#Injection Moulding Experts

Explore tagged Tumblr posts

Text

Unlock precision and efficiency with our custom plastic tumbler molds. Engineered for high-performance injection molding, our molds ensure flawless production of durable, stylish, and perfectly contoured tumblers. Whether you're creating for retail, promotional items, or custom branding, our molds offer consistent quality and fast turnaround. Trust in precision for your next tumbler production run! Email: [email protected]

#Plastic Tumbler Mould#Precision Molding#Custom Mould Design#High Efficiency Production#Durable Drink ware Solutions#Injection Moulding Experts#injection mould#supplier#factory#china

0 notes

Text

The Best News of Last Week

⚡ - Goodbye Fossil Fuels, Hello Renewables: The Energizing News You Need

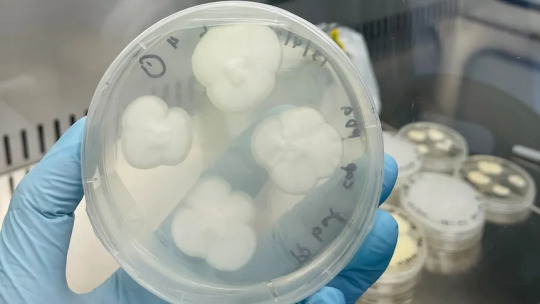

1. Fungi discovered that can eat plastic in just 140 days

Australian scientists have successfully used backyard mould to break down one of the world's most stubborn plastics — a discovery they hope could ease the burden of the global recycling crisis within years.

It took 90 days for the fungi to degrade 27 per cent of the plastic tested, and about 140 days to completely break it down, after the samples were exposed to ultraviolet rays or heat. We really see a solution within five years, according to environmental scientist Paul Harvey, an expert on global plastic pollution.

2. Topeka Zoo welcomes new African Lion as female sprouts mane

The Topeka Zoo has welcomed a new African Lion to its pride, a male, as one of its females started to sprout a mane following the 2021 passing of the pride’s last male.

The Topeka Zoo and Conservation Center announced on Thursday, April 13, that Tatu, a 4-year-old African Lion, has arrived in the Capital City. He comes to Topeka from the Denver Zoo and his arrival marks a time of growth for the zoo.

3. This barber opens his shop on his day off for children with special needs – and all of their haircuts are free

On his day off, Vernon Jackson still goes to work, opening up his Cincinnati barber shop, Noble Barber and Beauty, for VIP clients: children with special needs.

It's something he's done since 2021. "I was hearing so many horror stories that parents were going through with other barber shops and just the barbers or stylists having no patience with their child," Jackson told CBS News. "So I figured I would compromise by coming in on my day off so there were there would be no other barbers or stylists in the shop and I could give them the full attention that they need."

4. Renewables break energy records signalling ‘end of the fossil age’

Experts are calling time on the fossil age as new analysis shows wind and solar power produced a record amount of the world’s electricity last year.

The renewables generated 12 per cent of global electricity in 2022, up from 10 per cent the previous year, according to the report from clean energy think tank Ember. Last year, solar was the fastest-growing source of electricity for the 18th year in a row, rising by 24 per cent from 2021.

5. New nuclear medicine therapy cures human non-hodgkin lymphoma in preclinical model

A new nuclear medicine therapy can cure human non-Hodgkin lymphoma in an animal model A single dose of the radioimmunotherapy, was found to quickly eliminate tumour cells and extend the life of mice injected with cancerous cells for more than 221 days (the trial endpoint), compared to fewer than 60 days for other treatments and just 19 days in untreated control mice.

To explain it in simple terms because this is so freaking cool: There is a radioactive atom attached to a drug. The target cell eats the drug and the energy coming off of the radioactive atom kills the target cell

6. Colorado passes first US right to repair legislation for farmers

Colorado farmers will be able to legally fix their own equipment next year, with manufacturers including Deere & Co obliged to provide them with manuals for diagnostic software and other aids, under a measure passed by legislators in the first U.S. state to approve such a law.

Equipment makers have generally required customers to use their authorized dealers for repairs to machines such as combines and tractors.

7. When a softball player falls after hitting a grand slam, this is how her opponents reacted

youtube

----

That's it for this week :)

This newsletter will always be free. If you liked this post you can support me with a small kofi donation:

Buy me a coffee ❤️

Also don’t forget to reblog

1K notes

·

View notes

Text

Just a little something different:

Behold! A Scarab Occult Terminator, assembled by yours truly in his leisure time! This model here was built from thirteen separate pieces, and each of them had to be scraped and cleaned to look their best. There's this thing called mouldlines, made as an inevitable byproduct of the whole plastic injection molding process. It looks something like this.

