#Laminating Adhesives price

Explore tagged Tumblr posts

Text

Laminating Adhesives Market - Forecast(2023 - 2028)

The Laminating Adhesives Market size is estimated to reach US$3.1 billion by 2027 after growing at a CAGR of 5.9% during the forecast period 2022-2027. There are several laminating processes that are generally classified as either wet or dry laminating processes. The basic categories of laminating adhesives used are water-based, solvent-based, ultraviolet curable and hot melt adhesives

#Laminating Adhesives market share#Laminating Adhesives market size#Laminating Adhesives market place#market value#Laminating Adhesives price#Laminating Adhesives

2 notes

·

View notes

Note

Hello! I was wondering what company you use for your sticker sheets? I bough one from your Ko-Fi shop and really like the quality, and the pricing you were able to sell at is waaaaaay more reasonable compared to any of the companies I've seen and used myself. Is it a POD company, or a mass purchase of them to sell on your own?

Thank you for your time if you're able to respond!

I'm really glad you like the quality, because I actually make them by hand at home! (Please forgive the lighting, my bedroom is my office lmao.)

I don't use a company (and Idk what a POD company is sorry!) but making them at home gives a lot more freedom of stock, just be wary it can be very time consuming depending on how many you need to make.

I've had other people ask before, so here's a rundown of how I make my stickers at home: At most you'll need:

Printer

Sticker paper (this is the type that I use)

Laminator and lamination paper (the lamination paper that I use.) You can also use adhesive non-heat lamination paper if you don't have a laminator, gives you the same result, just be careful of bubbles. You will get double your worth out of a pack because we are splitting the pouches to cover two sticker sheets.

Your choice of a sticker cutting machine or just using scissors.

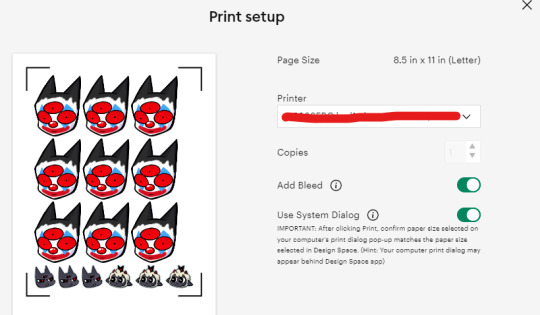

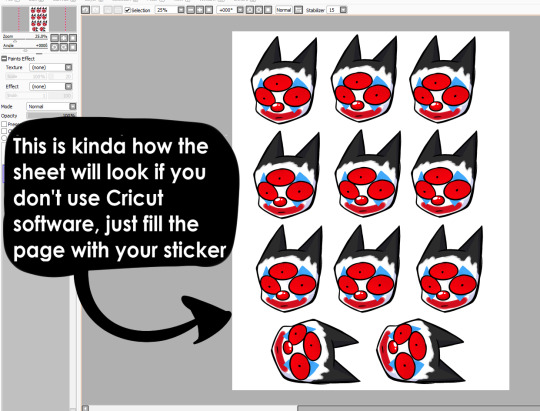

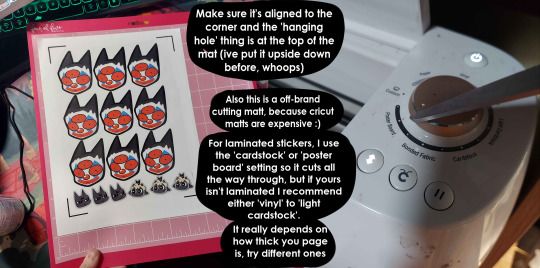

First, I use Cricut's software to print out the sticker sheet with the guidelines around the corners so the machine can read it. If you do NOT have a Cricut machine, open up your art program, make a canvas of 2550x3300 and fill it up with your sticker design with some cutting space between them. This the 8.5x11 size for the sticker page.

I usually have bleed selected so the cut comes out cleaner. Tip for non-Cricut users below: Increase the border around your sticker design to fake the 'bleed' effect for a cleaner cut.

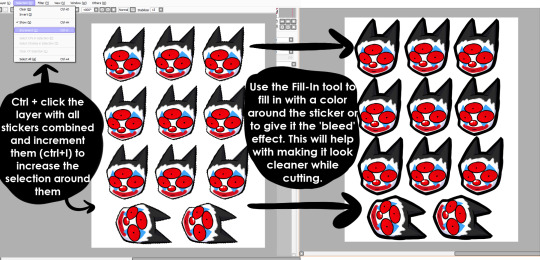

These are the print settings I use for my printer. I use the 'use system dialogue' to make sure I can adjust the settings otherwise it prints out low quality by default. Make sure if you're using the above paper that you have 'matte' selected, and 'best quality' selected, these aren't usually selected by default.

So you have your sticker sheet printed! Next is the lamination part. I use a hot laminator that was gifted to me, but there is no-heat types of lamination you can peel and stick on yourself if that's not an option.

(This is for protection and makes the colors pop, but if you prefer your stickers matte, you can skip to the cutting process.)

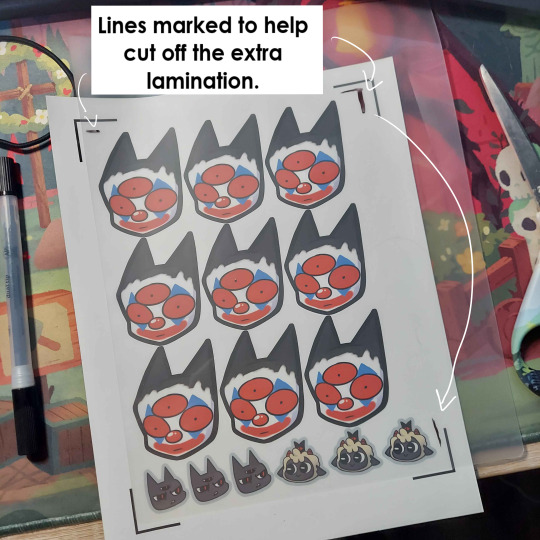

Important for Cricut users or those planning to get a Cricut: You're going to cut the lamination page to cover the stickers while also not covering the guidelines in the corners. First, take your lamination page and lay it over the sheet, take marker/pen and mark were the edges of your stickers are, and cut off the excess:

(I save the scrap to use for smaller stickers or bonuses later on)

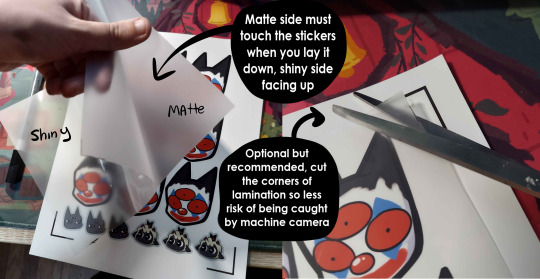

After you've cut out your lamination rectangle, separate the two layers and lay one down on your sticker sheet over your stickers with matte side down, shiny side up. (Save the other sheet for another sticker page)

The gloss of the lamination will prevent the machine from reading the guidelines, so be careful not to lay it over them. It also helps to cut the corners afterwards to prevent accidentally interfering with the guidelines.

Now put that bad boy in the laminator! (Or self seal if you are using non-heat adhesive lamination)

Congrats! You now have a laminated page full of stickers.

For non-cricut/folks cutting them out by hand: this is the part where you start going ham on the page with scisscors. Have fun~

Cutting machine: I put the page on a cutting mat and keep it aligned in the corner, and feed it into the machine. For laminated pages I go between 'cardstock' and 'poster board' so that it cuts all the way through without any issues, but for non-laminated pages or thinner pages, I stick for 'vinyl' and 'light card stock'. Kinda test around.

Now I smash that go button:

You have a sticker now!

The pros of making stickers at home is that you save some cost, and you have more control of your stock and how soon you can make new designs. (I can't really afford to factory produce my stickers anyway)

However, this can be a very time consuming, tedious process especially if you have to make a lot of them. There is also a LOT chance for some errors (misprints, miscuts, lamination bubbles, ect) that will leave you with B-grade or otherwise not-so-perfect or damaged stickers. (Little note, if you have page mess up in printing and can't be fed into the cricut machine, you can still laminate it and cut it out by hand too.)

I have to do a lot of sticker cutting by hand, so if you don't have a cricut don't stress too much about it. I have an entire drawer filled to the top of miscuts/misprints. I keep them because I don't want to be wasteful, so maybe one day they'll find another home. Sucks for my hand though.

