#Kaizen Foundation Training

Explore tagged Tumblr posts

Text

The Ultimate Guide to Operational Excellence for Modern Businesses

In today’s hyper-competitive and rapidly evolving business environment, companies can no longer afford to operate inefficiently. Operational excellence (OpEx) has become a non-negotiable requirement for businesses aiming to thrive. It’s not just about trimming costs—it's about building a resilient, agile, and high-performing organization that delivers exceptional value to customers, consistently and sustainably.

So, what exactly is Injection molding consultants operational excellence, and how can modern businesses achieve it? Let’s dive into this comprehensive guide to mastering operational excellence in 2025 and beyond.

What is Operational Excellence?

Operational excellence is a philosophy and mindset that drives continuous improvement across all aspects of a business. It involves aligning people, processes, and technology to deliver better performance, greater efficiency, and outstanding customer value.

At its core, operational excellence is about doing the right things, the right way, every time. It's not a one-time project, but a long-term commitment to building a culture of excellence.

The Pillars of Operational Excellence

Achieving operational excellence requires a solid foundation. Here are the core pillars that support an OpEx strategy:

1. Leadership Commitment

Leaders must not only support but embody the principles of operational excellence. Their commitment to transparency, accountability, and continuous improvement sets the tone for the entire organization.

2. Customer-Centric Culture

The voice of the customer must guide every decision. Understanding customer needs and delivering consistent value is the heartbeat of operational excellence.

3. Process Optimization

Every process—big or small—should be evaluated and optimized for efficiency and effectiveness. Lean principles, Six Sigma, and Kaizen are popular methodologies for this.

4. Data-Driven Decision Making

OpEx thrives on data. Businesses must leverage analytics and KPIs to make informed decisions, identify bottlenecks, and track performance.

5. Employee Empowerment

Operational excellence isn’t just a top-down initiative. Employees on the frontlines often have the best insight into inefficiencies. Empowering them to contribute ideas and take ownership fuels innovation and growth.

6. Technology Integration

Modern tools like automation, AI, and cloud platforms streamline operations, reduce errors, and improve scalability. Technology should be a partner, not a replacement, for human capability.

Why Operational Excellence Matters Now More Than Ever

In the post-pandemic world, businesses face constant disruption—whether from supply chain challenges, evolving customer expectations, or digital transformation. Operational excellence provides the agility and resilience needed to adapt quickly.

Companies that invest in OpEx are better positioned to:

Improve profit margins

Enhance customer satisfaction

Reduce waste and costs

Accelerate time to market

Navigate uncertainty and change with confidence

Steps to Achieving Operational Excellence

1. Assess Your Current State

Start by evaluating where your organization stands. Conduct internal audits, analyze performance data, and identify areas of waste or inefficiency.

2. Define Clear Objectives

Set specific, measurable goals aligned with your broader business strategy. Whether it’s reducing lead times by 30% or improving customer satisfaction scores, clarity is key.

3. Map and Standardize Processes

Use tools like value stream mapping to visualize workflows. Identify redundancies, gaps, and unnecessary steps. Then standardize best practices across teams to ensure consistency.

4. Invest in Training and Development

Build a culture of continuous learning. Equip teams with the skills and knowledge to identify problems, implement solutions, and drive improvement.

5. Implement the Right Tools

Adopt technologies that enhance visibility and control. Enterprise Resource Planning (ERP) systems, workflow automation tools, and predictive analytics platforms can be game changers.

6. Foster a Culture of Continuous Improvement

Create a feedback-rich environment where employees feel safe to speak up and experiment. Regularly review processes, celebrate small wins, and keep pushing the boundaries of what’s possible.

7. Monitor, Measure, and Adjust

Use KPIs to track progress and ROI. Common metrics include cycle time, first-pass yield, cost per unit, and customer retention rates. Use this data to fine-tune your approach continuously.

Common Pitfalls to Avoid

Operational excellence isn’t without challenges. Here are some traps to steer clear of:

Focusing Only on Cost-Cutting: True OpEx goes beyond trimming budgets—it’s about creating value and sustaining performance.

Neglecting Culture: Without buy-in from employees, even the best systems will fail.

Overcomplicating Processes: Simplicity breeds efficiency. Avoid creating unnecessary bureaucracy in the name of optimization.

Ignoring Technology Trends: Falling behind on digital tools can make your operations obsolete.

Real-World Examples

Some of the most successful companies have achieved greatness through operational excellence:

Toyota pioneered lean manufacturing, setting a global standard for efficiency and quality.

Amazon continuously optimizes its supply chain and fulfillment processes to deliver customer obsession at scale.

Southwest Airlines streamlines operations to maintain one of the lowest cost structures in the industry while ensuring high customer satisfaction.

Final Thoughts

Operational excellence isn’t a destination—it’s a journey of continuous improvement. For modern businesses, embracing this mindset is no longer optional; it’s essential. The world will keep changing, markets will keep evolving, and competition will keep growing. But with a solid OpEx foundation, your organization will be ready to face whatever comes next.

In the end, operational excellence is about empowering your people, delighting your customers, and future-proofing your business. Start small, stay consistent, and keep improving. The rewards will be well worth the effort.

Ready to begin your operational excellence journey? Start by identifying one process you can improve today—and build momentum from there.

Strategy Consulting Firms

Cost reduction consultants

Supply chain management consulting

Materials Engineering Consulting

Injection molding consultants

supply chain staffing

Staffing for Engineering

executive placement firms

staff augmentation services

Contingent staffing

Manufacturing staffing

Automotive staffing

warehouse staffing agency

0 notes

Text

Mastering Efficiency: A Deep Dive into the Lean Production 5S System

Source: operations1.com

Share Post:

LinkedIn

Twitter

Facebook

Reddit

Pinterest

In the industrial world, operational efficiency is the main factor in work completion and success achievement. Companies look for constant source that enhances workplace productivity, smooth methods, and eliminate waste. For such improvements, a systematic approach is introduced, named as the lean production 5S system. Being a Japanese manufacturing practice term, this system has become a crucial part of lean methodology, helping businesses in effectively organizing and managing their workplace. In this article, the lean production 5S system is explained in detail, including its meaning, origin, benefits, and implementation.

Understanding the Lean Production 5S System

The lean production 5S system is a systematic approach to workplace organization and standardization. The name “5S” refers to five Japanese words that begin with the letter ‘S’: Seiri, Seiton, Seiso, Seiketsu, and Shitsuke. Each element plays a crucial role in creating an efficient, safe, and organized work environment.

Here’s a breakdown of the 5S components:

Source – en.wikipedia.org

1. Seiri (Sort)

This step involves removing unnecessary items from the workspace. Only tools and materials that are essential to daily tasks should remain. Sorting helps reduce clutter, making it easier to find what is needed quickly.

2. Seiton (Set in Order)

Once the clutter is eliminated, the remaining tools and materials must be organized in a way that promotes efficiency. Every item should have a designated place, and its location should make sense for the workflow.

3. Seiso (Shine)

Cleaning the workspace regularly is vital. A clean environment not only promotes safety but also allows for better maintenance of equipment and a more pleasant workplace.

4. Seiketsu (Standardize)

This step focuses on creating standards for organizing and cleaning. Procedures should be documented and followed consistently. Visual aids such as charts, labels, and schedules can help maintain the standard.

5. Shitsuke (Sustain)

The final step is about discipline and habit. Employees should be trained and motivated to maintain the established procedures. Regular audits and reviews can help ensure that the 5S principles are being followed.

The Origin and Evolution of 5S

The lean production 5S system originated in Japan as part of the Toyota Production System (TPS). Toyota implemented this method to improve efficiency and quality in its manufacturing processes. Over time, 5S evolved and was adopted globally across various industries beyond manufacturing, including healthcare, education, logistics, and office environments.

