#Industrial Bioprocessing

Explore tagged Tumblr posts

Text

What are the key features of a Production Scale Bioreactor?

In the realm of industrial bioprocessing, the transition from laboratory-scale experiments to large-scale production is a critical phase. This step requires equipment that not only scales efficiently but also maintains the integrity of the biological processes involved. Fermenter Technologies has established itself as a leader in this field, offering state-of-the-art production scale bioreactors that cater to the diverse needs of industries ranging from pharmaceuticals to biofuels. These bioreactors are engineered to ensure that scaling up bioprocesses is both seamless and efficient, allowing for consistent production at an industrial level.

The Importance of Production Scale Bioreactors

Scaling Up: From Lab to Production

Scaling up from a laboratory setting to a production environment is a complex challenge that involves more than just increasing the volume of the reaction vessel. The entire process needs to be optimized for consistency, yield, and safety. Production scale bioreactors are designed to replicate the conditions of laboratory-scale bioreactors on a much larger scale, ensuring that the biological processes remain stable and efficient.

Key Features of Modern Production Scale Bioreactors

Precision Control: Advanced control systems allow for the precise monitoring and adjustment of parameters such as temperature, pH, dissolved oxygen, and agitation speed.

Scalability: The design of these bioreactors ensures that the transition from pilot-scale to full production is smooth and efficient.

Robust Construction: Built from high-quality materials, these bioreactors are designed to withstand the rigors of continuous operation in industrial environments.

Automation: Integration with automation systems allows for real-time monitoring and control, reducing the need for manual intervention and minimizing errors.

Fermenter Technologies: Pioneering Solutions in Bioprocessing

Company Overview

Fermenter Technologies is at the forefront of innovation in the field of bioprocessing equipment. With a deep understanding of the challenges faced by industries as they scale up their bioprocesses, the company has developed a range of production scale bioreactors that address these needs. Their commitment to quality, innovation, and customer satisfaction has made them a trusted partner for businesses worldwide.

Product Offerings

Fermenter Technologies offers a wide array of bioreactors designed to meet the specific requirements of various industries:

Stainless Steel Bioreactors: Ideal for applications requiring high durability and ease of cleaning, these bioreactors are commonly used in the pharmaceutical and food industries.

Single-Use Bioreactors: These bioreactors provide flexibility and reduce the risk of cross-contamination, making them ideal for biopharmaceutical production.

Hybrid Bioreactors: Combining the benefits of both stainless steel and single-use systems, these bioreactors offer versatility and efficiency.

Custom Bioreactors: Fermenter Technologies also offers fully customized solutions, tailored to the unique needs of each client.

Innovations in Bioreactor Design

At the heart of Fermenter Technologies’ success is their dedication to innovation. The company continually invests in research and development to enhance the performance and capabilities of their bioreactors. From improved mixing technology to advanced monitoring systems, every aspect of their bioreactors is designed to optimize bioprocesses and deliver consistent results at scale.

Applications of Fermenter Technologies’ Production Scale Bioreactors

Pharmaceutical Industry: Precision and consistency are paramount. Fermenter Technologies’ bioreactors are used to produce a wide range of pharmaceuticals, including vaccines, antibiotics, and biologics.

Biotechnology and Biofuels: These industries require bioreactors that can handle large-scale production of enzymes, bioethanol, and other bio-based products. Fermenter Technologies’ bioreactors maximize yield while minimizing energy consumption.

Food and Beverage Industry: Fermentation is a key process in the production of many food and beverage products. Fermenter Technologies offers bioreactors specifically designed to meet hygiene and safety requirements.

Agricultural and Environmental Applications: Bioreactors are used for large-scale production of biofertilizers and biopesticides, as well as environmental applications like bioremediation. Fermenter Technologies provides reliable and efficient solutions for these applications.

Why Choose Fermenter Technologies?

Commitment to Quality: Adhering to the highest standards of manufacturing and quality control, ensuring every bioreactor meets or exceeds industry standards.

Expert Support and Service: Comprehensive support from initial consultation to installation and beyond, ensuring clients get the most out of their investment.

Sustainable Solutions: Bioreactors designed to minimize energy consumption and waste, contributing to more sustainable bioprocessing practices.

How to Get Started with Fermenter Technologies

Consultation and Design: Collaborate with Fermenter Technologies’ experts to design a production scale bioreactor tailored to your specific bioprocess needs.

Manufacturing and Installation: Advanced facilities and skilled workforce ensure each bioreactor is built to the highest standards and installed for optimal production.

Ongoing Support and Maintenance: Ongoing support services ensure long-term success of your bioprocess, with expert assistance available for routine maintenance or any issues that arise.

Conclusion

Investing in a high-quality production scale bioreactor is essential for industries looking to scale up their bioprocesses. Fermenter Technologies offers cutting-edge solutions designed to meet the diverse needs of various industries. With a commitment to quality, innovation, and customer satisfaction, Fermenter Technologies is the go-to choice for businesses looking to enhance their bioprocessing capabilities.

Contact Fermenter Technologies:

Mobile Number: +91–8896456000

Email: [email protected]

Address: Plot №173 /3, Hall №5, Rajendra Nagar Industrial Area, Ghaziabad-201007, Uttar Pradesh, India

For more information or to get started with your production scale bioreactor needs, reach out to Fermenter Technologies today!

#fermenter technologies#Production Scale Bioreactor#production scale bioreactor Manufacturer#Pharmaceutical Manufacturing#Biotechnology Solutions#Industrial Bioprocessing

0 notes

Text

Revolutionizing Bioprocessing: Insights from the Global Continuous Bioprocessing Market Report

In recent years, the biopharmaceutical industry has witnessed a paradigm shift towards continuous bioprocessing methods. This transformative approach offers numerous advantages over traditional batch processing, including increased productivity, reduced manufacturing costs, and improved product quality. Continuous bioprocessing involves the uninterrupted flow of materials throughout the entire manufacturing process, from cell culture to purification and formulation.

The Global continuous Bioprocessing Market was valued at $250.1 million in 2023 and is expected to reach $1,639.1 million by 2033, growing at a CAGR of 20.68% between 2023 and 2033.