It took a fair bit of work, fussing over a lot of details, but as you can see I think the result speaks for itself! I had to manually drill those barrels too, that took quite a bit of work. There's an option for one unit to carry a heavy weapon, which has the lovely title of Soulreaper Cannon. It's basically a gilded Gatling gun. For that piece, there's a little cap on the end of the gun that you attach. That cap has the barrels of the weapon already drilled in as part of the mould itself. Just to show what I'm talking about, here. So the question is... why don't they design something similar for all the models? I'm no design expert, but that seems like it'd be a good way of making things easier.

Maybe people like drilling the barrels? Dunno.

(example of how the official models look, painted by the pros)

Either way, it's something I'm going to be doing myself as I continue building these models. I've about four more left, and each of them is about thirteen pieces just like the first. The leader of the unit has a fancy cloak, so that'll require me to do subassemblies to have it painted right. I'll need to paint two parts of him separately: the torso, cloak, and arms; and the legs. Part of me is worrying that I'll mess up somehow with drilling the barrels, but so long as I take my time, I'm sure I'll be fine. Besides! Imperfections just give the model more character, though I'll be trying my best to avoid making any!

Mistakes are part of life, and therefore inevitably part of the process. So long as I do my best not to make them, and learn from any that I do? All will be well. I certainly hope so at least :3

I really do need to work on that tag list...

#{ ✎ : ᴏᴏᴄ }#{ ✎ : ʜᴇᴀᴠʏ ʙʀᴇᴀᴛʜɪɴɢ }#warhammer 40k#Thousand Sons#Scarab Occult Terminator#forgive a young nerd's rambling

15 notes

·

View notes

Text

Expert mechanical design engineering company offering services such as 3D moulding products design, plastic mould design, 2D drafting DFM for mould manufacturing CNC programming for machines

Thiram is capable of providing product development and design. Our three decades of experience in the engineering field have helped us develop unmatched expertise in the market. Our strong material technology has helped us serve time and distance for the customers.

2 notes

·

View notes

Text

Join Us at IMTEX 2025 in Bangalore!

We're thrilled to invite you to experience innovation in industrial automation at IMTEX 2025 in Bangalore! Visit Dynemech's booth at the Bangalore International Exhibition Centre to discover our cutting-edge vibration control solutions at this premier manufacturing technology expo and industrial trade show.

As pioneers in indigenous manufacturing and exporters of vibration damping solutions, we will be showcasing our latest innovations and trends in vibration control for plastics processing machinery and equipment at this precision engineering event and automation solutions showcase.

Unparalleled Solutions for Vibration Damping

Dynemech brings forth state-of-the-art vibration damping solutions tailored for a diverse range of plastic machinery and machine tools. Whether it's blow moulding machines, extruders & extrusion lines, or injection moulding machines, we've got you covered through our exhaustive range of precision levelling mounts, Level Grip Mounts, Screw Support Circular Mounts, High Adjustment and Alignment Mounts, Viscous Damped Spring Isolators, and many more antivibration mounting systems.

Experience the Dynemech Advantage

With our advanced Dynemech Antivibration Technology and extensive expertise, we offer unmatched vibration reduction and isolation solutions. Our products are meticulously researched, designed, tested, and manufactured to elevate the performance and efficiency of your plastic machinery while matching the lifespan and minimizing maintenance costs. Our cutting-edge technology ensures superior machine stability and reduced maintenance requirements.

Quality You Can Rely On

At Dynemech (an ISO 9001 company), we take pride in delivering high-quality antivibration solutions that meet worldwide industry standards. Our commitment to industrial innovation drives us to continually improve our products, resulting in significant efficiency gains for our clients.

We extend a warm invitation to explore our stall and delve deeper into our comprehensive range of antivibration products and services, showcasing the latest in smart vibration control technology.

Event Details:

Date: January 23-29, 2025

Venue: Hall 3A, Stall A128, Bangalore International Exhibition Centre

Duration: 7 Days of Innovation

Featured Products:

Experience our premium range of vibration control solutions and precision-engineered isolation solutions:

DFL Series Mount - Advanced Vibration Isolation Technology

Wedge Mount - Precision Engineering for Machine Tools

Membrane Air Spring - Superior Stability

Anti Vibration Table - Research-Grade Performance

VHS & VHS-LA Series - Industry-Leading Antivibration Solutions

Why Visit Us?

