#Industrial Actuator Valve

Explore tagged Tumblr posts

Text

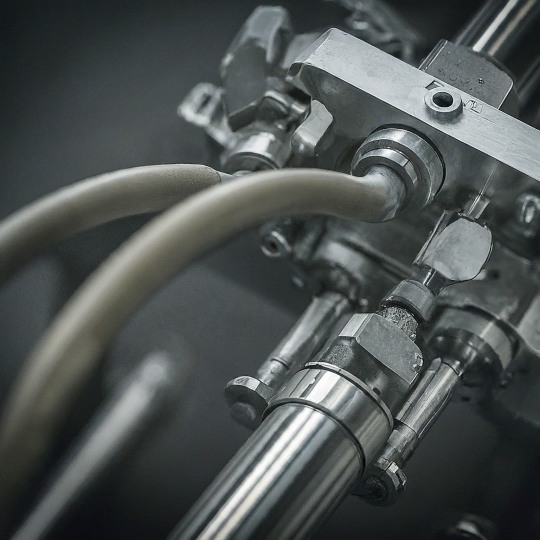

Actuator Valve: Enhancing Precision and Efficiency in Industrial Applications

In the fast-paced world of industrial operations, efficient control over fluid and gas flow is paramount. Actuator valves play a critical role in ensuring this control with precision, reliability, and automation. Whether you’re managing complex chemical processes, oil and gas operations, or manufacturing systems, actuator valves offer a streamlined solution that improves productivity while reducing manual intervention.

What is an Actuator Valve?

An actuator valve is a type of valve used to control the flow of a liquid or gas in a system, operated by an external actuator. Unlike traditional valves that require manual operation, actuator valves rely on pneumatic, hydraulic, or electric mechanisms to open, close, or adjust the valve position. This automation makes them an ideal choice for systems that require consistent and accurate regulation without the need for direct human input.

Types of Actuator Valves

There are several types of actuator valves, each designed for specific industrial requirements:

Pneumatic Actuator Valve: Powered by compressed air, these valves are commonly used in applications requiring fast response times and cost-effective operation.

Electric Actuator Valve: Using electric motors to operate, these valves are ideal for applications where energy efficiency is critical. They offer precise control and are often used in high-precision industries like manufacturing and automation.

Hydraulic Actuator Valve: Hydraulic-powered actuator valves are known for their strength and ability to operate under high-pressure systems, making them suitable for heavy-duty applications.

Key Benefits of Using Actuator Valves

Improved Efficiency: Automation of valve operations allows for better process control, minimizing errors and downtime. This leads to enhanced efficiency across your systems.

Precision and Consistency: Actuator valves are designed for accurate control, ensuring that flow rates are precisely regulated, which is crucial in industries where minor variations can lead to significant disruptions.

Safety: By automating the control process, actuator valves reduce the need for manual intervention in potentially hazardous environments, enhancing safety for workers.

Durability: Built from high-grade materials, actuator valves are designed to withstand extreme environments, from high pressure to corrosive conditions, ensuring long-lasting performance.

Applications of Actuator Valves

Actuator valves are used across a variety of industries, including:

Oil and Gas: In the oil and gas sector, precise flow control is critical to the success of operations. Actuator valves help regulate the flow of gas and liquids through pipelines, ensuring smooth and safe operation.

Chemical Processing: In chemical plants, where accurate control of different fluids is necessary for reactions, actuator valves provide reliability and safety.

Manufacturing: Automation is the backbone of manufacturing, and actuator valves help in maintaining the precision and consistency needed in automated processes.

Why Choose Prabha Electronics' Actuator Valves?

At Prabha Electronics, we are committed to providing high-quality actuator valves that meet the unique demands of your industry. Our valves are engineered for durability, precision, and safety, ensuring reliable performance in even the most demanding applications. Whether you need pneumatic, electric, or hydraulic actuators, our extensive range is designed to seamlessly integrate with your systems, offering unmatched efficiency.

Conclusion

In today’s industrial landscape, actuator valves are more than just components; they are vital to the smooth functioning of critical systems. By choosing Prabha Electronics' actuator valves, you invest in quality, performance, and reliability. Explore our range today and take the first step toward optimizing your flow control systems for enhanced productivity and safety.

#Actuator valve#industrial actuator valve#flow control valve#automation valve#pneumatic actuator valve#electric actuator valve#fluid control valve#industrial valves

0 notes

Text

Winging It: Best Butterfly Valve Manufacturers in Ahmedabad

Butterfly Valve Manufacturers in Ahmedabad – Explore Ahmedabad’s leading Butterfly Valve manufacturers & suppliers. Get quality valves for industrial applications from Gold Techno Casting.