Today, it is recognized as a foundational element of lean production practices and continuous improvement methodologies like Kaizen and Six Sigma.

Also Read: Lean Management Principles: Enhancing Efficiency and Reducing Waste

Why the Lean Production 5S System Matters?

Source – 5snews.com

Implementing the lean production 5S system can bring significant advantages to an organization, including:

1. Increased Productivity

By organizing the workspace and eliminating unnecessary items, employees spend less time searching for tools and materials, allowing them to focus more on value-added activities.

2. Improved Safety

A clean and orderly workplace reduces the risk of accidents and injuries. Clear labeling, proper storage, and regular cleaning all contribute to a safer environment.

3. Enhanced Quality

With standardized processes and a tidy workspace, the chances of errors and defects decrease. Employees can spot issues more easily, leading to faster problem-solving.

4. Greater Employee Satisfaction

An organized and efficient workspace fosters a positive work culture. Employees feel more in control of their environment, which can boost morale and job satisfaction.

5. Better Utilization of Space

By removing clutter and arranging tools effectively, organizations can optimize space usage, potentially reducing the need for larger facilities or additional storage.

Implementing the Lean Production 5S System

Rolling out the 5S system involves more than just cleaning and organizing—it requires a cultural shift and commitment from all levels of the organization.

Step 1: Training and Awareness

Educate your team about the purpose and benefits of 5S. Use workshops, presentations, and hands-on training sessions to explain each of the five steps.

Step 2: Initial 5S Event (Kaizen Blitz)

Organize a company-wide or departmental 5S event where employees sort, set in order, and shine their work areas. This creates momentum and demonstrates leadership commitment.

Step 3: Create Visual Management Tools

Develop checklists, floor markings, and signage to help standardize the process. Visual cues reinforce discipline and make the workspace self-explanatory.

Step 4: Assign Responsibilities

Clearly define roles and responsibilities for maintaining 5S. Designate team leaders and schedule regular audits to track progress.

Step 5: Sustain with Audits and Recognition

Regularly review and evaluate each area to ensure compliance. Recognize teams that consistently follow 5S practices to encourage ongoing participation.

Common Challenges and How to Overcome Them?

Source – fatfinger.io

1. Resistance to Change

Employees may be skeptical of new systems. Overcome this by involving them in planning and showing them how 5S will make their work easier.

2. Lack of Follow-Through

Without ongoing support, 5S efforts can fade. Assign ownership, conduct regular reviews, and celebrate successes to sustain the initiative.

3. Insufficient Training

Invest in thorough training to ensure everyone understands the system and their role within it. Use real-life examples to illustrate the benefits.

Also Read: Maximizing Efficiency: The Benefits of Production Scheduling Software

Industries Benefiting from the Lean Production 5S System

The lean production 5S system has proven effective in various sectors, including:

Manufacturing – Streamlining assembly lines and improving product quality.

Healthcare – Organizing surgical tools and reducing medical errors.

Warehousing – Enhancing inventory management and order fulfillment.

Education – Creating clutter-free classrooms and administrative offices.

Hospitality – Maintaining cleanliness and efficiency in kitchens and guest areas.

Case Study: 5S in Action

Company: XYZ Automotive

XYZ Automotive, a mid-sized car parts manufacturer, implemented the lean production 5S system across its production floor. Initially faced with inefficiencies and high defect rates, the company conducted a 5S audit and launched a training campaign.

Results After 6 Months:

30% increase in productivity

25% reduction in workplace accidents

40% improvement in product quality

The transformation not only improved operations but also boosted employee morale and customer satisfaction.

Tips for Sustaining 5S Long-Term

Engage Leadership – Leaders should model the behavior they want to see.

Incorporate 5S into Daily Routines – Make it part of standard operating procedures.

Celebrate Milestones – Recognize achievements to keep teams motivated.

Continuous Improvement – Use feedback to refine and improve the system.

Document Everything – Create manuals, videos, and checklists for easy reference.

Conclusion

The lean production 5S system is a structured initiative to improve the workplace environment. By implementing its principles, organizations manage to recognize their potential, achieve continuous improvement, and reduce waste. It can be applied in every industry, whether it’s manufacturing, healthcare, or service industries. The 5S system is a practical approach to making the workplace better.

The lean production 5S system needs continuous implementation to excel in operational efficiency. Disciplined and focused efforts on continuous improvements can contribute to a successful business.

0 notes

Text

Unlocking Continuous Improvement: The Power of KAIZEN Training

KAIZEN Training introduces a transformative approach to continuous improvement, empowering organizations to streamline processes, enhance efficiency, and drive sustainable growth.

Understanding KAIZEN Training:

KAIZEN, a Japanese term meaning “change for the better,” is a philosophy and methodology focused on incremental, continuous improvement in all aspects of an organization’s operations. KAIZEN Training equips individuals and teams with the tools, techniques, and mindset needed to identify inefficiencies, streamline processes, and implement solutions for ongoing improvement. The training typically covers key principles such as standardization, waste reduction, problem-solving, and employee engagement.

Why KAIZEN Training is Needed:

In today’s competitive business environment, organizations must constantly strive to enhance efficiency, quality, and customer satisfaction. KAIZEN Training is needed to instill a culture of continuous improvement within the organization, empowering employees at all levels to identify opportunities for optimization and take proactive steps to drive positive change. By investing in KAIZEN Training, organizations can foster innovation, adaptability, and resilience, positioning themselves for long-term success in an ever-changing marketplace.

Training Benefits:

Improved Efficiency: KAIZEN Training enables organizations to identify and eliminate waste, inefficiencies, and bottlenecks in processes, resulting in improved productivity and resource utilization.

Enhanced Quality: By standardizing processes and implementing continuous improvement initiatives, organizations can enhance product and service quality, leading to higher customer satisfaction and loyalty.

Increased Employee Engagement: KAIZEN Training encourages employee involvement and empowerment, fostering a culture of ownership, collaboration, and innovation throughout the organization.

Cost Savings: Continuous improvement initiatives driven by KAIZEN Training can lead to significant cost savings through reduced waste, improved resource utilization, and streamlined operations.

Sustainable Growth: By embracing a culture of continuous improvement, organizations can adapt to changing market dynamics, seize new opportunities, and achieve sustainable growth over time.

How 4C Consulting Helps You in Training:

At 4C Consulting, we understand the transformative power of KAIZEN Training in driving organizational excellence and continuous improvement. With a proven track record of implementing ISO standards at over 2000 clients and delivering more than 10,000 hours of ISO training, we are your trusted partner in KAIZEN Training. Our team of experienced trainers possesses deep expertise in KAIZEN principles, methodologies, and implementation strategies, enabling us to deliver impactful training solutions tailored to your organization’s unique needs and objectives.

When you choose 4C Consulting for KAIZEN Training, you can expect:

Comprehensive Curriculum: Our training programs cover all essential aspects of KAIZEN, including principles, tools, and techniques, providing participants with a solid foundation for driving continuous improvement.

Practical Exercises: We incorporate practical exercises, case studies, and real-world examples into our training sessions to reinforce learning and encourage hands-on application of KAIZEN principles.

Customized Solutions: We offer customized training solutions tailored to your organization’s specific industry, size, and objectives, ensuring relevance and effectiveness.

Continuous Support: We provide ongoing support and guidance to participants following the completion of training, including access to resources, tools, and expert advice to support the implementation of KAIZEN initiatives.

Measurable Results: We help organizations track and measure the impact of KAIZEN Training on key performance metrics, allowing for continuous improvement and optimization of training outcomes.

KAIZEN Training is essential for organizations seeking to foster a culture of continuous improvement and drive sustainable growth. With 4C Consulting as your training partner, you can empower your employees with the skills and knowledge needed to identify opportunities for optimization, streamline processes, and achieve operational excellence. Contact us today to learn more about our KAIZEN Training services and take the first step towards unlocking the full potential of your organization.

