#Lightweight Automotive Parts market

Explore tagged Tumblr posts

Text

PET Sheets Manufacturer & Supplier for Industries Worldwide: Lyka Global Plast

In today's industrial landscape, the demand for high-quality and versatile materials is ever-increasing. One such material that has gained significant prominence is PET (Polyethylene Terephthalate) sheets. Renowned for their exceptional properties, PET sheets are indispensable across various industries. Lyka Global Plast stands out as a leading manufacturer and supplier of PET sheets, serving industries worldwide with unwavering commitment to quality and innovation.

Understanding PET Sheets

Polyethylene Terephthalate (PET) is a thermoplastic polymer resin of the polyester family, extensively used in manufacturing sheets due to its unique combination of properties. PET sheets are known for their excellent mechanical strength, chemical resistance, and clarity. These sheets are lightweight, durable, and highly versatile, making them ideal for a wide range of applications.

Why Choose Lyka Global Plast for PET Sheets?

1. Quality Assurance

At Lyka Global Plast, quality is not just a promise; it is a commitment. Our PET sheets undergo rigorous quality control processes to ensure they meet the highest industry standards. From raw material selection to the final product, every step is meticulously monitored to deliver sheets that exhibit superior performance and longevity.

2. State-of-the-Art Manufacturing Facilities

Equipped with advanced manufacturing facilities, Lyka Global Plast leverages cutting-edge technology to produce PET sheets of unparalleled quality. Our state-of-the-art machinery and skilled workforce enable us to cater to diverse industrial needs with precision and efficiency.

3. Wide Range of Applications

PET sheets from Lyka Global Plast find applications across a multitude of industries. Whether it's packaging, automotive, electronics, construction, or signage, our PET sheets are designed to meet the specific requirements of each sector. Their exceptional clarity and chemical resistance make them ideal for packaging, while their mechanical strength is highly valued in automotive and construction applications.

4. Customization and Flexibility

Understanding that different industries have unique needs, we offer customization options for our PET sheets. From varying thicknesses to different dimensions, we provide tailored solutions that align perfectly with our clients' requirements. Our flexibility in manufacturing ensures that we can accommodate both small and large orders efficiently.

5. Sustainability Commitment

Sustainability is at the core of Lyka Global Plast's operations. Our PET sheets are recyclable and environmentally friendly, contributing to a circular economy. We are committed to reducing our carbon footprint and promoting sustainable practices across all stages of production.

Applications of PET Sheets

1. Packaging Industry

PET sheets are extensively used in the packaging industry due to their clarity, strength, and chemical resistance. They are ideal for food and beverage containers, blister packaging, and clamshells, ensuring product safety and integrity.

2. Automotive Industry

In the automotive sector, PET sheets are utilized for interior and exterior components due to their durability and resistance to impact and weathering. They contribute to lightweighting vehicles, enhancing fuel efficiency and performance.

3. Electronics Industry

The electronics industry benefits from PET sheets for their insulating properties and dimensional stability. They are used in displays, protective coverings, and electrical insulation applications, ensuring reliability and safety.

4. Construction Industry

PET sheets are valued in construction for their strength and versatility. They are used in glazing, roofing, and interior applications, providing durability and aesthetic appeal.

5. Signage and Advertising

The exceptional clarity and printability of PET sheets make them a preferred choice for signage and advertising materials. They ensure vibrant and durable displays for both indoor and outdoor use.

Conclusion

Lyka Global Plast is your trusted partner for high-quality PET sheets, serving industries worldwide with excellence. Our commitment to quality, innovation, and sustainability sets us apart as a leading manufacturer and supplier. Whether you need PET sheets for packaging, automotive, electronics, construction, or signage, Lyka Global Plast delivers solutions that meet and exceed your expectations. Explore our range of PET sheets and experience the difference in quality and performance.

#High-quality PET sheets manufacturer for industries#Best PET sheets supplier for global markets#Custom PET sheets manufacturer and exporter#Eco-friendly PET sheets for sustainable packaging#PET sheets for food packaging and safety#Durable PET sheets for automotive applications#Transparent PET sheets for electronics industry#UV-resistant PET sheets for construction projects#Printable PET sheets for signage and advertising#Affordable PET sheets supplier for bulk orders#PET sheets manufacturer for industrial use#PET sheets supplier with global shipping#PET sheets manufacturer with customization options#PET sheets for pharmaceutical packaging#Heat-resistant PET sheets for industrial applications#Lightweight PET sheets for aerospace industry#Impact-resistant PET sheets for automotive parts#PET sheets for greenhouse and agriculture#Recyclable PET sheets for environmental sustainability#PET sheets with FDA approval

0 notes

Text

#adhesives and sealants market#aftermarket parts#automotive sector#industrial lubricants#Lightweighting EVs#electronic vehicle#adhesives#sealants

0 notes

Text

Air Freight Forwarder in India: Seamless Logistics with Everfast Freight

In today's fast-paced global economy, air freight has become an indispensable solution for businesses looking to transport goods quickly and efficiently across borders. India, as a hub of international trade, witnesses significant demand for reliable air freight services. Everfast Freight, a leader in logistics, provides exceptional air freight forwarding services tailored to meet diverse business needs.

Why Choose Air Freight for Your Business? Air freight is the fastest mode of transporting goods internationally. Businesses opt for air freight to ensure:

Quick delivery: Ideal for time-sensitive shipments like medical supplies, high-value goods, or seasonal products. Global connectivity: Access to virtually any destination in the world. Reduced risk: Minimized chances of theft or damage due to shorter transit times. However, the success of air freight heavily depends on the expertise of the freight forwarder managing the process.

Everfast Freight: Your Trusted Air Freight Partner As a premier air freight forwarder in India, Everfast Freight stands out with its customer-centric approach and unmatched expertise. Here's why businesses rely on Everfast Freight:

Comprehensive Global Network Everfast Freight boasts a robust network of international partners, ensuring seamless delivery to any part of the world. From Europe to the Americas, Africa to Asia, your shipments are handled with precision and care.

Customized Solutions Every shipment is unique, and Everfast Freight understands this. They offer tailored solutions to accommodate the size, weight, and urgency of your cargo, ensuring cost-effectiveness without compromising on quality.

Transparent Pricing Hidden costs can disrupt a business's budget. Everfast Freight provides clear and transparent pricing, helping clients plan their logistics effectively.

Cutting-Edge Technology With advanced tracking systems, Everfast Freight enables clients to monitor their shipments in real time, providing peace of mind and transparency.

Experienced Team The company’s skilled professionals have in-depth knowledge of customs regulations, documentation, and compliance requirements, ensuring smooth clearance and on-time delivery.

Industries Benefiting from Everfast Freight's Air Freight Services Everfast Freight caters to a wide range of industries, including:

E-commerce: Rapid delivery of products to global customers. Pharmaceuticals: Safe and timely transportation of temperature-sensitive goods. Automotive: Swift delivery of parts to meet manufacturing deadlines. Fashion: Quick distribution of seasonal collections to international markets. How Everfast Freight Ensures Sustainability In addition to speed and reliability, Everfast Freight prioritizes sustainability in its air freight operations. By optimizing routes and consolidating shipments, the company reduces its carbon footprint while maintaining efficiency.

Partner with Everfast Freight Today Whether you're shipping lightweight parcels or bulky cargo, Everfast Freight ensures a hassle-free air freight experience. With their dedication to excellence, they help businesses in India stay competitive in the global market.

Contact Everfast Freight today to learn how their air freight forwarding services can transform your logistics strategy.

3 notes

·

View notes

Text

Upgrade Your Ford Mustang EcoBoost with the Injen Aluminum Intercooler Piping Kit

If you own a Ford Mustang EcoBoost and are looking to elevate its performance and aesthetic appeal, the Injen 15-19 Ford Mustang 2.3L EcoBoost Aluminum Intercooler Piping Kit is the perfect upgrade for you. This high-quality piping kit is designed to enhance your Mustang's power, efficiency, and style.

