#Jacquard jersey

Explore tagged Tumblr posts

Text

The Sopranos Tapestry Hoodie

#Nick Scacchetti#hbo#tv series#tapestry#tapestry hoodie#jacquard#the sopranos#David Chase#Sidney Wolinsky#William B. Stich#Conrad M. Gonzalez#crime#crime drama#black comedy#the mob#the mafia#mob boss#woke up this morning#alabama 3#Tony Soprano#James Gandolfini#New Jersey#Italian American#mobster#Jennifer Melfi#Lorraine Bracco#Timothy Van Patten#Allen Coulter#John Patterson#Drea de Matteo

897 notes

·

View notes

Text

#AMIRI#Panther Logo-Embroidered Appliquéd Wool-Blend Twill Bomber Jacket#Convertible-Collar Logo-Embroidered Satin-Jacquard Shirt#$950#Pacific Bones Appliquéd Suede and Full-Grain Leather Sneakers#$650#Skinny-Fit Distressed Patchwork Jeans#$1#190#Vintage Pegasus Oversized Distressed Logo-Print Cotton-Jersey T-Shirt

0 notes

Text

HUgE November 2010

Suit stud

MIHARAYASUHIRO

fabric_Cotton 100%

color_Black, Brown

The patchwork check pattern, which looks like a transfer print, is a jacquard reproduction of a photographic image. This is a representative piece that symbolizes this collection. Jacket ¥88,200, vest ¥48,300, shirt ¥17,850, pants ¥45,150, boots ¥77,700 (Mihara Yasuhiro Tokyo)

YVES SAINT LAURENT

fabric_Wool 50%, Cotton 50%

color_Ink

The Prince of Wales jersey material is dyed in a chic color. Add some fun with the inner cut-and-sew and belt. Suit ¥393,750, Cut-and-sew ¥44,100, Shoes ¥131,250, Belt, Reference Product (Gucci Group Japan Yves Saint Laurent Division)

LANVIN

fabric_Wool 30%, Silk 70% (Jacket)

/Wool 100% (Pants)

color_Navy

The collection fully demonstrates advanced tailoring techniques, such as material switching and raw edge techniques on the shoulders and pants pocket trimming. Jacket ¥295,050, shirt ¥60,900, belt ¥61,950, pants ¥77,700, boots ¥179,550 (Lanvin Japan)

COMME des GARÇONS MAN PLUS

fabric_Wool 100%

color_Grey

The protectors on the chest and elbows are an important element that symbolizes this season's collection. This innovative idea has opened up new possibilities for suits. Jacket ¥100,800, Shirt ¥26,250, Pants ¥35,700, Belt ¥9,450 Shoes ¥60,900 (Comme des Garcons)

BLACK FLEECE BY Brooks Brothers

fabric_Wool 100%

color_Grey

The design is typical of Thom Browne, with a short length and sleeves, a box silhouette, and authentic traditional specifications such as three-button step-back and hook vents. Jacket ¥157,500, turtleneck knit ¥31,500, pants ¥57,750, boots ¥94,500 (Brooks Brothers Japan)

MIHARAYASUHIRO

fabric_Wool 42%, Linen 40%, Polyester 9%, Acrylic 6%, Nylon 3% color_Black x White, Black, Khaki

The designs are carefully crafted with great care, including damage and repairs that make them look like they have been worn for many years. Jacket ¥89,250, Cropped pants ¥49,350 (Miharayasuhiro Tokyo)

YOHJI YAMAMOTO

fabric_Sheep Skin, Cotton 100%, Silk 100% (Jacket)/Cotton 100% (Pants)

color_Navy, Black

The combination of unevenly dyed Katsuragi and suede is a little rugged, but the silk lapels add elegance and balance to the look. Jacket ¥225,750, Pants ¥54,600 (Yohji Yamamoto Information Desk)

TAKAHIROMIYASHITATheSoloist.

fabric_Wool

100%

color_Camel, Grey, Navy

It took a lot of time to complete the garment using a wide variety of sewing machines. Despite its delicate design, it is comfortable and relaxing to wear. Jacket ¥82,950, Pants ¥40,950 (Pred PR)

RAF SIMONS

fabric_Wool 100%

color_Navy

Velcro and snap buttons are this season's signature designs. This is the perfect example of Raf Simons's tailoring, with a classic look and edgy details. Jacket ¥197,400, pants ¥73,500 (Saint Frère)

UNDERCOVERISM

fabric_Wool 100%

color_Grey Brown, Top Charcoal, Black

Unlike regular sewing, the fabric is sewn together with a merrowlock machine to give the details a three-dimensional look. The relaxed feel is just right. Jacket ¥69,300, Pants ¥50,400 (UNDERCOVERISM)

#my scans#fashion#archive fashion#avantgarde#2010s fashion#lanvin#raf simons#jun takahashi#undercover#takahiro miyashita#takahiromiyashita the soloist#thom browne#brooks brothers#yohji yamamoto#maison mihara yasuhiro#mihara yasuhiro#comme des garcons homme plus#ysl

13 notes

·

View notes

Text

The Late Show with Stephen Colbert:

Nicki wore a Chanel silk jacquard satin square scarf ($625), an Alaïa draped jersey dress ($2,430), a Balmain jacket with faux fur sleeves ($5,400), Area crystal embellished teardrop earrings ($240), Saint Laurent wavy cuff ($1,390) and (what looks like) Jimmy Choo love 85 pumps ($775).

#nicki minaj#nicki minaj fashion#nicki minaj style#fashion#the late show with stephen colbert#stephen colbert#chanel#balmain#area#alaïa#alaia#saint laurent#jimmy choo

28 notes

·

View notes

Text

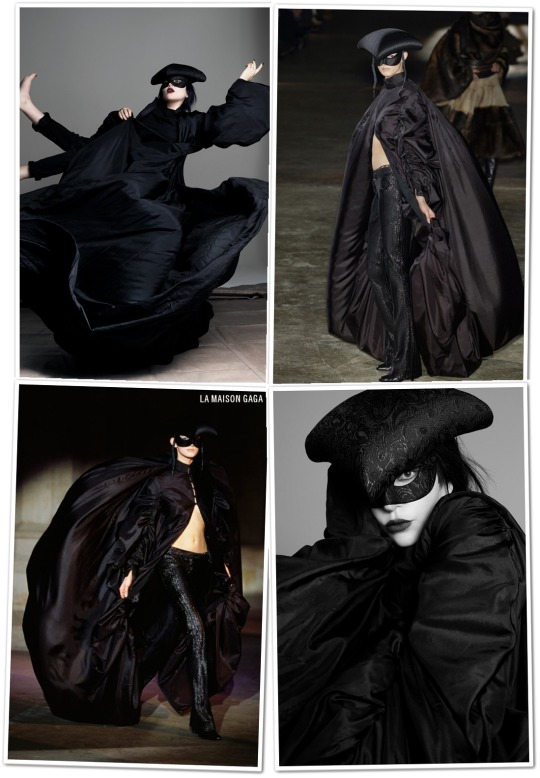

LADY GAGA AT THE CHROMATICA BALL PREMIERE

Lady Gaga joined her little monsters at the screen premiere of her highly-anticipated HBO "Chromatica Ball" Tour Film last night which took place at the Nya Studios in Los Angeles.

Styling by Nicola Formichetti and Hunter Clem with assistance by Erica Valle and Frankie Benkovic. Hair by Frederic Aspiras, glam by Sarah Tanno-Stewart and nails by Miho Okawara, respectively.

Gaga turned up in Argentinian Berlin-based emerging designer SELVA which was based on his "[603.628]km²" collection.

Her look featured a laminated white muslin calico cotton one-shoulder jacket and matching corset dress cut in the memory of an apron, stenced with holes for multiple sterling silver hooks and chains. A white lacquered shoulder sculpture made of discarded car parts pulled the whole look together. It was created in only two days!

Cristian 'Selva' Huygens started by developing and creating costumes for performances he produces, as well as for exhibitions inside ATM banks and interventions in public spaces around Berlin. The collection was inspired by his last trip to Kyiv, Ukraine where he also presented a collection of designs at a local metro station.

