#Industrialdesign

Explore tagged Tumblr posts

Photo

Anza Coffee

https://www.anzacoffee.com/products/anza-white_cf

156 notes

·

View notes

Text

#design#product#concept#furniture#diseño#industrialdesign#productdesign#designer#designideas#designinspiration

31 notes

·

View notes

Text

Chairs of Marcel Breuer: D40, CH66, B40

114 notes

·

View notes

Text

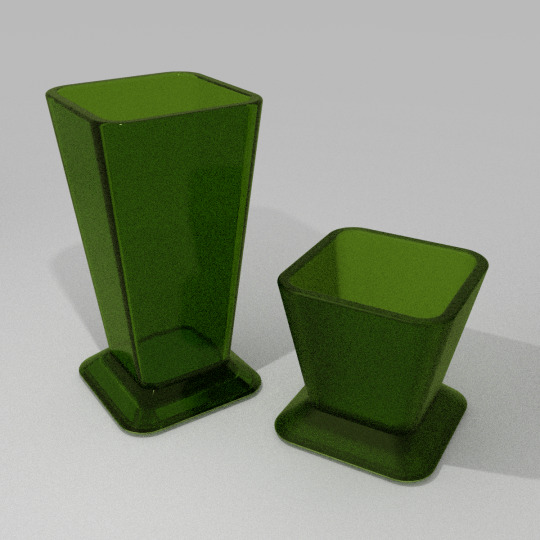

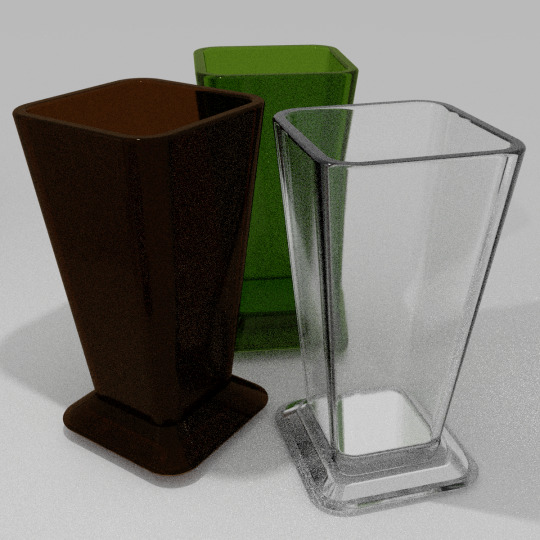

Tablife / differentiate your drinking image

#glasses#design#industrialdesign#angular#square#house#barware#cafeware#houseware#glass#longneck#shortneck#drinking#printable#colorglasses

7 notes

·

View notes

Text

Seffect / a rounded square cup to enjoy your coffee

#cup#coffee#alatable#coffeetable#cafebar#cafe#coffeeware#barware#servicing#waitering#industrialdesign#design#productdesign#ceramic#printable#espresso#greekcoffee#turkishcoffee#enjoymentfirst#sparetime#leisure#coffeeshop

6 notes

·

View notes

Text

Innovation Meets Construction – Building Beyond Limits

At Assure Projects, we believe that the future of industrial design lies in innovation and imagination. 🏗️✨ Every blueprint we craft and every structure we build pushes the boundaries of what's possible, merging creativity with expertise to redefine construction.

Our journey is one of bold visions, groundbreaking designs, and a relentless pursuit of excellence. From futuristic industrial spaces to innovative solutions, we’re not just building structures – we’re shaping the future. 🌟

Follow us to witness the blend of art and engineering in action, and let’s dream bigger together! 💡💪

#InnovationInConstruction#IndustrialDesign#AssureProjects#BuildingTheFuture#Construction#Architecture#DesignInnovation

2 notes

·

View notes

Text

Unleash the full potential of your business. Our expertise in product development drives your vision to success.