Live product demonstrations of our cutting-edge technology

Expert consultations on machine foundation solutions

Special exhibition offers

Networking opportunities with industry leaders

Don't miss this opportunity to transform your industrial automation solutions! Our technical experts will be available throughout the exhibition to discuss your specific requirements and showcase our precision manufacturing capabilities.

Book Your Meeting

Schedule a personalized consultation during the IMTEX exhibition. Contact us to reserve your slot!

To learn more about our products: https://www.vibrationmountsindia.com/products/

#PrecisionEngineering #PrecisionMeasuring #VibrationControl #AntiVibrationTable #Dynemech #AntiVibration #VibrationControl #PlasticMachinery #VibrationDamping #IMTEX2025 #IndustrialAutomation #Manufacturing #Innovation #DynemechSystems

📞 Contact Us: +91-9810760131; +91-9911145131 📧 Email: [email protected] 🌐 Explore Our Solutions: vibrationmountsindia.com | vibrationdampingpads.com

1 note

·

View note

Text

High-Quality Injection Moulding Machines for Prototypes and Mass Production

Quality is key when it comes to injection moulding machines. Our expert team ensures that all our moulding machines meet strict quality standards. Whether you're creating prototypes or scaling up for mass production, our plastic moulding solutions will meet your exact specifications. Let us help you find the right equipment for your business needs.

0 notes

Text

Plastic Parts Manufacturer

Durable Plastic Moulding Solutions

Modern Rubber and Plastic specializes in providing durable plastic molding solutions tailored to meet diverse industrial needs. With advanced manufacturing techniques and a commitment to precision, we deliver high-quality products that stand the test of time. Our expertise ensures that each molded part meets stringent quality standards, making them ideal for automotive, consumer goods, and industrial applications. Whether you need robust components for demanding environments or lightweight parts for specialized projects, our solutions combine reliability and cost-efficiency. Trust us for plastic molding that exceeds expectations in performance, durability, and functionality.

Plastic Injection Moulded Parts

Modern Rubber and Plastic offers premium plastic injection molded parts designed for a wide range of applications. Using state-of-the-art machinery and high-grade materials, we create components with exceptional accuracy and consistency. Our injection molding process ensures minimal waste and maximum efficiency, meeting the needs of industries such as electronics, automotive, and healthcare. From small, intricate parts to larger, complex assemblies, we deliver solutions tailored to your specific requirements. Experience the advantage of high-quality injection molded parts that enhance the performance and longevity of your products.

Versatile Plastic Parts

At Modern Rubber and Plastic, we manufacture versatile plastic parts that adapt to various industries and applications. Our innovative designs and advanced manufacturing processes ensure each product is durable, functional, and reliable. Whether for consumer goods, industrial equipment, or custom projects, our plastic parts are engineered to meet diverse demands. Our focus on versatility allows us to provide solutions for unique challenges while maintaining high-quality standards. Choose us for flexible and cost-effective plastic components that deliver unmatched performance in every application.

Custom Plastic Cases & Modules

Modern Rubber and Plastic specializes in crafting custom plastic cases and modules tailored to your specific needs. Our expert team works closely with clients to design and produce solutions that provide superior protection, functionality, and aesthetic appeal. Whether for electronics, medical devices, or industrial tools, our cases are engineered for precision and durability. With a focus on customization, we offer a range of sizes, colors, and features to meet your exact requirements. Trust us for innovative and high-quality plastic cases that enhance the value of your products.

Injection Moulded Plastic Parts

Modern Rubber and Plastic excels in producing top-notch injection-molded plastic parts for diverse industries. Our advanced injection molding technology ensures precision, durability, and efficiency in every product. Whether you require components for automotive, consumer electronics, or industrial machinery, our team delivers solutions that meet stringent quality standards. From prototyping to mass production, we provide seamless services tailored to your specifications. Partner with us for reliable injection-molded parts that enhance the performance and aesthetics of your products while ensuring long-term value.

Plastic Moulding Experts

As plastic molding experts, Modern Rubber and Plastic is your go-to partner for innovative and reliable solutions. With years of experience and a commitment to excellence, we deliver high-quality molded parts tailored to your industry’s unique requirements. Our state-of-the-art facilities and skilled professionals ensure precision, durability, and efficiency in every product we create. From concept to completion, we provide comprehensive support to meet your specific needs. Choose Modern Rubber and Plastic for expert plastic molding services that drive the success of your projects.

High-Quality Plastic Components

Modern Rubber and Plastic is dedicated to producing high-quality plastic components that exceed customer expectations. Our rigorous manufacturing processes and stringent quality controls ensure each component meets industry standards for durability, performance, and precision. Whether for automotive, healthcare, electronics, or other sectors, we offer components designed to perform under diverse conditions. Our commitment to quality and innovation makes us a trusted partner for businesses seeking reliable and cost-effective plastic solutions. Experience the difference with our expertly crafted plastic components.