Global Continuous Bioprocessing Overview

Global Continuous Bioprocessing refers to a manufacturing approach in the biopharmaceutical industry that involves the uninterrupted flow of materials and processes throughout the entire production chain.This methodology leverages advanced technologies such as automation, real-time monitoring, and control systems to enable continuous operation and optimization of biopharmaceutical manufacturing processes

The global continuous bioprocessing market is in a nascent stage and exhibits a fragmented landscape owing to the individual influence of both large and emerging players. Large, mid-sized, and emerging companies are actively developing and implementing continuous bioprocessing solutions

Grab the free sample page click here

Market Segmentation:

Segmentation 1: by Product

Segmentation 2: by Process

Segmentation 3: by Application

Segmentation 4: by End User

Segmentation 5: by Region

Recent Developments in the Continuous Bioprocessing Market

• Waters and Sartorius expanded their partnership to develop integrated analytical tools for downstream biomanufacturing following their successful collaboration in upstream processes. • Sartorius and Repligen Corporation launched an integrated system with Biostat STR and XCell ATF for upstream process intensification.

Visit our Life Sciences and Biopharma Vertical page for better understanding

Key Players in the market

• 3M • Bio-Rad Laboratories, Inc. • Thermo Fisher Scientific, Inc. • Merck KGaA • Sartorius AG • Danaher Corporation

Global Continuous Bioprocessing Market Report highlights several opportunities for market growth, including:

Expansion into New Therapeutic Areas: Continuous bioprocessing offers particular advantages for the production of high-value, low-volume biologics, such as personalized medicines and gene therapies, opening up new opportunities in emerging therapeutic areas.

Collaborative Partnerships: Strategic collaborations between biopharmaceutical companies, technology providers, and regulatory agencies can accelerate the development and adoption of continuous bioprocessing technologies, driving market growth and innovation.

Market Consolidation: As the market matures, we can expect to see increased consolidation through mergers and acquisitions as companies seek to enhance their capabilities and gain a competitive edge in the evolving bioprocessing landscape.

Upstream Bioprocessing Market

Upstream bioprocessing market refers to the segment of the biopharmaceutical manufacturing process that involves the cultivation and expansion of living cells or microorganisms to produce desired bioproducts such as therapeutic proteins, antibodies, vaccines, and other biologics.

Key components of upstream bioprocessing include cell culture media, growth factors, cell lines, bioreactors, and various equipment and consumables used for cell cultivation and expansion. Advancements in upstream bioprocessing technologies have led to increased productivity, higher yields, improved product quality, and reduced manufacturing costs in the biopharmaceutical industry.

Key Questions Answered

Q What is the estimated global market size for the continuous bioprocessing market?

Q What future trends are expected in the continuous bioprocessing market?

Q What does the supply chain of the continuous bioprocessing market look like?

QWhat does the value chain of the continuous bioprocessing market look like?

Q What is the regulatory framework within the continuous bioprocessing market?

Q What is the patent analysis trend based on country and year in the continuous bioprocessing market?

Q How has the COVID-19 outbreak affected the future trajectory of the continuous bioprocessing market?

Q What are the next frontiers in the continuous bioprocessing market?

Conclusion

Overall, Global Continuous Bioprocessing holds tremendous promise for transforming the biopharmaceutical manufacturing landscape, enabling companies to meet growing market demands, accelerate innovation, and deliver high-quality biologics more effectively and sustainably.

Global Continuous Bioprocessing Market Report provides a comprehensive overview of the current state and future outlook of the continuous bioprocessing market, highlighting the key drivers, challenges, and opportunities shaping its growth trajectory.

#Global Continuous Bioprocessing Market Report#Global Continuous Bioprocessing Market Industry#Global Continuous Bioprocessing Market

0 notes

Text

Navigating the Consumables Market: Trends, Growth, and Industry Insights

The Consumables Market is a dynamic and multifaceted sector that encompasses a wide range of industries, from healthcare to laboratories and beyond. In this blog post, we will explore key aspects of the Consumables Market, examining its various segments, growth drivers, and emerging trends.

Understanding the Consumables Market:

The Consumables Market is vast, covering a spectrum of industries such as healthcare, laboratories, and bioprocessing. The global Hospital Consumables market size was valued at USD 432561.2 million in 2022 and is expected to expand at a CAGR of 12.31% during the forecast period, reaching USD 868182.18 million by 2028. Hospital Consumables reference to frequently used accessories for hospitals. Its core essence lies in the supply of disposable products essential for daily operations, contributing to the efficiency and safety of various processes. Let's delve into some specific segments within the Consumables Market:

Dental Consumables Market: Dental consumables play a crucial role in dental care, ranging from disposable instruments to materials like crowns and braces. The dental consumables market is driven by technological advancements, an aging population, and a growing awareness of oral health.

Single-use Bioprocessing Market: Single-use bioprocessing consumables are gaining traction due to their cost-effectiveness and reduced risk of contamination. With the biopharmaceutical industry expanding, the demand for single-use bioprocessing solutions is on the rise.

Hospital Consumables Market: Hospitals rely heavily on consumables, including gloves, gowns, and medical supplies. The hospital consumables market is influenced by factors such as the increasing number of surgeries, the rise in healthcare infrastructure, and the emphasis on infection control.

Laboratory Consumables Market: Laboratories are critical hubs for research and testing, and consumables like pipettes, tubes, and slides are indispensable. The laboratory consumables market is driven by ongoing research and development activities, advancements in diagnostic technologies, and the demand for precision in testing.

Medical Consumables Market: The medical consumables market encompasses a broad spectrum, including wound care products, diagnostic kits, and infusion sets. Factors such as the global aging population, prevalence of chronic diseases, and advancements in healthcare infrastructure contribute to its growth.

Single-use Bioreactors Market: Single-use bioreactors are integral to biopharmaceutical manufacturing, offering flexibility and cost savings. The single-use bioreactors market is witnessing substantial growth, driven by the biopharmaceutical industry's expansion and the need for more efficient production processes.

Chromatography Consumables Market: Chromatography is a vital technique in analytical chemistry, and the consumables market associated with it includes columns, syringes, and filters. The chromatography consumables market is influenced by the increasing demand for precise analytical techniques in pharmaceuticals, food and beverage, and environmental testing.

Key Trends and Growth Drivers:

Technological Advancements: The Consumables Market is characterized by continuous technological advancements, such as the integration of smart technologies and the development of eco-friendly and sustainable consumables.