He mainly focuses on using discarded materials, all kinds of fabrics, metal connectors, and car parts as armatures. Conceptually, he describes his brand in one word: Brutalism. Every construction detail and mistake is shown. When it happens, he makes them even more visible. As the designer calls it, he develops 'honest clothes,' following the Brutalism concept.

She completed her look with the Pleaser Xtreme-1020 white vinyl platform ankle boots with lace-up front.

Gaga then sat down for a Q&A session, wearing another Germany-based emerging designer: AZIZ, who she previously introduced to us by rocking his designs both on-stage and on-screen at the tour!

This time, he crafted her a custom look which comprised a black stretch jersey long-sleeved elongated dress with a silicone drip-covered stiffened mesh cocoon structure with peek-a-boo slit for the head to come through, and matching gloves.

She crowned the look with a Philip Treacy Fall/Winter 2018 intricate black lace mask.

Our girl also rocked a bunch of white-gold and diamond rings by two French labels. The first ring is Djula's Délicatesse geometric lines large ring (€2,700).

The three other rings are all signed by AKILLIS and included the Tattoo large ring (€8,500), the Tattoo slim ring (€2,900) and the Capture Me ring (€5,250).

I couldn't help but notice how much the last ring resembles a bear trap, which is also depicted on the single cover for the first "Chromatica" single "Stupid Love", creating a great full circle moment.

Shop:

Djula "Délicatesse" Ring (€2,700.00)

AKILLIS "Tattoo" Large Ring (€8,500.00)

AKILLIS "Tattoo" Slim Ring (€2,900.00)

AKILLIS "Capture Me" Ring (€5,250.00)

Gaga rocked her signature sky-high Flamingo-1020 black vinyl platform boots from Pleaser.

The final look of the evening saw Gaga channeling her CBT "Sonnet" interlude by re-wearing her Alexander McQueen Fall/Winter 2002 "Supercalifragilisticexpialidocious" collection parachute coat which features a mandarin collar, eye-hook closure and exaggerated bishop sleeves, bubble back and train.

In McQueen's words: "This collection was inspired by Tim Burton. It started off dark and then got more romantic as it went along."

This coat was given to her by Daphne Guinness personally!

She also wore the matador-inspired black jacquard silk mask headpiece Philip Treacy created for Lee's collection.

For the short and black nails, Miho used the Aprés Gel Couleur in "Birnam Wood". Both the base and top coats are by Presto.

#May 2024#outerwear#Alexander McQueen#jackets#SELVA#dresses#gloves#AZIZ#hats#Philip Treacy#jewelry#AKILLIS#Djula#boots#Pleaser#nails#Aprés#Presto

9 notes

·

View notes

Text

FASHIONABLE FORTITUDE: MYTHERESA’S COLD-WEATHER EDIT

THE FASHIONISTO / PUBLISHED NOVEMBER 13, 2023

Layering for the cold, Keon Hee Lee wears a LEMAIRE virgin wool duffel coat and cotton jersey turtleneck top with a Brunello Cucinelli cashmere beanie and jacquard cardigan. Photo: Mytheresa

#Keon Hee Lee#mens style#menswear#wool#wool sweater#turtleneck#rollneck#rollkragenpullover#cardigan#wool cardigan#men's fashion#men's clothing#men's style#mytheresa#layering#luxury

9 notes

·

View notes

Text

Spell

Floating on a magic carpet on a trip to Washington state I went to their house but they weren't home so I waited in a nearby office. Up high in the canopy almost fell off the edge losing my keys my wallet my book. Pants around ankles. The square brown bldg with natural light, there was nature in and out. I had to hide in the woods when the police came, off to my next stop. I counted the villages from my work trips this year, and as I did I could see them in my mind like Google's monthly recap. Dallas Austin Nashville Montgomery Jersey city Reno jersey city again Orlando. Now to Columbus and Cleveland. What next. Island hopping in my jacquard tie print biplane. A page out of the Ozarks. Sorge is like a word you write on a napkin. But not one you write in lipstick. It's written in black ink from the heart, and shows up when you expose it to light, to heat, or to magic.

5 notes

·

View notes

Text

Learn About 2 Types of Circular Knitting Machine and Their Advantages

Comprehensive Guide of Single Jersey Circular Knitting Machine and Its Advantages

Single jersey knitting machine has one cylinder of around 30 inches. This machine can knit fabric with less GSM [gsm in fabric how to calculate] compared to a double jersey knitting machine. Knitting is done in one direction in this machine. The knitting in this machine takes place by the coordination of needle and sinker, where needle makes the loop and sinker push it toward the fabric. Sinker plays an important part in this machine. Using this fabric we can manufacture plain fabric which is used in the production of t-shirts, blouses, tops and casual dress. Since the invention of knitting plain fabric is being made. Plain fabric can be made using hand and machine both. Wool production is limited to 20 gauge using this fabric. The fabric made out of this machine has curling ends.

Advantages of Single Jersey Circular Knitting Machine

A- This machine is a good choice for mass production

B- This machine can manufacture a variety of products from lightweight to heavy-weight fabric.

C- Single jersey machine is easy to maintain and repair

D- Less expensive compared to double jersey knitting machine ]

E- It can switch between colors easily

Introducing Double Jersey Circular Knitting Machine and Its Advantages

A double jersey circular knitting machine is nothing but a single jersey knitting machine; the only difference in this type of knitting machine is that it has an extra set of needles which moves horizontally. In this machine there are 2 sets of needles adjacent to each other. This machine knit in 2 directions perpendicular to each other. Sinker is not required in this machine. The final product that is made out of this machine are sweaters, sweatshirt, hoodies, etc. The final product of this machine does not curl unlike a single jersey circular knitting machine.

Advantages of Double Jersey Circular Knitting Machine

A- Can produce fabric with different textures such as terry and pique

B- It can produce multiple patterns, such as stripes and jacquards

C- It can produce thicker fabric with higher insulated properties

Fabric is an important part of t-shirts or any garment manufacturing. We as a t-shirt manufacturer see that when a wholesaler buy t-shirts in bulk from us they check the quality of the fabric.

#textile#manufacturing#textiles#yarn#clothing#dyeing#knitting#business#fiber art#pattern#fabric#fiber#cotton#linen#wool#tshirt#weaving#small business#entrepreneur#india#made in india#trade#wholesale t shirts#wholesalers

5 notes

·

View notes

Text

Proenza Schouler’s Fall Winter 2025 collection reworks American classics with a perspective that feels both grounded and forward-thinking. The collection plays with contrast—where the rawness of the outdoors meets the sleekness of urban dressing, a tension the brand has long mastered. Proenza Schouler Fall Winter 2025 Collection Proenza Schouler Fall Winter 2025 Collection ADVERTISEMENT The codes from Spring Summer 2025 carry over, but with a seasonal shift. Stripes morph into plaid, textures become richer, and the silhouettes take on a new ease. Plush jacquards and thick knits set the tone in deep earth tones, electric blues, and bursts of apple green. Corduroy and denim—two workwear staples—are cut with generous proportions, making them feel instantly elevated. Shearling, leather, and soft knits wrap and drape in ways that feel instinctive, designed to move with the body rather than restrict it. Proenza Schouler Fall Winter 2025 Collection Shape is everything. Outerwear is voluminous yet polished, with draped coats and wide-leg trousers creating a sense of quiet confidence. Flowing pleated dresses and floral silk prints soften the sharper, structured elements. Pleated jersey—a house signature—returns with custom metal hardware details, while handcrafted leather flowers are appliquéd onto silk chiffon, bringing the collection closer to nature. Proenza Schouler Fall Winter 2025 Collection Proenza Schouler Fall Winter 2025 Collection ADVERTISEMENT The accessories strike a balance between form and function. The Days Carryall Tote, a new standout, arrives in optic white and black, while the Silo bag shifts into an exaggerated clutch and crossbody. The Reade Shoulder Bag is introduced with a purpose-driven design, made for everyday wear. Footwear leans into versatility: slouchy leather boots, sculptural pumps, and classic loafers round out the lineup. Shot by Tim Elkaïm at MANITOGA/The Russel Wright Design Center in upstate New York, the campaign captures models Mica Argañaraz, Julia Nobis, and Binx Walton in a setting that echoes the collection’s spirit—where nature and modernity coexist. Read the full article