👉🌐 https://www.pranathiss.com 👉📧 [email protected] 👉📲 +1 732 333 3037

#productdevelopment#productdesign#innovation#design#industrialdesign#productmanagement#product#prototype#softwaredevelopment#automation#technology#business#machinelearning#AI#futureofwork#digitaltransformation

4 notes

·

View notes

Text

Dark Artefact

#minimalistdesign#abstractart#modernart#industrialdesign#textureart#contemporarysculpture#artisanalcraft#minimalism#geometricart#handmade#creativeexpression#sculpturalart#tactileart#rawmaterials#conceptualdesign

2 notes

·

View notes

Text

My second design for the Submersible project Canson render for my industrial design class. We where tasked with designing a non threatening research submersible. (None threatening as in must not look like a torpedo)

May 29 2019

#theghostofdash#art#design#industrialdesign#submersible#research#shark#submarine#render#designrendering#rendering#canson#cansonrendering#pencil#pencildrawing#marker#markerdrawing#markerart#pencilart#charpex

3 notes

·

View notes

Text

Blueberry AI Introduces it Groundbreaking 3D Digital Asset Engine – 🥝KIWI Engine🥝

Blueberry AI, a leading AI-powered digital asset management company, proudly announces the release of the KIWI Engine, a high-performance 3D engine set to revolutionize industries such as gaming, advertising, and industrial design. KIWI Engine enables teams to streamline workflows by offering real-time 3D file previews in over 100 formats directly in the browser, with no need for high-performance hardware or software.

Boasting cutting-edge features such as centralized storage, AI-powered search, and blockchain-backed file tracking, KIWI Engine ensures secure, efficient collaboration while minimizing operational costs. Designed to enhance productivity, the engine supports large file transfers, cross-team collaboration, and eliminates the risk of file versioning errors or leaks.

With its easy-to-use interface and seamless integration with existing 3D tools, KIWI Engine by Blueberry AI is the ideal solution for companies looking to optimize their 3D asset management.

Unlocking New Capbabilites of 3D Digital Assets — 🥝KIWI Engine🥝 Unveils its Power

The KIWI Engine is a high-performance 3D engine that powers Blueberry AI developed by the industry-leading AI digital asset management company, Share Creators. With exceptional performance and an intuitive interface, the KIWI Engine significantly shortens production cycles for game development, advertising, and industrial design, while reducing operational costs to truly achieve cost-efficiency.

Key Standout Features of the KIWI Engine by Blueberry AI:

Browser-Based 3D Previews: No downloads required; view over 100 professional file formats directly in your browser, including 3DMax and Maya native files; no conversion needed. This functionality eliminates the need for high-performance hardware and boosts team productivity.

Seamless Large File Transfers: Easily share and preview large files within teams, facilitating smooth collaboration between designers and developers. The built-in 3D asset review feature enhances workflow precision and speed.

Addressing Common File Management Issues:

File Security & Control: With centralized storage and multi-level permissions, KIWI Engine ensures files remain secure. Blockchain logs track user activity, and version control with real-time backups prevents file loss or version errors, reducing the risk of leaks, especially during outsourcing or staff transitions.

Outsourcing Management: Control access to shared content with outsourcing teams, minimizing the risk of file misuse.

A One-Stop 3D File Preview Solution:

Broad Format Compatibility: KIWI Engine supports mainstream formats like 3DMax, Maya, Blender, OBJ, FBX, and more. It reduces the need for multiple software purchases by loading and previewing models from various design tools in one engine.

Multi-Format Preview: Combine different 3D file formats in a single workspace for simultaneous viewing and editing. This streamlines complex 3D projects, especially those involving cross-team collaboration.

Simplified 3D Previews for Non-Technical Users: KIWI Engine makes it easy for non-technical stakeholders, such as management, to quickly preview 3D assets without installing complex software. This enhances cross-department collaboration and accelerates decision-making.

Cost Savings on Software:

Traditional design projects often require expensive software purchases just to view files. With cloud technology, the KIWI Engine by Blueberry AI eliminates the need for costly software installations. Team members can preview and collaborate on 3D files online, reducing software procurement and maintenance costs while improving flexibility and efficiency.

