#Kraft Liner Paper Machine

Explore tagged Tumblr posts

Text

Double Layer Wires Kraft Liner Paper Machine

Net paper width: 2500mm

Basis weight: 100-200g/m2 Welcome contact me for more details Email: [email protected] WhatsAPP: +86 18539133178 https://www.leizhanchina.com/kraft-liner-paper-making-line/double-layer-wires-kraft-liner-paper-machine/

0 notes

Text

#40TPD Kraft Liner Board Paper Making Line Machine#our email: [email protected]#whatsapp: 8613782999672

0 notes

Text

3200MM Kraft Liner Paper Machine For Sale

0 notes

Text

Digital GSM Testing Machine To Test Basis Weight Of Paper - UEC

UEC’s digital GSM testing machine accurately tests the basis weight of paper, tissue, kraft liner, corrugated fiberboard, newsprint & art paper. Get rates.

0 notes

Text

Insights and Trends in the Global Industrial Packaging Market: Growth, Challenges, and Opportunities

Industrial Packaging: The Evolution of Packaging Materials Over the Years In Transportation Packaging Material Types: Paper, Plastic, Metal and Woven Sacks Paper has been one of the most widely used packaging materials for industrial products. Kraft paper and corrugated cardboard boxes are versatile materials that provide protection and allow easy printing of product information and branding. Their recyclable nature is also environment friendly. However, paper has limitations when it comes to moisture resistance and durability. Plastics like polyethylene, polypropylene and PET have gained substantial popularity in the past few decades. Rigid plastics effectively protect products from damage and moisture. They are lightweight and inexpensive. Flexible plastics in the form of bags, pouches and wraps mold well to products and reduce wastage of materials during packaging. Thermoformed plastic trays provide robust tamper-evident packaging solutions. However, different types of plastics require proper disposal methods as most are not bio-degradable. Metals like steel and aluminum sheets are especially suitable for harsh industrial environments. Metal drums, pails and cans resist dents and offer excellent barrier properties. Their recyclability is also an advantage. Nonetheless, metals add heaviness and rigidity that increases transportation costs. Woven sacks made from polypropylene or jute fibers are sturdy and cost-effective packs for granular, powdered or small parts. Rotomolding technology permits adding plastic liners inside bags to enhance moisture resistance. However, sacks are bulkier to handle and store compared to boxes or rigid containers. Packaging Machinery Automating Industrial Packaging Lines Automated packaging lines with machinery like filling machines, cartoners, wrapper, shrinkwrappers, palletizers and stretchwrappers have elevated production efficiencies. Robotic arms precisely place andassemble cartons. Volumetric filling technologies accurately dispense liquids and solids. Checkweighers maintain product weight uniformity. Centralized HMI systems monitor performance across all machines. Mobile and stationary stretch wrapping machines securely unitize packed loads for shipping. Automatic palletizers arrange boxes onto pallets at high speeds to optimize truck trailer space. Integrating digital printers onto lines customizes cartons with variable product/packaging details. Auto code date-printers track freshness and recalls/replenishments. Sophisticated vision systems verify codes, dates and package integrity. Barcode Scanning Enhancing Warehousing and Distribution Barcode scanning is integral to material management of inbound raw materials and outbound finished goods. Pallet tags and carton labels are scanned at each stage to update inventory levels and locations in warehouse management systems. Item IDs, quantities, production dates etc. are captured in databases for reports, shipments and traceability needs. Voice-directed picking via barcode scanners accurately directs warehouse workers to replenish materials across manufacturing and assembly lines. Scanners also guide put-away of finished goods while optimizing storage space utilization. During order fulfillment, scanners confirm orders are complete and accurate before dispatch. Two-dimensional barcodes like QR codes enable linking packaging to digital product brochures, instructions or assemblies online.

0 notes

Text

Kraft Liner Paper Making Machine

High Quality Kraft Liner Paper Making Machine More details: https://tpapermachine.com/high-quality-kraft-liner-paper-making-machine.html Welcome to contact for more information!

Email: [email protected]

WhatsApp: +86 18839545270

1 note

·

View note

Text

Kraft Liner Board Machine http://pulperchina.com/kraft-testliner-paper-machine.html

Email: [email protected]

Whatsapp:+86 18738406635

0 notes

Text

Machine Glazed Kraft Paper Market In-Depth Analysis, Growth Strategies and Comprehensive Forecast to 2030

The global machine glazed kraft paper market is estimated to be valued at US$ 9.3 billion in 2022 and is projected to reach US$ 14.5 billion by 2030, with a compound annual growth rate (CAGR) of 6% during the forecast period. According to Future Market Insights (FMI), the market has the potential to generate an incremental opportunity of US$ 5.4 billion during this period.

