#Industrial Conveyor Ovens

Explore tagged Tumblr posts

Text

Top Services Industrial Conveyor Ovens

Industrial conveyor ovens facilitate continuous material handling, eliminating the need for manual loading and unloading between heating processes.

0 notes

Text

Streamlining Industrial Processes: The Power of Industrial Conveyor Ovenshttps://thejpinnovations.com/

Industrial conveyor ovens have emerged as a game-changer in the world of manufacturing and processing. These specialized ovens have revolutionized the way industries handle heating, drying, curing, and baking processes on a large scale. With their ability to optimize production while maintaining consistent quality, industrial conveyor ovens are becoming an indispensable tool in various sectors.

At the heart of industrial conveyor ovens lies a conveyor belt system that seamlessly transports products through a heated chamber. This continuous and automated method ensures uniform heat distribution, enabling businesses to achieve higher output rates and meet demanding production schedules. By eliminating the need for manual handling, these ovens streamline manufacturing processes and reduce labor costs.

One of the key advantages of industrial conveyor ovens is their ability to provide precise temperature control. Temperature variations can have a significant impact on product quality, especially when dealing with delicate materials or precise manufacturing specifications. These ovens incorporate advanced heating elements and control systems that maintain a steady temperature profile throughout the entire process. This level of control reduces the risk of product defects and ensures that each item meets required standards.

Industrial conveyor ovens cater to a wide range of industries, including food processing, automotive, electronics, pharmaceuticals, and more. From baking and drying food products to curing coatings and adhesives, these ovens offer versatile solutions for various heat-related applications. Their ability to handle different sizes, shapes, and weights of products makes them adaptable to diverse production requirements.

The implementation of industrial conveyor ovens enhances operational efficiency, reduces production time, and improves product quality. With the automation and precision they provide, businesses can stay ahead in a competitive market by meeting customer demands promptly and consistently. As technology continues to advance, industrial conveyor ovens are expected to evolve further, incorporating smart features, energy-efficient designs, and enhanced safety measures. This ongoing progress ensures that businesses can continue to benefit from these ovens, enhancing their industrial processes and driving success.https://thejpinnovations.com/

#Jp Innovations#The JP Innovation#Impingement Conveyor Ovens#Impingement Conveyor Ovens india#Industrial Conveyor Ovens#Pizza ovens#restaurant pizza ovens#restaurant oven#commercial oven#commercial pizza oven#oven restaurant#pizza oven restaurant#commercial oven price#Electric pizza oven commercial#electric commercial oven#commercial oven for baking#commercial ovens for restaurants#oven for pizza shop#gas commercial oven#commercial pizza machine#best ovens for pizza#electric commercial pizza ovens

0 notes

Text

#Industrial Conveyor manufacturers in Bangalore india#Belt conveyor manufacturers in india#Conveyor belt suppliers and manufacturers in bangalore#Over head conveyor manufacturers#Conveyor System manufacturers in bangalore#Roller conveyor manufacturers in india#Conveyor oven manufacturers in india#Gravity roller Conveyor manufacturers in bangalore#Conveyor rollers manufacturers in bangalore

0 notes

Text

Industrial Conveyor Oven Manufacturer in Vasai

We are a Leading Industrial Conveyor Oven Manufacturer in Vasai. Specializes in Manufacturing and Marketing of Conveyor Ovens. We provide services in Vasai East Thane Mumbai. The Nirmal Tech Fab Industrial Conveyor Oven is designed with a user-friendly control system, allowing you to easily set cooking times, temperatures, and other settings with precision and accuracy.

0 notes

Text

A Comprehensive Guide to Batch Industrial Ovens: Exploring Tray Ovens and Conveyor Ovens

Industrial ovens play a crucial role in various manufacturing processes, where precise and controlled heating is required. Among the different types of industrial ovens available, batch industrial ovens stand out for their versatility and efficiency. In this comprehensive guide, we will delve into the world of batch industrial ovens, with a particular focus on two popular variants: Tray Ovens and Conveyor Ovens.

