#India’s Leading Aluminum Foil Manufacturers

Explore tagged Tumblr posts

Text

Why Are Aluminum Foils Used for Wrapping Food?

Aluminum foil is a kitchen item that has helped many families live a healthy lifestyle. The aluminium foil for food wrapping is non-toxic & an excellent conductor of heat & electricity. Pragya Flexifilm Industries is largest aluminium foil roll manufacturers. For Aluminium Foil Producers, call us!

#Foil Roll Manufacturer#Aluminium Foil for Food Wrapping#Aluminium Foil Producers#India’s Leading Aluminum Foil Manufacturers#Aluminium Foil Suppliers#Largest Aluminium Foil Roll Manufacturers

0 notes

Text

Aluminum Market: Products, Applications & Beyond

Aluminum is a versatile element with several beneficial properties, such as a high strength-to-weight ratio, corrosion resistance, recyclability, electrical & thermal conductivity, longer lifecycle, and non-toxic nature. As a result, it witnesses high demand from industries like automotive & transportation, electronics, building & construction, foil & packaging, and others. The high applicability of the metal is expected to drive the global aluminum market at a CAGR of 5.24% in the forecast period from 2023 to 2030.

Aluminum – Mining Into Key Products:

Triton Market Research’s report covers bauxite, alumina, primary aluminum, and other products as part of its segment analysis.

Bauxite is anticipated to grow with a CAGR of 5.67% in the product segment over the forecast years.

Bauxite is the primary ore of aluminum. It is a sedimentary rock composed of aluminum-bearing minerals, and is usually mined by surface mining techniques. It is found in several locations across the world, including India, Brazil, Australia, Russia, and China, among others. Australia is the world’s largest bauxite-producing nation, with a production value of over 100 million metric tons in 2022.

Moreover, leading market players Rio Tinto and Alcoa Corporation operate their bauxite mines in the country. These factors are expected to propel Australia’s growth in the Asia-Pacific aluminum market, with an anticipated CAGR of 4.38% over the projected period.

Alumina is expected to grow with a CAGR of 5.42% in the product segment during 2023-2030.

Alumina or aluminum oxide is obtained by chemically processing the bauxite ore using the Bayer process. It possesses excellent dielectric properties, high stiffness & strength, thermal conductivity, wear resistance, and other such favorable characteristics, making it a preferable material for a range of applications.

Hydrolysis of aluminum oxide results in the production of high-purity alumina, a uniform fine powder characterized by a minimum purity level of 99.99%. Its chemical stability, low-temperature sensitivity, and high electrical insulation make HPA an ideal choice for manufacturing LED lights and electric vehicles. The growth of these industries is expected to contribute to the progress of the global HPA market.

EVs Spike Sustainability Trend

As per the estimates from the International Energy Agency, nearly 2 million electric vehicles were sold globally in the first quarter of 2022, with a whopping 75% increase from the preceding year. Aluminum has emerged as the preferred choice for auto manufacturers in this new era of electromobility. Automotive & transportation leads the industry vertical segment in the studied market, garnering $40792.89 million in 2022.

In May 2021, RusAl collaborated with leading rolled aluminum products manufacturer Gränges AB to develop alloys for automotive applications. Automakers are increasingly substituting stainless steel with aluminum in their products owing to the latter’s low weight, higher impact absorption capacity, and better driving range.

Also, electric vehicles have a considerably lower carbon footprint compared to their traditional counterparts. With the growing need for lowering emissions and raising awareness of energy conservation, governments worldwide are encouraging the use of EVs, which is expected to propel the demand for aluminum over the forecast period.

The Netherlands is one of the leading countries in Europe in terms of EV adoption. The Dutch government has set an ambitious goal that only zero-emission passenger cars (such as battery-operated EVs, hydrogen FCEVs, and plug-in hybrid EVs) will be sold in the nation by 2030. Further, according to the Canadian government, the country’s aluminum producers have some of the lowest CO2 footprints in the world.

Alcoa Corporation and Rio Tinto partnered to form ELYSIS, headquartered in Montréal, Canada. In 2021, it successfully produced carbon-free aluminum at its Industrial Research and Development Center in Saguenay. The company is heralding the beginning of a new era for the global aluminum market with its ELYSIS™ technology, which eliminates all direct GHG emissions from the smelting process, and is the first technology ever to emit oxygen as a byproduct.

Wrapping Up

Aluminum is among the most widely used metals in the world today, and is anticipated to underpin the global transition to a low-carbon economy. Moreover, it is 100% recyclable and can retain its properties & quality post the recycling process.

Reprocessing the metal is a more energy-efficient option compared to extracting the element from an ore, causing less environmental damage. As a result, the demand for aluminum in the sustainable energy sector has thus increased. The efforts to combat climate change are thus expected to bolster the aluminum market’s growth over the forecast period.

#Aluminum Market#aluminum#chemicals and materials#specialty chemicals#market research#market research reports#triton market research

4 notes

·

View notes

Text

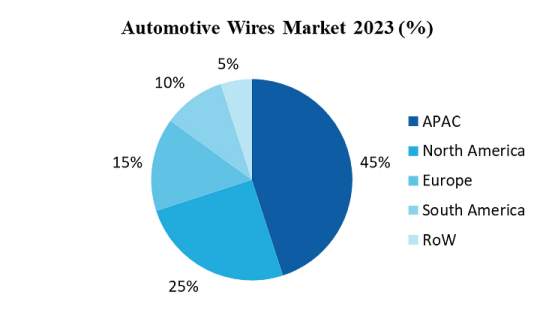

Automotive Wires Market-Industry Forecast, 2024–2030

Automotive Wires Market Overview:

Request Sample :

Automotive wire demand is expected to rise due to the growing trend of lightweight passenger automobiles as a means of reducing carbon emissions. In response to stringent regulations aimed at reducing carbon emissions from automobiles, manufactures will concentrate on producing aluminium automotive wires to reduce the vehicle’s overall weight. This is going to help in achieving the new regulations criteria. The rising focus on enhancing the standards for automotive wire will give opportunities for market expansion. For instance, according to US Auto Outlook 2024, light vehicle sales to grow 3.7% above last year’s level, rising to 16.1 million units. Additionally, the demand for automotive wires is expected to rise in parallel with the volume of vehicles being produced and the increasing demand from customers for better comfort, safety, and convenience.

Market Snapshot:

Automotives Wires Market — Report Coverage:

The “Automotive Wires Market Report — Forecast (2024–2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Automotives Wires Market.

AttributeSegment

By Material

· Copper

· Aluminium

· Others

By Vehicle Type

· Passenger Vehicles

· Light Commercial Vehicles

· Heavy Commercial Vehicles

By Propulsion

· ICE Vehicles

· Hybrid Vehicles

· Pure Electric Vehicles

By Transmission Type

· Electric wiring

· Data Transmission

By Application

· Engine wires

· Chassis wires

· Body and Lighting wires

· HVAC wires

· Dashboard / Cabin wires

· Battery wires

· Sensor wires

· Others

By End User

· OEM

· Aftermarket

By Geography

· North America (U.S., Canada and Mexico)

· Europe (Germany, France, UK, Italy, Spain, Russia and Rest of Europe),

· Asia-Pacific (China, Japan, South Korea, India, Australia & New Zealand and Rest of Asia-Pacific),

· South America (Brazil, Argentina, Chile, Colombia and Rest of South America)

· Rest of the World (Middle East and Africa).

COVID-19 / Ukraine Crisis — Impact Analysis:

The COVID-19 pandemic disrupted global supply chains, leading to delays in production and sales of automobiles which led to decrease in automotive wire manufacturing. Governments worldwide imposed lockdowns and restrictions, which led to shut down of mines, factories, and transportation networks, thus disrupting the supply of raw materials such as copper and aluminum, that are used in making automotive wires.

The Russia-Ukraine war had a huge impact on the global automotive wires market. Ukraine is a major manufacturer of copper, a material used as an automotive wiring component. The war has led to mining disruptions, which in turn has caused the shortages and increase in prices globally.

