#Injection Molding Machine Market 2022

Explore tagged Tumblr posts

Text

Injection Molding Machine Market Segmented On The Basis Of Material, Technology, End-Use, Region And Forecast 2030: Grand View Research Inc.

San Francisco, 28 Feb 2023: The Report Injection Molding Machine Market Size, Share & Trends Analysis Report By Material (Plastic, Metal), By Technology (Hydraulic, Electric, Hybrid), By End Use, By Region, And Segment Forecasts, 2022 – 2030 The global injection molding machine market size is expected to reach USD 22.03 billion by 2030, according to a new report by Grand View Research, Inc. It…

View On WordPress

#Injection Molding Machine Industry#Injection Molding Machine Market#Injection Molding Machine Market 2022#Injection Molding Machine Market 2030#Injection Molding Machine Market Revenue#Injection Molding Machine Market Share#Injection Molding Machine Market Size

0 notes

Text

0 notes

Text

Global Plastic Injection Molding Machine Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2030

An Injection molding machine, also known as an injection press, is a machine for manufacturing plastic products by the injection molding process. It consists of two main parts, an injection unit and a clamping unit. Machines are classified primarily by the type of driving systems: hydraulic, electric, or hybrid. Instead of being driven by a hydraulic system, all-electric machines use digitally controlled, high speed and highly efficient servo motors to drive the whole process. Each axis is controlled by an independent motor for injection, extruder, clamping and ejection. According to our (Global Info Research) latest study, the global Plastic Injection Molding Machine market size was valued at USD 10370 million in 2022 and is forecast to a readjusted size of USD 12560 million by 2030 with a CAGR of 2.8% during review period. The influence of COVID-19 and the Russia-Ukraine War were considered while estimating market sizes. From the analysis of product segment, small and medium-sized models (clamping force ≤ 650 tons) occupy more than 90% of the market. Injection molding machines are mainly used in general plastics industry, automotive industry and home appliance industry. Haitian International, ENGEL Holding GmbH, ARBURG GmbH, Sumitomo Heavy Industries, Milacron, Wittmann Battenfeld, Fanuc, Toshiba, Nissei Plastic, Husky, JSW Plastics Machinery, Toyo, Chenhsong, Yizumi, LK Technology, Cosmos Machinery, Tederic, UBE Machinery and Windsor are the key manufacturters of Plastic Injection Molding Machine. This report is a detailed and comprehensive analysis for global Plastic Injection Molding Machine market. Both quantitative and qualitative analyses are presented by manufacturers, by region & country, by Clamping Force and by Application. As the market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of selected competitors, along with market share estimates of some of the selected leaders for the year 2023, are provided.

Sample Request: https://www.reportsintellect.com/sample-request/2911740 Key Features Global Plastic Injection Molding Machine market size and forecasts, in consumption value ($ Million), sales quantity (Units), and average selling prices (USD/Unit), 2019-2030 Global Plastic Injection Molding Machine market size and forecasts by region and country, in consumption value ($ Million), sales quantity (Units), and average selling prices (USD/Unit), 2018-2029 Global Plastic Injection Molding Machine market size and forecasts, by Clamping Force and by Application, in consumption value ($ Million), sales quantity (Units), and average selling prices (USD/Unit), 2019-2030 Global Plastic Injection Molding Machine market shares of main players, shipments in revenue ($ Million), sales quantity (Units), and ASP (USD/Unit), 2019-2030

Inquire Request: https://www.reportsintellect.com/discount-request/2911740 The Primary Objectives in This Report Are: To determine the size of the total market opportunity of global and key countries To assess the growth potential for Plastic Injection Molding Machine To forecast future growth in each product and end-use market To assess competitive factors affecting the marketplace This report profiles key players in the global Plastic Injection Molding Machine market based on the following parameters - company overview, production, value, price, gross margin, product portfolio, geographical presence, and key developments. Key companies covered as a part of this study include Haitian International, ENGEL Holding GmbH, ARBURG GmbH, Sumitomo Heavy Industries and Milacron, etc. This report also provides key insights about market drivers, restraints, opportunities, new product launches or approvals, COVID-19 and Russia-Ukraine War Influence. Market Segmentation Plastic Injection Molding Machine market is split by Clamping Force and by Application. For the period 2018-2029, the growth among segments provides accurate calculations and forecasts for consumption value by Clamping Force, and by Application in terms of volume and value. This analysis can help you expand your business by targeting qualified niche markets. Market segment by Clamping Force Below 250T 250-650T Above 650T Market segment by Application Automotive Home Appliance General Plastic Others Major players covered Haitian International ENGEL Holding GmbH ARBURG GmbH Sumitomo Heavy Industries Milacron Wittmann Battenfeld Fanuc Toshiba Nissei Plastic Husky JSW Plastics Machinery Toyo Chenhsong Yizumi LK Technology Cosmos Machinery Tederic UBE Machinery Windsor Market segment by region, regional analysis covers North America (United States, Canada and Mexico) Europe (Germany, France, United Kingdom, Russia, Italy, and Rest of Europe) Asia-Pacific (China, Japan, Korea, India, Southeast Asia, and Australia) South America (Brazil, Argentina, Colombia, and Rest of South America) Middle East & Africa (Saudi Arabia, UAE, Egypt, South Africa, and Rest of Middle East & Africa)

0 notes

Text

According to Straits Research, the global injection molding machines market size was valued at USD 10724 Million in 2021. It is projected to reach from USD XX Million in 2022 to USD 16964 Million by 2030, growing at a CAGR of 5.9% during the forecast period (2022–2030).