Why Choose the Injen Aluminum Intercooler Piping Kit?

Performance Enhancement

The Injen intercooler piping kit is engineered to improve airflow to your Mustang's turbocharged engine. By replacing the restrictive factory piping with larger, smoother aluminum pipes, this kit reduces turbo lag and increases throttle response. The result is a noticeable boost in horsepower and torque, giving your EcoBoost Mustang the performance edge it deserves.

Superior Construction

Crafted from lightweight yet durable aluminum, the Injen piping kit ensures longevity and reliability under high-performance conditions. The polished finish not only adds a sleek, stylish look to your engine bay but also provides resistance against corrosion and wear. This means your piping kit will maintain its appearance and functionality for years to come. Ford Mustang EcoBoost Piping Kit

Easy Installation

The Injen 15-19 Ford Mustang EcoBoost Aluminum Intercooler Piping Kit is designed for a straightforward installation. With precise fitment for the 2015-2019 Ford Mustang 2.3L EcoBoost models, this kit includes all necessary hardware and detailed instructions, making it a hassle-free upgrade for both DIY enthusiasts and professional installers.

Benefits of Upgrading Your Mustang's Intercooler Piping

Increased Horsepower and Torque: By improving the efficiency of the airflow to your engine, the Injen piping kit helps maximize your Mustang's power output.

Enhanced Throttle Response: Reduced turbo lag means your Mustang will respond more quickly to your input, providing a more exhilarating driving experience.

Improved Engine Efficiency: Better airflow leads to more efficient combustion, which can result in improved fuel economy under certain driving conditions.

Stylish Appearance: The polished aluminum finish adds a high-performance look to your engine bay, making it as stylish as it is functional.

Why Buy from Performance Car Parts?

When you purchase the Injen Aluminum Intercooler Piping Kit from Performance Car Parts, you are not only getting a top-quality product but also the assurance of excellent customer service. Our team is dedicated to providing automotive enthusiasts with the best performance parts on the market. We offer competitive pricing, fast shipping, and a commitment to customer satisfaction.

Conclusion

Upgrading your Ford Mustang EcoBoost with the Injen 15-19 Ford Mustang 2.3L EcoBoost Aluminum Intercooler Piping Kit is an investment in both performance and style. Enhance your driving experience with improved power, efficiency, and a sleek engine bay appearance. Check out this must-have upgrade at Performance Car Parts today.

For more information and to place your order, visit our website or contact our knowledgeable team. Transform your Mustang EcoBoost into the ultimate performance machine with Injen and Performance Car Parts!

Ford Mustang EcoBoost Piping Kit

3 notes

·

View notes

Text

What to know about carbon fiber rings

Carbon fiber ring info

Hey Tumblr friends!

Are you in the market for a ring that's not only stylish but incredibly durable? Let me introduce you to the world of carbon fiber rings. As a custom jewelry designer with nearly 15 years of experience at Peacefield Titanium, I've crafted countless rings, but carbon fiber rings hold a special place due to their unique blend of modern elegance and robust performance. Here’s everything you need to know about these fantastic rings.

What is Carbon Fiber?

Carbon fiber is a high-tech material that's taken industries ranging from aerospace to automotive by storm, thanks to its formidable strength and lightweight properties. Made from thin, strong crystalline filaments of carbon, these fibers are woven together and set in resin to create a composite material that's both tough and flexible. Its sleek, distinctive appearance has made carbon fiber a popular choice in the world of jewelry, especially for rings.

Why Opt for Carbon Fiber Rings?

Durability

One of the standout features of carbon fiber is its incredible durability. This material is highly resistant to scratches and can withstand the wear and tear of daily activities without losing its luster. It’s perfect for anyone who leads an active lifestyle or works with their hands.

Lightweight Comfort

Despite their strength, carbon fiber rings are surprisingly lightweight, making them comfortable to wear throughout the day. This feature is a huge plus for those who aren't used to wearing rings regularly.

Unique Design

Each carbon fiber ring features a unique pattern due to the way the material is woven. This means no two rings are exactly alike, offering a unique aesthetic appeal that sets these rings apart from traditional metal bands.

Styles of Carbon Fiber Rings

At Peacefield Titanium, we offer a variety of carbon fiber rings to suit different tastes and preferences:

Classic Carbon Fiber Rings

For those who appreciate a sleek, modern look, our classic carbon fiber rings are a perfect choice. They showcase the natural black and gray weave of the carbon fiber, providing a sophisticated, minimalist style.

Carbon Fiber Rings with Inlays

For a touch of natural beauty, consider our carbon fiber rings with wood inlays. We incorporate materials like koa wood, which is known for its rich color and unique grain patterns, and whiskey barrel wood, which offers a rustic, earthy vibe.

Customizable Carbon Fiber Rings

The best part about choosing a carbon fiber ring from Peacefield Titanium is the ability to customize it. Whether you want to engrave a special message inside the band or choose a specific inlay that holds personal significance, we can tailor your ring to meet your specific desires.

Eco-Friendly and Sustainable

Opting for a carbon fiber ring is also a great choice for environmentally conscious individuals. At Peacefield Titanium, we strive to use sustainable practices in our crafting process, and carbon fiber's durability ensures that your ring will last for years, reducing waste.

Who Should Choose a Carbon Fiber Ring?

Carbon fiber rings are ideal for anyone looking for a modern, stylish ring that can handle the demands of daily life. They're especially popular among young professionals, active individuals, and those who are looking for something a little different from the norm.

Discover the Perfect Ring

Ready to explore the unique beauty and durability of carbon fiber rings? Visit Peacefield Titanium and find the perfect ring that not only suits your style but will also stand the test of time. Dive into our collection today and embrace the sophistication of carbon fiber!

Thanks for reading! Feel free to message or visit us if you have any questions about carbon fiber rings or if you'd like to see our complete collection. Whether you're looking for a wedding band or just a stylish new accessory, we're here to help you make the perfect choice.

2 notes

·

View notes

Text

Melamine Market is Expected to Grow at a CAGR of 3.87% during the forecast period until 2032

The melamine market has witnessed remarkable growth and diversification in recent years, propelled by a myriad of factors shaping the global landscape. Melamine, a nitrogen-rich organic compound, finds extensive applications across various industries, including construction, automotive, textiles, packaging, and food service. Its unique properties, such as high flame resistance, thermal stability, durability, and chemical inertness, have made melamine a versatile and indispensable material in numerous manufacturing processes and end-use applications.

One of the primary drivers of the melamine market is the increasing demand from the construction industry. Melamine-based products, such as melamine formaldehyde resins and melamine foam insulation, are widely used in construction applications such as laminates, decorative panels, flooring, countertops, and insulation materials. With rapid urbanization, infrastructure development, and construction activities on the rise globally, the demand for melamine-based construction materials is expected to surge.

Read Full Report: https://www.chemanalyst.com/industry-report/melamine-market-812

Moreover, the automotive sector represents another significant market for melamine, driven by the increasing demand for lightweight, durable, and aesthetically appealing materials. Melamine-based components, such as automotive interior trim, dashboard panels, door panels, and decorative parts, offer excellent properties such as scratch resistance, color stability, and surface finish, thereby enhancing the overall aesthetics and functionality of vehicles. As automotive manufacturers focus on improving fuel efficiency, reducing emissions, and enhancing passenger comfort and safety, the demand for melamine-based automotive materials is projected to grow substantially.

Furthermore, the textiles industry presents lucrative opportunities for the melamine market, particularly in the manufacturing of melamine-formaldehyde resins for textile finishing and coating applications. Melamine resins impart crease resistance, wrinkle resistance, and color fastness to textiles, thereby enhancing their durability, appearance, and performance. With the growing demand for high-quality textiles, home furnishings, and apparel, the demand for melamine-based textile additives is expected to increase.

