17.3 billion by 2031, registering a CAGR of 7.4% during the forecast period (2023-2031)

The latest Global Silicone Elastomers Market by straits research provides an in-depth analysis of the Silicone Elastomers Market, including its future growth potential and key factors influencing its trajectory. This comprehensive report explores crucial elements driving market expansion, current challenges, competitive landscapes, and emerging opportunities. It delves into significant trends, competitive strategies, and the role of key industry players shaping the global Silicone Elastomers Market. Additionally, it provides insight into the regulatory environment, market dynamics, and regional performance, offering a holistic view of the global market’s landscape through 2032.

Competitive Landscape

Some of the prominent key players operating in the Silicone Elastomers Market are

China National BlueStar

Dow Corning

KCC Corporation

Momentive Performance Material Inc.

Mesgo S.P.A

Shin-Etsu Chemical Co. Ltd

Reiss Manufacturing

Wacker Chemie

Zhejiang Xinan Chemical

Stockwell Elastomerics

Specialty Silicone Products

Get Free Request Sample Report @ https://straitsresearch.com/report/silicone-elastomers-market/request-sample

The Silicone Elastomers Market Research report delivers comprehensive annual revenue forecasts alongside detailed analysis of sales growth within the market. These projections, developed by seasoned analysts, are grounded in a deep exploration of the latest industry trends. The forecasts offer valuable insights for investors, highlighting key growth opportunities and industry potential. Additionally, the report provides a concise dashboard overview of leading organizations, showcasing their effective marketing strategies, market share, and the most recent advancements in both historical and current market landscapes.Global Silicone Elastomers Market: Segmentation

The Silicone Elastomers Market segmentation divides the market into multiple sub-segments based on product type, application, and geographical region. This segmentation approach enables more precise regional and country-level forecasts, providing deeper insights into market dynamics and potential growth opportunities within each segment.

By Product

High-temperature Vulcanize (HTV)

Room-temperature Vulcanize (RTV)

Liquid Silicone Rubber (LSR)

By Application

Electrical and Electronics

Automotive and Transportation

Industrial Machinery

Consumer Goods

Construction

Others

Stay ahead of the competition with our in-depth analysis of the market trends!

Buy Now @ https://straitsresearch.com/buy-now/silicone-elastomers-market

Market Highlights:

A company's revenue and the applications market are used by market analysts, data analysts, and others in connected industries to assess product values and regional markets.

But not limited to: reports from corporations, international Organization, and governments; market surveys; relevant industry news.

Examining historical market patterns, making predictions for the year 2022, as well as looking forward to 2032, using CAGRs (compound annual growth rates)

Historical and anticipated data on demand, application, pricing, and market share by country are all included in the study, which focuses on major markets such the United States, Europe, and China.

Apart from that, it sheds light on the primary market forces at work as well as the obstacles, opportunities, and threats that suppliers face. In addition, the worldwide market's leading players are profiled, together with their respective market shares.

Goals of the Study

What is the overall size and scope of the Silicone Elastomers Market market?

What are the key trends currently influencing the market landscape?

Who are the primary competitors operating within the Silicone Elastomers Market market?

What are the potential growth opportunities for companies in this market?

What are the major challenges or obstacles the market is currently facing?

What demographic segments are primarily targeted in the Silicone Elastomers Market market?

What are the prevailing consumer preferences and behaviors within this market?

What are the key market segments, and how do they contribute to the overall market share?

What are the future growth projections for the Silicone Elastomers Market market over the next several years?

How do regulatory and legal frameworks influence the market?

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Silicone Elastomers Market Market#Silicone Elastomers Market Market Share#Silicone Elastomers Market Market Size#Silicone Elastomers Market Market Research#Silicone Elastomers Market Industry#What is Silicone Elastomers Market?

0 notes

Text

0 notes

Text

Liquid Silicone Rubber Market to Hit $4.60 Billion by 2032

The global Liquid Silicone Rubber Market was valued at USD 2.19 Billion in 2024 and it is estimated to garner USD 4.60 Billion by 2032 with a registered CAGR of 9.7% during the forecast period 2024 to 2032.

Are you looking for the Liquid Silicone Rubber Market Research Report? You are at the right place. If you desire to find out more data about the report or want customization, Contact us. If you want any unique requirements, please allow us to customize and we will offer you the report as you want.

