#India Compressor Market Growth

Explore tagged Tumblr posts

Text

The compressor in AC and Fridge can Cool You Down

When it is hot and humid outside, one finds relief only by drinking water out of a fridge or sitting in an air-conditioned place. Ever wondered, how both of these types of equipment give such good cooling? Well, it is because of the compressor. Producers of refrigerators and air conditioners have started production in full swing and capacity from 60-70% amid an increase in demand prompted by the heatwave in quite a few parts of India and repressed demand of the previous two summers, impacted by the lockdowns imposed by during the pandemic.

It is not that the compressors are only used in the cooling equipment like air conditions and refrigerators, they are used in a number of industries. There is a booming growth in the industrial sector of India, and with the number of industries growing, the demand for compressors is also on the rise. Almost all motor vehicles have a compressor, which compresses the gas and converts it into liquid. Owing to environmental protocols in the country, minimal gas emissions, less noisy, and those which are energy efficient have a considerably high demand in the automotive industry.

India’s annual automobile production was 22.65 million in 2021. There were more two-wheelers because of an increasing middle class, and moreover, most of the folks in the country come from the young population. Furthermore, the interest of the companies to explore the rural markets further made a difference. Moreover, numerous initiatives by the Indian government and major companies will make the country among the leaders in the two-wheeler and four-wheelers in the near future.

The states which fall under the northern region of India like UP, Haryana, Uttarakhand, Punjab, and Himachal Pradesh will have the highest demand for compressors by the end of this decade. Industrial and automotive manufacturing are among the major areas of use for compressors in North India. Additionally, the support of the government in the development of industrial corridors like Amritsar–Delhi–Kolkata industrial corridor and the Delhi–Mumbai industrial corridor, along with the development of SMEs, will push the requirement for compressors in the whole of North India.

Energy-efficient compressors are ruling the roost in the Indian compressor market. The market will reach a value of $ 2,891.9 million in the year 2030. Because of the emphasis on efficiency of production and saving energy, the requirement for compressors that are energy-efficient will increase in the coming years. It would reduce energy costs and also protect the environment from the emission of GHG. Consequently, major companies have announced compressors, are more efficient when equated to conventional compressors. For example, Atlas Copco introduced novel versions of its XATS 288 and XAVS 238 portable compressors, having 27% lesser carbon emissions. They are 20% light and 10% further energy-efficient than the traditional compressors.

The demand for compressors is on the rise in India because of the increasing requirement for cooling equipment like AC and fridges, and also the increasing number of industries and vehicles bursting onto the scene.

#India Compressor Market Share#India Compressor Market Size#India Compressor Market Growth#India Compressor Market Applications#India Compressor Market Trends

1 note

·

View note

Text

Surging Sales of Automobiles Driving Indian Compressor Market Growth

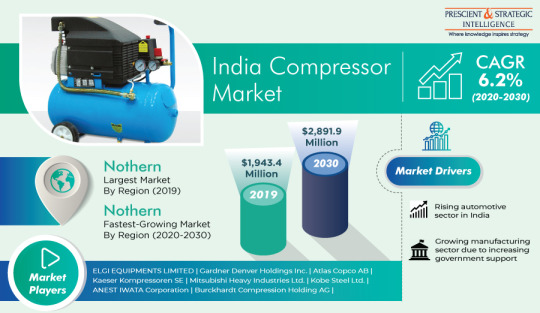

The Indian compressor market was valued at $1,943.4 million in 2019, and it is predicted to generate a revenue of $2,891.9 million by 2030. According to the estimates of the market research company, P&S Intelligence, the market will progress at a CAGR of 6.2% from 2020 to 2030. The expansion of the automotive industry is one of the major factors fueling the growth of the market. According to the India Brand Equity Foundation (IBEF), the automotive industry in India will generate a revenue of Rs. 16.16-18.18 trillion (US$ 251.4-282.8 billion) by 2026.

Additionally, the boom in the manufacturing sector, on account of the enactment of favorable government policies, is also predicted to propel the advancement of the market in the coming years. Besides, the inflow of huge foreign direct investments (FDI) is also driving the growth of the manufacturing sector in the country. Owing to these factors, the manufacturing sector in the country will attain a value of $1 trillion by 2025, as per various estimates. In this industry, industrial air compressors are extensively used for tool stamping, powering, and clamping.

For example, the government announced a reduction in the income tax rate to as much as 25% for all organizations having a turnover of up to $38.75 million, under the 2018–2019 Union Budget. Depending on type, the Indian compressor market is divided into rotary and positive displacement categories. Of these, the positive displacement category contributed higher revenue to the market in 2019. Moreover, this category is expected to hold the largest share in the market throughout the forecast period.

This is credited to the surging requirement for these compressors in various industries, such as semiconductor, chemical, stee, and automotive. In addition, these compressors are equipped with various features, such as better rotor profiles, and they are available in innovative designs, which is further boosting their popularity in the country. When lubrication type is taken into consideration, the market is categorized into oil-free and oil-flooded. Of these, the oil-flooded category dominated the market in 2019.

This was because of the less maintenance requirements and low initial cost of these compressors in comparison to the oil-free ones. The northern region dominated the Indian compressor market in 2019, and this trend is predicted to continue in the forthcoming years as well. This is ascribed to the expansion of the industrial manufacturing and automotive sectors in the region. Furthermore, the National Capital Region (NCR), which is situated in the northern part of the country, witnesses the large-scale usage of compressors, on account of the high automobile production and industrial growth. The region manufactures more than 30% of passenger cars and over 50% of two-wheelers in the country every year.

Hence, it is safe to say that the market will boom in the coming years, mainly because of the surge in the manufacturing and automotive sectors, owing to the implementation of favorable government policies in the country.

#India Compressor Market Share#India Compressor Market Size#India Compressor Market Growth#India Compressor Market Applications#India Compressor Market Trends#India Compressor Market Demand#India Compressor Market

0 notes

Text

Electric AC Motors Market — Forecast(2025–2031)

𝐃𝐫𝐢𝐯𝐢𝐧𝐠 𝐈𝐧𝐧𝐨𝐯𝐚𝐭𝐢𝐨𝐧: 𝐓𝐫𝐞𝐧𝐝𝐬 𝐒𝐡𝐚𝐩𝐢𝐧𝐠 𝐭𝐡𝐞 𝐄𝐥𝐞𝐜𝐭𝐫𝐢𝐜 𝐀𝐂 𝐌𝐨𝐭𝐨𝐫𝐬 𝐌𝐚𝐫𝐤𝐞𝐭 | IndustryARC™

The Electric AC Motors Market refers to the global industry involved in the design, manufacturing, distribution, and use of Alternating Current (AC) motors. These motors convert electrical energy into mechanical energy using alternating current, making them essential for various industrial, commercial, and residential applications.

👉 𝑫𝒐𝒘𝒏𝒍𝒐𝒂𝒅 𝑺𝒂𝒎𝒑𝒍𝒆 𝑹𝒆𝒑𝒐𝒓𝒕

𝐓𝐲𝐩𝐞𝐬 𝐨𝐟 𝐀𝐂 𝐌𝐨𝐭𝐨𝐫𝐬:

🔹𝐈𝐧𝐝𝐮𝐜𝐭𝐢𝐨𝐧 𝐌𝐨𝐭𝐨𝐫𝐬: Most commonly used, particularly in industrial applications.

🔹𝐒𝐲𝐧𝐜𝐡𝐫𝐨𝐧𝐨𝐮𝐬 𝐌𝐨𝐭𝐨𝐫𝐬: Provide constant speed operation and are widely used in applications requiring precision.

𝐀𝐩𝐩𝐥𝐢𝐜𝐚𝐭𝐢𝐨𝐧𝐬:

👉Industrial Use: Pumps, compressors, conveyors, and heavy machinery.

👉Commercial Use: HVAC systems, elevators, and fans.

