#In-Mold Labels Market Demand

Explore tagged Tumblr posts

Text

Glass vs. Plastic vs. Aluminum: Which Alcohol Packaging Wins?

Executive Summary

The alcohol packaging market is undergoing a seismic shift. As global consumption patterns evolve, so does the demand for packaging that is not only functional and aesthetically refined but also sustainable and tech-integrated. We project the alcohol packaging marketto surge from USD 68.8 billion in 2023 to USD 101.7 billion by 2032, growing at a compound annual growth rate (CAGR) exceeding 4.9%. The driving forces include increased consumption of premium and ready-to-drink (RTD) alcoholic beverages, rising sustainability consciousness, and innovation in packaging technologies.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40597-global-alcohol-packaging-market

Premiumization and Urban Lifestyle Trends Fueling Packaging Innovation

Craftsmanship Meets Convenience

Urbanization and shifting lifestyle dynamics are pushing consumers toward beverages that are both artisanal and accessible. The demand for craft beer, small-batch spirits, and RTD cocktails has created new packaging expectations centered on quality, branding impact, and shelf appeal. Consumers now prioritize premium cues such as embossed glass bottles, matte metal finishes, and biodegradable labels that reflect authenticity and brand story.

Rise of E-Commerce and On-the-Go Formats

With alcohol e-commerce and direct-to-consumer delivery services gaining traction, brands are investing in shock-resistant, temperature-regulating, and tamper-evident packaging. The shift toward smaller formats, including 100ml spirits, slim cans, and pouch packs, caters to urban, mobile lifestyles.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40597-global-alcohol-packaging-market

Sustainable Packaging: From Trend to Industry Mandate

Circular Economy and Material Innovation

The global momentum toward sustainability has turned into an operational mandate. Recyclable glass, aluminum, compostable plastics, and fiber-based packaging are rapidly replacing traditional petroleum-derived materials. Paper-based spirits bottles and refillable glass models have gained commercial viability, underscoring a fundamental industry transformation.

Lightweight Glass and Alternative Substrates

Despite its dominance, traditional glass packaging faces scrutiny for carbon intensity and fragility. Manufacturers are turning to lightweight glass, tempered options, and hybrid models that integrate post-consumer recycled (PCR) content.

Smart Packaging: Enhancing Safety, Branding, and Traceability

Authentication and Anti-Counterfeit Features

Smart packaging solutions have gone from experimental to essential. QR codes, NFC tags, and blockchain-enabled authentication mechanisms are now critical tools in combating counterfeiting and enhancing transparency. Brands are enabling consumers to trace product origin, verify authenticity, and engage in immersive storytelling via scannable packaging.

Safety-Driven Design

The integration of tamper-proof packaging, especially in RTD categories, is becoming an industry standard. Pouch formats with embedded straws and sealed openings are designed not just for convenience but to mitigate drink tampering risks—a major concern in nightlife and festival environments.

In-Depth Alcohol Packaging Market Segmentation Analysis

Alcohol Packaging Market By Material Type

Glass (53% Alcohol Packaging Market Share in 2023) Unmatched in product preservation and brand prestige, glass remains dominant. The market is rapidly shifting toward lightweight, tempered, and post-consumer recycled glass to balance sustainability with aesthetic demands.

Paper & Paperboard (CAGR: 6.2%) Growing environmental mandates are fueling demand for cartons, corrugated packaging, and molded fiber components.

Metal & Aluminum Cans Particularly relevant for beer and RTD segments due to recyclability, portability, and preservation benefits.

Alcohol Packaging Market By Alcohol Type

Beer (41.35% Share in 2023) The segment thrives on canned formats, now joined by paperboard cartons for multipacks and sleek secondary packaging for premium SKUs.

RTD Beverages (CAGR: 6.5%) The highest growth segment. Dominated by pouches, slim cans, and PET bottles optimized for on-the-go consumption and minimal environmental footprint.

Alcohol Packaging Market By Packaging Type

Bottles (56% Share) Glass and PET bottles remain central, especially in premium wine and spirits. Refillable systems and smart closures are trending.