Plastic Parts Manufacturer

Modern Rubber and Plastic is a leading plastic parts manufacturer committed to delivering exceptional quality and precision. With expertise in designing and producing versatile plastic components, we cater to a wide range of industries, including automotive, healthcare, electronics, and industrial applications. Our state-of-the-art facilities and advanced manufacturing processes ensure high durability, consistent performance, and cost-efficiency in every product. From custom designs to large-scale production, we provide tailored solutions that meet your specific needs. Trust Modern Rubber and Plastic for reliable and innovative plastic parts that enhance the performance and value of your products.

0 notes

Text

Step-by-Step Plastic Injection Moulding Process

Plastic injection moulding is a versatile manufacturing process widely used to create intricate and durable plastic components for various industries. At Topwell Moulding, we specialize in delivering high-quality injection moulding solutions to meet diverse production needs. This article delves into the step-by-step process of plastic injection moulding and highlights its significance in modern manufacturing.

1. Design and Prototyping

The process begins with designing the plastic part using advanced Computer-Aided Design (CAD) software. Once the design is finalized, a prototype is created to test functionality, fit, and aesthetics. This step ensures that the final product meets the required specifications.

Why it’s essential:

Prevents costly mistakes.

Ensures design feasibility and accuracy.

2. Mould Creation

A mould, typically made from hardened steel or aluminum, is crafted based on the product design. Precision is critical at this stage to achieve consistent results during production.

Key considerations:

Durability of the mould material.

Fine-tuning for seamless part release.

3. Material Selection

The appropriate plastic material, such as ABS, polypropylene, or nylon, is chosen based on the product’s requirements like strength, flexibility, and temperature resistance.

Popular materials:

Polyethylene (PE): Lightweight and durable.

Polycarbonate (PC): Strong and transparent.

4.PLASTIC INJECTION MOLDING Setup

The mould is mounted onto the injection moulding machine, and the plastic material is fed into the hopper. The machine melts the material and injects it into the mould cavity under high pressure.

Equipment involved:

Injection unit.

Clamping unit.

Cooling system.

5. Filling and Cooling

Molten plastic fills the mould cavity, conforming to its shape. Once the cavity is filled, the plastic cools and solidifies. The cooling time varies based on the material and part thickness.

Optimization tips:

Use precise temperature control for uniform cooling.

Minimize warping through proper mould design.

6. Ejection of the Part

Once cooled, the mould opens, and ejector pins push the finished part out. The part is inspected for defects like sink marks or flash.

Common issues to monitor:

Surface imperfections.

Dimensional accuracy.

7. Trimming and Finishing

Excess material (sprue, runners, or flash) is trimmed away, and finishing touches are applied to ensure the part meets aesthetic and functional requirements.

Finishing techniques:

Polishing.

Painting or coating.

8. Quality Control and Testing

Before mass production, the part undergoes rigorous quality checks to ensure it meets industry standards. Functional, dimensional, and durability tests are conducted.

Why Choose Topwell Moulding for Injection Moulding?

At Topwell Moulding, we combine cutting-edge technology, skilled craftsmanship, and years of experience to deliver top-tier plastic injection moulding solutions. From design to production, we ensure precision, quality, and efficiency at every step.

Our capabilities include:

Custom mould design.

High-volume production.

Expert guidance on material selection.

Whether you need prototypes or mass production, trust Topwell Moulding to bring your ideas to life. Visit www.topwellmoulding.com to explore our services and start your project today!

0 notes

Text

Carpet Cleaning in Beveridge for a Healthier Indoor Environment

Professional businesses working in the sector of carpet cleaning in Beveridge understand that sometimes emergency services are required and hence offer same-day services as well. Hot water method the most popular method in cleaning carpets is utilised for cleaning the carpets of all fine dust settlements along with tough stains. Professionals also after cleaning the carpets deodorize the carpets for a fresh smell and the carpets are dried properly for use.

Carpet hot water extraction is a highly effective method for deep cleaning carpets, and removing embedded dirt, allergens, and tough stains. Upholstery cleaning in Worongary is done using this process and it can remove the toughest of stains and also decrease bad odour significantly. This process involves injecting hot water and cleaning agents into the carpet, loosening grime, and extracting it using powerful suction. Professional experts have IICRC certification in water restoration damage and hence one can be assured of the quality of services.