The market of machine glazed kraft paper witnessed a total revenue of over US$ 9.1 billion in 2021, and it is expected to reach 1.6 times its current value by 2030. FMI highlights that the market is influenced by various industry factors, including concerns related to single-use materials and their impact on the environment.

Advancements in the market include the development of machine glazed kraft paper with odor neutrality and wet strength quality, providing high barrier protection against moisture and oxygen exposure. In February 2022, Sappi Limited invested a significant amount in expanding its mill facility in Italy for specialty papers, demonstrating the ongoing developments in the industry.

For More Insights on this Market, Get A Sample Report @ https://www.futuremarketinsights.com/reports/sample/rep-gb-13035

According to FMI's analysis, the market is expected to witness a rise of 270 basis share points (BPS) in H1-2022 (O) compared to H1-2021. However, when comparing the projected H1-2022 and the outlook period, a surge of 20 BPS has been observed. The growth rate is attributed to the high strength, durability, gloss, and smoothness offered by machine glazed kraft paper, as well as the increasing demand for sustainable packaging and superior printing quality. Printed machine glazed kraft paper is highly versatile and finds applications in branded packaging across various industries.

Machine glazed kraft paper, also known as M.G. kraft paper, features a shiny surface on one side and a rough surface on the other. It combines the strong tensile strength of kraft paper with the shine and softness of glossy paper, making it ideal for excellent printing. Moreover, machine glazed brown kraft paper is made from agricultural raw resources, making it an eco-friendly packaging option.

Machine glazed kraft paper is considered one of the most efficient and environmentally friendly packaging materials. It is used in the production of bags, pouches, wraps, sacks, labels, liners, envelopes, trays, cups, and bowls. The paper is available in two grades: bleached and unbleached, offering flexibility to meet various packaging needs.

View Full Report@ https://www.futuremarketinsights.com/reports/machine-glazed-kraft-paper-market

0 notes

Photo

Kraft Paper Making Line

1. Pulping Preparation of Kraft Paper Making First, the raw material will be conveyed into pulp machine to pulp; Second the pulp will get into the High density cleaner for removing heavy impurities; Then the pulp will be conveyed into the pulp screening machine for pulp screening(coarse and fine screen); Furthermore, the pulp will be transported into the pulp refining machine for producing high quality pulp; Finally, the pulp will enter the Inflow pressure screen for final processing and then it will be conveyed into paper machine for paper making. 2. Paper Making Process of Kraft Paper Making The pulp is conveyed into wire section by flow slurry box to form wet paper and get dehydration, and then the wet paper will get into press section to improve dryness, after pressing,the paper get into drying section to get further dehydration and strength the density and intensity. 3. Paper Making Machine Conving Machine: Chain Conveyor Hydrapulper Machine: D Type Hydrapulper/ Drum Pulp/ M.C. Hydrapulper Pulp Cleaning: High Density Cleaner Pulp Screening: Mid Consistency Pressure Screen,Inflow Pressure Screen Pulp Refining:Double Disc Refiner, Conical Refiner, Claflin Refiner

Email: [email protected]

0 notes

Text

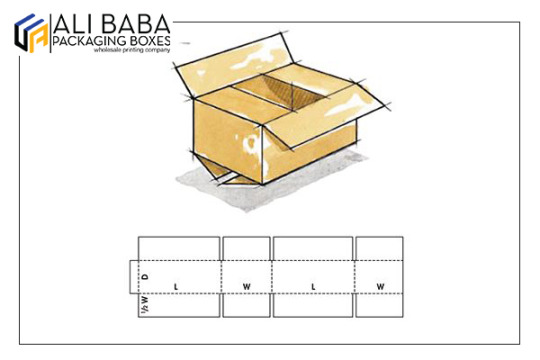

Print your custom cardboard boxes however you want with Alibaba packaging:

if you are thinking as to where to buy cardboard boxes, you ought to be totally aware of the few points of interest offered by these custom cardboard boxes manufactured by Alibaba packaging boxes. The best thing about these custom cardboard boxes is that they are moderate and they can complete various tasks for you. Indisputably, it is the best way to market your products. They are manufactured using eco-friendly material and you can reuse them too. You can get done custom cardboard box printing to improve your home. Just take some inspiration from the Web and start. You can store your sewing kit inside a box to avoid cluttering, you can even make a movie projector out of a cardboard box. It all depends on the quality of the custom printed cardboard boxes to see how long it will stay put.