👉Residential Use: Appliances like washing machines, refrigerators, and air conditioners.

👉Transportation: Electric vehicles (EVs) and railway systems.

👉 𝑭𝒐𝒓 𝑴𝒐𝒓𝒆 𝑰𝒏𝒇𝒐𝒓𝒎𝒂𝒕𝒊𝒐𝒏

𝐊𝐞𝐲 𝐓𝐫𝐞𝐧𝐝𝐬 :

🔹Increased demand for energy-efficient motors due to stringent energy regulations.

🔹Rising adoption of electric vehicles and renewable energy sources.

🔹Growth in industrial automation and robotics.

🔹Advancements in motor technologies, including IoT-enabled smart motors.

Get this Report on discount of $1000 on purchase of Credit Card

𝐂𝐡𝐚𝐥𝐥𝐞𝐧𝐠𝐞𝐬:

🚀High initial cost of energy-efficient motors.

🚀Availability of alternative technologies like DC motors in certain niches.

➡️ 𝐤𝐞𝐲 𝐏𝐥𝐚𝐲𝐞𝐫𝐬 : ABB | Siemens | GE | Nidec Motor Corporation | Nidec Corporation Global | Toshiba Corporation | WEG | Mitsubishi Electric | Rockwell Automation | Hitachi | Regal Rexnord | TECO Electric & Machinery Co., Ltd. | Johnson Electric | AMETEK | Schneider Electric | Baldor Electric Company | POLARIS PLATE HEAT EXCHANGERS, Member of Danfoss Group. | Danfoss | Emerson | Hyosung Heavy Industries UK | Hyosung Heavy Industries Worldwide | Havells India Ltd | Allied Motion Dordrecht BV | An Allient Company

#ElectricACMotors#EnergyEfficiency#IndustrialAutomation#SmartMotors#SustainableEnergy#EVMotors#ACMotorTechnology#RenewableEnergyIntegration#IoTInMotors#HVACSystems#EnergyEfficientMotors#IndustrialMachinery#MotorInnovation#VariableSpeedMotors#SmartManufacturing#GreenEnergySolutions#MotorEfficiency#CompactMotors#AdvancedACMotors#AutomationTrends

0 notes

Text

Understanding Cogged Belts in India: A Comprehensive Guide

Cogged belts are essential components in many mechanical systems, from automotive engines to industrial machines. These belts are designed with notched grooves, or "cogs," which increase flexibility, improve grip, and enhance efficiency. In India, the demand for cogged belts has grown steadily due to the rapid industrialization and modernization of various sectors. In this blog, we’ll explore the significance of cogged belts, their applications, and the growing market for them in India.

What is a Cogged Belt?

A cogged belt, also known as a notched belt, is a type of belt drive that has a series of grooves or teeth along its inner surface. These grooves are carefully engineered to provide better grip, reduce friction, and allow the belt to bend more easily around pulleys. The notches enhance the belt’s efficiency by reducing the overall tension required for operation, making it particularly useful in applications where a regular flat belt might not perform as effectively.

Cogged belts are often made from high-quality rubber, but they can also be constructed from synthetic materials, providing strength, durability, and resistance to wear and tear. They are typically reinforced with fibers such as polyester, aramid, or steel for additional strength.

Applications of Cogged Belts in India

Cogged belts are used in a wide variety of industries in India, thanks to their versatility and superior performance. Some of the most common applications include:

1. Automotive Industry

Cogged belts are commonly found in automotive engines, where they are used for driving the alternator, water pump, air conditioning compressor, and other critical components. Their ability to operate at high speeds, reduce noise, and provide greater power transmission efficiency makes them ideal for this purpose.

2. Agriculture

In the agriculture sector, cogged belts are used in machinery such as irrigation systems, tillers, and harvesters. The belts' ability to withstand tough conditions, including moisture and heavy loads, makes them a popular choice in farming equipment.

3. Industrial Machinery

Cogged belts play a crucial role in the operation of industrial machinery such as conveyors, pumps, and compressors. Their durability and ability to transmit power over long distances without slipping or stretching make them essential in manufacturing plants, factories, and other industrial facilities.

4. HVAC Systems

Heating, Ventilation, and Air Conditioning (HVAC) systems also rely on cogged belts to power various fans and blowers. The belts’ ability to handle high-torque loads without compromising on efficiency is vital in such systems.

5. Elevators and Escalators

The lift and escalator industry in India has seen rapid growth in urban areas. Cogged belts are used in these systems to ensure smooth and reliable operation, even under heavy load conditions.

Why Choose Cogged Belts for Your Business?

There are several reasons why businesses in India are increasingly turning to cogged belts for their operations:

1. Increased Efficiency

The notched design of cogged belts reduces friction and allows them to grip pulleys more effectively. This leads to better energy transmission and greater overall efficiency. In industries where reducing power consumption is crucial, cogged belts provide a cost-effective solution.

2. Durability

Cogged belts are built to last, even under heavy use. With the right maintenance, they can have a long service life, which reduces the frequency of replacements and maintenance costs for businesses.

3. Flexibility

The notched structure of the belt allows for greater flexibility, enabling it to bend around smaller pulleys without compromising on performance. This makes cogged belts ideal for tight spaces or applications where space constraints exist.

4. Noise Reduction

Cogged belts typically produce less noise compared to other types of belts, making them perfect for environments where noise reduction is important, such as in office buildings or residential areas.

5. High Power Transmission

Cogged belts are designed to transmit higher amounts of power without slipping, making them suitable for applications where substantial torque is needed.

Market Growth and Future Outlook in India

India's manufacturing and automotive sectors are expected to continue growing in the coming years, driving the demand for cogged belts. The Indian government’s focus on infrastructure development, coupled with the rise in domestic production and exports, will further fuel the need for high-quality cogged belts in various industries.

As industries continue to modernize and upgrade their machinery, the demand for advanced belt systems like cogged belts is poised to increase. Manufacturers in India are also responding to this demand by producing cogged belts that meet international standards, which will help local industries remain competitive on the global stage.

Additionally, with a greater emphasis on sustainability, Indian manufacturers are also exploring eco-friendly materials for the production of cogged belts, which could further influence market trends.

Conclusion

Cogged belts play a crucial role in powering machines and engines across various industries in India. Their ability to improve efficiency, reduce noise, and provide high power transmission makes them an indispensable component in modern machinery. As India continues to develop its industrial and automotive sectors, the demand for cogged belts is expected to rise, providing businesses with greater opportunities for growth and innovation.

Whether you are in the automotive, agriculture, industrial, or HVAC sector, investing in high-quality cogged belts will ensure that your operations remain efficient and cost-effective. With the continued advancements in materials and technology, the future of cogged belts in India looks promising, offering solutions to meet the challenges of an ever-evolving market.

0 notes

Text

India Automotive Compressor Market Size, Share and Forecast for 2032

India automotive compressor market is projected to witness a CAGR of 6.50% during the forecast period FY2025-FY2032, growing from USD 1.16 billion in FY2024 to USD 1.92 billion in FY2032. The market has experienced significant growth in recent years and is expected to maintain an expansion in the coming years owing to a considerable increase in requirement for electric vehicles, the growing popularity of electrically powered air conditioning systems, stringent government regulations on vehicle emissions, and increased demand for climate control and comfort features. The Indian automotive compressor market demand is expected to rise owing to the continuous shift toward electrification, surging investments in different research and development to enhance the performance of compressors, and increasing applications of compressors in all types of vehicles. The key drives, including continuous upgradation and advancements in the automotive industry coupled with a significant rise in requirement for energy-efficient compressors, are projected to foster the India automotive compressor market growth in the forecast period. Furthermore, the growing sales of passenger cars in India, growing customer preferences for energy-efficient vehicles, and expansion in the aftermarket sector are projected to result in different market growth opportunities for market players. According to data from the Federation of Automobile Dealers Associations, passenger vehicle (PV) retail sales reached a record high in FY2024, with a total of 3,948,143 units sold. This figure represents an 8.45% increase compared to the 3,640,399 units sold in the financial year 2023 (FY2023).