Google Map:--> https://maps.app.goo.gl/HPDJtfx5r7s11pun7

Butterfly Valve Manufacturers in Ahmedabad, Butterfly Valve Manufacturer & Supplier in Ahmedabad, Butterfly Valves in Ahmedabad, Cast Iron Butterfly Valve Manufacturer From Ahmedabad, Butterfly Valve, Butterfly Valve Manufacturer in Ahmedabad, Top Butterfly Valve Manufacturers in Ahmedabad, Cast Iron Teflon Seated Butterfly Valve in Ahmedabad, Pneumatic Actuator Wafer Type Butterfly Valve, Butterfly Valve Manufacturer & Supplier in Ahmedabad, India, Industrial Butterfly Valves Manufacturer in Ahmedabad, India, Top Damper Butterfly Valve Manufacturers in Ahmedabad, PP Butterfly Valve Manufacturer from Ahmedabad, Cast Iron Butterfly Valve Manufacturer from Ahmedabad, Ahmedabad, Gujarat, India, www.goldtechnocasting.com/butterfly-valve-manufacturers-in-ahmedabad.php, Gold Techno Casting

#Butterfly Valve Manufacturers in Ahmedabad#Butterfly Valve Manufacturer & Supplier in Ahmedabad#Butterfly Valves in Ahmedabad#Cast Iron Butterfly Valve Manufacturer From Ahmedabad#Butterfly Valve#Butterfly Valve Manufacturer in Ahmedabad#Top Butterfly Valve Manufacturers in Ahmedabad#Cast Iron Teflon Seated Butterfly Valve in Ahmedabad#Pneumatic Actuator Wafer Type Butterfly Valve#India#Industrial Butterfly Valves Manufacturer in Ahmedabad#Top Damper Butterfly Valve Manufacturers in Ahmedabad#PP Butterfly Valve Manufacturer from Ahmedabad#Cast Iron Butterfly Valve Manufacturer from Ahmedabad#Ahmedabad#Gujarat#www.goldtechnocasting.com/butterfly-valve-manufacturers-in-ahmedabad.php#Gold Techno Casting

0 notes

Text

Top- Rated Knife Edge Gate Valve Gear Box Manufacturer

Viral Industries is a leading knife edge gate valve gear box manufacturer company from India, exporting to USA, Canada, Europe & Gulf. A knife edge gate valve gearbox is a mechanical device used to operate knife edge gate valves, which are designed for controlling the flow of liquids or gases in industrial systems. Connect with us today and share your requirements.

#Knife Edge Gate Valve#Industrial Valve Manufacturer#Valve Gearbox#Valve Actuator#Viral industries#Mechanical Gate Valve

0 notes

Text

Market Dynamics: Factors Influencing the Marine Actuators and Valves Market

The Marine Actuators and Valves Market is a vital component of the maritime industry, providing essential devices for motion control and regulation of fluid flow on marine vessels. Valued at USD 2.8 Billion in 2022, this market is projected to reach USD 3.6 Billion by 2027, growing at a CAGR of 5.3%. The key drivers of this growth include the rise in global commercial trade and the increased demand for high-precision motion control devices. This comprehensive analysis explores the market dynamics, trends, and challenges faced by the Marine Actuators and Valves Industry.

Market Dynamics

Drivers

Increased Global Seaborne Trade

One of the primary drivers of the Marine Actuators and Valves Market is the rise in global seaborne trade. Seaborne trade remains the most economical mode of transporting goods, accounting for approximately 90% of world trade due to competitive freight costs. The International Chamber of Shipping highlights that improvements in maritime technology, such as larger vessels and more efficient port operations, have made sea transport increasingly cost-effective and efficient.

In 2022, global trade was estimated at USD 32 trillion, with USD 25 trillion in products and USD 7 trillion in services, reflecting a 10% rise in goods trade and a 15% increase in services trade from 2021. This significant growth in global trade drives the demand for marine vessels equipped with advanced actuators and valves, essential for handling bulk cargo, oil, gas, and minerals.

Get a Deeper Understanding of the Industry by Visiting: https://www.marketsandmarkets.com/Market-Reports/marine-actuator-valve-market-206171286.html

Restraints

Stringent Regulatory Norms

The marine industry is highly regulated to ensure the safety and reliability of marine operations. Manufacturers of marine actuators and valves must comply with numerous national and international regulations and standards. The International Maritime Organization (IMO) imposes stringent regulations that manufacturers must adhere to, ensuring the safe operation and minimal risk associated with marine components.