The global Liquid Silicone Rubber Market can be segmented on the basis of product type, Applications, distribution channel, market value, volume, and region [North America, Europe, Asia Pacific, Latin America, Middle East, and Africa]. The Liquid Silicone Rubber Industry 2024 report provides a comprehensive overview of critical elements of the industry including drivers, restraints, and management scenarios.

Download Sample PDF: @ https://www.vantagemarketresearch.com/liquid-silicone-rubber-market-1211/request-sample

Top Players

Dow Corning, Momentive Performance Materials Inc., KCC Corporation, Simtec Silicone Parts, LLC, Bluestar, Stockwell Elastomerics Inc., Zhejiang Xinan Chemical Industrial Group Co., Ltd., Shin-Etsu Chemical Co., Ltd., Wacker Chemie AG, Nusil Technology LLC, Laur Silicone.

Trending 2024: Liquid Silicone Rubber Market Report Highlights:

A comprehensive assessment of the parent Industry

Development of key aspects of the business

A study of industry-wide market segments

Evaluation of market value and volume in past, present, and future years

Evaluation of market share

Tactical approaches of market leaders

Innovative strategies that help companies to improve their position in the market

You Can Buy This Report From Here: https://www.vantagemarketresearch.com/buy-now/liquid-silicone-rubber-market-1211/0

Analysis Of The Top Companies, Product Types, and Applications In The Market Report:

This report provides sales, revenue growth rate, and verified information about the major players. Also includes a regional analysis and a labor cost analysis, tables, and figures. It also highlights characteristics such as technological growth. The product type segment is expected to continue to maintain its leading position in the future and capture a significant market share based on sales. This report provides analysis, discussion, forecast, and debate on key industry trends, market share estimates, Industry size, and other information. This report also discusses drivers, risks, and opportunities.

Global Liquid Silicone Rubber Market report contains detailed data and analysis on the Liquid Silicone Rubber Market drivers, restraints, and opportunities. Experts with market and industry knowledge as well as research experience from regional experts validate the report. The Liquid Silicone Rubber Market report provides forecast, historical and current revenue for each industry, region, and end-user segment.

Regions Included

-North America [United States, Canada, Mexico]

-South America [Brazil, Argentina, Columbia, Chile, Peru]

-Europe [Germany, UK, France, Italy, Russia, Spain, Netherlands, Turkey, Switzerland]

-Middle East & Africa [GCC, North Africa, South Africa]

-Asia-Pacific [China, Southeast Asia, India, Japan, Korea, Western Asia]

Global Liquid Silicone Rubber Market report data will help you make more informed decisions. For example, in relation to prices, distribution channels are means of marketing or identifying opportunities to introduce a new product or service. These results will also help you make more informed decisions about your existing operations and activities.

Read Full Research Report with [TOC] @ https://www.vantagemarketresearch.com/industry-report/liquid-silicone-rubber-market-1211

You Can Use The Liquid Silicone Rubber Market Report To Answer The Following Questions:

What are the growth prospects of the Liquid Silicone Rubber Market business?

Who are the key manufacturers in the Liquid Silicone Rubber Market space?

What Forecast Period for Global Liquid Silicone Rubber Industry Report?

What are the main segments of the global Liquid Silicone Rubber Market?

What are the key metrics like opportunities and market drivers?

The Liquid Silicone Rubber Market Insights

Product Development/Innovation: Detailed Information On Upcoming Technologies, R&D Activities, And Product Launches In The Market.

Competitive Assessment: In-Depth Assessment Of Market Strategies, Geographic And Business Segments Of Key Market Players.

Market Development: Comprehensive Information On Emerging Markets. This Report Analyzes The Market For Different Segments In Different Regions.

Market Diversification: Comprehensive Information On New Products, Untapped Regions, Latest Developments, And Investments In The Liquid Silicone Rubber Market.