0 notes

Text

How are the MBA/PGDM programs in Mumbai structured?

Introduction

Overview of Mumbai as an educational and business hub.

Importance of understanding the program structure when choosing an Top MBA PGDM Colleges In Mumbai.

General differences between MBA and PGDM programs in terms of structure and approach.

1. Duration and Format of the Programs

Full-Time Programs

Typically two years with a mix of academic and practical components.

Executive MBA/PGDM

Designed for working professionals, with shorter durations (12-18 months). Indian School of Management & Studies, (ISMS) Mumbai

Part-Time and Online Programs

Flexible schedules for professionals, lasting 2-3 years.

Integrated Programs

Combining undergraduate and postgraduate degrees for a five-year course.

2. Academic Structure

Core Curriculum

Focus on foundational subjects like marketing, finance, operations, and human resources.

First-year coursework usually includes compulsory subjects for all specializations.

Elective Courses

Allow students to customize their learning in the second year.

Range of electives offered, from data analytics to entrepreneurship.

3. Internship and Practical Components

Summer Internship Program

Typically spanning 8-12 weeks after the first year.

Provides exposure to real-world business challenges.

Live Projects and Industry Exposure

Hands-on opportunities to work on ongoing projects with companies. Kaizen School of Business Management, (KSBM) Mumbai

Capstone Projects

Comprehensive assignments to solve a real-world business problem, integrating all learned concepts.

4. Specialization Tracks

Overview of popular specializations offered by Mumbai colleges.

Marketing, finance, operations, HR, and data analytics.

Structure of specialization: mix of core and elective courses.

5. Pedagogical Approach

Case-Based Learning

Discussion and analysis of real-world business scenarios.

Classroom and Online Learning

Hybrid structures leveraging online tools and in-person interactions.

Workshops and Seminars

Regular sessions with industry leaders and academicians.

6. Global and Industry Exposure

Student Exchange Programs

Opportunities to study abroad and gain international exposure.

Corporate Interface

Frequent interaction with top executives through guest lectures and corporate sessions. The Second Wind, (TSW) Mumbai

7. Evaluation and Assessment

Continuous Assessment

Quizzes, assignments, presentations, and mid-term exams.

End-Term Examinations

Comprehensive assessments to test the understanding of core subjects.

Skill-Based Evaluations

Focus on soft skills, leadership, and problem-solving abilities.

8. Extracurricular and Co-Curricular Activities

Importance of student clubs, committees, and cultural events in holistic development.

Examples of popular events like management fests, hackathons, and case competitions.

9. Final Placement Preparation

Integration of placement training, mock interviews, and GD preparation into the program.

Focus on aligning academic learning with industry expectations.

Conclusion

Summary of how Mumbai’s MBA/PGDM programs are designed to balance theoretical knowledge with practical skills.

Encouragement to research individual colleges to identify the best-fit program structure.

Final thought on how a well-structured program can shape a successful career in business and management.

0 notes

Text

What is Total Quality Management?

Total Quality Management (TQM) is a structured approach for improving quality and performance across all areas of an organization. The ultimate goal is simple: meet or exceed customer expectations by making sure every aspect of the organization is working as smoothly and efficiently as possible. By focusing on quality at every stage, businesses can enhance customer satisfaction, improve efficiency, and build a strong reputation in the market.

Why is Total Quality Management Important?

In a world where customer expectations are constantly evolving, Total Quality Management provides a framework that helps companies remain competitive by consistently delivering high-quality products or services. When quality is managed effectively:

Customer satisfaction increases, resulting in higher loyalty and repeat business.

Operational efficiency improves, reducing costs and resource wastage.

Employee morale and engagement grow as they are actively involved in the quality-improvement process.

Brand reputation strengthens, as customers come to trust the brand’s commitment to quality.

Core Principles of Total Quality Management

At the heart of Total Quality Management are a few key principles, each designed to ensure that quality is maintained from the initial planning stages all the way through to the final customer delivery. Let’s explore these core concepts that every business implementing TQM should understand:

1. Customer Focus

Every successful TQM initiative begins with an intense focus on the customer. Understanding customer needs and expectations is critical, as they are the foundation upon which all other activities are built. In Total Quality Management, businesses make every effort to exceed customer expectations, not just meet them.

2. Continuous Improvement

Continuous improvement is the ongoing effort to enhance processes, products, and services. The principle of continuous improvement keeps a business agile and responsive to changes in the market, customer demands, and technological advancements. Techniques like Kaizen and Six Sigma often support continuous improvement efforts.

3. Employee Involvement

For TQM to work effectively, it requires engagement at every level of the organization. When employees are empowered and trained to improve their own processes, they become active participants in quality management. This involvement fosters a culture of responsibility and accountability.

4. Process-Centered Approach

A process-centered approach helps businesses focus on the steps required to complete any task, minimizing variation and errors. Process mapping and standardization are essential techniques within TQM that help teams visualize workflows, identify potential issues, and develop efficient procedures.

5. Integrated System

For TQM to thrive, all aspects of an organization need to be aligned and work in harmony. An integrated system means that each department understands how it contributes to the overall goals of the company. It ensures that no part of the business operates in isolation from the others.

6. Data-Driven Decision Making

TQM relies heavily on accurate and relevant data to drive decisions. By gathering performance metrics and customer feedback, businesses can pinpoint specific areas for improvement and develop targeted strategies.

7. Communication

Clear, effective communication supports every aspect of Total Quality Management. From the executive team to front-line employees, everyone needs to understand the goals of the TQM program and how they can contribute to it.

Implementing Total Quality Management

Implementing Total Quality Management can seem daunting, but breaking down the process into manageable steps makes it achievable for any organization. Here are some actionable steps for a successful TQM implementation:

Step 1: Define Quality Objectives

Set clear and measurable quality objectives that align with your company’s goals. This will be the roadmap for your TQM journey. Goals may include increasing customer satisfaction, reducing defect rates, or improving product durability.

Step 2: Build a TQM Team

Create a cross-functional team of employees from various departments to spearhead the TQM initiative. This team will be responsible for overseeing implementation, identifying areas for improvement, and driving continuous improvement.

Step 3: Employee Training

Provide training on the principles of TQM, quality improvement tools, and the importance of customer satisfaction. When employees understand the purpose and benefits of TQM, they are more likely to participate actively.

Step 4: Collect and Analyze Data

Use data analytics and customer feedback to understand current performance and identify areas for improvement. Look for patterns, such as recurring customer complaints or bottlenecks in production, that may indicate underlying issues.

Step 5: Identify and Implement Improvements

Based on your analysis, develop targeted strategies for improvement. Whether it’s reducing waste in production, improving response time, or upgrading a product, make sure every change aligns with your TQM goals.

Step 6: Measure Results

After implementing changes, measure their impact on quality and customer satisfaction. Are defects decreasing? Has customer feedback improved? Regular performance reviews are essential for ensuring long-term success.

Step 7: Encourage Continuous Feedback and Adjustment

TQM isn’t a one-time project; it’s a long-term commitment. Encourage employees to provide feedback on TQM efforts and be willing to make adjustments as needed. The most successful TQM programs adapt over time to meet new challenges.

Popular Tools and Techniques in Total Quality Management

Many tools and techniques are available to help organizations implement TQM effectively. Some of the most popular ones include:

1. Pareto Analysis

Also known as the 80/20 rule, Pareto Analysis helps companies identify the most impactful issues by focusing on the top 20% of problems that cause 80% of the consequences.

2. Fishbone Diagram (Ishikawa)

A Fishbone Diagram is a visual tool that helps teams identify the root causes of a problem by organizing potential causes into categories like people, processes, materials, and machinery.

3. Control Charts

Control charts track data over time to identify any variations in performance. These charts help organizations monitor processes and detect unusual deviations that may indicate a problem.