All components used in commercial and military ships undergo rigorous quality checks and testing to meet safety standards. The challenge for manufacturers lies in complying with these stringent regulatory norms while delivering high-quality products, which can be both time-consuming and costly.

Opportunities

Growing Use of Inland Waterways

The increasing use of inland waterways presents a significant opportunity for the Marine Actuators and Valves Market. Inland waterborne transport is an inexpensive and environmentally friendly mode of transporting goods. One horsepower (hp) of engine power can move 4,000 kg on water compared to just 150 kg on the road. This efficiency in fuel consumption and the ability to transport large quantities of goods make inland waterways a preferred mode of transport.

In India, the development of inland waterways, such as the Jal Marg Vikas Project on the Ganges River, aims to enhance the efficiency of goods transport. This project is expected to save approximately USD 15 million annually in coal transportation costs. The growth in inland waterway transport necessitates the manufacturing of marine vessels such as tugs, propelled barges, and ferries, subsequently boosting the demand for marine actuators and valves.

Challenges

Power Consumption, Noise, and Leakage Issues

Marine actuators and valves face several operational challenges, including power consumption, noise, and leakage issues. Designing energy-efficient actuators is critical as they consume more power than sensors. A faulty actuator can significantly increase electricity consumption, posing a challenge for manufacturers to create low-energy-consuming designs.

Conventional actuators may lead to excessive noise and oil leakage over time. These operational challenges necessitate regular maintenance and innovative designs to minimize noise and prevent leakage. The reliability and efficiency of actuators and valves are crucial for their widespread adoption in marine vessels.

Get Thorough Information in Our PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=206171286

Market Segmentation

This Research Report Categorizes the Marine Actuators and Valves Market Based on Platform, Product, Mechanism, Material, Design Characteristics, Component, Application, Sales Channel and Region:

By Platform:

Commercial

Defense

Unmanned

By Product:

Valves (Quarter-Turn & Multi-turn valves)

Actuators (Linear & Rotary actuators)

By Mechanism:

Pneumatic

Hydraulic

Electric

Hybrid

Mechanical

Manual

By Material:

Stainless Steel

Aluminum

Alloy-Based

Others

By Design Characteristics:

Valves, By Size

Actuators, By Torque

Actuators, By Thrust

By Component:

Valve Components

Actuator Components

By Application:

Fuel & Propulsion

Ballast & Bilge

Liquid Cargo

HVAC System

Portable Water System

Refrigeration System

Firefighting Systems

Other Applications

By Sales Channel:

OEM

Aftermarket

By Region:

North America

Europe

Asia Pacific

Middle East

Rest of the World

Discover All the Steps in Our Detailed Sample: https://www.marketsandmarkets.com/requestsampleNew.asp?id=206171286

By Solution

Hardware

The hardware segment is projected to grow at the highest CAGR during the forecast period. The demand for components such as communication and computing devices to improve operational efficiency drives this growth. Hardware components are essential for the effective functioning of marine actuators and valves, making them a critical aspect of market expansion.

By Product Type

Valves and Actuators

The market is segmented into valves (quarter-turn and multi-turn valves) and actuators (linear and rotary actuators). Quarter-turn valves are expected to hold the largest market share due to their extensive applications in liquid cargo systems, firefighting systems, and fuel and propulsion systems on marine vessels. Rotary actuators are anticipated to lead the actuator segment, driven by their high performance and reliability.

By Material

Stainless Steel

The stainless steel segment is expected to witness higher demand during the forecast period. Stainless steel's corrosion resistance, reliability, and lightweight properties make it a preferred material for marine actuators and valves.

By Sales Channel

OEM

The OEM segment is projected to acquire the largest market share during the forecast period. Ongoing fleet expansion programs by cargo and freight operators, as well as global naval forces, drive the demand for OEM marine actuators and valves. The increasing demand for commercial ships, such as containers, bulk carriers, and tankers, fuels the growth of the OEM segment.

By Ship Type

Commercial

The commercial segment is expected to dominate the market share during the forecast period. The rise in global commercial seaborne trade, increasing cargo vessel deliveries, and growing maritime tourism drive this segment's growth. The need for safe, high-performance actuators and valves systems further propels the demand in the commercial segment.

Regional Analysis

Asia-Pacific

The Asia-Pacific region is projected to hold the highest market share during the forecast period. The presence of major players, OEMs, and component manufacturers, along with the rise in seaborne trade, drives the growth of the marine actuators and valves market in the region. China, South Korea, and Japan, which hold over 90% of the global shipbuilding industry, significantly contribute to the market expansion.