Meta Therm Furnaces Pvt Ltd stands out as a trusted and reputed Industrial Oven manufacturers in India, offering an impressive range of ovens such as Tray Oven and Conveyor Oven. which ensures optimum performance and durability.

Understanding Batch Industrial Ovens Batch industrial ovens, as the name suggests, are designed to handle materials in batches. This means that a certain quantity of products or materials is processed at one time, offering flexibility in production scheduling. These ovens are commonly used in industries like food processing, pharmaceuticals, automotive, and electronics, among others.

The Working Principle of Batch Industrial Ovens Batch industrial ovens operate on the principle of convection heating, where heated air circulates within the oven chamber, evenly distributing heat to the products or materials. This ensures consistent and uniform heating, critical for achieving desired outcomes in the manufacturing process.

Tray Ovens: A Closer Look Tray ovens are a popular type of batch industrial oven commonly used in industries that require batch processing of smaller items. They are equipped with trays or shelves where products are placed for heating. Tray ovens offer precise temperature control and are ideal for applications like baking, curing, and drying.

Applications of Tray Ovens

Baking: Tray ovens are extensively used in bakeries for baking various products, including bread, pastries, cookies, and cakes. The precise temperature control ensures even baking and consistent product quality.

Curing: In industries like automotive and aerospace, tray ovens play a vital role in curing coatings and adhesives on small components. The controlled heating process enhances the bonding properties of the materials.

Drying: Tray ovens are efficient for drying small items or materials, such as pharmaceutical products, ceramics, and electronic components.

Conveyor Ovens: Streamlining Production Conveyor ovens, another type of batch industrial oven, are designed for continuous production processes. Instead of trays, these ovens feature a conveyor belt that moves the products through the heating chamber. Conveyor ovens are widely used for high-volume production and assembly lines.

Applications of Conveyor Ovens

Heat Treatment: Conveyor ovens are commonly used for heat treating metal components, such as annealing, tempering, and stress relieving. The continuous process ensures a consistent output and reduced production time.

Food Processing: In the food industry, conveyor ovens are employed for cooking, baking, and drying large quantities of food products, catering to the demands of fast-food chains and large-scale food production.

Industrial Drying: Conveyor ovens are effective in drying materials like textiles, paper, and wood products in bulk, ensuring efficient and speedy drying processes.

Selecting the Right Industrial Oven Choosing the right batch industrial oven for your specific application requires careful consideration of various factors:

Throughput: Evaluate the quantity of products or materials you need to process in each batch and how frequently you require production cycles.

Temperature Range: Different applications demand specific temperature ranges. Ensure the oven you choose can achieve and maintain the required temperatures.

Heating Technology: Consider the heating technology used in the oven, such as electric, gas, or infrared, depending on your heating requirements and energy efficiency goals.

Customization: Some manufacturers offer customization options to tailor the oven's features to your unique needs.

Batch industrial ovens, with their flexibility and efficiency, continue to be an indispensable tool in modern manufacturing processes. Tray ovens and conveyor ovens, as two popular variants, cater to different applications and production scales. Whether you require precise baking in smaller quantities or continuous high-volume production, there is a batch industrial oven suitable for your needs. Consider the specifics of your production requirements and make an informed decision to invest in the right industrial oven for your business.

We provide ideal solutions for those looking for Industrial Furnace manufacturers and suppliers in Mumbai, India or even exporter to the worldwide.

0 notes

Text

Today I randomly remembered a local brand of bread from my childhood and wondered why you don't see it on shelves any more. Googled the name and found out the bakery burned two workers to death in an oven in 1998! The bakery sent them inside a giant industrial oven to make repairs rather than spend £2500 to call out specialist contractors. The oven was supposed to be switched off for at least 12 hours before anyone could go in, but it had only been off for 2 hours and nobody checked the thermometer. The men were sent in, like dough, on a slow moving conveyor belt that they had no way of reversing. They were trapped in the oven for 17 minutes and died of burns - but the bosses escaped with a fine.