But yeah! This is how I make my stickers at home! Hope this is helpful to anyone curious

1K notes

·

View notes

Text

EPOXYSHİNE - DRAGON+ (3)

Epoxy floor coating is not just a practical choice for enhancing the durability of your flooring; it's also a stylish solution that can transform any space. Whether you're a homeowner looking to revamp your garage or a business owner seeking reliable commercial flooring solutions, understanding the benefits of epoxy will help you make informed decisions. As you search for "floor polishing near me," consider how an expertly applied epoxy coating can elevate your interiors while providing a long-lasting finish.

Epoxy Floor Coating

Epoxy floor coating is a highly durable and resilient flooring solution that has gained popularity in both residential and commercial spaces. This type of coating is made from a combination of resin and hardener, creating a strong bond when applied to existing concrete surfaces. The result is a seamless surface that can withstand heavy foot traffic, chemicals, and abrasions.

One of the major benefits of epoxy floor coating is its versatility. It can be customized in various colors and finishes, including high-gloss and matte textures. This means that property owners can choose a look that complements their interior design while still providing the durability they require. Additionally, the smooth finish of epoxy makes it easy to clean and maintain, which is particularly advantageous in commercial settings.

Furthermore, the installation process for epoxy floor coating is relatively quick, often completed within a few days. However, it’s essential to hire professionals who have the expertise and equipment to ensure a flawless application. The right team will properly prepare the surface, allowing for optimal adhesion and longevity of the coating.

Floor Polishing Near Me

When searching for floor polishing near me, it's essential to find a service that not only meets your expectations but also understands the unique needs of your flooring. Professional floor polishing can revitalize old surfaces, restoring their shine and luster while protecting them from future wear and tear.

Many local companies offer specialized services in floor polishing that cater to various materials, including hardwood, tile, and concrete. A quick search in your area will yield numerous options, allowing you to compare prices, services, and customer reviews to find the best fit for your needs.

Additionally, hiring professionals for floor polishing ensures that the job is done correctly and efficiently. They use advanced equipment and high-quality products that not only enhance the appearance of your floors but also extend their lifespan. So, don't hesitate to reac

Commercial Flooring Solutions

Commercial flooring solutions are essential for businesses seeking to enhance their aesthetic appeal while also ensuring durability and functionality. The choice of flooring can greatly influence the overall atmosphere of a commercial space, leading to improved employee morale and customer satisfaction.

Among the various options available, epoxy floor coatings stand out due to their seamless finish and resistance to heavy foot traffic. These coatings not only provide a sleek look but also protect the underlying surface from wear and tear, making them ideal for warehouses, retail spaces, and industrial environments.

Moreover, businesses often explore additional options such as vinyl flooring, carpet tiles, and laminate surfaces to meet specific needs. Each of these materials offers unique advantages, allowing business owners to choose the most suitable flooring solution that aligns with their operational demands and aesthetic preferences.

Metallic Epoxy Floor

A metallic epoxy floor offers a stunning visual appeal that enhances the aesthetic of any space. The reflective properties of the metallic pigments create a unique look, resulting in a three-dimensional effect that can mimic a variety of surfaces, such as water, marble, or even molten metal. This type of flooring is especially popular in modern homes, showrooms, and commercial spaces, providing an eye-catching yet durable surface.

One of the significant advantages of a metallic epoxy floor is its durability. This flooring solution is resistant to stains, chemicals, and impacts, making it ideal for high-traffic areas. Additionally, it is easy to clean and maintain, which means that business owners and homeowners can save time and resources. The seamless nature of epoxy flooring also contributes to a hygienic environment, especially in spaces like hospitals or laboratories.

Installing a metallic epoxy floor can be a customized process, allowing property owners to choose their preferred colors and patterns. Whether you’re looking for a sleek, industrial look or a vibrant, artistic finish, this flooring solution can be tailored to meet your unique vision. By consulting with professionals, you can ensure that your metallic epoxy floor is installed correctly and maximizes its longevity and beauty.

598 notes

·

View notes

Text

I would like to add as an artist who would actually produce my stickers completely from home back when I was doing Etsy- instead of relying on slave labor you could easily just. make the shit on your own?? I started making stickers out of paper and tape and when I got my first job I bought a cheap printer for my laptop and a cheap drawing tablet, started getting some sticker paper and adhesive lamination sheets and boom high quality stickers I could sell on Etsy. There are always ways you can produce materials yourself. Sew your own plushies. Make your own charms. Learn a new skill. Like, it just goes to show how fucking unskilled these "small businesses"- who just rely on others labor and resell it at a higher price- really are. The government WANTS you to feel like you are helpless without it. Adapt and overcome. learning is good! learn from your community. don't let them make you helpless!

6K notes

·

View notes

Text

Polyvinyl Butyral Film Market, Global Outlook and Forecast 2025-2032

Polyvinyl Butyral (PVB) film is a translucent thermoplastic resin film primarily made from polyvinyl butyral resin, which is plasticized using a plasticizer. This versatile material is primarily used in the production of laminated safety glass. PVB film boasts several desirable features such as high transparency, mechanical strength, and excellent adhesion to inorganic glass. It is resistant to heat, cold, and humidity, making it an essential material in a range of industries. Its notable flexibility and excellent optical clarity make it ideal for use in applications requiring robust, clear, and safe glass.

In the global market, PVB film is predominantly utilized for constructing safety glass in automobiles, buildings, and bulletproof materials. The transparency of the film allows it to maintain clear visibility while also offering enhanced protection against external forces, such as impacts and UV rays. In addition to its use in safety glass, PVB film is also widely applied in photovoltaic glass production, which is used in solar panels.

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/286915/global-polyvinyl-butyral-film-forecast-market-2025-2032-971

Market Size

The global Polyvinyl Butyral Film market is currently valued at USD 2509.90 million as of 2023, and it is expected to grow at a compound annual growth rate (CAGR) of 2.50% during the forecast period, reaching USD 2983.48 million by 2032. The PVB film market has been steadily expanding due to the increasing demand for safety glass, particularly in the automotive and construction industries, as well as in emerging applications like photovoltaic glass.

The market’s growth is being driven by the expanding infrastructure and construction sectors, along with rising safety regulations for vehicles and buildings. Furthermore, the increasing focus on renewable energy and solar technologies is adding a new layer of demand for PVB film in the solar panel industry.

Key Statistics:

Market Size (2023): USD 2509.90 million

Projected Market Size (2032): USD 2983.48 million

CAGR (2025-2032): 2.50%

Market Dynamics

Drivers

Several factors are driving the growth of the global Polyvinyl Butyral Film market:

Increasing demand for safety glass: As more construction projects and automobiles incorporate safety glass, PVB film's demand is rising. Its ability to maintain glass integrity under stress and impact, such as during car crashes, makes it an indispensable component in the safety glass sector.

Rising automotive production: The growing global automotive industry is a key driver for the PVB film market. As more automakers produce vehicles with enhanced safety features, PVB film’s use in laminated windshields and side windows continues to grow.

Renewable energy growth: The demand for photovoltaic glass used in solar panels is accelerating as the renewable energy market expands. PVB film plays a crucial role in the production of solar panel covers, which require high transparency and durability.

Restraints

However, some challenges persist:

Fluctuating raw material costs: The price volatility of raw materials used in the production of PVB film, such as polyvinyl butyral resin, can negatively impact the market.

Environmental concerns: While PVB film is recyclable, the disposal of non-recyclable laminated glass remains an issue. This environmental concern may hamper market growth in regions focused on sustainability.

Opportunities

The market also presents several growth opportunities:

Expansion in emerging markets: Rapid urbanization and industrialization in developing countries like India, China, and Brazil are fueling demand for PVB film, particularly in construction and automotive industries.

Technological advancements: Innovation in PVB film production, such as the development of more efficient, cost-effective, and eco-friendly manufacturing processes, presents opportunities for companies to enhance product offerings.

Challenges

Despite the opportunities, there are notable challenges:

Competitive pricing pressures: Companies must contend with intense price competition in the PVB film market, which can squeeze margins, especially for smaller manufacturers.

Economic uncertainties: Economic downturns or shifts in consumer preferences could slow down demand for products relying on PVB films, such as automobiles and construction projects.

Regional Analysis

The global PVB film market is geographically segmented into several key regions, each with distinct demand patterns.