Improving Collaboration and Resource Reuse:

Without intelligent tools, design resources are often recreated from scratch, leading to wasted time and costs. The KIWI Engine supports multi-format 3D file previews and includes AI-powered search and auto-tagging, enabling designers to easily find and reuse existing resources. This significantly enhances collaboration and reduces the security risks of transferring large files.

User-Friendly Interface and Experience:

The KIWI Engine adopts a clean, intuitive user interface, with a well-structured layout. A detailed list of grids and materials appears on the left, while function modules (controls, materials, grids, and lighting management) are on the right, ensuring a logical and smooth workflow. Personalized settings and organization-level global configurations further enhance productivity for teams of all sizes.

Grid and Material List: After loading a model, grids and materials are clearly displayed, allowing users to easily select and edit the necessary components.

Personalized Settings: Customize the interface to suit individual workflow preferences, improving work efficiency.

Organization Settings: For large teams or cross-project managers, global configuration options enable unified project management across multiple teams, saving time and resources.

KIWI Engine's Control Tool Module:

The KIWI Engine features an innovative control tool module, covering camera controls, display functions, and advanced rendering options that meet diverse project needs—from simple model viewing to complex scene operations.

Camera Controls: Features like auto-rotation and quick reset allow users to easily adjust the camera for 360-degree model views, ensuring smooth, flexible operation.

Display Functions:

Wireframe Display: Ideal for structured previews, enabling users to inspect model geometry during the design phase.

Double-Sided Display: Displays both sides of models, even if there are defects, minimizing repair time and improving workflow efficiency.

SSR (Screen Space Reflection): Enhances model reflection effects for high-quality renderings in complex scenes.

UV Check: Displays UV distribution, helping users accurately assess UV mapping for precise texture work.

Learn more about us at: Blueberry: Best Intelligent Digital Asset Management System (blueberry-ai.com)

#DAM#3DAssetManagement#3DAsset#GameDev#IndustrialDesign#Maya#3DSMax#Blender#3DRendering#3DModeling#CloudCollaboration#3DDesignSolutions#3DVisualization#3DViewer#CollaborativeDesign

2 notes

·

View notes

Photo

30 notes

·

View notes

Photo

Anza Coffee

https://www.anzacoffee.com/products/anza-white_cf

147 notes

·

View notes

Photo

Old.s #cardesign #design #automotivedesign #car #carsketch #cardesignworld #sketch #cardesigner #transportationdesign #cars #automotive #cardesigndaily #cardesigncommunity #industrialdesign #cardesignsketch #concept #conceptcar #art #carsofinstagram #supercar #vehicledesign #sketching #drawing #cardrawing #productdesign #autodesign #designer #carart #ferrari #d https://www.instagram.com/p/CpQNLApIPmS/?igshid=NGJjMDIxMWI=

#cardesign#design#automotivedesign#car#carsketch#cardesignworld#sketch#cardesigner#transportationdesign#cars#automotive#cardesigndaily#cardesigncommunity#industrialdesign#cardesignsketch#concept#conceptcar#art#carsofinstagram#supercar#vehicledesign#sketching#drawing#cardrawing#productdesign#autodesign#designer#carart#ferrari#d

44 notes

·

View notes

Text

Spirale Ash Tray | Achille Castiglioni for Alessi

67 notes

·

View notes

Text

Fall24 Sofa

#sofadesign#Fall24#furniture#industrialdesign#industrial#productdesign#product#furnituredesign#bench#craft#design#sofa

3 notes

·

View notes

Text

Ultimate Guide to PCB Testing Methods: Ensuring Quality and Reliability in Your Circuits

In the electronics sector, Printed Circuit Boards (PCBs) are the life-lines of virtually all gadgets that are in use in the modern society. From humble home appliances to gigantic industrial equipment, PCBs are the skeletal framework of hardware organization and connection of circuit elements. It is vital to guarantee the quality and dependability of these fundamental parts – thus enters PCB testing methods. It is our hope that this extensive hand will help identify the most suitable test strategies for PCB testing, why these techniques matter, and how to maximize your circuits’ functionality.