North America and Europe

North America and Europe also represent significant markets for marine actuators and valves. The presence of established manufacturers and continuous advancements in maritime technology drive market growth in these regions. The increasing focus on sustainable marine transportation and stringent regulatory norms further support market expansion.

Key Market Players

The Marine Actuators and Valves Companies is dominated by globally established players, including:

Moog Inc. (US)

Honeywell International Inc. (US)

Rotork plc (UK)

Emerson (US)

Curtiss-Wright Corporation (US)

IMI plc (UK)

Flowserve Corporation (US)

Rockwell Automation (US)

Kitz Corporation (Japan)

These companies possess diversified product portfolios, state-of-the-art technologies, and strong global sales and marketing networks. They continue to invest in research and development to enhance their product offerings and maintain a competitive edge in the market.

The Marine Actuators and Valves Market is poised for steady growth, driven by the rise in global commercial trade and the increasing demand for high-precision motion control devices. Despite challenges such as stringent regulatory norms and operational issues, the market is expected to expand significantly, reaching USD 3.6 billion by 2027.

Key trends, such as the growing use of inland waterways and advancements in maritime technology, will shape the future of the market. The presence of major players and continuous innovations in the industry will ensure the development of efficient, reliable, and sustainable marine actuators and valves, crucial for the evolving needs of the global marine industry.

About MarketsandMarkets™

MarketsandMarkets™ has been recognized as one of America's best management consulting firms by Forbes, as per their recent report.

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. We have the widest lens on emerging technologies, making us proficient in co-creating supernormal growth for clients.

Earlier this year, we formally transformed into one of America's best management consulting firms as per a survey conducted by Forbes.

The B2B economy is witnessing the emergence of $25 trillion of new revenue streams that are substituting existing revenue streams in this decade alone. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines - TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the 'GIVE Growth' principle, we work with several Forbes Global 2000 B2B companies - helping them stay relevant in a disruptive ecosystem. Our insights and strategies are molded by our industry experts, cutting-edge AI-powered Market Intelligence Cloud, and years of research. The KnowledgeStore™ (our Market Intelligence Cloud) integrates our research, and facilitates analysis of interconnections through applications, helping clients look at the entire ecosystem and understand the revenue shifts in their industry.

To learn more, visit www.MarketsandMarkets™.com or follow us on Twitter, LinkedIn and Facebook.

Contact: Mr. Rohan Salgarkar MarketsandMarkets™ INC.

630 Dundee Road Suite 430 Northbrook, IL 60062 USA: +1-888-600-6441

Email: [email protected]

#Marine Actuators and Valves#Marine Actuators and Valves Market#Marine Actuators and Valves Industry#Global Marine Actuators and Valves Market

0 notes

Text

The Silent Guardians: Unveiling the Role of Valve Automation in Modern Industry

The intricate network of pipes that snake through industrial facilities plays a vital role in keeping processes running smoothly. But the true unsung heroes of this network are the industrial valves – the silent guardians that control the flow of fluids and gases. Traditionally, these valves were operated manually, requiring constant human intervention. However, with advancements in technology, industrial valve automation has emerged as a game-changer, transforming the way these guardians operate and unlocking a multitude of benefits for modern industry.

Industrial Valves: The Backbone of Process Control

Industrial valves come in various types, each designed for a specific function. From regulating pressure and flow rates to completely isolating sections of piping, valves ensure the smooth and efficient operation of various processes. However, manual operation can be time-consuming, labor-intensive, and prone to human error.

Valve Automation: A Symphony of Efficiency and Control

Valve automation replaces manual operation with a combination of actuators and control systems. Actuators, powered by sources like compressed air, electricity, or hydraulics, provide the physical force to open, close, or adjust the position of the valve. Control systems, ranging from simple timers to sophisticated computer-based systems, provide the brains of the operation, sending signals to the actuators based on pre-programmed parameters or real-time process data.

The Symphony's Benefits: How Valve Automation Enhances Industry

The integration of valve automation offers a multitude of advantages:

Enhanced Process Control: Automated valves ensure precise and consistent control over flow rates and pressure, leading to improved product quality and process efficiency.

Improved Safety: Automated systems can react faster to process deviations or emergencies, minimizing safety risks associated with manual intervention.

Reduced Operational Costs: Valve automation minimizes labor requirements for valve operation and allows for remote monitoring, leading to reduced manpower needs and improved overall operational efficiency.