Companies in the market are significantly advancing the technologies of automotive compressors in terms of performance and efficiency to make air conditioning systems cost-effective, which further drives the India automotive compressor market growth in the forecast period. Also, companies in the Indian automotive compressor market are launching advanced compressors to offer overall safety and better driving experience to end-users.

For instance, in May 2022, MAHLE GmbH announced the introduction of its most powerful e-compressor with a peak power of 18 kW for thermal management in electric vehicles. MAHLE GmbH secured numerous orders in the commercial and passenger vehicle sector, and it is projected that the total order volume is nearly USD 1.48 billion.

Expansion of the Automotive Market Drives the India Automotive Compressor Market Demand

In India, the rapid growth of the automotive market is a key driver for the automotive compressor market growth. Key drivers, including rising disposable income, surging urbanization, and expanding infrastructure, are increasing vehicle requirements, further propelling the India automotive compressor market size in the forecast period. As a huge number of customers demand passenger cars and other products, the production of passenger vehicles and two-wheelers is accelerating, boasting the need for automotive compressors for various applications. For instance, according to the Society of Indian Automobile Manufacturers, from April 2022 to March 2023, the industry manufactured a total of 25,931,867 vehicles, encompassing passenger vehicles, commercial vehicles, three-wheelers, two-wheelers, and quadricycles. This marks an increase compared to the 23,040,066 units produced during the previous year, from April 2021 to March 2022. This growing requirement for vehicles motivates manufacturers to improve their production capabilities and invest in new technologies. Furthermore, the expansion of the automotive sector introduces different market growth opportunities for aftermarket sales, including replacement and maintenance of compressors, which can sustain demand for the long term. This market trend strengthens the automotive compressor market growth in the forecast period. Also, the Indian government issued new guidelines that are expected to increase the demand for automotive compressors in India and enhance the overall driving experience.

For instance, in December 2023, the Indian Ministry of Road Transport and Highways issued a notification that states that all trucks manufactured from October 2025 onwards must have factory-fitted AC cabins.

Growing Consumer Awareness of Comfort Features Propels the Market Growth

The rising emphasis on convenience and comfort in vehicles significantly impacts the requirement for automotive compressors in India. Climate control and easy accessibility of air conditioning systems in automotive make automotive compressors an essential component that further drives the automotive compressor market in India. With an increase in disposable income coupled with rapid urbanization, more buyers prefer vehicles that offer superior comfort and convenience, specifically in extreme weather conditions. Thereby, manufacturers are investing in different research and development activities to advance the performance of automotive compressors to offer rapid cooling and precise temperature control, driving the India automotive compressor market growth in the forecast period. In addition, enhanced cabin air quality systems are becoming a focal point, leading to the incorporation of advanced filtration and compressor technologies. This trend fosters sales and motivates the development of innovative compressor solutions personalized to consumer preferences. Companies in the market plan to announce collaboration to expand their market presence and bring a wider range of products.

For instance, in November 2024, Honda Motorcycle & Scooter India Pvt. Ltd. announced the introduction of its first V3 motorcycle engine with an electrical compressor to expand its product lineup and meet the diversifying requirements of today’s customers.

Passenger Cars Dominate the India Automotive Compressor Market Share

Passenger cars hold a significant share of India automotive compressor market owing to rising requirements for personal vehicles, growing focus on comfort features among consumers, and innovations in air conditioning technology. As the disposable income of consumers is rising and urbanization continues, more individuals are investing in passenger cars, leading to a higher requirement for reliable and efficient compressors. In addition, a significant advancement in compressor design and performance focused on enhancing energy efficiency and reducing carbon emissions surged the demand for automotive compressors in passenger cars. Overall, the robust performance of the passenger car market significantly propels the growth of India automotive compressor market.

For instance, in June 2022, Garrett Motion Inc. announced its latest development of a next-generation electric compressor to expand the company’s presence in the rising mild and full hybrid passenger vehicle segment.

North India is Expected to Dominate the India Automotive Compressor Market Size

North India is projected to lead the automotive compressor market size owing to different key factors, including rapid urbanization and industrialization in cities such as Chandigarh, Delhi, and Jaipur, as well as an increase in disposable incomes and a growing population. In addition, the growing demand for personal and commercial vehicles, as well as the presence of key automotive manufacturers coupled with suppliers, are anticipated to drive the need for automotive compressors. In addition, the growing focus on electric vehicles is also gaining traction across this region, which is also fostering the demand for automotive compressors. Furthermore, companies in the market are efficiently advancing the performance and durability of automotive compressors to be competitive and offer comfort to drivers and passengers.

For instance, in September 2023, Brose Fahrzeugteile SE & Co. KG, a leading company in India’s automotive compressor market, developed a high-voltage compressor with 800 volts of operating voltage that enables fast charging of EVs. The electric climate compressor ensures efficient air-conditioning of the interior and cooling of the vehicle battery.

Download Free Sample Report

Future Market Scenario (FY2025-FY2031F)

Growing electric vehicle adoption necessitates advanced compressors, creating new opportunities in the automotive compressor sector.

Rapid urbanization increases vehicle ownership, increasing demand for efficient automotive compressors in passenger and commercial vehicles.

Supportive government policies and incentives for the automotive industry foster growth, encouraging investment in compressor technologies.

Growing awareness of environmental issues drives demand for eco-friendly compressors, aligning with global trends toward sustainability in automotive technology.

Report Scope

“India Automotive Compressor Market Assessment, Opportunities and Forecast, FY2018-FY2032F”, is a comprehensive report by Markets and Data, providing in-depth analysis and qualitative and quantitative assessment of the current state of India automotive compressor market, industry dynamics, and challenges. The report includes market size, segmental shares, growth trends, opportunities, and forecast between FY2025 and FY2032. Additionally, the report profiles the leading players in the industry, mentioning their respective market share, business models, competitive intelligence, etc.

Click here for full report- https://www.marketsandata.com/industry-reports/india-automotive-compressor-market

Latest reports-

Contact

Mr. Vivek Gupta 5741 Cleveland street, Suite 120, VA beach, VA, USA 23462 Tel: +1 (757) 343–3258 Email: [email protected] Website: https://www.marketsandata.com

0 notes

Text

/PRNewswire/ -- The global AC Motors Market is anticipated to grow from estimated USD 4.60 billion in 2024 to USD 6.60 billion by 2029, at a CAGR of 7.5% during the forecast period. Industrial growth, rapid urbanization, and increased usage in HVAC systems, water treatment, and manufacturing activities are driving the demand for AC motors. The industries located in China, India, and Japan require AC motors for efficient operation, power pumps, fans, and compressors.

#ac motor#ac motors#ac motors market#motor#motors#electric motors#electric motor#energy#energia#power generation#utilities#power#utility#HVAC#hvac system#pumps#compressor#smart grid#water treatment#water treatment systems#water treatment plant#manufacturing#industrial automation

0 notes

Text

A Deep Dive into the Wine Cooler Market: Insights and Analysis

The global wine cooler market size is anticipated to reach USD 4.4 billion by 2030, according to a new report by Grand View Research, Inc. It is expected to expand at a CAGR of 6.8% during the forecast period. Increasing consumption of wine around the world, especially in India, China, and Japan is expected to fuel the growth.

Free-standing wine cooler segment held the largest market share of 52.2% during the forecast period and is expected to continue leading over the forecast period. Rapid product innovation and introduction of new products with wider dimensions for increased wine bottle storage is anticipated to bode well for the growth of the segment in the forthcoming years. For instance, in February 2019, Vinotemp launched a Technical Veneer Wrap option for its large-capacity private reserve series wine coolers at the Kitchen & Bath Industry Show, Las Vegas, Nevada.