0 notes

Photo

One of the most difficult things about starting a sweater brand is the high MOQ (minimum order quantity). FYI, generally, sweater MOQs are in the hundreds, but a few knitwear manufacturing suppliers will go as low as 50 pieces per style per color. Which, I get, can still feel kind of high for a startup brand. But, don’t give up; there are a few hacks, like using hacci fabric, that can help decrease your order size and still keep your costs low. Today, I am going to walk you through 3 different types of sweater manufacturing, to help you decide which is right for you and your brand. This is important because sweater supply chain is highly specialized. Before you can reach out to suppliers, you need to know what type of sweater you want. BUT BEFORE WE GET STARTED... I love helping startup brand founders succeed, so I created a bunch of free guides that will help you with your business. They won’t be free forever, so make sure to grab them while you can. WHAT YOU WILL LEARN… SHORT ON TIME? CLICK THROUGH THIS 60 SECOND SLIDE RECAP WHY I LOVE TEACHING PEOPLE ABOUT KNITWEAR MANUFACTURING AND SWEATERS Why do I love teaching people about sweaters? Take a walk down memory lane with me. I was still just a student at The Fashion Institute of Technology (FIT) studying Textile Development. Like many college kids, my friends and I spent more time in bars than in class (Hey, I’m a wild child (Labyrinth reference)! What can I say?). And like in any bar scene, we spent quite a bit of time chatting with strangers. The conversations went a little like this (I promise this is relevant to making clothes): Them – What do you do? Us – We’re in school for manufacturing. Them – What? Us – Like, how to make clothing. Them – (without fail, literally 99 times out of 100 – if I had a dollar for every time someone asked me this, I would probably be retired), oh cool, can you knit me a sweater? Us - Ummm, that’s not how clothing manufacturers work From the multitude of groundhog-day-like bar conversations, I realized just how little people knew about how clothes were made. It blew my mind that some people thought that all clothes were made by people sitting in a chair, knitting. So, this post will teach you all about actual sweater manufacturing. And, this topic will always have a special place in my heart. HAND KNITTING VS MACHINE KNITTING Sweaters are made directly from yarns (we get to skip the fabric step with knitwear manufacturing, but more on that in a little bit), and there are two different ways of making them: by hand or by machines - welcome to the future. I’ll teach you about both! WHAT IS HAND KNITTING? Hand-knitting is exactly what the bar folk were thinking; two needles and a ball of yarn (rocking chair not included). Each garment is hand-made by one person. And is generally under the ethical fashion cateogry of artisan custom clothing. With hand knitting, we rely on the skills of artisans. The labor-intensive work requires a large team of people. WHAT IS MACHINE KNITTING? Full fashion machine knitting, on the other hand, starts with a computer program. Basically, you can design a sweater from special software, press a button, and the machine gets to work with entire jumpers popping out at the end. It’s like living in the Jetsons. Compared to hand knitting, a lot fewer people are needed to create the sweaters because the machines are doing most of the work. Generally, a company will only have 1-2 people programming them. Pro tip. Complicated patterns that take people a really long time to hand knit, like tailored, knit jacquard pieces are especially great products for machines to do. A THIRD TYPE OF SWEATER FEW PEOPLE KNOW ABOUT Hacci sweater knits. So, what is hacci fabric? This is it. The big secret. This is my absolute favorite hack to help small brands PRODUCE custom sweaters. Hacci fabrics. Not to be confused with other knit fabrics like jerseys, or french terry fabric. Brushed hacci sweater fabric is a type of fabric that looks like a sweater knit fabric. The fabric can then be cut and sewn and made into a garment. These textiles basically sit between the worlds of knitwear manufacturing and traditional cut+sew. Instead of going from yarn straight to garment like other sweaters, hacci sweaters need to go though the cutting, sewing, and finishing process. And, as you will see in just a minute are a great hack to getting lower prices and lower MOQs. PROS AND CONS OF DIFFERENT KNITWEAR MANUFACTURING TECHNIQUES PROS OF HAND KNITTING Artisanal. Custom knit sweaters are 100% made by people. This means that each sweater is a little bit different and unique. Not only does the product feel one of a kind and special. But usually, hand-knit sweaters are sold by types of programs that help people. There are quite a few NGOs (non-governmental organizations, or international charities) and groups that help different at-risk communities find work knitting. (want to learn more about a few of these programs – scroll down to the bottom of the post.) Low MOQs (minimum order quantities). It is possible to make as little as 1 garment. All you need to do is hire one artisan to knit it. CONS OF HAND KNITTING Slow production. Because people make the garments, the process is much slower than an automated machine. Also, many of the groups that do this type of work tend not to do it full-time, so production times can be hard to track. Aging labor pool. The artisans that do this type of work tend to be much older. And finding workers to replace this aging population is difficult because young people today want to be TikTok famous, not work in a knitwear factory setting. Expensive. Like many other manufacturing options, time is money. Generally, the longer something takes to make, the more expensive it is. Hand-knitting is an extremely slow process. PROS OF MACHINE KNITTING A quick personal story. These machines are super cool, and as part of the textile curriculum at FIT, we had to learn how to program them ourselves. Cue a flashback of me spending hours of my life down in the basement of FIT (we used to call it the textile casino, because there were no windows or clocks), learning how to create knitting computer programs. Set it and forget it. Just like 3-D printing, once the samples are approved, and the program is set, you can make as many sweaters as you want with very little effort or (wo)man power. Good bulk prices. Because bulk production is so automated and requires minimal manpower, large bulk orders tend to have competitive pricing. CONS OF MACHINE KNITTING Sampling can be expensive. Although you can get a good rate for bulk orders, what tends to be expensive is the hiring of the engineers necessary to program the machines. Because the costs of labor are so high, development for these types of knit sweaters tends to be higher than other manufacturing options. Larger MOQ. MOQs usually start with about a few hundred pieces. While it is possible to press knit only once and get one sweater, it would not be economical. A lot of time is taken to program, sample, and tweak the computer program. Once all of that work is done, factories want to make sure the machine can run on autopilot for a while. Sit tight, I am going to get into the pros and cons of using hacci knit fabric at the end of the article in the price savings section. BENEFITS OF A KNITWEAR