If one tries to do such work by themselves then they may end up adding more water than required which can damage the carpet significantly and hence the seam might get damaged. Professionals use the best quality vacuum cleaners along with dehumidifiers and blowers to remove the water from the carpet to keep it dry. Moisture when present in locations like carpets attracts mould and hence one must keep the carpets dry.

Dust mites are a common allergen in carpets that generally give rise to respiratory issues and allergies. Professional service providers steam or dry clean carpets to remove dust mites and their allergens rather successfully. In these techniques, high-temperature water pierces deep into the carpet fibres, which guarantees their complete extraction. Such services target dust mites, thus upgrading indoor air quality for healthier living.

The removal of mould from carpets is vital for maintaining healthy and long-lasting ones. The growth of mould degrades the fibres of the carpet and is very hazardous to human health. Professional services adopt an advanced method for mould extraction. Anti-mould sprays and dehumidifiers are utilised by them to ensure the complete eradication of moulds, which indeed prevents future growth. Professionals generally go in accordance with global IICRC recommendations on safe remediation, not only accounting for visible mould growth but also its invisible spores.

Contact leading companies offering various services of carpet cleaning and more, to get in touch with them for a quick price quote.

Source

0 notes

Text

Comprehensive Damp Proofing Solutions to Protect Your Property | Universal Damp 💧🏡

Damp issues in homes and buildings are more than just an inconvenience—they can lead to significant damage if not addressed properly. Whether you are dealing with rising damp, condensation, or penetrating damp, these problems can compromise the structural integrity of your property, damage interior finishes, and create unhealthy living conditions. At Universal Damp, we specialise in providing comprehensive damp proofing services that are designed to effectively tackle these issues and protect your property from long-term damage.

Our team of experts is dedicated to delivering reliable, lasting solutions tailored to the specific needs of each property. With years of experience in the industry, we have the knowledge and expertise to assess and address any type of damp problem. We work with homeowners, property developers, landlords, and businesses across the UK, providing top-tier damp protection that keeps buildings dry and secure.

Understanding Damp and the Importance of Damp Proofing 💧🛠️

Damp is caused when moisture enters a building in ways that exceed the building’s ability to expel it. This can happen due to a variety of factors, including poor drainage, weather conditions, or structural issues. The most common types of damp in the UK include:

Rising Damp: Moisture rises through the walls of a building from the ground, often due to an inadequate or failed damp proof course (DPC).

Penetrating Damp: Water infiltrates from the outside, typically through cracks in the walls or roof, causing water to seep inside.

Condensation: Moisture in the air condenses on cold surfaces inside the property, leading to damp patches, mould growth, and mildew.

Damp not only affects the appearance and comfort of your home but also compromises the building’s structural integrity. If left untreated, it can cause timber to rot, plaster to crumble, and paint to peel. That’s why damp proofing is essential for maintaining a dry, safe, and healthy living environment.

Professional Damp Proofing Solutions for Every Property 🏠🔒

At Universal Damp, we offer a range of expert damp proofing services to address different types of damp problems. We understand that each property is unique, and therefore, we provide tailored solutions that are designed to target the root cause of the issue and deliver lasting results.

Rising Damp Treatment 🌿

Rising damp occurs when moisture from the ground rises through the walls via capillary action. It’s often seen in older buildings with a failed or missing damp proof course (DPC). Our team can provide effective damp proofing solutions by installing a new DPC or repairing existing ones. We use state-of-the-art injection systems that create a waterproof barrier in the walls, stopping moisture from rising and preventing damage to the building’s structure.

Penetrating Damp Prevention 🌧️

Penetrating damp happens when water infiltrates the external walls, usually through cracks, damaged brickwork, or faulty gutters. This type of damp is often more common in older homes where external maintenance may be lacking. To protect your property, we offer waterproof coatings, sealants, and cavity wall treatments that provide a long-term barrier against water ingress. Our experts carry out a full inspection of your external walls and roof to identify potential problem areas and recommend the best solution to prevent water from penetrating.

Condensation Control 💨

Condensation is a common problem in homes, particularly during the colder months. It occurs when warm, moist air comes into contact with cold surfaces, such as windows, walls, and ceilings. Over time, this can lead to mould growth and damage to wallpaper, paint, and timber. Our damp proofing services for condensation control include improving ventilation through the installation of extract fans, air bricks, or specialist dehumidifiers. We can also advise on how to manage humidity levels within the property, helping to prevent future condensation issues.

Basement Waterproofing & Tanking 🔒

Basements and cellars are particularly prone to damp due to their location below ground level. This makes them vulnerable to water ingress from the surrounding soil. Universal Damp offers specialist basement waterproofing services, including tanking systems, sump pumps, and drainage solutions, to protect your basement from flooding and moisture build-up. Our tanking systems create a watertight barrier that prevents moisture from seeping into your basement, allowing you to use the space with confidence.