North America

The North American market, particularly the United States, holds a significant share in the global PVB film market. In 2023, the North American market size was USD 654.01 million, and it is expected to grow at a CAGR of 2.14% from 2025 through 2032. The region's demand for automotive safety glass, as well as its growing focus on green energy and solar panel applications, drives the demand for PVB film.

Europe

Europe is another important region for PVB film, particularly in the automotive and construction sectors. With stringent safety standards and environmental regulations, Europe has seen a steady rise in demand for high-quality laminated glass for both residential and commercial applications.

Asia-Pacific

Asia-Pacific is anticipated to witness the highest growth rate during the forecast period, fueled by rapid industrialization, urbanization, and the growing automotive and construction markets. China, Japan, and India are expected to be key growth drivers in this region.

South America

The South American market is growing at a moderate pace due to the increasing demand for automotive safety features and improving infrastructure in countries like Brazil and Argentina.

Middle East and Africa

In this region, demand for PVB film is largely driven by the construction and automotive sectors, particularly in countries like Saudi Arabia, UAE, and South Africa.

Competitor Analysis

Key Companies

Eastman – Known for its global presence and diverse range of products, Eastman is a leader in the PVB film market, offering high-quality films for automotive and construction applications.

DowDuPont – A major player in the materials sector, DowDuPont provides advanced PVB films that are widely used in safety glass production.

Sekisui – A prominent manufacturer of PVB films, Sekisui offers a range of high-performance products used in automotive, construction, and solar industries.

Trosifol – A leading global supplier of PVB film, Trosifol is known for its products used in both safety and photovoltaic glass applications.

Kuraray – A Japanese company that produces PVB films for a variety of applications, including construction, automotive, and solar panels.

Global Polyvinyl Butyral Film Market: Market Segmentation Analysis

This report provides a deep insight into the global Polyvinyl Butyral Film market, covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market size, competitive landscape, development trend, niche market, key market drivers and challenges, SWOT analysis, value chain analysis, etc.

The analysis helps the reader to shape the competition within the industries and strategies for the competitive environment to enhance the potential profit. Furthermore, it provides a simple framework for evaluating and assessing the position of the business organization. The report structure also focuses on the competitive landscape of the Global Polyvinyl Butyral Film Market. This report introduces in detail the market share, market performance, product situation, operation situation, etc., of the main players, which helps the readers in the industry to identify the main competitors and deeply understand the competition pattern of the market.

In a word, this report is a must-read for industry players, investors, researchers, consultants, business strategists, and all those who have any kind of stake or are planning to foray into the Polyvinyl Butyral Film market in any manner.

Market Segmentation (by Application)

Construction

Automotive

Photovoltaic Glass Industry

Others

Market Segmentation (by Type)

Construction Grade

Automotive Grade

Solar Grade

Key Company

Eastman

DowDuPont

GVC

Sekisui

Trosifol

Kuraray

J&S Group

ChangChun

Zhejiang Decent

Lifeng Group

Xinfu Pharm

DuLite

Aojisi

Huakai PVB

Liyang PVB

Meibang

Geographic Segmentation

North America (USA, Canada, Mexico)

Europe (Germany, UK, France, Russia, Italy, Rest of Europe)

Asia-Pacific (China, Japan, South Korea, India, Southeast Asia, Rest of Asia-Pacific)

South America (Brazil, Argentina, Columbia, Rest of South America)

The Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, South Africa, Rest of MEA)

FAQ

What is the current market size of Polyvinyl Butyral Film?

➣ The global Polyvinyl Butyral Film market was valued at USD 2509.90 million in 2023, with expectations to reach USD 2983.48 million by 2032.

Which are the key companies operating in the Polyvinyl Butyral Film market?

➣ Key companies include Eastman, DowDuPont, Sekisui, Trosifol, and Kuraray, among others.

What are the key growth drivers in the Polyvinyl Butyral Film market?

➣ The main growth drivers are the increasing demand for safety glass, the growing automotive production, and the expansion of renewable energy technologies.

Which regions dominate the Polyvinyl Butyral Film market?

➣ North America, Europe, and Asia-Pacific dominate the market, with Asia-Pacific expected to see the highest growth rate.

What are the emerging trends in the Polyvinyl Butyral Film market?

➣ Emerging trends include advancements in eco-friendly manufacturing processes, increased demand for photovoltaic glass, and expansion in emerging markets.

Key Benefits of This Market Research: • Industry drivers, restraints, and opportunities covered in the study • Neutral perspective on the market performance • Recent industry trends and developments • Competitive landscape & strategies of key players • Potential & niche segments and regions exhibiting promising growth covered • Historical, current, and projected market size, in terms of value • In-depth analysis of the Polyvinyl Butyral Film Market • Overview of the regional outlook of the Polyvinyl Butyral Film Market:

Key Reasons to Buy this Report: • Access to date statistics compiled by our researchers. These provide you with historical and forecast data, which is analyzed to tell you why your market is set to change • This enables you to anticipate market changes to remain ahead of your competitors • You will be able to copy data from the Excel spreadsheet straight into your marketing plans, business presentations, or other strategic documents • The concise analysis, clear graph, and table format will enable you to pinpoint the information you require quickly • Provision of market value (USD Billion) data for each segment and sub-segment • Indicates the region and segment that is expected to witness the fastest growth as well as to dominate the market • Analysis by geography highlighting the consumption of the product/service in the region as well as indicating the factors that are affecting the market within each region • Competitive landscape which incorporates the market ranking of the major players, along with new service/product launches, partnerships, business expansions, and acquisitions in the past five years of companies profiled • Extensive company profiles comprising of company overview, company insights, product benchmarking, and SWOT analysis for the major market players • The current as well as the future market outlook of the industry concerning recent developments which involve growth opportunities and drivers as well as challenges and restraints of both emerging as well as developed regions • Includes in-depth analysis of the market from various perspectives through Porter’s five forces analysis • Provides insight into the market through Value Chain • Market dynamics scenario, along with growth opportunities of the market in the years to come • 6-month post-sales analyst support

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/286915/global-polyvinyl-butyral-film-forecast-market-2025-2032-971

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Product Details: Material: High quality durable PVC VinylRoll Size: Large Size in cms: 45 x 1000 cm[Need 3 Rolls to cover a 10 ft by 10 ft Wall Size.] Ideal Surface: This self-adhesive wallpaper is ideal to decorate walls of bedrooms, living room, hall, kitchen, bathroom, kids room, play room, nursery, study, office, restaurants, furniture, putty wall and tile wall.You can give it a quick makeover to your refrigerator, wardrobe, kitchen cabinets, table top, beds. Just ensure the surface is smooth and clean. HOME DECOR, MULTI-USE: This decorative textured self-adhesive pvc wallpaper is ideal to decorate wall of bedroom, living room, hall, kitchen, bathroom, kids room, play room, nursery, study, office, restaurants, etc. Can be applied on furniture, putty wall or renovate kitchen counter tops, cupboard, shelf liner, furniture, dining table, centre table, home/office desk, side tables, almirah, fridge, drawers, lamination, and tiles as well. MATERIAL: PVC Vinyl ROLL SIZE: Large Size in cms: 45 x 1000 cm [Need 3 Rolls to cover a 10 ft by 10 ft Wall Size.] SAFE FOR WALLS: This embossed decorative stickers contact paper is Removable, Waterproof, Heat resistant, Oil-resistant, Re-positionable and Eco-friendly. Wolpin white wall decal is made with High quality Eco and durable PVC material. Accent the wall, kitchen, furniture and bathroom in your home with this bright, lively wallpaper. JUST PEEL & STICK: Easy to apply! This wall paper can be applied to any smooth, clean and dry Surface. There are gridlines on the back for easy measurement and cutting. It’s easy to remove or re-use and they don't leave sticky messes behind. CUSTOMER NOTE: If you wish to reposition the stickers after they have been applied on the walls; remove the stickers carefully to avoid any damage. The stickers can be reapplied, but its adhesive properties might be reduced. For newly painted walls, it’s suggested to wait for 4 weeks before applying the decal. DO NOT apply on wet walls. [ad_2]

0 notes

Text

Top Rated Cosmetic Dental Services in Sydney - Miranda Dental Centre

Cosmetic Dentistry Sydney - Miranda Dental Centre

Cosmetic dentistry Sydney involves improving the aesthetics of your teeth, whether thats by means of teeth whitening, fillings, veneers or crowns.