Optimized Production: Automated valves enable faster response times and precise control, leading to optimized production cycles and increased output.

Data-Driven Decision Making: Advanced control systems can collect and analyze data from automated valves, providing valuable insights for process optimization and predictive maintenance.

The Future of Valve Automation: A Glimpse into a Smarter Industrial Landscape

The future of valve automation is brimming with possibilities. The integration of smart technologies like sensors and communication capabilities is paving the way for "smart" valve actuators. These actuators provide real-time feedback on valve position, performance parameters, and potential issues, enabling predictive maintenance and remote monitoring within the framework of the Industrial Internet of Things (IIoT).

Freture Techno: Your Partner in Industrial Valve Automation

Freture Techno, a leading manufacturer of industrial valves and automation solutions in Mumbai, India, understands the critical role of valve automation in modern industry. They offer a comprehensive range of high-quality industrial valves, actuators, and control systems to cater to diverse industrial needs. Their commitment to innovation ensures that their solutions are reliable, efficient, and integrate seamlessly with modern automation technologies.

Embrace the Silent Guardians of Efficiency:

By partnering with Freture Techno, you can leverage the power of valve automation to unlock a new era of process control, safety, and efficiency in your industrial operations. Consider Freture Techno as your trusted partner for all your industrial valve automation needs, and experience the silent symphony of enhanced performance in your industry.

0 notes

Text

How Electric Actuators Are Transforming Industries

Electric actuators are revolutionizing industries across the globe by providing efficient and precise control of mechanical systems. These devices are used in a wide range of applications, from manufacturing and robotics to aerospace and automotive industries. With their ability to provide accurate and reliable movement, electric actuators are changing the way industries operate and helping businesses improve their productivity and efficiency.

One of the key advantages of electric actuators is their speed and accuracy. Unlike traditional hydraulic or pneumatic actuators, electric actuators can be controlled with high precision, allowing for more consistent and reliable performance. This level of control is especially important in industries where accuracy is critical, such as medical equipment manufacturing or robotics.

Electric actuators are also more energy-efficient than their hydraulic or pneumatic counterparts. By using electricity to power their movement, electric actuators can reduce energy consumption and operating costs. This is particularly beneficial for industries looking to improve their sustainability and reduce their environmental impact.

Furthermore, electric actuators are easier to install and maintain compared to traditional actuators. With fewer moving parts and a simpler design, electric actuators require less maintenance and repairs, saving businesses time and money in the long run. This ease of use also makes electric actuators ideal for industries with limited space or resources for maintenance.

In addition to their efficiency and reliability, electric actuators are also versatile in their applications. These devices can be customized to fit specific industry needs, making them suitable for a wide range of tasks, from simple positioning to complex automation processes. Whether used in industrial robots, medical devices, or aerospace equipment, electric actuators bring precision and efficiency to any industry.

Overall, electric actuators are transforming industries by providing a cost-effective, energy-efficient, and precise solution for mechanical control systems. As businesses continue to adopt these advanced technologies, the benefits of electric actuators will only continue to grow, leading to improved productivity and performance across various industries.

0 notes

Text

ANBI Group is one of the leading Valve suppliers in Dubai, UAE. Visit www.anbisolutions.com for more products.

#anbionline#anbigroup#valves#valve#gatevalve#engineering#pumps#ballvalve#oilandgas#hydraulics#flange#fitting#construction#controlvalves#butterflyvalve#industry#pneumatic#fittings#actuators#plumbing#industrial#flexiblehose#hydraulicpump#castings#filter#butterfly#work#hydraulicparts

1 note

·

View note

Text

Unlocking Precision and Power: A Guide to Hydraulic Servo Actuators

Introduction: In the realm of automation and motion control, hydraulic servo actuators reign supreme for their unmatched blend of raw power and exceptional precision. These marvels of engineering combine the potent force of hydraulics with the meticulous control of electronic systems. This comprehensive guide delves into the world of hydraulic servo actuators, exploring their inner workings,…

View On WordPress

#Electrohydraulic Actuators#Feedback Mechanisms#Flight Control Systems#High Force Applications#Hydraulic servo actuators#Industrial automation#Linear Actuators#Motion Control Systems#Proportional Valves#Robotics#Rotary Actuators

0 notes

Text

The Marine Actuators and Valves Market size is expected to reach USD 3.6 Billion by 2027 from USD 2.8 Billion in 2022, at a Compound Annual Growth Rate (CAGR) of 5.3% from 2022 to 2027. The key factor driving the growth of the worldwide Marine Actuators and Valves Industry is the increase in global commercial trade and the spike in demand for high-precision motion control devices on board marine vessels. Additionally, the growing commercial and defence fleets of nations worldwide is driving the market for marine actuators and valves that can meet the requirements of sustainable marine transportation.