Key Takeaways:

Copper wires segment is Leading the Market

Copper wires segment holds the largest share in the automotive wires market with respect to market segmentation by material. Electrification will be the biggest driver to copper demand for vehicles. Copper is used throughout electric vehicle powertrains, from foils in each cell of the battery to the windings of an electric motor. In total, each electric vehicle can generate over 30kg of additional copper demand. According to a report by IDTechEx, the demand for copper from the automotive industry was just over 3MT in 2023 but is set to increase to 5MT in 2034. Because of its electrical and chemical characteristics, copper is used in every part of the battery. There are lot of tiny cells in the battery, and each one has a copper foil to carry electricity out of the cell. Large copper bars placed throughout the battery also convey the energy from each cell to the high-voltage connections, which in turn power the motor and electronics. Such parts and components with the copper are driving the market growth of copper wires in automotive wires market.

Inquiry Before Buying :

Passenger Vehicles are Leading the Market

Passenger Vehicles segment is leading the Automotive Wires Market by Application. The passenger vehicle category is currently holding the largest share in the automotive wires market because of a combination of factors including large production volumes, a wide range of wiring requirements, technological developments, and the increasing adoption of electric vehicles. For instance, according to Global and EU Auto industry 2023 report by The European Automobile Manufacturers’ Association (ACEA), European car production grew substantially, reaching nearly 15 million units, marking a significant year-on-year improvement of 12.6%. The growing popularity of electric vehicles (EVs) is also contributing to the growth of the passenger vehicle segment in the automotive wires market. EVs have more complex wiring systems due to the integration of batteries, motors, and charging infrastructure.

Integration of Smart Systems in Automobiles

Global demand for automotive wires is primarily driven by the integration of smart systems in automobiles. Modern automobiles have more wires because electronic control units (ECUs) are becoming more and more popular. Each ECU has been connected to a variety of sensors, actuators, and other ECUs through a complex network of connections. Automotive manufacturers are using sophisticated wiring solutions, such as light-weight harnesses, insulated cables and high-temperature-resistant wires to manage the rising number of connections and ensure reliable performance. For instance, In July 2024, Compal Electronics Inc, a leading contract electronics manufacturer from Taiwan, announced plans to build its first European factory in Poland. The company intends to invest more than $15.4 million to target automotive electronics clients. This strategic move marks Compal’s expansion into the European market. The need for complex and more advanced wiring solutions will continue to grow as automobiles become more technologically advanced, fueling the worldwide automotive wires market’s expansion.

Schedule A Call :

Fluctuating cost of materials to hamper the market

The market for automotive wires is significantly impacted by the price fluctuations of raw materials, particularly copper and aluminum. These materials are necessary for making automobile wires, and the market’s ability to expand may be severely hindered by their price instability. For instance, vehicle automation requires multiple sensors, as well as additional on-board computers. A standard autonomous system, with 12 cameras, seven Light Detection and Ranging sensors (LiDARs), eight radars and one automated driving control unit, will all depend on copper connections to function safely and reliably.

Buy Now :

For more details on this report — Request for Sample

Key Market Players:

Product/Service launches, approvals, patents and events, acquisitions, partnerships, and collaborations are key strategies adopted by players in the Automotive Wires Market. The top 10 companies in this industry are listed below:

Aptiv plc

Yazaki Corporation

Furukawa Electric Co., Ltd

Sumitomo wiring systems

Nexans SA

Fujikura Ltd

Samvardhana Motherson International Ltd

Leoni AG

Lear Corporation

THB Electronics

Scope of the Report:

Report MetricDetails

Base Year Considered

2023

Forecast Period

2024–2030

CAGR

5.7%

Market Size in 2030

$ 6.8 Billion

Segments Covered

By Material, By Vehicle Type, By Propulsion, By Transmission Type, By Application, By End User and By Geography.

Geographies Covered

North America (U.S., Canada and Mexico), Europe (Germany, France, UK, Italy, Spain, Russia and Rest of Europe), Asia-Pacific (China, Japan, South Korea, India, Australia & New Zealand and Rest of Asia-Pacific), South America (Brazil, Argentina, Chile, Colombia and Rest of South America), Rest of the World (Middle East and Africa).

Key Market Players

1. Aptiv plc

2. Yazaki Corporation

3. Furukawa Electric Co., Ltd

4. Sumitomo wiring systems

5. Nexans SA

6. Fujikura Ltd

7. Samvardhana Motherson International Ltd

8. Leoni AG

9. Lear Corporation

10. THB Electronics

For more Automotive Market reports, please click here

0 notes

Text

Leading Aluminium Foil Manufacturer in India - Marudhar

Marudhar Aluminium Foils is a leading manufacturer of high-quality house foils, laminates and lids for the health care, food and beverages, FMCG and industrial sectors in India. The company's state-of-the-art manufacturing facilities and commitment to innovation ensure that they deliver reliable and efficient packaging solutions.

A team of experienced professionals dedicated to continuously improve the products and staying updated with the latest industry trends. Their commitment to quality, innovation and customer service remains unparalleled in the industry.

Marudhar stands as a premier aluminum foil manufacturer in India, specializing in high-quality aluminum rolling, aluminum coils, aluminum foils, and aluminum remelting solutions. With a commitment to quality and innovation, we deliver a comprehensive range of aluminum products tailored to diverse industry needs.

0 notes

Text

The Plastic Films Market is experiencing rapid growth driven by rising e-commerce

The plastic films market enjoys widespread applications across various end-use industries such as packaging, agriculture, construction, and electrical & electronics. Plastic films offer several advantages over traditional materials including moisture barrier properties, durability, lightweight and transparency. They are extensively used for flexible packaging of food products, beverages, consumer goods and industrial applications. The growth of e-commerce and online shopping has propelled demand for plastic films from the packaging sector. The Global Plastic Films Market is estimated to be valued at US$157.5 billion in 2024 and is expected to exhibit a CAGR of 7.2% over the forecast period 2024 to 2031. Key Takeaways Key players operating in the plastic films market are Amcor plc, Berry Global Group, Sealed Air Corporation, DuPont, Toray Industries, Jindal Poly Films, RPC Group, and DS Smith. They collectively account for over 30% share of the global market. The Plastic Films Market Demand has been witnessing strong growth globally driven by the expanding food & beverage industry and burgeoning e-commerce sector. Especially in Asia Pacific, growth in the standard of living has boosted consumption of packaged foods and beverages, thereby augmenting plastic films usage. The plastic films market is extending its footprint globally on account of rising export activities from leading producers based in Asia Pacific and Europe. Many developing countries in South America, Middle East & Africa and Asia are emerging as lucrative markets providing ample opportunities for plastic film manufacturers. Market Key Trends One of the key trends gaining momentum in the plastic films market is the increasing replacement of conventional plastics with bioplastics. Bioplastic films made from renewable sources such as cellulose, starch, polylactic acid and polyhydroxyalkanoates offer superior compostability and sustainability. The development of bio-based barrier films, shrink films and stretch films with properties comparable to petroleum-based films will further bolster the adoption of bioplastics in food packaging and other applications over the forecast period.

Porter's Analysis Threat of new entrants: Low capital required for manufacturing plants enables easy entry which increases competition in the market. Bargaining power of buyers: Large number of suppliers in the market gives buyers more options but commodity nature of products limits their power. Bargaining power of suppliers: Major suppliers have established relationships with end-use industry players reducing their individual bargaining power. Threat of new substitutes: Availability of alternative materials like paper and aluminum foils poses threat of substitution to plastic films. Competitive rivalry: Large number of global and regional players operate in a price-sensitive market increasing competition. Geographical Regions North America accounts for the largest share of the plastic films market owing to high demand from various end-use industries like packaging, personal care, construction and others in United States and Canada. Asia Pacific region is expected to grow at the fastest rate during the forecast period due to rapid industrialization and infrastructure development activities in major economies like China and India increasing consumption of plastic films in packaging, agriculture and construction applications.

Get more insights on Plastic Films Market

For Enhanced Understanding, Dive into the Report in the Language that Connects with You.

French

German

Italian

Russian

Japanese

Chinese

Korean

Portuguese

About Author:

Money Singh is a seasoned content writer with over four years of experience in the market research sector. Her expertise spans various industries, including food and beverages, biotechnology, chemical and materials, defense and aerospace, consumer goods, etc. (https://www.linkedin.com/in/money-singh-590844163)

#Coherent Market Insights#Plastic Films Market#Plastic Films#Flexible Packaging#Polymer Films#Polyethylene Film#Polypropylene Film#Plastic Packaging#Industrial Films#Barrier Films#Shrink Films#Stretch Films#Laminated Films

0 notes

Text

Foil sealing machines are ideal for small and medium-sized manufacturing units that need to seal plastic containers with foil. The machine uses an induction coil to generate a strong electromagnetic field that heats the aluminum foil. The heat sealing layer then melts and flows on the lips of the containers, forming a hermetic seal.