Additionally, the packaging industry represents a significant market for melamine, driven by the rising demand for lightweight, durable, and eco-friendly packaging materials. Melamine-based products, such as melamine-formaldehyde resins and melamine foam packaging, offer excellent properties such as thermal insulation, moisture resistance, and shock absorption, making them ideal for packaging applications such as food packaging, electronics packaging, and industrial packaging. As consumers increasingly prioritize sustainability, recyclability, and environmental friendliness, the demand for melamine-based packaging solutions is expected to grow.

Despite the promising outlook, the melamine market faces challenges and constraints, including fluctuating raw material prices, regulatory compliance issues, and environmental concerns related to formaldehyde emissions. However, industry stakeholders are actively addressing these challenges through initiatives focused on product innovation, sustainability, and regulatory compliance. Moreover, strategic partnerships, mergers, and acquisitions are driving consolidation and market expansion in the melamine industry.

In conclusion, the melamine market is poised for continued growth and innovation, driven by its versatile applications, inherent properties, and compatibility with evolving market trends. By leveraging its strengths in construction, automotive, textiles, packaging, and other sectors, the melamine market can navigate towards a more sustainable and prosperous future, ensuring its relevance and competitiveness in the global marketplace.

About us:

ChemAnalyst is an online platform offering a comprehensive range of market analysis and pricing services, as well as up-to-date news and deals from the chemical and petrochemical industry, globally.

Being awarded ‘The Product Innovator of the Year, 2023’, ChemAnalyst is an indispensable tool for navigating the risks of today's ever-changing chemicals market.

The platform helps companies strategize and formulate their chemical procurement by tracking real time prices of more than 400 chemicals in more than 25 countries.

ChemAnalyst also provides market analysis for more than 1000 chemical commodities covering multifaceted parameters including Production, Demand, Supply, Plant Operating Rate, Imports, Exports, and much more. The users will not only be able to analyse historical data but will also get to inspect detailed forecasts for upto 10 years. With access to local field teams, the company provides high-quality, reliable market analysis data for more than 40 countries.

Contact us:

420 Lexington Avenue, Suite 300

New York, NY

United States, 10170

Email-id: [email protected]

Mobile no: +1-3322586602

#Melamine#Melaminemarket#Melaminemarketsize#Melaminemarkettrends#Melaminemarketgrowth#Melaminemarketshare#Melaminedemand

2 notes

·

View notes

Text

Unleashing Manufacturing Potential: The Strength of Materials.

Introduction: In the dynamic world of manufacturing, the choice of materials plays a vital role in delivering high-quality products quickly and flexibly. From acrylic/plexiglass to PETG, polycarbonate, polystyrene, polyethylene, polypropylene, sheet metal, wire, wood, and printing, each material brings unique attributes to the production process. This blog post explores the power of these materials, housed under one roof, enabling companies to excel with short lead times and unparalleled adaptability.

Acrylic/Plexiglass: Acrylic, also known as plexiglass, is a lightweight, impact-resistant material used extensively for signage, display cases, and protective barriers. Its transparency and ease of molding make it perfect for complex designs.

PETG: PETG is a durable and transparent plastic with excellent impact resistance. Its versatility and chemical resistance make it a popular choice in packaging, displays, and medical devices.

Polycarbonate: Renowned for its outstanding impact resistance and transparency, polycarbonate finds applications in automotive parts, safety glasses, and architectural glazing. Its strength and aesthetic appeal are unmatched.

Polystyrene: With its lightweight nature and affordability, polystyrene is a go-to material for packaging, consumer electronics, and insulation. Its moldability and insulating properties are key advantages.

Polyethylene and Polypropylene: Polyethylene and polypropylene offer exceptional chemical resistance, durability, and flexibility. They are commonly used in food packaging, automotive components, medical equipment, and piping systems.

Sheet Metal and Wire: Sheet metal and wire provide structural integrity to machinery, enclosures, and architectural elements. Their strength and reliability are crucial for various manufacturing applications.

Wood: Wood adds warmth and aesthetic appeal to furniture, cabinetry, and other products. Its natural beauty, strength, and sustainability make it a popular choice.

Printing: Printing techniques enhance the appearance and functionality of manufactured goods. From branding to decorative elements, printing personalizes and differentiates products in the market.

Conclusion: In the manufacturing industry, the selection of materials can make all the difference. Acrylic, PETG, polycarbonate, polystyrene, polyethylene, polypropylene, sheet metal, wire, wood, and printing enable companies to achieve short lead times and adapt to changing market needs. The power of these materials ensures the production of high-quality, customized products that meet customer demands efficiently. With a diverse range of materials under one roof, manufacturers can thrive in today's fast-paced environment.

Website:- https://acrylicplexiglass.ca/

Phone no.:- (647)774-7623, (647)825-1324

Address:- 622 Magnetic Dr, North York, ON M3J 3J2, Canada

E- Mail:- [email protected]

Gmail:- [email protected]

2 notes

·

View notes

Text

Automotive Heat Shields Market Trends, Innovations, and Future Outlook to 2030

The Automotive Heat Shields market is expected to grow from USD 12.67 Billion in 2024 to USD 16.31 Billion by 2030, at a CAGR of 4.30% during the forecast period.

The automotive heat shields market has emerged as a critical component of the global automotive industry, driven by the increasing demand for enhanced vehicle performance, efficiency, and safety. Automotive heat shields are designed to protect various components of a vehicle from excessive heat generated by the engine, exhaust systems, and other high-temperature areas. These shields play a vital role in improving the longevity of automotive parts, reducing heat-related wear and tear, and ensuring optimal performance.

One of the key factors contributing to the growth of the automotive heat shields market is the rising emphasis on lightweight materials in vehicle manufacturing. With stringent regulations aimed at reducing carbon emissions and improving fuel efficiency, automakers are incorporating lightweight heat shields made of advanced materials such as aluminum, composites, and multi-layered insulating fabrics. These materials not only reduce the overall weight of the vehicle but also enhance thermal management capabilities.

For More Insights into the Market, Request a Sample of this Report https://www.reportprime.com/enquiry/sample-report/19917

The increasing adoption of electric and hybrid vehicles (EVs and HEVs) has further accelerated the demand for automotive heat shields. EVs and HEVs generate significant heat from their batteries and powertrain systems, necessitating efficient heat shielding solutions to maintain safety and performance. Manufacturers are focusing on developing innovative heat shields tailored to the unique requirements of these vehicles, contributing to market expansion.

Regional dynamics play a crucial role in shaping the automotive heat shields market. In developed regions such as North America and Europe, the market is driven by the presence of leading automakers, advanced manufacturing capabilities, and stringent regulatory frameworks. Meanwhile, the Asia-Pacific region is witnessing rapid growth due to increasing vehicle production, rising disposable incomes, and the growing popularity of electric mobility in countries like China, Japan, and India.

Market Segmentations

By Type: Rigid Heat Shield, Flexible Heat Shield, Textile Heat Shield

By Applications: Passenger Vehicle, Light Commercial Vehicle

Get Full Access of This Premium Report https://www.reportprime.com/checkout?id=19917&price=3590

The competitive landscape of the automotive heat shields market is characterized by continuous innovation and strategic collaborations. Major players such as Dana Incorporated, ElringKlinger AG, Tenneco Inc., Lydall, Inc., and Autoneum are investing heavily in research and development to introduce advanced heat shield solutions. These companies are also expanding their manufacturing capacities and forging partnerships with automakers to strengthen their market position.

Despite the promising growth prospects, the automotive heat shields market faces several challenges. The fluctuating prices of raw materials and the high cost of advanced heat shielding technologies can impact profitability for manufacturers. Additionally, the complexity of designing heat shields for modern vehicles with compact engine compartments and intricate powertrains presents a technical challenge.

The future of the automotive heat shields market is promising, with numerous opportunities on the horizon. The global shift toward electric and autonomous vehicles is expected to drive innovation in heat shielding technologies. Furthermore, the integration of smart heat shields equipped with sensors and data-monitoring capabilities is anticipated to become a key trend, enhancing the efficiency and safety of next-generation vehicles.