Commercial application is expected to continue leading in terms of overall market share throughout the forecast period. Growing popularity of wine among millennial is the key factor driving the segment growth. Residential segment, on the other hand, is expected to expand at the fastest CAGR over the forecast period. The tradition of drinking wine with dinner in various countries including U.S. and China is the key factor driving the demand for wine cooler from residential sector.

Europe is expected to remain dominant region in terms of overall market share throughout the forecast period. It is expected to expand at a CAGR of 6.0% from 2024 to 2030, driven by increasing consumption wine.

Gather more insights about the market drivers, restrains and growth of the Wine Cooler Market

Wine Coolers Market Report Highlights

• Free-standing wine coolers accounted for the dominant market share of 52.2% in 2023 owing to their portability.

• Residential wine coolers is expected to emerge as the fastest-growing CAGR during the forecast period.

• Europe held more than 34.0% share of global wine coolers market due increasing consumption of wine coupled with rising awareness regarding the health benefits of wine

• Asia Pacific is expected to expand at a CAGR of 7.4% over the forecast period owing to increasing consumption wine

Wine Coolers Market Segmentation

Grand View Research has segmented the global wine cooler market report based on product, technology, distribution channel, application, and region:

Wine Cooler Product Outlook (Revenue, USD Million, 2018 - 2030)

• Free-standing

• Countertop

• Built-in

Wine Cooler Technology Outlook (Revenue, USD Million, 2018 - 2030)

• Compressor-based

• Thermoelectric

Wine Cooler Distribution Channel Outlook (Revenue, USD Million, 2018 - 2030)

• Offline

• Online

Wine Cooler Application Outlook (Revenue, USD Million, 2018 - 2030)

• Residential

• Commercial

Wine Cooler Regional Outlook (Revenue, USD Million, 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o Germany

o UK

o France

o Italy

o Spain

• Asia Pacific

o China

o Japan

o India

• Latin America

o Brazil

o Argentina

• Middle East and Africa (MEA)

o South Africa

o Saudi Arabia

Order a free sample PDF of the Wine Cooler Market Intelligence Study, published by Grand View Research.

#Wine Cooler Market#Wine Cooler Market Size#Wine Cooler Market Share#Wine Cooler Market Analysis#Wine Cooler Market Growth

0 notes

Text

Exploring the Industrial Lubricants Market: Key Players, Trends, and Ecosystem

Industrial lubricants are a backbone for efficient machinery operations across multiple industries, ranging from automotive and manufacturing to construction and energy. These lubricants are essential for reducing friction, minimizing wear and tear, and ensuring smooth performance of critical equipment. As industrial demands grow more intricate, the need for advanced and sustainable lubricants has also risen sharply. This article dives into the various aspects of the industrial lubricants market, from major players and manufacturers to evolving trends and emerging technologies.

Key Players in the Industrial Lubricants Market

The global industrial lubricants market is valued at USD 63.9 billion in 2024 and is projected to reach USD 74.3 billion by 2029, growing at 3.1% cagr from 2024 to 2029. The industrial lubricants market thrives on the contributions of several globally recognized leaders. These companies not only drive innovation but also shape the future of lubrication technology. Among the notable names are:

ExxonMobil Corporation: A pioneer in developing high-performance lubricants for heavy machinery, compressors, and turbines.

Royal Dutch Shell PLC: Known for its wide range of mineral-based and synthetic lubricants catering to diverse industrial needs.

Chevron Corporation: Specializes in lubricants designed to perform under extreme operating conditions.

BP PLC (Castrol): Renowned for innovative lubricants with a focus on energy efficiency and sustainability.

TotalEnergies: A key player that emphasizes eco-friendly lubricants to support the global shift toward greener operations.

Fuchs Petrolub SE: A trusted name for customized solutions across niche industrial applications.

These companies are continuously investing in research and development to create lubricants that meet the demands of modern industries while adhering to environmental regulations.

Leading Manufacturers, Producers, and Suppliers

The industrial lubricants market functions through a seamless network of manufacturers, producers, and suppliers who ensure the availability of high-quality products worldwide.

Manufacturers: Major companies like ExxonMobil and Shell spearhead the production of industrial lubricants on a massive scale, utilizing cutting-edge technology to enhance product performance.

Producers: Entities like Valvoline and Sinopec focus on refining base oils, the primary component of lubricants, ensuring their quality aligns with industrial standards.

Suppliers: Distributors such as PetroChoice and Calumet Specialty Products act as the crucial link between producers and end-users, ensuring timely delivery across regions.

Trends Driving the Industrial Lubricants Market

Several key trends are reshaping the landscape of the industrial lubricants market, reflecting the sector's dynamic nature and response to global challenges:

Transition to Synthetic Lubricants: Industries are increasingly turning to synthetic lubricants for their superior performance, extended service life, and ability to operate under extreme conditions.

Sustainability and Environmental Concerns: With growing awareness of climate change, manufacturers are focusing on producing biodegradable lubricants with low environmental impact.

Digitalization and IoT Integration: Smart lubrication systems equipped with IoT sensors are being adopted to monitor performance in real-time, optimize lubricant usage, and predict maintenance schedules.

Energy Efficiency Prioritization: Energy-efficient lubricants are gaining prominence as companies seek to reduce operational costs and energy consumption.

Growth in Emerging Markets: Rapid industrialization in regions like Asia-Pacific, particularly in countries such as India and China, is creating new opportunities for lubricant manufacturers.

Technological Innovations in the Market

Innovation is a cornerstone of the industrial lubricants market, with technology playing a critical role in product development. Key advancements include:

Nanotechnology Applications: The use of nanoparticles in lubricants enhances thermal stability, wear resistance, and overall efficiency.

Additive Innovations: Advanced additives are being formulated to improve anti-wear, anti-corrosion, and extreme-pressure capabilities.

AI and Predictive Maintenance: Artificial intelligence tools are now integrated into lubrication systems to provide predictive insights, minimizing machinery downtime and operational disruptions.

Eco-Friendly Formulations: Research into bio-based lubricants derived from renewable resources is paving the way for sustainable alternatives.

The Industrial Lubricants Ecosystem

The industrial lubricants ecosystem is a complex network of stakeholders, from raw material suppliers to end-users. Collaboration is key to ensuring the smooth functioning of this ecosystem. For example:

Raw Material Suppliers: They play a critical role by providing high-grade base oils and additives essential for lubricant production.

Distributors and Retailers: These intermediaries ensure that industrial lubricants reach customers across geographies without delays.

End-Users: Industries such as manufacturing, automotive, and construction depend heavily on lubricants to maintain productivity and reduce downtime.

Regulatory agencies and industry associations also play an integral part by establishing quality standards and promoting responsible usage and disposal practices.

To Get Deeper Insights Download PDF Brochure

The industrial lubricants market is undergoing a significant transformation driven by technological advancements, sustainability imperatives, and expanding industrial activities. As the demand for high-performance and eco-friendly lubricants continues to rise, key players are leveraging innovation to stay ahead in this competitive landscape. Understanding the trends, technologies, and ecosystem dynamics is crucial for stakeholders aiming to harness the full potential of this vital market while addressing the challenges of a rapidly changing global environment.

#IndustrialLubricants#MarketTrends#KeyPlayers#Sustainability#LubricationSolutions#IndustrialGrowth#OilAndGas#Manufacturing#EcosystemAnalysis#GlobalMarketInsights

0 notes

Text

Gas Jet Compressor Market Analysis: Strategic Insights, Challenges, and Opportunities

The gas jet compressor market is a dynamic arena, playing a crucial role in various industrial applications. Its significance lies in its ability to efficiently compress and transport gases without moving parts, making it a reliable and low-maintenance solution. As global industries evolve, the market's landscape is shifting, driven by innovative technologies, economic changes, and increasing environmental awareness.