Check Out More Reports

Global Biosimilars Market : Report Forecast by 2032

Global Bio-Adhesives Market: Report Forecast by 2032

Global Marché des aligneurs clairs: Report Forecast by 2032

Global Zero Emission Vehicle (ZEV) Market: Report Forecast by 2032

Global Tactical Data Link Market: Report Forecast by 2032

#Liquid Silicone Rubber Market#Liquid Silicone Rubber Market 2024#Global Liquid Silicone Rubber Market#Liquid Silicone Rubber Market outlook#Liquid Silicone Rubber Market Trend#Liquid Silicone Rubber Market Size & Share#Liquid Silicone Rubber Market Forecast#Liquid Silicone Rubber Market Demand#Liquid Silicone Rubber Market sales & price

0 notes

Text

Silicone Elastomers Market Trends: Growth, Drivers, and Opportunities Through 2024-2034

Silicone Elastomers Market Trends are witnessing robust growth due to their wide range of applications in industries such as automotive, healthcare, and electronics. The Silicone Elastomers Market is experiencing a rising demand, thanks to their durability and flexibility.

The silicone elastomers market trends is expected to grow from $7.41 billion in 2023 to $13.94 billion by 2034, representing a compound annual growth rate (CAGR) of 5.94% during the 2024-2034 forecast period.

Request a free sample report of the Silicone Elastomers Market Trends

Market Growth

The growth of the silicone elastomers market is primarily driven by the rising demand for high-performance materials across various industries, including automotive and healthcare. In the automotive sector, silicone elastomers are favored for their durability, temperature resistance, and flexibility, enhancing vehicle performance and safety. Meanwhile, in healthcare, these materials are essential for medical devices and applications due to their biocompatibility and resistance to sterilization processes. Additionally, the growing emphasis on sustainable and eco-friendly materials is further propelling the adoption of silicone elastomers, positioning them as a key component in innovative product development across diverse sectors.

Download Complete TOC of the Silicone Elastomers Market

Key Technologies

Liquid Silicone Rubber (LSR): Known for its flexibility and strength, LSR is widely used in medical devices and automotive parts.

High-Temperature Vulcanized (HTV) Elastomers: These are used in applications requiring high heat resistance, such as in engine components.

Room-Temperature Vulcanized (RTV) Elastomers: Commonly used in construction and sealing applications, RTV elastomers are easy to process and apply.

Get more market insights on Advanced materials chemicals

Demand Drivers

Automotive Industry Growth: The rising demand for lightweight, durable materials in automotive manufacturing is driving demand for Silicone Elastomers Market solutions.

Medical Devices: The healthcare industry is increasingly using silicone elastomers due to their biocompatibility and flexibility.

Electronics: The growing electronics industry is adopting silicone elastomers for their insulation properties.

Building and Construction End-Use Industry Application to Lead the Market

The building and construction sector is set to dominate the market, driven by the versatile applications and superior properties of silicone elastomers. Valued for their flexibility, durability, and resistance to extreme temperatures, these materials are essential for sealing, glazing, and insulation in residential and commercial projects. The emphasis on sustainable construction and green building standards further boosts demand, as silicone elastomers are non-toxic and environmentally friendly. With stricter building regulations and a focus on energy efficiency, the use of silicone elastomers is expected to rise significantly, fueling market growth in the coming years.

Key Market Players

• Dow • Wacker Chemie AG • Momentive Performance Materials • Shin-Etsu Chemical Co., Ltd. • China National Bluestar (Group) Co., Ltd. • Rogers Corporation • Cabot Corporation • Reiss Manufacturing Inc. • MESGO S.p.A. • CHT Germany GmbH • Bellofram Elastomers • Specialty Silicone Products, Inc. • DuPont • Avantor, Inc. • Wynca Group (Zhejiang Xin'an Chemical Group Co., Ltd.)

Conclusion

Silicone Elastomers Market Trends are set for significant growth, driven by innovations in material technology and rising demand from key industries. The Silicone Elastomers Market trends will continue to shape the future of this market.

BIS Research, recognized as a best market research company, provides premium market intelligence reports on deep technologies poised to cause significant market disruption in the coming years.

At BIS Research, we focus exclusively on technologies related to precision medicine, medical devices, diagnostics, life sciences, artificial intelligence (AI), machine learning (ML), Internet of Things (IoT), big data analysis, blockchain technology, 3D printing, advanced materials and chemicals, agriculture and FoodTech, mobility, robotics and UAVs, and aerospace and defense, among others