Pouches (CAGR: 6.3%) Emerging as an eco-conscious and convenience-first format, especially in single-serve cocktails and wine.

Alcohol Packaging Market By Size & Capacity

Standard Packs (59% Share) Continues as the primary packaging size, especially in wine and spirits.

Single-Serve Units Gaining traction across all categories as health, moderation, and trial consumption increase.

Alcohol Packaging Market By Distribution Channel

Supermarkets & Hypermarkets (45.5% Share) Still the leading channel, benefiting from visibility, variety, and convenience.

Online Retail (CAGR: 6.5%) Accelerated by lockdown-era buying habits, this channel demands tamper-proof, insulated, and customizable packaging solutions.

Regional Alcohol Packaging Market Insights

North America

Dominated by premium spirits and innovation in RTD. Leading players are pioneering biodegradable formats, refillable bottles, and direct-to-consumer models.

Europe

Regulatory-driven innovation with an emphasis on circular packaging, deposit-return systems, and post-Brexit export readiness in labeling and compliance.

Asia-Pacific

Fastest-growing market driven by urbanization, youthful demographics, and premiumization. Regional giants are adopting glass alternatives, including molded fiber and paper bottles.

Competitive Landscape and Innovation Spotlight

Leading Alcohol Packaging Market Players

Amcor PLC – Sustainability-first innovations in metal and plastic alternatives

Ball Corporation – Pioneers in lightweight, recyclable aluminum cans

Ardagh Group S.A. – Stronghold in premium glass packaging

Diageo – First to introduce paper-based whisky bottles via Pulpex

Jinx Drinx – Disruptive pouch formats tackling drink safety and convenience

Notable Innovation Highlights

Diageo & Pulpex: The world’s first 100% paper-based bottle for spirits

Jinx Drinx x Zenpack: Anti-DFSA tamper-proof pouches embedded with safety straws

Strategic Growth Outlook 2025–2032

Transition to Refillable and Returnable Systems: Brands are piloting closed-loop systems in urban centers and premium product lines.

Rise of AI-Powered Smart Labels: Enabling real-time temperature monitoring, freshness indicators, and personalized engagement via augmented reality.

Increased Use of Digital Twins and Blockchain: Ensuring full transparency across the supply chain, from bottling plant to consumer hands.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40597-global-alcohol-packaging-market

Conclusion

The alcohol packaging market landscape is not just evolving—it’s being reinvented. With sustainability mandates, consumer expectations for safety and aesthetics, and the digitization of product packaging, the next decade offers fertile ground for innovation. Stakeholders investing in recyclable, refillable, and tech-enhanced packaging solutions are best positioned to lead in this competitive global arena.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

1 note

·

View note

Text

Concord Industries: Leading Power Cord Manufacturer in India Delivering Quality, Safety, and Custom

Concord Industries: Trusted Power Cord Manufacturer in India Powering Homes, Industries & Innovations

India’s electrical infrastructure is evolving rapidly, with increasing demand for safe, efficient, and durable electrical components across sectors. At the core of every appliance, machine, and electronic device is a crucial connector — the power cord. As one of the most respected power cord manufacturers in India, Concord Industries has built a strong legacy of delivering high-performance, compliant, and customizable power cords that serve a wide range of applications.

For over two decades, Concord Industries has been the go-to supplier for OEMs, appliance manufacturers, IT hardware providers, and commercial buyers seeking safe and reliable power connectivity across India and globally.

Why Concord Industries Leads the Indian Power Cord Market

Power cords are more than just cables — they are essential for electrical safety, energy efficiency, and equipment performance. A poorly made cord can lead to overheating, electrical failure, or even fire hazards. Concord Industries addresses these concerns through:

Superior raw materials like pure copper and heat-resistant insulation

Advanced testing protocols that guarantee product safety and durability

Customization options for a wide variety of appliances and industrial uses

Strict compliance with ISI, CE, and RoHS standards

Whether it’s a domestic mixer, an office computer, or industrial machinery, Concord ensures each cord performs flawlessly.

