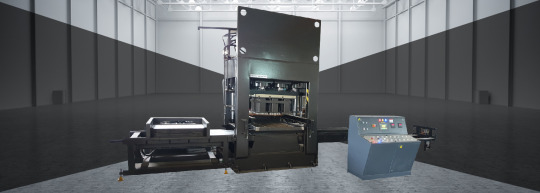

#Investing Casting Conveyors Manufacturer in India

Explore tagged Tumblr posts

Text

What are the Role of Conveyors in Investment Casting?

Investment casting conveyors are specialized systems designed to handle the unique challenges posed by the investment casting process. They serve several critical functions:

Material Handling: From the initial wax patterns to the final metal castings, conveyors transport components between various stages of production. This includes moving molds through ceramic coating, drying, dewaxing, and metal pouring stations.

Precision Control: Conveyors ensure that each mold or casting moves through the process at a controlled pace, optimizing the conditions for ceramic coating, wax removal, and metal filling. This precision is essential to maintain the integrity and dimensional accuracy of the final products.

Temperature and Environment Management: Some conveyors are equipped with heating or cooling elements to maintain the molds at specific temperatures during crucial stages of the process. This control helps prevent defects such as cracking or incomplete metal fills.

Automation and Efficiency: By automating the transport of molds and castings, conveyors minimize manual handling and reduce the risk of errors or damage. This automation not only enhances efficiency but also allows for continuous operation, thereby increasing overall production throughput.

Advantages of Investment Casting Conveyors

1. Precision Control:

Investment casting conveyors ensure consistent and precise movement of molds and castings throughout the manufacturing process. This controlled handling is crucial for maintaining dimensional accuracy and ensuring that each component meets strict quality standards.

2. Optimized Material Flow:

By automating the transport of materials, conveyors optimize the flow of wax patterns, ceramic-coated molds, and metal castings between various production stages. This reduces bottlenecks and ensures a smooth, continuous workflow, thereby improving overall production efficiency.

3. Enhanced Quality Assurance:

Conveyors play a critical role in quality assurance by minimizing handling errors and reducing the risk of defects during transport. This helps to preserve the integrity of molds and castings, ultimately leading to higher-quality finished products.

4. Increased Production Throughput:

Automation provided by conveyors allows for faster and more efficient processing of molds and castings. This increased throughput translates to higher production volumes without sacrificing product quality, meeting the demands of diverse industries.

5. Temperature and Environment Control:

Some conveyors are equipped with heating or cooling elements to maintain optimal temperatures during critical stages of the casting process. This control helps to prevent thermal shock and ensures consistent material properties in the final castings.

6. Reduced Labor Costs and Manual Handling:

Automation via conveyors reduces the need for manual handling of molds and castings, thereby lowering labor costs and minimizing the risk of operator error or injury. This also frees up skilled personnel for more specialized tasks.

7. Customization and Adaptability:

Modern investment casting conveyors can be customized to meet specific production requirements, including the handling of different materials, sizes, and weights of molds and castings. This adaptability ensures compatibility with various casting applications and manufacturing environments.

8. Operational Efficiency and Energy Savings:

Conveyors designed with energy-efficient components and operational modes contribute to overall energy savings and reduced operational costs. This eco-friendly approach aligns with sustainability goals while maintaining high levels of productivity.

Challenges and Considerations

While investment casting conveyors offer significant benefits, their design and implementation require careful consideration of factors such as:

Material Compatibility: Conveyors must be compatible with the materials used in each stage of the casting process, including wax, ceramics, and various metals.

Maintenance: Regular maintenance and cleaning are essential to prevent buildup of casting residues or contaminants that could compromise product quality.

Safety: Conveyors must meet stringent safety standards to protect workers and prevent accidents, particularly in environments with high temperatures or heavy machinery.

Conclusion

Investment casting conveyors are indispensable assets in the manufacturing landscape, enabling precise control and efficient handling of materials throughout the intricate investment casting process. As industries continue to demand higher levels of quality and productivity, the role of these conveyors will only grow in importance. Innovations in technology and design will further refine their capabilities, ensuring that investment casting remains a cornerstone of modern manufacturing for years to come.

Best Investing Casting Conveyors Manufacturer in India

If you are looking for Investment casting Conveyors Manufacturer in India, look no further than Arsai Conveyor Systems Private Limited, we are a leading manufacturer and supplier of Investment casting Conveyors in India.

For more details, please contact us!

Website :- https://www.arsaiconveyor.com/

Contact No. :- +91–9811772712, +91–9810773412

Email :- [email protected], [email protected]

#Investing Casting Conveyors Manufacturer in India#Best Investing Casting Conveyors Manufacturer in India#arsai conveyor#conveyor manufacturer in India

1 note

·

View note

Text

Auto Pallet Stacker System manufacturer in coimbatore

Introducing the Auto Pallet Stacker System - 15 Bricks, a highly efficient solution for automating the pallet stacking process. Designed and manufactured by a leading Auto Pallet Stacker System manufacturer in Coimbatore, this advanced system is engineered to improve the productivity and accuracy of stacking operations. With a range of powerful features, it is an ideal choice for industries looking to enhance their material handling.

Equipped with a 15 H.P/11.25 KW hydraulic motor, the Auto Pallet Stacker System ensures smooth operation, while the 3 H.P/2.25 KW conveyor system optimizes material flow. The system also includes a high-performance pan mixer machine and a hopper vibrator for greater efficiency. The stacker is powered by a robust 3 H.P/2.25 KW hydraulic motor and features a travel motor of the same power for reliable movement and positioning. It has a pallet chain conveyor and hydraulic-free fill system to simplify stacking tasks, cutting down on labor requirements significantly.

The machine's control is managed through a PLC system, providing precise control over its operations. With a stacker cycle time of 15 seconds and a robust hydraulic pump, the Auto Pallet Stacker System Coimbatore ensures high output with minimal downtime. The system is designed with durable components, including grained hard chromed sliding rods and steel casting sliding bushes, ensuring longevity and optimal performance.

As trusted Auto Pallet Stacker System exporters in Coimbatore, India, we take pride in offering a high-quality product designed to meet the demanding needs of modern industries. With a land requirement of 1.5 acres and a production capacity of 12 laborers per shift, the Auto Pallet Stacker System is an investment that improves operational efficiency and productivity. Experience the benefits of automation with our advanced system, tailor-made for the evolving industrial landscape.

For more details on the Auto Pallet Stacker System, feel free to contact us today!

Website Link : -http://www.bennyenterprises.net/

Contact no : - 9360623765

Mail id : - [email protected]

Address :- Site No:13, Thadagam Road,K.N.G.Pudur Pirivu,

Opp: Indian Oil Petrol Pump, Next to Agarwal School, Somayampalayam (PO), Coimbatore - 641 108,Tamil Nadu, India

Socail media link

facebook link :- https://www.facebook.com/Bennyindustries

short describiton :- Benny Enterprises specializes in manufacturing innovative block-making machines and construction equipment. With a commitment to quality and precision, the company provides cutting-edge solutions for the construction industry, including automatic block-making machines, tile-making machines, and custom-designed equipment to meet various industrial needs.

#Auto Pallet Stacker System#Auto Pallet Stacker#Auto Pallet Stacker System manufacturer in Coimbatore#Benny Enterprises

0 notes

Text

Sustainable Manufacturing Practices in the Indian Drum Motor Industry

The drum motor industry in India has witnessed significant growth over the past few decades. This growth has been driven by the increasing demand for efficient conveyor systems across various industries, including food processing, logistics, and mining. As the industry expands, there is a growing emphasis on sustainable manufacturing practices. Drum motor manufacturers in India are increasingly adopting eco-friendly techniques to reduce their environmental impact while maintaining high production standards. This article delves into the sustainable manufacturing practices being adopted by drum motor manufacturers and suppliers in India, highlighting the key areas of focus and the benefits these practices bring.