0 notes

Text

0 notes

Text

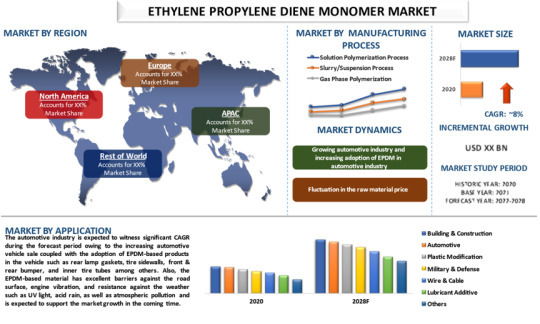

Ethylene Propylene Diene Monomer (EPDM) Market: Current Analysis and Forecast (2022-2028)

According to a new report published by UnivDatos Markets Insights, the Ethylene Propylene Diene Monomer (EPDM) Market is expected to grow at a CAGR of around 8% from 2022-2028. The analysis has been segmented into Manufacturing Process (Solution Polymerization Process, Slurry/Suspension Process, and Gas Phase Polymerization); Application (Building & Construction, Automotive, Plastic Modification, Military & Defense, Wire & Cable, Lubricant Additive, and Others); Region/Country.

The Ethylene Propylene Diene Monomer (EPDM) market report has been aggregated by collecting informative data on various dynamics such as market drivers, restraints, and opportunities. This innovative report makes use of several analyses to get a closer outlook on the Ethylene Propylene Diene Monomer (EPDM) market. The Ethylene Propylene Diene Monomer (EPDM) market report offers a detailed analysis of the latest industry developments and trending factors in the market that are influencing the market growth. Furthermore, this statistical market research repository examines and estimates the Ethylene Propylene Diene Monomer (EPDM) market at the global and regional levels.

Market Overview

Ethylene Propylene Diene Monomer (EPDM) is a synthetic material obtained from natural gas and thermal cracking petroleum products such as naphtha. EPDM is widely used in low-slope buildings, automotive applications, and construction applications due to their longer durability and superior resistance to environmental factors such as UV, ozone, and other weather condition. In recent times, the EPDM witnessed significant demand due to its increasing demand from the automotive industry, manufacturing & construction industry attributed to its lower cost, higher moldability, and longer durability. Also, the EPDM could be used as an alternative to silicon rubber and could also be incorporated in the hose, O-ring, accumulator bladder, diaphragms, and connectors for wire & cables among many other applications on the account of their higher resistance towards tearing, abrasive, solvent, and temperature.

Factors such as technological advancement coupled with the growing number of industries and manufacturing units along with the new product launches in the market are some of the prominent factors that are positively influencing the market growth globally.

Some of the major players operating in the market include DowDuPont Inc., Exxon Mobil Corporation, Lion Elastomers, Johns Manville, SK Global Chemical Co. Ltd, Lanxess AG, Mitsui Chemical Inc., PetroChina Company Limited, Kumho Polychem, and Versalis S.p.A.

COVID-19 Impact

The recent covid-19 pandemic has disrupted the world and has brought a state of shock to the global economy. The global pandemic has impacted the manufacturing industry along with supply chain disruption, regulatory and policy changes, labor reliance, working capital management, and liquidity & solvency management. The Ethylene Propylene Diene Monomer (EPDM) market has been significantly affected during these times owing to the gap between supply and demand.

The global Ethylene Propylene Diene Monomer (EPDM) market report is studied thoroughly with several aspects that would help stakeholders in making their decisions more curated.

Based on application, the market is segmented into building & construction, automotive, plastic modification, military & defense, wire & cable, lubricant additive, and others. The automotive industry is expected to witness significant CAGR during the forecast period owing to the increasing automotive vehicle sale coupled with the adoption of EPDM-based products in the vehicle such as rear lamp gaskets, tire sidewalls, front & rear bumper, and inner tire tubes among others. Also, the EPDM-based material has excellent barriers against the road surface, engine vibration, and resistance against the weather such as UV light, acid rain, as well as atmospheric pollution and is expected to support the market growth in the coming time.

Based on the manufacturing process, the market is segmented into solution polymerization process, slurry/suspension process, and gas phase polymerization. The solution polymerization segment is expected to witness significant growth during the forecast period due to the higher concentration and lower required amount for the optimized performance. Additionally, solution polymerization is used to manufacture both crystalline and amorphous polymer grades and is expected to support market growth.