#Injection Molding Machines Market Size#Injection Molding Machines Market Share#Injection Molding Machines Market Growth#Injection Molding Machines Market Trends#Injection Molding Machines Market Players

0 notes

Text

ALPLA strengthens injection molding with new ALPLAinject division

The global ALPLA Group is setting the course for further growth in injection molding by establishing the ALPLAinject division. By concentrating all injection molding expertise and capacity under this brand, the plastic packaging specialist is increasing efficiency, speeding up the market launch of new products, and unlocking new market segments.

ALPLAinject stands for high-quality injection-molded parts such as closures, caps, jars, and multi-part packaging components such as pumps or deodorant sticks. With this new division, the international ALPLA Group is setting the course for further growth. The ALPLAinject brand brings together all human and technical resources in this area in one central organizational structure. It comprises a total of three core technologies – injection blow molding and compression molding in addition to injection molding – as well as global toolmaking, development, and sales.

Standardized processes, centralized product, and technology development; and shorter distances will ensure greater flexibility and efficiency in the future. "With ALPLAinject, we are focusing on the specific requirements of the dynamic injection molding market. We combine technological expertise and regional market knowledge, promote the global roll-out of innovative processes, and enable our customers to bring new products to market faster," emphasizes the new ALPLAinject managing director Michael Feltes, who had already been Business development director in the injection molding section of the Group since October 2022. The global headquarters of ALPLAinject are located at the ALPLA headquarters in Hard. There are also global teams in all nine regions of the ALPLA Group.

Injection molding drives growth

ALPLAinject manufactures roughly 60 billion injection-molded parts per year at 43 plants around the world. The division has more than 600 machines and systems. As a pioneer in packaging solutions and recycling, ALPLA also relies on technological innovation. ALPLAinject scores highly with its decades of experience in lightweight, alternative, and recyclable materials; and energy-saving production facilities.

‘The injection molding sector offers enormous potential and is one of our strategic growth drivers. The competitive market environment requires maximum cost-effectiveness and flexibility. As its injection molding division, ALPLAinject will continue to ensure our competitiveness in the future,’ says ALPLA CEO Philipp Lehner with conviction. The new division reports directly to the CEO.

0 notes

Text

Asia-Pacific Leads, Rest of the World Grows: Insights into the Injection Molding Machine Market

Introduction

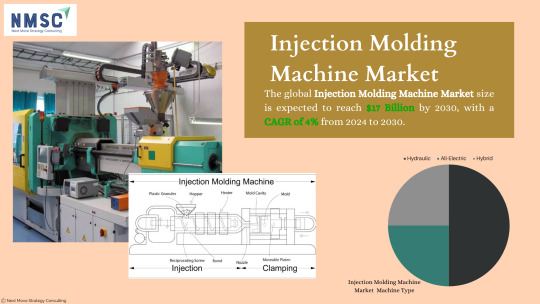

The injection molding machine market is a critical segment within the broader manufacturing industry, facilitating the production of a wide range of plastic products across various sectors. As per a study by Next Move Strategy Consulting, the global Injection Molding Machine Market is anticipated to reach a value of USD 17.22 billion by 2030, with a compound annual growth rate (CAGR) of 3.7%. This article aims to delve deeper into the dynamics of this market, with a particular focus on the contrasting trends observed in the Asia-Pacific region and the rest of the world (ROW).

Request for a sample PDF report: https://www.nextmsc.com/injection-molding-machine-market/request-sample

Asia-Pacific's Dominance in the Market

Asia-Pacific stands out as the undisputed leader in the injection molding machine market, boasting the largest market share globally. In 2022, the region commanded a market value of USD 7.12 billion, a testament to its robust manufacturing ecosystem and strategic initiatives undertaken by key players.

One of the primary factors driving Asia-Pacific's dominance is the expansion of manufacturing facilities by regional giants. For instance, Sumitomo (SHI) Demag China's announcement in February 2023 regarding the construction of a new 43,000 square-feet facility to double injection molding machine production in China underscores the commitment to meet escalating demand effectively.

Moreover, the automotive industry's expansion and diversification in the region further fuel the demand for injection molding solutions. Japan, with its reputation for automotive innovation and quality, serves as a prime example. As the world's third-largest automotive producer, Japan operates 78 factories across 22 prefectures, employing over 5.5 million individuals. This thriving automotive sector creates a sustained demand for high-quality injection molding machines, propelling market growth in the region.

Partnerships and collaborations also play a crucial role in driving the Asia-Pacific injection molding machine industry forward. SOLIZE India Technologies' partnership with Toray Engineering D Solutions in December 2022 to supply 3D injection molding machines for the Indian market exemplifies the collaborative efforts aimed at meeting regional demands efficiently.