Increasing Healthcare Expenditure: With a growing emphasis on healthcare infrastructure globally, the demand for consumables in hospitals and medical facilities is on the rise, driving market growth.

Biopharmaceutical Industry Expansion: The biopharmaceutical industry's rapid growth, marked by increasing research and development activities, is a significant factor contributing to the expansion of the Consumables Market.

Focus on Single-Use Solutions: The shift towards single-use solutions, particularly in bioprocessing and biopharmaceutical manufacturing, is a prevailing trend due to cost-effectiveness and reduced risk of contamination.

Conclusion:

The Consumables Market is dynamic and responsive to the evolving needs of various industries. As technological innovations continue to shape the landscape, and industries like healthcare and biopharmaceuticals expand, the demand for consumables will remain robust. Stay tuned for further insights as we track the ever-changing Consumables Market landscape.

#Consumables Market#Consumables Industry#dental consumables market#Single-use Bioprocessing Market#Consumables Industry Research Reports#Hospital Consumables Market#Laboratory consumables market

0 notes

Text

A fungus converts cellulose directly into a novel platform chemical

The fungus Talaromyces verruculosus can produce the chemical erythro-isocitric acid directly from cheap plant waste, thus making it interesting for industrial utilization. Using the natural abilities of the non-genetically modified fungus, a research team from Jena has discovered a method for the efficient conversion of cellulose into a form of isocitric acid. The new production method could significantly simplify the previously complex and multi-stage process for obtaining platform chemicals from cellulose by requiring only a single bioprocess. Thanks to the new cost-effective method, the rarely utilized sister molecule of the intensively used citric acid can benefit a sustainable circular economy—provided there is a market for it. The study was published by a research team from the Leibniz Institute for Natural Product Research and Infection Biology—Hans Knöll Institute (Leibniz-HKI) in the journal ACS Sustainable Chemistry & Engineering.

Read more.

16 notes

·

View notes

Text

Nothing appears remarkable about a dish of fresh ravioli made with solein. It looks and tastes the same as normal pasta.

But the origins of the proteins which give it its full-bodied flavour are extraordinary: they come from Europe’s first factory dedicated to making human food from electricity and air.

The factory’s owner, Solar Foods, has started production at a site in Vantaa, near the Finnish capital of Helsinki, that will be able to produce 160 tonnes of food a year. It follows several years of experimenting at lab scale.

Solar Foods has already gained novel food approval for solein in Singapore, and is seeking to introduce its products in the US this autumn, followed by the EU by the end of 2025 – and the UK too, if the regulator can get through the deluge of cannabis-related products.

The factory’s output may be small in terms of the global food industry, but Pasi Vainikka, the Solar Foods co-founder and chief executive, hopes that proving its technology works will be a crucial step in revolutionising what humans eat.

Food and agriculture is responsible for about a quarter of all planet-heating carbon emissions. Its share of pollution is likely to grow as other industries shift to using green electricity, and ever-expanding middle-classes demand more meat for their tables. Up to now the focus for some climate campaigners has been to try to persuade people to eat less meat and more plants. Non-farmed proteins such as solein might make that approach more appealing.

Solein comes in the form of a yellowish powder made up of single-cell organisms, similar to yeast used in baking or beer-making. The company is hoping for those proteins to be used in meat alternatives, cheese and milkshakes, and as an egg replacement ingredient in noodles, pasta and mayonnaise.

The ravioli it served up this week was made with solein replacing egg, with a solein version of cream cheese. The Finnish confectioner Fazer has already sold chocolate bars in Singapore with added solein (which is also a handy source of iron for vegans). A Singaporean restaurant last year created a solein chocolate gelato, replacing dairy milk.

Vainikka was researching renewable energy systems at a Finnish research institute in 2014 when he met his co-founder, Juha-Pekka Pitkänen, a bioprocesses scientist. Pitkänen told him of soil-dwelling microbes that release the energy they need to live from oxidising hydrogen (rather than the glucose used by humans, for instance).

Together they built a 200-litre fermenter in a garage near Helsinki, to prove the technology could be used for food, but then went into the wild “finding new potatoes to grow”. All Vainikka will say on solein’s origins is that they found it somewhere “close to shore” in the Baltic Sea.

Almost all food consumed by humans at the moment ultimately comes from plants, which use energy from the sun for photosynthesis. That process converts carbon dioxide and water into the molecules they need to grow. Solar Foods instead uses the same renewable electricity from the sun to split water apart. It then feeds the hydrogen and oxygen to the microbes in a brewing vessel, plus carbon dioxide captured from the air from the company’s office ventilation system.

The claim that the proteins are made out of thin air is “never more than 95% true”, says Vainnika: 5% of the mixture in the brewing vessel is a solution containing other minerals needed by cells, such as iron, magnesium, calcium and phosphorus. The microbes are then pasteurised (killing them), then dried in a centrifuge and with hot air. That leaves a powder that can be used in food.

The process could also use CO2 from, for instance, burning fuels – although the molecule would end up back in the atmosphere once humans eat the solein and breathe out the carbon again. The real climate benefits from solein come from cutting the vast tracts of land used – and abused through deforestation on an epic scale – for animal feed and pasture. Instead, renewed forests could trap carbon.

Efficient US farmers get 3.3 tonnes of soya beans from each harvest of a hectare, according to the UN’s Food and Agriculture Organization. By contrast, Solar Foods’ pilot factory takes up a fifth of a hectare to produce 160 tonnes a year.

“As we can relieve pressures on agricultural land, they can rewild and return to being climate sinks,��� Vainikka says.

Other companies are pursuing the same dream. Dozens are using microbes to create animal feed, although they often require sugars or fossil fuel feedstocks. One US rival, Air Protein, has opened a factory in California using similar “hydrogenotrophs” – hydrogen eaters. It has the backing of the food multinational Archer-Daniels-Midland, the British bank Barclays and GV (formerly Google Ventures).

The Dutch company Deep Branch, which is making fish food, claims its Proton protein will be 60% less carbon-intensive than conventional proteins. Deep Branch is looking at taking the CO2 produced by the UK biomass power generator Drax.

The companies have produced their test products. Now they face the challenge of proving their technology works at scale.

Vainikka says that is the key problem for cultured meat, or lab-grown meat. The market value of newly listed companies such as Beyond Meat soared during the coronavirus pandemic bubble, only to come crashing down as sales slumped. The opening of Solar Foods’ first factory will be crucial in persuading investors that the company will not suffer the same fate.