Ethylene Propylene Diene Monomer (EPDM) Market Geographical Segmentation Includes:

North America (United States, Canada, and Rest of North America)

Europe (Germany, United Kingdom, Spain, Italy, France, and the Rest of Europe)

Asia-Pacific (China, Japan, India, and the Rest of Asia-Pacific)

Rest of the World

Asia-Pacific is anticipated to grow at a substantial CAGR during the forecast period. This is mainly due to the rapid industrialization and growing automotive industries along with the electronic & electrical industry, consumer goods industry, and medical sector in the region. Also, the ongoing infrastructural projects and increasing disposable income of the individual are expected to support market growth in the coming time. Furthermore, EPDM has also been used as a substitute for thermoplastic olefins and thermoplastic vulcanizate in the manufacturing industry. Also, the lower cost of the raw material coupled with the lower cost of production associated with the lower labor cost propels the market for the EPDM. Moreover, the growing research & development activities, increasing investment, and technological investment are expected to derive the market in the coming time. For instance, in March 2022, Arlanxeo a Netherland-based firm announced to increase in its production capacity by 15% for its EPDM plant based in Changzhou, China.

The major players targeting the market include:

DowDuPont Inc.

Exxon Mobil Corporation

Lion Elastomers

Johns Manville

SK Global Chemical Co. Ltd

Lanxess AG

Mitsui Chemical Inc.

PetroChina Company Limited

Kumho Polychem

Versalis S.p.A.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=31683

Competitive Landscape

The degree of competition among prominent global companies has been elaborated by analyzing several leading key players operating worldwide. The specialist team of research analysts sheds light on various traits such as global market competition, market share, most recent industry advancements, innovative product launches, partnerships, mergers, or acquisitions by leading companies in the Ethylene Propylene Diene Monomer (EPDM) market. The major players have been analyzed by using research methodologies for getting insight views on global competition.

Key questions resolved through this analytical market research report include:

• What are the latest trends, new patterns, and technological advancements in the Ethylene Propylene Diene Monomer (EPDM) market?

• Which factors are influencing the Ethylene Propylene Diene Monomer (EPDM) market over the forecast period?

• What are the global challenges, threats, and risks in the Ethylene Propylene Diene Monomer (EPDM) market?

• Which factors are propelling and restraining the Ethylene Propylene Diene Monomer (EPDM) market?

• What are the demanding global regions of the Ethylene Propylene Diene Monomer (EPDM) market?

• What will be the global market size in the upcoming years?

• What are the crucial market acquisition strategies and policies applied by global companies?

We understand the requirement of different businesses, regions, and countries, we offer customized reports as per your requirements of business nature and geography. Please let us know If you have any custom needs.

Browse Related Newsletter from UnivDatos Market Insights

Titanium Dioxide Market - SWOT Analysis [2023-2028]

Recycled Carbon Fiber Market - SWOT Analysis [2023-2028]

About Us:

UnivDatos Market Insights: Your Partner in Data-Driven Market Strategies. Unlock growth opportunities and make smart decisions with our expert research and insights.

Contact us:

UnivDatos Market Insights (UMI)

Email: [email protected]

Web: https://univdatos.com

LinkedIn: www.linkedin.com/company/univ-datos-market-insight/

Ph: +91 7838604911

0 notes

Text

US Silicone Market: Growth Trajectory, Technological Innovations, Sustainability Initiatives, and Market Dynamics from 2023 to 2032

In 2023, the US silicone market reached a significant valuation of approximately $4.07 billion, highlighting its pivotal role across diverse industries. This versatile market segment is poised for robust growth, with projections indicating a steady compound annual growth rate (CAGR) of 4.9% from 2024 to 2032. By the end of this forecast period, the market is anticipated to expand to USD 6.26 billion, driven by technological advancements, expanding applications, and evolving consumer preferences for high-performance materials.

Versatility and Applications

Silicones are synthetic compounds derived from silicon, oxygen, and other elements, known for their exceptional versatility and performance characteristics. They exhibit properties such as heat resistance, stability across a wide temperature range, water repellency, and electrical insulation, making them indispensable in various industries. The US silicone market caters to applications in construction, automotive, electronics, healthcare, personal care, and industrial manufacturing sectors, among others.

Key Drivers of Market Growth

Several factors contribute to the growth of the US silicone market. In the construction industry, silicones are utilized in sealants, adhesives, and coatings for enhancing building durability, weather resistance, and energy efficiency. The automotive sector relies on silicones for gaskets, lubricants, and automotive fluids, contributing to improved vehicle performance and longevity. In electronics, silicones play a crucial role in protecting electronic components from moisture, heat, and mechanical stress, ensuring reliability and longevity of devices.