MEDIUM MATERIAL FOR CARDBOARD BOX PRINTING:

At present, over 80% of items are bundled and stored in various sorts of cardboard boxes, going from paperboard to corrugated small cardboard boxes, comprising of the manufacturing material regularly utilized in the printing industry. Cardboard can be viewed as a sort of paper, and relying upon the cardboard box printing hardware, it tends to be produced in a solitary layer (utilizing a Fourdrinier) or in numerous layers (utilizing a cardboard cylinder machine). For the most part, the materials utilized for the custom printed cardboard boxes are partitioned into three classes: paper, paperboard, and cardboard. For functional purposes, cardboard can be considered as being utilized in the assembling of boxes and barrels. Little boxes are by and large created utilizing paperboard, while bigger boxes are made with folded cardboard. Barrels can be made by twisting layers of Kraft paper until the required strength is gotten, while the base can be made of squeezed cardboard or metal. The best is commonly made of indistinguishable material from the base. The contrast among carton board and paperboard is that the last has experienced a press to accomplish uniform thickness; this task likewise gives the item better brilliance and consistency.

KEEP THE BASIC ELEMENTS IN MIND WHILE ORDERING YOUR BOXES:

In the case that the box is getting ready for graphic imprinting on it, paperboard must be utilized with the goal that the end product is of good quality and visual clarity. The cardboard box printing is structured to make cardboard boxes for moving that meets the business prerequisites of the customer, just as the necessities of the item to be contained in the case, which decide box's style, sort of cardboard, corners, conclusion, joint sorts, and different elements. It must be reviewed that there is a request utilized while determining the size of the custom cardboard boxes, which should consistently be: front, base, and stature (i.e., length, width, and profundity). There is a wide scope of cardboard that can be utilized to make little collapsing boxes, and an assortment of coatings that can improve certain qualities, for example, water opposition, oil obstruction, visual appearance, and so on. Be that as it may, the type of cardboard chosen must meet the essential needs settled, for example, the legitimate bond of inks, sufficient surface region for quality cardboard boxes, appropriate acknowledgment of glues, and simplicity of gathering without causing breaks, wrinkles, or tears when collapsing.

MAKE USE OF CORRUGATED CARDBOARD:

Corrugated cardboard box printing is basically framed utilizing two fundamental components: the 'liner' or spread, and the 'medium' or fluted sheet which is the part which is corrugated. The liner or spread is made of Kraft or semi-Kraft paper and structures a level profile that covers the whole surface region of the ridged cardboard sheet. The corrugated paper (or medium) is joined to this level profile. The diverse assortments of corrugated cardboard have different blends of liner and medium. The medium that is custom cardboard boxes printing is a sort of paper that is ordinarily fabricated utilizing bagasse or straw; its consistency is more springy than the liner and it has a wavy 'fluted' structure. When appended to the liner, it shapes a consistent structure of circular segments that gives more noteworthy opposition, as the load continued is appropriated among the numerous curves the structure the layered cardboard.

TYPES OF CARDBOARD BOX PRINTING:

Cardboard box Printing utilizing the correct strategy by the help of Alibaba packaging boxes. Great printing is fundamental to ensure the correspondence and acknowledgment of your item. Regardless of whether it is a logo, scanner tag or multi-shaded print.

Flexo print:

Flexo custom cardboard boxes printing is the most normally utilized printing technique in the corrugated cardboard industry. It uses water-based inks.

High-quality print (HQP):

HQP is done on unique flexographic printers and accomplishes a higher quality than flexography. A progressively exact, amazing print subsequently, this is the correct procedure for items requiring photograph quality.

OFFSET printing:

Offset custom printed cardboard boxes produce the most splendid result with the keenest value quality proportion. offset printed packaging recounts the tale of your item, builds item refinement, adds to mark understanding, addresses the purchaser, satisfies a need, allures, and affects your image acknowledgment.

Pre-printed liner (PPL):

For large print runs, we frequently use a pre-printed liner (PPL), pre-printing and handling the external layer of paper, before utilizing this to deliver the small cardboard boxes bundling. PPL can be utilized amid occasional highs to guarantee the premium quality result.

Specific coatings (PE):

By adding an additional covering to your bundling, the cardboard boxes for moving will be antistatic, water safe or oxidation safe.

IMPORTANCE OF CARDBOARD SHOE BOXES:

Securing shoes in cardboard shoe boxes has various points of interest. Not solely do shoe boxes shield your shoes from the persevering achieved by changing temperatures and dampness, buildup and bugs- - along these lines dragging out the life of your shoes- - they furthermore extend storage space. Shoes are peculiarly shaped products that can be hard to store in little spaces, and pressing them in corners and sliding them under beds can be perilous to the material and limit of the shoe. Cardboard Shoe boxes empower you to make adequately stackable limit units that can be concealed away in closets, slide under beds or even be stacked impeccably in an open room. With Alibaba packaging boxes service in the market, you don’t have to worry about where to buy cardboard boxes anymore.