1. Energy Efficiency

One of the primary areas where drum motor manufacturers in India are focusing their sustainability efforts is energy efficiency. The manufacturing process of drum motors involves several energy-intensive stages, including metal casting, machining, and assembly. To mitigate the environmental impact, manufacturers are investing in energy-efficient machinery and adopting practices that reduce energy consumption.

Use of Renewable Energy: Many drum motor suppliers in India are shifting towards renewable energy sources such as solar and wind power. Installing solar panels on factory rooftops and utilizing wind turbines helps reduce reliance on fossil fuels, thereby decreasing carbon emissions.

Energy-efficient Equipment: Upgrading to energy-efficient motors and machinery can significantly reduce energy consumption. For instance, variable frequency drives (VFDs) are being used to optimize the speed and torque of motors, reducing energy wastage.

2. Waste Reduction

Waste management is a critical aspect of sustainable manufacturing. Drum motor manufacturers are implementing various strategies to minimize waste generation and promote recycling.

Lean Manufacturing: Lean manufacturing principles, such as just-in-time production and continuous improvement, help reduce waste by optimizing production processes and eliminating unnecessary steps. This results in lower material waste and higher efficiency.

Recycling and Reusing Materials: Manufacturers are increasingly focusing on recycling scrap metal, plastic, and other materials used in the production of drum motors. By setting up recycling programs and reusing materials, they can significantly reduce the amount of waste sent to landfills.

3. Eco-friendly Materials

The choice of materials plays a crucial role in sustainable manufacturing. Drum motor manufacturers in India are exploring the use of eco-friendly and sustainable materials to reduce their environmental footprint.

Biodegradable Lubricants: Traditional lubricants used in drum motors often contain harmful chemicals. By switching to biodegradable lubricants, manufacturers can reduce soil and water contamination.

Recyclable Components: Designing drum motors with recyclable components ensures that at the end of their life cycle, the parts can be easily recycled rather than discarded. This approach not only reduces waste but also conserves natural resources.

4. Water Conservation

Water is a vital resource in the manufacturing process, particularly in operations such as cooling and cleaning. Drum motor manufacturers are adopting water conservation practices to reduce their water usage and minimize environmental impact.

Closed-loop Water Systems: Implementing closed-loop water systems allows manufacturers to recycle and reuse water within the production process. This reduces the need for fresh water and minimizes wastewater discharge.

Rainwater Harvesting: Some manufacturers are investing in rainwater harvesting systems to collect and store rainwater for use in their manufacturing processes. This not only reduces the demand for municipal water but also helps in groundwater recharge.

5. Emission Control

Controlling emissions is essential for sustainable manufacturing. Drum motor manufacturers are taking steps to reduce air and greenhouse gas emissions from their production facilities.

Advanced Filtration Systems: Installing advanced filtration systems in factories can help capture and reduce particulate matter and harmful emissions. This ensures cleaner air quality both inside and outside the manufacturing facility.

Carbon Footprint Reduction: Many manufacturers are setting targets to reduce their carbon footprint by implementing energy-efficient practices, using renewable energy, and optimizing logistics to reduce transportation emissions.

6. Sustainable Supply Chain

Sustainability in manufacturing extends beyond the factory floor. Drum motor manufacturers are working towards creating sustainable supply chains by collaborating with eco-conscious suppliers and optimizing logistics.

Supplier Audits: Conducting regular audits of suppliers to ensure they adhere to sustainable practices helps maintain the integrity of the supply chain. This includes evaluating their energy use, waste management, and labor practices.

Optimized Transportation: Using efficient transportation methods and optimizing logistics can reduce the carbon footprint associated with the delivery of raw materials and finished products. This includes using electric or hybrid vehicles and optimizing delivery routes.

7. Community Engagement and Employee Well-being

Sustainable manufacturing is not just about environmental impact; it also involves social responsibility. Drum motor manufacturers in India are increasingly focusing on community engagement and ensuring the well-being of their employees.

Local Community Initiatives: Many manufacturers are involved in community development programs, such as tree planting, education initiatives, and supporting local businesses. This fosters goodwill and creates a positive impact on the surrounding communities.

Employee Health and Safety: Ensuring a safe and healthy work environment is paramount. Manufacturers are investing in safety training, ergonomic equipment, and wellness programs to enhance employee well-being.

Conclusion

The adoption of sustainable manufacturing practices by drum motor manufacturers in India is not only beneficial for the environment but also offers long-term economic advantages. By focusing on energy efficiency, waste reduction, eco-friendly materials, water conservation, emission control, sustainable supply chains, and community engagement, these manufacturers are paving the way for a greener and more sustainable future. As the demand for drum motors and other industrial components continues to rise, the commitment to sustainability will play a crucial role in shaping the industry’s growth and success.

By embracing these practices, drum motor manufacturers and suppliers in India are setting an example for other industries to follow. As sustainability becomes a core value in manufacturing, it is imperative for companies to continually innovate and strive for practices that protect the environment while ensuring economic viability. This approach not only enhances the reputation of drum motor manufacturers in India but also contributes to the global efforts towards sustainable development.

0 notes

Text

How 3D Printing Is Used In Automotive | Western Experience: Figures and Facts | Will India expect a boom in additive technologies? | The potential of 3D printing for the automotive market

Automotive is one of the first industries where 3D technology has found commercial use: back in 1988, Ford began using 3D printers to print individual prototype elements.

Today, this sector of the economy makes the most of the advances in additive technologies and 3D scanning . 3D printing is the ideal way to create prototypes, functional parts and assemblies, as well as tooling and molds. It saves time and money in the product development and casting stages by enabling the production of geometrically complex parts with high detail. 3D scanners and specialized software at a new level solve the problems of geometry control and reverse engineering , shortening the production time of cars, contributing to higher product quality and a decrease in the percentage of scrap.

Some major automakers have already started mass production of components for their classic models or custom cars on 3D printers . Market leaders are investing heavily in the creation of additive technology centers for pilot production. For example, BMW has such a center - it produces more than 100 thousand components per year, and in 2019 it is planned to open another large complex.

Advances in 3D printing technologies and the development of new materials with improved physical properties also allow the introduction of radically new, innovative ideas. For example, the Michelin Visionary Concept 'airless' tire technology with the ability to change the tread pattern depending on the weather eliminates punctures, low pressure problems and other driving risks.

Perhaps a fully 3D printed car is a reality in the not too distant future. However, all of the above are the achievements of Western automakers. What is the situation and prospects for the development of additive technologies in India? In this article, we will focus on the advantages of 3D printing , consider the application of innovations in the domestic car market, as well as practical examples of implementation.

How 3D printing is used in the automobile manufacturing

Additive technologies effectively solve the following problems of automotive manufacturing:

· creation of functional prototypes;

· creation of burned-out and lost-wax models for casting ;

· production of tooling and molds;

· small-scale production.

Prototyping will optimize production for those enterprises that produce cars (but not assemble ready-made models), as well as manufacturers of auto components supplied to the conveyor.

By means of topological optimization, the designer can define almost any desired geometry of the part and make changes to the design at later stages of development. The 3D model is transferred from CAD to a 3D printer, which quickly prints prototypes, tooling or molds for molding products . This reduces production costs, product development and time-to-market. In particular, the enterprise can set up the operational production of components, timed to coincide with the production of a car.

Accessories and products that meet the required strength characteristics can be produced directly at the factory with just one 3D printer. It will print parts of various nomenclature, which is impossible when using machine tools and other traditional tools.

Technologies mainly used for prototyping:

· FDM (fused deposition modeling );

· SLA ( laser stereolithography );

· SLS ( Selective Laser Sintering ).

Tooling and molds, which are printed from plastics and photopolymer resin , will be several times cheaper than metal ones.

Functional products can also be made using metal 3D printers (for example, using SLM technology). Metal 3D printing is also suitable for small batch production, including the creation of customized products. The latest developments in the field of metal powders have paved the way for the manufacture of lighter, denser, and in some cases more durable parts. Thanks to topological optimization on a 3D printer, it is possible to grow components of complex shapes and textures (with a cellular structure, internal channels, etc.), including all-metal ones, which were previously assembled from several elements.