Moreover, the healthcare and personal care industries leverage silicones in medical implants, prosthetics, skincare products, and pharmaceutical formulations due to their biocompatibility and hypoallergenic properties. Industrial applications such as mold making, textile coatings, and aerospace adhesives further drive demand for silicones, highlighting their broad applicability and indispensable role in modern manufacturing processes.

Technological Advancements and Innovation

Continuous innovation in silicone technology enhances product performance and expands application possibilities. Manufacturers invest in research and development to develop advanced formulations that meet stringent performance standards and regulatory requirements. Innovations include high-temperature resistant silicones, self-healing materials, silicone-based 3D printing resins, and eco-friendly formulations that reduce environmental impact.

Furthermore, advancements in processing techniques such as liquid silicone rubber (LSR) molding and hybrid silicone technologies enable customization, precision molding, and integration of silicones into complex manufacturing processes. These technological advancements not only improve product durability and efficiency but also support sustainable practices by reducing waste and enhancing resource utilization throughout the silicone product lifecycle.

Market Segmentation and Regional Dynamics

The US silicone market is segmented based on product types such as elastomers, fluids, resins, gels, and other specialty silicones. Elastomers, including LSR and high consistency rubber (HCR), dominate the market due to their flexibility, durability, and resistance to extreme temperatures and environmental conditions. Fluid silicones find extensive use in lubricants, release agents, and cosmetic formulations, benefiting from their low surface tension and non-toxic properties.

Geographically, key regions driving market growth include technology hubs in California, industrial centers in the Midwest, and healthcare and consumer product markets on the East Coast. Regional manufacturing capabilities, infrastructure investments, and strategic partnerships with end-users contribute to market expansion and innovation in silicone-based solutions across various sectors.

Sustainability and Regulatory Landscape

The US silicone industry is committed to sustainability initiatives, focusing on reducing carbon footprint, enhancing energy efficiency, and promoting recyclability of silicone products. Manufacturers adhere to stringent regulatory frameworks such as REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and FDA (Food and Drug Administration) guidelines to ensure product safety, environmental stewardship, and compliance with health and safety standards.

Efforts to develop bio-based silicones and eco-friendly alternatives further underscore industry commitment to sustainable innovation. Collaborations with academic institutions, research organizations, and government agencies support advancements in sustainable chemistry, circular economy practices, and lifecycle assessments, driving the evolution of silicone materials towards greater environmental responsibility and resource efficiency.

Market Expansion and Emerging Applications

The US silicone market is expanding its footprint across emerging applications and niche sectors. Silicone-based materials are increasingly used in renewable energy technologies such as solar panels and wind turbines, where they provide encapsulation, insulation, and protection against environmental elements. The growing demand for energy-efficient buildings and sustainable infrastructure drives the adoption of silicone sealants, coatings, and thermal insulating materials, supporting efforts to reduce carbon emissions and enhance energy conservation.

Moreover, silicone elastomers and adhesives are integral to advanced manufacturing processes in industries such as aerospace, where they offer lightweight, high-performance solutions for aerospace components, seals, and gaskets. Silicone's ability to withstand extreme temperatures and harsh environmental conditions positions it as a preferred material in demanding applications, including automotive under-the-hood components, marine coatings, and medical devices.

Consumer Trends and Product Innovation

Consumer preferences for eco-friendly and health-conscious products are influencing product innovation within the US silicone market. Manufacturers are responding with silicone formulations that are free from volatile organic compounds (VOCs), phthalates, and other harmful chemicals, aligning with regulatory requirements and consumer expectations for safer, sustainable materials. Silicone-based personal care products, including skincare formulations, hair care treatments, and cosmetic enhancements, capitalize on silicone's sensory attributes, emollient properties, and biocompatibility, catering to discerning consumers seeking effective and luxurious products.

Furthermore, advancements in silicone-based 3D printing materials and additive manufacturing techniques offer opportunities for customized product development and rapid prototyping across diverse industries. Silicones' inherent flexibility, durability, and compatibility with complex geometries enable innovative design solutions and functional prototypes, driving efficiency and creativity in product development cycles.

Future Outlook and Strategic Imperatives

Looking ahead, the US silicone market is poised for continued growth driven by technological innovation, expanding applications, and sustainable development initiatives. Key strategic imperatives include fostering industry collaboration, enhancing product differentiation through advanced formulations, and leveraging digitalization and smart technologies for operational efficiency and customer engagement.