Why Choose Universal Damp for Your Damp Proofing Needs? 🌟

Choosing the right company for damp proofing is crucial to ensuring that your property remains safe and dry. At Universal Damp, we are committed to providing high-quality solutions and exceptional service. Here’s why our clients trust us:

Expert Knowledge and Experience: With years of experience in the damp proofing industry, our team has the skills and expertise to handle even the most complex damp issues. We stay up to date with the latest techniques and best practices to ensure the best results for our clients.

Tailored Solutions: We don’t believe in one-size-fits-all solutions. Each property is unique, and we take the time to assess your specific damp problem, creating a tailored treatment plan that addresses the issue at its core.

Long-Lasting Results: Our focus is on delivering permanent solutions that prevent future damp problems from occurring. We use only high-quality materials and the most effective techniques to ensure that your property remains dry and protected for years to come.

Transparent Pricing and No Hidden Fees: We believe in honesty and transparency. Our pricing is clear and competitive, and we will provide you with a detailed breakdown of costs before any work begins.

Customer Satisfaction: Our commitment to customer satisfaction is at the heart of everything we do. We provide clear communication throughout the entire process, ensuring that you are fully informed every step of the way.

Get in Touch for Professional Damp Proofing Services 📞🔑

Don’t let damp issues affect the safety and comfort of your home or business. If you’re experiencing any type of damp, contact Universal Damp today for a professional consultation. Our team will assess the condition of your property, identify the source of the problem, and provide a detailed plan for damp proofing and moisture prevention. By choosing Universal Damp, you can trust that you are investing in high-quality, long-lasting solutions that will protect your property from the damaging effects of damp for years to come.

1 note

·

View note

Text

Achieve perfect precision with our plastic measuring cup molds! Designed for accuracy, durability, and fast production, our custom molds ensure every cup is molded to perfection—whether for kitchen use or industrial applications. Streamline your manufacturing process with our high-efficiency molds that deliver consistent, top-quality measuring cups every time. Email: [email protected]

#Measuring Cup Mould#Precision Moulding#Custom Mould Design#Kitchen Essentials Mould#Accurate Measurements#Efficient Production#Injection Molding Experts#Durable Moulds#Food Grade Moulds#High Volume Molding#injection mould#factory#manufacturer#china

0 notes

Text

Top Seepage Experts in Delhi: Protect Your Home from Water Damage

Water seepage is a massive stress on your home's structural integrity. Track Seal Waterproofing is the best seepage expert in Delhi because we offer solutions to help manage water damage. Seepage issues can get out of hand if proper steps are not taken in time, whether from the terrace or through walls. Read on, as in this blog, we shed some light on the ideal answers to initiate fixing water leakage and even how Track Seal Waterproofing will inevitably protect your property.

Solution for Water Seepage from Terrace

Terrace water seepage is common and usually happens in the rainy season for most homeowners. If you're looking to install a metal roof system around any body of water, be aware that constant submersion in water can lead to cracking and even weaken the structural integrity. Track Seal Waterproofing is one of the top seepage experts in Delhi, providing specialized treatments to eliminate this problem. We use high quality waterproofing material that acts as a barrier, removing penetration of water from the terrace and longevity. Our unique solution includes prepping the surface, filling cracks and applying a waterproof coating over areas subject to harsh weather.

2. Effective Solution for Water Seepage in Walls

Dripping walls cause damp patches, which cause paint to peel off and mould to affect your home's appearance and human health. Track Seal Waterproofing offers a multi-layered treatment solution for water seepage in walls and resolves the problem from its roots. We locate cracks or weak spots on the external/internal wall surfaces and apply suitable sealants when necessary. Water will not be able to penetrate through the walls, which leads to dry and more hygienic interior living.

3. Comprehensive Solution for Seepage in Wall

You may need to address these solutions on film with more chronic problems like rising dampness and water seeping through a foundation. Track Seal Waterproofing uses injection grouting techniques and waterproof coatings, the best solution for seepage in the wall. These approaches ensure moisture does not come into the space to cause more leaks in the future. WeWork works very delicately to inspect all affected areas and design a specific solution that repairs not only current symptoms but also avoids future fear.

Conclusion

Professionals are usually required to help protect your house from damage resulting due to water. Track Seal Waterproofing is the best dampness solutions service provider in Delhi, which provide a unique solution of all type water and seepage problems like Damp wall treatment & leakage for any walls, terraces. Whether you need a stop gap arrangement against the water which is seeping from terrace or you are losing sleep over wall dampness, we offer proven results to keep the house safe & dry with minimal damage on long term basis. We would be happy to help you protect your investment with the best waterproofing options in Toronto.