With meat protein, which is much more expensive than plants or cellular agriculture, there is simply no competition on price for each kilo. But Solar Foods and rivals could face other problems. Conservative politicians particularly in the US and Italy have identified lab-grown food as a threat to their ranching and farming cultures.

Vainikka argues that these fears are misplaced. He wants “coexistence of new and old”, with artisanal, high-quality farms remaining alongside cell farming that can deliver cheap, bulk foods. He argues it is “the opportunity of the century for the meat industry” to focus on quality rather than churning out as much cheap (and heavily subsidised) meat as possible. And plant agriculture will also remain, he argues.

“The future is not powder: the main body of food will still come through plants,” he says. The occasional “salami with the cultural heritage, that can remain. The meat in your lasagne during lunch will be done by cellular agriculture.”

3 notes

·

View notes

Text

کتابهای زبان اصلی در زمینه بیوتکنولوژی: منابع کلیدی برای دانشجویان و پژوهشگران

بیوتکنولوژی یک رشته میانرشتهای است که اصول زیستشناسی و تکنولوژی را ترکیب میکند و کاربردهای زیادی در زمینههای پزشکی، داروسازی، کشاورزی و محیطزیست دارد. برای آشنایی با این حوزه و بهروز ماندن در آن، مطالعه کتابهای معتبر ضروری است. در اینجا بهترین کتابهای زبان اصلی در زمینه بیوتکنولوژی معرفی شدهاند:

"Molecular Biotechnology: Principles and Applications of Recombinant DNA" – مرجعی جامع برای بیوتکنولوژی مولکولی و کاربردهای DNA نوترکیب.

"Biotechnology for Beginners" – منبعی ساده و مفید برای مبتدیان در زمینه بیوتکنولوژی.

"Principles of Gene Manipulation and Genomics" – بررسی اصول دستکاری ژن و ژنومیک.

"Industrial Biotechnology: Sustainable Growth and Applications" – تمرکز بر کاربردهای بیوتکنولوژی در صنعت و تولید محصولات.

"Bioprocess Engineering: Basic Concepts" – منبع اصلی برای درک فرآیندهای بیولوژیکی در صنعت.

"Genomes 4" – کتابی جامع در زمینه ژنومیک و تجزیه و تحلیل دادههای ژنتیکی.

"Biotechnology: Academic Cell Update Edition" – پوششدهی کامل به مفاهیم بیوتکنولوژی.

"Biotechnology: Science and Technology" – مرجعی جامع در زمینه بیوتکنولوژی مولکولی و کاربردهای آن.

این کتابها به دانشجویان، پژوهشگران و متخصصان بیوتکنولوژی کمک میکنند تا دانش خود را گسترش دهند و با آخرین پیشرفتها در این حوزه آشنا شوند.

0 notes

Text

Bioprocess containers Market Industry Forecast, 2024–2030

Bioprocess Containers Market Overview

Request Sample :

A major trend is the growing demand for single-use bioprocess containers. Single-use bioprocess containers eliminate cleaning requirements between batches and reduce the risk of batch failure due to cross-contamination. Additionally, single-use systems are also cost effective. Respondents identified lower-cost single use devices as the most important area of interest for new products and technologies in 2023. Another notable trend is the rise in upstream bioprocess products driven by increasing demand for biopharmaceuticals, including biologics and gene therapies. As the industry focuses on enhancing cell culture, fermentation, and early-stage production efficiencies, there is a heightened need for advanced upstream bioprocess products to support these developments. According to a February 2024 article in BioProcess International, the top areas in upstream production were cell-culture media, bioreactors, and information technology (IT), which encompasses automation, software, and networking. Interest in IT solutions among respondents grew from 21.1% in 2022 to 29% in 2023.

COVID-19 / Ukraine Crisis — Impact Analysis:

The COVID-19 pandemic significantly accelerated the growth of the bioprocess containers market, driven by the urgent demand for vaccine production and biologics manufacturing. As pharmaceutical companies ramped up production, flexible and scalable solutions like single-use bioprocess containers became critical for handling cell cultures, reagents, and drug formulations. Additionally, disruptions in global supply chains and a heightened focus on healthcare infrastructure underscored the importance of efficient bioprocessing technologies. Post-pandemic, the market continues to grow, with increased interest in biologics, gene therapies, and personalized medicine fueling demand for flexible manufacturing solutions.

The Ukraine-Russia war has disrupted global supply chains, impacting the bioprocess containers market. The conflict has led to shortages of raw materials, increased transportation costs, and delays in production for biopharma manufacturing. Europe, a key region for bioprocessing, has been particularly affected by rising energy prices and supply chain instability. Companies have been forced to seek alternative suppliers and adjust logistics strategies to mitigate these disruptions. Despite the challenges, the growing demand for biologics and vaccines continues to drive the market, with manufacturers prioritizing resilient, flexible bioprocess solutions to ensure production continuity.

Key Takeaways 2D Bioprocess Containers are the Largest Segment

2D bioprocess containers dominate the bioprocess containers markets due to their cost-effectiveness and operational efficiency. Offering benefits such as easier storage, reduced contamination risk, and simplified handling, 2D containers meet the industry’s growing demand for scalable and flexible solutions. Additionally, their structure minimizes contamination risks and allows for easier handling, streamlining workflows and reducing labor-intensive procedures. As the biopharmaceutical industry grows, there is an increasing demand for scalable and flexible solutions to meet diverse production needs. 2D containers cater to these requirements by enabling single-use options that simplify transitions between processes, making them ideal for adaptable production setups.

Inquiry Before Buying:

Bioprocess Containers Market Segment Analysis — By Application

Cell culture is a major application of bioprocess containers (BPCs), playing a crucial role in the biomanufacturing industry. BPCs are extensively used for growing and maintaining mammalian, microbial, and insect cells, offering flexibility and scalability in production. They are designed with features like ports for sampling and reagent addition, and integrated sensors for monitoring environmental conditions. The increasing demand for biologics, including therapeutic proteins and vaccines, has driven the widespread adoption of BPCs in cell culture, making it a key focus in the development and manufacturing of biopharmaceutical products. According to Merck 2024, Merck invested $24.84 million to expand cell culture media production in Kansas, USA.