#Marine Actuators and Valves#Marine Actuators and Valves Market#Marine Actuators and Valves Industry#Global Marine Actuators and Valves Market#Marine Actuators and Valves Market Companies#Marine Actuators and Valves Market Size#Marine Actuators and Valves Market Share#Marine Actuators and Valves Market Growth#Marine Actuators and Valves Market Statistics

0 notes

Text

Actuator Valves in Modern Gas Control Systems

Actuator valves are crucial components in various industrial and commercial applications, offering precision, safety, and efficiency in gas control systems. Whether in heating, ventilation, or automated gas distribution, actuator valves provide the necessary automation that enhances operational efficiency and safety. In this blog, we delve into the key features, benefits, and applications of actuator valves and why choosing a high-quality valve like the one from Prabha Electronics can make a significant difference.

What is an Actuator Valve?

An actuator valve is an automated control device that regulates the flow of gases or fluids through a system. It combines a valve with an actuator that uses electric, hydraulic, or pneumatic power to move the valve to the desired position. This automation eliminates manual intervention, ensuring consistent and precise control, which is especially important in complex or hazardous environments.

Key Features of Actuator Valves

Precision Control: Actuator valves provide accurate flow control, crucial in applications requiring fine-tuning of gas pressure or volume.

Durability and Reliability: Built with robust materials, these valves are designed to withstand harsh environments, including high temperatures, corrosive substances, and continuous operation.

Safety: Automation reduces the risk of human error, enhancing overall safety by ensuring valves operate within set parameters.

Ease of Integration: These valves are compatible with various control systems, making them easy to integrate into existing setups without extensive modifications.

Energy Efficiency: Actuator valves help reduce energy consumption by optimizing gas flow, making systems more sustainable and cost-effective.

Applications of Actuator Valves

Actuator valves find applications in various industries, including:

Oil and Gas: Ensuring precise flow control in pipelines and gas distribution networks.

HVAC Systems: Regulating airflow in heating, ventilation, and air conditioning systems to maintain optimal indoor conditions.

Manufacturing: Used in automated production lines to control the flow of gases essential for various processes.

Water Treatment: Controlling the flow of chemicals and gases in water and wastewater treatment plants.

Why Choose Prabha Electronics’ Actuator Valve?

Prabha Electronics offers a high-performance actuator valve designed to meet the demands of modern industrial applications. Our valves are engineered for durability, reliability, and precise control, ensuring your systems operate at their best. Here’s why our actuator valves stand out:

Superior Build Quality: Made with high-grade materials to resist corrosion and wear, ensuring a long service life.

Advanced Engineering: Our valves are designed to deliver smooth operation, even under challenging conditions.

Cost-Effective Solutions: We provide value without compromising on quality, making our actuator valves a wise investment for any gas control system.

Conclusion

Choosing the right actuator valve is essential for maintaining efficiency, safety, and performance in any gas control system. Prabha Electronics’ actuator valves offer the precision and reliability needed for industrial and commercial applications, ensuring your operations run smoothly and safely. Invest in quality, and experience the difference that our advanced actuator valves can make in your system.

#Actuator Valve#Gas Control Valve#Industrial Actuator Valve#Automation Valve#Precision Gas Control#Gas Flow Valve

0 notes

Text

Butterfly Valve Manufacturers in Ahmedabad - Top Quality

Discover leading Butterfly Valve Manufacturers in Ahmedabad. Get high-quality products and competitive prices. Your trusted source for valve solutions.

Google Map:--> https://maps.app.goo.gl/pmF6ogWW6EPkpfYq7

Butterfly Valve Manufacturers in Ahmedabad, Butterfly Valve Manufacturer & Supplier in Ahmedabad, Butterfly Valves in Ahmedabad, Cast Iron Butterfly Valve Manufacturer From Ahmedabad, Butterfly Valve, Butterfly Valve Manufacturer in Ahmedabad, Top Butterfly Valve Manufacturers in Ahmedabad, Cast Iron Teflon Seated Butterfly Valve in Ahmedabad, Pneumatic Actuator Wafer Type Butterfly Valve, Butterfly Valve Manufacturer & Supplier in Ahmedabad, India, Industrial Butterfly Valves Manufacturer in Ahmedabad, India, Top Damper Butterfly Valve Manufacturers in Ahmedabad, PP Butterfly Valve Manufacturer from Ahmedabad, Cast Iron Butterfly Valve Manufacturer from Ahmedabad, Ahmedabad, Gujarat, India, www.goldtechnocasting.com/butterfly-valve-manufacturers-in-ahmedabad.php, Gold Techno Casting