A pivotal driver for the growth of the gas jet compressor market is the rising demand across industries like oil and gas, petrochemicals, and power generation. These compressors are particularly valued for their ability to handle diverse gas compositions while maintaining efficiency. With the global energy transition underway, the demand for systems that support renewable energy projects and cleaner operations has surged, further boosting the adoption of gas jet compressors.

One of the key trends shaping the market is the integration of advanced materials and smart technologies. Manufacturers are exploring hybrid systems that combine gas jet compressors with other technologies to meet specific operational requirements. For example, in the energy sector, these systems are being designed to adapt to fluctuating gas inputs, a common challenge in renewable energy sources like biogas or hydrogen. Moreover, the inclusion of IoT-enabled monitoring systems allows real-time performance tracking and predictive maintenance, reducing downtime and operational costs.

Regionally, the market's growth varies, with Asia-Pacific emerging as a focal point. Rapid industrialization in countries like India and China has spurred demand for reliable and efficient gas handling solutions. Infrastructure development, rising natural gas production, and a push for sustainable industrial practices contribute significantly to this growth. North America and Europe also remain important markets, driven by their focus on energy efficiency and technological innovation.

Despite its positive outlook, the gas jet compressor market faces several challenges. High initial investment costs can deter adoption, particularly for small and medium-sized enterprises. While these compressors offer long-term savings due to reduced maintenance and energy efficiency, the upfront expenditure remains a barrier for some businesses. Additionally, competition from alternative technologies, such as mechanical and centrifugal compressors, poses a threat, especially in applications where other options might offer comparable performance at a lower cost.

Economic factors also play a significant role in shaping the market. Fluctuations in raw material prices and global supply chain disruptions can impact production costs and delivery timelines. Additionally, economic slowdowns in key industries like oil and gas or manufacturing can affect the overall demand for these systems.

However, opportunities abound for companies willing to innovate and adapt. The ongoing shift toward sustainable practices presents a unique chance to enhance the environmental performance of gas jet compressors. Developing more energy-efficient systems and incorporating recyclable materials can help align these products with global sustainability goals. Expanding into emerging markets, where industrialization and energy demands are on the rise, also offers significant growth potential.

Regulatory frameworks further influence market dynamics. Governments worldwide are implementing stricter environmental regulations, encouraging industries to adopt cleaner and more efficient technologies. Gas jet compressors, known for their relatively low environmental impact, are well-positioned to benefit from this trend. By meeting or exceeding these regulations, manufacturers can gain a competitive edge and capture a larger market share.

In conclusion, the gas jet compressor market is a complex and evolving field. Its growth is driven by industrial demand, technological advancements, and the global shift toward sustainability. Challenges such as high costs, economic fluctuations, and competition require strategic navigation. However, the market's potential remains strong, offering opportunities for innovation, geographic expansion, and alignment with environmental goals. For stakeholders across industries, the gas jet compressor market presents a compelling landscape of challenges and rewards, ready to be explored and harnessed.

Request smaple PDF Report : https://www.pristinemarketinsights.com/get-free-sample-and-toc?rprtdtid=NTI0&RD=Gas-Jet-Compressor-Market-Report

#GasJetCompressorMarket#GasJetCompressorMarketTrends#GasJetCompressorMarketInsights#GasJetCompressorMarketAnalysis#GasJetCompressorMarketGrowth#GasJetCompressorMarketForecast

0 notes

Text

Refrigeration Compressor Market to Reach USD 53,732.1 Million by 2032

The Refrigeration compressors find a large number of applications, such as in domestic refrigeration, commercial refrigeration, and refrigeration systems used in the transportation industry. The major use of a refrigeration compressor is in the process of food preservation. Various refrigeration compressors are available depending upon the type of application, such as in equipment cooling, and for the transportation industry, and chemical industry, among others.

The performance of a refrigeration system depends upon the performance of the refrigeration compressor. Refrigeration compressors find a large number of applications, such as in domestic refrigeration, commercial refrigeration, and refrigeration systems used in the transportation industry. The major use of a refrigeration compressor is in the process of food preservation. Various refrigeration compressors are available depending upon the type of application, such as in equipment cooling, and for the transportation industry, and chemical industry, among others.

Refrigeration can be defined as the process of heat removal from a substance or an enclosed space for the purpose of reducing the temperature. A refrigeration compressor is a basic and crucial part of the refrigeration system. It makes use of compression to increase the temperature of low-pressure gas and remove vapor from the evaporator. The performance of a refrigeration system depends upon the performance of the refrigeration compressor.

Browse Full Report Here: https://www.futuremarketinsights.com/reports/refrigeration-compressor-market

Refrigeration Compressor Market: Trends, Drivers, Restraints

With evolving technology, the use of refrigerators for household purposes is becoming economical. Attributing to this trend, the market for global refrigeration compressors is expected to grow. Commercial refrigerators are mainly used for food storage, and merchandising purposes; these refrigerators contain a remote condensing unit. With rising processed and frozen food consumption globally, the refrigeration compressor market is expected to grow at a fast pace. Many companies are focusing on cost reduction in the manufacturing of refrigeration compressors.

In the last few years, retails stores across the globe are flourishing at a rapid rate. Many major players in the retail sector are expanding in various countries, especially in growing economies. Attributing to this rapid growth of the retail sector, there is a rise in the number of supermarkets and hypermarkets that require large refrigeration systems. This trend is responsible for the growth of the global refrigeration compressor market. Refrigeration systems are widely used in the transportation industry to move perishable food items from one place to another. As the demand for frozen foods, packed foods, etc. is increasing rapidly, the refrigeration compressor market is experiencing rapid growth in the transportation industry. The pharmaceutical industry also needs highly advanced refrigeration systems for the process of cooling certain raw materials, and finished and semi-finished products. As the pharmaceutical industry is experiencing steep growth, the demand for refrigeration compressors is expected to increase.

Refrigeration Compressor Market: Market Participants

Examples of some of the market participants in the global refrigeration compressor market identified across the value chain include:

Bitzer SE

Emerson Electric Co.

Dorin S.p.A.

Embraco

Mitsubishi Electric Corporation

Frascold SpA

GMCC Company

Fusheng Co. Ltd.

Hanbell Precise Machinery Co. Ltd.

Huayi Compressor Barcelona S.L.

Danfoss

Mayekawa Mfg. Co. Ltd.

Panasonic Corporation of North America

Torad Engineering

Rechi Precision Co., Ltd.

Tecumseh Products Company LLC

Ramco (India)

The research report presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, and statistically supported and industry-validated market data. It also contains projections using a suitable set of assumptions and methodologies. The research report provides analysis and information according to market segments such as geographies, application, and industry.

Regional analysis includes:

North America (U.S., Canada)

Latin America (Mexico. Brazil)

Western Europe (Germany, Italy, France, U.K, Spain)

Eastern Europe (Poland, Russia)

Asia Pacific (China, India, ASEAN, Australia & New Zealand)

Japan

Middle East and Africa (GCC Countries, S. Africa, Northern Africa)

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

By Segmentation:

The global refrigeration compressor market can be segmented on the basis of the type of compressor, application, refrigerant used and industry.

On the basis of type of compressor, the global refrigeration compressor market is segmented as:

Reciprocating compressor

Screw compressor

Centrifugal compressor

Rotary compressor

Scroll Compressor

Others

On the basis of application, the global refrigeration compressor market is segmented as:

Domestic

Commercial

On the basis of refrigerant used, the global refrigeration compressor market is segmented as:

CO2

R290

R410A

Others

On the basis of type of industry, the global refrigeration compressor market is segmented as:

Food and beverages

Logistics and transportation

Chemical

Pharmaceutical

Automobile

Others

0 notes

Text

AC Capacitor Manufacturers in India: Powering the HVAC and Appliance Industry

In a country like India, where temperature extremes are common, air conditioning systems and cooling appliances have become essential for both residential and industrial applications. Behind the smooth operation of these systems lies a critical component: the AC capacitor. Capacitors play a vital role in regulating the power and ensuring efficient operation of air conditioning systems, refrigerators, and other HVAC equipment. As demand for energy-efficient solutions rises, the importance of reliable AC capacitor manufacturers in India continues to grow.