0 notes

Text

Overview of Round Bars: Types, Applications and Advantages

Rajkrupa Metal Industries is a top Round Bars Manufacturers in India. We've established ourselves as one of the leading names in the Round Bars industry. Because of its strong commercial and technical staff capabilities, Rajkrupa Metal Industries has purposefully positioned itself as a leading Round Bar manufacturer.

What Are Round Bars?

Round bars are long, cylindrical pieces of metal that are produced through various manufacturing processes such as rolling, drawing, or extruding. They come in a variety of sizes, materials, and finishes, making them suitable for an extensive range of applications. The diameter of round bars can vary significantly, from a few millimeters to several inches, depending on their intended use.

Types of Round Bars

Round bars can be classified based on the material they are made from. Here are some of the most common types:

Stainless Steel Round Bars:

Highly resistant to corrosion and staining

Used in environments where hygiene and durability are critical

Carbon Steel Round Bars:

Known for their strength and hardness

Widely used in construction and manufacturing

Alloy Steel Round Bars:

Enhanced mechanical properties due to alloying elements

Ideal for applications requiring higher strength and toughness

Aluminum Round Bars:

Lightweight and corrosion-resistant

Commonly used in aerospace, automotive, and marine industries

Brass Round Bars:

Good corrosion resistance and excellent machinability

Often used in plumbing and electrical applications

Applications of Round Bars

Round bars are incredibly versatile and are used in various industries for numerous applications:

Construction:

Used as reinforcement bars in concrete structures

Employed in the fabrication of beams, columns, and other structural components

Manufacturing:

Utilized in the production of machine parts, tools, and equipment

Essential in the creation of fasteners such as bolts, nuts, and screws

Automotive:

Applied in the making of shafts, axles, and other critical components

Used in the production of engine parts and transmission systems

Aerospace:

Used in the construction of aircraft frames and landing gear

Integral in the manufacture of engine components

Marine:

Employed in the construction of ships and submarines

Used in the production of various marine hardware

Advantages of Round Bars

Round bars offer several advantages that make them a preferred choice for many applications:

Corrosion Resistance:

Materials like stainless steel and aluminium provide excellent resistance to corrosion, extending the lifespan of the components made from round bars.

Cost-Effectiveness:

Due to their widespread availability and ease of production, round bars are often more cost-effective compared to other forms of metal products.

Strength and Durability:

Round bars are known for their high tensile strength and durability, making them suitable for heavy-duty applications.

Versatility:

The wide range of materials and sizes available allows for round bars to be used in diverse industries and applications.

Machinability:

Round bars are easy to machine, cut, and shape, facilitating their use in manufacturing processes.

We are also top quality Aluminium Bronze Round Bar Manufacturer In India.We have established ourselves as one of the market's top names in Aluminium Bronze Round Bar. Rajkrupa Metal Industries has deliberately positioned itself as a top-tier manufacturer and retailer worldwide. Aluminium Bronze Round Bar Suppliers are well-known for their high strength, corrosion resistance, and thermal and electrical conductivity.

#Round Bars Manufacturers in India#Round Bars Manufacturers#Round Bars#Aluminium Bronze Round Bar Manufacturer In India#Aluminium Bronze Round Bar Manufacturer#Aluminium Bronze Round Bar#Aluminium Bronze Round Bar Suppliers

0 notes

Text

How Round Bars Are Revolutionizing the Manufacturing Industry

The round bar is a forgotten icon at the center of the manufacturing revolution that is taking place in the industry. These versatile cylindrical metal bars have become indispensable across various sectors, driving innovation, efficiency, and superior product quality. Whether you are an industrial designer or a production manager, understanding the pivotal role of round bars can offer insights into their growing demand and impact.

What Are Round Bars?

Round bars are long, cylindrical metal products made from materials such as stainless steel, carbon steel, aluminum, and alloys. They come in a variety of diameters and lengths, making them suitable for diverse applications. Their high tensile strength, durability, and machinability make them a preferred choice in industries such as construction, automotive, aerospace, and manufacturing.

Applications of Round Bars in the Manufacturing Industry

Automotive Sector: Round bars are widely used in the production of axles, engine components, and suspension systems. Their ability to withstand high stress and wear ensures the longevity and reliability of automotive parts.

Construction Industry: From reinforcement in concrete structures to scaffolding and frames, round bars are essential for ensuring stability and strength in construction projects.

Aerospace Engineering: The aerospace industry relies on lightweight yet durable materials. Round bars made of aluminum or titanium alloys are commonly used in manufacturing aircraft components like landing gear and structural frames.

Machine Tools and Equipment: Round bars are indispensable in creating machine shafts, fasteners, and precision tools, facilitating efficient manufacturing processes.

Oil and Gas Sector: In harsh and corrosive environments, round bars made of stainless steel or duplex alloys are used in pipelines, drilling equipment, and valves to ensure durability and safety.

Benefits of Using Round Bars

The growing demand for round bars can be attributed to the numerous advantages they offer:

Strength and Durability: Round bars are known for their robustness, making them ideal for heavy-duty applications.

Corrosion Resistance: Stainless steel round bars, in particular, provide excellent resistance to rust and corrosion, extending their lifespan in challenging environments.

Versatility: With multiple grades and finishes available, round bars can cater to specific industrial requirements.

Cost-Effectiveness: High machinability reduces manufacturing costs and improves production efficiency.

The Role of Round Bar Importers and Suppliers in India

India has emerged as a key player in the global round bar market, thanks to its advanced manufacturing capabilities and quality standards. The country is home to numerous round bar suppliers, including Nippon Alloys Inc, a renowned name in the industry.

Innovations in Round Bar Manufacturing

The advancements in material science and manufacturing technologies have further enhanced the functionality and applications of round bars:

Customized Alloy Compositions: Manufacturers like Nippon Alloys Inc are developing specialized alloy compositions to meet specific industrial demands, such as high-temperature resistance or enhanced machinability.

Precision Engineering: CNC machining and other precision technologies have enabled the production of round bars with exceptional dimensional accuracy.

Sustainability: Eco-friendly manufacturing practices, including recycling and energy-efficient processes, are shaping the future of round bar production.

The Global Impact of Round Bars

The global round bar market is witnessing robust growth, driven by increasing industrialization and infrastructure development. Round bar importers are playing a vital role in bridging the supply-demand gap, ensuring the availability of quality products worldwide. With India emerging as a hub for round bar manufacturing, the country’s exports are contributing significantly to global industrial progress.

Leading Round Bar Importer in India | Quality Materials

Nippon Alloys Inc. stands out as the leading Round Bar Importer in India. With a reputation for excellence, we source premium materials from trusted manufacturers worldwide to ensure our customers receive only the best. Our extensive range of round bars is designed to meet the demands of diverse industries, including construction, manufacturing, and engineering.

As a trusted Round Bar Exporter in India, We take pride in delivering precision-engineered products to clients across the globe. Our round bars are known for their durability, corrosion resistance, and impeccable finish, making them the preferred choice for various applications.

In addition to importing and exporting, We are also a reliable Round Bar Supplier in India. We maintain a vast inventory to meet bulk orders and ensure timely delivery. Our commitment to quality, competitive pricing, and exceptional customer service has solidified our position as a trusted name in the industry.

For More Detail

Website: nipponalloys.com

Product: Round Bar Suppliers

Other Product: Alloy Round Bar Supplier in India, Monel Round Bar Importer in India.

#Round bar Supplier in India#Round bar Supplier#Round bar#Alloy Round Bar Supplier in India#Monel Round Bar Importer in India

0 notes

Text

Germany Auto Component Market: Insights, Growth Drivers, Key Players, and Future Trends in the Automotive Industry

The Germany auto component market is a global leader, serving as the backbone of the automotive supply chain not only in Europe but across the world. With its established reputation for manufacturing high-quality auto parts and components, Germany continues to be a central player in the automotive industry. The demand for automotive components in Germany has surged due to the growing automotive market, which includes both traditional vehicles and the rapidly expanding electric vehicle (EV) sector.