0 notes

Text

Europe Thermal Pallet Covers Market Size, Competitors Strategy, Regional Analysis and Industry Growth by Forecast to 2028

Business Market Insights recently announced the release of the market research titled Europe Thermal Pallet Covers Market Outlook to 2028 | Share, Size, and Growth. The report is a stop solution for companies operating in the Europe Thermal Pallet Covers market. The report involves details on key segments, market players, precise market revenue statistics, and a roadmap that assists companies in advancing their offerings and preparing for the upcoming decade. Listing out the opportunities in the market, this report intends to prepare businesses for the market dynamics in an estimated period.

Is Investing in the Market Research Worth It?

Some businesses are just lucky to manage their performance without opting for market research, but these incidences are rare. Having information on longer sample sizes helps companies to eliminate bias and assumptions. As a result, entrepreneurs can make better decisions from the outset. Europe Thermal Pallet Covers Market report allows business to reduce their risks by offering a closer picture of consumer behavior, competition landscape, leading tactics, and risk management.

A trusted market researcher can guide you to not only avoid pitfalls but also help you devise production, marketing, and distribution tactics. With the right research methodologies, Business Market Insights is helping brands unlock revenue opportunities in the Europe Thermal Pallet Covers market.

If your business falls under any of these categories – Manufacturer, Supplier, Retailer, or Distributor, this syndicated Europe Thermal Pallet Covers market research has all that you need.

What are Key Offerings Under this Europe Thermal Pallet Covers Market Research?

Global Europe Thermal Pallet Covers market summary, current and future Europe Thermal Pallet Covers market size

Market Competition in Terms of Key Market Players, their Revenue, and their Share

Economic Impact on the Industry

Production, Revenue (value), Price Trend

Cost Investigation and Consumer Insights

Industrial Chain, Raw Material Sourcing Strategy, and Downstream Buyers

Production, Revenue (Value) by Geographical Segmentation

Marketing Strategy Comprehension, Distributors and Traders

Global Europe Thermal Pallet Covers Market Forecast

Study on Market Research Factors

Who are the Major Market Players in the Europe Thermal Pallet Covers Market?

Europe Thermal Pallet Covers market is all set to accommodate more companies and is foreseen to intensify market competition in coming years. Companies focus on consistent new launches and regional expansion can be outlined as dominant tactics. Europe Thermal Pallet Covers market giants have widespread reach which has favored them with a wide consumer base and subsequently increased their Europe Thermal Pallet Covers market share.

Report Attributes

Details

Segmental Coverage

Type

Aluminum Foil

Polymer

and Others

Regional and Country Coverage

North America (US, Canada, Mexico)

Europe (UK, Germany, France, Russia, Italy, Rest of Europe)

Asia Pacific (China, India, Japan, Australia, Rest of APAC)

South / South & Central America (Brazil, Argentina, Rest of South/South & Central America)

Middle East & Africa (South Africa, Saudi Arabia, UAE, Rest of MEA)

Market Leaders and Key Company Profiles

CargoWise Solutions Ltd

CSafe Global

Eceplast

ECOCOOL

Insulated Products Corporation

PAC Worldwide Corporation

Protek Cargo

QProducts & Services

Thermal Packaging Solutions

Other key companies

What are Perks for Buyers?

The research will guide you in decisions and technology trends to adopt in the projected period.

Take effective Europe Thermal Pallet Covers market growth decisions and stay ahead of competitors

Improve product/services and marketing strategies.

Unlock suitable market entry tactics and ways to sustain in the market

Knowing market players can help you in planning future mergers and acquisitions

Visual representation of data by our team makes it easier to interpret and present the data further to investors, and your other stakeholders.

Do We Offer Customized Insights? Yes, We Do!

The Business Market Insights offer customized insights based on the client’s requirements. The following are some customizations our clients frequently ask for:

The Europe Europe Thermal Pallet Covers Market market report can be customized based on specific regions/countries as per the intention of the business

The report production was facilitated as per the need and following the expected time frame

Insights and chapters tailored as per your requirements.

Depending on the preferences we may also accommodate changes in the current scope.

Author’s Bio: Bhavesh Shinde Senior Market Research Expert at Business Market Insights

0 notes

Text

Explore Aluminum Foil Paper for Food Packaging

When it comes to modern food packaging materials, aluminum foil plays a significant role. It is used in numerous households to keep food warm and fresh for a prolonged duration. Along with the households, it holds immense prominence in the commercial food industry. This blog explores aluminum foil paper for food packaging and its popular uses, which make it the perfect packaging material.

Exploring Aluminium Foil Paper for Food Packaging

What is Aluminium Foil?

Aluminum foil is a thin metal sheet that is extensively used for typically used for food wrapping and covering. It exhibits excellent barrier properties that protect the wrapped item from contaminants, moisture, and lights. The aluminium foil for food wrapping is perfect for preserving the flavour, aroma, and quality of food products.

Key Features of Aluminum Foil Paper

Flexibility: The reason that makes aluminium foil for food wrapping so popular is its flexibility. It can easily comply with the food item shape to ensure secure packaging.

Protective Barrier: It shows excellent resistance against moisture and air. This allows the food to remain fresh for an extended time.

Heat Conductivity: Its excellent heat conductive property makes it perfect for reheating food and keeping it warm.

Uses of Aluminium Foil for Food Wrapping

Aluminum Food Packaging Foil: The aluminum foil paper for food packaging offers a protective barrier against moisture, dust, and other external elements. This ensures the food item reaches the end-user in the best condition.

Food Items Wrapping: It is used to wrap food items and cooked meals.

Aluminum Foil Roll: The aluminum foil roll can be easily unwinded and cut as per requirements.

When it comes to choosing aluminum foil for food packaging, consider your product specification. Consider elements like thickness, size, and length to find the ideal packaging foil for your needs. Pragya Flexifilm Industries are leading aluminium foil manufacturers in India. Whether you want aluminium foil for household or commercial requirements, we provide high-quality foil paper for your needs. Buy top-notch aluminium foil for food wrapping for long freshness. Contact Pragya Flexifilm Industries today to discuss your packaging needs.

#aluminium foil for food wrapping#Aluminium Foil for Food Wrapping#Aluminium Foil Manufacturers#Uses of Aluminium Foil#Key Features of Aluminum Foil#aluminium foil manufacturers in India

0 notes

Text

Food Aluminum Foil Market to See Huge Growth by 2028

Latest released the research study on Global Food Aluminum Foil Market, offers a detailed overview of the factors influencing the global business scope. Food Aluminum Foil Market research report shows the latest market insights, current situation analysis with upcoming trends and breakdown of the products and services. The report provides key statistics on the market status, size, share, growth factors of the Food Aluminum Foil The study covers emerging player’s data, including: competitive landscape, sales, revenue and global market share of top manufacturers are China Hongqiao Group Limited (China), Alcoa (United States), Hydro (Norway), United Company RUSAL PLC (Russia), Ess Dee Aluminium Ltd (India), Alufoil Products Pvt. Ltd. (India), Nicholl Food Packaging Ltd (United Kingdom), Wyda Packaging (South Africa), Penny Plate LLC (United States), Alcoa Corporation (United States)

Free Sample Report + All Related Graphs & Charts @: https://www.advancemarketanalytics.com/sample-report/28954-global-and-united-states-food-aluminum-foil-market

Food Aluminum Foil Market Definition:

Food Aluminum foils offer many advantages to the packaging and food industries and the consumer including consumer friendliness & recyclability. Consumers can freeze or heat food products in the foil container directly. Other applications of aluminum include beverage, confectionary, personal care, health care and other industrial uses. The global aluminum foil packaging market is expected to show high growth over coming years. The major growth is expected in the developing markets owing to strong economic growth and increasing middle class with growing disposable income. The change in life style which includes changed food habits has led to increased demand for packaging.