Western experience: numbers and facts

The Renault Sport Formula One team was one of the first to use 3D printing for prototyping. Today, a small group of engineers are given the opportunity to produce hundreds of parts per week for wind tunnel testing, develop innovative parts for testing and installation on fireballs, and generally accelerate the R&D process. Thanks to SLA and SLS technologies, the manufacture of complex automotive parts does not take weeks, but only a few hours.

BMW has 3D printed a batch of thousands of metal parts for the BMW i8 Roadster. The convertible soft top of this roadster features an additive manufactured aluminum alloy component with an innovative bionic design that follows natural shapes. The new product has a higher degree of rigidity compared to its analogue, which was produced by injection molding, as well as less weight.

Renowned Italian racing motorcycle manufacturer Aprilia uses FDM printing for prototyping to optimize bike design and aerodynamics. For example, in preparation for the motorcycle season, the Aprilia Racing team created a series of PLA gearbox prototypes on a Sharebot QXXL 3D printer to test and determine the optimal geometry. 3D printing eliminated tooling, time and money, and one final mold was produced from testing.

Company Steeda Autosports , the largest manufacturer of accessories for Ford, the technology uses full-color 3D-printing for prototyping various components - from the cap to the oil can cast tubes cold intake system. The result: Reduced time to market by several weeks, saving $ 3,000 per piece in lower machining and mold costs.

Michelin uses metal 3D printers to insert in a mold for separating the sipes - the most wear-out parts of the tire. The choice of a new technology, instead of the previously used stamping and milling, is due to the fine-grained structure of the metal, better thermal conductivity and, as a consequence, less wear.

0 notes

Text

Industrial Rubber Market - Trends, Segments, Share, Growth, Demand, Key Player Profile and Forecast 2023

Regionally, Global Industrial Rubber Market is spanned across five regions namely Asia Pacific, North America, Europe, Latin America, and the Middle East & Africa.

Asia Pacific dominated the Global Industrial Rubber Market in 2016 owing to the growing demand from the automotive, construction, and electronics industries in the region. The high production and sales of automotive coupled with the increased per capita income is expected to drive the demand for Industrial Rubber in the region. The high investments in research & development is another factor likely to fuel the market growth. For instance, Apollo tires formally inaugurated their global research & development center near Chennai, India in 2016.

The Advanced Engineering Centre is working towards the integration of electronics into tire technology. Moreover, Myanmar business circle proposed the government to open rubber sale centers in Mon state, a major rubber producer of the country. According to the Myanmar Rubber Planters and Producers’ Association, the authorities are drawing up Rubber Law for the central rubber markets across the country. The organization also proposed a tax exemption for the imports of formic acid, which is expensive and plays an important role in high-quality rubber production. Rapid industrialization and urbanization in the region is expected to further fuel the market growth over the assessment period.

Get Free Sample @ https://www.marketresearchfuture.com/sample_request/6083

North America was the second largest region in the Global Industrial Rubber Market in 2016 on account of the growing demand from automotive and reviving construction industries in the region. Rising adoption of fuel-efficient automotive owing to the stringent regulations in the region is likely to boost the market growth further.

Europe is projected to witness a significant growth due to the high production and exportation of various automotive parts in the region. Furthermore, the investments in medical & healthcare to maintain hygienic environment are expected to fuel the market growth.

Latin America is projected to witness a significant growth owing to the high demand for Industrial Rubber from the automotive industry, especially in Mexico.

The infrastructural and construction activities in the GCC countries are likely to fuel the demand for Industrial Rubber in the Middle East & Africa over the assessment period.

Key Players:

Some of the manufacturers operating in the Global Industrial Rubber Market are LANXESS (Germany), Bridgestone Corporation (Japan), LG Chem (South Korea), Sinopec (China), The Goodyear Tire & Rubber Company (U.S.), KUMHO PETROCHEMICAL (South Korea), TSRC (Taiwan), JSR Corporation (Japan), Versalis S.p.A. (Italy), PJSC "Nizhnekamskneftekhim" (Russia), and ZEON CORPORATION (Japan).

Browse Key Industry Insights spread across 100 pages with 59 market data tables & 15 figures & charts from the report, “Industrial Rubber Market Information: By Type (Natural, Synthetic), Product (Tires, Seals, Hoses), Product Processing (Extrusion, Calendering), End-Use Industry (Automotive, Building & Construction) and Region – Growth Potential, Price Trends, Competitive Market Share & Forecast 2023” in detail along with the table of contents: https://www.marketresearchfuture.com/reports/industrial-rubber-market-6083

Segmentation:

Global Industrial Rubber Market is segmented by Type, Product, Product Processing, End Use Industry and Region.

On the Basis of the Type, Global Industrial Rubber Market is bifurcated into natural and synthetic.

Based on the Product, Global Industrial Rubber Market is segmented into tires, seals, shock-absorbing parts, conveyor belts, hoses, roofing, adhesives & sealants, sports equipment, and others.

On the Basis of the Product Processing, the market is segmented into extrusion, calendering, roller die, coating, molding & casting.

On the Basis of the End Use Industry, Global Industrial Rubber Market is segmented into automotive, building & construction, industrial manufacturing, electrical & electronics, and others.

Read our Blogs @ http://mrfrblog.com

Related Chemicals and Materials Market Research Report @ https://www.marketresearchfuture.com/categories/chemicals-market-report

NOTE: Our team of researchers are studying Covid19 and its impact on various industry verticals and wherever required we will be considering covid19 footprints for a better analysis of markets and industries. Cordially get in touch for more details.

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research & Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by Components, Application, Logistics and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

Contact: Market Research Future +1 646 845 9312 Email: [email protected]

0 notes

Text

Foundry Market Growing Tremendously with Better Market Opportunities From 2020-2023

JUNE 15, 2020: India is the second largest producer of castings, globally. The Indian Foundry industry produces various types of metal castings and cast components for application in the power, automotive, defense, railways, machine tools, agro machinery, tractor, earth-moving and mining machinery, electrical machinery, and oil and natural gas industries. The automobile sector is a major consumer of castings produced in the country. Currently, there are around 4,500 foundry units in the small, medium and large-scale sector. Out of these, 1500 units have international quality accreditation.

Global foundry market insights:

In 2017, global castings production witnessed an increase of ~5.3% from 2016, and reached a value of ~110 Mn tonnes. Based on total output, Russia had the highest growth in 2017, with an increase of ~8.3% in production from 2016. China increased its production by 2 Mn tonnes, reaching a total of 49.4 Mn in 2017. Increasing production of light vehicles worldwide is acting as a key growth driver for the global foundry market. The growth in production of light vehicles is expected to increase demand for new cast metal parts, across the world, and also lead to the replacement of old metal casting products with more energy efficient metal casting solutions.

To Request A Sample Copy Of This Report @: radiantinsights.com/research/foundry-market-in-india-2018-2023/request-sample

India foundry market insights:

Casting production in India reached a value of 11 Mn tonnes in 2018, and is expected expand at a compound annual growth rate (CAGR) of ~12.7% from 2018 until 2023. The automobile sector consumes around 40% of castings produced in India. As of 2018, aluminum castings contributed around 15% of the total castings production in the country. The share is expected to increase considerably by the end of 2023, owing to a shift in demand from iron to lighter castings materials for manufacturing fuel-efficient automobiles and electronic vehicles (EVs). Expansion of infrastructure by the government is expected to generate demand for a wide variety of machinery and equipment such as cranes, fans, motors, appliances, pumps, conveyor equipment, etc. which, in turn, will create fresh demand for metal castings.

The major foundry clusters are located in Batala, Jalandhar, Ludhiana, Agra, Pune, Kolhapur, Sholapur, Rajkot, Mumbai, Ahmedabad, Belgaum, Coimbatore, and Chennai, among other Indian cities. Each of these foundry units caters to some specific end-use market. The Coimbatore cluster is famous for pump-set castings, the clusters in Kolhapur and Belgaum are known for automotive castings, and the Rajkot cluster is famous for diesel engine castings. Some of the notable companies producing metal castings include Electrosteel Castings Ltd., Hinduja Foundries Ltd., Nelcast Ltd., and Tata Metaliks Ltd., among others.