4. PDCA Cycle (Plan-Do-Check-Act)

The PDCA cycle is an iterative approach to problem-solving and continuous improvement. It involves planning changes, implementing them, checking their effectiveness, and acting based on results.

5. Six Sigma

Six Sigma is a methodology that uses statistical tools and techniques to improve process quality. By reducing variation and minimizing defects, Six Sigma helps businesses achieve higher quality standards and more reliable performance.

Benefits of Total Quality Management

The benefits of Total Quality Management extend beyond product quality alone. Implementing TQM can lead to:

Higher customer satisfaction: By focusing on customer needs, businesses build trust and loyalty.

Cost savings: Reduced waste and streamlined processes translate to lower production costs.

Improved employee engagement: Employees feel valued and motivated when they are part of the improvement process.

Increased competitive advantage: Companies that consistently deliver quality gain a reputation that sets them apart from competitors.

Common Challenges in Implementing Total Quality Management

While TQM offers substantial benefits, it’s not without its challenges. Here are some common hurdles and tips for overcoming them:

Resistance to Change

One of the biggest obstacles in TQM implementation is employee resistance. People may fear that changes in quality management will impact their roles. To overcome this, communicate the benefits of TQM clearly and ensure that employees understand how they’ll be positively impacted.

Resource Constraints

Implementing TQM can require a significant initial investment, especially for small businesses. This can include the cost of training, new technology, and additional resources. To manage this, start with small-scale improvements that yield quick wins, gradually building towards more comprehensive changes.

Sustaining Momentum

TQM is a long-term commitment, which means maintaining enthusiasm over time can be challenging. Regular communication, rewards for improvement, and leadership support are essential for sustaining momentum.

Quality Over Bureaucracy

A common pitfall in TQM is getting bogged down by bureaucracy. Too many controls and checks can slow down processes rather than improve them. Focus on what adds value, and avoid excessive documentation that doesn’t directly impact quality.

The Future of Total Quality Management

With advancements in technology, Total Quality Management is evolving. Automation, AI, and big data analytics are enabling companies to monitor quality in real-time, respond faster to issues, and predict potential problems before they arise. The future of TQM looks promising, with technology playing a pivotal role in maintaining high standards across industries.

Total Quality Management is not a quick fix but a powerful strategy for long-term success. It aligns everyone in the organization toward a common goal: delivering outstanding quality that meets customer expectations. By embracing TQM, companies can achieve sustainable growth, enhance customer satisfaction, and build a reputation for excellence. With a commitment to continuous improvement, the benefits of TQM will resonate throughout every level of your organization, ultimately leading to increased customer loyalty and profitability.

0 notes

Text

Kaizen Mastery: Training Strategies for Continuous Improvement

In today's fast-paced and ever-changing business world, continuous improvement is essential for organizations to stay competitive and thrive. One of the most effective approaches to continuous improvement is Kaizen, a Japanese term meaning "change for the better" or "continuous improvement." Kaizen is not just a one-time event, but a mindset and philosophy that focus on making small, incremental changes to improve processes, systems, and products. To fully embrace the Kaizen mindset and achieve mastery, organizations must invest in Kaizen training for their employees. In this blog post, we will explore the importance of Kaizen training and some strategies for continuous improvement.

Why is Kaizen Training Important?

Kaizen training is crucial for organizations that want to achieve continuous improvement. It equips employees with the necessary knowledge and skills to identify and eliminate waste, streamline processes, and improve efficiency. Kaizen training also promotes a culture of continuous improvement, where employees are encouraged to come up with ideas for improvement and implement them. This not only leads to better processes and products but also boosts employee morale and engagement.

Strategies for Kaizen Training

1) Start with the basics: Before diving into the more advanced concepts of Kaizen, it is essential to start with the basics. Employees should first understand the principles of Kaizen, such as continuous improvement, teamwork, and respect for people. This foundation will help them grasp the more complex techniques and tools of Kaizen.

2) Hands-on training: Kaizen is a practical approach to continuous improvement, and therefore, training should be hands-on. Employees should be given the opportunity to apply the concepts they have learned in real-life scenarios. This could include participating in Kaizen events, where they can work with their colleagues to identify and implement improvements in processes or products.

Also Read: TPM Training

3) Use visual aids: Kaizen training can be enhanced by using visual aids such as videos, diagrams, and case studies. These aids help employees understand the concepts better and visualize how they can be applied in their work.

4) Encourage collaboration: Kaizen is a team effort, and therefore, training should also promote collaboration. Employees should be encouraged to work together and share ideas for improvement. This not only leads to better solutions but also fosters a culture of teamwork and continuous improvement.

0 notes

Text

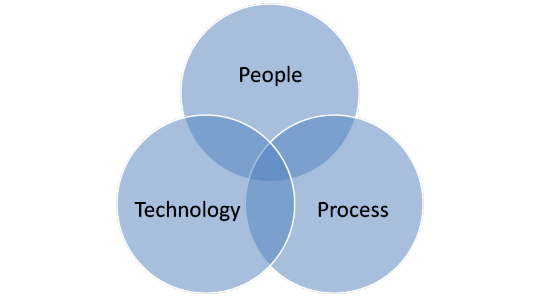

Decoding Success Understanding the People-Process-Technology Nexus

In the realm of organizational success, the interplay between people, process, and technology forms a dynamic nexus that drives efficiency, innovation, and competitiveness. Known as the People-Process-Technology (PPT) nexus, this triad represents the cornerstone of modern business operations. In this blog, we delve into the intricacies of the PPT nexus, deciphering its significance and exploring how organizations can leverage it to unlock new levels of success.

The Role of People

At the heart of the PPT nexus lies the human element – people. Employees, stakeholders, and customers constitute the lifeblood of any organization, bringing diverse skills, experiences, and perspectives to the table. Engaged and empowered employees form the foundation of organizational success, driving innovation, collaboration, and customer satisfaction. Effective leadership, clear communication, and a supportive work culture are essential for nurturing a motivated and high-performing workforce.

The Importance of Process

Processes represent the operational workflows and procedures that govern how work is conducted within an organization. Streamlined and efficient processes enable organizations to optimize resource allocation, minimize waste, and deliver consistent results. From procurement and production to sales and customer service, well-defined processes ensure clarity, accountability, and alignment across departments and functions. Continuous process improvement methodologies such as Lean Six Sigma and Kaizen enable organizations to identify inefficiencies, eliminate bottlenecks, and drive operational excellence.

Leveraging Technology

Technology serves as an enabler within the PPT nexus, providing organizations with the tools and infrastructure needed to support and enhance their operations. From enterprise resource planning (ERP) systems and customer relationship management (CRM) software to cloud computing and artificial intelligence (AI), technology solutions offer opportunities to streamline workflows, improve decision-making, and enhance collaboration. By leveraging technology effectively, organizations can stay agile, responsive, and competitive in today's digital landscape.

Achieving Synergy and Integration

While each component of the PPT nexus plays a distinct role, their true power lies in their integration and synergy. Organizations that excel in business operations understand the importance of aligning people, process, and technology initiatives to achieve common goals and objectives. Cross-functional collaboration, communication, and coordination are essential for ensuring that all elements of the PPT nexus work together seamlessly to drive organizational success.

Building a Culture of Excellence

Building a culture of excellence requires a holistic approach that prioritizes the development of people, the optimization of processes, and the strategic adoption of technology. Organizations must invest in employee training and development, provide opportunities for collaboration and innovation, and foster a culture of continuous learning and improvement. By empowering employees to take ownership of their work, embrace change, and drive innovation, organizations can create a culture of excellence that fuels growth and success.