ROW Market: Steady Growth Amidst Challenges

While Asia-Pacific leads the injection molding machine market, the rest of the world (ROW) presents a different landscape characterized by steady growth and unique challenges. Despite not matching the dominance of Asia-Pacific, ROW exhibits promising growth prospects driven by governmental initiatives and evolving manufacturing landscapes.

In September 2022, Argentina's government enacted tax and regulatory benefits for the automotive industry, offering incentives for investments in machinery and infrastructure. These initiatives aim to boost exports and attract investments, thereby driving demand for advanced machinery including injection molding machines.

Similarly, the United Arab Emirates (UAE) has emerged as a key player in various industries, including automotive, electronics, packaging, and consumer goods. The UAE's emphasis on industrial transformation towards smart manufacturing, as demonstrated by the Smart Manufacturing Incentive Program launched by the Abu Dhabi Department of Economic Development in June 2023, creates a conducive environment for the adoption of advanced injection molding solutions.

While ROW showcases steady growth, challenges such as regulatory complexities and geopolitical uncertainties persist. However, concerted efforts by governments and industry stakeholders are expected to mitigate these challenges and foster a conducive environment for market growth.

Inquire before buying: https://www.nextmsc.com/active-seat-belt-system-market/inquire-before-buying

Emerging Trends and Opportunities

In addition to regional dynamics, several emerging trends and opportunities are shaping the global injection molding machine market.

Customization and Personalization: Consumer preferences are increasingly favoring personalized products tailored to individual needs and tastes. Injection molding machines equipped with advanced software and automation capabilities enable manufacturers to efficiently produce customized components and products, catering to niche markets and enhancing customer satisfaction.

Medical and Healthcare Applications: The healthcare sector presents lucrative opportunities for the injection molding machine market, driven by the growing demand for medical devices, pharmaceutical packaging, and diagnostic equipment. With stringent quality standards and regulatory requirements, manufacturers are investing in state-of-the-art injection molding technologies to ensure precision, reliability, and compliance with medical industry standards.

Circular Economy Initiatives: Sustainability is a pressing concern for industries worldwide, prompting a shift towards circular economy models that prioritize resource efficiency, waste reduction, and recycling. Injection molding machines capable of processing recycled materials and biodegradable polymers are in high demand, aligning with corporate sustainability goals and regulatory mandates aimed at reducing environmental impact.

Industry 4.0 Integration: The integration of Industry 4.0 technologies, such as Internet of Things (IoT) sensors, data analytics, and predictive maintenance, is revolutionizing the injection molding process. Smart injection molding machines equipped with real-time monitoring and predictive analytics capabilities enable proactive maintenance, minimize downtime, and optimize production efficiency, thereby enhancing overall operational performance and competitiveness.

Reshoring and Nearshoring Trends: The ongoing geopolitical uncertainties and supply chain disruptions have prompted many manufacturers to reassess their sourcing strategies and consider reshoring or nearshoring production closer to their primary markets. This trend presents opportunities for injection molding machine suppliers to partner with local manufacturers and provide on-demand production solutions tailored to regional requirements, reducing lead times and transportation costs.

Advanced Materials Development: The injection molding machine market is witnessing a surge in demand for machines capable of processing advanced materials, including composites, bioplastics, and high-performance polymers. These materials offer superior mechanical properties, chemical resistance, and thermal stability, making them ideal for demanding applications in industries such as aerospace, automotive, and electronics. Injection molding machines equipped with specialized capabilities for handling these materials are poised to capitalize on this growing market segment.

Focus on Energy Efficiency: With increasing emphasis on sustainability and energy conservation, there is a growing demand for injection molding machines designed to minimize energy consumption and reduce carbon emissions. Manufacturers are investing in energy-efficient technologies such as servo-driven systems, variable frequency drives, and regenerative braking systems to optimize energy usage throughout the production process. Energy-efficient injection molding machines not only lower operational costs but also contribute to environmental preservation, aligning with corporate sustainability objectives and regulatory mandates.

Adoption of Hybrid and Electric Machines: The shift towards greener manufacturing practices and stricter emissions regulations is driving the adoption of hybrid and electric injection molding machines. These machines offer significant advantages over traditional hydraulic models, including higher energy efficiency, reduced noise levels, and lower maintenance requirements. As environmental awareness continues to grow, manufacturers are increasingly turning to hybrid and electric machines to enhance their sustainability credentials and gain a competitive edge in the market.

Digital Twin Technology: Digital twin technology is revolutionizing the injection molding process by enabling virtual simulations and predictive modeling of machine behavior. By creating digital replicas of physical injection molding machines, manufacturers can optimize process parameters, identify potential issues, and test new configurations in a risk-free virtual environment. Digital twin technology enhances operational efficiency, reduces time-to-market, and enables data-driven decision-making, ultimately improving overall productivity and profitability.

Focus on Worker Safety and Ergonomics: As occupational health and safety regulations become more stringent, there is a growing emphasis on designing injection molding machines with enhanced safety features and ergonomic design principles. Manufacturers are integrating advanced safety systems such as light curtains, safety interlocks, and automated guarding to protect operators from hazards and minimize the risk of workplace injuries. Additionally, ergonomic enhancements such as adjustable controls, intuitive interfaces, and ergonomic workstations improve operator comfort and productivity, leading to a safer and more efficient working environment.