End-user segment growth insights:

Automotive: The foundry market is linked directly with the development of the overall automotive sector. Growth of the automobile industry is expected to generate huge demand for castings producers. Based on volume, India is currently the fourth largest automobile industry, globally. Rapid growth of the automotive sector has also led to the steady development of other subsidiary industries like the auto component industry, indicating huge demand for castings.

Pipes and fittings: The pipe sector in India is poised for steady growth due to substantial investments and capacity additions. Companies produce a wide range of steel, cement and PVC pipes, which are used in various industries. Demand for castings is expected to expand with the growth of the pipes and fittings market in India.

Power: Consistent power supply and availability of quality electrical equipment are necessary for the growth of the Indian economy from a global perspective. As of December 2018, India had a power generating capacity of ~349.28 GW. The Government of India has targeted an addition of ~88.5 GW under the 12th Five-Year Plan (2012-2017), and another ~100 GW under the 13th Five-Year Plan (2017-2022). The foundry industry is expected to benefit from such power generation installations.

Government initiatives:

A Vision Plan 2020 has been initiated by The Institute of Indian Foundrymen (IIF) to recommend the needed initiatives for rapid growth, and emerge as a leading supplier of quality castings in the global market by 2020. An implementing agency for the India Foundry Mission (IFM) will have full authority to represent it, demonstrate the pilots and implement recommendations, and monitor market growth.

Key growth drivers of the market:

• Foundries across India are presently upgrading facilities and technologies in a bid to improve their productivity and increase their capacity. To cater to the growing demand, this industry is embarking on major expansions and technological initiatives, with investments of over INR 10 Bn, since 2011.

• Majority of the foundry units in India fall under the MSME sector, which has registered consistent growth over the years. There are around 51 Mn MSME units spread across the country. About 55.3% of the MSMEs are based out of rural areas, indicating the deployment of a significant rural workforce in the MSME sector.

• Re-implementation of Public Procurement Policy, Pradhan Mantri MUDRA Yojana, Make in India, Startup India, and Skill India initiatives are helping in the growth of the MSME sector in the country.

Key deterrents to the growth of the market

Since most of the castings manufacturing units fall under small and medium enterprises (SMEs), they cannot use advanced technological equipment or automation due to high costs, thus limiting their marketing strength. It is challenging for them to sustain their position in the global marketplace. The inability to meet the domestic demand for castings and to supply quality products to the global market acts as a huge barrier for the industry to grow further.

Companies covered:

1. Ashok Iron Works Pvt. Ltd.

2. Brakes India Pvt. Ltd.

3. DCM Engineering Ltd.

4. Electrosteel Castings Ltd.

5. Hinduja Foundries Ltd.

6. Jayaswal Neco Industries Ltd.

7. Menon and Menon Ltd.

8. Nelcast Ltd.

9. Sanmar Foundries Ltd.

10. Tata Metaliks Ltd.

To Browse Full Research Report @: radiantinsights.com/research/foundry-market-in-india-2018-2023

Table of Contents

Chapter 1: Executive summary

Chapter 2: Socio-economic indicators

Chapter 3: Introduction

3.1. Foundry market definition

3.2. Foundry process flow

3.3. Types of casting process - overview

Chapter 4: Global foundry market

4.1. Market overview

4.2. Top casting producing countries - volume-wise (2017)

4.3. Top 10 casting producing countries - per plant comparison; volume-wise (2016 and 2017)

4.4. Top gray iron producing countries (2018)

4.5. Top ductile iron producing countries (2018)

4.6. Top malleable iron producing countries (2018)

4.7. Top steel producing countries (2018)

4.8. Product-wise market segmentation (2017)

4.8.1. Gray iron

4.8.2. Ductile iron

4.8.3. Malleable iron

4.8.4. Steel

4.8.5. Copper base

4.8.6. Aluminum

4.8.7. Others

Continued……………….

To See More Reports of This Category by Radiant Insights: https://latestmarkettrends.news.blog/

About Radiant Insights: Radiant Insights is a platform for companies looking to meet their market research and business intelligence requirements. It assist and facilitate organizations and individuals procure market research reports, helping them in the decision making process. The Organization has a comprehensive collection of reports, covering over 40 key industries and a host of micro markets. In addition to over extensive database of reports, experienced research coordinators also offer a host of ancillary services such as, research partnerships/ tie-ups and customized research solutions.

Media Contact:

Company Name: Radiant Insights, Inc

Contact Person: Michelle Thoras

Email:

Phone: (415) 349-0054

Address: 201 Spear St #1100, Suite #3036

City: San Francisco

State: California

Country: United States

0 notes

Text

Mining Equipment Market Profile | Dynamics and Growth | Forecast To 2025

The global Mining Equipment Market is estimated to reach USD 284.93 billion by 2025 due to the rise in demand for control technologies for mineral extraction maneuvers. The industry players are drawing upon adopting core motion and control technologies to operate accurate, dependable and efficient. They are keen on profiling unmatchable breadth of technological components to surge their profitability in terms of delivering value-added services catering to their customer needs. Modern-day technology has improved assembly time to make machine navigation guide easier to understand.

By product type, the market can be segmented into underground mining machinery, drills and breakers, mineral processing machinery, surface mining machinery, crushing, pulverizing, and screening equipment, and parts and attachments. Based on application industries, the market has been categorized into metal, coal, and mineral. The mining equipment market has been split by function type, which includes transportation, excavation, and processing.

Request Sample Copy of this Market Research @ https://www.millioninsights.com/industry-reports/mining-equipment-market-size/request-sample

In order to study the span of the industry, the mining equipment market has been geographically segmented into the five key regions of North America, Europe, the Asia Pacific, the Middle East, and Africa, and Latin America. The market adoption has been bolstered across Asia Pacific and Latin America due to the increasing demand for metals in heavy-duty industries. The industry players are bringing in fuel-efficient devices so as to cater to lower diesel consumption levels.

The key players have identified current market dynamics in terms of its size, supply-demand value chain mechanism, prevailing trends, governing factors, drivers, challenges and opportunities, their competitive landscape and product innovation. Players are entering into business partnerships with fellow contestants and are significantly investing in innovation strategies, which is estimated to drive the cellular vendors to reach new growth markets. The market participants have identified the major distribution channels, supply chain mechanism, industry cost structure and production capabilities. Considering the changing competitive dynamics and the current scenario of the industry, it has set the mining equipment market to grow at an exponential rate during the forecast years.

The competitive landscape showcases the profiles and business strategies of the major players, along with their recent developments. The mining equipment industry is highly fragmented with the presence of major players such as Caterpillar, Inc., Komatsu Ltd., Metso Corporation, Atlas Copco AB, CNH Industrial NV, Sandvik AB, Hitachi Co., Doosan Group, Ltd., AB Volvo, Liebherr Group, Bell Equipment Limited, Astec Industries Incorporated, China Coal Energy Company Limited, Corum Group, Bradken Limited, Hyundai Heavy Industries Company Limited, RCR Tomlinson Limited, Kopex SA, Terex Corporation, Techint Group, and Wirtgen Group Holding GmbH, among others.

Numerous research and development activities have made ground-breaking innovation and design that have helped in minimizing the costs of emerging systems maintenance solutions, Disposal, and energy consumption.

KGHM ZANAM S.A. is a polish manufacturer of mining machinery and equipment such as steel structures, crushers, castings, shaft equipment, conveyor belts, etc. They also deliver their services to underground zinc, lead and salt mines. Also, depending on customer needs and operating conditions, KGHM ZANAM S.A. offers a weighing system for a remotely operated fire-extinguisher and transported material. Haul trucks are yet another push-out unloading system that maneuvers transported outputs and are increasing the efficiency of narrow mine headings.