In this article, we will explore the factors driving the growth of the Germany auto component market, examine key industry players, the impact of emerging technologies, and discuss the latest trends that are shaping the market's future.

Market Overview and Growth Drivers

The Germany auto component market has seen remarkable growth in the past decades, largely due to its deep integration with the global automotive industry. With over 800 suppliers, Germany is home to some of the world’s most significant automotive companies such as Volkswagen, BMW, Mercedes-Benz, Audi, and Porsche. As these companies advance in vehicle electrification, automated driving technologies, and autonomous vehicles, the demand for auto components in the country is expected to continue increasing.

Key Drivers of Growth:

Technological Innovation – Technological advancements in electric vehicle components, smart manufacturing, and automated systems are expanding the demand for advanced auto components.

Government Initiatives – Germany’s commitment to clean energy through policies such as the "German National Strategy for Electric Mobility" encourages investments in EV auto components, ranging from electric powertrains to advanced batteries.

Consumer Demand – Increasing consumer interest in electric vehicles and connected vehicles also drives demand for innovative components like sensors, actuators, and advanced infotainment systems.

Sustainability Push – The automotive industry in Germany is placing greater emphasis on sustainability, leading to a push for greener components like eco-friendly plastics, lightweight materials, and energy-efficient systems.

Explore the Latest Trends in Germany’s Auto Component Market Now: https://bityl.co/R0Xt

Key Segments of the Germany Auto Component Market

The Germany auto component market is diverse, with many sub-segments playing key roles in vehicle production. These segments include:

Powertrain Components – These include engines, transmissions, exhaust systems, and powertrain electronics. Powertrain systems are crucial to vehicle performance, especially with the rising demand for EV-related components like battery management systems and electric motor components.

Chassis and Suspension – With a focus on safety and performance, chassis and suspension parts continue to see high demand, particularly as automakers focus on creating more stable, durable, and fuel-efficient vehicles.

Interior Components – From seating systems to dashboards, infotainment, and electronic control units, interior components play a crucial role in enhancing vehicle comfort and driving experience.

Exterior Components – The production of body panels, bumpers, and lighting components remains critical. Additionally, advancements in materials and lightweight alloys help improve the fuel efficiency of vehicles.

Electric Vehicle (EV) Components – As electric mobility grows, Germany’s auto component manufacturers are stepping up to produce key EV components such as lithium-ion batteries, charging modules, power converters, and thermal management systems.

Autonomous Driving Components – With major German automakers investing heavily in autonomous vehicles, components like sensors, cameras, and LIDAR systems have become indispensable in enhancing self-driving technology.

Technological Innovations and Emerging Trends in the Auto Component Market

Germany is known for pioneering technological innovations in the auto component market. These technological advancements are enhancing vehicle efficiency, safety, and customer satisfaction, all while reducing emissions and environmental impact.

Electric Vehicle Battery Technology – As a crucial component of EVs, advances in lithium-ion batteries and solid-state batteries will enhance the energy density and lifespan of EVs, making them more competitive in terms of range and efficiency.

Autonomous Vehicle Technologies – German manufacturers are leading the charge in autonomous driving, particularly with advanced driver-assistance systems (ADAS) and AI-driven components. These developments are transforming components like sensors, cameras, and radar technologies, enabling vehicles to drive themselves safely.

Connected Car Components – The demand for connected vehicle technologies is on the rise, and this extends to auto components like infotainment systems, telematics, and integrated communication systems that enable real-time data processing.

Sustainability and Lightweight Materials – Automakers in Germany are focusing more on sustainable manufacturing, leading to the growth of auto components made from recyclable materials and lightweight options like carbon fiber, which help improve vehicle fuel efficiency.

Smart Manufacturing and Automation – Smart factories using AI, machine learning, and robotics in manufacturing and assembly lines make it easier to produce high-quality, precision auto components at scale.

Challenges in the Germany Auto Component Market

Despite the growth, there are several challenges facing the Germany auto component market:

Supply Chain Disruptions – Global supply chain issues have impacted raw material prices, as well as the availability of essential components, creating delays in production.

Global Competition – Companies from countries such as China and South Korea are competing aggressively in the auto component market, putting pressure on Germany to maintain its global competitive edge.

Regulatory Pressure – Stringent emissions regulations and the push for zero-emission vehicles force manufacturers to adapt rapidly to new standards, adding cost pressures to their operations.

Economic Volatility – Fluctuations in global economic conditions can affect consumer demand for vehicles, thus impacting the demand for auto components.

Investment Opportunities in the Germany Auto Component Market

Investors interested in the Germany auto component market are likely to find opportunities in key areas like electric vehicles, smart manufacturing, autonomous driving, and alternative materials. Companies focusing on these innovations can provide lucrative investment opportunities as German automakers continue to lead the way in advanced automotive technologies.

Conclusion

Germany’s auto component market remains robust due to its technological leadership, established supplier networks, and commitment to green mobility. With electric vehicles and autonomous driving technologies on the rise, auto component manufacturers in Germany are well-positioned to thrive in the changing automotive landscape.

#auto component market#auto component market size#auto component market share#auto component market demand

0 notes

Text

Coil Coatings Market Outlook: Innovations and Growth Drivers

The coil coatings market has evolved over the past few decades, driven by technological advancements, growing environmental awareness, and increasing demand across key industries. As we look to the future, the market is expected to experience significant growth, fueled by continued innovations in materials and a shift toward more sustainable, high-performance solutions. However, there are also several challenges and market dynamics that will shape the future of the coil coatings industry.

Growth Drivers

The coil coatings market is witnessing robust demand, particularly in the construction, automotive, and appliance sectors. One of the major growth drivers is the increasing demand for durable, corrosion-resistant materials in architectural applications. The global construction industry is expanding, and coil-coated metals are crucial in the production of building materials such as roofing panels, facades, and siding. These materials not only offer superior protection against the elements but also add aesthetic value to buildings, making them an attractive choice for architects and builders alike.

In addition, the automotive industry is poised to continue driving the demand for coil-coated materials. With the increasing production of vehicles, particularly in emerging markets, manufacturers require materials that are lightweight, durable, and resistant to corrosion. Coil coatings provide these benefits while also offering a wide range of colors and finishes that contribute to the overall design of vehicles. As automotive production grows, especially in countries like China, India, and other parts of Asia-Pacific, the demand for coil coatings is expected to rise.

Furthermore, the growing emphasis on sustainability is expected to propel the market. Eco-friendly coil coatings, such as those with low VOC content and high recyclability, are gaining traction in both developed and developing economies. Governments around the world are tightening environmental regulations, pushing manufacturers to invest in more sustainable production processes. This trend aligns with the increasing consumer demand for environmentally responsible products and is expected to boost the market for eco-friendly coil coatings in the years ahead.

Technological Innovations and Material Advancements

The future of the coil coatings market is also heavily influenced by ongoing technological innovations. Manufacturers are increasingly turning to advanced coating formulations to enhance the performance and durability of coil-coated materials. One such innovation is the development of high-performance fluoropolymer and silicone-modified polyester coatings, which offer superior resistance to harsh environmental conditions, UV degradation, and corrosion.

Nanotechnology is also playing a significant role in the evolution of coil coatings. By incorporating nanoparticles into the coatings, manufacturers are able to improve the scratch resistance, surface hardness, and overall durability of the coatings. These advancements are particularly beneficial in high-maintenance environments, where coil-coated materials are exposed to extreme conditions such as urban pollution, marine environments, or industrial settings.