North America Dominates the Market

North America leads the global bioprocess container (BPC) market due to its advanced biopharmaceutical industry and substantial investments in research and development. The United States and Canada are at the forefront, driving significant growth with a strong focus on innovative single-use technologies and sophisticated manufacturing processes. The region’s robust infrastructure, presence of major biopharma companies, and commitment to cutting-edge advancements make North America a key player in the BPC market, particularly in applications such as cell culture, media preparation, and downstream processing. The United States dominates the pharmaceutical industry, home to some of the world’s largest companies like Pfizer, Johnson & Johnson, Merck & Co. and AbbVie. In July 2024, Despite the expected decrease in COVID-related revenue, Pfizer’s revenue rose 3% operationally to $28.2 billion. In December 2023, Pfizer finalized the $43 billion acquisition of Seagen (a biotech company), doubling its oncology pipeline. Such developments are a major catalyst for growth in the bioprocess container market, as it leads to a significant increase in the production of biopharmaceuticals, particularly in the oncology space.

Bioprocess Containers Market Drivers

Single Use Systems

The cost-effectiveness of single-use systems is a major driver of the bioprocess containers market. Single-use bioprocess containers significantly reduce operational costs compared to traditional stainless-steel systems by eliminating the need for time-consuming cleaning, sterilization, and maintenance. This leads to lower capital and operational expenses, making single-use systems an attractive option for biopharmaceutical manufacturers looking to streamline their processes and improve efficiency. As a result, the adoption of single-use bioprocess containers is increasing, driven by their economic advantages and the growing demand for flexible and cost-efficient manufacturing solutions. BioPlan’s 19th Annual Report and Survey of Biopharmaceutical Manufacturing indicates a substantial rise in the use of commercial-scale single-use (SUS) bioreactors, which grew from 32.5% in 2019 to 43% in 2022. This 32% increase is primarily due to the heightened demand for flexibility and rapid deployment in bioproduction during the COVID-19 pandemic.

Schedule A Call :

Rising Demand for Biopharmaceuticals

The rising demand for biopharmaceuticals is a key driver of the bioprocess containers market, particularly due to the increasing prevalence of chronic diseases such as cancer, diabetes, and autoimmune disorders among the aging population. As the global population of individuals aged 60 and above continues to grow, with significant increases in regions like North America, Europe, and parts of Asia, the need for advanced biologic treatments, including monoclonal antibodies, vaccines, and cell therapies, is intensifying. Bioprocess containers play a critical role in the production, storage, and transportation of these biopharmaceutical products, making them essential to meeting the growing demand. This surge in biopharmaceutical production is, in turn, driving the expansion of the bioprocess containers market. According to IDF projections, the number of adults living with diabetes will increase by 46% to 783 million by 2045, representing one in eight adults. The American Cancer Society (ACS) estimates that by 2050, the number of cancer cases is expected to rise to 35 million.

Bioprocess Containers Market Challenges

Regulatory Requirements

Regulatory requirements in the bioprocess container market pose a significant challenge due to the need to comply with stringent standards across various regions and applications. Manufacturers must navigate complex regulations, such as those from the FDA, ISO, and USP, which require rigorous validation and documentation. Staying up-to-date with evolving guidelines and ensuring that containers meet these standards is crucial for maintaining product safety and efficacy, but it adds complexity and cost to the manufacturing process. According to Cytiva, single-use bioprocess technologies are advanced but lack specific regulations, creating uncertainty about their suitability for therapeutic production and leaving bio manufacturers concerned about their appropriateness.

Buy Now :

Bioprocess Containers Market Key Players

Product/Service launches, approvals, patents and events, acquisitions, partnerships and collaborations are key strategies adopted by players in the Bioprocess Containers Market. The top 10 players in the Bioprocess Containers Market are

Lonza Group AG

Corning Incorporated

Entegris, Inc.

Parker Hannifin Corporation

Meissner Filtration Products, Inc.

Merck KGaA

Avantor Inc.

Sartorius AG

Thermo Fisher Scientific Inc.

Cytiva,

For more Lifesciences and Healthcare Market reports, please click here

#Bioprocessing 🌱#PharmaceuticalManufacturing 💊#SingleUseTechnology 🧪#BiotechIndustry 🧬#BioprocessContainers 🏭#LabTechnology 🔬#BiopharmaInnovation 🚀#HealthcareManufacturing 🏥

0 notes

Text

polycarbonate laboratory bottles

Polycarbonate laboratory bottles are essential for scientific research, medical testing, and industrial applications. Known for their high impact resistance, clarity, and autoclavability, these bottles offer a durable and safe solution for liquid storage. Unlike glass bottles, polycarbonate lab bottles provide excellent shatterproof properties, making them a preferred choice for labs worldwide.

Email Us : [email protected]

Key Features of Polycarbonate Laboratory Bottles

High-Temperature Resistance – Withstand autoclaving and sterilization processes.

Shatterproof & Durable – Safer than glass bottles, preventing breakage risks.

Chemical Compatibility – Ideal for storing various solutions and reagents.

Leakproof Design – Ensures safe handling and storage of liquids.

Clear Visibility – Provides easy monitoring of contents.

Best Polycarbonate Laboratory Bottles from Foxx Life Sciences

If you're looking for premium-quality polycarbonate lab bottles, Foxx Life Sciences offers a superior range of options. One of the top choices is the EZBio® Square Polycarbonate Bottle 1L – Sterilized.

Product Highlights:

✅ 1L capacity with a 38-430mm VersaCap for secure sealing ✅ Made from high-quality, autoclavable polycarbonate✅ Pre-sterilized and ready for immediate use ✅ Square shape for easy storage and handling✅ Leakproof and durable for long-term lab use

Applications of Polycarbonate Laboratory Bottles

Chemical Storage – Secure storage of laboratory reagents.

Media Preparation – Used in microbiology and biotechnology labs.

Sample Transport – Ideal for safely transporting liquid samples.

Pharmaceutical & Medical Uses – Used in research and drug development.

Where to Buy the Best Polycarbonate Laboratory Bottles?

Foxx Life Sciences is a trusted provider of high-quality lab solutions, offering durable and reliable polycarbonate laboratory bottles for various scientific applications. You can explore their premium range, including the EZBio® Square Polycarbonate Bottle 1L, for all your laboratory needs.