We offer the full range of cosmetic dentistry Sydney procedures at our premier dental clinic in Sydney. Our cosmetic dentist Sydney services include teeth straightening, teeth whitening, composite fillings, porcelain veneers, ceramic onlays, smile makeover, implants, and much more. Trust our cosmetic dentists in Sydney to help you create the smile of your dreams.Our team of Sydney cosmetic dentists has years of experience and the latest in cosmetic dentistry Sydney equipment and cosmetic dental techniques to ensure you achieve the look you desire. We are constantly striving to research, educate and develop our skills using the latest concepts and best techniques to achieve perfect results for a beautiful smile with cosmetic dentist Sydney.

Cosmetic dental treatments can remedy a number of dental problems, such as deformed teeth, crooked teeth, and discolored teeth. Whatever aspect you are not happy with your teeth, we are confident we can help. Residents of Sydney trust Miranda Dental Center for all types of cosmetic dentistry to deliver incredible results. Our cosmetic dental practice offers the following treatments.

Teeth whitening is a procedure that lightens teeth and helps remove stains and discolouration. This is considered the most advanced form of teeth whitening. This technology is far more advanced and fast than the traditional bleaching system. Laser whitening will get your smile that is four shades whiter in just 45 minutes. We offer Sydney’s most competitive price for Teeth whitening. We will also provide you with a professional whitening plan and cosmetic dentistry specially customized to your unique needs and smile. This technology is created to ensure optimum safety and comes in different treatment types and strengths to fit your lifestyle and sensitivity.

Composite fillings are glass or quartz filler mixtures in a resin medium that produces a tooth-coloured filling. They are sometimes referred to as composites or filled resins. Composite fillings provide good durability and resistance to fracture in small-to-mid size restorations that must withstand moderate chewing pressure. Less tooth structure is removed when the dentist prepares the tooth, resulting in a smaller filling than that of an amalgam. Composites can also be “bonded” or adhesively held in a cavity, often allowing the dentist to make a more conservative repair to the tooth.

Porcelain Veneers are a fast, easy and permanent solution for achieving a beautiful, healthy, well-proportioned smile. Porcelain veneers, also called porcelain laminates, are ideal for teeth that have spaces or those that are crooked, chipped, misshapen or discoloured. Porcelain veneers can replace tooth structure lost from grinding or over-aggressive brushing. In some cases, porcelain laminates can be used faster than time-consuming orthodontic treatments.

A very conservative and cosmetically appealing option to repair a back tooth missing a significant amount of tooth structure is a “ceramic” or porcelain only.These restorations are a strong restorative option and have a high esthetic appeal due to the strong resemblance to the natural tooth due to the translucency of porcelain.

Why Do You Need to See a Cosmetic Dentist for Cosmetic Dentistry Sydney?

If you decide to improve the appearance of your teeth and smile, you should go to a cosmetic dentist who has additional experience in cosmetic dentistry Sydney.

All the experts at Sydney Cosmetic Dental Clinic are under one roof to ensure that your new smile is formed to the maximum and lasts a long time as well as looks stunning.

Our team of experts works together in Sydney to plan your Cosmetic Dental case so that all your Cosmetic Dentistry Sydney procedures you need can work together in the best possible way.

For example, if the veneers are planned after you have straightened your teeth, our orthodontist will place your teeth in the most ideal position dictated by our cosmetic dentist to not only create the best result but to reduce the amount of tooth reduction required for the veneer and in some cases, they completely avoid tooth reduction.

We also ensure that your teeth are ideally positioned to receive an implant for any missing teeth.

When you are looking for the best cosmetic dentist Sydney, Sydney residents turn to Miranda Dental Center again and again as we provide beautiful restorations balanced with your face structure.

#Cosmetic dental treatments#cosmetic dentist Sydney#laser whitening#Porcelain veneers#Teeth Whitening

0 notes

Text

Hindustan Group Your Trusted Source for the Best PF Resin in India

PF resin, also known as phenolic resin, is a synthetic polymer that is widely used in a variety of industrial and commercial applications. It is known for its high strength, durability, and resistance to heat and chemicals. Hindustan Group is one of the leading manufacturers of PF resin in India, with a proven track record of providing high-quality products to a wide range of customers.

Hindustan Group's Best Pf Resin Suppliers in India using the latest state-of-the-art technology and equipment. The company uses only the finest raw materials and has a team of highly skilled and experienced engineers and technicians who ensure that the products meet the highest quality standards. Hindustan Group's PF resin is available in a variety of grades and specifications to meet the specific needs of its customers.

Hindustan Group's PF resin is used in a wide range of applications, including:

Automobile: PF resin is used in a variety of automobile components, such as brake linings, clutch plates, and gaskets.

Electrical: PF resin is used in electrical insulation and circuit boards.

Construction: PF resin is used in adhesives, laminates, and plywood.

Foundry: PF resin is used in sand molds and cores.

Others: PF resin is also used in a variety of other applications, such as abrasives, paints, and coatings.

Hindustan Group is committed to providing its customers with the best possible products and services. The company has a dedicated team of customer service representatives who are always available to answer questions and provide assistance. Hindustan Group also offers a variety of value-added services, such as technical support and product training.

If you are looking for a reliable and trusted source of PF resin in India, Hindustan Group is the perfect choice. The company offers a wide range of high-quality products at competitive prices. Hindustan Group is also committed to providing its customers with the best possible products and services.

Here are some of the benefits of choosing Hindustan Group for your PF resin needs:

High-quality products: Hindustan Group uses the latest state-of-the-art technology and equipment to manufacture its PF resin, ensuring that the products meet the highest quality standards.

Wide range of products: Hindustan Group offers a wide range of PF resin grades and specifications to meet the specific needs of its customers.

Competitive prices: Hindustan Group offers its PF resin products at competitive prices.

Dedicated customer service: Hindustan Group has a dedicated team of customer service representatives who are always available to answer questions and provide assistance.

Value-added services: Hindustan Group also offers a variety of value-added services, such as technical support and product training.

If you are looking for the best PF resin in India, contact Hindustan Group today. The company is committed to providing its customers with the highest quality products and services.

0 notes

Text

Laminating Adhesives Market

The Laminating Adhesives Market size is estimated to reach US$3.1 billion by 2027 after growing at a CAGR of 5.9% during the forecast period 2022-2027. There are several laminating processes that are generally classified as either wet or dry laminating processes

#Laminating Adhesives market share#Laminating Adhesives market size#Laminating Adhesives market value#Laminating Adhesives market place#Laminating Adhesives price#Laminating Adhesives

0 notes

Text

Effortlessly Create Professional Name Tags with a Name Tag Machine

25mm Starter "S Type" Badge Maker Kit:

Versatile Press (accepts other size button badge tooling (optional)25 mm Button Making ToolingUniversal Paper Circle Cutter100 Button Badges (sets of 25mm components)

With this badge machine setup you will also be able to make: keyrings, bottle opener keyrings, lanyard badges, paper clip fridge magnets, fridge magnets, mirror keyrings, clip button badges, cartoon keyrings & more products coming...

What is a Name Tag Machine?

A name tag machine is a compact device designed to produce high-quality name tags on demand. These machines offer features such as:

Customizable Designs: Add names, logos, and even QR codes.

Durable Materials: Create tags using plastic, metal, or laminated paper.

Portability: Compact and easy to set up for on-site usage.

Benefits of Using a Name Tag Machine

Cost Efficiency

Avoid outsourcing name tag printing. Create high-quality tags at a fraction of the cost.

Customisation Flexibility

Personalize tags with company branding, colors, and unique designs tailored to specific events.

Time Savings

Print name tags instantly without waiting for external suppliers.

Versatile Applications

Perfect for conferences, trade shows, schools, retail stores, and more.

44mm Starter "S Type" Badge Maker Kit:

Versatile Press (accepts other size button badge tooling (optional)44 mm Button Making ToolingUniversal Paper Circle Cutter100 Button Badges (sets of 44mm components)

With this badge machine setup you will also be able to make: keyrings, bottle opener keyrings, lanyard badges, paper clip fridge magnets, fridge magnets, mirror keyrings, clip button badges, cartoon keyrings & more products coming...

Note: currently GOLD colour (new release 2024 improved model ) machines in stock only.

How Does a Name Tag Machine Work?

Design Creation: Use pre-installed software or upload your designs to the machine.

Material Selection: Choose from a variety of materials such as metal plates, plastic sheets, or adhesive labels.

Printing or Engraving: The machine either prints or engraves the design onto the tag material.