Wide Range of Power Cord Solutions

Concord Industries manufactures power cords for:

Household Appliances: Mixer grinders, irons, fans, kettles, toasters

IT & Office Equipment: Computers, monitors, printers, routers

Industrial Machines: Compressors, pumps, CNC equipment, tools

Medical & Laboratory Devices: Diagnostic equipment, monitors, analyzers

Consumer Electronics: LED TVs, home theaters, gaming consoles

Each cord is engineered for optimal conductivity, flexibility, and safety.

Key Features of Concord Power Cords

Pure Copper Conductors Offer high conductivity with minimal power loss and superior heat resistance.

Flame-Retardant, Heat-Resistant Insulation Made with high-quality PVC or rubber sheathing to withstand daily use and harsh conditions.

Custom Plug Configurations Compatible with Indian and international plug types — 2-pin, 3-pin, straight, or angled.

ISI, CE & RoHS Certified Concord’s products meet domestic and global safety and environmental standards.

Durability Under Stress Designed to endure frequent bending, coiling, and long operating hours.

Customization for OEMs and Appliance Brands

As a reliable power cord manufacturer in India, Concord offers tailor-made solutions to leading appliance brands and OEMs. Our customization capabilities include:

Variable cable lengths and thickness

Different sheath colors and materials

Branding through private labeling

Plug configuration based on geographic or product requirements

Packaging options for retail, assembly line, or bulk supply

This flexibility makes Concord a preferred partner for large and small-scale manufacturers across India and abroad.

World-Class Manufacturing Facilities

Concord Industries’ manufacturing units are equipped with:

Automated extrusion and molding systems

High-voltage, flame, and insulation resistance testing labs

Mechanical strength and bending durability test setups

Quality assurance teams ensuring 100% compliance

Every power cord goes through rigorous testing for electrical continuity, plug-pin strength, insulation quality, and flame resistance before reaching the customer.

Sustainability and Safety First

Concord Industries believes in responsible manufacturing. All products are:

RoHS Compliant (free from hazardous materials like lead and mercury)

Manufactured using eco-friendly, low-waste processes

Packaged in recyclable materials to reduce environmental impact

We ensure that product safety goes hand-in-hand with environmental responsibility.

Why Distributors, Retailers, and Exporters Choose Concord

Consistent product quality and certification

Large-scale production capabilities

Flexible delivery timelines and logistics

Competitive pricing and strong after-sales support

Trusted by top-tier Indian appliance and electronics brands

Conclusion

As the demand for reliable and efficient electrical systems continues to grow, Concord Industries stands out as a leader among power cord manufacturers in India. Combining advanced technology, industry expertise, and a customer-first approach, Concord delivers power cords that are built for safety, built to last, and built to perform.

If you're looking for a trusted partner for certified, customizable, and high-performance power cords, look no further than Concord Industries — where power meets precision.

Visit:- https://concordindustries.in/power-cord-manufacturer/

0 notes

Text

Mastering Complex Injection Mold Design: Why It Matters and How Expertise Drives Results

Even the most advanced molding machines rely on smart mold design to deliver consistent, durable parts. When molds involve intricate shapes, tight tolerances, or demanding production cycles, design becomes mission-critical. That’s where deep expertise—built over 20+ years in global manufacturing—makes the difference.

Why Mold Design Can Make or Break Performance

Injection molds can cost tens—or hundreds—of thousands of dollars. They often run for millions of cycles and must produce parts with consistent quality every time. A design that isn’t finely tuned can lead to defects, costly downtime, and shortened tool life, turning what should be an asset into a liability.

A well-thought-out mold must address:

Complex geometry: intricate contours, living hinges, undercuts

Material flow: matching resin behavior with gate paths

Thermal control: cooling channels need to keep parts uniform

Ejection mechanics: pin placements, lifters, or robotic inserts

Maintenance needs: steel choice, wear expectations, service access

Design isn’t just about tool geometry. It’s about anticipating real-world manufacturing challenges and solving them before production begins.

Key Aspects of Advanced Mold Design

Flow & Fill Analysis Before production starts, designers use simulation software to visualize how molten plastic travels. This ensures gates, runners, and cooling are optimized—and avoids surprises once tool steel is cut.