What is an AC Capacitor?

An AC capacitor is an essential part of air conditioners, refrigerators, and various cooling systems. It stores and releases electrical energy to start and run the compressor and fan motors. There are typically two types of AC capacitors:

Start Capacitors: These provide the initial boost needed to start the compressor and fan motors. Once the system is running, they disconnect from the circuit.

Run Capacitors: These help maintain a constant supply of energy to keep the motors running efficiently. Run capacitors are designed for continuous operation and are critical for the long-term efficiency of AC systems.

Given their importance, the performance and reliability of an AC capacitor directly affect the overall efficiency of the air conditioning or refrigeration system.

Why AC Capacitors are Crucial for HVAC Systems

Air conditioning systems rely heavily on capacitors to function properly. The capacitor helps regulate the electrical flow to the compressor, ensuring that the air conditioner starts smoothly and operates efficiently. A faulty or low-quality AC capacitor can lead to a range of issues, including poor cooling performance, higher energy consumption, and even motor failure.

Because of this, choosing the right capacitor from trusted AC capacitor manufacturers in India is essential for both OEMs (Original Equipment Manufacturers) and after-market service providers. High-quality capacitors improve the energy efficiency of appliances and reduce the likelihood of breakdowns, leading to lower maintenance costs and longer product lifespans.

The Growing Demand for AC Capacitors in India

As the Indian economy grows and urbanization continues, there is a sharp rise in the demand for air conditioners, refrigerators, and other cooling systems. With the increase in demand, there’s a parallel growth in the need for reliable and high-performance capacitors to ensure the efficiency of these systems.

In addition to household appliances, commercial buildings, industrial setups, and retail establishments are also heavily reliant on air conditioning and HVAC systems, further driving the need for capacitors. This expansion creates immense opportunities for AC capacitor manufacturers in India to meet the growing market demand while delivering quality products.

Leading AC Capacitor Manufacturers in India

Several AC capacitor manufacturers in India have established a solid reputation for producing capacitors that meet both national and international quality standards. These manufacturers cater to a variety of industries, providing AC capacitors for HVAC systems, refrigeration units, and other cooling applications.

TIBCON: TIBCON is one of the leading names in capacitor manufacturing in India. Known for producing high-quality run and start capacitors, TIBCON capacitors are trusted by OEMs and service professionals in the HVAC and refrigeration industry. The company’s focus on quality control and adherence to global standards ensures that their capacitors deliver consistent performance and energy efficiency.

Keltron Capacitors: Based in Kerala, Keltron has been a prominent player in the Indian capacitor manufacturing market. Their AC capacitors are widely used in air conditioning systems and refrigerators, ensuring smooth operation and extended equipment lifespan.

Deki Electronics: Deki Electronics specializes in producing high-performance film capacitors for a range of applications, including HVAC systems. Their capacitors are known for their durability and ability to withstand extreme temperatures and electrical surges, making them a preferred choice for industrial and commercial air conditioning units.

Cosmos Capacitors: Cosmos Capacitors is another key player in the Indian capacitor industry. Their AC capacitors are designed for high reliability and long service life, making them ideal for both residential and commercial air conditioning systems.

Benefits of Choosing Indian AC Capacitor Manufacturers

Opting for AC capacitor manufacturers in India offers several advantages:

Cost-Effective Solutions: Indian manufacturers are known for providing high-quality capacitors at competitive prices. The combination of skilled labor and efficient manufacturing processes allows these companies to offer affordable solutions without compromising on quality.

Local Availability: With several leading manufacturers based in India, businesses can benefit from shorter lead times and quicker delivery of products. This is especially important for HVAC service providers who need to replace capacitors quickly during peak summer months.

Customization Options: Many AC capacitor manufacturers in India offer customized solutions based on specific requirements. Whether it’s a particular voltage rating or size, Indian manufacturers are flexible and can meet the unique needs of their clients.

Global Standards: Indian manufacturers are committed to maintaining global quality standards. Many of them comply with ISO certifications and follow stringent quality control measures to ensure their capacitors meet international specifications.

The Role of Innovation in AC Capacitor Manufacturing

As energy efficiency becomes a key focus in the appliance industry, AC capacitor manufacturers in India are increasingly investing in innovation to develop capacitors that help reduce energy consumption. Advanced capacitor technologies are being incorporated to improve the energy performance of air conditioners and refrigeration units, aligning with global environmental initiatives.

By producing capacitors that support energy-efficient HVAC systems, Indian manufacturers are playing a vital role in helping businesses and households reduce their carbon footprint while also lowering electricity bills.

Conclusion

The air conditioning and refrigeration industry in India continues to expand, and with it, the demand for high-quality AC capacitors is on the rise. AC capacitor manufacturers in India are well-positioned to meet this growing demand by offering reliable, energy-efficient, and cost-effective capacitor solutions for HVAC systems.

With a focus on quality, innovation, and customization, these manufacturers ensure that the capacitors they produce enhance the performance of air conditioning units and other cooling systems. As the country continues to experience rapid urbanization and industrial growth, the importance of trusted Indian AC capacitor manufacturers will only continue to grow, powering the future of energy-efficient cooling systems across industries.

0 notes

Text

Air Compressors and Their Impact on Manufacturing Productivity

In the world of manufacturing, where speed, precision, and efficiency determine success, air compressors stand as unsung heroes. These versatile machines quietly power countless tools and processes, enabling industries to meet high production demands. From streamlining operations to supporting cutting-edge technology, air compressors play a key role in boosting productivity. But how do they make such a profound impact? Let’s explore the world of compressed air and uncover how it pushes innovation, reduces costs, and ensures sustainable growth in modern manufacturing.

Impact of air compressors on manufacturing productivity:

Powering seamless operations:

Air compressors are the backbone of efficiency in manufacturing, delivering reliable energy for an array of tools and machinery.

Uninterrupted power: Unlike electric tools prone to fluctuations, air-powered systems maintain constant performance, ensuring smooth workflows.

Multi-tool capability: A single air compressor can power multiple devices simultaneously, eliminating the need for multiple energy sources and reducing working complexities.

Ease of maintenance: Pneumatic tools powered by air compressors have fewer moving parts, resulting in reduced wear and tear and less downtime.

Imagine an assembly line breaking due to tool failure; it’s costly and time-consuming. Air compressor manufacturers minimise such risks, keeping production lines buzzing efficiently.

Lowering costs:

One of the biggest advantages of high pressure air compressor manufacturers in India is their ability to reduce production costs while increasing output.

Energy efficiency: Modern air compressors, like rotary screw and oil-free models, consume less energy while delivering high output, making them cost-effective.

Durable and long-lasting: Air-powered tools have longer lifespans compared to their electric counterparts, reducing the need for frequent replacements.

Labour savings through automation: Many manufacturing processes, such as material handling and packaging, can be automated using compressed air, cutting labour costs and enhancing precision.

For example, automated spray painting powered by air compressors not only saves paint but also ensures a flawless finish, reducing waste and rework.

Driving advanced manufacturing techniques:

Modern high pressure air compressor manufacturers in India thrive on innovation, and air compressors are key enablers of advanced techniques.

Laser cutting and 3D printing: Compressed air ensures precise cutting by removing waste and keeping systems cool. In 3D printing, it powers pneumatic systems to control material deposition accurately.

Robotics: Many robotic arms depend on pneumatic systems for their movements, offering flexibility and speed in tasks like assembly and quality checks.