Market Trend:

Increase in the availability of foils in various forms

Market Drivers:

Increased demand in chocolates and snacks industry as well as pharmaceutical industry

Market Opportunities:

Deploying technological advancements to produce improvement in product quality

The Global Food Aluminum Foil Market segments and Market Data Break Down are illuminated below:

by Type (Heavy Gauge Foil, Medium Gauge Foil, Light Gauge Foil), Application (Meat Snacks, Dried Fruits, Biscuits, Drinks, Other), Distribution Channel (Offline, Online), Form (Box, Wrapper, Other)

Region Included are: North America, Europe, Asia Pacific, Oceania, South America, Middle East & Africa

Country Level Break-Up: United States, Canada, Mexico, Brazil, Argentina, Colombia, Chile, South Africa, Nigeria, Tunisia, Morocco, Germany, United Kingdom (UK), the Netherlands, Spain, Italy, Belgium, Austria, Turkey, Russia, France, Poland, Israel, United Arab Emirates, Qatar, Saudi Arabia, China, Japan, Taiwan, South Korea, Singapore, India, Australia and New Zealand etc.

Enquire for customization in Report @: https://www.advancemarketanalytics.com/enquiry-before-buy/28954-global-and-united-states-food-aluminum-foil-market

Strategic Points Covered in Table of Content of Global Food Aluminum Foil Market:

Chapter 1: Introduction, market driving force product Objective of Study and Research Scope the Food Aluminum Foil market

Chapter 2: Exclusive Summary – the basic information of the Food Aluminum Foil Market.

Chapter 3: Displayingthe Market Dynamics- Drivers, Trends and Challenges of the Food Aluminum Foil

Chapter 4: Presenting the Food Aluminum Foil Market Factor Analysis Porters Five Forces, Supply/Value Chain, PESTEL analysis, Market Entropy, Patent/Trademark Analysis.

Chapter 5: Displaying market size by Type, End User and Region 2015-2020

Chapter 6: Evaluating the leading manufacturers of the Food Aluminum Foil market which consists of its Competitive Landscape, Peer Group Analysis, BCG Matrix & Company Profile

Chapter 7: To evaluate the market by segments, by countries and by manufacturers with revenue share and sales by key countries (2021-2026).

Chapter 8 & 9: Displaying the Appendix, Methodology and Data Source

Finally, Food Aluminum Foil Market is a valuable source of guidance for individuals and companies in decision framework.

Data Sources & Methodology The primary sources involves the industry experts from the Global Food Aluminum Foil Market including the management organizations, processing organizations, analytics service providers of the industry’s value chain. All primary sources were interviewed to gather and authenticate qualitative & quantitative information and determine the future prospects.

In the extensive primary research process undertaken for this study, the primary sources – Postal Surveys, telephone, Online & Face-to-Face Survey were considered to obtain and verify both qualitative and quantitative aspects of this research study. When it comes to secondary sources Company's Annual reports, press Releases, Websites, Investor Presentation, Conference Call transcripts, Webinar, Journals, Regulators, National Customs and Industry Associations were given primary weight-age.

For Early Buyers | Get Up to 20% Discount on This Premium Report: https://www.advancemarketanalytics.com/request-discount/28954-global-and-united-states-food-aluminum-foil-market

What benefits does AMA research study is going to provide?

Latest industry influencing trends and development scenario

Open up New Markets

To Seize powerful market opportunities

Key decision in planning and to further expand market share

Identify Key Business Segments, Market proposition & Gap Analysis

Assisting in allocating marketing investments

Definitively, this report will give you an unmistakable perspective on every single reality of the market without a need to allude to some other research report or an information source. Our report will give all of you the realities about the past, present, and eventual fate of the concerned Market.

Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Europe or Southeast Asia.

Contact Us:

Craig Francis (PR & Marketing Manager) AMA Research & Media LLP Unit No. 429, Parsonage Road Edison, NJ New Jersey USA – 08837

0 notes

Text

Aluminium Wire Prices, Pricing, Demand & Supply, Market Analysis | ChemAnalyst

For the Quarter Ending June 2023

North America

The United States Aluminum Wire market has experienced interesting trends recently. Initially, prices rose due to a 25% increase in local interest rates by the US Federal Reserve Board, aimed at controlling inflation. This decision proved beneficial, leading to increased demand, particularly within the photovoltaic system industry. Alcoa, a prominent player in the US Aluminum industry, played a crucial role in the energy transition by investing in Aluminum Wire mills in Brazil and resuming mining operations in Western Australia, which in turn strengthened the domestic market. The automotive sector, with Tesla's electric vehicle sales leading the way, also contributed significantly to the increased consumption of Aluminum. However, supply constraints persisted due to reduced local mine production and export restrictions imposed by Indonesian suppliers. The modernization efforts in Brazilian and Australian mines also affected the production rates in the US. In August, Aluminum Wire prices stabilized as demand from the automotive industry remained steady despite economic uncertainties. Bauxite imports from Guinea surged, which helped boost feedstock inventory, as Guinea's mines adopted sustainable practices and increased output. Market uncertainties, elevated inventory levels, and rising interest rates prompted cautious buyer behavior. Competition from Chinese producers dampened downstream automotive demand, while the renewable energy sector held promise for driving Aluminum Wire demand. Additionally, anticipated adverse weather conditions could impact production costs in the forthcoming months.

Asia-Pacific

The South Korean aluminum wire market experienced a series of price fluctuations in the third quarter of 2023. In July, prices surged due to reduced manufacturer offers and weakened purchasing activity. High prices for PRN packaging materials and low recycling rates negatively impacted Aluminum's durability, leading to predictions of reduced domestic demand and increased overseas recycling. As a result, domestic aluminum wire prices initially declined, following a similar trend in India where production levels dipped due to weak demand. Global economic uncertainty and increased import tariffs on raw Aluminum further pressured prices, which prompted cautious buying. The rise in US interest rates also dampened export demand from sectors like automotive manufacturing, adding to the pressure. However, by mid-Q3 2023, South Korean aluminum wire prices rebounded thanks to steady inquiries from the power and distribution sector. Yet, concerns about the US debt ceiling, sluggish domestic consumption, limited policy stimulus, and a gloomy global economic outlook persisted. Stable supply led to increased local inventory levels, with boosted imports of bauxite from Guinea promoting sustainable fuel use in mining. Demand remained subdued in construction but surged in the battery foil and electrical/electronic sectors. Short-term expectations indicated a positive trend in aluminum prices with a focus on downstream consumption intensity. Overall, the market displayed resilience despite ongoing challenges.

Get Real Time Prices of Aluminium Wire: https://www.chemanalyst.com/Pricing-data/aluminium-wire-1361

Europe

The Aluminium Wire market in Germany has shown a stable trend in the third quarter. Prices initially surged due to improved economic conditions and reduced local inventories. Indonesian export restrictions tightened supply, resulting in higher spot market prices. Additionally, a contract with Indian rail giant Alston increased demand for Aluminium Wires, as parts were to be produced in France, leading to higher export quotas from Germany. The European market is considering lifting the ban on Russian Aluminium imports as supply and demand have stabilized, thanks to Russia's largest Aluminium producer, Russell. Alcoa's mining permit for its Aluminium Wire mine in Western Australia and government recognition of Aluminum's importance further bolstered the market. Domestic Aluminium Wire supplies remained tight due to the Indonesian mining ban and reduced German factory activity. The electric vehicle sector's recovery and a 0.25% rate hike stabilized inflation and boosted demand. In August, prices remained static due to high Bauxite supply and limited local orders. Meanwhile, downstream industries like shipbuilding, clean energy, and automotive showed promise, with companies like Volvo and Tesla expanding production across Europe. Despite economic uncertainties and cautious buyers, the Aluminium Wire market is expected to see increased demand in the coming months as production rates rise and economic conditions stabilize.

About Us:

ChemAnalyst is an online platform offering a comprehensive range of market analysis and pricing services, as well as up-to-date news and deals from the chemical and petrochemical industry, globally.

Being awarded ‘The Product Innovator of the Year, 2023’, ChemAnalyst is an indispensable tool for navigating the risks of today's ever-changing chemicals market.

The platform helps companies strategize and formulate their chemical procurement by tracking real time prices of more than 400 chemicals in more than 25 countries.

ChemAnalyst also provides market analysis for more than 1000 chemical commodities covering multifaceted parameters including Production, Demand, Supply, Plant Operating Rate, Imports, Exports, and much more. The users will not only be able to analyse historical data but will also get to inspect detailed forecasts for upto 10 years. With access to local field teams, the company provides high-quality, reliable market analysis data for more than 40 countries.