MANUFACTURING SUPPLY CHAIN So, what happens in sweater production is that when the yarns are knit, instead of being knit into a flat piece of fabric (to then be cut and sewn), they are actually knit into the shape of a garment directly. It’s important to note that this is only possible with knitting. Woven fabrics (like the ones found in button-down shirts, jeans, etc.) are always cut and sewn. If you have been reading the blog for a while, you might remember there are 5 levels in the garment supply chain: Fiber�� Yarns Fabric Dyeing/printing Garment cut + sew But, as I just mentioned, the only exception to this rule is when making a sweater. You can cut out the fabric, step making your supply chain only 4 levels. And, being able to go directly from yarns to garment is good for 2 reasons. The first is traceability. Traceability is being able to track where everything comes from in all of the stages of the supply chain. The fewer stages in the supply chain, the less to keep track of and audit. Basically less work. The second benefit is reduced carbon emissions. Very few suppliers in fashion are vertical, meaning very few suppliers conduct all 5 levels of the supply chain under one roof. What typically happens is that the fibers and yarns are produced in one country, and are then shipped to another country to be made into fabric. The apparel fabrics are then sent to a third country to be cut and sewn into a garment. And, lastly the garment is shipped to a forth location to actually be sold to customers. By being able to cut out an entire level of the supply chain, a whole lot of transportation can be avoided, reducing supply chain emissions. HOW TO DECREASE YOUR SWEATER MANUFACTURING MOQ AND COST You can take the girl out of the Walmart supply chain, but you can’t take the Walmart cost savings hacks out of the girl. A big part of my job, when I worked in fast fashion, was figuring out ways to chop down the price of our products without degrading their performance of the product. Basically, mission impossible. One of the most difficult things about starting a sweater brand is the high MOQ. Generally, sweater MOQs are generally at least 100 pieces per style per color. Which, I get, can still feel kind of high for a startup brand. But, don’t give up. There are a few things I have in my bag of manufacturing cost savings tricks that can help decrease your order size and still keep your costs low. To make lower MOQs and still keep manufacturing costs affordable, there are 4 things to consider: hacci fabrics, blended yarns, fabric weight, and colors. These are the good tricks most sweaters manufacturers won’t share. HACCI FABRICS Cut and sew manufacturing using Hacci fabric tends to have a much lower MOQs than machine knitting. It requires no special machinery or training. And it is much cheaper than a hand knit or full fashion knit even though there is an extra level in the supply chain. The only drawback is that after sewing the garment, the seams tend to be quite heavy. But most people don’t notice, and this does not seem to take away from the customer experience. BLENDED YARNS The average consumer can’t tell the difference between 100% merino wool, and a wool acrylic (cheaper than wool) blend. Actually, sometimes they even think that the wool/acyclic blend feels more like a luxury knit sweater! What they can feel is a low-quality wool yarn that feels itchy and scratchy. So, instead of going for that 100% wool label and compromising the quality of wool fibers, opt for a blend. Cost-effective fibers to consider for this hack are cotton, acrylic, and nylon. The other nice thing about sweaters is that you can skip the spandex. Generally, sweater constructions naturally have a lot of stretch, so you don’t need elastic added to them. And, because elastic is one of the most expensive fibers around, this helps to reduce the price. FABRIC WEIGHT The lighter the fabric, the less fiber resources, and the more money you can save. Now, there comes a point where a fabric becomes too thin and feels cheap. But, usually, it is possible to decrease the weight a little bit to save some money without anyone really noticing. COLORS Instead of using custom-dyed colors, use stock yarns from your knitwear manufacturing partner. The process of lab dips and dying custom colors is not just expensive, but it is also time-consuming. By using the yarn colors factories have available (and some factories have up to 30- 50 options to choose from), you can get your production cheaper and faster. MY FAVORITE KNITWEAR MANUFACTURING SUPPLIERS Are you a designer who needs help getting your sweaters made, and tired of googling for things like sweater manufacturers near me, with no restults? Here are a few of the best sweater manufacturers around! HANDKNIT SUPPLIERS, FOR CUSTOM MADE KNITWEAR KOCO Knit - Indian artisan knitwear manufacturing, “KOCO was established in Australia by Danielle Chiel in partnership with women who live in rural villages of Tamil Nadu, southern India. What began as a solution to producing hand-knitted garments offshore is now a sisterhood of artisans and a business with the United Nations Global Goals for Sustainable Development entwined in our DNA. We have scaled the art of hand knitting to produce commercial quantities of garments, all entirely hand knitted.” Knitlab Peru - Move over cashmere sweaters, I am obsessed with sustainable alpaca these days. “Our practice involves working with knitting artisans that have formally set up their own small businesses and communities. Each leader, in turn, has their own group of knitters or a workshop.” MACHINE KNIT SUPPLIERS Shima - “Always at the forefront of knitting technology, SHIMA SEIKI computerized flat knitting machines are the global standard of the industry.” Stoll M1 - “Nowadays, knitting companies are facing an increasing pressure trying to cover the wide product range requirements and needs of their customers and to produce more economically at the same time. Customers, on the other hand, expect constant ability to deliver knit products, with an increasingly changing assortment and a decreasing order volume for each item.” Stoll provides these much-needed solutions. And, in NYC, they have a showroom open to the public where you can view the machines in action! HACCI FABRIC SUPPLIERS SwatchOn - a super easy platform, with unbeatable low MOQ wholesale prices. And, over 200,000 fabrics to choose from! They even have hard-to-find rib hacci sweater fabrics. Plus, they have amazing customer service! Fabric Wholesale Direct - Another global, online option, with great prices, and even better reviews - with a seemingly never-ending selection of fabric types. And, you can buy as little as one fabric yard! WANT ACCESS TO MY LIST OF OVER 500 SUPPLIERS? Check out The Sourcing Bootcamp, and my other private consultancy services! WHAT DO YOU THINK? What type of knitted garment are you going to make - hand, machine, or hacci? Let me know in the comments! Answer Hacci fabric is a type of textile that looks like a sweater. It can be cut + sewn to make garments that look like sweaters for a fraction of the price of traditional sweater manufacturing. Question #5 What does hacci fabric feel like? Answer Hacci fabric feels and looks like a sweater. Schema.org's references: FAQPage Google's documentation: FAQ Page Source link