Gate and Runner Strategy Gate location influences surface finish, part strength, and cycle time. Choosing between a hot or cold runner system is another high-stakes decision that depends on production volume, aesthetics, and resin type.

Cooling System Design Uneven cooling is often the root of warping, sink marks, and internal stresses. Complex parts benefit from conformal cooling or baffles to maintain consistent temperatures.

Ejector Configuration For sharp features, thin walls, or delicate details, ejection must be smooth. Ejector pins, stripper plates, sleeves, or automation must be planned into the tool from the start.

Material Suitability & Venting Each resin has unique flow and cooling characteristics. Draft angles, wall thickness, vent placement—all must align with material properties to prevent defects like burn marks or incomplete fills.

Integrating Inserts and Features Metal inserts, threaded components, in-mold labels—integrating these complicates design. Precision alignment, overmolding concerns, and maintenance access all add layers of engineering complexity.

Why Two Decades of Experience Matter

Even the best simulations can’t replace decades spent troubleshooting real-world molds. An experienced designer knows, for instance:

When ejector pins might wear unevenly

How tool steel grades behave in different climates

The subtle tweaks needed for consistent shot-to-shot quality

How maintenance schedules impact tool life

Consultants with global backgrounds bring lessons from European, Asian, and North American production lines—helping manufacturers avoid pitfalls others already solved.

Benefits of Expert-Led Mold Design

Companies that tap into seasoned consultants gain:

Less risk and fewer revisions

Quicker start-up, faster time-to-market

Improved part consistency and reduced scrap

Longer-lasting tools and fewer emergency downtime events

Lower total cost per part—thanks to optimizations in cycle and durability

When expertise is applied early, every part in the cycle benefits—from design through production and service.

Collaboration Drives Success

Advanced mold design isn’t a solo effort. It requires coordination across functions:

CAD designers translate part needs into mold form

Material engineers define resin properties and constraints

Production teams highlight wear patterns and bottlenecks

Quality teams provide feedback on part performance and complaints

Project leads synchronize costs, timelines, and revisions

Consultants serve as bridge-makers, turning this collective knowledge into practical tool solutions.

Proven Results in Action

Experts with decades of experience have seen—and solved—complex molding challenges, such as:

Multi-cavity molds requiring conformal cooling

High-precision inserts for medical components

Heat-critical automotive parts with internal bosses

Molded interlocks or hinges on thin-walled parts

Leveraging proven practices means avoiding costly trial-and-error—and getting to optimal designs faster.

Final Words

Complex injection mold design is more than a technical task. It’s a strategic step that determines whether production is efficient, parts are reliable, and tools stay serviceable for the long haul.

With over 20 years of global experience, consultancy expertise ensures that designs are battle-tested, production-ready, and aligned with your product’s lifecycle goals.

Discover how smart mold design can elevate your engineering workflow and slash production risks:

👉 https://amlaconsultancy.com/complex-injection-mold-design-techniques/

Your next mold could be your best—when it starts with the right design.

0 notes

Text

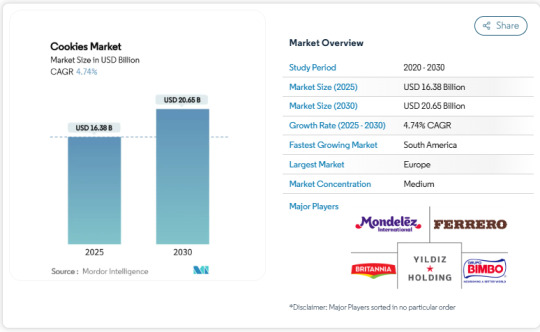

Global Cookies Market to Hit USD 20.65 Billion by 2030 Amid Demand for Portion-Controlled and Fortified Treats

The global cookies market size is valued at USD 16.38 billion in 2025 and is forecasted to reach USD 20.65 billion by 2030, advancing at a CAGR of 4.74% over the forecast period. Growth is supported by stable snacking demand worldwide, coupled with health-focused reformulations and premium positioning that align with evolving consumer preferences. Although conventional formats continue to dominate the size of the market, portion-controlled, fortified, and plant-based cookies are capturing incremental value, countering input cost volatility and broadening the overall market base.