Embracing Change and Innovation

In today's rapidly evolving business landscape, organizations must embrace change and innovation to stay ahead of the curve. The PPT nexus provides a framework for organizations to adapt, innovate, and thrive amidst uncertainty and disruption. By fostering a culture of agility, resilience, and adaptability, organizations can leverage the collective power of people, process, and technology to navigate challenges, seize opportunities, and achieve sustainable growth.

youtube

Conclusion

In conclusion, the People-Process-Technology nexus represents a dynamic framework for organizational success in the digital age. By understanding the interconnectedness and interdependence of people, process, and technology initiatives, organizations can unlock new opportunities, drive innovation, and achieve lasting success. As organizations continue to navigate the complexities of modern business operations, embracing the PPT nexus enables them to build a culture of excellence, drive collaboration, and adapt to changing market dynamics with confidence and resilience.

SITES WE SUPPORT

Workflow technology process - Wix

SOCIAL LINKS Facebook Twitter LinkedIn

0 notes

Text

When HR partners up with Agile to run a Kaizen program

August 2022, The Agile Center of Excellence partnered with Human Resource (incdluing the fantastic Ha Bui) to ensure smooth onboarding and active engagement in the WeKaizen development program.

-------------

Let's first have a look at WeKaizen's missions:

Empowering Employees: Enhance Kaizen capabilities through Lean Production training, equipping all employees with the essential skills and mindset to drive continuous improvement.

Cultivating a Kaizen Culture: Promote implemented Kaizen initiatives, fostering instant reward and recognition to incentivize participation and celebrate success

--------------

Let me precise that WeKaizen program is open to all Techcombank employees, encompassing everyone from top managers to regional relationship managers. WeKaizen program encourages participants to identify areas for improvement in internal processes and even discover simple ways to boost employee happiness:

No problem is too small or too big, isn't it?!

Here are the key areas where we provided crucial support:

Kaizen Practice - Collaborative Problem-Solving Teams brainstorm and collaborate to devise solutions (Kaizen) for specific team challenges.

Kaizen Fair - Showcasing Excellence Recognizing and rewarding outstanding individuals and teams with the most impactful Kaizen initiatives.

The HR team actually entrusted our members with their foundational coaching skills to guide participants in refining their ideas and achieving success.

In a coaching point of view, our success hinges on our ability to help participants transform their initial ideas into concrete concepts with actionable plans.

Despite considerable workload pressures facing our team with delivering the bank's core functionalities, the Head of Transformation and the new Head of Agile approached me with this request.

Partnering with my experienced colleague Son Le and the energetic Hien Nhu, they were the perfect fit! Togehter we embarked on this initiative, initially with some reservations about tackling complex problems with diverse groups for next following Saturdays...

The experience proved to be absolutely rewarding and engaging!

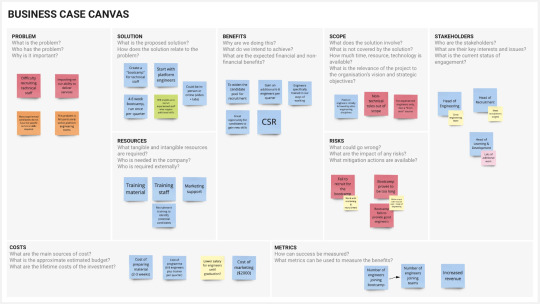

While numerous pre-existing canvases (Lean Startup Canvas, Product Canvas, Team Canvas, etc.) existed, I, after thorough research, proposed using a novel canvas tailored to encourage emergent concepts through Design Thinking methodologies.

The Proposed Canvas:

Inspired by a Business Case Canvas and a Product Vision template, here's the structure we suggested for facilitating the exercise:

Why? Identify the problem/opportunity and the overall vision to address it.

What? Describe the potential solution to tackle the identified issue.

End User? Define the individuals most impacted by the problem or the prime beneficiaries of the solution.

What the Success looks like? Outline the idealistic impact on users and the market if the solution is implemented.

Success Measurement: Determine the key metrics to gauge success.

Timeline & Milestones: Establish a feasible timeline and key milestones for achieving the desired outcome.

How-To: Define the essential steps to bring the solution to life.

Who's Involved? Identify the necessary team members or profiles required for implementation.

Stakeholders: Pinpoint sponsors and individuals accountable for the initiative's success.

Resources: Determine the necessary technical components and procurement needs.

Constraints: Acknowledge and understand the current limitations.

Risk Assessment: Identify and address potential risks.

Through collaborative refinement sessions with various groups, our team successfully enhanced over 20 Canvases. Additionally, we equipped participants with effective pitching skills to present their ideas within a five-minute timeframe. Remember that the most impactful Canvases will be presented to the bank's divisional heads.

We were excited to witness the continued success of the WeKaizen program and the positive impact it is having on Techcombank!

#productvision#Kaizen#banking#coaching#agile consulting#agile coach#team coaching#techcombank#vision#scrummaster

0 notes

Text

TWI Job Methods

TWI Job Methods develops capability in improving the effectiveness and efficiency of the methods applied in your organisations' work. This is a foundational skill for Kaizen - rapid continuous improvement. Call us at (0)771 479 4807.

1 note

·

View note

Text

#SA 8000:2014 Internal Auditor Training#AS 9100 Internal Auditor Training#SA 8000:2014 Awareness Training#ISO 17025:2017 Awareness Training#Integrated Management System Internal Auditor Training#ISO 45001:2018 Auditor Transition Training#ISO 45001:2018 Internal Auditor Training#ISO/IEC 27001:2013 Awareness Training#AS 9110 Awareness Training#AS 9120 Internal Auditor Training#AS 9100 Awareness Training#ISO 17025:2017 Internal Auditor Training#Kaizen Foundation Training#API Q1 Internal Auditor Training#AS 9110 Internal Auditor Training#Poka Yoke Course Training

0 notes

Link

#ISO 14001:2015 Awareness Training#ISO 45001:2018 Awareness Training#Kaizen Foundation Training#Poka Yoke Course Training#ISO 9001:2015 Documentation Training#ISO 9001:2015 Awareness Training#ISO 27001:2017 Internal Auditor Training Houston#AS 9100 Internal Auditor Training#AS 9120 Internal Auditor Training

0 notes

Text

What Is Kaizen

In February 2019, an article on mlb.com by Greg Johns states: "The official motto of the (Seattle) Mariners' Spring Training -- as posted boldly on the team's clubhouse walls at the Peoria Sports Complex -- is "Kaizen." 1 Every year the manager of the team creates a mantra. "This year, (Manager Scott) Servais chose a Japanese word: Kaizen," writes Ryan Divish for the Seattle Times.2 What does kaizen mean? How does a word made famous by the Toyota Production System (TPS) in the lean manufacturing world become the motto for a professional baseball team?

Simply translated from Japanese to English, kai = change and zen = good. Kaizen essentially means good change; it is also commonly used to say continuous improvement, where small improvements over time produce big results. The core of lean manufacturing in the TPS is identifying and removing waste, maximizing processes that add value, and continuously improving the systems and processes of the organization. Kaizen is one of the foundations of the TPS because the entire philosophy is based on the idea that everything can be improved. Every process has the potential to be better tomorrow than it is today.

"It sounds like a mystical Japanese philosophy passed down by wise, bearded sages who lived in secret caves" say Brett and Kate Mckay.3 But we aren't talking about zen gurus who levitate above a foggy mountaintop in full lotus. We are talking about Toyota, arguably the best manufacturing system in the world. We are talking about a professional baseball team's season motto. How does kaizen go from zen monk, to titans of industry, to a sports team? Because it is such a simple concept. Everything can be better than it is now. Small improvements over time produce massive results. You don't have to change the entire system today, or in the next week, or even the next month. However, make a small incremental improvement every single day and you will have made large strides forward after a while.