Introduction

Firstly, an increase in the capability of different electronic devices leads to higher necessary requirements to the PCBs used in their production. Performing tests on the PCBs is an essential step in the manufacturing process done to confirm that a given board performs as a unit to the expected levels. This guide aims at explaining various techniques of PCB testing with a view of having a better understanding on how to achieve quality and reliability on the circuits.

Why PCB Testing is Crucial

PCB Testing When it comes to the potential defects on PCBs, there are shorts, opens, and some component placements. They can cause device failure, decline in performance level, and sometimes also pose safety issues. Through high-quality testing regimes, it becomes easier to address problems before they reach the customer, and thus manufacturers will have reliable and efficient products. Key reasons for PCB testing include:

Detecting Manufacturing Defects: Solder bridges, missing and placed in wrong position components, all can be detected in the initial stages easily.

Ensuring Functionality: Ensuring that the PCB does what is wanted and needed when it is in use, and under several conditions.

Quality Assurance: Ensuring that the business meets industry standards, and what clients require of them.

Cost Efficiency: Decreasing the likelihood of rework and recall by identifying possible defects before they get to the customer.

Types of PCB Testing Methods

These are the types of PCB Testing Methods:

Visual Inspection

Technique one as also referred to as the VI or visual inspection is the simplest and basic type of testing done on PCBs. The technique entails inspecting the board with naked eyes for some of the common faults including solder bridges, missing parts, and misalignment issues.

Automated Optical Inspection (AOI)

AOI employs cameras and software algorithms to check PCBs for defects and performs the inspections singly. This method of inspection is far more efficient than the manual inspection and simultaneously versatile enough to identify numerous problems.

X-ray Inspection

Some functions which include examination of features of BPCs that could not be easily inspected include solder joints under components through x-ray inspection. It is especially effective in inspecting defects in BGA (Ball Grid Array) and other various packages as well.

In-Circuit Testing (ICT)

ICT entails applying different voltage across the PCB to checks on the electrical characteristics of the needy part and connections. The use of this method is highly recommended for the identification of functional problems and verification of the circuit’s goodness.

Functional Testing (FCT)

Functional testing evaluates the effectiveness of the PCB pointing to the fact that it can be tested when placed in use. This method enables the certification of that the PCB works as expected under actual environment.

Flying Probe Testing

In flying probe testing, the probes are moved around to test the electrical properties of the created PCB. Lower to medium volume production runs can be made easily by using this technique; hence it is advantageous in this regard.

Boundary Scan Testing

Boundary scan testing also called as JTAG testing extends test circuitry into all the components for testing the connections between them. Although, this method is very efficient for identifying connection problems and faults.

Burn-In Testing

Burn-in testing puts the PCB in a state of operational stress for a long time to capture early-life failures. This aspect makes the method reliable for the long term since it is likely to identify problems that may occur when the equipment is in use for a long time.

Detailed Analysis of Each Testing Method works

These are the detailed analysis of each testing method works:

Visual Inspection

Pros:

Simple and low-cost

Determined to be a system for the reporting of noticeable defects as soon as they are observed.

Cons:

Time-consuming for complex boards

Limited to visible defects

Automated Optical Inspection (AOI)

Pros:

Fast and accurate

Is capable of detecting various kinds of defects.

Non-destructive

Cons:

High initial setup cost

May need to have better settings optimized for specific boards.

X-ray Inspection

Pros:

Examines hidden features

Ideal for complex packages

Cons:

Expensive equipment

Requires skilled operators

In-Circuit Testing (ICT)

Pros:

Thorough electrical testing

High fault coverage

Cons:

Requires custom fixtures

Not for all the boards or servers that you wish to build.

Functional Testing (FCT)

Pros:

Ensures real-world performance

Detects system-level issues

Cons:

Time-consuming

The mathematical test object can involve complex arrangements of test configurations.