0 notes

Photo

One of the most difficult things about starting a sweater brand is the high MOQ (minimum order quantity). FYI, generally, sweater MOQs are in the hundreds, but a few knitwear manufacturing suppliers will go as low as 50 pieces per style per color. Which, I get, can still feel kind of high for a startup brand. But, don’t give up; there are a few hacks, like using hacci fabric, that can help decrease your order size and still keep your costs low. Today, I am going to walk you through 3 different types of sweater manufacturing, to help you decide which is right for you and your brand. This is important because sweater supply chain is highly specialized. Before you can reach out to suppliers, you need to know what type of sweater you want. BUT BEFORE WE GET STARTED... I love helping startup brand founders succeed, so I created a bunch of free guides that will help you with your business. They won’t be free forever, so make sure to grab them while you can. WHAT YOU WILL LEARN… SHORT ON TIME? CLICK THROUGH THIS 60 SECOND SLIDE RECAP WHY I LOVE TEACHING PEOPLE ABOUT KNITWEAR MANUFACTURING AND SWEATERS Why do I love teaching people about sweaters? Take a walk down memory lane with me. I was still just a student at The Fashion Institute of Technology (FIT) studying Textile Development. Like many college kids, my friends and I spent more time in bars than in class (Hey, I’m a wild child (Labyrinth reference)! What can I say?). And like in any bar scene, we spent quite a bit of time chatting with strangers. The conversations went a little like this (I promise this is relevant to making clothes): Them – What do you do? Us – We’re in school for manufacturing. Them – What? Us – Like, how to make clothing. Them – (without fail, literally 99 times out of 100 – if I had a dollar for every time someone asked me this, I would probably be retired), oh cool, can you knit me a sweater? Us - Ummm, that’s not how clothing manufacturers work From the multitude of groundhog-day-like bar conversations, I realized just how little people knew about how clothes were made. It blew my mind that some people thought that all clothes were made by people sitting in a chair, knitting. So, this post will teach you all about actual sweater manufacturing. And, this topic will always have a special place in my heart. HAND KNITTING VS MACHINE KNITTING Sweaters are made directly from yarns (we get to skip the fabric step with knitwear manufacturing, but more on that in a little bit), and there are two different ways of making them: by hand or by machines - welcome to the future. I’ll teach you about both! WHAT IS HAND KNITTING? Hand-knitting is exactly what the bar folk were thinking; two needles and a ball of yarn (rocking chair not included). Each garment is hand-made by one person. And is generally under the ethical fashion cateogry of artisan custom clothing. With hand knitting, we rely on the skills of artisans. The labor-intensive work requires a large team of people. WHAT IS MACHINE KNITTING? Full fashion machine knitting, on the other hand, starts with a computer program. Basically, you can design a sweater from special software, press a button, and the machine gets to work with entire jumpers popping out at the end. It’s like living in the Jetsons. Compared to hand knitting, a lot fewer people are needed to create the sweaters because the machines are doing most of the work. Generally, a company will only have 1-2 people programming them. Pro tip. Complicated patterns that take people a really long time to hand knit, like tailored, knit jacquard pieces are especially great products for machines to do. A THIRD TYPE OF SWEATER FEW PEOPLE KNOW ABOUT Hacci sweater knits. So, what is hacci fabric? This is it. The big secret. This is my absolute favorite hack to help small brands PRODUCE custom sweaters. Hacci fabrics. Not to be confused with other knit fabrics like jerseys, or french terry fabric. Brushed hacci sweater fabric is a type of fabric that looks like a sweater knit fabric. The fabric can then be cut and sewn and made into a garment. These textiles basically sit between the worlds of knitwear manufacturing and traditional cut+sew. Instead of going from yarn straight to garment like other sweaters, hacci sweaters need to go though the cutting, sewing, and finishing process. And, as you will see in just a minute are a great hack to getting lower prices and lower MOQs. PROS AND CONS OF DIFFERENT KNITWEAR MANUFACTURING TECHNIQUES PROS OF HAND KNITTING Artisanal. Custom knit sweaters are 100% made by people. This means that each sweater is a little bit different and unique. Not only does the product feel one of a kind and special. But usually, hand-knit sweaters are sold by types of programs that help people. There are quite a few NGOs (non-governmental organizations, or international charities) and groups that help different at-risk communities find work knitting. (want to learn more about a few of these programs – scroll down to the bottom of the post.) Low MOQs (minimum order quantities). It is possible to make as little as 1 garment. All you need to do is hire one artisan to knit it. CONS OF HAND KNITTING Slow production. Because people make the garments, the process is much slower than an automated machine. Also, many of the groups that do this type of work tend not to do it full-time, so production times can be hard to track. Aging labor pool. The artisans that do this type of work tend to be much older. And finding workers to replace this aging population is difficult because young people today want to be TikTok famous, not work in a knitwear factory setting. Expensive. Like many other manufacturing options, time is money. Generally, the longer something takes to make, the more expensive it is. Hand-knitting is an extremely slow process. PROS OF MACHINE KNITTING A quick personal story. These machines are super cool, and as part of the textile curriculum at FIT, we had to learn how to program them ourselves. Cue a flashback of me spending hours of my life down in the basement of FIT (we used to call it the textile casino, because there were no windows or clocks), learning how to create knitting computer programs. Set it and forget it. Just like 3-D printing, once the samples are approved, and the program is set, you can make as many sweaters as you want with very little effort or (wo)man power. Good bulk prices. Because bulk production is so automated and requires minimal manpower, large bulk orders tend to have competitive pricing. CONS OF MACHINE KNITTING Sampling can be expensive. Although you can get a good rate for bulk orders, what tends to be expensive is the hiring of the engineers necessary to program the machines. Because the costs of labor are so high, development for these types of knit sweaters tends to be higher than other manufacturing options. Larger MOQ. MOQs usually start with about a few hundred pieces. While it is possible to press knit only once and get one sweater, it would not be economical. A lot of time is taken to program, sample, and tweak the computer program. Once all of that work is done, factories want to make sure the machine can run on autopilot for a while. Sit tight, I am going to get into the pros and cons of using hacci knit fabric at the end of the article in the price savings section. BENEFITS OF A KNITWEAR MANUFACTURING SUPPLY CHAIN So, what happens in sweater production is that when the yarns are knit, instead of being knit into a flat piece of fabric (to then be cut and sewn), they are actually knit into the shape of a garment directly. It’s important to note that this is only possible with knitting. Woven fabrics (like the ones found in button-down shirts, jeans, etc.) are always cut and sewn. If you have been reading the blog for a while, you might remember there are 5 levels in the garment supply chain: Fiber Yarns Fabric Dyeing/printing Garment cut + sew But, as I just mentioned, the only exception to this rule is when making a sweater. You can cut out the fabric, step making your supply chain only 4 levels. And, being able to go directly from yarns to garment is good for 2 reasons. The first is traceability. Traceability is being able to track where everything comes from in all of the stages of the supply chain. The fewer stages in the supply chain, the less to keep track of and audit. Basically less work. The second benefit is reduced carbon emissions. Very few suppliers in fashion are vertical, meaning very few suppliers conduct all 5 levels of the supply chain under one roof. What typically happens is that the fibers and yarns are produced in one country, and are then shipped to another country to be made into fabric. The apparel fabrics are then sent to a third country to be cut and sewn into a garment. And, lastly the garment is shipped to a forth location to actually be sold to customers. By being able to cut out an entire level of the supply chain, a whole lot of transportation can be avoided, reducing supply chain emissions. HOW TO DECREASE YOUR SWEATER MANUFACTURING MOQ AND COST You can take the girl out of the Walmart supply chain, but you can’t take the Walmart cost savings hacks out of the girl. A big part of my job, when I worked in fast fashion, was figuring out ways to chop down the price of our products without degrading their performance of the product. Basically, mission impossible. One of the most difficult things about starting a sweater brand is the high MOQ. Generally, sweater MOQs are generally at least 100 pieces per style per color. Which, I get, can still feel kind of high for a startup brand. But, don’t give up. There are a few things I have in my bag of manufacturing cost savings tricks that can help decrease your order size and still keep your costs low. To make lower MOQs and still keep manufacturing costs affordable, there are 4 things to consider: hacci fabrics, blended yarns, fabric weight, and colors. These are the good tricks most sweaters manufacturers won’t share. HACCI FABRICS Cut and sew manufacturing using Hacci fabric tends to have a much lower MOQs than machine knitting. It requires no special machinery or training. And it is much cheaper than a hand knit or full fashion knit even though there is an extra level in the supply chain. The only drawback is that after sewing the garment, the seams tend to be quite heavy. But most people don’t notice, and this does not seem to take away from the customer experience. BLENDED YARNS The average consumer can’t tell the difference between 100% merino wool, and a wool acrylic (cheaper than wool) blend. Actually, sometimes they even think that the wool/acyclic blend feels more like a luxury knit sweater! What they can feel is a low-quality wool yarn that feels itchy and scratchy. So, instead of going for that 100% wool label and compromising the quality of wool fibers, opt for a blend. Cost-effective fibers to consider for this hack are cotton, acrylic, and nylon. The other nice thing about sweaters is that you can skip the spandex. Generally, sweater constructions naturally have a lot of stretch, so you don’t need elastic added to them. And, because elastic is one of the most expensive fibers around, this helps to reduce the price. FABRIC WEIGHT The lighter the fabric, the less fiber resources, and the more money you can save. Now, there comes a point where a fabric becomes too thin and feels cheap. But, usually, it is possible to decrease the weight a little bit to save some money without anyone really noticing. COLORS Instead of using custom-dyed colors, use stock yarns from your knitwear manufacturing partner. The process of lab dips and dying custom colors is not just expensive, but it is also time-consuming. By using the yarn colors factories have available (and some factories have up to 30- 50 options to choose from), you can get your production cheaper and faster. MY FAVORITE KNITWEAR MANUFACTURING SUPPLIERS Are you a designer who needs help getting your sweaters made, and tired of googling for things like sweater manufacturers near me, with no restults? Here are a few of the best sweater manufacturers around! HANDKNIT SUPPLIERS, FOR CUSTOM MADE KNITWEAR KOCO Knit - Indian artisan knitwear manufacturing, “KOCO was established in Australia by Danielle Chiel in partnership with women who live in rural villages of Tamil Nadu, southern India. What began as a solution to producing hand-knitted garments offshore is now a sisterhood of artisans and a business with the United Nations Global Goals for Sustainable Development entwined in our DNA. We have scaled the art of hand knitting to produce commercial quantities of garments, all entirely hand knitted.” Knitlab Peru - Move over cashmere sweaters, I am obsessed with sustainable alpaca these days. “Our practice involves working with knitting artisans that have formally set up their own small businesses and communities. Each leader, in turn, has their own group of knitters or a workshop.” MACHINE KNIT SUPPLIERS Shima - “Always at the forefront of knitting technology, SHIMA SEIKI computerized flat knitting machines are the global standard of the industry.” Stoll M1 - “Nowadays, knitting companies are facing an increasing pressure trying to cover the wide product range requirements and needs of their customers and to produce more economically at the same time. Customers, on the other hand, expect constant ability to deliver knit products, with an increasingly changing assortment and a decreasing order volume for each item.” Stoll provides these much-needed solutions. And, in NYC, they have a showroom open to the public where you can view the machines in action! HACCI FABRIC SUPPLIERS SwatchOn - a super easy platform, with unbeatable low MOQ wholesale prices. And, over 200,000 fabrics to choose from! They even have hard-to-find rib hacci sweater fabrics. Plus, they have amazing customer service! Fabric Wholesale Direct - Another global, online option, with great prices, and even better reviews - with a seemingly never-ending selection of fabric types. And, you can buy as little as one fabric yard! WANT ACCESS TO MY LIST OF OVER 500 SUPPLIERS? Check out The Sourcing Bootcamp, and my other private consultancy services! WHAT DO YOU THINK? What type of knitted garment are you going to make - hand, machine, or hacci? Let me know in the comments! Answer Hacci fabric is a type of textile that looks like a sweater. It can be cut + sewn to make garments that look like sweaters for a fraction of the price of traditional sweater manufacturing. Question #5 What does hacci fabric feel like? Answer Hacci fabric feels and looks like a sweater. Schema.org's references: FAQPage Google's documentation: FAQ Page Source link