I am a huge fan of Tim Ferriss and highly recommend both his bestselling books and world famous podcast. A theme that is constantly repeated by Tim is that when people try to learn a new skill, get rid of a bad habit, or implement a positive habit, they often start too big and end up failing very quickly. Just look at the classic New Years resolution to start going to the gym. Go to any gym the first week of January and it is packed with people who have the best intentions to change their lifestyle and become healthier, happier people. I applaud anyone who is trying to make this change in their life. But most of them drop out of the routine within a few weeks. Why? Often, they go cold turkey from not exercising at all to telling themselves they are going to go to the gym one hour per day, 5 days per week. That is a massive change for someone who is starting at zero or close to it. They make it the first two days, but on the third day, life or work or family get in the way and they miss a session. They start missing more days and pretty soon it's back to the way it was before. In this example, and many like it, the kaizen approach would be best. Rather than jumping from zero to one hour a day five days per week, start with 10 or 20 minutes one, two, or three days a week. Start small. Give yourself a goal that you can achieve so you don't feel like a complete failure when you don't live up to the unrealistic expectations you set for yourself. Build up from there. After all, 10 minutes of exercise two days a week is a hell of a lot better than zero. Pretty soon that turns into 15 minutes and then again becomes 3 days per week. Eventually, you might build up to the original goal. But small, incremental, continuous improvement got you there. Not diving in head first. Get the wheel turning and then use the momentum to keep moving forward.

"Big, giant goals can be awe-inspiring. But like many awe-inspiring things — a lion, a black hole, the Grand Canyon — they can also swallow you whole... Our quest to become better often feels like a roller coaster ride with its proverbial ups and downs. By the time you’re headed down Self-Improvement Mountain for the twentieth time, you’re vomiting out the side of your cart in self-disgust, cursing yourself that you once again bought a ticket to ride" write Brett and Kate McKay.3 Kaizen is the philosophy that will end your roller coaster of starting and stopping. In an article on inc.com titled Don't Try to Be the Best. Just Be 1% Better Every Day, James Altucher writes that if you can improve 1% every day "you will be 3800% better (38 times better!) in one year. Nobody does that. That's what superheroes do. You will be a superhero. Then everyone else will be worrying how they can compete with you." 4 Making that 1% change might not even be noticeable from one day to the next. But if you continue to making those 1% improvements over time, "you suddenly find a very big gap between people who make slightly better decisions on a daily basis and those who don't. (James Clear)." 5

Unfortunately for the Seattle Mariners, an article published by cbssports.com on September 6, 2019 was titled "The Mariners have been eliminated and the longest postseason drought in North American sports is one year longer." 6 Kaizen didn't end their historic playoff drought. However, Mike Axisa does write in that article "The Mariners have found some potential long-term building blocks this season." So one step better? Maybe. But professional sports are weird, and not always a reflection of real life. As the cliche saying goes, progress not perfection. Remember, kaizen is a philosophy and belief and system all at the same time. Believe that you can make everything better tomorrow than it is today. Use the system of small, manageable, incremental improvements and see where you land six months from now. One is more than zero, and two is twice as big as one. Those small numbers add up, as long as you believe change is possible.

Kaizen = Good change.

- Tyson

References:

"Mallex injury opens door for OF prospects," by Greg Johns, February 16, 2019, https://www.mlb.com/mariners/news/mallex-smith-injury-opens-door-for-prospects-c304044944

"Mariners Sunday mailbag: Explaining the Japanese origin of the team’s new slogan," by Ryan Divish, March 31, 2019 at 6:00 am Updated April 1, 2019 at 8:38 am, https://www.seattletimes.com/sports/mariners/mariners-sunday-mailbag-explaining-the-japanese-origin-of-the-teams-new-slogan/

"Get 1% Better Every Day: The Kaizen Way to Self-Improvement," by Brett and Kate McKay, July 31, 2020 • Last updated: September 5, 2020, https://www.artofmanliness.com/articles/get-1-better-every-day-the-kaizen-way-to-self-improvement/

"Don't Try to Be the Best. Just Be 1% Better Every Day," by Quora, written by James Altucher, NOV 15, 2016, https://www.inc.com/quora/dont-try-to-be-the-best-just-be-1-better-every-day.html

"Continuous Improvement: How It Works and How to Master It," by James Clear, https://jamesclear.com/continuous-improvement

"The Mariners have been eliminated and the longest postseason drought in North American sports is one year longer," by Mike Axisa, Sep 6, 2019 at 12:38 pm ET, https://www.cbssports.com/mlb/news/phillies-introduce-dave-dombrowski-as-new-president-what-to-make-of-his-j-t-realmuto-and-payroll-comments/

Other sources:

https://www.kaizen.com/what-is-kaizen.html

https://www.leanproduction.com/kaizen.html

https://theleanway.net/what-is-continuous-improvement

https://www.mindtools.com/pages/article/newSTR_97.htm

1 note

·

View note

Text

Unfolding the Secrets of the Toyota Production System

In the world of manufacturing, the Toyota Production System (TPS) stands as a paragon of efficiency and excellence. Originating in Japan but embraced worldwide, the TPS has transformed the way industries approach production, ensuring minimal waste and maximum value.

In this article, we’ll explore the intricacies of the Toyota Production System, the principles that underpin it, and how it has become a blueprint for lean manufacturing and operational excellence.

1: Understanding the Toyota Production System

The Toyota Production System, often referred to as lean manufacturing, is a comprehensive approach to production that was developed by Toyota in the mid-20th century. It is founded on the principles of continuous improvement and efficiency, with a relentless focus on eliminating waste in all aspects of production.

Key Elements of the Toyota Production System:

Just-in-Time (JIT): This principle emphasizes producing only what is needed when it is needed, and in the necessary quantity.

Jidoka: Jidoka, or autonomation, refers to the automation of problematic processes to prevent defects and errors.

Standardization: TPS promotes standardized work methods and processes to ensure consistency and quality.

Continuous Improvement (Kaizen): Continuous improvement is at the core of TPS, encouraging incremental changes for ongoing progress.

Respect for People: TPS values the skills and insights of employees, involving them in decision-making and encouraging their contributions.

2: The 14 Principles of the Toyota Production System

Base your management decisions on a long-term philosophy.

Create a continuous process flow to bring problems to the surface.

Use “pull” systems to avoid overproduction.

Level out the workload (heijunka).

Build a culture of stopping to fix problems, to get quality right the first time.

Standardized tasks and processes are the foundation for continuous improvement and employee empowerment.

Use visual control so no problems are hidden.

Use only reliable, thoroughly tested technology that serves your people and processes.

Grow leaders who thoroughly understand the work, live the philosophy, and teach it to others.

Develop exceptional people and teams who follow your company’s philosophy.

Respect your extended network of partners and suppliers by challenging them and helping them improve.

Go and see for yourself to thoroughly understand the situation (genchi genbutsu).

Make decisions slowly by consensus, thoroughly considering all options; implement decisions rapidly.

Become a learning organization through relentless reflection and continuous improvement (kaizen).

3: The Impact of the Toyota Production System

Reduced Waste: TPS eliminates various forms of waste, including overproduction, defects, waiting, and excessive inventory.

Higher Quality: The focus on standardized processes and continuous improvement results in higher product quality.

Cost Savings: Efficient production processes and waste reduction translate into cost savings for businesses.

Flexibility: TPS enables rapid changes in production to meet shifting market demands.

Empowerment: The TPS philosophy of respecting people fosters a sense of ownership and empowerment among employees.

4: The Global Spread of TPS

The principles of the Toyota Production System have transcended borders and industries, inspiring companies worldwide to adopt lean manufacturing practices. The success stories of these adopters underscore the universal applicability of TPS principles, with examples from industries as diverse as aerospace, healthcare, and technology.

5: Challenges in Implementing TPS

While the benefits of TPS are undeniable, implementing it can pose several challenges:

Cultural Change: Shifting from traditional manufacturing to lean practices requires a cultural change and a willingness to embrace new methods.