Cutting and Finishing: Tags are shaped and polished for a professional finish.

Features to Look For in a Name Tag Machine

Ease of Use: Intuitive interfaces and simple design software for quick operation.

Printing or Engraving Options: Decide between full-color printing or professional engraving based on your needs.

Material Compatibility: A versatile machine should handle various materials like plastic, wood, and metal.

Portability: Lightweight machines are ideal for events or offices with limited space.

Durability: Ensure the machine can handle bulk orders and produce consistent results.

Who Can Benefit from a Name Tag Machine?

Event Planners

Create custom name tags for conferences, weddings, and trade shows.

Corporations

Design employee badges with logos and job titles for a polished and professional look.

Retail Businesses

Produce name tags for staff that align with your brand identity.

Schools and Universities

Personalize name badges for students, faculty, and staff.

Small Businesses

Save money and time by printing tags in-house for your growing team.

Why Choose BadgeMachine for Your Name Tag Machine?

High-Quality Machines

Durable and efficient machines built to meet professional standards.

bnCustom Design Assistance

Our design experts are available to help you create the perfect name tag template.

Affordable Solutions

Competitive pricing and bulk discounts for small and large businesses alike.

Excellent Customer Support

From setup to troubleshooting, our team is here to guide you every step of the way.

Eco-Friendly Options

Machines compatible with sustainable materials to reduce environmental impact.

Get Started with BadgeMachine Today

A name tag machine is a game-changer for businesses and organizations that value efficiency, personalization, and professionalism. At BadgeMachine, we offer a wide range of name tag machines designed to fit your unique needs.

Ready to simplify name tag production? Contact us today to learn more about our name tag machines and how they can revolutionize your branding!

0 notes

Text

Laminate Veneers Cost in Dubai: A Guide to a Perfect Smile

If you're dreaming of a flawless smile, laminate veneers might be the perfect solution. These thin, custom-made shells are designed to cover the front surface of your teeth, improving their appearance. Dubai has become a hotspot for cosmetic dentistry, offering state-of-the-art facilities and skilled professionals. But how much do laminate veneers cost in Dubai, and what factors influence the price? Let’s dive into the details.

What Are Laminate Veneers?

Laminate veneers are ultra-thin, tooth-colored shells typically made from porcelain or composite resin. They are bonded to the front surface of your teeth to correct various dental issues, such as:

Discolored or stained teeth

Chipped or broken teeth

Gaps between teeth

Minor misalignments

Uneven or worn-down teeth

Benefits of Laminate Veneers

Enhanced Aesthetics

Achieve a natural, radiant smile with veneers that mimic the appearance of real teeth.

Durability

Porcelain veneers are stain-resistant and can last up to 15 years with proper care.

Minimally Invasive

Veneer application typically involves minimal removal of tooth enamel compared to other restorative procedures.

Quick Results

Transform your smile in just a few appointments.

laminate veneers cost in Dubai

The laminate veneers cost in Dubai varies based on several factors. On average, the price ranges between AED 1,000 to AED 2,500 per tooth.

Factors Influencing the Cost

Material

Porcelain veneers are generally more expensive than composite veneers due to their superior durability and aesthetics.

Dentist’s Expertise

Highly experienced cosmetic dentists may charge premium fees for their expertise.

Technology Used

Clinics employing advanced tools like 3D imaging and CAD/CAM technology may have higher costs.

Number of Veneers Required

The total cost depends on how many teeth need veneers.

Clinic Location and Reputation

Premium dental clinics in prime Dubai locations may charge more for their services.

Why Choose Dubai for Laminate Veneers?

Dubai offers a blend of luxury, expertise, and innovation in dental care. Here’s why it’s a top destination for cosmetic dentistry:

World-Class Facilities: Cutting-edge technology and modern clinics ensure exceptional results.

Skilled Professionals: Dubai is home to experienced cosmetic dentists specializing in veneer applications.

Convenient Appointments: Clinics cater to the schedules of busy professionals and international patients.

Luxury Experience: Enjoy high-quality care in a comfortable, premium setting.

The Veneer Procedure: What to Expect

Consultation

Your dentist evaluates your teeth, discusses your goals, and creates a personalized treatment plan.

Tooth Preparation

A thin layer of enamel is removed to make space for the veneers.

Impressions or Scans

Digital scans or molds are taken to create custom veneers.

Application

Once the veneers are ready, they are bonded to your teeth using a strong adhesive.

Final Adjustments

Your dentist ensures the veneers fit perfectly and look natural.

Caring for Your Laminate Veneers

To maintain your veneers and prolong their lifespan:

Brush and floss daily using non-abrasive toothpaste.

Avoid biting into hard objects like ice or pencils.

Limit consumption of stain-causing foods and drinks like coffee and red wine.

Visit your dentist regularly for check-ups and cleanings.

Why Choose Dr. Aburas Dental Center for Laminate Veneers?

At Dr. Aburas Dental Center, we specialize in delivering exceptional cosmetic dentistry results, including high-quality laminate veneers. Here’s what sets us apart:

Expert Dentists: Our team has years of experience in smile makeovers.

Advanced Technology: We use the latest tools to ensure precision and comfort.

Customized Solutions: Each veneer is tailored to match your unique smile.

Patient-Centric Care: We prioritize your comfort and satisfaction throughout the process.

Transform Your Smile Today

If you’re considering laminate veneers in Dubai, now is the time to take the first step. Contact Dr. Aburas Dental Center to schedule a consultation and discover how veneers can enhance your smile and confidence.

#LaminateVeneersDubai#CosmeticDentistry#DrAburasDentalCenter#SmileMakeoverDubai#PorcelainVeneers#DubaiDentalCare#PerfectSmile#VeneersCostDubai#LuxuryDentalCare#DubaiDentist

0 notes

Text

Global Graphic Roll Laminator Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2035

A Graphic Roll Laminator use large rolls of film to laminate documents that are of just about any size, and a number of documents that can be cut or trimmed when finished. Items are placed at the opening on one sheet of plastic (the plastic sheets that are lined with adhesive). There is a roller on top that holds the top layer of laminate in place. As the machine starts, the item is run though and the two sheets of adhesive-lined plastic are heated to the extent that they will adhere permanently together around the document. According to our (Global Info Research) latest study, the global Graphic Roll Laminator market size was valued at USD 319 million in 2022 and is forecast to a readjusted size of USD 388.9 million by 2035 with a CAGR of 2.9% during review period. The influence of COVID-19 and the Russia-Ukraine War were considered while estimating market sizes. The Major regions to sale Graphic Roll Laminator are North America and China, which accounted for about 57% of sales market share in total. North America is the largest consumption region with a sales share of 30%. The leading players are ACCO, Wenzhou Guangming, Royal Sovereign, GMP, D&K, accounting for 57 percent revenue market share. The market segment by two types: Heat Graphic Roll Laminator and Cold Graphic Roll Laminator. The applications of Graphic Roll Laminator are Printing Shop and Printing Factory. Printing Shop is the dominated application, which accounts for nearly 70% of total consumption This report is a detailed and comprehensive analysis for global Graphic Roll Laminator market. Both quantitative and qualitative analyses are presented by manufacturers, by region & country, by Type and by Application. As the market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of selected competitors, along with market share estimates of some of the selected leaders for the year 2025, are provided.