Browse Full Research Report @ https://www.millioninsights.com/industry-reports/mining-equipment-market-size

Market Segment:

Mining Equipment Outlook (Revenue, USD Billion, 2014 - 2025) • Underground Mining Equipment • Low Profile Dump Trucks (LPDT) • Load Haul and Dump (LHD) Loaders • Surface Mining Equipment • Electric Shovels • Excavators • Dumpers • Others • Crushing, Pulverizing, & Screening Equipment • Drills & Breakers • Others

Mining Equipment Application Outlook (Revenue, USD Billion, 2014 - 2025) • Metal Mining • Non-Metal Mining • Coal Mining

Mining Equipment Regional Outlook (Revenue, USD Billion, 2014 - 2025) • North America • U.S. • Canada • Europe • Germany • U.K. • Spain • France • Finland • Sweden • Poland • Russia • Asia Pacific • China • India • Japan • Australia • Indonesia • South Korea • Philippines • New Zealand • Latin America • Chile • Peru • Middle East & Africa • Saudi Arabia • South Africa • Iran • Egypt • Ghana

For More Details Please Visit www.millioninsights.com

0 notes

Text

Global Engineering Plastics Market is expected to grow at a CAGR of 6.8% during the forecast period 2018-2023

According to the new market research report by IndustryARC titled “Engineering Plastics Market By Type (ABS, PA, PC, POM, PMMA, PEEK, PET, PBT, Cast Nylon); By End-User (Aerospace, Building & Construction, Food, Mechanical, Medical, Others); By Application (CD/DVD, Medical Implants, Advanced Batteries, Shoes, Others); By Geography – Forecast Period (2018–2023),” the market will be driven by the replacement of metal parts by engineering plastics in various industries.

Asia Pacific Dominates the Engineering Plastics Market

Asia Pacific has the largest share in the Engineering Plastics Market due to the growing demand for engineering plastics by the end-user industries such as electrical & electronics, and automotive & transportation. The increase in the production of automotive parts in the region will bolster the market over the forecast period. China is the largest market for engineering plastics. The country’s engineering plastics market is primarily driven by the rapid growth of the automotive and transportation industry and the easy availability of feedstock.

Selected Regulatory Analysis Done in theEngineering Plastics Market Report

The automotive and transportation sector will dominate the Engineering Plastics Market over the forecast period. Engineering plastics are used in the automotive industry for applications in the wheel well, connectors and housing, under the hood components, headlamps, and fog lamps. The automotive sector growth rate is high in Asia-Pacific, particularly in China, India, Japan, and South Korea. The automotive and transportation market in these countries will drive the demand for engineering plastic products over the forecast period.

To access/purchase the Engineering Plastics Market report, click the link below: https://industryarc.com/Report/15507/engineering-plastics-market.html

Selected Driving Factors Mentioned in the Engineering Plastics Market Report

• Growth of the end-user industries such as electrical, electronics, packaging, automotive, construction, and consumer appliances will drive the demand for engineering plastic products.

• The easy availability of raw materials and low cost of production will boost the demand for engineering plastics.

• The benefits of engineering plastics such as flame resistance, durability, chemical resistance, and wear resistance compared to commodity plastics will provide ample opportunities for the engineering plastics market.

• Major investments by governments and companies in developing new technologies will propel the growth of the engineering plastics market.

Key Players of the Engineering Plastics Market

BASF SE, Covestro, and Celanese Corporation are the key players of the engineering plastics market. — BASF produces engineering plastics for extrusion, injection molding, and blow molding. The engineering plastics produced by BASF are developed for applications in the automotive & engineering, and electrical & electronic sectors. — Covestro offers products which have a desirable balance of properties such as impact strength and heat resistance to other materials. — Celanese provides high-performance engineering resins that offer resistance to friction and wear, and deliver good mechanical properties such as stiffness and strength.

The Engineering Plastics Market Is Segmented as Indicated Below:

The growing demand for electronic and electrical appliances will propel the growth of the engineering plastics market.

A. Engineering Plastics Market –By Type 1. ABS 2. Acetal 3. Acrylic 4. Bakelite 5. High Performance Materials 6. Nylon 7. PETP 8. Polycarbonate 9. Polyethylenes (PE) 10. Polypropylene (PP) 11. Polyurethane 12. PTFE 13. PVC 14. PEK 15. PEEK

B. Engineering Plastics Market – By Application 1. Abrasion Resistant Liners 2. Acid Trays 3. Anti-Corrosive Liners 4. Braking Tray Liners 5. Bearings 6. Bench Top 7. Boat Chopping Board 8. Boat Windscreen 9. Bolts & Nuts 10. Bottle Line Wear Plate 11. Buffer Pads 12. Bushes 13. Chain Guide 14. Chevron Packing’s 15. Conveyor Mechanisms 16. Cooling Towers 17. Cutting Boards 18. Display 19. Electrical Insulator 20. Exhaust Ducts 21. Feedscrolls 22. Food Production 23. Fume Ducting 24. Gaskets 25. Gears 26. Guards 27. Guide Strips 28. Guide Wheels 29. Heat Seal Surfaces 30. High Precision Parts 31. Hoppers 32. Insulators 33. Kicker Arms 34. Lantern Rings 35. Level Indicators 36. Lighting 37. Machine Guards 38. Metal Detector Chutes 39. Nuts and Bolts 40. Piston Rings 41. Piston Seals and Cups 42. Plating Tanks and Hoods 43. Pressure Plates 44. Pump Components 45. Rollers 46. Safety Glass and Guards 47. Scraper Blades 48. Seals 49. Security Windows 50. Self-Lubricating Parts 51. Sightglass 52. Skylights 53. Slide Bearings 54. Slideways 55. Terminal Boards 56. Thermal Insulators 57. Thrust Washers 58. Valve Bodies 59. Valve Components 60. Washer 61. Wear Pads 62. Wear Plates 63. Others

C. Engineering Plastics Market – By End User 1. Aerospace 2. Automotive 3. Building 4. Food 5. Packaging 6. Mechanical 7. Medical 8. Oil & gas 9. Semiconductor 10. Construction 11. Others

D. Engineering Plastics Market – By Geography (33+ countries) E. Engineering Plastics Market Entropy F. Company Profiles 1. BASF SE 2. Covestro 3. Solvay S.A. 4. Celanese Corporation 5. DuPont 6. LG Chem 7. Evonik Industry AG 8. Lanxess AG 9. Company 9 10. Company 10

More than 10 companies are profiled in this report

G. Appendix: Abbreviations, Sources, Research Methodology, Bibliography, Compilation of Experts, Disclaimer.

What can you expect from the report?

The Engineering Plastics Market Report is prepared with the main agenda to cover the following 20 points:

1. Market Size by Product Categories 2. Market Trends 3. Manufacturer Landscape 4. Distributor Landscape 5. Pricing Analysis 6. Top 10 End User Analysis 7. Product Benchmarking 8. Product Developments 9. Mergers & Acquisition Analysis 10. Patent Analysis 11. Demand Analysis (By Revenue & Volume) 12. Country-level Analysis (15+) 13. Competitor Analysis 14. Market Shares Analysis 15. Value Chain Analysis 16. Supply Chain Analysis 17. Strategic Analysis 18. Current & Future Market Landscape Analysis 19. Opportunity Analysis 20. Revenue and Volume Analysis

Any other major customizations can be discussed with our team. We can also provide you with a separate quote based on your requirements. You can drop an e-mail to [email protected] to learn more about our consulting services.

Media Contact

Mr. Venkat Reddy Sales Manager Email 1: [email protected] Or Email 2: [email protected] Contact Sales: +1-614-588-8538 (Ext-101)

About IndustryARC

IndustryARC is a Research and Consulting Firm that publishes more than 500 reports annually, in various industries such as Agriculture, Automotive, Automation & Instrumentation, Chemicals and Materials, Energy and Power, Electronics, Food & Beverages, Information Technology, and Life Sciences & Healthcare.