#custom cardboard boxes#cardboard packaging boxes#printing cardboard boxes#wholesale cardboard boxes#cardboard boxes for moving#custom size cardboard boxes

1 note

·

View note

Text

200T Kraft Liner Paper Making Project

This is our customer's project, and the complete pulping equipment was purchased from our company.

Contact us for more details

Email: [email protected] WhatsAPP: +86 18539133178 https://www.leizhanchina.com/kraft-liner-paper-making-line-case/200t-kraft-liner-paper-making-project/

0 notes

Text

Carton box manufacturers in ap

Packaging is a vital aspect for expanding the time frame of realistic usability of items. From travel to getting to setting up on retail retires, Packaging assumes a vital part. Be that as it may, it is likewise serious areas of strength for an instrument. All of you would concur that the item leaves a profound effect on individuals' psyches. It prompts serious areas of strength for a. With regards to item marking, Packaging investigates every possibility to capture everyone's attention. One significant part of Packaging is that it needn't bother with to be most intense or most brilliant, yet it must be interesting and utilitarian. There is a wide assortment of Packaging boxes to investigate. In any case, today we will drive your concentration towards Corrugated container boxes - the most convenient yet exemplary Packaging material. It is all over, be it a pizza home conveyance Packaging box, the front of an enormous electronic machine or getting an internet based conveyance of a couple of day to day use things and so forth. Carton Boxes are made of kraft paper sheets containing air sections. They are the ideal blend of underlying unbending nature and padding solace. They contain lines of air sections, bringing truly necessary adaptability. They are superior to the cardboard boxes. Cardboard boxes have just a single thick paper, yet ridged boxes are made of one, two, or three layers of liners and woodwinds.

Related Searches Are: Carton Box suppliers in ap, Box suppliers in ap, Cardboard Box suppliers in ap, Packing Box suppliers in ap, Package Boxes suppliers in ap, Carton box manufacturers in ap, Printed boxes suppliers in ap, Corrugated box suppliers in ap, Yarn boxes suppliers in ap, Tobacco boxes suppliers in ap, Egg boxes suppliers in ap, Aqua boxes suppliers in ap, Water Bottles boxes suppliers in ap, Fruit packaging boxes suppliers in ap, Oil packaging boxes suppliers in ap, Vegetable packaging boxes suppliers in ap, Industrial packaging boxes suppliers in Karnataka, Liquor boxes suppliers in ap, Shoe boxes suppliers in Tamilnadu For More Info: http://primepackindustries.com or Call Us: +91 988 553 4567, +91 863 2210758

#Carton box manufacturers in ap#Printed boxes suppliers in ap#Corrugated box suppliers in ap#Yarn boxes suppliers in ap

0 notes

Text

How To Test The Paper For Its Stiffness

It is no wonder that paper testing instruments are highly crucial in order to test the quality, durability, and other characteristics of the paper before using it for the desired purpose. Moreover, they are also significant to know the economical value of the paper.

Among those various characteristics, stiffness is one significant. Stiffness, in the paper industry, refers to the ability of the paper to resist bending. In other words, it is the resistance to a force that causes the paper to bend. It is important to the end-use performance of several papers. These papers could be those used for folders, writing, playing cards, cups, posters, etc.

Stiffness is also a crucial mechanical property of paperboard which is used in packaging boxes. These boxes must be able to withstand deformation, damage, or bulging, when a product is being filled into them, when it is inside them, when the box is kept in the storage, and when it is stacked from above. To make sure of the above conditions it is essential to test and know the stiffness of the box. A stiffness tester for paper is used to perform this test.

What Is A Stiffness Tester?

The digital stiffness tester by UEC is an easy-to-use instrument that determines the stiffness of the paper. Applicable under ISO 2493, DIN 53121, BS 3748, NF Q 03-048, SCAN P29, and TAPPI T 556 standards, this tester is also a helpful tool in knowing the economic value of the paper.

To perform the test, a specimen is mounted on the tester with one end fastened into the clamp. The clamping jaws make sure that the specimen is accurately placed in the center. The digital panel shows the optimum force required to bend the specimen to a particular angle. The assembly of all the components makes sure that the test gives precise results without any errors. The tester is used to test writing, printing, copier, duplex, art, kraft liner, and fluting paper.