0 notes

Photo

One of the most difficult things about starting a sweater brand is the high MOQ (minimum order quantity). FYI, generally, sweater MOQs are in the hundreds, but a few knitwear manufacturing suppliers will go as low as 50 pieces per style per color. Which, I get, can still feel kind of high for a startup brand. But, don’t give up; there are a few hacks, like using hacci fabric, that can help decrease your order size and still keep your costs low. Today, I am going to walk you through 3 different types of sweater manufacturing, to help you decide which is right for you and your brand. This is important because sweater supply chain is highly specialized. Before you can reach out to suppliers, you need to know what type of sweater you want. BUT BEFORE WE GET STARTED... I love helping startup brand founders succeed, so I created a bunch of free guides that will help you with your business. They won’t be free forever, so make sure to grab them while you can. WHAT YOU WILL LEARN… SHORT ON TIME? CLICK THROUGH THIS 60 SECOND SLIDE RECAP WHY I LOVE TEACHING PEOPLE ABOUT KNITWEAR MANUFACTURING AND SWEATERS Why do I love teaching people about sweaters? Take a walk down memory lane with me. I was still just a student at The Fashion Institute of Technology (FIT) studying Textile Development. Like many college kids, my friends and I spent more time in bars than in class (Hey, I’m a wild child (Labyrinth reference)! What can I say?). And like in any bar scene, we spent quite a bit of time chatting with strangers. The conversations went a little like this (I promise this is relevant to making clothes): Them – What do you do? Us – We’re in school for manufacturing. Them – What? Us – Like, how to make clothing. Them – (without fail, literally 99 times out of 100 – if I had a dollar for every time someone asked me this, I would probably be retired), oh cool, can you knit me a sweater? Us - Ummm, that’s not how clothing manufacturers work From the multitude of groundhog-day-like bar conversations, I realized just how little people knew about how clothes were made. It blew my mind that some people thought that all clothes were made by people sitting in a chair, knitting. So, this post will teach you all about actual sweater manufacturing. And, this topic will always have a special place in my heart. HAND KNITTING VS MACHINE KNITTING Sweaters are made directly from yarns (we get to skip the fabric step with knitwear manufacturing, but more on that in a little bit), and there are two different ways of making them: by hand or by machines - welcome to the future. I’ll teach you about both! WHAT IS HAND KNITTING? Hand-knitting is exactly what the bar folk were thinking; two needles and a ball of yarn (rocking chair not included). Each garment is hand-made by one person. And is generally under the ethical fashion cateogry of artisan custom clothing. With hand knitting, we rely on the skills of artisans. The labor-intensive work requires a large team of people. WHAT IS MACHINE KNITTING? Full fashion machine knitting, on the other hand, starts with a computer program. Basically, you can design a sweater from special software, press a button, and the machine gets to work with entire jumpers popping out at the end. It’s like living in the Jetsons. Compared to hand knitting, a lot fewer people are needed to create the sweaters because the machines are doing most of the work. Generally, a company will only have 1-2 people programming them. Pro tip. Complicated patterns that take people a really long time to hand knit, like tailored, knit jacquard pieces are especially great products for machines to do. A THIRD TYPE OF SWEATER FEW PEOPLE KNOW ABOUT Hacci sweater knits. So, what is hacci fabric? This is it. The big secret. This is my absolute favorite hack to help small brands PRODUCE custom sweaters. Hacci fabrics. Not to be confused with other knit fabrics like jerseys, or french terry fabric. Brushed hacci sweater fabric is a type of fabric that looks like a sweater knit fabric. The fabric can then be cut and sewn and made into a garment. These textiles basically sit between the worlds of knitwear manufacturing and traditional cut+sew. Instead of going from yarn straight to garment like other sweaters, hacci sweaters need to go though the cutting, sewing, and finishing process. And, as you will see in just a minute are a great hack to getting lower prices and lower MOQs. PROS AND CONS OF DIFFERENT KNITWEAR MANUFACTURING TECHNIQUES PROS OF HAND KNITTING Artisanal. Custom knit sweaters are 100% made by people. This means that each sweater is a little bit different and unique. Not only does the product feel one of a kind and special. But usually, hand-knit sweaters are sold by types of programs that help people. There are quite a few NGOs (non-governmental organizations, or international charities) and groups that help different at-risk communities find work knitting. (want to learn more about a few of these programs – scroll down to the bottom of the post.) Low MOQs (minimum order quantities). It is possible to make as little as 1 garment. All you need to do is hire one artisan to knit it. CONS OF HAND KNITTING Slow production. Because people make the garments, the process is much slower than an automated machine. Also, many of the groups that do this type of work tend not to do it full-time, so production times can be hard to track. Aging labor pool. The artisans that do this type of work tend to be much older. And finding workers to replace this aging population is difficult because young people today want to be TikTok famous, not work in a knitwear factory setting. Expensive. Like many other manufacturing options, time is money. Generally, the longer something takes to make, the more expensive it is. Hand-knitting is an extremely slow process. PROS OF MACHINE KNITTING A quick personal story. These machines are super cool, and as part of the textile curriculum at FIT, we had to learn how to program them ourselves. Cue a flashback of me spending hours of my life down in the basement of FIT (we used to call it the textile casino, because there were no windows or clocks), learning how to create knitting computer programs. Set it and forget it. Just like 3-D printing, once the samples are approved, and the program is set, you can make as many sweaters as you want with very little effort or (wo)man power. Good bulk prices. Because bulk production is so automated and requires minimal manpower, large bulk orders tend to have competitive pricing. CONS OF MACHINE KNITTING Sampling can be expensive. Although you can get a good rate for bulk orders, what tends to be expensive is the hiring of the engineers necessary to program the machines. Because the costs of labor are so high, development for these types of knit sweaters tends to be higher than other manufacturing options. Larger MOQ. MOQs usually start with about a few hundred pieces. While it is possible to press knit only once and get one sweater, it would not be economical. A lot of time is taken to program, sample, and tweak the computer program. Once all of that work is done, factories want to make sure the machine can run on autopilot for a while. Sit tight, I am going to get into the pros and cons of using hacci knit fabric at the end of the article in the price savings section. BENEFITS OF A KNITWEAR MANUFACTURING SUPPLY CHAIN So, what happens in sweater production is that when the yarns are knit, instead of being knit into a flat piece of fabric (to then be cut and sewn), they are actually knit into the shape of a garment directly. It’s important to note that this is only possible with knitting. Woven fabrics (like the ones found in button-down shirts, jeans, etc.) are always cut and sewn. If you have been reading the blog for a while, you might remember there are 5 levels in the garment supply chain: Fiber Yarns Fabric Dyeing/printing Garment cut + sew But, as I just mentioned, the only exception to this rule is when making a sweater. You can cut out the fabric, step making your supply chain only 4 levels. And, being able to go directly from yarns to garment is good for 2 reasons. The first is traceability. Traceability is being able to track where everything comes from in all of the stages of the supply chain. The fewer stages in the supply chain, the less to keep track of and audit. Basically less work. The second benefit is reduced carbon emissions. Very few suppliers in fashion are vertical, meaning very few suppliers conduct all 5 levels of the supply chain under one roof. What typically happens is that the fibers and yarns are produced in one country, and are then shipped to another country to be made into fabric. The apparel fabrics are then sent to a third country to be cut and sewn into a garment. And, lastly the garment is shipped to a forth location to actually be sold to customers. By being able to cut out an entire level of the supply chain, a whole lot of transportation can be avoided, reducing supply chain emissions. HOW TO DECREASE YOUR SWEATER MANUFACTURING MOQ AND COST You can take the girl out of the Walmart supply chain, but you can’t take the Walmart cost savings hacks out of the girl. A big part of my job, when I worked in fast fashion, was figuring out ways to chop down the price of our products without degrading their performance of the product. Basically, mission impossible. One of the most difficult things about starting a sweater brand is the high MOQ. Generally, sweater MOQs are generally at least 100 pieces per style per color. Which, I get, can still feel kind of high for a startup brand. But, don’t give up. There are a few things I have in my bag of manufacturing cost savings tricks that can help decrease your order size and still keep your costs low. To make lower MOQs and still keep manufacturing costs affordable, there are 4 things to consider: hacci fabrics, blended yarns, fabric weight, and colors. These are the good tricks most sweaters manufacturers won’t share. HACCI FABRICS Cut and sew manufacturing using Hacci fabric tends to have a much lower MOQs than machine knitting. It requires no special machinery or training. And it is much cheaper than a hand knit or full fashion knit even though there is an extra level in the supply chain. The only drawback is that after sewing the garment, the seams tend to be quite heavy. But most people don’t notice, and this does not seem to take away from the customer experience. BLENDED YARNS The average consumer can’t tell the difference between 100% merino wool, and a wool acrylic (cheaper than wool) blend. Actually, sometimes they even think that the wool/acyclic blend feels more like a luxury knit sweater! What they can feel is a low-quality wool yarn that feels itchy and scratchy. So, instead of going for that 100% wool label and compromising the quality of wool fibers, opt for a blend. Cost-effective fibers to consider for this hack are cotton, acrylic, and nylon. The other nice thing about sweaters is that you can skip the spandex. Generally, sweater constructions naturally have a lot of stretch, so you don’t need elastic added to them. And, because elastic is one of the most expensive fibers around, this helps to reduce the price. FABRIC WEIGHT The lighter the fabric, the less fiber resources, and the more money you can save. Now, there comes a point where a fabric becomes too thin and feels cheap. But, usually, it is possible to decrease the weight a little bit to save some money without anyone really noticing. COLORS Instead of using custom-dyed colors, use stock yarns from your knitwear manufacturing partner. The process of lab dips and dying custom colors is not just expensive, but it is also time-consuming. By using the yarn colors factories have available (and some factories have up to 30- 50 options to choose from), you can get your production cheaper and faster. MY FAVORITE KNITWEAR MANUFACTURING SUPPLIERS Are you a designer who needs help getting your sweaters made, and tired of googling for things like sweater manufacturers near me, with no restults? Here are a few of the best sweater manufacturers around! HANDKNIT SUPPLIERS, FOR CUSTOM MADE KNITWEAR KOCO Knit - Indian artisan knitwear manufacturing, “KOCO was established in Australia by Danielle Chiel in partnership with women who live in rural villages of Tamil Nadu, southern India. What began as a solution to producing hand-knitted garments offshore is now a sisterhood of artisans and a business with the United Nations Global Goals for Sustainable Development entwined in our DNA. We have scaled the art of hand knitting to produce commercial quantities of garments, all entirely hand knitted.” Knitlab Peru - Move over cashmere sweaters, I am obsessed with sustainable alpaca these days. “Our practice involves working with knitting artisans that have formally set up their own small businesses and communities. Each leader, in turn, has their own group of knitters or a workshop.” MACHINE KNIT SUPPLIERS Shima - “Always at the forefront of knitting technology, SHIMA SEIKI computerized flat knitting machines are the global standard of the industry.” Stoll M1 - “Nowadays, knitting companies are facing an increasing pressure trying to cover the wide product range requirements and needs of their customers and to produce more economically at the same time. Customers, on the other hand, expect constant ability to deliver knit products, with an increasingly changing assortment and a decreasing order volume for each item.” Stoll provides these much-needed solutions. And, in NYC, they have a showroom open to the public where you can view the machines in action! HACCI FABRIC SUPPLIERS SwatchOn - a super easy platform, with unbeatable low MOQ wholesale prices. And, over 200,000 fabrics to choose from! They even have hard-to-find rib hacci sweater fabrics. Plus, they have amazing customer service! Fabric Wholesale Direct - Another global, online option, with great prices, and even better reviews - with a seemingly never-ending selection of fabric types. And, you can buy as little as one fabric yard! WANT ACCESS TO MY LIST OF OVER 500 SUPPLIERS? Check out The Sourcing Bootcamp, and my other private consultancy services! WHAT DO YOU THINK? What type of knitted garment are you going to make - hand, machine, or hacci? Let me know in the comments! Answer Hacci fabric is a type of textile that looks like a sweater. It can be cut + sewn to make garments that look like sweaters for a fraction of the price of traditional sweater manufacturing. Question #5 What does hacci fabric feel like? Answer Hacci fabric feels and looks like a sweater. Schema.org's references: FAQPage Google's documentation: FAQ Page Source link