Conclusion

Polycarbonate laboratory bottles are an excellent choice for labs requiring durability, clarity, and chemical resistance. Whether you need bottles for chemical storage, media preparation, or sample transport, Foxx Life Sciences provides high-quality, leakproof options.

🔗 Explore more at Foxx Life Sciences and get the best polycarbonate lab bottles today!

Contact Us : [email protected]

0 notes

Text

Brazil, South Africa, and Australia are the new opportunity grounds for Precision Fermentation market players

According to a recent research, Industry revenue for Precision Fermentation is expected to rise to $130.7 billion by 2035 from $2.7 billion of 2023. U.S., Germany and Japan are the top 3 markets and combinely holds substantial demand share. The revenue growth of market players in these countries is expected to range between 36.8% and 53.6% annually for period 2024 to 2035.

Industry transition including environmental impact reduction and consumer education, are transforming the supply chain of Precision Fermentation market. Sustained efforts towards lowering greenhouse gas emissions and preserving resources by optimizing bioprocessing methods.

Check detailed report here - https://datastringconsulting.com/industry-analysis/precision-fermentation-market-research-report

Research Study addresses the market dynamics including opportunities, competition analysis, industry insights for Type (Microbial, Algal, Fungal), Application (Food & Beverage, Pharmaceuticals, Industrial) and Process (Batch, Continuous, Fed-batch).

Industry Leadership and Strategies

Companies such as Novozymes, DSM, Perfect Day, Geltor, Sigma-Aldrich, Thermo Fisher, Sartorius and Eppendorf are well placed in the market. Below table summarize the strategies employed by these players within the eco-system.

Applications

Leading Players

Player's Strategies

Microbial Enzymes

Novozymes, DSM

Leading the charge in sustainable enzyme production

Alternative Proteins

Perfect Day, Geltor

Innovating in animal-free protein alternatives

Evolving & Shifting Regional Markets

North America and Europe are the two most active and leading regions in the market. With different regional dynamics and industry challenges like regulatory barriers, scale-up costs and market penetration; market supply chain from input suppliers to end-users is expected to evolve & expand further, especially within emerging markets

The market in emerging countries is expected to expand substantially between 2024 and 2030, supported by market drivers such as sustainability in production, health and nutrition, and innovation in biomaterials.

About DataString Consulting

DataString Consulting assist companies in strategy formulations & roadmap creation including TAM expansion, revenue diversification strategies and venturing into new markets; by offering in depth insights into developing trends and competitor landscapes as well as customer demographics. Our customized & direct strategies, filters industry noises into new opportunities; and reduces the effective connect time between products and its market niche.

DataString Consulting offers complete range of market research and business intelligence solutions for both B2C and B2B markets all under one roof. DataString’s leadership team has more than 30 years of combined experience in Market & business research and strategy advisory across the world. Our Industry experts and data aggregators continuously track & monitor high growth segments within more than 15 industries and 60 sub-industries.

https://datastringconsulting.com/downloadsample/precision-fermentation-market-research-report

0 notes

Text

Application and Advantages of Lab Scale Fermenter

Understanding Lab-Scale Bioreactors

Lab-scale bioreactors, often referred to as benchtop bioreactors, are compact vessels designed to facilitate the growth and manipulation of various biological entities under controlled conditions. These reactors mimic the natural environment of microorganisms or cells, providing optimal conditions for proliferation, metabolism, and product formation.

Components and Design

The design of lab-scale bioreactors is meticulously crafted to emulate the conditions prevalent in industrial-scale fermenters while maintaining versatility and ease of operation. Key components typically include:

Vessel: The core of the bioreactor, where the biological culture resides. Vessels come in various sizes and configurations, accommodating different volumes and types of cultures.

Agitation System: Ensures uniform mixing of nutrients, gases, and metabolites within the culture. Agitation mechanisms may include stirrers, impellers, or spargers, depending on the specific requirements of the culture.

Temperature Control: Precise temperature regulation is essential for maintaining optimal growth conditions. Bioreactors are equipped with heating elements and cooling jackets, along with temperature probes and controllers to monitor and adjust temperature levels.

pH and Dissolved Oxygen Control: Maintaining appropriate pH and dissolved oxygen levels is crucial for cell viability and productivity. Bioreactors are equipped with sensors and controllers to regulate these parameters through the addition of acids, bases, or oxygen.

Monitoring and Control Systems: Advanced bioreactors are integrated with sophisticated monitoring and control systems, allowing real-time monitoring of key parameters such as temperature, pH, dissolved oxygen, and biomass concentration. Automated control algorithms facilitate precise adjustment of operating conditions to optimize culture performance.

Applications and Advantages of Lab Scale Bioreactor

The versatility of lab-scale bioreactors extends across a wide range of applications in biotechnology, pharmaceuticals, and academia:

Bioprocess Development: Lab-scale bioreactors serve as invaluable tools for the optimization and scale-up of bioprocesses. Researchers can fine-tune culture conditions, evaluate the impact of different parameters, and optimize productivity before transitioning to larger scales.

Cell Culture and Tissue Engineering: Bioreactors play a pivotal role in the cultivation of mammalian cells and tissues for various applications, including regenerative medicine, drug discovery, and tissue engineering. Controlled environments within bioreactors facilitate the growth and differentiation of cells into functional tissues.

Microbial Fermentation: Microbial fermentation processes, such as the production of antibiotics, enzymes, and biofuels, are extensively studied and optimized using lab-scale bioreactors. These reactors allow researchers to explore different microbial strains, media formulations, and process conditions to maximize product yields and quality.

Biological Research and Education: Bioreactors serve as indispensable tools for biological research and education, providing students and researchers with hands-on experience in culturing and manipulating biological systems. Benchtop bioreactors enable reproducible experimentation and data collection, fostering a deeper understanding of bioprocess principles and techniques.

Challenges and Future Directions

While lab-scale bioreactors offer tremendous potential, several challenges persist in their design and operation:

Scalability: Translating results from lab-scale bioreactors to larger industrial-scale fermenters remains a challenge due to differences in hydrodynamics, mass transfer, and mixing dynamics. Bridging this scalability gap requires advanced computational modeling, process optimization, and scale-up strategies.

Sterility and Contamination Control: Maintaining sterility and preventing contamination are critical aspects of bioreactor operation, particularly in cell culture and pharmaceutical applications. Robust sterilization protocols, aseptic techniques, and stringent quality control measures are essential to minimize the risk of contamination.