Another key trend in the market is the growth of smart coatings. These coatings incorporate technologies such as self-cleaning properties, anti-graffiti surfaces, and anti-bacterial features. The development of coatings that can respond to environmental stimuli, such as temperature or humidity changes, will further enhance the value of coil-coated materials in specialized applications, such as high-performance buildings and healthcare facilities.

Regional Outlook

Regionally, the future of the coil coatings market will be shaped by the continued industrialization and urbanization of developing economies. Asia-Pacific, led by countries like China and India, will remain a dominant market for coil coatings. The growing construction sector, coupled with rising automotive production, will drive demand for coil-coated materials in this region.

North America and Europe will continue to be important markets, driven by stringent environmental regulations and a strong emphasis on sustainable construction practices. The demand for coil coatings with low VOC content, energy-efficient properties, and long-lasting durability will increase as the construction industry embraces green building standards.

Challenges and Market Dynamics

Despite the promising outlook, the coil coatings market faces certain challenges. One of the primary concerns is the volatility of raw material prices, particularly for metals such as steel and aluminum. Fluctuations in the cost of these materials can impact the pricing of coil-coated products, affecting profit margins for manufacturers.

Additionally, competition from alternative coating technologies, such as powder coatings and liquid coatings, may pose a challenge to the growth of the coil coatings market. While coil coatings offer several advantages, such as uniformity and cost-effectiveness, these alternatives are often chosen for specific applications due to their own unique benefits.

Conclusion

The future of the coil coatings market is promising, with substantial growth expected in key regions and industries. Technological advancements, particularly in sustainability and performance, will drive innovation, offering new opportunities for manufacturers to meet the demands of environmentally conscious consumers and industries. While challenges such as raw material price volatility and competition from alternative coatings remain, the coil coatings market is well-positioned to thrive in the coming years, driven by its critical role in the construction, automotive, and appliance sectors. As manufacturers continue to innovate and adapt to shifting market dynamics, the market’s future looks bright, with exciting opportunities for growth and development.

Get Free Sample and ToC : https://www.pristinemarketinsights.com/get-free-sample-and-toc?rprtdtid=NDgx&RD=Coil-Coatings-Market-Report

0 notes

Text

Recycled Plastics Market to Grow at 8.7% CAGR, Supported by Sustainability Trends

Recycled plastics are rapidly becoming the cornerstone of global sustainability efforts. With mounting concerns over environmental degradation and resource scarcity, industries and governments worldwide are emphasizing the use of recycled materials. In 2023, the recycled plastics market was valued at USD 70.0 billion, highlighting its established significance. Projections show that this figure will exceed USD 121.7 billion by 2030, driven by a CAGR of 8.7% from 2024 to 2030. This growth reflects not just consumer demand but also regulatory frameworks promoting a circular economy and eco-friendly alternatives to traditional materials.

Market Dynamics

Drivers of the Recycled Plastics Market

One of the primary drivers is the increased awareness of plastic pollution and its harmful environmental impact. Consumers and businesses alike are opting for sustainable solutions, encouraging manufacturers to integrate recycled plastics into their products. Furthermore, regulatory pressures such as bans on single-use plastics and mandates for recycled content in packaging have created a thriving market. Economic incentives, including reduced production costs and energy savings, further boost the adoption of recycled materials across industries.

Restraints Hindering Market Growth

Despite its potential, the recycled plastics market faces significant hurdles. A major restraint is the limited availability of high-quality recyclable materials, particularly in developing regions. Additionally, the lack of uniform recycling standards and infrastructure creates inefficiencies in collection and processing. High initial costs for establishing recycling facilities and the complexities of sorting and cleaning materials also act as barriers to market expansion.

Download Sample Report @ https://intentmarketresearch.com/request-sample/recycled-plastics-market-3069.html

Types of Recycled Plastics

Recycled plastics are classified mainly into two categories: post-consumer and post-industrial plastics.

Post-consumer recycled plastics are materials recovered from consumer products, such as beverage bottles, containers, and packaging. These are processed to create new products, reducing the reliance on virgin plastic.

Post-industrial recycled plastics originate from manufacturing waste like scraps and offcuts. As these materials are often clean and uniform, they are easier and less costly to recycle.

Common polymer types used in recycling include polyethylene terephthalate (PET), polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC). Each of these has distinct applications, ranging from bottles to automotive parts.

Applications of Recycled Plastics

Packaging Industry

The packaging sector is the largest consumer of recycled plastics, driven by increased demand for sustainable solutions in food, beverage, and e-commerce packaging. Lightweight, durable, and cost-effective recycled materials like PET and HDPE dominate this space, reducing the environmental footprint while maintaining product safety.

Construction and Building Materials

In the construction industry, recycled plastics are used to manufacture products such as pipes, decking, insulation, and roofing materials. Their lightweight nature, corrosion resistance, and cost advantages make them an appealing alternative to traditional materials. Incorporating recycled plastics into infrastructure projects supports green construction practices.

Automotive Sector

The automotive industry is increasingly turning to recycled plastics for vehicle manufacturing. Recycled polypropylene (PP) and polyethylene (PE) are widely used in car interiors, bumpers, and under-the-hood components. The use of recycled plastics not only reduces production costs but also decreases the vehicle's overall weight, improving fuel efficiency. As electric vehicles (EVs) gain traction, recycled materials are playing a critical role in aligning the sector with sustainability goals.

Consumer Goods

Recycled plastics are gaining popularity in the production of everyday consumer items, including furniture, toys, and electronics. Manufacturers use recycled materials to create durable and aesthetically pleasing products, often marketing them as eco-friendly. Brands that embrace recycled plastics often enjoy a competitive advantage, as consumers increasingly favor sustainable products in their purchasing decisions.

Textile Industry

The textile sector has seen a rise in the use of recycled plastics, particularly in the production of synthetic fibers like polyester. These materials are commonly repurposed to create fabrics for clothing, upholstery, and carpets. Recycled fibers reduce dependence on virgin polyester, lowering energy consumption and greenhouse gas emissions associated with textile manufacturing.

Regional Insights

North America: Innovation Hub

North America stands at the forefront of innovation in the recycled plastics market, driven by strong environmental policies and corporate commitments to sustainability. Governments in the U.S. and Canada actively support recycling initiatives through funding and legislation, such as extended producer responsibility (EPR) programs. A thriving consumer awareness movement further propels the demand for recycled plastic products in the region.

Europe: Sustainability Leadership

Europe is a global leader in sustainability and environmental protection. EU regulations, including the European Green Deal and the Circular Economy Action Plan, are transforming the way plastics are recycled and reused. With advanced recycling technologies and a robust waste management infrastructure, countries like Germany, the Netherlands, and Sweden lead the way in achieving high recycling rates.

Asia-Pacific: Emerging Potential

Asia-Pacific represents both a challenge and an opportunity for the recycled plastics market. While it remains the largest consumer and producer of plastics, the region struggles with inadequate recycling infrastructure. However, growing urbanization, government initiatives, and corporate investment in recycling plants are turning the tide. Countries like China, Japan, and India are emerging as key players in the market.

Latin America and Middle East: Rising Awareness

In Latin America and the Middle East, the market for recycled plastics is expanding due to increasing awareness and government-backed sustainability programs. Despite challenges like insufficient infrastructure, initiatives promoting waste segregation and recycling have gained momentum, paving the way for future growth.

Access Full Report @ https://intentmarketresearch.com/latest-reports/recycled-plastics-market-3069.html

Technological Innovations in Plastic Recycling

Innovation is at the heart of the recycled plastics industry. Advancements in recycling technology, such as chemical recycling, have revolutionized the way plastics are processed. Unlike traditional mechanical recycling, chemical methods break plastics down to their molecular level, enabling the recovery of high-purity materials suitable for a wider range of applications. Other promising innovations include:

AI-Powered Sorting: Enhances efficiency in waste management.

Bioplastics Recycling: Enables sustainable reuse of biodegradable plastics.

Multi-layer Plastic Solutions: Overcomes challenges in recycling complex packaging.