These emerging trends and developments underscore the dynamic nature of the injection molding machine market and highlight the opportunities for innovation and growth. By staying abreast of these trends and investing in cutting-edge technologies, manufacturers can position themselves for success in an increasingly competitive landscape

Conclusion

In conclusion, the injection molding machine market is undergoing significant transformation, driven by regional dynamics, emerging trends, and technological advancements. While Asia-Pacific maintains its dominance, the rest of the world presents promising growth opportunities amidst challenges.

Sustainable practices, technological innovations, and digitalization are shaping the future of the industry, offering manufacturers new avenues for growth and differentiation. As stakeholders navigate this evolving landscape, collaboration, innovation, and adaptability will be key to unlocking the full potential of the injection molding machine market.

Also Browse:

0 notes

Text

Acrylonitrile Butadiene Styrene Market Analysis 2023-2033

Global Acrylonitrile Butadiene Styrene Market Key Insights

During the forecast period of 2023~2033, the acrylonitrile butadiene styrene market is expected to reach an estimated value of ~USD 43 billion by the end of 2033 by expanding at a CAGR of ~6%. Further, the market generated a revenue of ~USD 27 Billion in the year 2022. The immense opportunity for the development of the sports sector is estimated to boost the market growth in the coming years.

Market Definition of Acrylonitrile Butadiene Styrene

Acrylonitrile butadiene styrene(ABS), with the chemical formula (C8H8)x, (C4H6)y, and (C3H3N)z, is a popular thermoplastic polymer. About 105 °C (221 °F) is the temperature at which it transitions to glass. Since ABS is amorphous, it possesses a proper melting point. Styrene and acrylonitrile are polymerized with polybutadiene to create ABS, a terpolymer. Additionally, injection molding frequently uses the thermoplastic polymer acrylonitrile butadiene styrene. Owing to its low production cost and simplicity of machining, this engineering plastic is one of the most widely used thermoplastic polymers. Along with these useful qualities, it also has good high- and low-temperature performance, chemical and impact resistance, structural strength, and stiffness.

Global Acrylonitrile Butadiene Styrene Market: Growth Drivers

The growth of the global acrylonitrile butadiene styrene market can majorly be attributed to the increasing usage of the product in the automobile, supported by the increasing investment by key market players in innovation and research and development. For instance, with the slogan “Designing Today for the Passengers of Tomorrow,” Covestro LLC began concentrating on the interior of cars at the VDI Congress on “Plastics in Automotive Engineering.” The company also unveiled three new polycarbonate mixes, including Bayblend T85 XAT, an antistatic and dust-free interior panel that can be used to meet a variety of requirements for usage in automobile interiors. On the other hand, the rising collaboration between major market players to increase product production and improve supply chains are estimated to boost market growth. For instance, in order to produce styrene monomer utilizing bio-based hydrocarbons (Neste RE) and its derivatives of mass balance renewable plastics, such as acrylonitrile butadiene styrene, or bio-ABS, CHIMEI Corporation worked with Mitsubishi Corporation to establish a renewable plastic supply chain.

The global acrylonitrile butadiene styrene market is also estimated to grow majorly on account of the following:

Rising demand in the medical industry

Growing construction sector

High use in apparatuses, auto ancillaries

Rising carbon dioxide emissions

Expanding automobile industry

Request Sample Copy of Report@ https://www.researchnester.com/sample-request-4517

Global Acrylonitrile Butadiene Styrene Market: Restraining Factor

There are various alternatives available for acrylonitrile butadiene styrene such as ASA copolymers. They are less preferred as their price highly fluctuates as compared to other alternatives. Hence this factor is expected to be the major hindrance for the growth of the global acrylonitrile butadiene styrene market during the forecast period.

Global Acrylonitrile Butadiene Styrene Market Segmentation

By Applications (Appliances, Electrical & Electronics, Automotive, Building & Construction, Consumer Goods, Sports Equipment, Musical Instruments, And Others)

Given the increasing demand for appliances including safety helmets, sports equipment, vacuum cleaners, cellphones, and cameras, the appliances segment is predicted to have the biggest market size by the end of 2033. In 2021, headgear sales on an international scale totaled USD 4,612,295.

By Region

The Latin Americaacrylonitrile butadiene styrene market is anticipated to hold the largest market share by the end of 2033 among the market in all the other regions. The growth of the market can be attributed to the rising production and demand for lightweight vehicles. For instance, the number of lightweight vehicles, such as battery electric vehicles, sold in Latin America increased from 1,000 in 2018 to 9,000 in 2020. Moreover, the increasing investment in manufacturing lightweight vehicles and the rising demand for vehicles across the globe are predicted to boost the market growth.