When it comes to testing the folding box board, the UEC’s Taber stiffness tester is used. This device is used to evaluate the stiffness and resiliency of paperboard, plastics, metallic sheets, and other loose materials.

Wrapping up

UEC’s wide reliable, accuracy-driven, and high-performance collection, makes it one of the leading manufacturers, suppliers, and exporters of paper testing instruments. Manufacturers and laboratories can get in touch to know more about testing machines and even get sample testing done before purchase.

0 notes

Text

Manufacturers of Release Liner Market to Benefit from Lucrative Growth Opportunities on Account of Increasing Adoption

Persistence Market Research – PMR’s latest study on Chemicals & Materials provides deep industry insights and associated services to help clients realize their maximum business potential across the globe.

Market Overview Release liner is a carrier web material made up of paper or plastic. Release liners are coated on one or both the sides with release agent (chemical used to prevent one material from bonding to surfaces of another material). These releasing agents provide a releasing effect when kept in contact with any kind of stick materials. Adhesive (substance when applied to the surfaces of any materials binds them together and resists separation) and mastic (kind of gum) are of the stick material used for releasing agents. Release liners are available in different colors in the market; it can be a printed or non-printed release liner. Commercial coating companies are engaged in the manufacturing of release agent, providing unique solutions to their clients, based on a wide variety of substrates used to manufacture releasing agents. Commonly used releasing agents for release liner are cross linkable silicone and other coating materials that have low surface energy.

On the basis of materials used to manufacture release liner, global release liner market can be fragmented into paper release liner (super calandered kraft paper, clay coated kraft paper, machine finished kraft paper and machine glazed paper), plastic film release liner and others (poly coated kraft papers and poly coated BO-PET film). Release liner can be used as pressure-sensitive labels and pressure-sensitive tape. Release liners have major application in label stocks industry and packaging industry. Other major application of release liners are in the field of graphic arts, envelopes, medical, tapes and hygiene.

To remain ‘ahead’ of your competitors, request for a sample @ https://www.persistencemarketresearch.com/samples/3531

North America has the largest market share for release liner products, followed by Europe and Asia Pacific. The U.S. and China are the largest markets for release liner in the global market owing to increased food and pharmaceutical business in these countries. North America is expected to maintain its dominance in the forecasted period with Europe showing marginal growth. However, Asia Pacific region is expected to witness highest growth in the coming future owing to increasing domestic demand by the food and pharmaceutical industry in the developing countries such as India and China. Increasing demand from the end-user industry for better labelling is driving the global release liner market. Additionally, with increasing investment in the food and pharmaceutical industry, demand for better quality packaging is expected to increase, in turn demand for release liner is expected to increase. Also, with increasing population paired with rising international trade, demand for quality packaging and labelling is expected to increase, further increasing the demand for release liner products in the global market.

Get A Customized Scope To Match Your Need Ask An Expert – [email protected]

Owing to increasing demand from the food and pharmaceutical companies paired with increasing demand from the other end-user industry for better packaging and labelling. The multinational players operating in the market are influenced to invest in the emerging markets of Asia-Pacific. Also, the regional players have increased their production to some extent to compete in the market. Global release liner market is dominated by multinational companies. However, there are some companies operating in the market, but at niche level. Some of the major companies operating in the global release liner market are Gascogne Laminates, 3M Company, Rayven Inc and Sil Tech

For critical insights on this market, request for methodology here @ https://www.persistencemarketresearch.com/methodology/3531

Key geographies evaluated in this report are:

North America

Europe

APAC

Latin America

U.S

Canada

France, Germany, Italy, Spain, and the UK

Eastern Europe

CIS

China

India

Japan

Australia

Others

Argentina

Brazil

Others

Key features of this report

Drivers, restraints, and challenges shaping the Release Liner market dynamics

Latest innovations and key events in the industry

Analysis of business strategies of the top players

Release Liner market estimates and forecasts (2015 -2021)

For in-depth competitive analysis, buy now@ https://www.persistencemarketresearch.com/checkout/3531

About Us: Persistence Market Research

Contact Us:

Persistence Market Research USA

Address – 305 Broadway, 7th Floor, New York City, NY 10007 United States U.S. Ph. – +1-646-568-7751 USA-Canada Toll-free – +1 800-961-0353

Sales – [email protected] Website – https://www.persistencemarketresearch.com

0 notes

Text

Kraft Paper Machine

Kraft liner board machine use waste paper, white shavings, virgin pulp as material. Email: [email protected] Whatsapp: +86 18738406635 http://pulperchina.com/2023/07/20/kraft-testliner-paper-machine/

0 notes