105 notes

·

View notes

Text

IR Conveyor Ovens manufacturer in haryana - GBM Industries

Upgrade your production line with the state-of-the-art IR Conveyor Ovens from GBM Industries. Known for their speed, reliability, and energy efficiency, these ovens cater to diverse industries like food processing, electronics, and automotive. Enhance your operations with precise heating technology and customizable features.

Don't miss out—

0 notes

Text

Industrial Oven Applications: Revolutionizing Industries with Precision Heating

Industrial ovens are essential across various industries, delivering efficient heating solutions for diverse processes. From baking to curing, drying to sterilizing, industrial oven applications are versatile and indispensable. These robust machines cater to industries like manufacturing, pharmaceuticals, food processing, and more, ensuring high performance and reliable results.

Types of Industrial Ovens and Their Uses

Batch Ovens Batch ovens are designed for smaller-scale production processes. Industries use them for tasks like curing coatings, annealing metals, or baking ceramics. Their flexibility allows operators to handle multiple products in separate batches, making them ideal for custom or irregular processing.

Continuous Ovens Continuous ovens are designed for high-volume operations, featuring conveyor belts that ensure seamless movement of products. These ovens are commonly used in food processing for baking bread or biscuits and in automotive industries for curing paint or powder coatings on components.

Drying Ovens Drying ovens remove moisture from materials, a critical process in sectors like pharmaceuticals and electronics. For example, in the production of electronic components, drying ovens eliminate any residual solvents to ensure product quality.

Curing Ovens These ovens are integral to industries dealing with paints, adhesives, or polymers. Curing ovens heat materials to a specific temperature, facilitating chemical reactions that enhance product properties such as durability and strength.

Annealing Ovens Commonly used in metal and glass industries, annealing ovens heat materials to reduce internal stress, enhance flexibility, and improve structural integrity. They are critical for manufacturing robust and reliable products.

Vacuum Ovens Vacuum ovens are utilized in applications requiring a controlled environment. They are ideal for sensitive materials, such as delicate electronic components or specialized pharmaceutical products, ensuring precise and contamination-free processing.

Key Industrial Applications

Food Processing Industry The food processing industry extensively depends on industrial ovens for processes such as baking, drying, and roasting. These ovens ensure consistency, quality, and efficiency, enabling large-scale production of items like bread, cookies, and snack foods.

Automotive and Aerospace Industries Automotive and aerospace manufacturers use industrial ovens for heat-treating metals, curing coatings, and processing composite materials. For example, aerospace components undergo curing in industrial ovens to meet stringent safety and performance standards.

Pharmaceutical Industry Industrial ovens play a vital role in sterilizing equipment and materials in the pharmaceutical industry. They are also used for drying medicinal powders and ensuring contamination-free production environments.

Electronics Manufacturing In electronics, industrial ovens are essential for curing adhesives, drying coatings, and soldering components. Their precision ensures the longevity and reliability of delicate electronic parts.

Metalworking Industry Metalworking relies on ovens for processes like annealing, tempering, and stress-relief. These applications enhance the strength and durability of metals, making them suitable for demanding environments.

Chemical Industry The chemical industry benefits from industrial ovens in applications like drying raw materials, curing chemical coatings, and processing polymers. These ovens ensure that chemical reactions occur under controlled conditions for optimal results.

Advantages of Industrial Ovens

Efficiency and Precision Industrial ovens offer precise temperature control, ensuring consistent and high-quality results. This precision is essential for meeting industry standards and producing reliable products.

Scalability From small-scale batch ovens to large continuous systems, industrial ovens can be scaled to match production needs, making them versatile for industries of all sizes.

Energy Efficiency Modern industrial ovens are designed with energy-saving technologies, reducing operational costs while maintaining performance.

Customization Industrial ovens can be tailored to specific processes, allowing industries to achieve optimal outcomes. Features like adjustable temperature ranges, specialized materials, and automation make them highly adaptable.

Future Trends in Industrial Oven Applications

As industries evolve, so do the requirements for heating technologies. The future of industrial oven applications will focus on incorporating smart technologies, such as IoT-enabled controls for remote monitoring and automation. These advancements will enhance efficiency, reduce downtime, and ensure sustainable practices.