Flying Probe Testing

Pros:

Flexible and adaptable

Cost-effective for small batches

Cons:

Slower than ICT for big volumes

Applicable only when the board is specially designed

Boundary Scan Testing

Pros:

Interconnections have high fault coverage.

Said; No need to have physical access to the test points

Cons:

Requires boundary scan-enabled components

Complex setup

Burn-In Testing

Pros:

Identifies early-life failures

Ensures long-term reliability

Cons:

Time-consuming and costly

Perhaps stressful to the board

Choosing the Right Testing Method

The choice of the appropriate method of PCB testing can be influenced by several factors such as the level of complexity of the PCB and the numbers of boards to be tested as well as the actual costs of the testing process and other features. Consider the following when choosing a testing method:

Board Complexity: Great board densities or component placement can be a determinant as to whether one needs AOI or X-ray inspection.

Production Volume: Applications that are characterized by high volumes can be easily facilitated by ICT while the low to medium volume applications may require flying probe testing.

Budget: Both manual inspection and AOI are favorable for various production volumes, while X-ray and ICT are more expensive at the beginning.

Specific Requirements: There are two types of the test, namely Functional Test and Burn-In Test that should be made so as to attain the long term reliability in applications that are critical.

Best Practices for PCB Testing

Using the best techniques in testing PCBs increases the quality and reliability of the circuits that you are working on. Here are some key practices to follow:

Early Testing: It is recommended to carry out the tests when the product is still in its design and manufacturing phase so that problems can be noted earlier before they reach a very catastrophic level.

Automate Where Possible: Use method such as automation to reduce the time and improve on the quality of the testing.

Regular Calibration: It is necessary to check if all the testing equipment used for calibration are accurate.

Comprehensive Coverage: This way, you will be able to ensure that there are no defects that are not tested as the best testing approach combines all types of testing methods.

Document Everything: Ensure that you keep records of the tests performed, the results obtained, as well as any measures taken to correct the breaches.

Common Challenges and How to Overcome Them

These are the common challenges and how to overcome them:

False Positives/Negatives

Automated testing methods maybe good some times, they give you the results that are either positive or negative and this will lead to unnecessary rework or more alarming leaving critical defects unfound. In order to avoid this, make sure that testing algorithms and testing equipment are updated and fine-tuned from time to time.

Component Access

Some of the testing techniques involve handling parts of the circuit and with high density board this can be very difficult. Some of the ways in which testbench implementation can be avoided are as follows Boundary scan testing and X-ray inspection.

High Costs

Some form of testing such as X-ray and ICT testing is often very costly. The effectiveness must come with reasonable prices; try to combine some of the mentioned approaches to cover all the aspects without spending too much money.

Future Trends in PCB Testing

About the future, it can be stated that its trends will be in fact linked to the tendencies in technologies and expectations towards ever higher quality and quantity of tested PCBs. Key trends to watch include:

AI and Machine Learning: Using of intelligence algorithms and machine learning in testing algorithms to enhance the efficiency and the minimization of false negative or false positives.

IoT and Smart Manufacturing: Higher testing flexibility and opportunities for the continuous test process supervision.

Advanced Imaging Techniques: The need for better techniques that would enhance the detection of defects within a printed circuit.

Environmental Stress Testing: More focus in the testing of PCBs under different environmental pressures in order to improve on its longevity.

Conclusion

Quality and reliability of packaged circuits have to be maintained to contribute positively in any electronic equipment. This paper seeks to explain the common testing techniques for PCB so that PCB manufacturers are able to test and see if they are free from defects and if they are functional. This ultimate guide will give you a full insight on the available options in PCB testing that will enable you make the best decision that will give you perfect circuits.

The aim is to help you understand how to attain the best quality of PCBs, what methods are worth following, and what trends drive future improvements, thus contributing to the quality of the final electronic products and, consequently, consumer satisfaction.

#PCBTesting#Electronics#CircuitBoard#QualityControl#Engineering#Technology#Manufacturing#IndustrialDesign#Tech#Innovation

2 notes

·

View notes