Get More Insights: https://www.mordorintelligence.com/industry-reports/cookies-market

Cookies Market Key Trends

Rising Demand for Portion-Controlled Indulgence

The cookies industry is witnessing a notable shift towards portion-controlled indulgence snacks. Health-conscious consumers are opting for mini-cookies and single-serve packs to enjoy treats without overconsumption. This trend has driven major brands to reformulate recipes to meet the FDA’s upcoming 2028 “healthy” labeling rules, requiring tighter thresholds on saturated fat, sodium, and added sugars. Market leaders report premium pricing on portion-controlled lines, translating to favourable margins despite raw-material inflation.

Urban On-the-Go Breakfast Culture Accelerates Demand

Rapid urbanisation in Asia-Pacific and Latin America has driven a transformation in breakfast habits, with consumers opting for convenient cookie-based breakfast alternatives. Brands such as Olyra Foods are addressing this trend with fortified breakfast biscuits that offer high fibre and low sugar in portable formats. This pivot towards breakfast-positioned cookies is expanding the market share of cookies among time-constrained professionals in metropolitan hubs.

Fortification and Nutrient Enhancement Fuel Market Growth

Fortified cookies are growing as consumers seek functional foods that deliver health benefits beyond basic indulgence. Companies are incorporating proteins, vitamins, minerals, and plant-based nutrients into cookies, transforming them into purposeful snacks that appeal to children, seniors, and athletes. This fortification trend is strengthening the position of cookies as versatile products aligned with both indulgence and health-conscious consumption patterns.

Gifting and Premiumisation Strengthen Emotional Positioning

Cookies have become popular gifting items beyond traditional holidays, extending into corporate gifts and personal celebrations. Brands like La Monarca Bakery launched new premium assortments, such as Mexican cookies featuring wedding cookies, cinnamon cookies, and Polvorones, emphasising artisanal craftsmanship and heritage appeal. This strategy is enhancing the value share of premium cookie lines in gifting markets.

Cookies Market Segmentation

By Product Type

Butter/Shortbread and Plain Cookies remain the leading segment with a market share of 33.85% in 2024, driven by their familiarity and classic appeal.

Bar Cookies are the fastest-growing, projected to advance at a CAGR of 6.05% through 2030. Their portion-control format resonates with health-conscious consumers seeking convenient, nutrient-rich options.

Molded/Drop Cookies continue to grow steadily due to manufacturing versatility, while Sandwich and Cream-filled Cookies maintain a niche in indulgent snacking.

By Category

Conventional Cookies accounted for 92.11% of the cookies market size in 2024, underlining mainstream consumer preferences.

Free-from Cookies are gaining momentum with a forecast CAGR of 6.77%, reflecting rising demand for allergen-free and vegan formulations that cater to specific dietary needs and command premium pricing.

By Distribution Channel

Hypermarkets and Supermarkets lead cookie distribution with a market share of 39.55% in 2024, leveraging broad consumer access and promotional reach.

Online Retail is the fastest-growing channel, advancing at a CAGR of 6.68% through 2030. Direct-to-consumer subscription services and e-commerce platforms provide brands with deeper consumer insights and higher margins.

By Packaging Format

Pouches and Sachets dominate packaging, accounting for 63.43% of market share in 2024, offering convenience and freshness.

Cartons are projected to grow at 5.88% CAGR, driven by premium gifting and sustainable packaging demands that elevate brand differentiation.

By Geography

Europe retained leadership with a cookies market share of 30.12% in 2024, benefiting from heritage brands, premium offerings, and robust regulatory standards.

South America is projected to record the fastest growth at a CAGR of 6.89%, driven by rising health-conscious snacking trends and investments like Nestlé’s USD 550.8 million expansion in Brazil.

Asia-Pacific continues to provide growth opportunities through rising middle-class consumption in countries like China and India, while North America remains a mature market focusing on premium, fortified, and direct-to-consumer innovations.

Cookies Market Key Players

The cookies sector maintains moderate market concentration with global conglomerates competing alongside regional specialists.