By empowering such techniques, air compressor manufacturers stay ahead in an increasingly competitive market.

Ensuring workplace safety and quality:

Safety and quality are non-negotiable in manufacturing, and air compressors contribute greatly to both.

Cleaner processes: Oil-free air compressors ensure contamination-free production, which is important in industries like food, pharmaceuticals, and electronics.

Noise reduction: Advanced models operate quietly, creating a safer and more comfortable environment for workers.

Enhanced tool safety: Air-powered tools are commonly lighter and safer to use than electric tools, reducing the risk of injuries.

In a factory producing electronics, for example, even minor contamination can lead to defective products. Oil-free compressors ensure the highest standards of cleanliness and reliability.

Customisation for diverse industries:

One of the standout features of air compressor manufacturers is their adaptability to different manufacturing needs.

Automotive: From spray painting to assembling components, air compressors support various processes.

Textile: They automate weaving, spinning, and dyeing machines, improving speed and consistency.

Food and beverage: Compressors help in packaging, cooling, and even producing carbonated drinks.

Healthcare: Oil-free compressors provide the clean air required in pharmaceutical manufacturing.

This versatility allows air compressor manufacturers across industries to tailor air compressor solutions to their unique requirements, maximising efficiency.

Supporting sustainable manufacturing:

Sustainability is no longer a choice; it’s a necessity. Air compressors align with this vision by promoting eco-friendly operations.

Energy conservation: Variable speed drive (VSD) compressors adjust their output to match demand, significantly reducing energy waste.

Waste reduction: Compressed air systems minimise material wastage in processes like painting, packaging, and assembly.

Lower emissions: Efficient air compressors contribute to reduced carbon footprints, making them a vital component of green manufacturing initiatives.

Innovation in compressor technology:

The evolution of air compressors continues to redefine their role in manufacturing.

IoT and smart systems: Internet-connected compressors allow real-time monitoring, predictive maintenance, and operational insights, preventing downtime and maximising productivity.

High-pressure models: These are ideal for heavy-duty tasks like forging and metal fabrication.

Portable compressors: Lightweight and mobile, they offer flexibility for smaller manufacturing setups.

By investing in these advancements, high pressure air compressor manufacturers in India can future-proof their operations and adapt to changing industry demands.

A future built on compressed air:

The role of air compressors in manufacturing is only set to grow. As industries adopt poor practices and aim for higher efficiency, these machines will remain indispensable. Arising trends like additive manufacturing, smart factories, and sustainable production further underscore the importance of investing in advanced air compressor systems.

Summary:

Air compressors are more than just tools; they are motivations for transformation in manufacturing. By powering critical operations, enabling innovation, and supporting sustainability, they help manufacturers achieve higher productivity and profitability. As the industry evolves, air compressor manufacturers will resume to play a central role, ensuring businesses remain competitive and environmentally responsible. Investing in the right air compressor technology can unlock significant productivity gains and give manufacturers a competitive edge in today’s dynamic market.

0 notes

Text

Composites Market Dynamics: Opportunities, Challenges, and Growth Forecast

The global composites market was valued at USD 93.69 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 7.2% from 2023 to 2030. This growth is primarily driven by the increasing demand for lightweight components, particularly in the automotive and transportation sectors. Additionally, the growing adoption of advanced lightweight components across various manufacturing industries is expected to further boost market growth during the forecast period.

Composites are widely used in the aerospace and defense sectors due to their ability to significantly reduce the weight of military aircraft and helicopters. The reduction in weight is critical for enhancing fuel efficiency and improving overall performance, making it a key driver of growth in these industries.

Regional Insights

Asia Pacific:

The Asia Pacific region dominated the global composites market, accounting for 45.4% of the global demand in 2022. The region is expected to continue its strong growth trajectory during the forecast period, largely driven by the presence of key manufacturers in major economies such as China, India, and Japan. These countries serve as key hubs for industries like automotive, construction, aerospace, and electronics, which are major consumers of composite materials.

US:

In the United States, the demand for composites is primarily fueled by the growing need for lightweight materials in the automotive industry. The increasing capacity of the electrical and electronics sectors, along with steady growth in the automotive and aerospace industries, are expected to contribute significantly to the market expansion in the U.S. over the forecast period.

Europe:

In Europe, the demand for composites is predominantly driven by Western European countries, where large-scale manufacturing industries are well-established. The automotive, aerospace and defense, construction, and electrical and electronics sectors play a key role in driving the demand for composites. The emergence of new aircraft manufacturers, such as Commercial Aircraft Corporation of China, Ltd., is expected to further boost aircraft production and intensify competition among manufacturers, stimulating growth in the composite materials market.

Central & South America:

The composites market in Central and South America is showing solid growth, particularly in Brazil, where the construction sector has seen robust expansion in recent years. This growth, along with the increasing demand for composites in other end-use industries, makes the region an attractive market for both regional and local players, further strengthening the demand for composite materials.

Browse through Grand View Research's Category Advanced Interior Materials Industry Research Reports.

The New England air compressor market size was estimated at USD 225.0 million in 2024 and is projected to grow at a CAGR of 3.5% from 2025 to 2030.

The Central and South America geosynthetics market size was estimated at USD 1.16 billion in 2024 and is projected to grow at a CAGR of 6.4% from 2025 to 2030.

Key Composites Companies

The competitive rivalry among manufacturers in the composites market is intense, driven by the presence of both global and regional players competing for market share. As the demand for composite materials increases across various industries, such as automotive, aerospace, construction, and electronics, manufacturers are vying to offer innovative and cost-effective solutions.

Some prominent players in the composites market include:

Teijin Ltd.

Toray Industries, Inc.

Owens Corning

PPG Industries, Inc.

Huntsman Corporation LLC

SGL Group

Hexcel Corporation

DuPont

Compagnie de Saint-Gobain S.A.

Weyerhaeuser Company

Momentive Performance Materials, Inc.

Cytec Industries (Solvay, S.A.)

China Jushi Co., Ltd.

Kineco Limited

Veplas Group

Order a free sample PDF of the Market Intelligence Study, published by Grand View Research.

0 notes

Text

Power Up Your Performance with the Best Air Compressors

The report on the global air compressor market offers a detailed analysis of the segments and sub-segments within the air compressor industry. It covers both global and regional markets for the period from 2015 to 2023. According to the report, the global air compressor market is projected to grow at a compound annual growth rate (CAGR) of 5.0% over the updated forecast period from 2023 to 2030, with an estimated market value reaching approximately USD 43.5 billion by 2030.

What is an Air Compressor?

An air compressor is a machine that converts power into potential energy stored in compressed air, which can then be used to operate tools, machinery, and equipment across various industries, including manufacturing, automotive, and construction. These compressors are essential for multiple applications, such as pneumatic tools, spray painting, and handling heavy machinery.

Get Sample pages of Report: https://www.infiniumglobalresearch.com/reports/sample-request/850

Market Drivers and Growth Factors

The growth of the air compressor market is driven by several key factors:

Industrial Growth: The expansion of industries such as manufacturing, construction, and mining is driving demand for air compressors as essential tools in these sectors. Increased industrial activities in emerging economies further contribute to market growth.

Energy Efficiency and Sustainability: With rising emphasis on energy-efficient and environmentally friendly solutions, the demand for advanced, energy-efficient air compressors is increasing. Innovations such as variable speed drives and oil-free compressors are reducing energy consumption and improving operational efficiency, making them attractive to consumers.

Increasing Use in the Automotive Sector: Air compressors are widely used in the automotive industry for tasks such as painting, tire inflation, and engine assembly. The automotive sector's growth, particularly in electric vehicles, is driving demand for compressors with specific applications tailored to this segment.

Infrastructure Development: Growing investments in infrastructure, especially in developing regions, are leading to an increase in demand for air compressors used in various construction activities.