Sample Plan: https://www.reportsintellect.com/sample-request/2911809 Key Features: Global Graphic Roll Laminator market size and forecasts, in consumption value ($ Million), sales quantity (Units), and average selling prices (USD/Unit), 2018-2029 Global Graphic Roll Laminator market size and forecasts by region and country, in consumption value ($ Million), sales quantity (Units), and average selling prices (USD/Unit), 2018-2029 Global Graphic Roll Laminator market size and forecasts, by Type and by Application, in consumption value ($ Million), sales quantity (Units), and average selling prices (USD/Unit), 2018-2029 Global Graphic Roll Laminator market shares of main players, shipments in revenue ($ Million), sales quantity (Units), and ASP (USD/Unit), 2018-2025

Inquire Request: https://www.reportsintellect.com/discount-request/2911809 The Primary Objectives in This Report Are: To determine the size of the total market opportunity of global and key countries To assess the growth potential for Graphic Roll Laminator To forecast future growth in each product and end-use market To assess competitive factors affecting the marketplace This report profiles key players in the global Graphic Roll Laminator market based on the following parameters - company overview, production, value, price, gross margin, product portfolio, geographical presence, and key developments. Key companies covered as a part of this study include ACCO, Wenzhou Guangming, Royal Sovereign, GMP and D&K, etc. This report also provides key insights about market drivers, restraints, opportunities, new product launches or approvals, COVID-19 and Russia-Ukraine War Influence. Market Segmentation Graphic Roll Laminator market is split by Type and by Application. For the period 2018-2035, the growth among segments provides accurate calculations and forecasts for consumption value by Type, and by Application in terms of volume and value. This analysis can help you expand your business by targeting qualified niche markets. Market segment by Type Heat Graphic Roll Laminator Cold Graphic Roll Laminator Market segment by Application Printing Shop Printing Factory Major players covered ACCO Wenzhou Guangming Royal Sovereign GMP D&K Zhejiang Liming Shanghai Dragon Vivid Laminating Technologies Shanghai Loretta Kala Audley Beijing Fulei Supply55 USI Marabu North America Market segment by region, regional analysis covers North America (United States, Canada and Mexico) Europe (Germany, France, United Kingdom, Russia, Italy, and Rest of Europe) Asia-Pacific (China, Japan, Korea, India, Southeast Asia, and Australia) South America (Brazil, Argentina, Colombia, and Rest of South America) Middle East & Africa (Saudi Arabia, UAE, Egypt, South Africa, and Rest of Middle East & Africa)

0 notes

Text

Polyvinyl Butyral (PVB) Films and Sheets Market, Global Outlook and Forecast 2025-2032

Polyvinyl Butyral (PVB) films and sheets are essential materials used in various industries due to their unique set of properties, including high transparency, high adhesion to glass, and excellent toughness and flexibility. PVB films are predominantly used as an interlayer between glass sheets to produce laminated glass, which is commonly used in automotive windows, architectural glass, solar panels, and other safety-critical applications.

The PVB films and sheets market comprises the manufacturing and distribution of these materials, with applications ranging across construction, automotive, solar energy, and other niche sectors. Laminated glass, made with PVB, provides enhanced safety, sound insulation, UV filtration, and impact resistance. As such, PVB films serve as an integral component in various manufacturing processes for both consumer products and industrial uses.

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/286916/global-polyvinyl-butyral-films-sheets-forecast-market-2025-2032-100

Market Size

The global market for Polyvinyl Butyral (PVB) films and sheets was valued at USD 962.80 million in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 5.10%, reaching USD 1363.81 million by 2032. This growth is driven by the increasing demand for laminated glass in industries such as construction, automotive, and solar energy. Additionally, the growing awareness of safety features and technological advancements in glass manufacturing have contributed to market expansion.

Regional markets are showing significant growth, with North America, Europe, and Asia-Pacific being major contributors to this trend. North America's PVB films and sheets market was valued at USD 250.88 million in 2023 and is projected to grow at a CAGR of 4.37% through 2032. This indicates a steady demand for PVB in sectors like automotive and architectural glass, particularly with the rise in vehicle safety standards and the booming construction industry.

Market Dynamics (Drivers, Restraints, Opportunities, and Challenges)

Drivers

Growing Construction Industry: The increasing demand for high-performance glass in buildings, especially in commercial and residential constructions, is a key driver for PVB films. Laminated glass, produced with PVB films, offers improved safety and aesthetic appeal, which are crucial for modern architecture.

Rising Automotive Safety Regulations: As vehicle manufacturers and governments worldwide focus on enhancing road safety, the demand for laminated glass in vehicles has surged. PVB films provide shatterproof and impact-resistant properties, which are critical for automotive safety standards.

Expansion of Solar Energy: The solar energy sector has seen significant growth due to the global push for sustainable energy solutions. PVB films, used in the production of solar panels, enhance their durability and efficiency. As solar energy adoption increases, the demand for PVB films in this sector is expected to rise.

Restraints

Raw Material Price Fluctuations: The cost of polyvinyl alcohol (PVA), the primary raw material for producing PVB films, is subject to price fluctuations. These fluctuations can impact the overall cost of PVB production, posing challenges for manufacturers.

Environmental Concerns: The disposal and recyclability of PVB films can be a significant challenge, as the materials are not easily biodegradable. With increasing environmental regulations, manufacturers are facing pressure to find sustainable and eco-friendly alternatives or develop recycling methods for PVB-based products.

Opportunities

Technological Advancements: Innovation in PVB film production, such as the development of multi-functional PVB films with advanced UV filtering and noise reduction properties, presents an opportunity for growth. These innovations can cater to new market demands, such as energy-efficient buildings and smart automobiles.

Emerging Markets: Regions such as Asia-Pacific and South America offer untapped growth potential, driven by the rapid industrialization and urbanization in these areas. The expanding automotive and construction industries in countries like India and Brazil are expected to drive demand for PVB films.

Challenges

Competition from Alternative Materials: The PVB film market faces stiff competition from other interlayer materials, such as ethylene vinyl acetate (EVA) and thermoplastic polyurethane (TPU), which also offer safety and durability features. The adoption of these alternatives may limit the growth of the PVB market.

Supply Chain Disruptions: Global supply chain disruptions, such as those caused by the COVID-19 pandemic or geopolitical issues, have affected the manufacturing and distribution of PVB films. Such disruptions may lead to delays and increased costs.

Regional Analysis

The demand for Polyvinyl Butyral (PVB) films and sheets varies significantly across regions, with North America, Europe, and Asia-Pacific being the key markets.

North America: The North American market is poised for steady growth due to the booming construction industry and increasing automotive safety standards. The region's focus on energy-efficient buildings and smart technologies further boosts the demand for laminated glass, thus driving the PVB films market.

Europe: Europe is another prominent region, with countries like Germany, France, and the UK leading the market. The European Union’s stringent regulations on vehicle safety and building codes contribute to the widespread use of PVB films in both the automotive and construction sectors. Moreover, the adoption of green energy solutions, such as solar power, provides significant opportunities for PVB manufacturers.

Asia-Pacific: Asia-Pacific is expected to see the highest growth rate during the forecast period, owing to rapid industrialization in countries like China and India. The automotive and construction industries are growing, and the demand for PVB films in laminated glass applications is increasing. The region's focus on renewable energy sources also creates a growing demand for PVB films in solar panels.

South America: While smaller in comparison to other regions, the South American market is expanding due to the increasing adoption of PVB films in both automotive and construction industries. Growth in countries like Brazil and Argentina contributes to the demand for PVB-based products.

Middle East and Africa (MEA): The MEA region is gradually increasing its adoption of PVB films, particularly in the construction industry, driven by infrastructural development and a growing focus on automotive safety. However, the market in this region remains relatively underdeveloped compared to others.

Competitor Analysis

The global Polyvinyl Butyral (PVB) films and sheets market is highly competitive, with key players such as Eastman Chemical, KURARAY, SEKISUI CHEMICAL, Kingboard Chemical Holdings, and Huakai Plastic leading the market. These companies dominate through extensive product portfolios, established supply chains, and strong research and development (R&D) capabilities.

Eastman Chemical is a global leader in the production of PVB films, offering a wide range of products for automotive, construction, and solar applications.

KURARAY is known for its high-quality PVB films and has a strong presence in both automotive and construction markets.

SEKISUI CHEMICAL focuses on advanced PVB technologies, including the development of eco-friendly PVB films, positioning itself as a leader in sustainability.

Global Polyvinyl Butyral (PVB) Films and Sheets Market: Market Segmentation Analysis

This report provides a deep insight into the global Polyvinyl Butyral (PVB) Films and Sheets market, covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market size, competitive landscape, development trend, niche market, key market drivers and challenges, SWOT analysis, value chain analysis, etc.

The analysis helps the reader to shape the competition within the industries and strategies for the competitive environment to enhance the potential profit. Furthermore, it provides a simple framework for evaluating and assessing the position of the business organization. The report structure also focuses on the competitive landscape of the Global Polyvinyl Butyral (PVB) Films and Sheets Market. This report introduces in detail the market share, market performance, product situation, operation situation, etc., of the main players, which helps the readers in the industry to identify the main competitors and deeply understand the competition pattern of the market.

In a word, this report is a must-read for industry players, investors, researchers, consultants, business strategists, and all those who have any kind of stake or are planning to foray into the Polyvinyl Butyral (PVB) Films and Sheets market in any manner.