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

Titanium Fasteners Manufacturer in UK: Forging Excellence

Introduction: When it comes to precision engineering, the United Kingdom boasts a remarkable reputation as a hub for the finest Titanium Fasteners Manufacturers UK. These manufacturers play a pivotal role in various industries by supplying top-tier titanium fasteners that are crucial for the structural integrity and longevity of countless applications. In this blog post, we will take an in-depth look into the world of Titanium Fasteners Manufacturing in the UK, exploring the exceptional qualities, innovative processes, and the impact this industry has on both domestic and global markets.

Why Choose Titanium Fasteners?

Titanium Fasteners are renowned for their exceptional qualities, making them the top choice for critical applications across various sectors. Let's delve into the reasons why:

1. Unmatched Strength-to-Weight Ratio

Titanium's impressive strength-to-weight ratio outshines traditional materials like steel and aluminum. This unique characteristic ensures that Titanium Fasteners UK provide robust structural support while keeping the overall weight of the assembly to a minimum.

2. Exceptional Corrosion Resistance

One of titanium's standout features is its remarkable resistance to corrosion. This resistance extends to harsh environments, including saltwater exposure, acidic conditions, and extreme temperatures, making Titanium Fasteners ideal for marine and aerospace applications.

3. Biocompatibility

In the medical and healthcare sector, biocompatibility is paramount. Titanium's biocompatibility ensures that fasteners can be safely used in medical implants and equipment without adverse reactions or complications.

The UK's Titanium Fasteners Manufacturing Expertise

The Titanium Fasteners Manufacturers are renowned for their commitment to precision, innovation, and quality. Here are some key aspects that set them apart:

1. Cutting-Edge Manufacturing Techniques

Leading Titanium Fasteners Suppliers in UK employ state-of-the-art manufacturing techniques, including CNC machining, hot forging, and advanced quality control processes. This ensures that each fastener meets the highest industry standards.

2. Sustainable Practices

Many UK titanium fastener manufacturers prioritize sustainability by using eco-friendly processes and sourcing titanium from responsible suppliers. This not only benefits the environment but also aligns with the growing demand for sustainable solutions in various industries.

3. Customization and Adaptability

UK titanium fastener manufacturers excel in providing customized solutions tailored to the unique requirements of clients. Whether it's a complex aerospace application or a specialized medical device, the industry's flexibility and adaptability shine through.

Global Impact

The UK's Titanium Fasteners Manufacturers have a substantial global footprint, with their products reaching markets worldwide. Their reputation for excellence and precision makes them a top choice for international clients seeking reliable and high-performance fasteners.

Titanium Fasteners Manufacturer in UK

Ladhani Metal Corporation an industry leading Titanium Fasteners Manufacturer in UK. We are major Titanium Tank Suppliers in India

We are also leading,

Titanium Foil Manufacturer in India

Titanium Sheet Manufacturer in India

Titanium Fittings Manufacturer in India

Titanium Fasteners Manufacturer in India

Titanium Clading Manufacturer in India

Conclusion

In conclusion, the United Kingdom's Titanium Fasteners Manufacturing industry stands as a testament to precision engineering, innovation, and quality. With their exceptional qualities, commitment to sustainability, and global reach, UK-based Titanium Fasteners Manufacturers are at the forefront of providing essential components that power critical applications across the globe. For projects where strength, durability, and reliability are non-negotiable, the UK's Titanium Fasteners are the top choice, reaffirming the nation's position as a leader in precision engineering.

0 notes

Text

Quality Aluminium Products in Chennai: Your Trusted Supplier

Chennai The bustling metro city located in Southern India, is renowned for its manufacturing prowess. There are a myriad of businesses shaping the city's landscape and the city's future, the Best aluminium company in chennai stands out as a leading player that is a pioneer in the field of innovation and changing the way industries are run with innovative aluminium solutions. This article explores the history and impact of this significant actor, showing the way it has grown into a reputable name in the world of aluminium.

An Legacy of Excellence

The Aluminium Company in Chennai boasts a rich legacy of excellence that dates back many decades. From its modest beginnings to becoming a key player in the aluminium sector its commitment to quality, innovation, and customer satisfaction has not wavered. Over the years it has built up a vast pool of knowledge and expertise, as well as industry information, bringing it to the top of the market for aluminium.

A Wide Variety of Products

The genesis of the Aluminium Company's achievement is its wide range of products. Whatever it is, whether it's aluminium sheets foils, coils, extrusions, or custom-designed components The company serves diverse industries including automotive, aerospace, construction, electronics, and packaging. Its cutting-edge manufacturing facilities outfitted with advanced technology ensure that the aluminum is of the highest quality. products that are in line with the strictest international standards.

Pioneering Innovation

Innovation is the heartbeat in the Aluminium Company in Chennai. With a dedicated staff of research and development, the business continuously studies new techniques and processes to enhance product performance, durability, and sustainability. From light alloys for cars that are fuel efficient to rust-proof aluminium for maritime use The company's dedication to innovating and leading the way remains unwavering.

Centric Customer Approach

One of the hallmarks of this Aluminium Company in Chennai is its commitment to customer service. Recognizing that each client has unique requirements and needs, the company provides personalized solutions designed to meet specific industry needs. The knowledgeable sales and support staff work closely with customers to comprehend their requirements and supply customers with the best aluminum products and services.

Sustainability and Eco-Friendliness

In an era where environmental sustainability is of paramount importance, this Aluminium Company in Chennai takes great pride in its environmentally responsible methods. From responsible sourcing of raw materials to the implementation of energy efficient manufacturing processes and more, the company is committed to cutting down its carbon footprint. By offering recyclable aluminium products, it is able to support the sustainability goals of its customers and helps to create a more sustainable planet.

Quality Assurance and Certifications

The Aluminium Company in Chennai places the highest importance upon quality and assurance. In adhering to rigorous quality control measures, the company ensures their products are in good condition and meet international standards of quality. To demonstrate the company's commitment to excellence, the company has a variety of certifications which confirm that it is in conformity to industry-specific standards and guidelines.

Contributing to Chennai's growth

Beyond its remarkable contribution to the industry of aluminium It also plays an important role in Chennai's economic development. With its highly trained and committed workforce, it generates employment opportunities, fostering talent development within the region. In addition, through collaboration with local companies and suppliers it helps strengthen the city's industrial economy.

Conclusion

The Aluminium Company in Chennai stands tall as a symbol of excellence, innovation, and sustainability within the aluminium industry. Its relentless pursuit of quality, customer satisfaction, and environmentally-friendly practices has earned it the trust of industries not only in Chennai but across the nation. As this business continues to grow and evolve and grow, it has left an imprintable footprint on Chennai's landscape of industry that solidifies its status as an established name in the field of aluminium solutions.

0 notes

Text

Supplier of Aluminium Sheets in Ahmedabad

Pruthvi Enterprise is an ISO 9001:2015 Certified Company, India's most trustworthy brand in the aluminum industry since 2017. We are Stockiest and suppliers of Aluminium Coils, Sheets, Pipes, Plates, and Chequered Plates in India.Pruthvi Enterprise is one of the best Aluminium Sheets manufacturers, Suppliers and Exporters in Ahmedabad, Gujarat and India. We use the best quality Aluminum alloy in fabricating Aluminum Sheet. As per the requirement, customers can easily mold our Aluminum sheets into desired shapes and sizes. We are also leading Manufacturer and supplier of aluminum tubes in Ahmedabad and india.Aluminum Sheet Is Any Aluminum Sheet Metal Thicker Than Foil But Slim Than 6mm; It Comes In Various Shapes Counting Diamond Plate, Extended, Perforated, And Painted Aluminum Sheet.In transportation, aluminum sheets are used to create sheets for vehicle bodies and tractor trailers. In household machines and cookware, people utilize the sheet and building and improvement, manufacturers shape it into items, including siding, gutters, roofs, and garages.SpecificationStandards: ASTM B221, ASTM-B-209M, EN573, EN485, AMS 4003 Grade: Aluminium Alloy 1100 (UNS A91100) Thickness: 1.0-400 mm Width: 25-3000 mm Type: Hot-Rolled (HR) / Cold-Rolled (CR) Sheet / Plates/ Strips/ Coils/ Chequered Plates Processing: Cutting, Forming Drilling/ Machining, Grinding, TestingApplicationAutomotive Building Electrical Aerospace Packaging TransportationPruthvi Enterprise is a Supplier of Aluminium Sheets in Ahmedabad, covering areas like Rakhial, Vatva, Odhav, Naroda, Aslali, Narol, Changodar, Kathwada, Bavla, Sanand, Vani, Vatva D Zone, Dhandhuka, Dholka, Viramgam, Keral, Kathvada I and II, and others.For further details, please contact our professional team for a conversation. Read the full article

#Ahmedabad#Aslali#Bavla#Cathwada#Changodar#Dhandhuka#Naroda#Narol#Odhav#PruthviEnterprise#Rakhial#Sanand#SupplierofAluminiumSheets#Vatva

0 notes

Text

The listing of Ess Dee Aluminium Ltd. in the National Stock Exchange (NSE) and Bombay Stock Exchange (BSE) in 2006 was nothing short of magic. Apart from this win, Sudip also garnered massive attention when he took over India Foils Ltd. in 2008. It hit the newspaper headlines and was described as a historical takeover of the leading oil manufacturer and exporter of aluminum foil with roots that can be traced back to 1960. In fact, Forbes India even labeled Sudip Dutta as "The Wrapper Tycoon" in 2009.