0 notes

Photo

One of the most difficult things about starting a sweater brand is the high MOQ (minimum order quantity). FYI, generally, sweater MOQs are in the hundreds, but a few knitwear manufacturing suppliers will go as low as 50 pieces per style per color. Which, I get, can still feel kind of high for a startup brand. But, don’t give up; there are a few hacks, like using hacci fabric, that can help decrease your order size and still keep your costs low. Today, I am going to walk you through 3 different types of sweater manufacturing, to help you decide which is right for you and your brand. This is important because sweater supply chain is highly specialized. Before you can reach out to suppliers, you need to know what type of sweater you want. BUT BEFORE WE GET STARTED... I love helping startup brand founders succeed, so I created a bunch of free guides that will help you with your business. They won’t be free forever, so make sure to grab them while you can. WHAT YOU WILL LEARN… SHORT ON TIME? CLICK THROUGH THIS 60 SECOND SLIDE RECAP WHY I LOVE TEACHING PEOPLE ABOUT KNITWEAR MANUFACTURING AND SWEATERS Why do I love teaching people about sweaters? Take a walk down memory lane with me. I was still just a student at The Fashion Institute of Technology (FIT) studying Textile Development. Like many college kids, my friends and I spent more time in bars than in class (Hey, I’m a wild child (Labyrinth reference)! What can I say?). And like in any bar scene, we spent quite a bit of time chatting with strangers. The conversations went a little like this (I promise this is relevant to making clothes): Them – What do you do? Us – We’re in school for manufacturing. Them – What? Us – Like, how to make clothing. Them – (without fail, literally 99 times out of 100 – if I had a dollar for every time someone asked me this, I would probably be retired), oh cool, can you knit me a sweater? Us - Ummm, that’s not how clothing manufacturers work From the multitude of groundhog-day-like bar conversations, I realized just how little people knew about how clothes were made. It blew my mind that some people thought that all clothes were made by people sitting in a chair, knitting. So, this post will teach you all about actual sweater manufacturing. And, this topic will always have a special place in my heart. HAND KNITTING VS MACHINE KNITTING Sweaters are made directly from yarns (we get to skip the fabric step with knitwear manufacturing, but more on that in a little bit), and there are two different ways of making them: by hand or by machines - welcome to the future. I’ll teach you about both! WHAT IS HAND KNITTING? Hand-knitting is exactly what the bar folk were thinking; two needles and a ball of yarn (rocking chair not included). Each garment is hand-made by one person. And is generally under the ethical fashion cateogry of artisan custom clothing. With hand knitting, we rely on the skills of artisans. The labor-intensive work requires a large team of people. WHAT IS MACHINE KNITTING? Full fashion machine knitting, on the other hand, starts with a computer program. Basically, you can design a sweater from special software, press a button, and the machine gets to work with entire jumpers popping out at the end. It’s like living in the Jetsons. Compared to hand knitting, a lot fewer people are needed to create the sweaters because the machines are doing most of the work. Generally, a company will only have 1-2 people programming them. Pro tip. Complicated patterns that take people a really long time to hand knit, like tailored, knit jacquard pieces are especially great products for machines to do. A THIRD TYPE OF SWEATER FEW PEOPLE KNOW ABOUT Hacci sweater knits. So, what is hacci fabric? This is it. The big secret. This is my absolute favorite hack to help small brands PRODUCE custom sweaters. Hacci fabrics. Not to be confused with other knit fabrics like jerseys, or french terry fabric. Brushed hacci sweater fabric is a type of fabric that looks like a sweater knit fabric. The fabric can then be cut and sewn and made into a garment. These textiles basically sit between the worlds of knitwear manufacturing and traditional cut+sew. Instead of going from yarn straight to garment like other sweaters, hacci sweaters need to go though the cutting, sewing, and finishing process. And, as you will see in just a minute are a great hack to getting lower prices and lower MOQs. PROS AND CONS OF DIFFERENT KNITWEAR MANUFACTURING TECHNIQUES PROS OF HAND KNITTING Artisanal. Custom knit sweaters are 100% made by people. This means that each sweater is a little bit different and unique. Not only does the product feel one of a kind and special. But usually, hand-knit sweaters are sold by types of programs that help people. There are quite a few NGOs (non-governmental organizations, or international charities) and groups that help different at-risk communities find work knitting. (want to learn more about a few of these programs – scroll down to the bottom of the post.) Low MOQs (minimum order quantities). It is possible to make as little as 1 garment. All you need to do is hire one artisan to knit it. CONS OF HAND KNITTING Slow production. Because people make the garments, the process is much slower than an automated machine. Also, many of the groups that do this type of work tend not to do it full-time, so production times can be hard to track. Aging labor pool. The artisans that do this type of work tend to be much older. And finding workers to replace this aging population is difficult because young people today want to be TikTok famous, not work in a knitwear factory setting. Expensive. Like many other manufacturing options, time is money. Generally, the longer something takes to make, the more expensive it is. Hand-knitting is an extremely slow process. PROS OF MACHINE KNITTING A quick personal story. These machines are super cool, and as part of the textile curriculum at FIT, we had to learn how to program them ourselves. Cue a flashback of me spending hours of my life down in the basement of FIT (we used to call it the textile casino, because there were no windows or clocks), learning how to create knitting computer programs. Set it and forget it. Just like 3-D printing, once the samples are approved, and the program is set, you can make as many sweaters as you want with very little effort or (wo)man power. Good bulk prices. Because bulk production is so automated and requires minimal manpower, large bulk orders tend to have competitive pricing. CONS OF MACHINE KNITTING Sampling can be expensive. Although you can get a good rate for bulk orders, what tends to be expensive is the hiring of the engineers necessary to program the machines. Because the costs of labor are so high, development for these types of knit sweaters tends to be higher than other manufacturing options. Larger MOQ. MOQs usually start with about a few hundred pieces. While it is possible to press knit only once and get one sweater, it would not be economical. A lot of time is taken to program, sample, and tweak the computer program. Once all of that work is done, factories want to make sure the machine can run on autopilot for a while. Sit tight, I am going to get into the pros and cons of using hacci knit fabric at the end of the article in the price savings section. BENEFITS OF A KNITWEAR MANUFACTURING