#engineering plastic products#Engineering Plastics market#engineering plastic material#engineering plastics applications

0 notes

Text

Global Engineering Plastics Market is Expected to Grow at a CAGR of 6.8% During the Forecast Period 2018-2023.

According to the new market research report by IndustryARC titled “Engineering Plastics Market By Type (ABS, PA, PC, POM, PMMA, PEEK, PET, PBT, Cast Nylon); By End User (Aerospace, Building & Construction, Food, Mechanical, Medical, Others); By Application (CD/DVD, Medical Implants, Advanced Batteries, Shoes, Others); By Geography – Forecast Period (2018–2023),” the market will be driven by the replacement of metal parts by engineering plastics in various industries. Asia Pacific Dominates the Engineering Plastics Market Asia Pacific has the largest share in the Engineering Plastics market due to the growing demand for engineering plastics by the end user industries such as electrical & electronics, and automotive & transportation. The increase in the production of automotive parts in the region will bolster the market over the forecast period. China is the largest market for engineering plastics. The country’s engineering plastics market is primarily driven by the rapid growth of the automotive and transportation industry, and the easy availability of feedstock. Selected Regulatory Analysis Done in the Engineering Plastics Market Report The automotive and transportation sector will dominate the Engineering Plastics Market over the forecast period. Engineering plastics are used in the automotive industry for applications in wheel well, connectors and housing, under the hood components, head lamps, and fog lamps. The automotive sector growth rate is high in Asia-Pacific, particularly in China, India, Japan, and South Korea. The automotive and transportation market in these countries will drive the demand for engineering plastic products over the forecast period. Talk to one of our sales representatives about the Engineering Plastics Market report in the link below: https://industryarc.com/support.php?id=15507 Selected Driving Factors Mentioned in the Engineering Plastics Market Report Growth of the end user industries such as electrical, electronics, packaging, automotive, construction, and consumer appliances will drive the demand for engineering plastic products. The easy availability of raw materials and low cost of production will boost the demand for engineering plastics. The benefits of engineering plastics such as flame resistance, durability, chemical resistance, and wear resistance compared to commodity plastics will provide ample opportunities for the engineering plastics market. Major investments by governments and companies in developing new technologies will propel the growth of the engineering plastics market. To access/purchase the Engineering Plastics Market report, click the link below: https://industryarc.com/Report/15507/engineering-plastics-market.html Key Players of the Engineering Plastics Market BASF SE, Covestro, and Celanese Corporation are the key players of the engineering plastics market. BASF produces engineering plastics for extrusion, injection molding, and blow molding. The engineering plastics produced by BASF are developed for applications in the automotive & engineering, and electrical & electronic sectors. Covestro offers products which have a desirable balance of properties such as impact strength and heat resistance to other materials. Celanese provides high performance engineering resins that offer resistance to friction and wear, and deliver good mechanical properties such as stiffness and strength. The Engineering Plastics Market Is Segmented as Indicated Below: The growing demand for electronic and electrical appliances will propel the growth of the engineering plastics market. Engineering Plastics Market Analysis –By Type ABS Acetal Acrylic Bakelite High Performance Materials Nylon PETP Polycarbonate Polyethylenes (PE) Polypropylene (PP) Polyurethane PTFE PVC PEK PEEK Engineering Plastics Market Growth – By Application Abrasion Resistant Liners Acid Trays Anti-Corrosive Liners Braking Tray Liners Bearings Bench Top Boat Chopping Board Boat Windscreen Bolts & Nuts Bottle Line Wear Plate Buffer Pads Bushes Chain Guide Chevron Packing’s Conveyor Mechanisms Cooling Towers Cutting Boards Display Electrical Insulator Exhaust Ducts Feedscrolls Food Production Fume Ducting Gaskets Gears Guards Guide Strips Guide Wheels Heat Seal Surfaces High Precision Parts Hoppers Insulators Kicker Arms Lantern Rings Level Indicators Lighting Machine Guards Metal Detector Chutes Nuts and Bolts Piston Rings Piston Seals and Cups Plating Tanks and Hoods Pressure Plates Pump Components Rollers Safety Glass and Guards Scraper Blades Seals Security Windows Self-Lubricating Parts Sightglass Skylights Slide Bearings Slideways Terminal Boards Thermal Insulators Thrust Washers Valve Bodies Valve Components Washer Wear Pads Wear Plates Others Engineering Plastics Market Share – By End User Aerospace Automotive Building Food Packaging Mechanical Medical Oil & gas Semiconductor Construction Others Engineering Plastics Market Forecast – By Geography (33+ countries) Engineering Plastics Market Entropy Company Profiles BASF SE Covestro Solvay S.A. Celanese Corporation DuPont LG Chem Evonik Industry AG Lanxess AG Company 9 Company 10 More than 10 companies are profiled in this report Appendix: Abbreviations, Sources, Research Methodology, Bibliography, Compilation of Experts, Disclaimer. Related Reports: Biodegradable Plastic Market Carbon Fiber Reinforced Plastic Market What can you expect from the Engineering Plastics Market Report? The Engineering Plastics Market Report is prepared with the main agenda to cover the following 20 points: Engineering Plastics Market Size by Product Categories Engineering Plastics Market Trends Engineering Plastics Manufacturer Landscape Distributor Landscape Pricing Analysis Top 10 End User Analysis Product Benchmarking Product Developments Mergers & Acquisition Analysis Patent Analysis Demand Analysis (By Revenue & Volume) Country level Analysis (15+) Competitor Analysis Engineering Plastics Market Growth Analysis Engineering Plastics Market Forecast Analysis Engineering Plastics Market Shares Analysis Engineering Plastics Market Value Chain Analysis Engineering Plastics Market Supply Chain Analysis Engineering Plastics Market Strategic Analysis Current & Future Market Landscape Analysis Engineering Plastics Market Opportunity Analysis Engineering Plastics Market Revenue and Volume Analysis FAQs: Does IndustryARC publish country, geography, or application–based reports in Engineering Plastics? Yes, we do have separate reports and database as mentioned below: Engineering Plastics Market Analysis (2018–2023) North America Engineering Plastics Market Forecast (2018–2023) South America Engineering Plastics Market Growth (2018–2023) 4. Europe Engineering Plastics Market Share (2018–2023) Asia Pacific Engineering Plastics Market Share (2018–2023) Middle East & Africa Engineering Plastics Market Growth (2018–2023) Aerospace Engineering Plastics Market Analysis (2018–2023) Automotive Engineering Plastics Market Growth (2018–2023) Does IndustryARC provide customized reports and charge additionally for limited customization? Yes, we can customize the report by extracting data from our database of reports and annual subscription databases. We can provide the following free customizations: Increase the level of data in application or end user industry. Increase the number of countries in geography or product chapter. Find out market shares for other smaller companies or companies that are of interest to you Company profiles can be requested based on your interest. Patent analysis, pricing, product analysis, product benchmarking, and value and supply chain analysis can be requested for a country or end use segment. Any other major customizations can be discussed with our team. We can also provide you with a separate quote based on your requirements. You can drop an e-mail to [email protected] to learn more about our consulting services. Media Contact Mr. Venkat Reddy Sales Manager Email : [email protected] Contact Sales: +1-614-588-8538 (Ext-101)

0 notes

Text

Industrial Rubber Market Share - Growth, Analysis, Forecast, Overview, Demand, Size, Trends and Outlook 2023

Key Players:

Some of the manufacturers operating in the Global Industrial Rubber Market Share are LANXESS (Germany), Bridgestone Corporation (Japan), LG Chem (South Korea), Sinopec (China), The Goodyear Tire & Rubber Company (U.S.), KUMHO PETROCHEMICAL (South Korea), TSRC (Taiwan), JSR Corporation (Japan), Versalis S.p.A. (Italy), PJSC "Nizhnekamskneftekhim" (Russia), and ZEON CORPORATION (Japan).

Regional Analysis:

Regionally, Global Industrial Rubber Market is spanned across five regions namely Asia Pacific, North America, Europe, Latin America, and the Middle East & Africa.