#Butterfly Valve Manufacturers in Ahmedabad#Butterfly Valve Manufacturer & Supplier in Ahmedabad#Butterfly Valves in Ahmedabad#Cast Iron Butterfly Valve Manufacturer From Ahmedabad#Butterfly Valve#Butterfly Valve Manufacturer in Ahmedabad#Top Butterfly Valve Manufacturers in Ahmedabad#Cast Iron Teflon Seated Butterfly Valve in Ahmedabad#Pneumatic Actuator Wafer Type Butterfly Valve#India#Industrial Butterfly Valves Manufacturer in Ahmedabad#Top Damper Butterfly Valve Manufacturers in Ahmedabad#PP Butterfly Valve Manufacturer from Ahmedabad#Cast Iron Butterfly Valve Manufacturer from Ahmedabad#Ahmedabad#Gujarat#www.goldtechnocasting.com/butterfly-valve-manufacturers-in-ahmedabad.php#Gold Techno Casting

0 notes

Text

mondaymotivation Keep improving yourself, opportunity is coming your way.

motivationoftheday

website: https://www.nirmal.co.in/

#Nirmal Industrial Controls#Pressure Relief Valve Manufacturer#Self Actuated Pressure Control Valves#Pressure Regulator Skid#Self Actuated Valve Manufacturers In India#Self Actuated Pressure#D62 Series#Thermal Relief Valve

0 notes

Text

What is a mtd industrial electric ball valve actuator?

The mtd industrial electric ball valve actuator is a kind of valve control equipment widely used in chemical industry, petroleum, electric power and other fields. The electric actuator drives the ball to rotate to realize the opening and closing control of the valve.

It has the advantages of simple structure, good sealing, and long service life, and is an indispensable key equipment in industrial automation control systems. This article will start with industrial electric valves and introduce the actuators of industrial electric ball valves in detail.

What is a mtd industrial electric valve actuator?

MTD industrial electric valve actuator refers to the control and adjustment of the fluid medium in industrial production by controlling the switch state of the valve through electric actuators (such as motors, reducers, travel switches, control systems, etc.).

According to different types and structures of valves, industrial electric valve actuators can be divided into the following types:

Ball valve: Ball valve is a common valve type with simple structure, good sealing performance and long service life. It is widely used in chemical industry, petroleum, electric power and other fields. The switch control of the electric actuator of the ball valve usually adopts a 90-degree rotation method, and the ball is driven to rotate through the electric actuator, so as to realize the opening and closing control of the valve.

Butterfly valve: Butterfly valve is a type of valve with simple structure, small size, light weight and good corrosion resistance, which is widely used in automatic control systems. Butterfly valve electric actuators usually adopt the method of rotation and tilting, and the valve disc is driven to rotate and tilt through the electric actuator, so as to realize the opening and closing control of the valve.

Two-way electric valve: Two-way electric valve is a valve used to control the diversion and confluence of fluid medium between two pipelines. Its structure is generally linear or quarter-stroke, and usually consists of two channels and a valve disc. The disc of the two-way electric valve moves up and down through the electric actuator, so as to realize the opening and closing control of the valve.

Three-way electric valve: Three-way electric valve is a valve used to control the diversion and confluence of fluid media between different pipelines. Its structure is generally T-shaped or Y-shaped, and usually consists of two exits and one entrance. The disc of the three-way electric valve is rotated by the electric actuator to realize the opening and closing control of the valve.

In addition, according to the requirements of valve material, working temperature and pressure, industrial electric valve actuators can also be divided into stainless steel electric valve actuators, cast iron electric valve actuators, copper electric valve actuators, high temperature electric valve actuators and other types.

What is a mtd industrial electric ball valve actuator?

An electric valve is a type of valve that operates using an electric actuator. Electric valves are widely used in industrial automation to control the flow of liquids or gases in a variety of applications. Among the different types of electric valves available, the electric ball valve is one of the most popular and versatile ones.

Electric ball valves consist of a ball with a hole in the middle that rotates within a valve body to control the flow of fluid. When the ball is rotated 90 degrees, the hole aligns with the valve body's inlet and outlet, allowing the fluid to flow through the valve. When the ball is rotated 90 degrees in the opposite direction, the hole is perpendicular to the inlet and outlet, blocking the flow of fluid.