0 notes

Text

Aluminium Coil Manufacturers

Printed Circuit Board Entry

Marudhar’s Printed Circuit Board (PCB) entry sheets are manufactured with state-of-the-art equipment which matches international standards. Tight thickness tolerance, flatness, dimensional accuracy, grease-free surface and hardness optimal for burr-free drilling required in the manufacture of PCB are ensured. Marudhar Industries is one of the leading Aluminium Coil Manufacturer, supplier, and exporters in india. We Provoide High Quality Aluminium Coil at best price.

Continuous upgrades and process improvement enable us to keep pace with the demands of its ever-growing clientele.

Aluminum PCB (Printed Circuit Board) Entry Sheets

Specifications:

Marudhar’s Printed Circuit Board (PCB) entry sheets are manufactured with state-of-the-art equipment which matches international standards. Tight thickness tolerance, flatness, dimensional accuracy and grease-free surface and hardness optimal for burr-free drilling required in the manufacture of PCB are ensured.

Continuous upgrades and process improvement enable us to keep pace with the demands of its ever-growing clientele. Application Standards:

ASTM-B-209M, Aluminium association — aluminium standards and data, Marudhar manufacturing limits (as applicable).

Packing:

The PCB entry sheets are wrapped with HDPE, hardboard on top and bottom of the stack, hoop iron along the length of the sheets and is placed on wooden skids with runners and finally put in wooden boxes. Silica gel packets for moisture protection are used.

Applications:

Electronic circuit boards

Foil Stock

Marudhar’s foil stock is produced from high-quality rolling ingots and concast coils. Manufactured with sophisticated equipment, the foil stock is free of surface and subsurface defects. Matching international quality standards, it can be rolled to thin gauges of aluminium foil for a number of applications.

Foil Stock

Specifications:

Marudhar’s foil stock is produced from high-quality rolling ingots and concast coils. Manufactured with sophisticated equipment, the foil stock is free of surface and subsurface defects. Matching international quality standards, it can be rolled to thin gauges of aluminium foil for a number of applications.

Stringent quality checks ensure a world-class range of sheets, extrusions and foil products from Marudhar. Continuous upgrades and process improvement enable it to keep pace with the demands of its ever-growing markets. Flatness:

Less than 20 I units (typical)

Wedge:

Within 0.7% (typical)

Coil Build-up Quality:

Weave — 2 mm (max), total shift 5 mm (max)

Surface Quality:

Suitable for foil rolling

Application Standards:

ASTM — B -209M, Aluminium association — aluminium standards and data, Marudhar manufacturing limits (as applicable).

Packing:

Foil stock is wrapped in HDPE fabric and hardboard, strapped with hoop iron and placed in an eye-to-sky or eye-to-wall position. Moisture protection is provided with silica gel packets.

Applications:

Pharma / Confectioneries / Cigarette Foils

Foils

Tetra packs Closure Stock (PP Caps)

Marudhar’s closure stock is rolled to very fine tolerances to yield more closure per ton of stock and to allow uninterrupted operation of high-speed, multiple-cavity presses. Its strength, high formability, low earring and printable surfaces make it ideal for pilfer-proof caps and vial seals.

PP Cap Sheets (Closure Stock)

Specifications:

Marudhar’s closure stock is rolled to very fine tolerances to yield more closure per ton of stock and to allow uninterrupted operation of high-speed, multiple-cavity presses. Its strength, high formability, low earring and printable surfaces make it ideal for pilfer-proof caps and vial seals.

Packing:

Sheet: Sheets are placed in wooden boxes on wooden skids with runners along the length of the sheet. They are wrapped in HDPE with hardboard on top and bottom of the stack. Hoop iron strapping runs along the length of the sheets. Silica gel packets are put in the boxes for moisture protection.

Alternatively, they are wrapped in a poly-laminated gunny or polythene, strapped with a hoop iron strap and clip and placed on a wooden pallet. Edge guards are used and the sheets are wrapped with protective thermocol sheets.

Coil: Coil is placed on wooden pallets in either eye-to-sky or eye-to-wall condition, wrapped in HDPE fabric and hardboard, and strapped with hoop iron. Silica gel packets are used for moisture protection.

Applications:

Pilfer-Proof Caps

Vial Seals

Cream Containers & Caps

Fin Stock (HVAC)

By meeting the stringent specifications of globally competitive companies, Marudhar’s flat fin stock has proved its worth in air conditioners, car radiators and heat exchangers. With the help of high-quality ingots, state-of-the-art gauge ,shape control and precision slitting. We manufacture fin stock that has tight gauge tolerances and excellent slit edges. A tight build-up combined with internal sound metallurgical properties produce good drawability required for all types of finning.

Fin Stock [HVAC Foils]

Specifications:

By meeting stringent specifications of globally competitive companies, Marudhar’s flat fin stock has proved its worth in air conditioners, car radiators and heat exchangers. With the help of high-quality ingots, state-of-the-art gauge and shape control and precision slitting, we manufacture fin stock that has tight gauge tolerances and excellent slit edges. A tight build-up combined with internal sound metallurgical properties produce good draw ability required for all types of finning;

Packing:

Marudhar’s flat fin stock is packed on wooden skids in either eye-to-sky or eye-to-wall condition, wrapped in HDPE fabric and hardboard and strapped with hoop iron. Moisture protection is ensured with silica gel packets and as the final step, the entire packed product is placed in a wooden cage.

Applications:

Air Conditioners

Car Radiators

Automobile Heat Exchangers

Tread Plated

Marudhar’s pattern sheets are ideal for decorative applications and interior panelling for trucks, cabins, etc. Available in five designs — diamond, five-bar, two-bar, propeller, and north star — the sheets can be bent easily or curved to take the shape of the structure in which they are fixed. Pattern sheets are light, rust-free, hygienic and easy to clean, and because they are made from aluminium, they are resistant to corrosion and denting.

The sheets are manufactured with state-of-the-art equipment employing sophisticated process technology. With stringent quality control measures in place, the company sets the standard in aluminium panelling.

Pattern Sheets/Coils (Chequered/Tread Plates)

Specifications:

Marudhar’s pattern sheets are ideal for decorative applications and interior panelling for trucks, cabins, etc.

Available in five designs — diamond, five-bar, two-bar, propeller, north star — the sheets can be bent easily or curved to take the shape of the structure in which they are fixed. Pattern sheets are light, rust-free, hygienic and easy-to-clean and because they are made from aluminium, they are resistant to corrosion and denting.

The sheets are manufactured with state-of-the-art equipment employing sophisticated process technology. With stringent quality control measures in place, the company sets the standard in aluminium panelling.

Packing:

Marudhar’s pattern sheets are packed with a poly-laminated gunny, hardboard, strapped with hoop iron and clip, and placed on a pallet.

Applications:

Decorative applications like interior panelling for trucks, cabins, etc.

Cast Coil

Marudhar’s cold rolled coils/sheets are precision-finished to match international standards. They have good shape, high tolerance, versatility and blemish-free surfaces. They are used in commercial and general engineering applications such as bus bodies, cladding and fan blades. The company meets the demands of its ever-growing clientele with continuous upgrades and process improvement.