Energy efficiency will remain a top priority, with innovations aimed at reducing carbon footprints and operational costs. Additionally, the demand for customized solutions will drive the development of ovens tailored to niche industries and emerging applications.

Industrial oven applications are a cornerstone of modern manufacturing and production. Their adaptability, performance efficiency, and dependable operation make them essential across a wide range of industries. As technology advances, these ovens will continue to adapt, meeting the evolving needs of industries and contributing to global innovation.

0 notes

Text

What Is Industrial Cleaning & Why Do You Need It?

Industrial cleaning plays an important role in your bottom line, customer satisfaction, and overall brand reputation. Since most industrial and manufacturing facilities operate around the clock, it is common for dirt, grime, and other hazardous materials to accumulate. Even with regular cleaning, operation managers often face challenges in maintaining these facilities. That’s where industrial and commercial cleaning comes in, making sure that the facility is properly cleaned.

What is Industrial Cleaning?

Industrial cleaning refers to the cleaning of industrial facilities such as power plants, factories, and warehouses. The process involves a clear understanding of the equipment and products to use in cleaning the facility. The most common approaches include manual cleaning, form cleaning, industrial floor cleaning, and sanitation or decontamination. Other important components of industrial cleaning include:

Care and attention to cleaning the facility without interfering with production

Use of specialized equipment in cleaning and sanitizing the facility

Time and flexibility in cleaning the facility quickly around production schedules

What Is Industrial Cleaning Services?

Industrial cleaning services comprise several tasks related to cleaning an industrial facility. The industrial cleaning company maintains a team of certified staff who are continuously trained on industrial standards to provide safe cleaning practices. Combined with quality cleaning equipment, the company offers the following industrial cleaning services:

Commercial Tile and Grout Cleaning: The service helps maintain the integrity of tiled areas, which helps to reduce slip hazards and increase durability.

Industrial Exhaust Cleaning: Cleaning of the exhaust helps to remove potentially hazardous residue, protecting the health and safety of the employees. This can also help in lowering operational and maintenance costs.

Commercial Restroom Cleaning: Through proper sanitization of your facility’s restroom, you can prevent the spread of germs while maintaining a clean environment for all employees.

Industrial Oven Cleaning: Containment of industrial ovens, including bake and curing ovens helps to extend their lifetime and avoid the risk of product contamination.

Commercial Drain Treatment: This service helps to avoid costly clogs by ensuring that the drains are clear of debris and contaminants.

Combustible Dust Removal: Safe removal of combustible dust helps in preventing fires and explosions within the facility.

Overhead Cleaning and Painting: Cleaning and painting of overhead structures help in reducing product contamination and, the risk of dirt explosion, and ensuring your facility complies with industry standards for a safe and brighter environment.

Commercial Window Cleaning: This is a vital cleaning service for maintaining the professional appearance of your facility’s windows and ensuring clear visibility.

Dust Collector Cleaning: if your facility deals with hazardous dust particulates, you are required to maintain a strict annual air duct cleaning to protect your employees.

The list of industrial and commercial cleaning services is quite extensive. Other services covered include exhaust stack cleaning, facility deep cleaning, dry ice blasting, and high-pressure washing. Paint spray booths and stacks, conveyor systems, heat exchangers and ventilators, walls, ceilings, roof fans and ventilators, and more.

Why You Need Industrial Cleaning Services

Dirt and debris tend to accumulate in different spaces within an industrial facility. Although regular cleaning helps in removing surface dirt, industrial janitorial services focus on removing even the stubbornest dirt. By performing a thorough deep cleaning with specialized tools and techniques, industrial cleaners help prevent harm to the workers and your expensive machinery.

Ensure Health and Safety: industrial cleaning services remove the accumulation of dust, dirt, and hazardous materials that pose serious health risks. With the use of eco-friendly products and specialized equipment, professional cleaners eliminate contaminants to maintain a safe working environment.