How a electric ball valve works in industrial automatic equipment?

In industrial automation, electric ball valves are often used in applications that require precise control over the flow rate, pressure, and temperature of fluids. Some examples include chemical processing, water treatment, HVAC systems, and oil and gas refineries. Electric ball valves can be made from a variety of materials, including stainless steel, brass, and PVC, to suit different environments and applications.

One of the main advantages of electric ball valves is their ability to operate automatically, which reduces the need for manual intervention and increases efficiency. An electric actuator is used to rotate the ball inside the valve body, allowing the valve to open or close in response to signals from a control system. The actuator can be controlled using different types of signals, such as a 4-20mA signal or a digital signal, depending on the application's requirements.

The electric actuator is typically mounted on top of the valve body and connected to the ball using a mechanical linkage. When the actuator receives a signal, it rotates the ball to the desired position, allowing the fluid to flow through the valve. The actuator can also be programmed to operate at specific intervals or in response to certain conditions, such as changes in temperature or pressure.

Conclusion

To sum up, the industrial electric ball valve actuator has become an indispensable key equipment in the industrial automation control system due to its advantages of simple structure, long service life and high control precision.

With the continuous development and progress of the industrial field, industrial electric ball valve actuators will also continue to innovate and develop to meet the needs of different industries. We believe that in the future development, industrial electric ball valve actuators will continue to play an important role, providing a strong guarantee for the safe, efficient and reliable operation of industrial production.

MTD Actuator Valve Inc. (exported by Ningbo leadwin international trade)specialized in manufacturing electric actuators, Valve accessories and automated products. We have a first-rated team composed of professional research, management and sales. For more details about industrial electric ball valve actuator visit our website https://www.mtd-actuator.com

1 note

·

View note

Text

Nirmal Industrial Control Pvt Ltd Nirmal | Self Actuated Pressure Control Valves | Safety Relief Valves Nirmal has established itself as an expert in control valve solutions required for services such as manufacturing; in the field of self-actuated pressure control valves, low -pressure nitrogen blanketing systems, reduction in gas pressure with safety shut off & metering skids

#Nirmal Industrial Control Pvt Ltd#Nirmal | Self Actuated Pressure Control Valves | Safety Relief Valves#Nirmal has established itself as an expert in control valve solutions required for services such as manufacturing; in the field of self-act#low -pressure nitrogen blanketing systems#reduction in gas pressure with safety shut off & metering skids

0 notes

Text

#bestindustry#bestoffers#OnTimeDelivery#bestprice#goodservice#donateorgansavelife#DrugFreeIndia

#pneumatictimer

This is accomplished via a reservoir of oil, driven by air pressure on the top of the oil through a needle valve to control the speed. With a Proportion-Air F-Series mass flow controller, the traditional reservoir of oil is not necessary.

#bestindustry#bestoffers#OnTimeDelivery#bestprice#goodservice#donateorgansavelife#DrugFreeIndia#pneumatictimer Pneumatic timers are used in industrial systems for the precise control of air input signals. They are used in place of elec#where the use of electricity is either unavailable or unsafe#such as applications in which flammable materials are present.#biggest problem with pneumatic timers and inert gases is that gases escape into the atmosphere. There is always a consistent leak of these#so you will have to replace these gases. Using compressed air is a much more economical endeavor.#Pneumatic timers are used when you need to delay the air signal coming in or going out of your air component. Depending on the model chosen#the air time delay may be adjusted from 0.5 to 60 seconds.#Time delay valve is a combination of a pneumatically actuated 3/2 direction control valve#an air reservoir and a throttle relief valve. The time delay function is obtained by controlling the air flow rate to or from the reservoir#Control and speed in pneumatic systems are more difficult because of the compressed air than compared with electrical or hydraulic systems.#a device requires a specific speed#you might have to add more equipment to the pneumatic system to make it work at the desired levels.#This is accomplished via a reservoir of oil#driven by air pressure on the top of the oil through a needle valve to control the speed. With a Proportion-Air F-Series mass flow controll#the traditional reservoir of oil is not necessary.

0 notes

Text

ANBI Group is one of the leading Valve suppliers in Dubai, UAE. Visit www.anbisolutions.com for more products.

#anbionline#anbigroup#valves#valve#gatevalve#engineering#pumps#ballvalve#oilandgas#hydraulics#flange#fitting#construction#controlvalves#butterflyvalve#industry#pneumatic#fittings#actuators#plumbing#industrial#flexiblehose#hydraulicpump#castings#filter#butterfly#work#hydraulicparts

0 notes