#Seepage experts Delhi#Waterproofing services Delhi#Best seepage solutions#Foundation waterproofing#Wall seepage treatmen#Residential waterproofing Delhi

0 notes

Text

How to Improve the Quality of Plastic Injection Molds?

Do you want to make high-quality plastic parts with injection molding? Curious about how mold quality impacts the final product? What can you do to ensure your molds give the best results? Let's check out the factors to improve the quality of your plastic injection molds.

Plastic injection moulding is a key method used to manufacture everything from little plastic parts to significant components. High-quality moulds are important for achieving the greatest outcomes. The quality of the mould has a direct influence on the finished product, from its appearance to its strength and durability. Here are some practical methods you may take to boost the quality of plastic injection moulds.

1. Choose the Right Material

The quality of your mould begins with the material you employ to create it. The mould material should be strong and resistant to damage, especially if you're making a big number of pieces. Hardened steel, stainless steel, and aluminium are examples of commonly used materials. Steel is more costly, but it has more durability and can generate higher-quality parts over time.

2. Design with Precision

A well-designed mould is necessary to deliver high-quality results. Pay particular attention to design elements like wall thickness, cooling channels, and draft angles. Proper design ensures that the plastic flows smoothly throughout the mould, lowering the possibility of flaws such as warping or partial filling. Use modern CAD (Computer-Aided Design) equipment to generate accurate and detailed designs.

3. Use High-Quality Injection Machines

The quality of the injection moulding machine has an important impact on the overall quality of the mould. Ensure that your machines are properly maintained and calibrated. Machines with upgraded controls can deliver more constant pressure and temperature, which are critical for making high-quality moulds.

4. Implement Rigorous Quality Control

Quality control is essential at every stage of the injection molding process. Regularly inspect molds for wear and tear and check the finished products for any defects. Using tools like Coordinate Measuring Machines (CMM) can help in accurately measuring parts and ensuring they meet specifications.

5.Optimize the Cooling Process

Cooling is a critical phase in injection molding that affects the quality of the final product. Uneven or inadequate cooling can lead to defects such as warping or shrinkage. To optimize cooling, ensure that the cooling channels in the mold are well-designed and that the coolant flows efficiently throughout the mold. Using conformal cooling techniques, where cooling channels are designed to follow the shape of the part, can further enhance the cooling efficiency.

6. Use Proper Mold Maintenance

Regular maintenance of molds is key to extending their life and ensuring consistent quality. Clean the mold regularly to remove any residues or buildup. Also, inspect the mold components like ejector pins and slides to ensure they are functioning properly. Lubricate moving parts to prevent wear and replace any worn-out components promptly.

7. Control Injection Parameters

The parameters used during the injection process, such as temperature, pressure, and injection speed, significantly affect the quality of the molded parts. Fine-tuning these parameters can help reduce defects and improve overall product quality. Consider conducting trials to determine the optimal settings for your specific mold and material.

To improve the quality of plastic injection molds, use the right materials, design them accurately, use good machines, and maintain strict quality control. Regular maintenance and having skilled workers also help in making high-quality molds. By paying attention to these factors, you can produce parts that meet or exceed your quality expectations.

If you would like to discuss your requisites with one of our experts. You can submit you files here and our team will contact you as soon as possible.

0 notes

Text

Enhancing Production Efficiency of Plastic Industrial Tray Moulds Strategies and Innovations

In the realm of manufacturing, the Plastic Industrial Tray Mould stands as a critical component in the production of a wide array of plastic trays used across various industries. These molds are essential for creating durable, cost-effective, and uniform products that meet the demands of the market. However, the efficiency of these molds can significantly impact the overall production process. This article explores various strategies and innovations aimed at enhancing the production efficiency of Plastic Industrial Tray Moulds.

It is imperative to understand the factors that contribute to the efficiency of Plastic Industrial Tray Moulds. These include the quality of the mold material, the design of the mold, the maintenance routine, and the technology used in the molding process. By addressing these factors, manufacturers can optimize their production lines and reduce downtime.

The material of the Plastic Industrial Tray Mould plays a pivotal role in its durability and efficiency. High-quality steel, such as P20 or H13, is often used due to its good wear resistance and heat resistance. Investing in good materials can cause longer mold life, reducing the need for frequent replacements and reducing production interruptions.