Aluminium Alloy Cast Coil

Specifications:

Our cast coils are used to produce superior-quality Insulation Cladding, Flooring Sheets, Roof Sheets, Nets, Balls Chain, Circles, Chequered Sheets, Cold Rollind, Utensils Making and many more products.Aluminium and its alloy cast coils are of a smooth surface, have no burr and are of high quality in terms of flatness and surface roughness.

According to the analysis, the chemical composition, homogenizing, shearing, intrinsic properties organization, hardness and other mechanical properties of materials will affect the application. In common the cast coils come with the tempers range as O. The thickness is 6–8mm and the width is 762–1250mm.

Product Name Aluminium Alloys Cast Coil Grades 1070, 1060, 1050, 1100, 1200, 1235, 3003, 3004, 3105, 8011, 8079, GEQ Temper O Specification Thickness: 6–8mm Width: 762–1250mm Quantity tolerance ±10% ID 200, 305, 405 and 505mm Surface treatment Mill finish Application Insulation Cladding, Flooring Sheets, Roof Sheets, Nets, Balls Chain, Circles, Chequered Sheets, Cold Rolling, Utensils Making and many more products Packaging Wooden Pallet Remark Aluminium Alloys Cast Coils can be customized

Application:

Insulation Cladding, Flooring Sheets, Roof Sheets, Nets, Balls Chain, Circles, Chequered Sheets, Cold Rolling, Utensils Making and many more products.

Slit quality:

Free from nicks, cuts and burrs.

Coil build-up:

Uniform and tight enough to be handled horizontally.

Applicable standards:

ASTM — SB -209M, Aluminium association — aluminium standards and data, Marudhar manufacturing limits (as applicable).

Packing:

Aluminium Alloys Cast Coils are placed on wooden skids in an eye-to-wall position. It is wrapped in HDPE fabric and hardboard and strapped with hoop iron. Moisture protection is ensured with silica gel packets and the entire packed product is placed in a wooden box. Cable Armouring Strips

Marudhar meets global standards in the manufacture of its cable wrap stock, which is widely used in various cable brands.

With the help of high-quality ingots and state-of-the-art control systems, Marudhar manufactures cable wrap stock with tighter gauge tolerances and meets excellent elongation and length requirements.

Cable Armouring Strips Stock (Cable Armoring Coils)

Specifications:

Our aluminium cable armouring strip stock is used as a conductor to wound on the core of the underground cables. Aluminium strip for cable armouring is required with high electrical conductivity According to the analysis, the chemical composition, cold rolling, shearing, heat treatment processes, internal properties organization, electrical conductivity, hardness and mechanical properties of materials will affect the application of cable core armouring winding.

In common, the aluminum strips alloys used in dry type transformers are 1050, 1060, 1070 and 1100 the temper is O which means soft, the thickness is 0.170–2.3mm and the width is 150–1250mm.

Product Name Aluminium Strip for cable core armouring Grades 1050,1060,1070, 1100 Temper O, H18 Specification Thickness: 0.150–2.3mm Width: 150–1250mm Quantity tolerance ±10% ID 152.4, 200, 305, 405 and 505mm Surface treatment Mill finish Application Cable Core Armouring Packaging Wooden Pallet Remark Aluminium Strip can be customized.

Chemical Composition:

1050 Aluminium Strip Chemical composition (%) Element Al Si Fe Mg Zn Mn Ti Cu V Standard Value ≥99.5 0.0431 0.203 0.0013 0.0093 0.0104 0.0200 0.0022 0.0039 1060 Aluminium Strip Chemical composition (%) Element Al Si Fe Mg Zn Mn Ti Cu V Standard Value ≥99.6 0.0431 0.203 0.0013 0.0093 0.0104 0.0200 0.0022 0.0039 1070 Aluminium Strip Chemical composition (%) Element Al Si Fe Mg Zn Mn Ti Cu V Standard Value ≥99.7 0.0431 0.203 0.0013 0.0093 0.0104 0.0200 0.0022 0.0039 1100 Aluminium Strip Chemical composition (%) Element Al Si Fe Mg Zn Mn Ti Cu V Standard Value ≥99.0 0.0431 0.203 0.0013 0.0093 0.0104 0.0200 0.0022 0.0039

Application:

Underground cables and Telecom Cables core winding and armouring, distribution/power grid cables winding, electric cable sheathing/shielding parts.

Slit quality:

Free from nicks, cuts and burrs. Lateral flatness on all slitted edges as per standards.

Coil build-up:

Uniform and tight enough to be handled horizontally.

Applicable standards:

ASTM — SB -209M, Aluminium association — aluminium standards and data, Marudhar manufacturing limits (as applicable).

Packing:

Cable Armouring Strips Stock is placed on wooden skids in an eye-to-wall position. It is wrapped in HDPE fabric and hardboard and strapped with hoop iron. Moisture protection is ensured with silica gel packets and the entire packed product is placed in a wooden box.

GEQ Coils/Sheets

Marudhar leads in the production of exceptional GEQ coils/sheets. Our expertise ensures industry-leading standards, delivering coils/sheets known for their top-tier quality and performance. With a dedication to precision and innovation, we tailor products to your exact requirements, guaranteeing reliability and excellence across various applications.

GEQ Strips Stock

Specifications:

Our general engineering quality stock is used to produce superior-quality INSULATION CLADDING, FLOORING SHEETS, NETS, BALLS CHAIN, CIRCLES. Aluminium GEQ Stock is of a smooth surface, has no burr and is of high quality.

According to the analysis, the chemical composition, cold rolling, shearing, heat treatment processes, intrinsic properties organization, hardness and other mechanical properties of materials will affect the application.

In common the GEQ alloy comes with the tempers range as O, H12, H14, H16, H18, H22, H24 and H26. The thickness is 0.150–4mm and the width is 50–1250mm.

Product Name Aluminium GEQ Strips (IN COILS AND SHEETS FORM) Grades GEQ Temper O, H12, H14, H16, H18, H22, H24, H26 Specification Thickness: 0.150–4mm Width: 50–1250mm Quantity tolerance ±10% ID 76, 152.4, 200, 305, 405 and 505mm Surface treatment Mill finish Application Insulation Cladding, Flooring Sheets, Nets, Ball Chains, Circles Packaging Wooden Pallet Remark Aluminium Strip can be customized with cut to width and cut to length for sheets form requirements with tight tolerane of ±1mm

Application:

Insulation Cladding, Flooring Sheets, Nets, Ball Chains, Circles.

Slit Quality:

Free from nicks, cuts and burrs.

Coil build-up:

Uniform and tight enough to be handled horizontally.

Applicable standards:

ASTM — SB -209M, Aluminium association — aluminium standards and data, Marudhar manufacturing limits (as applicable).

Packing:

Cable GEQ Strips Stock is placed on wooden skids in an eye-to-wall position. It is wrapped in HDPE fabric and hardboard and strapped with hoop iron. Moisture protection is ensured with silica gel packets and the entire packed product is placed in a wooden box.

Transformer Strips

Marudhar consistently adheres to global benchmarks in the production of its transformer strip, a crucial component widely integrated into diverse transformer brands. Leveraging premium-grade ingots and cutting-edge control mechanisms, Marudhar ensures the fabrication of transformer strip featuring enhanced gauge tolerances, while surpassing exacting elongation and length prerequisites.

Transformer Strips Stock

Specifications:

Our aluminium transformer strip stock is used as a conductor in dry-type transformers to wound on the core instead of copper winding. Aluminium strip for transformer wingding is required with high electrical conductivity (AA1100: >59% IACS, AA1050: >59.5% IACS, AA1060: >61.3% IACS, AA1070: >62.6% IACS), soft, smooth surface, no burr and high quality.

According to the analysis, the chemical composition, cold rolling, shearing, heat treatment processes, internal properties organization, electrical conductivity, hardness and mechanical properties of materials will affect the application on transformer winding.

In common, the aluminum strips alloys used in dry type transformers are 1050, 1060 and 1070 the temper is O which means soft, the thickness is 0.130–4.0mm and the width is 10–1250mm.

Product Name Aluminium Strip for Transformer Winding Grades 1050,1060,1070, 1100 Temper O Specification Thickness: 0.130–4mm Width: 10–1250mm Quantity tolerance ±10% ID 152.4, 200, 305, 405 and 505mm Surface treatment Mill finish Application Transformer Winding Packaging Wooden Pallet Remark Aluminium Strip can be customized.