The market research report on global acrylonitrile butadiene styrene also includes the market size, market revenue, Y-o-Y growth, and key player analysis applicable for the market in North America (U.S., and Canada), Latin America (Brazil, Mexico, Argentina, Rest of Latin America), Asia-Pacific (China, India, Japan, South Korea, Singapore, Indonesia, Malaysia, Australia, New Zealand, Rest of Asia-Pacific), Europe (U.K., Germany, France, Italy, Spain, Hungary, Belgium, Netherlands & Luxembourg, NORDIC (Finland, Sweden, Norway, Denmark), Ireland, Switzerland, Austria, Poland, Turkey, Russia, Rest of Europe), and Middle East and Africa (Israel, GCC (Saudi Arabia, UAE, Bahrain, Kuwait, Qatar, Oman), North Africa, South Africa, Rest of Middle East and Africa).

Key Market Players Featured in the Global Acrylonitrile Butadiene StyreneMarket

Some of the key players of the global acrylonitrile butadiene styrene market areAmpa Plastics Group (Pty) Ltd, 3M, Convestro LLC, INEOS AG, SABIC, BASF SE, CHIMEI Corporation, Asahi Kasei Corporation, Kumho Petrochemical, Formosa Chemicals & Fibre Corp.,and others.

0 notes

Text

Polypropylene Injection Molding Market- Future Growth Prospects for the Global Leaders

The latest market report published by Credence Research, Inc. “Global Polypropylene Injection Molding Market: Growth, Future Prospects, and Competitive Analysis, 2016 – 2028. The global polypropylene injection molding market has witnessed steady growth in recent years and is expected to grow at a CAGR of 3.90% between 2023 and 2030. The market was valued at USD 105.8 billion in 2022 and is expected to reach USD 138.2911858 billion in 2030.

The Polypropylene Injection Molding Market refers to the industry segment dedicated to the manufacturing of plastic products and components using the injection molding process, specifically using polypropylene as the primary material. Polypropylene (PP) is a thermoplastic polymer widely used in various industries due to its favorable properties, including high impact strength, chemical resistance, low moisture absorption, and cost-effectiveness. Injection molding is a popular manufacturing method for creating a wide range of products, including automotive parts, packaging containers, consumer goods, medical devices, and more.

The Polypropylene Injection Molding Market encompasses businesses and manufacturers that utilize injection molding machines and molds to shape and form polypropylene material into desired products. This market may involve various stakeholders, such as raw material suppliers, mold makers, injection molding machine manufacturers, and the companies that actually produce the finished polypropylene injection-molded products.

Here are some of the key offerings within the polypropylene injection molding market:

Custom Injection Molding Services: Many companies in this market provide custom injection molding services, where they work closely with clients to design and manufacture plastic components tailored to specific requirements. This includes creating molds, selecting materials, and optimizing the injection molding process for cost-effective production.

Standard Plastic Components: Manufacturers often produce a wide range of standard plastic components using polypropylene injection molding. These may include items like caps, closures, containers, and various consumer and industrial products.

Automotive Parts: Polypropylene injection molding is commonly used in the automotive industry to produce a variety of parts, such as interior trim components, exterior body panels, engine components, and functional parts like brackets and clips.

Packaging Solutions: Polypropylene is a popular material for packaging applications due to its durability and versatility. The market offers a variety of packaging solutions, including bottles, containers, and packaging inserts for industries like food and beverage, pharmaceuticals, and cosmetics.

Some of the major players in the market and their market share are as follows:

ALPLA

Amcor PLC

AptarGroup Inc. (CSP Technologies)

BERICAP

Berry Global Inc.

EVCO Plastics

HTI Plastics

IAC Group

Magna International

Browse 247 pages report Polypropylene Injection Molding Market By Applications (Packaging, Building and Construction, Consumer Goods, Electronics, Automotive and Transportation, Healthcare, Other Applications) -Growth, Future Prospects & Competitive Analysis, 2016 – 2030 - https://www.credenceresearch.com/report/polypropylene-injection-molding-market

Key Segments

By Applications

Packaging

Building and Construction

Consumer Goods

Electronics

Automotive and Transportation

Healthcare

Other Applications

Here are some of the major challenges and risks associated with the polypropylene injection molding market:

Raw Material Price Volatility: The cost of polypropylene resin, the primary raw material used in injection molding, can be subject to fluctuations due to factors such as oil prices, supply and demand imbalances, and geopolitical events. This volatility can affect production costs and profit margins for injection molding companies.

Environmental Regulations: Increasing environmental regulations and consumer demand for sustainable products are putting pressure on injection molding companies to adopt more environmentally friendly practices. This may require investments in recycling and waste management systems, as well as the development of eco-friendly materials.

Competition: The polypropylene injection molding market is highly competitive, with numerous players vying for market share. This competition can lead to pricing pressures and the need for companies to differentiate themselves through innovation, quality, and customer service.

Quality Control: Maintaining consistent product quality is crucial in injection molding. Variations in temperature, pressure, and other factors can lead to defects in molded products. Companies must invest in quality control measures to minimize defects and ensure customer satisfaction.

Why to Buy This Report-

The report provides a qualitative as well as quantitative analysis of the global Polypropylene Injection Molding Market by segments, current trends, drivers, restraints, opportunities, challenges, and market dynamics with the historical period from 2016-2020, the base year- 2021, and the projection period 2022-2028.

The report includes information on the competitive landscape, such as how the market's top competitors operate at the global, regional, and country levels.