Training and Education: Employees need to be trained in TPS principles and encouraged to become active participants in the continuous improvement process.

Resistance to Change: Resistance from employees or management can hinder the successful implementation of TPS.

Supply Chain Coordination: Coordinating with suppliers to align with lean principles can be complex but is crucial for success.

6: The Future of the Toyota Production System

Industry 4.0 Integration: TPS will integrate with Industry 4.0 technologies like IoT, AI, and automation for even greater efficiency.

Sustainability: Environmental sustainability will play an increasingly significant role in TPS implementation.

Global Adoption: More industries and companies worldwide will embrace TPS principles for lean and efficient production.

Human-Centric Approach: The emphasis on respecting people and developing exceptional teams will remain a central tenet.

Conclusion

The Toyota Production System is more than a manufacturing methodology; it’s a philosophy that has transformed the world of production and management. Its relentless pursuit of efficiency, quality, and waste reduction has revolutionized industries, making it a benchmark for operational excellence. As TPS principles continue to evolve and adapt to changing times, the future holds a promise of even greater efficiency, sustainability, and global adoption, ensuring that the legacy of TPS endures in the manufacturing landscape for generations to come.

The Toyota Production System is a paradigm of efficiency and waste reduction. With its principles of continuous improvement and respect for people, it has left an indelible mark on industries worldwide, fostering a culture of operational excellence.

Curious to learn more? Explore our articles on Enterprise Wired

#ToyotaProductionSystem#LeanManufacturing#OperationalExcellence#Efficiency#Sustainability#QualityMatters#WasteReduction

0 notes

Text

Driving Continuous Improvement with KAIZEN Implementation: A Strategic Approach for Operational Excellence

KAIZEN Implementation is a powerful strategy that focuses on continuous improvement, driving efficiency and enhancing productivity across all levels of an organization. Derived from Japanese management principles, KAIZEN emphasizes small, incremental changes rather than large-scale transformations, allowing companies to build a culture of continuous improvement. Implementing KAIZEN effectively can lead to significant operational excellence, making it a crucial approach for businesses aiming to optimize their processes and maintain a competitive edge.

Understanding KAIZEN Implementation

KAIZEN, which means "change for the better," is a philosophy that encourages all employees, from top management to frontline workers, to suggest and implement improvements in their work processes. The KAIZEN Implementation process is systematic, focusing on eliminating waste, improving productivity, and ensuring that changes are sustainable over time.

Key aspects of KAIZEN Implementation include:

Employee Involvement: KAIZEN thrives on the active participation of all employees. By encouraging everyone to contribute ideas for improvement, organizations can tap into a wealth of knowledge and experience from all levels.

Focus on Small Changes: Unlike other management strategies that may rely on major overhauls, KAIZEN focuses on making small, manageable changes. These incremental improvements are easier to implement and more sustainable in the long term.

Continuous Improvement: KAIZEN is not a one-time initiative but an ongoing process. By continuously seeking ways to improve, organizations can maintain a culture of excellence and adaptability.

Waste Reduction: A core principle of KAIZEN Implementation is the elimination of waste in all forms—whether it’s time, resources, or effort. By identifying and removing waste, companies can improve efficiency and reduce costs.

Standardization: Once a process improvement has been successfully implemented, it is standardized to ensure consistency and to serve as a foundation for further enhancements.

Importance of KAIZEN Implementation

KAIZEN Implementation offers numerous benefits that contribute to the overall success of an organization. These include:

Enhanced Efficiency:

By streamlining processes and reducing waste, KAIZEN helps organizations operate more efficiently, leading to cost savings and improved productivity.

Improved Employee Morale:

Involving employees in the improvement process fosters a sense of ownership and pride in their work, which can lead to higher job satisfaction and lower turnover rates.

Greater Flexibility:

Organizations that embrace KAIZEN are better equipped to adapt to changes in the market or industry. Continuous improvement allows businesses to remain agile and responsive.

Sustainable Growth:

The ongoing nature of KAIZEN Implementation ensures that improvements are sustainable over time, contributing to long-term growth and success.

Implementing KAIZEN in Your Organization

To successfully implement KAIZEN, organizations should follow these steps:

Educate and Train Employees: Begin by educating employees about the principles of KAIZEN and how they can contribute to the process. Training sessions and workshops can help build a strong foundation for implementation.

Encourage Participation: Create a culture where all employees feel comfortable sharing their ideas for improvement. Regular meetings, suggestion boxes, and recognition programs can help encourage participation.

Implement Changes: Start with small, manageable changes that can be quickly implemented. Monitor the impact of these changes and make adjustments as needed.

Standardize Successful Changes: Once an improvement has proven successful, standardize the process to ensure consistency and build upon it for future enhancements.

Monitor and Review: Continuously monitor the results of KAIZEN Implementation and review the processes regularly. This will help identify new opportunities for improvement and ensure that the culture of continuous improvement is maintained.

KAIZEN Implementation is a proven strategy for driving continuous improvement and achieving operational excellence. By focusing on small, incremental changes and involving all employees in the process, organizations can build a culture of excellence that is sustainable over the long term. At 4C Consulting, we specialize in helping businesses implement KAIZEN effectively, providing the guidance and support needed to achieve lasting improvements. Contact us now.

0 notes

Text

Combination of Lean, TPM, TQM, Kaizen, Six Sigma | Best practices of Operational Excellence Journey Methodologies | Reducing Lead time of manufacturing

Our answer is yes. Every tool/methodology has unique features that helps for every business. Seven Steps Business Transformation is in the field of helping organisations in their Journey of Excellence. As combination of business excellence and operational excellence, every company where we have helps got substantial benefits and improvement in their overall performance.

Quite often, we come across industry leaders who ask a common question … “will this particular tool/methodology will be applicable for us”. Having worked with hundreds of organisations and multiple business sectors, we find that adapting best practices of all methodologies will certainly give edge in results. As you are aware, every religion has some of the best practices which can be adapted by every living being on this earth.

One of MNC having operations in India has invited us to help them in reducing Lead time of manufacturing which they felt can significantly help in improving ontime delivery performance which in turn can help them getting improved business. Core business model of this organisation was a high mix and low volume and non-stock production has been the need. Every order is a make to order type. Upon our in-depth study, we found that improvement is needed not only in manufacturing area but also in pre-manufacturing stage. i.e. from the time the order was received to the time the order was released to production. The process involved in designing the product and improving the effectiveness of design and process specialists. We find that the time taken for an order to get released to production has been nearly 80% of the total time in many cases. Lean product development methodology has been introduced along with waste elimination – primarily elimination of over processing in pre-production areas. Lead time trackers were introduced with dashboards and visual tracking systems. Review of orders with highest lead time was done on periodic basis – Daily at operations level and weekly at management level (top 3). This resulted in reduction of pre-production lead time by over 90%.. from 20 days to <2 days.

Second focus area was to reduce Manufacturing lead time and alignment of ontime performance in line with Customer required date (CRD). Here, we find application of Value Stream Mapping tools, Bottleneck management, Single Minute Exchange of Dies –(SMED) which we have called as Quick change-over as generic name. Apart from this, Total Productive Maintenance concepts such as Autonomous Maintenance has helped in improved uptime of machines. Kanban – a lean methodology has helped in ensuring availability of regular RM and consumables. There were certain bottleneck operations which needed resolution where we had to use Theory of Constraints to handle this. After consistent application of This company not only made Indian operations a benchmark in their group but became most preferred partner for customers too

As the story goes about a mechanic who had used a hammer to tap the machine to make it working from breakdown, the key aspect is to identify where to tap. Even though there no limit of information available in the form of books, case studies etc., on various tools and methodologies, application of such tools, timing of deployment of the right tool becomes the key for success. There are some foundation tools such as 5S which is very essential before applying other tools such as TPM. Like wise, before even starting problem solving tools and techniques such as 7QC tools, orderliness and visual factory will help in minimizing major obvious defects. When there is need to set right basic conditions and establish basis stability, deployment of Six Sigma methodology becomes overkill.