SUPPLY CHAIN So, what happens in sweater production is that when the yarns are knit, instead of being knit into a flat piece of fabric (to then be cut and sewn), they are actually knit into the shape of a garment directly. It’s important to note that this is only possible with knitting. Woven fabrics (like the ones found in button-down shirts, jeans, etc.) are always cut and sewn. If you have been reading the blog for a while, you might remember there are 5 levels in the garment supply chain: Fiber Yarns Fabric Dyeing/printing Garment cut + sew But, as I just mentioned, the only exception to this rule is when making a sweater. You can cut out the fabric, step making your supply chain only 4 levels. And, being able to go directly from yarns to garment is good for 2 reasons. The first is traceability. Traceability is being able to track where everything comes from in all of the stages of the supply chain. The fewer stages in the supply chain, the less to keep track of and audit. Basically less work. The second benefit is reduced carbon emissions. Very few suppliers in fashion are vertical, meaning very few suppliers conduct all 5 levels of the supply chain under one roof. What typically happens is that the fibers and yarns are produced in one country, and are then shipped to another country to be made into fabric. The apparel fabrics are then sent to a third country to be cut and sewn into a garment. And, lastly the garment is shipped to a forth location to actually be sold to customers. By being able to cut out an entire level of the supply chain, a whole lot of transportation can be avoided, reducing supply chain emissions. HOW TO DECREASE YOUR SWEATER MANUFACTURING MOQ AND COST You can take the girl out of the Walmart supply chain, but you can’t take the Walmart cost savings hacks out of the girl. A big part of my job, when I worked in fast fashion, was figuring out ways to chop down the price of our products without degrading their performance of the product. Basically, mission impossible. One of the most difficult things about starting a sweater brand is the high MOQ. Generally, sweater MOQs are generally at least 100 pieces per style per color. Which, I get, can still feel kind of high for a startup brand. But, don’t give up. There are a few things I have in my bag of manufacturing cost savings tricks that can help decrease your order size and still keep your costs low. To make lower MOQs and still keep manufacturing costs affordable, there are 4 things to consider: hacci fabrics, blended yarns, fabric weight, and colors. These are the good tricks most sweaters manufacturers won’t share. HACCI FABRICS Cut and sew manufacturing using Hacci fabric tends to have a much lower MOQs than machine knitting. It requires no special machinery or training. And it is much cheaper than a hand knit or full fashion knit even though there is an extra level in the supply chain. The only drawback is that after sewing the garment, the seams tend to be quite heavy. But most people don’t notice, and this does not seem to take away from the customer experience. BLENDED YARNS The average consumer can’t tell the difference between 100% merino wool, and a wool acrylic (cheaper than wool) blend. Actually, sometimes they even think that the wool/acyclic blend feels more like a luxury knit sweater! What they can feel is a low-quality wool yarn that feels itchy and scratchy. So, instead of going for that 100% wool label and compromising the quality of wool fibers, opt for a blend. Cost-effective fibers to consider for this hack are cotton, acrylic, and nylon. The other nice thing about sweaters is that you can skip the spandex. Generally, sweater constructions naturally have a lot of stretch, so you don’t need elastic added to them. And, because elastic is one of the most expensive fibers around, this helps to reduce the price. FABRIC WEIGHT The lighter the fabric, the less fiber resources, and the more money you can save. Now, there comes a point where a fabric becomes too thin and feels cheap. But, usually, it is possible to decrease the weight a little bit to save some money without anyone really noticing. COLORS Instead of using custom-dyed colors, use stock yarns from your knitwear manufacturing partner. The process of lab dips and dying custom colors is not just expensive, but it is also time-consuming. By using the yarn colors factories have available (and some factories have up to 30- 50 options to choose from), you can get your production cheaper and faster. MY FAVORITE KNITWEAR MANUFACTURING SUPPLIERS Are you a designer who needs help getting your sweaters made, and tired of googling for things like sweater manufacturers near me, with no restults? Here are a few of the best sweater manufacturers around! HANDKNIT SUPPLIERS, FOR CUSTOM MADE KNITWEAR KOCO Knit - Indian artisan knitwear manufacturing, “KOCO was established in Australia by Danielle Chiel in partnership with women who live in rural villages of Tamil Nadu, southern India. What began as a solution to producing hand-knitted garments offshore is now a sisterhood of artisans and a business with the United Nations Global Goals for Sustainable Development entwined in our DNA. We have scaled the art of hand knitting to produce commercial quantities of garments, all entirely hand knitted.” Knitlab Peru - Move over cashmere sweaters, I am obsessed with sustainable alpaca these days. “Our practice involves working with knitting artisans that have formally set up their own small businesses and communities. Each leader, in turn, has their own group of knitters or a workshop.” MACHINE KNIT SUPPLIERS Shima - “Always at the forefront of knitting technology, SHIMA SEIKI computerized flat knitting machines are the global standard of the industry.” Stoll M1 - “Nowadays, knitting companies are facing an increasing pressure trying to cover the wide product range requirements and needs of their customers and to produce more economically at the same time. Customers, on the other hand, expect constant ability to deliver knit products, with an increasingly changing assortment and a decreasing order volume for each item.” Stoll provides these much-needed solutions. And, in NYC, they have a showroom open to the public where you can view the machines in action! HACCI FABRIC SUPPLIERS SwatchOn - a super easy platform, with unbeatable low MOQ wholesale prices. And, over 200,000 fabrics to choose from! They even have hard-to-find rib hacci sweater fabrics. Plus, they have amazing customer service! Fabric Wholesale Direct - Another global, online option, with great prices, and even better reviews - with a seemingly never-ending selection of fabric types. And, you can buy as little as one fabric yard! WANT ACCESS TO MY LIST OF OVER 500 SUPPLIERS? Check out The Sourcing Bootcamp, and my other private consultancy services! WHAT DO YOU THINK? What type of knitted garment are you going to make - hand, machine, or hacci? Let me know in the comments! Answer Hacci fabric is a type of textile that looks like a sweater. It can be cut + sewn to make garments that look like sweaters for a fraction of the price of traditional sweater manufacturing. Question #5 What does hacci fabric feel like? Answer Hacci fabric feels and looks like a sweater. Schema.org's references: FAQPage Google's documentation: FAQ Page Source link

0 notes

Photo