Regional Analysis

North America: North America is one of the leading markets for air compressors due to its established industrial base, particularly in the United States. The demand is also driven by the increased adoption of energy-efficient air compressors and the use of advanced technology.

Europe: Europe is another significant market, with a focus on sustainable and energy-efficient solutions. Countries such as Germany, France, and the United Kingdom are major contributors to the market due to the high demand in automotive and manufacturing sectors.

Asia-Pacific: The Asia-Pacific region is expected to experience the highest growth rate over the forecast period, driven by rapid industrialization, urbanization, and infrastructure development in countries such as China, India, and Japan. The growth of the automotive and construction industries in this region also fuels demand for air compressors.

Rest of the World: The air compressor market in Latin America, the Middle East, and Africa is gradually expanding as industrialization and infrastructure development increase. However, growth rates are slower compared to more developed regions.

Competitive Landscape

The global air compressor market is competitive, with several key players focusing on product innovation, strategic partnerships, and regional expansion to strengthen their market position. Major players include:

Atlas Copco AB: A leader in the air compressor market, Atlas Copco offers a range of compressors known for efficiency and reliability. The company is focused on sustainable solutions and continuous innovation.

Ingersoll Rand Inc.: Ingersoll Rand provides industrial solutions and air compressors designed to improve energy efficiency. The company is known for its diversified compressor portfolio and emphasis on customer-driven innovations.

Siemens AG: Siemens provides compressors that are widely used in various industrial applications, particularly in automation and process industries. The company focuses on integrating digital technology for improved performance.

Hitachi Ltd.: Hitachi offers a range of air compressors with a strong focus on technology and sustainability. Its compressors are used in industries such as construction, automotive, and manufacturing.

Kaeser Compressors: Known for high-quality industrial compressors, Kaeser Compressors emphasizes energy efficiency and durability in its products, catering to a global market.

Report Overview : https://www.infiniumglobalresearch.com/reports/global-air-compressor-market

Challenges and Opportunities

Challenges:

High Initial Investment: The cost of high-quality, energy-efficient air compressors can be a barrier for small to mid-sized companies, especially in developing regions.

Maintenance Requirements: Regular maintenance is essential for optimal air compressor performance, which can lead to additional costs and downtime. This can be a challenge for industries that rely heavily on constant operation.

Energy Consumption: Despite improvements, air compressors can still consume significant amounts of energy. The industry faces ongoing challenges in reducing energy use to meet environmental regulations and lower operational costs.

Opportunities:

Growth in Industrial Automation: As industries increasingly adopt automation, demand for advanced air compressors integrated with IoT and digital technologies will continue to grow. These smart compressors provide real-time monitoring and efficiency improvements.

Development of Oil-Free Compressors: Oil-free air compressors are seeing a surge in demand due to their environmentally friendly attributes and reduced contamination risk. Industries such as food and beverage, pharmaceuticals, and electronics that require contaminant-free air benefit from this innovation.

Emerging Markets: Growing industrialization in emerging economies presents an opportunity for manufacturers to expand their market presence. Companies are investing in these regions, tapping into the rising demand for air compressors across various applications.

Conclusion

The global air compressor market is expected to grow significantly due to industrial expansion, increasing demand for energy-efficient equipment, and the rise of automation across multiple sectors. North America and Europe currently hold substantial shares, while the Asia-Pacific region is poised for rapid growth over the forecast period. With an estimated CAGR of 5.0%, the market is projected to reach approximately USD 43.5 billion by 2030.

0 notes

Text

India Automotive Compressor Market Size, Share and Forecast for 2032

India automotive compressor market is projected to witness a CAGR of 6.50% during the forecast period FY2025-FY2032, growing from USD 1.16 billion in FY2024 to USD 1.92 billion in FY2032. The market has experienced significant growth in recent years and is expected to maintain an expansion in the coming years owing to a considerable increase in requirement for electric vehicles, the growing popularity of electrically powered air conditioning systems, stringent government regulations on vehicle emissions, and increased demand for climate control and comfort features. The Indian automotive compressor market demand is expected to rise owing to the continuous shift toward electrification, surging investments in different research and development to enhance the performance of compressors, and increasing applications of compressors in all types of vehicles. The key drives, including continuous upgradation and advancements in the automotive industry coupled with a significant rise in requirement for energy-efficient compressors, are projected to foster the India automotive compressor market growth in the forecast period. Furthermore, the growing sales of passenger cars in India, growing customer preferences for energy-efficient vehicles, and expansion in the aftermarket sector are projected to result in different market growth opportunities for market players. According to data from the Federation of Automobile Dealers Associations, passenger vehicle (PV) retail sales reached a record high in FY2024, with a total of 3,948,143 units sold. This figure represents an 8.45% increase compared to the 3,640,399 units sold in the financial year 2023 (FY2023).

Companies in the market are significantly advancing the technologies of automotive compressors in terms of performance and efficiency to make air conditioning systems cost-effective, which further drives the India automotive compressor market growth in the forecast period. Also, companies in the Indian automotive compressor market are launching advanced compressors to offer overall safety and better driving experience to end-users.

For instance, in May 2022, MAHLE GmbH announced the introduction of its most powerful e-compressor with a peak power of 18 kW for thermal management in electric vehicles. MAHLE GmbH secured numerous orders in the commercial and passenger vehicle sector, and it is projected that the total order volume is nearly USD 1.48 billion.

Expansion of the Automotive Market Drives the India Automotive Compressor Market Demand

In India, the rapid growth of the automotive market is a key driver for the automotive compressor market growth. Key drivers, including rising disposable income, surging urbanization, and expanding infrastructure, are increasing vehicle requirements, further propelling the India automotive compressor market size in the forecast period. As a huge number of customers demand passenger cars and other products, the production of passenger vehicles and two-wheelers is accelerating, boasting the need for automotive compressors for various applications. For instance, according to the Society of Indian Automobile Manufacturers, from April 2022 to March 2023, the industry manufactured a total of 25,931,867 vehicles, encompassing passenger vehicles, commercial vehicles, three-wheelers, two-wheelers, and quadricycles. This marks an increase compared to the 23,040,066 units produced during the previous year, from April 2021 to March 2022. This growing requirement for vehicles motivates manufacturers to improve their production capabilities and invest in new technologies. Furthermore, the expansion of the automotive sector introduces different market growth opportunities for aftermarket sales, including replacement and maintenance of compressors, which can sustain demand for the long term. This market trend strengthens the automotive compressor market growth in the forecast period. Also, the Indian government issued new guidelines that are expected to increase the demand for automotive compressors in India and enhance the overall driving experience.

For instance, in December 2023, the Indian Ministry of Road Transport and Highways issued a notification that states that all trucks manufactured from October 2025 onwards must have factory-fitted AC cabins.

Growing Consumer Awareness of Comfort Features Propels the Market Growth

The rising emphasis on convenience and comfort in vehicles significantly impacts the requirement for automotive compressors in India. Climate control and easy accessibility of air conditioning systems in automotive make automotive compressors an essential component that further drives the automotive compressor market in India. With an increase in disposable income coupled with rapid urbanization, more buyers prefer vehicles that offer superior comfort and convenience, specifically in extreme weather conditions. Thereby, manufacturers are investing in different research and development activities to advance the performance of automotive compressors to offer rapid cooling and precise temperature control, driving the India automotive compressor market growth in the forecast period. In addition, enhanced cabin air quality systems are becoming a focal point, leading to the incorporation of advanced filtration and compressor technologies. This trend fosters sales and motivates the development of innovative compressor solutions personalized to consumer preferences. Companies in the market plan to announce collaboration to expand their market presence and bring a wider range of products.

For instance, in November 2024, Honda Motorcycle & Scooter India Pvt. Ltd. announced the introduction of its first V3 motorcycle engine with an electrical compressor to expand its product lineup and meet the diversifying requirements of today’s customers.

Passenger Cars Dominate the India Automotive Compressor Market Share