These technologies are critical in addressing the inefficiencies and limitations of current recycling systems.

Environmental and Economic Benefits of Recycled Plastics

Environmental Benefits

Recycling plastics significantly reduces the environmental impact associated with plastic waste. By diverting plastic waste from landfills and oceans, recycling minimizes pollution and conserves natural resources. Furthermore, the process requires less energy compared to producing virgin plastics, which means lower greenhouse gas emissions. Recycled plastics also contribute to preserving biodiversity by reducing the harmful effects of plastic pollution on marine and terrestrial ecosystems.

Economic Benefits

Recycled plastics are not just environmentally friendly; they’re economically advantageous too. Industries using recycled materials benefit from reduced raw material costs and energy savings. Governments and private players investing in recycling infrastructure create job opportunities, bolstering local economies. Additionally, products made with recycled plastics often find favor with eco-conscious consumers, offering businesses a competitive edge in the market.

Challenges Facing the Recycled Plastics Market

While the potential of recycled plastics is immense, the industry is not without its challenges.

Contamination Issues: Contaminants in collected plastic waste make the recycling process less efficient and more expensive.

Collection and Sorting Inefficiencies: Lack of uniform recycling systems leads to inconsistent material quality and supply chain issues.

Limited Public Awareness: Many consumers remain unaware of proper recycling practices, contributing to low recycling rates.

Economic Viability: For some businesses, using virgin plastics is still cheaper than investing in recycled materials, slowing adoption.

Addressing these challenges requires collaboration between governments, industries, and consumers, along with technological advancements.

Buy Now @ https://intentmarketresearch.com/payments/checkout-single-NjA=

Future Prospects of the Recycled Plastics Market

The future of the recycled plastics market is promising, underpinned by regulatory pressures, technological innovation, and shifting consumer preferences. As global leaders implement stricter environmental laws, the demand for recycled plastics will continue to surge. Moreover, advancements in recycling processes, such as enzymatic degradation and bio-inspired solutions, hold the potential to make recycling more efficient and cost-effective.

Emerging Trends to Watch

Increased Use of Chemical Recycling: Transforming complex plastics into reusable materials on a larger scale.

Collaboration Across Industries: Partnerships between consumer goods, packaging, and recycling companies to promote circularity.

Sustainable Packaging Designs: Developing packaging materials optimized for recycling and reuse.

With these trends driving the industry, the recycled plastics market is well-positioned to achieve its forecasted growth and become a cornerstone of global sustainability efforts.

About Us

Intent Market Research (IMR) is dedicated to delivering distinctive market insights, focusing on the sustainable and inclusive growth of our clients. We provide in-depth market research reports and consulting services, empowering businesses to make informed, data-driven decisions.

Our market intelligence reports are grounded in factual and relevant insights across various industries, including chemicals & materials, healthcare, food & beverage, automotive & transportation, energy & power, packaging, industrial equipment, building & construction, aerospace & defense, and semiconductor & electronics, among others.

We adopt a highly collaborative approach, partnering closely with clients to drive transformative changes that benefit all stakeholders. With a strong commitment to innovation, we aim to help businesses expand, build sustainable advantages, and create meaningful, positive impacts.

Contact Us

US: +1 463-583-2713

0 notes

Text

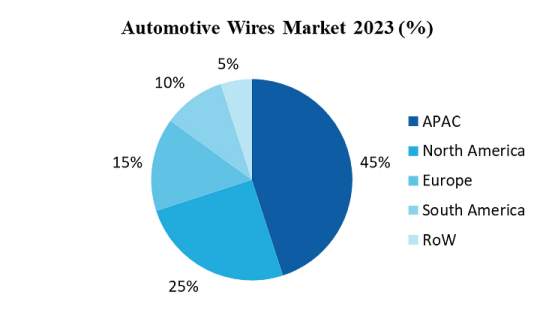

Automotive Wires Market-Industry Forecast, 2024–2030

Automotive Wires Market Overview:

Request Sample :

Automotive wire demand is expected to rise due to the growing trend of lightweight passenger automobiles as a means of reducing carbon emissions. In response to stringent regulations aimed at reducing carbon emissions from automobiles, manufactures will concentrate on producing aluminium automotive wires to reduce the vehicle’s overall weight. This is going to help in achieving the new regulations criteria. The rising focus on enhancing the standards for automotive wire will give opportunities for market expansion. For instance, according to US Auto Outlook 2024, light vehicle sales to grow 3.7% above last year’s level, rising to 16.1 million units. Additionally, the demand for automotive wires is expected to rise in parallel with the volume of vehicles being produced and the increasing demand from customers for better comfort, safety, and convenience.

Market Snapshot:

Automotives Wires Market — Report Coverage:

The “Automotive Wires Market Report — Forecast (2024–2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Automotives Wires Market.

AttributeSegment

By Material

· Copper

· Aluminium

· Others

By Vehicle Type

· Passenger Vehicles

· Light Commercial Vehicles

· Heavy Commercial Vehicles

By Propulsion

· ICE Vehicles

· Hybrid Vehicles

· Pure Electric Vehicles

By Transmission Type

· Electric wiring

· Data Transmission

By Application

· Engine wires

· Chassis wires

· Body and Lighting wires

· HVAC wires

· Dashboard / Cabin wires

· Battery wires

· Sensor wires

· Others

By End User

· OEM

· Aftermarket

By Geography

· North America (U.S., Canada and Mexico)

· Europe (Germany, France, UK, Italy, Spain, Russia and Rest of Europe),

· Asia-Pacific (China, Japan, South Korea, India, Australia & New Zealand and Rest of Asia-Pacific),

· South America (Brazil, Argentina, Chile, Colombia and Rest of South America)

· Rest of the World (Middle East and Africa).

COVID-19 / Ukraine Crisis — Impact Analysis:

The COVID-19 pandemic disrupted global supply chains, leading to delays in production and sales of automobiles which led to decrease in automotive wire manufacturing. Governments worldwide imposed lockdowns and restrictions, which led to shut down of mines, factories, and transportation networks, thus disrupting the supply of raw materials such as copper and aluminum, that are used in making automotive wires.

The Russia-Ukraine war had a huge impact on the global automotive wires market. Ukraine is a major manufacturer of copper, a material used as an automotive wiring component. The war has led to mining disruptions, which in turn has caused the shortages and increase in prices globally.

Key Takeaways:

Copper wires segment is Leading the Market

Copper wires segment holds the largest share in the automotive wires market with respect to market segmentation by material. Electrification will be the biggest driver to copper demand for vehicles. Copper is used throughout electric vehicle powertrains, from foils in each cell of the battery to the windings of an electric motor. In total, each electric vehicle can generate over 30kg of additional copper demand. According to a report by IDTechEx, the demand for copper from the automotive industry was just over 3MT in 2023 but is set to increase to 5MT in 2034. Because of its electrical and chemical characteristics, copper is used in every part of the battery. There are lot of tiny cells in the battery, and each one has a copper foil to carry electricity out of the cell. Large copper bars placed throughout the battery also convey the energy from each cell to the high-voltage connections, which in turn power the motor and electronics. Such parts and components with the copper are driving the market growth of copper wires in automotive wires market.

Inquiry Before Buying :

Passenger Vehicles are Leading the Market

Passenger Vehicles segment is leading the Automotive Wires Market by Application. The passenger vehicle category is currently holding the largest share in the automotive wires market because of a combination of factors including large production volumes, a wide range of wiring requirements, technological developments, and the increasing adoption of electric vehicles. For instance, according to Global and EU Auto industry 2023 report by The European Automobile Manufacturers’ Association (ACEA), European car production grew substantially, reaching nearly 15 million units, marking a significant year-on-year improvement of 12.6%. The growing popularity of electric vehicles (EVs) is also contributing to the growth of the passenger vehicle segment in the automotive wires market. EVs have more complex wiring systems due to the integration of batteries, motors, and charging infrastructure.