Maintain Operational Efficiency: Buildup of dirt and grime usually interfere with machinery operations, and can increase cases of breakdowns and costly repairs. Industrial cleaning ensures that your facility functions more efficiently at all times, reducing downtime caused by equipment breakdowns or health-related absences.

Regulatory Compliance: If your facility does not adhere to health and safety regulations, you may end up having hefty fines, legal problems, or even potential shutdowns. Since professional industrial cleaners are well-versed with the latest developments in safety and environmental regulations, they help ensure that your facility meets all the required standards.

Protect Product Quality: Unclean environments can cause contamination and defects that compromise product quality, especially in industries like pharmaceuticals, food processing, and electronics. With industrial and commercial cleaning services, you can make sure that your environments are not contaminated, which helps in maintaining a high standard of cleanliness in your products.

Reliable Industrial Cleaning from DMS Janitorial

Finding the right industrial and commercial cleaner company helps in ensuring you get the best possible service. At DMS Janitorial, we are committed to providing proper care in all cleaning processes while preventing safety hazards. Our skilled cleaners are experienced in using high-grade equipment and products that can handle even the most challenging industrial cleaning needs. Get in touch with us today for inquiries and guidance on proper industrial cleaning services for your facility.

0 notes

Text

Heat Treatment Furnaces and Industrial Conveyor Ovens Online from Savage-Engineered

Heat treatment furnaces are required to transform metallic and hard pieces into liquid. Choosing the best range of ovens and furnaces is a crucial thing that you can get according to your requirements.

From the best range of custom ovens to choose the best range of heat treat furnaces and from industrial conveyor ovens to a variety of other types of ovens, you will get the best units of ovens and furnaces with a complete guide and delivery to your address in secure way. Choose the best units and get delivery on time – right to your address.

Savage-Engineered has become the trusted and secure source offering you the best units of industrial conveyor ovens and the best units of heat treatment furnace with a complete guide.

Check al details; go through the technical specifications, features and user guide to get delivery on time right to your address.

Savage-Engineered focus on quality and ensure you will get the best range on time. Custom ovens are designed specifically according to your needs and for industrial purposes.

So, what you are waiting for, stay in touch with the experts and get the best range of custom ovens, heat treatment furnace, and Industrial conveyor ovens. Check all details and get the best range of such units on time.

0 notes

Text

Mastering Pizza Perfection: A Guide to Restaurant Pizza Ovens https://thejpinnovations.com/

Pizza is a beloved food all around the world, and it's no secret that the secret to making the perfect pizza lies in the oven. If you're running a restaurant that serves pizza, investing in the right pizza oven is crucial for achieving delicious results every time. Here are some things to consider when selecting a restaurant pizza oven for your restaurant:

Type of Pizza Oven: There are three main types of pizza ovens: deck ovens, conveyor ovens, and wood-fired ovens. Deck ovens are great for cooking traditional, thin-crust pizzas. Conveyor ovens are designed for high-volume pizza production, such as in a fast-food restaurant. Wood-fired ovens offer a unique, smoky flavor and are great for Neapolitan-style pizzas.

Size and Capacity: Consider the size of your restaurant and the volume of pizzas you will be making. This will help you determine the size and capacity of the pizza oven you need.

Temperature and Cooking Time: Look for a pizza oven that can reach high temperatures quickly and maintain them consistently. This is important for achieving a crispy crust and evenly cooked toppings.

Energy Efficiency: Pizza ovens can be energy-intensive, so look for models that are energy-efficient to help keep operating costs down.

Maintenance and Support: Pizza ovens require regular cleaning and maintenance to ensure they are working properly. Look for a model that is easy to clean and comes with maintenance and support services.