Major nations in each region with their import/export statistics

The global Polypropylene Injection Molding Market report also includes the analysis of the market at a global, regional, and country-level along with key market trends, major players analysis, market growth strategies, and key application areas.

Browse Complete Report- https://www.credenceresearch.com/report/polypropylene-injection-molding-market

Visit our Website- https://www.credenceresearch.com/

Related Reports- https://www.credenceresearch.com/report/water-based-barrier-coatings-market

https://www.credenceresearch.com/report/polymeric-asphalt-modifiers-market

Browse Our Blog- https://www.linkedin.com/pulse/polypropylene-injection-molding-market-size-worth-usd-vanshika-shukla

About Us -

Credence Research is a viable intelligence and market research platform that provides quantitative B2B research to more than 10,000 clients worldwide and is built on the Give principle. The company is a market research and consulting firm serving governments, non-legislative associations, non-profit organizations, and various organizations worldwide. We help our clients improve their execution in a lasting way and understand their most imperative objectives. For nearly a century, we’ve built a company well-prepared for this task.

Contact Us:

Office No 3 Second Floor, Abhilasha Bhawan, Pinto Park, Gwalior [M.P] 474005 India

0 notes

Text

Robot Operating System (ROS) Market Size, Share | Forecast to 2029

According to Precision Business Insights, the global Robot Operating System Ros Market is poised to grow at a significant CAGR of 9.4% from 2023-2029

The global Robot Operating System (ROS) Market size was valued at USD X billion in 2022 and is poised to grow at a significant CAGR of 9.4% during the forecast period 2023-29. It also includes market size and projection estimations for each of the five major regions from 2023 to 2029. The research report includes historical data, trending features, and market growth estimates for the future. Furthermore, the study includes a global and regional estimation and further split by nations and categories within each region. The research also includes factors and barriers to the Robot Operating System (ROS) Market growth, as well as their impact on the market's future growth. The report gives a comprehensive overview of both primary and secondary data.

View the detailed report description here - https://www.precisionbusinessinsights.com/market-reports/global-robot-operating-system-ros-market

The global Robot Operating System (ROS) Market segmentation:

1)ByRobot Type : SCARA Robots, Articulated Robots, Cartesian Robots, Parallel Robots and Collaborative Robots.

2)By Application : Plastic Injection and Blow Molding, Pick and Place, Testing and Quality Inspection, Metal Stamping and Press Trending, Co-Packing and End of Line Packaging, Computer Numerical Control Machine Tending and Printed Circuit Board Handling and Information Communication and Technology.

3) By End User : Electrical and Electronics, Automotive, Plastics, Rubber, and Chemicals, Food and Beverages, Healthcare, Metal and Machinery.

The primary factors of the Robot Operating System (ROS) Market drivers are the increasing demand for industrial automation among smes and large enterprises. The Robot Operating System (ROS) Market report helps to provide the best results for business enhancement and business growth. It further helps to obtain the reactions of consumers to a novel product or service. It becomes possible for business players to take action for changing perceptions. It uncovers and identifies potential issues of the customers. It becomes easy to obtain the reactions of the customers to a novel product or service. It also enlightens further advancement, so it suits its intended market.

The Robot Operating System (ROS) Market research report gives a comprehensive outlook across the region with special emphasis on key regions such as North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Asia Pacific was the largest region in the Robot Operating System (ROS) Market report, accounting for the highest share in 2022. It was followed by Asia Pacific, and then the other regions .Request sample report at -https://www.precisionbusinessinsights.com/request-sample/?product_id=37487

The important profiles and strategies adopted by Robot Operating System (ROS) Market key players are ABB, FANUC, KUKA AG, Yaskawa Electric Corporation, Denso, Microsoft, Omron, Universal Robots, Clear path Robotics, iRobot Corporation. covered here to help them in strengthening their place in the market.

About Precision Business Insights: We are a market research company that strives to provide the highest quality market research insights. Our diverse market research experts are enthusiastic about market research and therefore produce high-quality research reports. We have over 500 clients with whom we have a good business partnership and capacity to provide in-depth research analysis for more than 30 countries. In addition to deliver more than 150 custom solutions, we already have accounts with the top five medical device manufacturers.

Precision Business Insights offers a variety of cost-effective and customized research services to meet research requirements. We are a leading research service provider because of our extensive database built by our experts and the services we provide.

Contact:

Mr. Satya

Precision Business Insights| Toll Free: +1 866 598 1553

Email: [email protected] House, 152 – 160 City Road, London EC1V 2NXWeb: https://precisionbusinessinsights.com/| D U N S® Number: 852781747

#robot operating system ros market size#robot operating system ros market share#robot operating system ros market growth#robot operating system ros market trends#robot operating system ros market dynamics

0 notes

Text

Medical Injection Molding Machine Market Outlook On The Basis Of Product, System, Material, Region And Forecast to 2030: Grand View Research Inc.