Chemical Composition:

1050 Aluminium Strip Chemical composition (%) Element Al Si Fe Mg Zn Mn Ti Cu V Standard Value ≥99.5 0.0431 0.203 0.0013 0.0093 0.0104 0.0200 0.0022 0.0039 1060 Aluminium Strip Chemical composition (%) Element Al Si Fe Mg Zn Mn Ti Cu V Standard Value ≥99.6 0.0431 0.203 0.0013 0.0093 0.0104 0.0200 0.0022 0.0039 1070 Aluminium Strip Chemical composition (%) Element Al Si Fe Mg Zn Mn Ti Cu V Standard Value ≥99.7 0.0431 0.203 0.0013 0.0093 0.0104 0.0200 0.0022 0.0039 1100 Aluminium Strip Chemical composition (%) Element Al Si Fe Mg Zn Mn Ti Cu V Standard Value ≥99.0 0.0431 0.203 0.0013 0.0093 0.0104 0.0200 0.0022 0.0039

Application:

Power Transformer winding and metal cladding, distribution/power transformer winding, electric cable sheathing/shielding parts.

Slit quality:

Free from nicks, cuts and burrs. Lateral fillets on all slitted edges as per standards.

Coil build-up:

Uniform and tight enough to be handled horizontally.

Applicable standards:

ASTM — SB -209M, Aluminium association — aluminium standards and data, Marudhar manufacturing limits (as applicable).

Packing:

Cable Transformer Strips Stock is placed on wooden skids in an eye-to-sky position. It is wrapped in HDPE fabric and hardboard and strapped with hoop iron. Moisture protection is ensured with silica gel packets and the entire packed product is placed in a wooden box.

Eyelet Stock

Marudhar upholds international standards in the fabrication of its eyelet stock, a fundamental material extensively utilised in a variety of applications. Through the utilisation of primary ingots and advanced control systems, Marudhar delivers eyelet stock with meticulous gauge tolerances, alongside meeting stringent elongation and length criteria, establishing a product of unparalleled quality and reliability.

Eyelet Strips Stock

Specifications:

Our aluminium eyelet strip stock is used to produce superior-quality eyelets. It comprises two parts — EYELETS RIVET TORUS STOCK and EYELETS RIVET FLAT STOCK. Aluminium eyelets rivet torus stock is soft, of a smooth surface, has no burr and is of high quality. According to the analysis, the chemical composition, cold rolling, shearing, heat treatment processes, intrinsic properties organization, hardness and other mechanical properties of materials will affect the application.

In common, for making the aluminium eyelets rivet torus stock the alloys used are 1050 and 1100 with the temper O which means soft, the thickness is 0.120–0.200mm and the width is 12–1250mm. While the eyelets rivet flat stock comes with GEQ alloy having tempers range as O, H12, H14, H22 and H24. The thickness is 0.120–0.350mm and the width is 18–1250mm.

Product Name Aluminium Strips for Eyelets Grades 1050, 1100, 8011, GEQ Temper O, H12, H14, H22, H24 Specification Thickness: 0.150–0.350mm Width: UPTO 1250mm Quantity tolerance ±10% ID 76, 152.4, 200, 305, 405 and 505mm Surface treatment Mill finish Application Eyelets Rivet Torus and Eyelets Rivet Flat parts Packaging Wooden Pallet Remark Aluminium Strip can be customized.

Chemical Composition:

1050 Aluminium Strip Chemical composition (%) Element Al Si Fe Mg Zn Mn Ti Cu V Standard Value ≥99.5 0.0431 0.203 0.0013 0.0093 0.0104 0.0200 0.0022 0.0039 1100 Aluminium Strip Chemical composition (%) Element Al Si Fe Mg Zn Mn Ti Cu V Standard Value ≥99.0 0.0431 0.203 0.0013 0.0093 0.0104 0.0200 0.0022 0.0039

Application:

Eyelets assembly comprising eyelets rivet torus and eyelets rivet flat parts.

Slit quality:

Free from nicks, cuts and burrs.

Coil build-up:

Uniform and tight enough to be handled horizontally.

Applicable standards:

ASTM — SB -209M, Aluminium association — aluminium standards and data, Marudhar manufacturing limits (as applicable). Marudhar Industries is one of the leading Aluminium Coil Manufacturer in India

Packing:

Eyelets Strips Stock is placed on wooden skids in an eye-to-sky position. It is wrapped in HDPE fabric and hardboard and strapped with hoop iron. Moisture protection is ensured with silica gel packets and the entire packed product is placed in a wooden box.

0 notes

Text

Retort Packaging Market ,Size, Share Demand, Trends and Analysis Research Report Till 2027

Global Retort Packaging Market is segmented by product type into pouches, trays, cartons & others; by material type into cast polypropylene, polyester (PET), polyethylene (PE), aluminum foil, paper & paperboard and others; by application type into food, beverages and pharmaceuticals and by regions.

According to IBEF, APEDA have a percentage share of its exports which records as 38.21% in cereals, 28.4% in food products, 7.8% in fresh food and vegetables, 6.7% in processed fruits and vegetables, 04.3% in floriculture and other processed food by 17.9% in 2016 which is thriving the retort packaging market to anticipate at a CAGR of 7.6% during the forecast period i.e. 2019-2027.

Get Exclusive Sample Data Report Copy Of This Report @ https://www.researchnester.com/sample-request-1388

The market segmented into the application types is expected to generate high demand for retort packaging by the food and beverage sector. The food and beverage packaging in pouches are expected to lead the product type on account of its easy handling and better application. The various other materials required for manufacturing of retort packaging is anticipated to fuel the market by PET material type during the forecast period.

Asia Pacific which is expected to lead the market of retort packaging on account of its rising food and beverage sector which is generating high demand for retort packaging in the market. The rising market demand in the countries of Asia Pacific such as China, India and others are expected to rise on the back of increasing investment in food and beverages, high industrialization and increasing per capita income.

North America is expected to drive the market at a substantial rate owing to the demand for ready to eat food items during the forecast period. Other regions are also driving the market at a healthy growth rate which is anticipated to propel the demand of retort packaging during the forecast period.

Curious about this latest version of report? Obtain Report Details @ https://www.researchnester.com/reports/retort-packaging-market/1388

Steady Application in Food Industry

Retort packaging are extensively used in the food industry to protect the food inside it with high integrity and food grade packaging offered by the retort packaging market. The rising demand for the ready to eat foods are projecting the growth of the retort packaging market which is anticipated to raise the market demand during the forecast period. The high protection by several layers and food grade hygienic material are preserving the food from external temperature and pressure which is probable to drive the market of retort packaging during the forecast period.

However, the banning of plastic grade products for food packaging and its toxic behavior towards food are expected to dampen the market growth. Moreover, the rising awareness among consumers for health and stringent government regulations are expected to create a hindrance to the market growth further over the forecast period.

This report also provides the existing competitive scenario of some of the key players of the global Retort packaging market which includes company profiling:

Bemis Company Inc.,

Bemis Company Inc.,

Clifton Packaging Group Limited,

Flair Flexible Packaging Corporation,

Clondalkin Industries BV,

Tetra Pak International S.A,

Sonoco Product Company,

Winpak Ltd.,

Sealed Air Corp and Amcor Limited

Get Exclusive Sample Report Copy Of This Report @ https://www.researchnester.com/sample-request-1388

The profiling enfolds key information of the companies which encompasses business overview, products and services, key financials and recent news and developments. On the whole, the report depicts detailed overview of the global Retort packaging market that will help industry consultants, equipment manufacturers, existing players searching for expansion opportunities, new players searching possibilities and other stakeholders to align their market centric strategies according to the ongoing and expected trends in the future.

About Research Nester

Research Nester is a leading service provider for strategic market research and consulting. We aim to provide unbiased, unparalleled market insights and industry analysis to help industries, conglomerates and executives to take wise decisions for their future marketing strategy, expansion and investment, etc. We believe every business can expand to its new horizon, provided a right guidance at a right time is available through strategic minds. Our out of box thinking helps our clients to take wise decision so as to avoid future uncertainties.

Contact Us

AJ Daniel Email: [email protected] U.S. Phone: [+1 646 586 9123] U.K. Phone: [+44 203 608 591]

0 notes