Investing in the right pizza oven for your restaurant can make all the difference in the quality of the pizza you serve. Consider these factors when selecting a pizza oven and choose one that fits your restaurant's needs and budget. With the right pizza oven, you'll be able to master pizza perfection and keep your customers coming back for more. https://thejpinnovations.com/

#Jp Innovations#The JP Innovation#Impingement Conveyor Ovens#Impingement Conveyor Ovens india#Industrial Conveyor Ovens#Pizza ovens#restaurant pizza ovens#restaurant oven#commercial oven#commercial pizza oven#oven restaurant#pizza oven restaurant#commercial oven price#Electric pizza oven commercial#electric commercial oven#commercial oven for baking#commercial ovens for restaurants#oven for pizza shop#gas commercial oven#commercial pizza machine#best ovens for pizza#electric commercial pizza ovens

0 notes

Text

#industrial#industries#dryer oven manufacturers in bangalore#climate control oven manufacturers in bangalore#oven#ovenparts#hot air dryer manufacturers in bangalore#hot air chamber manufacturers in india#hot air oven manufacturers in bangalore

2 notes

·

View notes

Text

Enhance Your Production Efficiency with GBM Industries’ IR Conveyor Oven:

🚀 Enhance your production game with GBM Industries' IR Conveyor Oven! 🔥 This cutting-edge solution boosts efficiency, ensures consistent quality, and saves energy. Perfect for streamlining industrial processes and achieving top-notch results. 🌟 🛠️

Take the next step and visit our latest article now !! Enhance Your Production Efficiency with GBM Industries’ IR Conveyor Oven

0 notes

Text

Dry Ice Blasting in Malaysia: A Revolutionary Cleaning Technology

In recent years, industrial cleaning in Malaysia has witnessed a major shift towards more efficient and environmentally friendly methods. Among these, dry ice blasting has emerged as a cutting-edge solution for cleaning machinery, equipment, and surfaces across a variety of sectors. This non-abrasive and non-toxic cleaning technique is gaining popularity due to its effectiveness and sustainability.

What is Dry Ice Blasting?

Dry ice blasting, also known as CO2 blasting, involves using compressed air to propel small pellets of dry ice (solid carbon dioxide) at high speeds towards the surface being cleaned. Upon impact, the dry ice rapidly sublimates (turns directly from a solid to a gas), creating a micro-explosion that dislodges contaminants such as dirt, grease, paint, and mold from surfaces. This process is highly effective and does not leave any residue, as the dry ice simply evaporates.

This method is especially beneficial in Malaysia, where industries such as manufacturing, food processing, automotive, and electronics face significant challenges with regular cleaning maintenance. Unlike traditional cleaning methods that use harsh chemicals or abrasive techniques, dry ice blasting in Malaysia is a safer, more efficient, and environmentally friendly option.

Advantages of Dry Ice Cleaning Solutions

There are numerous advantages to choosing dry ice cleaning over conventional methods:

Non-Abrasive: Unlike sandblasting or other abrasive cleaning techniques, dry ice blasting does not damage the surface being cleaned. It is gentle yet effective, making it ideal for delicate equipment and machinery.

Environmentally Friendly: Dry ice blasting is a sustainable cleaning solution as it doesn’t produce harmful chemicals or waste. Since the dry ice evaporates into gas, it leaves no secondary waste or residue.

Minimal Downtime: Traditional cleaning often involves lengthy disassembly of equipment. With dry ice blasting, maintenance time is significantly reduced, allowing businesses to get back to production faster.

Cost-Effective: While the initial setup of dry ice blasting equipment can be an investment, the long-term savings come from reduced downtime, less waste disposal, and fewer chemical cleaning agents.

No Water Usage: In many industries, water is a scarce and expensive resource. Dry Ice Blasting Malaysia Dry ice cleaning eliminates the need for water, helping businesses conserve this valuable resource and minimize water waste.

Applications of Dry Ice Blasting in Malaysia

Dry ice blasting has a wide range of applications across various sectors in Malaysia:

Food Industry: In food processing, cleanliness is a priority. Dry ice blasting is particularly effective in cleaning conveyor belts, molds, and ovens without leaving any residue that could contaminate food products.

Electronics and Automotive: For electronics manufacturers and automotive maintenance, dry ice blasting offers a precise and safe cleaning method for sensitive parts like circuit boards, engines, and electrical components.