Mondelēz International, Inc. continues to strengthen its portfolio through partnerships like its June 2024 deal with Lotus Bakeries to expand the Biscoff brand in India.

Ferrero International S.A. leverages premiumisation with indulgent offerings under multiple brands.

Britannia Industries Ltd. dominates the Indian market with a broad product range catering to both mass and premium segments.

Grupo Bimbo SAB de CV enhances distribution scale across the Americas, integrating cookies into its extensive bakery network.

Yildiz Holding A.S. maintains strong positions in Europe and the Middle East with diversified biscuit and cookie offerings.

New entrants are disrupting traditional sales channels via direct-to-consumer models, while leading firms invest in digital marketing, e-commerce, and data analytics to remain competitive. Strategic acquisitions and joint ventures continue as companies seek to consolidate market share and expand product portfolios.

To Know More about this market, Visit: https://www.mordorintelligence.com/ja/industry-reports/cookies-market

Conclusion

The global cookies market is set for steady growth to USD 20.65 billion by 2030, underpinned by rising portion-controlled snack demand, fortified functional products, and premium gifting trends. While conventional formats continue to dominate the overall market size, segments such as bar cookies, free-from formulations, and online retail are growing rapidly, expanding the market share of cookies within broader snacking categories. Key players are focusing on reformulation to meet new health regulations, investing in sustainability-led packaging, and leveraging direct-to-consumer channels to enhance margins and consumer loyalty. As consumer expectations shift towards healthier yet indulgent treats, the cookies market remains well-positioned to balance traditional appeal with modern nutritional and convenience demands.

0 notes

Text

Conductive Inks Market Growth Forecast Driven by Flexible Electronics Demand Rise

The Conductive Inks Market is undergoing substantial transformation, powered largely by the accelerating demand for flexible electronics. As industries worldwide transition from rigid circuit board architectures to bendable, stretchable, and ultra-thin designs, conductive inks have emerged as the key enabling material in this shift. Composed primarily of conductive metals such as silver and copper or carbon-based alternatives, these inks allow for seamless electronic circuit printing onto a variety of substrates, ranging from plastic and paper to fabric and glass.

With the consumer electronics industry prioritizing miniaturization and energy efficiency, the need for circuit designs that are lightweight and adaptable has become urgent. Conductive inks offer an ideal solution, particularly in applications where traditional wiring methods are no longer feasible. These include wearable technologies, foldable displays, printable batteries, and healthcare diagnostics equipment, where innovation depends heavily on the ability to embed conductivity in flexible materials.

One of the primary growth drivers is the explosive rise in flexible electronics, which has seen rapid deployment in sectors such as healthcare, automotive, consumer gadgets, and energy. The compatibility of conductive inks with low-cost, additive manufacturing techniques, including screen printing and inkjet printing, makes them particularly suitable for mass production of printed electronics. This has led to increasing commercialization of products like smartwatches, fitness bands, electronic skin patches, flexible touchscreens, and smart labels.

As the demand for flexible electronics rises, manufacturers and developers are scaling up investments in R&D to create more robust, stretchable, and printable conductive materials. The emphasis has been on improving conductivity at low curing temperatures, enhancing adhesion on polymer films, and ensuring mechanical resilience under strain. These technical advancements are supporting the expansion of conductive inks from laboratory environments to mainstream industrial manufacturing.

Silver-based conductive inks continue to dominate the market due to their high electrical conductivity, chemical stability, and proven performance in high-precision electronic applications. They are widely used in photovoltaics, RFID antennas, touchscreen panels, and printed sensors. However, the relatively high cost of silver poses a challenge for its widespread adoption in disposable and large-volume applications.

This cost constraint is prompting a shift toward alternative materials. Copper-based inks are gaining traction, especially in high-volume manufacturing, owing to their cost efficiency. Despite their susceptibility to oxidation, recent innovations in encapsulation technologies have significantly improved their stability. At the same time, carbon-based inks, including graphene and carbon nanotubes, are being explored for their flexibility, environmental benefits, and compatibility with low-temperature processing. These emerging alternatives are contributing to broader accessibility and use cases for conductive inks across industries.