Asia Pacific dominated the Global Industrial Rubber Market in 2016 owing to the growing demand from the automotive, construction, and electronics industries in the region. The high production and sales of automotive coupled with the increased per capita income is expected to drive the demand for Industrial Rubber in the region. The high investments in research & development is another factor likely to fuel the market growth. For instance, Apollo tires formally inaugurated their global research & development center near Chennai, India in 2016.

Get Free Sample @ https://www.marketresearchfuture.com/sample_request/6083

The Advanced Engineering Centre is working towards the integration of electronics into tire technology. Moreover, Myanmar business circle proposed the government to open rubber sale centers in Mon state, a major rubber producer of the country. According to the Myanmar Rubber Planters and Producers’ Association, the authorities are drawing up Rubber Law for the central rubber markets across the country. The organization also proposed a tax exemption for the imports of formic acid, which is expensive and plays an important role in high-quality rubber production. Rapid industrialization and urbanization in the region is expected to further fuel the market growth over the assessment period.

North America was the second largest region in the Global Industrial Rubber Market in 2016 on account of the growing demand from automotive and reviving construction industries in the region. Rising adoption of fuel-efficient automotive owing to the stringent regulations in the region is likely to boost the market growth further.

Europe is projected to witness a significant growth due to the high production and exportation of various automotive parts in the region. Furthermore, the investments in medical & healthcare to maintain hygienic environment are expected to fuel the market growth.

Latin America is projected to witness a significant growth owing to the high demand for Industrial Rubber from the automotive industry, especially in Mexico.

The infrastructural and construction activities in the GCC countries are likely to fuel the demand for Industrial Rubber in the Middle East & Africa over the assessment period.

Browse Key Industry Insights spread across 100 pages with 59 market data tables & 15 figures & charts from the report, “Industrial Rubber Market Information: By Type (Natural, Synthetic), Product (Tires, Seals, Hoses), Product Processing (Extrusion, Calendering), End-Use Industry (Automotive, Building & Construction) and Region – Growth Potential, Price Trends, Competitive Market Share & Forecast 2023” in detail along with the table of contents: https://www.marketresearchfuture.com/reports/industrial-rubber-market-6083

Segmentation:

Global Industrial Rubber Market is segmented by Type, Product, Product Processing, End Use Industry and Region.

On the Basis of the Type, Global Industrial Rubber Market is bifurcated into natural and synthetic.

Based on the Product, Global Industrial Rubber Market is segmented into tires, seals, shock-absorbing parts, conveyor belts, hoses, roofing, adhesives & sealants, sports equipment, and others.

On the Basis of the Product Processing, the market is segmented into extrusion, calendering, roller die, coating, molding & casting.

On the Basis of the End Use Industry, Global Industrial Rubber Market is segmented into automotive, building & construction, industrial manufacturing, electrical & electronics, and others.

NOTE: Our team of researchers are studying Covid19 and its impact on various industry verticals and wherever required we will be considering covid19 footprints for a better analysis of markets and industries. Cordially get in touch for more details.

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research & Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by Components, Application, Logistics and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

Contact: Market Research Future +1 646 845 9312 Email: [email protected]

0 notes

Text

Industrial Rubber Market Size - Overview, Trends, Forecast, Revenue, COVID-19 Analysis, Demand and Outlook 2023

Segmentation:

Global Industrial Rubber Market Size is segmented by Type, Product, Product Processing, End Use Industry and Region.

On the Basis of the Type, Global Industrial Rubber Market is bifurcated into natural and synthetic.

Based on the Product, Global Industrial Rubber Market is segmented into tires, seals, shock-absorbing parts, conveyor belts, hoses, roofing, adhesives & sealants, sports equipment, and others.

On the Basis of the Product Processing, the market is segmented into extrusion, calendering, roller die, coating, molding & casting.

On the Basis of the End Use Industry, Global Industrial Rubber Market is segmented into automotive, building & construction, industrial manufacturing, electrical & electronics, and others.

Get Free Sample @ https://www.marketresearchfuture.com/sample_request/6083

Key Players:

Some of the manufacturers operating in the Global Industrial Rubber Market are LANXESS (Germany), Bridgestone Corporation (Japan), LG Chem (South Korea), Sinopec (China), The Goodyear Tire & Rubber Company (U.S.), KUMHO PETROCHEMICAL (South Korea), TSRC (Taiwan), JSR Corporation (Japan), Versalis S.p.A. (Italy), PJSC "Nizhnekamskneftekhim" (Russia), and ZEON CORPORATION (Japan).

Regional Analysis:

Regionally, Global Industrial Rubber Market is spanned across five regions namely Asia Pacific, North America, Europe, Latin America, and the Middle East & Africa.

Asia Pacific dominated the Global Industrial Rubber Market in 2016 owing to the growing demand from the automotive, construction, and electronics industries in the region. The high production and sales of automotive coupled with the increased per capita income is expected to drive the demand for Industrial Rubber in the region. The high investments in research & development is another factor likely to fuel the market growth. For instance, Apollo tires formally inaugurated their global research & development center near Chennai, India in 2016.

The Advanced Engineering Centre is working towards the integration of electronics into tire technology. Moreover, Myanmar business circle proposed the government to open rubber sale centers in Mon state, a major rubber producer of the country. According to the Myanmar Rubber Planters and Producers’ Association, the authorities are drawing up Rubber Law for the central rubber markets across the country. The organization also proposed a tax exemption for the imports of formic acid, which is expensive and plays an important role in high-quality rubber production. Rapid industrialization and urbanization in the region is expected to further fuel the market growth over the assessment period.

Browse Key Industry Insights spread across 100 pages with 59 market data tables & 15 figures & charts from the report, “Industrial Rubber Market Information: By Type (Natural, Synthetic), Product (Tires, Seals, Hoses), Product Processing (Extrusion, Calendering), End-Use Industry (Automotive, Building & Construction) and Region – Growth Potential, Price Trends, Competitive Market Share & Forecast 2023” in detail along with the table of contents: https://www.marketresearchfuture.com/reports/industrial-rubber-market-6083

North America was the second largest region in the Global Industrial Rubber Market in 2016 on account of the growing demand from automotive and reviving construction industries in the region. Rising adoption of fuel-efficient automotive owing to the stringent regulations in the region is likely to boost the market growth further.

Europe is projected to witness a significant growth due to the high production and exportation of various automotive parts in the region. Furthermore, the investments in medical & healthcare to maintain hygienic environment are expected to fuel the market growth.

Latin America is projected to witness a significant growth owing to the high demand for Industrial Rubber from the automotive industry, especially in Mexico.

The infrastructural and construction activities in the GCC countries are likely to fuel the demand for Industrial Rubber in the Middle East & Africa over the assessment period.

COVID-19 Study in Detail:

Impact of COVID-19 on Iso-Propyl Alcohol Market @ https://www.marketresearchfuture.com/report/covid-19-impact-iso-propyl-alcohol-industry

Impact of COVID-19 on Steel Extruded Products Market @ https://www.marketresearchfuture.com/report/covid-19-impact-steel-extruded-products-market

Corona virus Outbreak and Plastic Films Market @ https://www.marketresearchfuture.com/report/covid-19-impact-plastic-films-market

NOTE: Our teams of researchers are studying COVID-19 and its impact on various industry verticals and wherever required we will be considering COVID-19 footprints for a better analysis of markets and industries. Cordially get in touch for more details.

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research & Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by Components, Application, Logistics and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

Contact: Market Research Future +1 646 845 9312 Email: [email protected]

0 notes

Text

Industrial Rubber Market Revenue - Growth, Analysis, Forecast, Scope, Size, Overview, Share and Outlook 2023

Segmentation:

Global Industrial Rubber Market Revenue is segmented by Type, Product, Product Processing, End Use Industry and Region.

On the Basis of the Type, Global Industrial Rubber Market is bifurcated into natural and synthetic.