Mold Remediation: For industries facing mold and mildew issues, particularly in humid environments like Malaysia, dry ice cleaning provides a quick and effective solution without the need for chemicals.

Industrial Equipment: Heavy machinery, such as turbines, engines, and compressors, requires frequent cleaning to maintain performance. Dry ice blasting effectively removes contaminants while preventing wear and tear on the equipment.

Why Choose Dry Ice Blasting in Malaysia?

Malaysia’s humid climate and rapid industrial development present unique challenges for businesses in maintaining cleanliness and efficiency. Traditional cleaning methods often fall short, either damaging expensive equipment or leaving harmful residues. Dry Ice Blasting Malaysia provides a unique solution to these challenges. It helps companies maintain high standards of cleanliness, reduce maintenance costs, and comply with environmental regulations. The growing demand for dry ice cleaning solutions reflects a shift toward sustainability and better operational efficiency.

Furthermore, businesses in Malaysia can benefit from local suppliers and service providers offering dry ice blasting services. This ensures that companies can access expert cleaning services and the latest technology without delays.

1 note

·

View note

Text

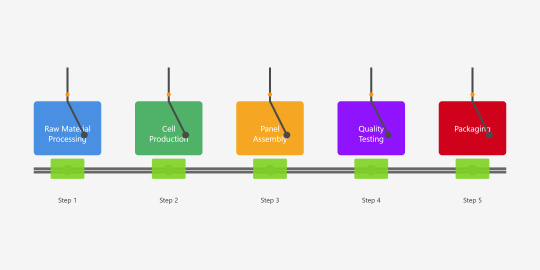

How to Design a Solar Panel Factory: 7 Expert Tips (2024)

Why This Matters: A Simple Introduction

Imagine a factory that makes solar panels while using very little energy itself - that's what we're talking about today! Just like a chef needs a well-designed kitchen to cook great meals, solar panel makers need smart factories to create high-quality panels. In this guide, we'll explore how to build the perfect solar panel factory that's both efficient and environmentally friendly.

"The solar industry isn't just about making panels cheaper anymore -- it's about making them better and smarter." - Solar Energy World, 2024

Why Factory Design is More Important Than Ever

Think about this: when you're baking cookies, having a modern oven with good temperature control helps you make better cookies, right? The same goes for solar panels! Recent studies show that well-designed factories can work up to 95% more efficiently than older ones. That means they can make more panels while using less energy and creating less waste.

How Smart Factories are Changing the Game

Let's break down the numbers in a way that's easy to understand:

7 Smart Ways to Build the Perfect Factory

1. Robots and Smart Machines (Advanced Automation)

Think of this like having a super-smart kitchen where:

Robots handle materials carefully (like having an extra set of careful hands)

Computers check everything is perfect (like having a master chef watching every step)

Machines fix problems before they happen (like knowing your oven needs fixing before it breaks)

Everything works together smoothly (like a well-rehearsed dance)

2. Smart Building Design

Imagine a building that:

Uses its own solar panels for power (like growing your own vegetables)

Makes the most of natural light (like having big windows in your house)

Keeps temperature just right (like a smart thermostat)

Reuses heat instead of wasting it (like using bath water to water plants)

3. Modern Production Lines

Recent breakthroughs have made solar panels much better. For example, new materials called "perovskites" help panels convert almost 30% of sunlight into electricity - that's huge! Our production lines use:

Smart material handling (like having a conveyor belt in a restaurant kitchen)

Precise cutting tools (like having a perfect bread slicer)

Automatic assembly (like a machine that decorates cakes perfectly)

Smart testing systems (like having a food taster check every dish)

4. Better Quality Checking

We use:

Computer vision (like having eyes that can spot tiny problems)

Real-time testing (like tasting food while cooking)

Heat cameras (like seeing where heat escapes from your house)

Automatic problem spotting (like spell-check for solar panels)

5. Waste Reduction

Just like reducing food waste in a kitchen:

Recycling materials (like composting vegetable scraps)

Reusing water (like collecting rainwater for plants)

Saving silicon (like saving leftover ingredients)