Market Segmentation (by Application)

Construction

Ground Transportation

Solar Energy

Others

Market Segmentation (by Type)

Films

Sheets

Key Company

Eastman Chemical

KURARAY

SEKISUI CHEMICAL

Kingboard Chemical Holdings

Huakai Plastic

Zhejiang Decent Plastic

Tiantai Kanglai Industrial

Zhejiang Pulijin Plastic

Geographic Segmentation

North America (USA, Canada, Mexico)

Europe (Germany, UK, France, Russia, Italy, Rest of Europe)

Asia-Pacific (China, Japan, South Korea, India, Southeast Asia, Rest of Asia-Pacific)

South America (Brazil, Argentina, Columbia, Rest of South America)

The Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, South Africa, Rest of MEA)

FAQ

What is the current market size of Polyvinyl Butyral (PVB) Films and Sheets?

➣ The current market size of Polyvinyl Butyral (PVB) Films and Sheets was USD 962.80 million in 2023 and is expected to grow to USD 1363.81 million by 2032.

Which are the key companies operating in the Polyvinyl Butyral (PVB) Films and Sheets market?

➣ Key players in the market include Eastman Chemical, KURARAY, SEKISUI CHEMICAL, Kingboard Chemical Holdings, and Huakai Plastic.

What are the key growth drivers in the Polyvinyl Butyral (PVB) Films and Sheets market?

➣ Key growth drivers include the growing demand for laminated glass in construction and automotive sectors, increasing safety regulations, and the rise of renewable energy solutions such as solar power.

Which regions dominate the Polyvinyl Butyral (PVB) Films and Sheets market?

➣ The major regions dominating the market are North America, Europe, and Asia-Pacific, with North America leading in automotive applications and Asia-Pacific showing the highest growth potential.

What are the emerging trends in the Polyvinyl Butyral (PVB) Films and Sheets market?

➣ Emerging trends include innovations in eco-friendly PVB films, increasing adoption in solar energy applications, and technological advancements in laminated glass for both safety and aesthetic purposes.

Key Benefits of This Market Research: • Industry drivers, restraints, and opportunities covered in the study • Neutral perspective on the market performance • Recent industry trends and developments • Competitive landscape & strategies of key players • Potential & niche segments and regions exhibiting promising growth covered • Historical, current, and projected market size, in terms of value • In-depth analysis of the Polyvinyl Butyral (PVB) Films and Sheets Market • Overview of the regional outlook of the Polyvinyl Butyral (PVB) Films and Sheets Market:

Key Reasons to Buy this Report: • Access to date statistics compiled by our researchers. These provide you with historical and forecast data, which is analyzed to tell you why your market is set to change • This enables you to anticipate market changes to remain ahead of your competitors • You will be able to copy data from the Excel spreadsheet straight into your marketing plans, business presentations, or other strategic documents • The concise analysis, clear graph, and table format will enable you to pinpoint the information you require quickly • Provision of market value (USD Billion) data for each segment and sub-segment • Indicates the region and segment that is expected to witness the fastest growth as well as to dominate the market • Analysis by geography highlighting the consumption of the product/service in the region as well as indicating the factors that are affecting the market within each region • Competitive landscape which incorporates the market ranking of the major players, along with new service/product launches, partnerships, business expansions, and acquisitions in the past five years of companies profiled • Extensive company profiles comprising of company overview, company insights, product benchmarking, and SWOT analysis for the major market players • The current as well as the future market outlook of the industry concerning recent developments which involve growth opportunities and drivers as well as challenges and restraints of both emerging as well as developed regions • Includes in-depth analysis of the market from various perspectives through Porter’s five forces analysis • Provides insight into the market through Value Chain • Market dynamics scenario, along with growth opportunities of the market in the years to come • 6-month post-sales analyst support

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/286916/global-polyvinyl-butyral-films-sheets-forecast-market-2025-2032-100

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] ◆ Wallpapers are cut and adjusted according to the length and breadth of the wall when applied in your living room, dining space or bedroom with the help of Wallpaper paste or any recommended adhesive. ◆ Simply cut the Wallpaper according to your desired size and stick on to the surface of the wall with the provided adhesive. ◆ It is also recommended to brush the surface of the wall to remove any dirt or unwanted particles before applying the Wallpaper.PPK24X9 ◆ Part of Lighting and Interior Decoration: With the development of digital printing, Wallpapers have evolved into a lighting feature and is used along with the lighting of the room in which it is applied. ◆ Wallpapers are available in floral, abstract and geometric patterns etc. ◆ Contemporary interior designing focuses on the use of Wallpapers to highlight a specific area of a room to create the desired effect along with the furnishing and lights. ◆ Wallpaper are used in interior decoration to decorate and enhance the interior walls of your room to elevate its look and feel. ◆ Wallpapers are usually available in the form of rolls and are an integral part of contemporary interior designing. ◆ They are also known as lining papers. "MATERIAL:PPK24X9 PVC Vinyl ROLL SIZE: Large Size in cms: 45 x 500 cm [Need 5 Rolls to cover a 10 ft by 10 ft Wall Size.]" HOME DECOR, MULTI-USE:PPK24X9 This decorative damask floral pattern self-adhesive pvc wall art is ideal to decorate wall of bedroom, living room, hall, kitchen, bathroom, kids room, school, study, office, restaurants, furniture, smooth putty wall, kitchen counter tops, cupboard, shelf liner, dining table, centre table, home/office desk, side tables, almirah, fridge, drawers, lamination, and tiles as well. CUSTOMER NOTE: If you wish to reposition the stickers after they have been applied on the walls; remove the stickers carefully to avoid any damage. The stickers can be reapplied, but its adhesive properties might be reduced. For newly painted walls, it’s suggested to wait for 4 weeks before applying the decal. DO NOT apply on wet walls. SAFE FOR WALLS: This damask pattern decorative contact paper is Removable, Waterproof, Heat resistant, Oil-resistant, Re-positionable and Eco-friendly. floral wall decal is made with High quality Eco and durable PVC material. Accent the wall, kitchen, furniture and bathroom in your home with this bright, lively wallpaper. High-Quality Material: Crafted from premium vinyl PVC material, Self-Adhesive Waterproof Wallpaper ensures durability and longevity. Its waterproof properties make it ideal for various applications, including kitchen cabinets, tabletops, and wooden wardrobes. [ad_2]

0 notes

Text

Who are the best plywood suppliers in Bangalore?

Bangalore, also referred to as India's Silicon Valley, is a developing hub for infrastructure improvement and home décor in addition to innovation and creativity. Bangalore flaunts a roaring development and inside plan business and is quite possibly of the quickest developing city in the country.

For these businesses, plywood is a fundamental material in light of its affordability, toughness, and versatility. Here are the things you should be aware to pick wisely assuming you're searching for the top plywood company in Bangalore.

Why Choose Quality Plywood?

Plywood's strength and style make it a popular material for building, interior design, and furniture production. It is made by adhering thin wood veneer sheets together with resin under intense pressure. The end product is a material that, with the right care, can endure strong loads, not warp, and persist for many years.

Opting for high-quality plywood ensures:

Durability: High-quality plywood is perfect for long-term use because it can withstand wear and strain.

Aesthetic Appeal: A well-finished Plywood improves the appearance of interiors and furniture.

Moisture Resistance: The risk of warping or damage is decreased by treating high-quality plywood to withstand dampness.

Versatility: The best plywood in India has several uses, including wall paneling, cabinets, dividers, and furniture.

Factors to Consider When Choosing a Plywood Supplier

With so many plywood factories in Bangalore, it's essential to know what to look for before choosing the best plywood in India. Here are a few essential things to think about:

1. Quality Assurance

Make sure that when you are searching for a plywood factory near me, complies with international certifications or industry standards like ISI. Seek out products that are bonded with long-lasting adhesives and constructed from premium hardwood.

2. Product Variety

To meet various needs, a reliable provider would provide a variety of alternatives, such as fire-resistant plywood, BWP, marine, and commercial plywood.

3. Customization

You can save time and effort on your project by working with suppliers who provide customized services like pre-laminated plywood or customized cuts.

4. Price Transparency

Affordability is crucial, but make sure the cost corresponds to with the quality. Steer clear of vendors selling excessively low-cost goods since they might sacrifice performance and durability. You can also search for the best plywood factory near me.

5. Customer Reviews and Ratings

You can learn more about a supplier's dependability, caliber, and customer support by reading online reviews and evaluations. Select vendors who have a solid track record in the industry.

6. After-Sales Support

A reputable supplier offers first-rate customer service, resolving any product problems and providing advice on maintenance.