The design of the Plastic Industrial Tray Mould is another critical aspect. A well-designed mold will have fewer parts, which simplifies the assembly and disassembly process, thus reducing the time required for maintenance and cleaning. Additionally, the design should facilitate easy ejection of the finished product, reducing the risk of product damage and reducing the time spent on post-molding operations.

Maintenance is a crucial yet often overlooked aspect of enhancing the efficiency of Plastic Industrial Tray Moulds. Regular cleaning and inspection can prevent the build-up of residue, which can cause poor product quality and reduced mold life. Implementing a preventive maintenance schedule can help identify and address potential issues before they escalate, thus avoiding costly production delays.

Technology plays a significant role in improving the efficiency of Plastic Industrial Tray Moulds. The use of computer-aided design (CAD) and computer-aided manufacturing (CAM) can streamline the design and production process, reducing errors and improving the accuracy of the mold. Furthermore, the integration of automation and robotics can increase the speed of the molding process, causing higher output and reduced labor costs.

Another strategy to enhance the production efficiency of Plastic Industrial Tray Moulds is to optimize the injection molding process itself. This can be achieved by fine-tuning the injection parameters such as temperature, pressure, and speed. Each of these parameters can significantly impact the quality of the final product and the cycle time of the molding process.

In addition to the above strategies, continuous improvement, and innovation are key to enhancing the production efficiency of Plastic Industrial Tray Moulds. This can involve researching and implementing new materials, exploring advanced cooling techniques to reduce cycle times, and staying abreast of trends in mold design and technology.

Collaboration with suppliers and industry experts can also provide valuable insights into practices and emerging technologies that can be leveraged to improve the efficiency of Plastic Industrial Tray Moulds. Sharing knowledge and experiences can cause the development of more effective strategies and the adoption of innovative solutions.

Lastly, training and education of the workforce are essential. Employees who are well-versed in techniques and technologies will be better equipped to operate the machinery efficiently and troubleshoot any issues that may arise. Investing in the professional development of the team can produce a more skilled and efficient workforce.

In conclusion, enhancing the production efficiency of Plastic Industrial Tray Moulds is a multifaceted endeavor that requires a combination of high-quality materials, innovative design, diligent maintenance, advanced technology, process optimization, continuous improvement, collaboration, and workforce development. By focusing on these areas, manufacturers can ensure that their Plastic Industrial Tray Moulds operate efficiently, causing increased productivity and a competitive edge in the market.

0 notes

Text

AI and Tech Startups to Get £100m Investment Injection with Scott Dylan launching NexaTech Ventures

AI technology start-ups have been given a huge boost with the launch of a brand new £100 million fund to transform the growth of the industry. British entrepreneur and investor Scott Dylan has launched the new venture capital firm NexaTech Ventures to help rising stars in the AI and tech industry to access the funds and business support they need to grow and succeed.

Scott Dylan created NexaTech Ventures to shake up the world of AI and Tech Startup investment. Not only is the firm offering promising AI entrepreneurs the funding to help grow their businesses, NexaTech Ventures will provide strategic guidance, mentorship and hands-on support to help them succeed in the long term.

Scott said: “It is all well and good throwing money at talented people, but if they don’t get strategic business support then they will struggle to scale their businesses successfully.

“NexaTech Ventures aims to rip up the old venture capital playbook. We will be investing in every aspect of the businesses we work with to create long term, stable and solid companies.

“AI is a huge part of our world right now and it is growing at a rapid rate. Investing in AI start-ups just makes so much sense to me. We want to help to mould, nurture and grow this sector to help businesses benefit from AI positively,” he said.

The fund is designed to help innovators in the healthcare, finance, logistics and creative industries with funding, mentorship and strategic support.

NexaTech Ventures will be offering AI tech inventors the chance to garner advice from industry leaders and meet potential partners and future customers. They will have access to expert mentorship as they navigate the challenges of growing and scaling the business. The team will also be offering strategic scaling support, so the companies can grow without losing their innovative edge.

NexaTech Ventures will be focusing on the high impact industries — healthcare, finance, logistics and creative, including digital media, film and music.

In healthcare, AI is helping to revolutionise patient care and advance medical research. In the finance sector, AI has been redefining areas such as fraud detection, personalised banking, and investment strategies. Logistics companies can use AI to optimise their systems and enhance operational efficiency. AI can help the digital media, film and music industries to reach audiences in novel ways and take artistic expression to the next level.

A New Approach to Venture Capital

Scott Dylan has shaken up the world of venture capital with the launch of his new firm NexaTech Ventures. By combining significant financial resources with industry expertise and a hands-on approach to support and mentorship, NexaTech Ventures will drive the growth of the next phase of technological innovation.

0 notes