Process Intensification: Enhancing productivity and efficiency through process intensification strategies is a key focus area in bioreactor development. Integration of online monitoring and control systems, advanced analytics, and novel bioreactor designs can streamline bioprocesses and maximize resource utilization.

Conclusion

Lab-scale bioreactors represent the cornerstone of bioprocessing innovation, offering a platform for exploration, discovery, and optimization across diverse biological applications. As advances in biotechnology continue to accelerate, the role of lab-scale bioreactors in shaping the future of bioprocessing becomes increasingly pronounced. By addressing challenges, embracing technological advancements, and fostering interdisciplinary collaboration, we can unlock the full potential of lab-scale bioreactors and propel bioprocessing into a new era of sustainability, efficiency, and impact.

#lab scale bioreactor#lab scale bioreactor manufacturer#lab scale bioreactor supplier#lab scale bioreactor manufacturer in India#fermenter technologies

2 notes

·

View notes

Text

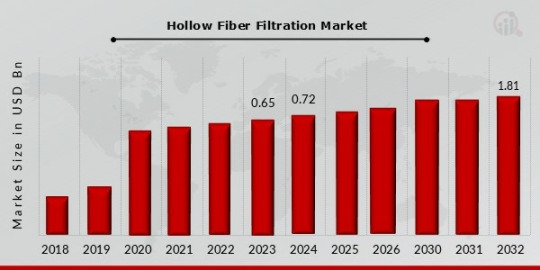

Hollow Fiber Filtration Market Size, Growth Outlook 2035

Hollow Fiber Filtration Market Size was estimated at 0.65 (USD Billion) in 2023. The Hollow Fiber Filtration Industry is expected to grow from 0.72 (USD Billion) in 2024 to 1.81 (USD Billion) by 2032. The Hollow Fiber Filtration Market CAGR (growth rate) is expected to be around 12.14% during the forecast period (2024 - 2032).

Market Overview

The Hollow Fiber Filtration Market is growing rapidly due to increasing demand for biopharmaceutical manufacturing, cell culture applications, and protein purification. Hollow fiber filtration is widely used in ultrafiltration, microfiltration, and virus filtration, making it a crucial technology in bioprocessing and industrial applications. The expansion of the biopharmaceutical sector, rising demand for advanced filtration techniques, and growing adoption of single-use filtration systems are key market drivers.

Market Size and Share

Hollow Fiber Filtration Market Size was estimated at 0.65 (USD Billion) in 2023. The Hollow Fiber Filtration Industry is expected to grow from 0.72 (USD Billion) in 2024 to 1.81 (USD Billion) by 2032. The Hollow Fiber Filtration Market CAGR (growth rate) is expected to be around 12.14% during the forecast period (2024 - 2032). The market is experiencing steady growth, with North America leading due to its advanced bioprocessing facilities and strong presence of pharmaceutical manufacturers. Asia-Pacific is emerging as a high-growth region, fueled by increasing investments in biopharmaceutical production and biotechnology research. The market is expected to grow as more pharmaceutical companies shift toward continuous bioprocessing and advanced filtration methods.

Growth Drivers

Increasing Biopharmaceutical Production: The rise in monoclonal antibody (mAb) production, cell and gene therapies, and recombinant protein manufacturing is driving demand for hollow fiber filtration.

Advancements in Single-Use Technologies: Growing adoption of single-use filtration systems is reducing contamination risks and improving operational efficiency.

Rising Focus on Virus Filtration and Purification: With increasing concerns about viral contamination in biologics, demand for efficient filtration technologies is surging.

Expanding Research in Biotechnology and Cell Therapy: Hollow fiber systems are widely used in cell culture harvesting, perfusion bioreactors, and protein concentration.

Challenges and Restraints

High Initial Investment Costs: Advanced filtration systems require significant capital investment, which can limit adoption.

Complexity in Process Optimization: The efficiency of hollow fiber filtration depends on operational parameters, requiring specialized expertise.

Regulatory Compliance Challenges: Strict guidelines for biopharmaceutical manufacturing and filtration technologies can delay product approvals.

Regional Analysis

North America: Dominates the market due to strong biopharmaceutical industry, high R&D investments, and technological advancements.

Europe: Witnessing significant adoption of hollow fiber filtration for virus removal and protein purification.

Asia-Pacific: Expected to register the fastest growth due to rising biopharmaceutical production and increasing government support for biotechnology research.

Segmental Analysis

The market is segmented based on:

Filtration Type:

Ultrafiltration

Microfiltration

Virus Filtration

Application:

Biopharmaceutical Processing

Cell Culture & Harvesting

Protein Concentration

Water Treatment

Food & Beverage Processing

End-User:

Biopharmaceutical Companies

Academic & Research Institutes

Contract Research & Manufacturing Organizations

Key Market Players

3M Company

Polyflux International

Koch Membrane Systems

Fresenius Medical Care AG

Arkema SA

Asahi Kasei Corporation

Recent Developments

Launch of next-generation hollow fiber filtration modules for continuous bioprocessing applications.

Increasing adoption of automation and AI in bioprocess filtration systems for enhanced efficiency.

Expansion of biopharmaceutical manufacturing facilities to meet the growing demand for biologics.

For more information, please visit us at @marketresearchfuture.

#Hollow Fiber Filtration Market Size#Hollow Fiber Filtration Market Share#Hollow Fiber Filtration Market Growth#Hollow Fiber Filtration Market Analysis#Hollow Fiber Filtration Market Trends#Hollow Fiber Filtration Market Forecast#Hollow Fiber Filtration Market Segments

0 notes

Text

Navigating the Landscape of Consumables in Healthcare: Trends, Innovations, and Market Dynamics

In the dynamic realm of healthcare, consumables play a pivotal role, serving as essential tools in various settings, from laboratories to dental clinics. This blog explores the multifaceted world of consumables, shedding light on market trends, innovations, and the impact of these indispensable items on the broader healthcare landscape.

Consumables Market Overview:

Market Size and Growth: The global consumables market is witnessing robust growth, with a projected valuation exceeding USD 1.4 trillion by 2026. This expansive market encompasses a wide array of products, including medical, dental, laboratory, and single-use bioprocessing consumables.