San Francisco, 11 Sep 2023: The Report Medical Injection Molding Machine Market Size, Share & Trends Analysis Report By Product (Hydraulic, Electric, Hybrid), By Material (Plastics, Metal), By Region, And Segment Forecasts, 2022 – 2030 The global medical injection molding machine market size is anticipated to reach USD 2.61 billion by 2030, according to a new report by Grand View Research, Inc.…

View On WordPress

0 notes

Text

0 notes

Text

#Plastic Injection Molding Machine Market#Plastic Injection Molding Machine Market share#Plastic Injection Molding Machine Market size

0 notes

Text

0 notes

Text

0 notes

Text

Global Hydraulic Filter Market Outlook in Comparison to 2022-2032 Growth Forecast

The global hydraulic filter market is estimated at USD 2,124.3 Million in 2022 and is forecast to surpass USD 3,251.8 Million by 2032, growing at a CAGR of 4.3% from 2022 to 2032.

The hydraulic filters guard the hydraulic system from injury because of the particles or oil contamination. Approximately 1 million particles enter the compression system every moment and can affect hydraulic system parts. In order to increase the hydraulic component lifetime, the need to maintain good water filtration system is necessary as the adulteration of compression oil is easy. The effectiveness of the system is measured by its ability to remove impurities, removing particles and purifying the oil.

For More Insights into the Market, Request a Sample of This Report: https://www.factmr.com/connectus/sample?flag=S&rep_id=3477?SP

The readability score of the Hydraulic filter Market Demand report is good as it offers chapter-wise layout with each section divided into a smaller sections.

The report encompasses graphs and tables to show the entire assembling. Pictorial demonstration of the definite and estimated values of key segments is visually appealing to readers.

This Hydraulic filter market outlook report explicates on vital dynamics such as the drivers, restraints and opportunities for key players and competitive analysis of Hydraulic filter along with key stakeholders as well as emerging players associated with the manufacturing of product.

Competitive Landscape: Top Companies in Hydraulic Filter Market

The global hydraulic filter market is highly fragmented and competitive owing to the existence of many domestic and regional players. Various marketing strategies are adopted by key players such as mergers and acquisitions, expansions, collaborations and partnerships.

Also, new product development as a strategic approach is adopted by the leading companies to upscale their market presence among consumers. These strategies have resulted in the growth of hydraulic filter market.

Fact.MR has provided detailed information about price points of key manufacturers in hydraulic filter market positioned across regions, sales growth, production capacity, and speculative technological expansion in the recently published report.

For instance:

In January 2019, Eaton Corporation plc – a multinational power management company – announced that the Aftermarket division of its Vehicle Group’s has entered an agreement with Bezares SA – a leading manufacturer of pumps, motors, and hydraulic systems – to improve its presence in North America. The company also declared that the partnership with Bezares will enable the company to offer a comprehensive mobile power hydraulic portfolio, including hydraulic filters, to cater to the North American customers’ dynamic needs.

In March 2019, UFI Filters – an Italian manufacturer in the hydraulic filter market – announced that it has expanded its aftermarket base in the UK with the launch of a new warehouse and a dedicated office. The new distribution center features over 3,000 SKUs in its aftermarket catalogue. The company aims to benefit from its newly-appointed supply chain partner DB Schenker – a German logistics company – to gain momentum in highly fragmented Irish and UK Aftermarkets, in the coming years.

For In-Depth Competitive Analysis, Buy Now:

Global Hydraulic Filter Market by Category:

· By Product Type, Global Hydraulic Filter Market is segmented as:

Suction Filter

Pressure Filter

Return Line Filter

Off-line Filter

Breather Filter

Other Product Type

· By Technology Type, Global Hydraulic Filter Market is segmented as:

With Sensor

Without Sensor

· By End-Use Industry, Global Hydraulic Filter Market is segmented as:

Industrial

Steel

Machine Tools

Presses

Pulp and Paper

Power Generation

Plastic Injection Molding

Marine

Mobile

Construction

Agriculture

Mining

Forestry

Material Handling/Lifting

· By Distribution Channel, Global Hydraulic Filter Market is segmented as:

Original Equipment Manufacturer (OEM)

Aftermarket

· By Region, Global Hydraulic Filter Market is segmented as:

North America

Latin America

Europe

East Asia

South Asia & Oceania

MEA

How will be insights and market estimations provided in the report on the Demand of Hydraulic filter make a difference?

The study takes a closer look at the major economic turmoil, with a focus on the recent COVID-19 pandemic disruptions

The assessment of key growth dynamics highlights the attractiveness of new automation technologies and offers readers insight on the prospect of these during the forecast period

The study tries to offer a balance perspective of the opportunities in mature and the most lackluster markets

Provides scrutiny of the industry trends that have shaped recent government policies

Provides an account of major breakthroughs in all segments that might change the course of the market considerably

Provides an incisive analysis of socio-political milieu in which the key markets operate, and how will that influence the lucrativeness of the overall Hydraulic filter Market

Analyzes how collaborations and partnerships among players from different industries shape the key growth dynamics in the near future

Evaluates the role of various stages of funding on new growth avenues in key regional markets

Contact: US Sales Office: 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583 E-Mail: [email protected]

0 notes

Text

Polyether Ether Ketone (PEEK) Market Growth, Global Revenue Forecast, Company Share, and Competitive Landscape 2030

Polyether ether ketone (PEEK) is a high-performance thermoplastic material that is known for its excellent mechanical, thermal, and chemical properties. It belongs to a family of semi-crystalline polymers that exhibit high heat resistance, low flammability, excellent chemical resistance, and good electrical properties. PEEK is often used in the aerospace, automotive, medical, and industrial sectors due to its unique combination of properties.