By embracing these opportunities and addressing challenges such as raw material costs, supply chain disruptions, and regulatory complexities, stakeholders in the US silicone market can navigate the evolving landscape and capitalize on emerging trends to sustain growth, innovation, and competitiveness in the global marketplace.

0 notes

Text

Silicone Elastomers Market Projected to Reach $15.1 Billion by 2031

Meticulous Research®—a leading global market research company, published a research report titled, ‘Silicone Elastomers Market by Type (Liquid Silicone Rubber (LSR), High-temperature Vulcanize (HTV)), Process (Extrusion, Molding), End-use Industry (Automotive, Healthcare, Electrical & Electronics, Construction), and Geography - Global Forecast to 2031.’

According to the latest report from Meticulous Research®, the silicone elastomers market is projected to reach $15.1 billion by 2031, with a compound annual growth rate (CAGR) of 7.9% from 2024 to 2031. This growth is driven by the increasing application of silicone elastomers in medical devices, advancements in material science, and high demand in the electrical and electronics sectors. However, environmental concerns, sustainability issues, and stagnant growth in developed countries pose challenges to market expansion.

Market growth opportunities are anticipated through the integration of silicone elastomers with IoT devices and their rising use in the automotive industry. Nonetheless, fluctuations in raw material prices remain a significant challenge.

The silicone elastomers market is segmented by type, process, and end-use industry. Types include room-temperature vulcanize (RTV), liquid silicone rubber (LSR), and high-temperature vulcanize (HTV). In 2024, HTV is expected to hold the largest market share of over 52%, driven by advancements in manufacturing technologies and its extensive use in high-temperature applications in the automotive and electronics industries. The LSR segment is projected to experience the highest CAGR due to innovations in material science and increasing demand for high-volume production in the automotive and healthcare sectors.

By process, the market is divided into extrusion, molding, calendering, and others. The molding process segment is anticipated to account for the largest share of over 45% in 2024, driven by the demand for LSR injection molding for complex parts and advancements in molding technologies. This segment is also expected to register the highest CAGR during the forecast period.

In terms of end-use industry, the market is segmented into automotive, aviation & aerospace, consumer goods, electrical & electronics, healthcare, energy, industrial machinery, construction, and others. The electrical & electronics segment is expected to hold the largest share of over 35% in 2024, due to the increasing use of silicone elastomers in components like power supplies and circuit boards. The healthcare segment is projected to grow at the highest CAGR, driven by the demand for biocompatible materials and silicone elastomers in medical devices and implants.

Geographically, the silicone elastomers market is divided into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Asia-Pacific is expected to dominate with a share of over 53% in 2024, driven by rapid economic development, particularly in China and India, and the growing healthcare and construction industries. This region is also projected to register the highest CAGR of over 9% during the forecast period.

Key players in the silicone elastomers market include Momentive Performance Materials, Inc. (U.S.), China National Bluestar (Group) Co., Ltd. (China), The Dow Chemical Company (U.S.), Shin-Etsu Chemical Co., Ltd. (Japan), Wacker Chemie AG (Germany), DuPont de Nemours, Inc. (U.S.), among others.

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5844

Key Questions Answered in the Report:

What are the high-growth market segments in terms of the type, process, and end-use industry?

What is the historical market size for the silicone elastomers market?

What are the market forecasts and estimates for 2024–2031?

What are the major drivers, restraints, opportunities, challenges, and trends in the silicone elastomers market?

Who are the major players in the silicone elastomers market, and what are their market shares?

What is the competitive landscape like?

What are the recent developments in the silicone elastomers market?

What are the different strategies adopted by major market players?

What are the trends and high-growth countries?

Who are the local emerging players in the silicone elastomers market, and how do they compete with other players?

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Silicone Elastomers Market#Silicone Rubber#Silicone Injection Molding#Liquid Silicone Rubber#Silicone Rubber for Medical Devices

0 notes

Text

Data Center Distribution Transformer Market by Three Phase: Details Inside

According to the United States International Trade Commission, the global count of physical data centers reached approximately 8,000 by 2021. This growth aligns with the continuous technological strides and expansion of services within data centers. The surge in IT investments reflects the drive to streamline operations and bolster data storage capabilities. Concurrently, the escalating demand for electricity, coupled with strategically supportive policies aimed at fortifying existing grid infrastructures, has contributed to the sustained expansion of the data center distribution transformer market.