Dental Consumables Market: A Smile in Every Detail

Market Dynamics: The dental consumables market is thriving, driven by the increasing focus on oral health worldwide. In 2021, the global dental consumables market was valued at approximately USD 27.7 billion, with an expected CAGR of 6.3% from 2022 to 2028.

Single-Use Bioprocessing Market: Efficiency Redefined

Advancements and Demand: The single-use bioprocessing market is experiencing unprecedented demand, with a projected CAGR of 17.5% from 2021 to 2028. The shift towards single-use technologies in bioprocessing is driven by their cost-effectiveness and efficiency in manufacturing processes.

Hospital and Laboratory Consumables Market: Critical Components of Healthcare

Industry Reports and Trends: Hospital and laboratory consumables are integral to healthcare operations. Industry research reports indicate a steady growth trajectory, with an increasing emphasis on sustainability and the adoption of eco-friendly materials.

Medical Consumables Market: Ensuring Patient Care

Market Size and Revenue: The medical consumables market, encompassing a wide range of products such as wound care supplies and diagnostic consumables, is anticipated to reach USD 273.5 billion by 2028, with a CAGR of 6.2%. This growth is propelled by advancements in patient care and the rising prevalence of chronic diseases.

Chromatography Consumables Market: Precision in Analysis

Market Trends and Size: The chromatography consumables market is witnessing steady growth, with an estimated value of USD 11.5 billion by 2026. This is attributed to the increasing adoption of chromatography techniques in pharmaceutical and biotechnology industries.

Healthcare Consumables Market: Shaping the Future of Healthcare

Emerging Trends: The broader healthcare consumables market is marked by transformative trends, including the integration of digital technologies, the rise of point-of-care testing, and a growing focus on sustainable practices. These trends are reshaping the way healthcare consumables are manufactured, distributed, and utilized.

Conclusion: Innovations and Beyond

In conclusion, the consumables market in healthcare is a dynamic and evolving landscape. From dental clinics to bioprocessing facilities, consumables play an indispensable role in ensuring the efficiency, safety, and sustainability of healthcare practices. As the demand for healthcare consumables continues to grow, fueled by technological advancements and a focus on patient-centric care, the industry is poised for further innovations that will shape the future of healthcare delivery.

#Consumables Market#Dental consumables market#Single-use Bioprocessing Market#Consumables Industry Research Reports

0 notes

Text

Why Amity Noida Stands Out as a Leading Biotechnology College!

Biotechnology is transforming industries, from healthcare to agriculture and environmental science. Choosing the right biotechnology college is crucial for students who aspire to innovate and make a difference. Amity Noida has established itself as a premier institution offering BSc Biotechnology courses with state-of-the-art facilities, experienced faculty, and global opportunities.

In this blog, we will explore why Amity Noida is the best choice for students looking for a BSc biotechnology college in Delhi NCR and why it stands out as a top biotechnology university in India.

1. World-Class Infrastructure and Research Facilities

One of the major reasons Amity Noida is recognized as a top biotechnology collegeis its cutting-edge infrastructure. The university is equipped with modern laboratories, high-tech research centers, and well-stocked libraries that support hands-on learning.

The labs at Amity Noida are designed to give students practical exposure to genetics, microbiology, bioinformatics, and molecular biology. With advanced equipment and research-oriented learning, students can conduct experiments, analyze results, and gain real-world scientific experience. Such exposure helps bridge the gap between theory and application, preparing students for careers in biotech research, pharmaceuticals, and healthcare.

2. Comprehensive BSc Biotechnology Courses

Amity Noida offers BSc Biotechnology courses that are structured to provide in-depth knowledge and practical skills. The curriculum includes a mix of theoretical studies, laboratory work, and industrial training, ensuring students are well-prepared for future careers.

The courses cover essential topics such as genetic engineering, industrial microbiology, bioprocess engineering, bioinformatics, and environmental biotechnology. Unlike many other universities, Amity Noida ensures that students get access to internships, workshops, and industry projects, making them job-ready by the time they graduate.

3. Experienced Faculty and Industry Mentorship

A great biotechnology university in India is defined by its faculty, and Amity Noida takes pride in its team of experienced professors, researchers, and industry experts. The faculty members come from diverse backgrounds, including top research institutions and global biotech companies, providing students with valuable insights into the industry.

In addition to regular coursework, students benefit from mentorship programs, guest lectures, and collaborations with biotech firms. These interactions help students understand the latest trends, challenges, and career opportunities in the biotechnology field.

4. Affordable Biotechnology Course Fees and Scholarships

Many students hesitate to pursue higher education in biotechnology due to financial concerns. However, Amity Noida offersflexible biotechnology course fees and scholarship opportunities for deserving students.

The university provides merit-based scholarships, financial aid programs, and easy installment plans to ensure that quality education is accessible to all students. This makes Amity Noida one of the most affordable yet prestigious biotechnology universities in India.

5. Industry Collaborations and Placement Opportunities

A major advantage of studying at Amity Noida is the strong industry connections that the university has built over the years. As a leading BSc biotechnology college in Delhi NCR, Amity Noida partners withtop pharmaceutical companies, research labs, and biotech firms to provide students with excellent placement opportunities.

The Career Resource Center (CRC) at Amity Noida helps students with resume building, interview preparation, and networking with top recruiters. Many graduates from Amity Noida have secured jobs in leading biotech firms such as Biocon, Serum Institute, Sun Pharma, and Dr. Reddy’s Laboratories.

6. Global Exposure and Research Opportunities

Biotechnology is a global field, and Amity Noida ensures that its students are prepared for international careers. The university collaborates with prestigious international institutions and research centers, allowing students to participate in exchange programs, joint research projects, and global conferences.

Students also get opportunities to publish their research in top scientific journals, attend biotech summits, and work with renowned scientists and industry experts. This global exposure makes Amity Noida a preferred choice for students aiming to work in international biotech industries, research labs, and pharmaceutical companies.

Conclusion: The Right Choice for Aspiring Biotechnologists

Choosing a biotechnology college that provides quality education, industry exposure, and research opportunities is essential for building a successful career. Amity Noida stands out as a top BSc biotechnology college in Delhi NCR because of its modern infrastructure, expert faculty, industry collaborations, and strong placement record.

If you are looking for a bio technology course that can help you achieve your career goals, Amity Noida is the perfect place to start your journey. With its comprehensive courses, affordable biotechnology course fees, and global opportunities, it is truly a leading biotechnology university in India.

0 notes