In a nutshell, in order to deliver the customer what they need – in this case improved business results, we had to deploy combination of many tools/methodologies in the right sequence at the right time.

Seven Steps Business Transformation Systems is India based organisation helping organisations in their Journey of Excellence. We have consultants with wide experience in industry segments such as manufacturing, services, retail, logistics, food, construction, Information Technology, Education, Health care services. Our consultants are experts in deployment of Total Productive Maintenance, Lean manufacturing, lean services, Lean hospitals, Lean Health care, Lean Construction, Lean office.

We work with multiple industry sectors such as Automotives, Equipment manufacturing, defence products, pharmaceuticals, Aerospace components, high precision manufacturing, apparel to name a few.

Personal Development Programs

Basics of Business Excellence

Value Added Quality Management Systems

Total Productive Maintenance (TPM)

Lean Thinking & Lean Management

Leadership Training Programs

1 note

·

View note

Text

Total Quality Management (TQM): An In-Depth Guide

In today's highly competitive market, Total Quality Management (TQM) has become essential for companies striving for excellence and customer satisfaction. TQM represents a comprehensive, organization-wide effort aimed at enhancing quality, productivity, and overall performance. It encourages a culture of continuous improvement, where every employee, process, and department plays a role in quality enhancement.

What is Total Quality Management (TQM)?

Total Quality Management (TQM) is a structured management approach that seeks to improve the quality of products and services continuously. Rooted in the principles of customer focus, process optimization, and team collaboration, TQM aims to achieve long-term success by satisfying customer needs and reducing waste.

Principles of Total Quality Management

The foundation of TQM rests on several principles that guide organizations toward quality improvement:

Customer Focus: Every action within TQM begins and ends with the customer. Understanding customer needs and meeting or exceeding their expectations is the primary goal.

Leadership Commitment: Management plays a critical role by fostering a culture that values quality at every level of the organization.

Continuous Improvement: A never-ending improvement mindset is essential for maintaining high standards.

Employee Involvement: Every team member is empowered to contribute to the quality management process.

Process Approach: Instead of focusing on individual tasks, TQM emphasizes a holistic view of processes that produce the final product.

Core Concepts of TQM

1. Customer-Centric Approach

A customer-centric approach is central to TQM. Organizations must understand customer requirements through research, feedback, and customer interaction, allowing them to refine processes to match these needs.

2. Leadership and Vision

Effective TQM implementation requires leaders to provide a clear vision, set measurable objectives, and create an environment that encourages employees to take ownership of quality issues.

3. Data-Driven Decision Making

TQM emphasizes the use of data to make informed decisions. Data collection, statistical analysis, and regular feedback loops help in tracking progress and identifying areas for improvement.

4. Continuous Improvement Techniques

To foster continuous improvement, TQM utilizes various tools and methodologies. Techniques like Kaizen, Six Sigma, and Lean Manufacturing are commonly integrated into TQM frameworks.

Top Benefits of Total Quality Management

Implementing TQM brings numerous advantages, from improving product quality to enhancing operational efficiency. Here are some key benefits:

Higher Customer Satisfaction: TQM helps companies meet and exceed customer expectations, leading to improved satisfaction and loyalty.

Increased Efficiency: By identifying and eliminating inefficiencies, TQM reduces waste and minimizes errors, thereby optimizing resource usage.

Enhanced Employee Morale: When employees are engaged in quality processes and empowered to make improvements, they tend to show higher levels of motivation and commitment.

Improved Profitability: Quality improvements lead to cost savings, enhanced productivity, and greater revenue.

Competitive Advantage: Companies with strong TQM practices often enjoy a competitive edge by consistently delivering high-quality products.

Implementing Total Quality Management in Your Organization

To successfully adopt TQM, organizations should take a structured, step-by-step approach:

1. Establish Clear Objectives and Goals

Set clear, measurable goals that align with the organization’s overall mission and customer expectations. Goal-setting provides a roadmap for employees and management, facilitating an organized implementation of TQM principles.

2. Employee Training and Development

Investing in employee training is essential to ensure that everyone understands TQM principles and their roles in achieving quality objectives. Training programs should cover areas like quality control, problem-solving techniques, and communication skills.

3. Process Improvement and Optimization

Identify key processes that directly impact quality and optimize them through process mapping, reengineering, or streamlining. Regularly analyze these processes for improvement.

4. Use of Quality Tools

Leverage quality tools such as:

Pareto Analysis: Identifies the most common sources of defects.

Control Charts: Monitor processes for stability.

Cause-and-Effect Diagrams: Identify root causes of quality issues.

5. Implement Feedback Mechanisms

Continuous feedback from customers, suppliers, and employees is vital. It provides insights into process weaknesses and areas where improvement can bring substantial results.

6. Regular Audits and Reviews

Conduct regular audits to evaluate the effectiveness of TQM practices. Audits help ensure adherence to standards and allow for adjustments to improve the program continuously.

Key TQM Tools and Techniques

TQM employs several tools to help organizations achieve quality goals:

1. Six Sigma

Six Sigma is a data-driven method that seeks to eliminate defects and variations, aiming for near-perfection in quality. By focusing on process improvement and statistical analysis, Six Sigma ensures consistent output.

2. Lean Manufacturing

Lean Manufacturing minimizes waste without compromising productivity. It focuses on streamlining operations, eliminating non-value-adding processes, and maximizing efficiency.

3. Kaizen

The concept of Kaizen emphasizes small, ongoing changes to improve quality and productivity. Kaizen involves every employee in the organization and fosters a culture of continuous improvement.

4. ISO Certification

The International Organization for Standardization (ISO) provides guidelines and standards for quality management. Achieving ISO certification demonstrates a company’s commitment to quality standards, boosting customer trust and credibility.

The Role of Technology in Total Quality Management

In today's digital age, technology plays a crucial role in supporting TQM efforts. From data collection to quality monitoring, technology offers tools that can enhance efficiency and accuracy.

Data Analytics: Advanced data analytics provide insights into customer preferences, process inefficiencies, and quality bottlenecks.

Automation: Automating repetitive tasks frees up resources and reduces the risk of human error.

Quality Control Software: This software helps in tracking defects, managing compliance requirements, and providing real-time quality data.

Challenges of Total Quality Management

Despite its advantages, TQM poses several challenges, particularly during its initial implementation phase.

Resistance to Change: Employees may resist new processes and methods, especially if they’re accustomed to traditional practices.

Initial Costs: Implementing TQM involves training, process changes, and investment in quality control tools, which can be costly.

Complexity in Large Organizations: For larger organizations, coordinating TQM across multiple departments and processes can be a complex undertaking.

Measuring the Success of TQM

To assess the effectiveness of TQM, organizations can use various metrics and key performance indicators (KPIs):

Customer Satisfaction Scores: Feedback from customers directly reflects the quality of products and services.

Defect Rate: Monitoring the defect rate helps identify issues in production that impact quality.

Employee Engagement: High employee engagement often correlates with a strong commitment to quality.

Financial Performance: Improved profitability and cost savings are clear indicators of successful TQM.

Examples of Successful TQM Implementation

Some of the world's most successful companies, such as Toyota, Motorola, and Xerox, have set benchmarks in TQM practices:

Toyota: The Toyota Production System (TPS) combines Lean and TQM principles, emphasizing waste reduction and continuous improvement.

Motorola: As the pioneer of Six Sigma, Motorola made quality an integral part of its operations, significantly reducing defects and boosting efficiency.

Xerox: Xerox implemented TQM to turn around its declining quality, focusing on customer needs and continuous improvement.

Conclusion: Total Quality Management for a Competitive Edge