Based on the Product, Global Industrial Rubber Market is segmented into tires, seals, shock-absorbing parts, conveyor belts, hoses, roofing, adhesives & sealants, sports equipment, and others.

On the Basis of the Product Processing, the market is segmented into extrusion, calendering, roller die, coating, molding & casting.

On the Basis of the End Use Industry, Global Industrial Rubber Market is segmented into automotive, building & construction, industrial manufacturing, electrical & electronics, and others.

Key Players:

Some of the manufacturers operating in the Global Industrial Rubber Market are LANXESS (Germany), Bridgestone Corporation (Japan), LG Chem (South Korea), Sinopec (China), The Goodyear Tire & Rubber Company (U.S.), KUMHO PETROCHEMICAL (South Korea), TSRC (Taiwan), JSR Corporation (Japan), Versalis S.p.A. (Italy), PJSC "Nizhnekamskneftekhim" (Russia), and ZEON CORPORATION (Japan).

Get Free Sample @ https://www.marketresearchfuture.com/sample_request/6083

Regional Analysis:

Regionally, Global Industrial Rubber Market is spanned across five regions namely Asia Pacific, North America, Europe, Latin America, and the Middle East & Africa.

Asia Pacific dominated the Global Industrial Rubber Market in 2016 owing to the growing demand from the automotive, construction, and electronics industries in the region. The high production and sales of automotive coupled with the increased per capita income is expected to drive the demand for Industrial Rubber in the region. The high investments in research & development is another factor likely to fuel the market growth. For instance, Apollo tires formally inaugurated their global research & development center near Chennai, India in 2016.

The Advanced Engineering Centre is working towards the integration of electronics into tire technology. Moreover, Myanmar business circle proposed the government to open rubber sale centers in Mon state, a major rubber producer of the country. According to the Myanmar Rubber Planters and Producers’ Association, the authorities are drawing up Rubber Law for the central rubber markets across the country. The organization also proposed a tax exemption for the imports of formic acid, which is expensive and plays an important role in high-quality rubber production. Rapid industrialization and urbanization in the region is expected to further fuel the market growth over the assessment period.

North America was the second largest region in the Global Industrial Rubber Market in 2016 on account of the growing demand from automotive and reviving construction industries in the region. Rising adoption of fuel-efficient automotive owing to the stringent regulations in the region is likely to boost the market growth further.

Europe is projected to witness a significant growth due to the high production and exportation of various automotive parts in the region. Furthermore, the investments in medical & healthcare to maintain hygienic environment are expected to fuel the market growth.

Latin America is projected to witness a significant growth owing to the high demand for Industrial Rubber from the automotive industry, especially in Mexico.

The infrastructural and construction activities in the GCC countries are likely to fuel the demand for Industrial Rubber in the Middle East & Africa over the assessment period.

COVID-19 Study in Detail:

Impact of COVID-19 on Iso-Propyl Alcohol Market @ https://www.marketresearchfuture.com/report/covid-19-impact-iso-propyl-alcohol-industry

Impact of COVID-19 on Steel Extruded Products Market @ https://www.marketresearchfuture.com/report/covid-19-impact-steel-extruded-products-market

Corona virus Outbreak and Plastic Films Market @ https://www.marketresearchfuture.com/report/covid-19-impact-plastic-films-market

NOTE: Our teams of researchers are studying COVID-19 and its impact on various industry verticals and wherever required we will be considering COVID-19 footprints for a better analysis of markets and industries. Cordially get in touch for more details.

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research & Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by Components, Application, Logistics and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

Contact: Market Research Future +1 646 845 9312 Email: [email protected]

0 notes

Text

Covid-19 Analysis on Industrial Rubber Market - Trends, Overview, Forecast, Revenue, Scope, Growth, Companies & Outlook 2023

Market Research Future Published a Half Cooked Research Report on Global Industrial Rubber Market Research Report – Forecast to 2023

Regionally, Covid-19 Analysis on Industrial Rubber Market is spanned across five regions namely Asia Pacific, North America, Europe, Latin America, and the Middle East & Africa.

Asia Pacific dominated the Global Industrial Rubber Market in 2016 owing to the growing demand from the automotive, construction, and electronics industries in the region. The high production and sales of automotive coupled with the increased per capita income is expected to drive the demand for Industrial Rubber in the region. The high investments in research & development is another factor likely to fuel the market growth. For instance, Apollo tires formally inaugurated their global research & development center near Chennai, India in 2016.

The Advanced Engineering Centre is working towards the integration of electronics into tire technology. Moreover, Myanmar business circle proposed the government to open rubber sale centers in Mon state, a major rubber producer of the country. According to the Myanmar Rubber Planters and Producers’ Association, the authorities are drawing up Rubber Law for the central rubber markets across the country. The organization also proposed a tax exemption for the imports of formic acid, which is expensive and plays an important role in high-quality rubber production. Rapid industrialization and urbanization in the region is expected to further fuel the market growth over the assessment period.

North America was the second largest region in the Global Industrial Rubber Market in 2016 on account of the growing demand from automotive and reviving construction industries in the region. Rising adoption of fuel-efficient automotive owing to the stringent regulations in the region is likely to boost the market growth further.

Europe is projected to witness a significant growth due to the high production and exportation of various automotive parts in the region. Furthermore, the investments in medical & healthcare to maintain hygienic environment are expected to fuel the market growth.

Latin America is projected to witness a significant growth owing to the high demand for Industrial Rubber from the automotive industry, especially in Mexico.

Get Free Sample @ https://www.marketresearchfuture.com/sample_request/6083

The infrastructural and construction activities in the GCC countries are likely to fuel the demand for Industrial Rubber in the Middle East & Africa over the assessment period.

Key Players:

Some of the manufacturers operating in the Global Industrial Rubber Market are LANXESS (Germany), Bridgestone Corporation (Japan), LG Chem (South Korea), Sinopec (China), The Goodyear Tire & Rubber Company (U.S.), KUMHO PETROCHEMICAL (South Korea), TSRC (Taiwan), JSR Corporation (Japan), Versalis S.p.A. (Italy), PJSC "Nizhnekamskneftekhim" (Russia), and ZEON CORPORATION (Japan).

Segmentation:

Global Industrial Rubber Market is segmented by Type, Product, Product Processing, End Use Industry and Region.

On the Basis of the Type, Global Industrial Rubber Market is bifurcated into natural and synthetic.

Based on the Product, Global Industrial Rubber Market is segmented into tires, seals, shock-absorbing parts, conveyor belts, hoses, roofing, adhesives & sealants, sports equipment, and others.

On the Basis of the Product Processing, the market is segmented into extrusion, calendering, roller die, coating, molding & casting.

On the Basis of the End Use Industry, Global Industrial Rubber Market is segmented into automotive, building & construction, industrial manufacturing, electrical & electronics, and others.

NOTE: Our team of researchers are studying Covid19 and its impact on various industry verticals and wherever required we will be considering covid19 footprints for a better analysis of markets and industries. Cordially get in touch for more details.

COVID-19 Study in Detail:

Impact of COVID-19 on Iso-Propyl Alcohol Market @ https://www.marketresearchfuture.com/report/covid-19-impact-iso-propyl-alcohol-industry

Impact of COVID-19 on Steel Extruded Products Market @ https://www.marketresearchfuture.com/report/covid-19-impact-steel-extruded-products-market

Corona virus Outbreak and Plastic Films Market @ https://www.marketresearchfuture.com/report/covid-19-impact-plastic-films-market

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research & Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by Components, Application, Logistics and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

Contact: Market Research Future +1 646 845 9312 Email: [email protected]

0 notes

Text

Industrial Rubber Market Trends - Growth, Analysis, Global, Share, Overview, Forecast, Scope, Size and Outlook 2023

Market Research Future Published a Half Cooked Research Report on Global Industrial Rubber Market Research Report – Forecast to 2023

Regional Analysis:

Regionally, Global Industrial Rubber Market Trends is spanned across five regions namely Asia Pacific, North America, Europe, Latin America, and the Middle East & Africa.