Integration of Smart Systems in Automobiles

Global demand for automotive wires is primarily driven by the integration of smart systems in automobiles. Modern automobiles have more wires because electronic control units (ECUs) are becoming more and more popular. Each ECU has been connected to a variety of sensors, actuators, and other ECUs through a complex network of connections. Automotive manufacturers are using sophisticated wiring solutions, such as light-weight harnesses, insulated cables and high-temperature-resistant wires to manage the rising number of connections and ensure reliable performance. For instance, In July 2024, Compal Electronics Inc, a leading contract electronics manufacturer from Taiwan, announced plans to build its first European factory in Poland. The company intends to invest more than $15.4 million to target automotive electronics clients. This strategic move marks Compal’s expansion into the European market. The need for complex and more advanced wiring solutions will continue to grow as automobiles become more technologically advanced, fueling the worldwide automotive wires market’s expansion.

Schedule A Call :

Fluctuating cost of materials to hamper the market

The market for automotive wires is significantly impacted by the price fluctuations of raw materials, particularly copper and aluminum. These materials are necessary for making automobile wires, and the market’s ability to expand may be severely hindered by their price instability. For instance, vehicle automation requires multiple sensors, as well as additional on-board computers. A standard autonomous system, with 12 cameras, seven Light Detection and Ranging sensors (LiDARs), eight radars and one automated driving control unit, will all depend on copper connections to function safely and reliably.

Buy Now :

For more details on this report — Request for Sample

Key Market Players:

Product/Service launches, approvals, patents and events, acquisitions, partnerships, and collaborations are key strategies adopted by players in the Automotive Wires Market. The top 10 companies in this industry are listed below:

Aptiv plc

Yazaki Corporation

Furukawa Electric Co., Ltd

Sumitomo wiring systems

Nexans SA

Fujikura Ltd

Samvardhana Motherson International Ltd

Leoni AG

Lear Corporation

THB Electronics

Scope of the Report:

Report MetricDetails

Base Year Considered

2023

Forecast Period

2024–2030

CAGR

5.7%

Market Size in 2030

$ 6.8 Billion

Segments Covered

By Material, By Vehicle Type, By Propulsion, By Transmission Type, By Application, By End User and By Geography.

Geographies Covered

North America (U.S., Canada and Mexico), Europe (Germany, France, UK, Italy, Spain, Russia and Rest of Europe), Asia-Pacific (China, Japan, South Korea, India, Australia & New Zealand and Rest of Asia-Pacific), South America (Brazil, Argentina, Chile, Colombia and Rest of South America), Rest of the World (Middle East and Africa).

Key Market Players

1. Aptiv plc

2. Yazaki Corporation

3. Furukawa Electric Co., Ltd

4. Sumitomo wiring systems

5. Nexans SA

6. Fujikura Ltd

7. Samvardhana Motherson International Ltd

8. Leoni AG

9. Lear Corporation

10. THB Electronics

For more Automotive Market reports, please click here

0 notes

Text

3D Printing Materials Market Valued at USD 2,836.6 Million in 2025

Exploring the Dynamic World of 3D Printing Materials Market 2034

The world of 3D Printing Materials Market has come a long way since its inception, evolving from a niche technology to a mainstream manufacturing process. At the heart of this transformation is the ever-expanding universe of 3D printing materials. These materials are not just a means to an end; they are pivotal in defining what can be created, how it can be produced, and what industries can benefit from this cutting-edge technology. In this blog, we will delve into the key aspects of the 3D printing materials market, exploring the types, applications, and future trends shaping this exciting field.

Sample copy report:

https://wemarketresearch.com/reports/request-free-sample-pdf/3d-printing-materials-market/1338

Types of 3D Printing Materials

Thermoplastics: Thermoplastics are among the most widely used materials in 3D printing. They are known for their ease of use, affordability, and versatility. Popular thermoplastics include:

PLA (Polylactic Acid): Known for its eco-friendly nature and ease of printing, PLA is a favorite among hobbyists and beginners.

ABS (Acrylonitrile Butadiene Styrene): This material offers greater strength and durability, making it ideal for functional prototypes and end-use parts.

PETG (Polyethylene Terephthalate Glycol): Combining the ease of printing with durability, PETG is commonly used in applications requiring resistance to impact and moisture.

Resins: Resins are liquid materials that solidify under UV light and are used primarily in SLA (Stereolithography) and DLP (Digital Light Processing) printers. They offer high resolution and detail, making them suitable for applications such as jewelry and dental products. Key types include:

Standard Resins: Ideal for detailed models and prototypes.

Tough Resins: Engineered for increased durability and impact resistance.

Flexible Resins: Designed to produce parts with rubber-like properties.

Metals: Metal 3D printing is used for high-performance applications in industries such as aerospace, automotive, and medical. Metal powders, such as titanium, aluminum, and stainless steel, are used in processes like SLM (Selective Laser Melting) and EBM (Electron Beam Melting). Metal 3D printing offers:

High Strength-to-Weight Ratio: Essential for aerospace and automotive components.

Complex Geometries: Allows for the creation of intricate designs that are difficult to achieve with traditional manufacturing methods.

Composites: Composite materials combine thermoplastics with reinforcing fibers, such as carbon fiber or glass fiber, to enhance strength and rigidity. These materials are used in applications where lightweight and high strength are critical, including in the automotive and sports equipment industries.

Innovations Driving the 3D Printing Materials Market

The 3D printing materials market is experiencing rapid innovation, driven by advancements in technology and changing industry needs. Here’s a closer look at some of the latest innovations that are transforming the landscape of 3D printing materials:

Nanomaterials: Nanotechnology is making waves in the 3D printing industry by enabling the creation of materials with enhanced properties at the nanoscale. Nanomaterials can improve strength, durability, and thermal resistance, making them ideal for high-performance applications. For example, incorporating nanoparticles into polymers can enhance their mechanical properties, leading to more robust and reliable printed parts.

Bio-inks and Bioprinting: Bioprinting is revolutionizing the medical and research fields by enabling the creation of living tissues and organs. Bio-inks, which are made from natural and synthetic biopolymers, are used in this process to print cellular structures. These materials can be tailored to support cell growth and tissue development, opening up new possibilities for regenerative medicine and personalized healthcare.

Applications of 3D Printing Materials Market

The versatility of 3D printing materials market has led to their adoption across various sectors:

Aerospace: Lightweight and durable materials are used to manufacture complex parts and components, reducing overall weight and fuel consumption.

Healthcare: Custom prosthetics, implants, and dental products are tailored to individual patients using biocompatible materials.

Automotive: 3D printing enables rapid prototyping and production of lightweight parts, enhancing vehicle performance and reducing time-to-market.

Consumer Goods: Customized products, from eyewear to home decor, benefit from the flexibility and personalization offered by 3D printing.

Future Trends in 3D Printing Materials Market

As the 3D printing industry continues to evolve, several trends are likely to shape the future of 3D printing materials:

Biodegradable and Sustainable Materials: There is a growing focus on developing eco-friendly materials that reduce environmental impact. Innovations in biodegradable plastics and recycling processes are set to make 3D printing more sustainable.

Advanced Metal Alloys: The development of new metal alloys with enhanced properties will open up new possibilities for high-performance applications in industries such as aerospace and defense.

Multi-Material Printing: Advances in multi-material printing technologies will allow for the creation of complex objects with varying properties in a single print, expanding the range of applications and functionalities.

Smart Materials: The integration of materials that respond to environmental changes (such as temperature or pressure) will lead to the development of "smart" products with adaptive capabilities.

Benefits of 3D Printing Materials Market Report:

Analyst Support: Get your query resolved by our expert analysts before and after purchasing the report.

Customer Satisfaction: Our expert team will assist with all your research needs and customize the report.

Inimitable Expertise: Analysts will provide deep insights into the reports.

Assured Quality: We focus on the quality and accuracy of the report.

Conclusion