Based on the global scenario, the market for data center distribution transformer was valued at $6766.22 million in 2022 and is expected to reach $10797.49 million by 2030, progressing at a CAGR of 6.16% during the forecast period 2023-2030.

Insights into the latest Phase Type Technologies

Single-phase:

Using single-phase distribution transformers for data centers is a strategic move that meets the evolving needs of modern data centers. These transformers are central to data center power distribution because they efficiently convert and distribute electrical power.

Manufacturers specializing in single-phase transformers have responded to the needs of the data center by developing innovative solutions. Companies such as Schneider Electric SE, Eaton Corporation Plc, Hitachi ABB Power Grids, and Siemens AG are known for their expertise in manufacturing high-quality single-phase transformers for data centers. By integrating these transformers, data centers can optimize their power systems, improve energy efficiency, and ensure a reliable power supply for critical IT equipment.

Three-phase:

With rising energy demands and swift tech progress, ultra-large-capacity three-phase transformers are now pivotal, reshaping power distribution. Established leaders such as Siemens AG, ABB Ltd, etc., recognized the need for high-voltage, high-power transformers to expand power transmission grids. Data center distribution transformer manufacturers have made significant strides in innovating materials, design, and digital control systems to meet demand. ABB has implemented advanced cooling techniques using innovative materials such as liquid silicone rubber (LSR) insulation. These advances have improved transformers’ efficiency, reliability, and performance in modern power systems.

As Triton’s analysis indicates, the data center distribution transformer market by three-phase is expected to advance at the fastest CAGR of 6.22% over the projected years 2023-2030.

Impact of Sustainability Trend on Phase Change Solutions

1. Integration of Renewable Energy Sources:

One of the key trends revolutionizing data center power distribution is the integration of renewable energy sources. Solar, wind, and hydropower offer important solutions to environmental problems associated with fossil fuels.

Data centers consume a lot of energy and contribute significantly to global electricity consumption. Recent statistics underscore the rapid adoption of renewable energy in data centers. According to a report from the Solar Energy Industries Association (SEIA), the installation of solar panels on data center rooftops has increased by 10% in the past year alone. Tech giants like Google and Microsoft have committed to powering their data centers with 100% renewable energy, highlighting the sector’s push toward sustainability.

2. Impact on Transformer Phase Type:

Integrating renewable energy sources has profound implications for various aspects of data center design and requires reevaluating transformer phase configurations. Because renewable energy sources bring irregular power generation, transformer phase configurations must be carefully considered. This is critical for a seamless and reliable power supply that harmonizes with the variable output of renewable energy sources.

Companies that power their data centers with renewable energy have been able to reduce their operating costs by about 40%, according to a report by Forbes. This burgeoning trend is not just changing business management but also shaping the landscape of renewable energy Power Purchase Agreements (PPA), in which the data center sector is actively involved. Notable examples include Amazon and Microsoft, which signed renewable power contracts in 2021 PPA.

The rise of renewable energy is reshaping the distribution transformer market dynamics in the North American region. The regional market claims a dominant share of over 40% due to increased reliance on renewables in power generation. Demand for energy-efficient infrastructure drives the North America data center distribution transformer market and is projected to evolve with a CAGR of 35.25% in the studied years.

Conclusion

In the ever-evolving data center landscape, the expansion of distribution transformers stands out prominently. The rapid global spread of data centers, surging power requisites, and calculated incorporation of renewable energy have collectively revolutionized the global data center distribution transformer market. Single-phase transformers optimize rural distribution efficiency, while their three-phase counterparts spearhead cutting-edge power infrastructure, shaping an efficient and sustainable energy paradigm for the future.

FAQs:

Q1) Which segments are studied in the market?

The segments reviewed in the market include by Phase type (single-phase and three-phase), insulation (oil immersed and dry type), voltage range (below 650 kVA, 650-1250 kVA, 1250-2500 kVA, and above 2500 kVA), and distribution channel (OEMs, market distributors, online retailers, and electrical contractor).

Q2): What geographies are studied in the data center distribution transformer market?

Latin America, Europe, North America, Asia-Pacific, Middle East & Africa.

0 notes

Text

0 notes

Text

0 notes