7. Location and Accessibility

To save time and money on logistics, pick suppliers who offer delivery services or are conveniently placed.

Do some research before deciding on particular plywood factories in Bangalore? Check to see whether your seller can accommodate your request. Choosing an expensive option isn't always required. To determine whether they have previously created superior plywood solutions, look through their work portfolio.

Look for genuine client testimonials to make sure your vendor can fulfill their commitments. Verify that they can deliver on time without compromising on price or quality.

Tips for Making the Right Purchase

1. Understand Your Needs

Determine the kind of plywood you need for your project before you visit a provider. Take into account elements like finish, thickness, and moisture resistance.

2. Check for Certifications

Certifications are always requested to make sure the plywood satisfies industry requirements for quality and safety.

3. Inspect the Product

Examine the plywood for consistency, smoothness, and finishing if at all possible. Look for any obvious flaws or indications of warping.

4. Compare Prices

Visit several vendors to evaluate their services and costs. Although cost is a consideration, put quality above cost to prevent problems later.

5. Seek Expert Advice

Consult an interior designer or constructor if you're not sure what to choose; they can offer appropriate suggestions based on their knowledge.

Why Bangalore is a Hub for Plywood Supplies

A considerable demand for premium building materials, such as plywood, has been fueled by Bangalore's booming startup scene and the real estate industry's explosive rise. Because Bangalore's architects, interior designers, and homeowners value creative and eco-friendly solutions, plywood is a common material for furnishings and décor.

Furthermore, Bangalore's excellent position in southern India guarantees convenient access to manufacturing facilities and raw materials, allowing local suppliers to provide prompt delivery and cheap prices.

Conclusion

It's crucial to find a balance between qualities, variety, and cost while searching for the top plywood company in Bangalore. A decent buy can be guaranteed by knowing your necessities, investigating your potential outcomes, and assessing suppliers as indicated by their product offerings, reputation, and certifications.

Plywood of superior quality from a reliable provider will act as an establishment for enduring and visually engaging results, whether you're constructing another house, redesigning the insides, or making custom furnishings. Take as much time as is needed, get your work done, and pursue an educated choice to stay away from any problems.

#best plywood in india#cost of plywood board#plywood cost in bangalore#commercial ply board#plywood factories in bangalore#plywood company in bangalore#plywood sheet cost in bangalore#bangalore plywood#best plywood for wardrobe#plywood price bangalore

0 notes

Text

Reliable Cabinet Repair Near Me: Why Dr. Cabinet Is Your Top Choice

Cabinets play a big role in keeping your home functional and looking its best. Over time, wear and tear can leave them scratched, dented, or misaligned. That’s where Dr. Cabinet steps in. We provide expert cabinet repair services designed to match your style and budget. Whether it’s a quick fix or a more detailed repair, we ensure your cabinets look and work like new again. Ready to give your cabinets the care they deserve? We’re here to help!

Why Choose Dr. Cabinet for Cabinet Repair?

When it comes to cabinet repair, your home deserves the best care. Dr. Cabinet stands out as a trusted choice for homeowners looking for quality craftsmanship, reliability, and value. Here’s a closer look at why Dr. Cabinet should be your go-to for cabinet repairs.

Experienced Professionals

At Dr. Cabinet, experience truly matters. Our team of skilled technicians has years of hands-on experience handling all types of cabinet issues. From fixing loose hinges to repairing deep scratches, we’ve seen and repaired it all. No two cabinets are the same, and our expertise allows us to provide tailored solutions for each unique challenge. When you choose Dr. Cabinet, you’re hiring experts who know what they’re doing, ensuring your cabinets are restored to their best condition.

Use of Quality Materials

Repairing cabinets isn’t just about a quick fix—it’s about ensuring long-term durability. That’s why at Dr. Cabinet, we use only high-quality materials that match or exceed the original build of your cabinetry. Simple repairs should last for years, not months. Whether it’s selecting the right wood filler, matching paint, or replacing hardware, we prioritize materials that enhance the beauty and functionality of your cabinets.

Affordable Pricing

Good cabinet repairs shouldn’t cost a fortune. At Dr. Cabinet, we take pride in offering competitive pricing that fits a variety of budgets. Our goal is clear: to provide top-tier service without overcharging. You’ll find pricing that’s fair and transparent. We provide detailed estimates upfront so you know exactly what to expect—no hidden fees, no surprises. High quality doesn’t have to mean high prices when you work with us.

Customer-Centric Approach

What sets Dr. Cabinet apart is our focus on you, the customer. From the first call to the last touch-up, we prioritize your needs and preferences. Have a specific look or finish in mind? We’ll work closely with you to make it happen. Need the job done quickly? We’ll accommodate your timeline. Everything we do revolves around making sure you’re happy with the results. After all, your satisfaction is not just a goal but our mission.

Choosing Dr. Cabinet means choosing quality, affordability, and dedication to exceptional service. Let us bring life back to your cabinets—we promise you’ll notice the difference.

Common Cabinet Repair Issues Dr. Cabinet Solves

Cabinets take a beating over time—from constant opening and closing to exposure to water, heat, and daily wear. Many homeowners feel stuck deciding between costly replacements or living with damaged cabinets. This is where Dr. Cabinet steps in with practical, budget-friendly solutions to common cabinet problems. Let’s explore how we fix these issues to breathe new life into your cabinets.

Peeling Laminate Cabinets

Peeling laminate can make cabinets look old and neglected. Dr. Cabinet can save you from a full replacement. The repair process involves:

Carefully removing the loose laminate.

Cleaning the surface to ensure proper adhesion.

Reapplying the laminate with professional-grade adhesive or replacing the sheet entirely.

This straightforward fix not only improves the look of your cabinets but also extends their lifespan. Plus, it’s far more affordable than buying new cabinets.

Broken Hinges or Handles

A cabinet with a broken hinge or handle may seem minor, but it can disrupt your daily routine and damage the door further over time. We specialize in:

Replacing worn-out, rusted, or broken hinges.

Aligning hinges to ensure smooth operation.

Installing durable handles that match or enhance your original hardware.

Our team ensures everything is securely fastened, giving your cabinets a fresh, functional upgrade. Who doesn't love cabinets that feel sturdy and new again?

Worn-Out Finishes or Stains

Over time, your cabinets’ finish can fade, chip, or stain—especially in high-use areas like kitchens and bathrooms. Dr. Cabinet restores these surfaces by:

Sanding down worn patches and repairing imperfections.

Applying fresh stains or paint that match your cabinetry’s original color or your desired look.

Sealing the surface to protect against future damage.

This process not only revives your cabinets but also adds a layer of protection to keep them looking great for years to come.

Misaligned Cabinet Doors

Misaligned cabinet doors are frustrating. They get stuck, won’t fully close, or look uneven. Dr. Cabinet has the tools and techniques to quickly correct this, including:

Adjusting hinges to realign doors precisely.

Tightening screws or replacing hinge plates if needed.

Ensuring doors operate smoothly without rubbing or sagging.

Think of it like a tune-up for your cabinets—they’ll function better and look polished in no time.

Water Damage Repairs

Water damage is one of the most serious issues for cabinets. Left untreated, moisture can rot the wood and lead to mold growth. Dr. Cabinet’s solution includes:

Removing swollen or damaged materials.

Drying and treating the affected areas to prevent further rot.

Replacing compromised sections with durable, moisture-resistant materials.

We also offer advice to protect your cabinets from future exposure. With our help, you won’t just repair water damage; you’ll prevent it from coming back.

By addressing these common problems, Dr. Cabinet ensures your cabinets stay functional and beautiful without breaking the bank. Stay tuned for even more ways we can help restore your space.

The Process of Cabinet Repair with Dr. Cabinet

When your cabinets need some TLC, Dr. Cabinet ensures a hassle-free experience from start to finish. With attention to detail at every stage, we make your cabinets look and function their best again. Here’s how we do it.

Initial Consultation and Inspection

The process starts with a friendly consultation. We’ll meet you at your home to assess the condition of your cabinets. Are there scratches, broken hinges, or water damage? Our trained technicians carefully inspect every detail to understand the root of the issues.

During this step, we’ll listen to your goals—whether you want a simple repair or a complete transformation. Feeling unsure about what’s wrong? Don’t worry, we’ll explain everything so you’re never left guessing. Our team believes every project deserves a tailored approach because no two cabinets are the same.

Providing a Comprehensive Quote