PEEK can be processed by various methods, including injection molding, extrusion, and machining. It is often used to replace metal parts due to its high strength-to-weight ratio, and it is also used in applications where high temperature resistance is required. Additionally, PEEK is biocompatible, making it suitable for medical implants and devices.

PEEK is an expensive material compared to other thermoplastics, which limits its use in certain applications. However, its unique properties make it an ideal choice for demanding applications where other materials may not be suitable.

Global polyether ether ketone market was valued at US$ 634.9 Million in 2021, in terms of revenue, and is expected to exhibit a CAGR of 7.18% during the forecast period (2022 to 2030).

One of the major drivers for the growth of the PEEK market is its increasing use as a replacement for traditional materials such as metal and ceramics in various applications due to its superior properties such as high strength-to-weight ratio, high-temperature resistance, and excellent chemical resistance. Additionally, the increasing demand for lightweight and fuel-efficient vehicles in the automotive industry is expected to further boost the demand for PEEK.

Geographically, Asia-Pacific is expected to be the fastest-growing market for PEEK due to the increasing demand from emerging economies such as China and India, where the industrial and automotive sectors are rapidly growing. North America and Europe are also significant markets for PEEK, driven by the presence of established end-use industries and increasing demand for high-performance materials.

Major players operating in the global polyether ether ketone (PEEK) market include Zyex Ltd., Solvay S.A., Victrex plc, Panjin Zhongrun High Performance Polymers Co. Ltd., Caledonian Industries Ltd., Quadrant EPP Surlon India Ltd., Evonik Industries AG, and Jrlon Inc.

The polyether ether ketone (PEEK) market is expected to grow at a steady pace in the coming years, driven by increasing demand from various end-use industries and the development of new grades and applications of PEEK. Some of the factors that are expected to drive the growth of the PEEK market are:

Growing demand from the aerospace industry: PEEK is used extensively in the aerospace industry due to its high strength-to-weight ratio and excellent temperature resistance, making it an ideal material for components in aircraft engines and other critical applications.

Increasing use in the medical industry: PEEK is biocompatible and has excellent mechanical properties, making it an ideal material for medical implants and devices. The growing demand for minimally invasive surgical procedures is expected to drive the demand for PEEK in the medical industry.

High-performance applications in the automotive industry: PEEK is increasingly being used in high-performance automotive applications, such as lightweight components in electric and hybrid vehicles, to improve fuel efficiency and reduce emissions.

Development of new grades and applications: The development of new grades of PEEK and the introduction of new applications in various end-use industries are expected to drive the growth of the PEEK market. For example, the development of carbon fiber reinforced PEEK is expected to provide improved mechanical properties and open up new applications in the aerospace and automotive industries.

The demand for polyether ether ketone (PEEK) is expected to continue to grow in the coming years, driven by its unique combination of mechanical, thermal, and chemical properties that make it ideal for use in a wide range of end-use industries. Some of the factors that are expected to drive the demand for PEEK are:

Aerospace industry: The aerospace industry is a significant user of PEEK due to its high strength-to-weight ratio and excellent temperature resistance. PEEK is used extensively in aircraft engine components and other critical applications.

Medical industry: PEEK is biocompatible and has excellent mechanical properties, making it an ideal material for medical implants and devices. The demand for PEEK in the medical industry is expected to continue to grow as the trend towards minimally invasive surgical procedures and the use of medical implants and devices increases.

Automotive industry: The automotive industry is another major user of PEEK due to its high-performance properties. PEEK is increasingly being used in lightweight components in electric and hybrid vehicles to improve fuel efficiency and reduce emissions.

Industrial applications: PEEK is used in a wide range of industrial applications, including oil and gas, chemical processing, and electrical insulation. Its excellent chemical resistance and high-temperature resistance make it an ideal material for use in harsh environments.

Polyether ether ketone (PEEK) offers a number of benefits that make it an ideal material for various applications across different industries. Some of the key benefits of PEEK are:

High strength and stiffness: PEEK has excellent mechanical properties, including high strength and stiffness, making it ideal for high-performance applications in industries such as aerospace and automotive.

Excellent temperature resistance: PEEK has a high melting point and can withstand high temperatures, making it ideal for use in applications where exposure to high temperatures is a concern.

Chemical resistance: PEEK is resistant to a wide range of chemicals, including acids, bases, and organic solvents, making it suitable for use in harsh chemical environments.

Biocompatibility: PEEK is biocompatible and can be used in medical implants and devices, such as spinal implants and dental implants.

Lightweight: PEEK is a lightweight material, making it ideal for use in applications where weight is a concern, such as aerospace and automotive.

Durability: PEEK has excellent wear and abrasion resistance, making it ideal for use in applications where durability is a concern.

Overall, the unique combination of mechanical, thermal, and chemical properties of PEEK make it a versatile material that can be used in a wide range of applications across various industries, providing numerous benefits to end-users.

0 notes