Smart packaging (like using just the right amount of wrapping)

6. Smart Resource Management

Think of this like managing a restaurant's supplies:

Smart tracking of materials (like knowing what's in your fridge)

Ordering just what's needed (like buying fresh ingredients daily)

Perfect timing of production (like preparing dishes just before serving)

Using energy wisely (like turning off appliances when not in use)

7. Earth-Friendly Operations

We care about our planet:

No harmful emissions (like using electric cars instead of gas ones)

Using clean energy (like powering your home with solar panels)

Recycling everything possible (like sorting household waste)

Working with green suppliers (like buying from local organic farms)

Using Next-Generation Technology

At Sunpal Solar, we're proud to make state-of-the-art solar panels. Our PERC 550W solar panel is a great example of combining smart manufacturing with high performance. Here's how we make them:

Step-by-Step Production Process

Preparing Raw Materials

Cleaning silicon (like washing vegetables)

Making thin wafers (like slicing bread)

Creating special surfaces (like adding texture to cookie dough)

Making Solar Cells

Adding PERC technology (like adding a special ingredient)

Adding anti-reflection coating (like glazing a cake)

Creating electrical contacts (like adding wiring to a lamp)

Putting Panels Together

Connecting cells (like building a puzzle)

Sealing everything together (like wrapping a present)

Adding frames and protection (like putting food in containers)

Checking Everything

Testing how well it works (like taste-testing food)

Looking for any problems (like checking for burned spots)

Making sure it will last (like checking food expiration dates)

How Computers Make Everything Smarter

Modern factories use artificial intelligence (AI) to:

Schedule work better (like planning your week)

Fix problems early (like maintaining your car)

Check quality automatically (like spell-checking your writing)

Save energy (like having a smart home)

Being Kind to the Environment

Our factories care about nature:

Zero waste goals (like using every part of ingredients)

No carbon pollution (like riding a bike instead of driving)

Smart water use (like taking shorter showers)

Clean energy use (like using wind and solar power)

Planning for the Future

To stay successful, we think about:

Room to grow (like having an expandable house)

Flexible equipment (like having multi-use kitchen tools)

Easy updates (like being able to update your phone)

Using resources wisely (like saving for the future)

Money Matters

When building a smart factory, consider:

Starting costs (like buying kitchen equipment)

When you'll earn money back (like saving on energy bills)

Lower running costs (like efficient appliances saving money)

Environmental benefits (like solar panels paying for themselves)

Looking Ahead

The future of solar panel making is exciting! Smart factories will:

Spend less money to run

Make more panels faster

Help protect nature

Make better quality panels

Learning from Others

Recent research from industry experts shows amazing progress. For example, new perovskite-silicon panels can convert almost 30% of sunlight into electricity - much better than older panels! This shows how important good factory design is for making the best products.

Making It All Work Together

Think of a solar panel factory like a symphony orchestra:

Every part must work perfectly (like musicians playing together)

Timing is crucial (like keeping the beat in music)

Quality must be consistent (like hitting the right notes)

Everything must work as one (like different instruments making beautiful music)

Final Thoughts

Building an energy-efficient solar panel factory is like creating a perfect recipe - it takes the right ingredients, proper tools, and careful attention to detail. By following these strategies, we can make better solar panels while protecting our environment.

Want to learn more about our advanced manufacturing and our PERC 550W solar panels? Visit us at Sunpal Solar.

#solar panel#sunpal#sunpal power#sunpal solar#solar energy#Best practices for solar panel manufacturing#PERC 550W solar panel production process explained#Sustainable solar factory design guide#Green manufacturing technology trends 2024

0 notes

Text

Top-Quality Gas-Fired Belt Conveyor Oven for Your Needs 🚀

Looking for a reliable gas-fired belt conveyor oven? 🔥 Discover how this top-tier solution meets your baking and heating needs efficiently. Click now to learn more and take your operations to the next level!⬆️

✅ Learn More Today : Top-Quality Gas Fired Belt Conveyor Oven By GBM Industries

0 notes