The application landscape for conductive inks is rapidly diversifying. In the healthcare sector, the use of printed biosensors, medical electrodes, and wearable monitoring systems is increasing. These devices require ultra-thin, skin-conformable electronic circuits that only printed conductive inks can provide. In the automotive sector, in-mold electronics and flexible interior control panels are becoming the norm, replacing traditional wiring with lighter, integrated printed circuits. Smart packaging applications, including interactive labels and temperature-sensitive displays, are also leveraging conductive inks for enhanced functionality and brand engagement.

Another promising area of growth lies in the integration of conductive inks into energy devices such as flexible solar panels and printed batteries. These innovations are particularly appealing in off-grid and wearable energy scenarios where conventional battery formats are impractical. Furthermore, the rise of smart textiles, which embed sensors and conductive paths directly into garments, is creating new commercial avenues for ink manufacturers targeting the fashion and healthcare industries.

Regionally, Asia-Pacific dominates the global conductive inks market, primarily due to its massive electronics manufacturing base and early adoption of flexible electronics technologies. Countries such as China, Japan, South Korea, and Taiwan are at the forefront of both production and innovation. China’s rapid expansion in OLED displays and smartphone components has made it a central player, while Japan continues to lead in research and development of novel ink formulations. South Korea’s dominance in display manufacturing also positions it as a critical region for conductive ink consumption.

North America is emerging as a high-potential growth market, supported by rising R&D investments, especially in healthcare wearables and aerospace applications. The region is also witnessing growth in 3D printing and smart packaging solutions that depend on printable electronics. Europe, meanwhile, is focusing on sustainable ink formulations and regulatory frameworks, encouraging eco-friendly innovation in the market.

Looking ahead, the global conductive inks market is expected to experience robust expansion through 2030. Increasing industrial automation, the Internet of Things (IoT), and energy storage innovation are projected to amplify demand further. Companies are strategically aligning their portfolios to cater to both premium applications requiring high-performance inks and mass-market segments demanding cost-effective alternatives. Key players are also forming partnerships with material science firms, electronics OEMs, and research institutions to maintain technological leadership and secure long-term growth.

The future of the conductive inks market is inextricably tied to the evolution of flexible electronics. As industries push the boundaries of design, functionality, and form factor, the role of conductive inks will only deepen, unlocking new product classes and redefining the way circuits are integrated into the world around us.

#ConductiveInks#FlexibleElectronics#PrintedElectronics#MaterialScience#WearableTech#SmartDevices#GrapheneInks#SilverInks#MarketResearch#ElectronicsInnovation

0 notes

Text

Eco-Friendly Plates and Bowls Sets for a Greener Kitchen

Sustainability starts at home—and what better place to begin than in your kitchen? With the growing demand for conscious living, many homeowners are now choosing eco-friendly alternatives that are stylish, functional, and kind to the planet. From biodegradable materials to artisanal handmade designs, eco-conscious luxury dinner set options are now more accessible than ever. And if you're in the market for the best dinner plates that align with your green lifestyle, you're in the right place.

Not only do these sets elevate your everyday dining, but they also contribute to reducing environmental impact. Whether you're curating a rustic kitchen or a sleek modern setup, there's an eco-friendly luxury dinner set that fits your style while offering the best dinner plates made from sustainable, non-toxic materials.

1. Why Choose Eco-Friendly Dinnerware?

Sustainable dinnerware is more than a trend—it's a responsible choice. Here’s why eco-friendly options matter:

Reduce plastic waste: Many biodegradable plates are made from bamboo, palm leaf, or wheat straw.

Non-toxic and safe: Free from harmful chemicals like BPA and lead.

Stylish and unique: Often handcrafted or minimally designed for natural elegance.

Durable and reusable: Unlike disposable plates, these are built to last without harming the environment.

Choosing sustainable sets also means supporting ethical production and small artisans who prioritize eco-conscious craftsmanship.

2. Top Eco-Friendly Materials for Plates and Bowls

Here are some of the best sustainable materials you’ll find in today’s green luxury dinner set collections:

Bamboo: Lightweight, durable, and fast-growing—making it highly renewable.

Areca Palm Leaf: Naturally fallen palm leaves, molded into plates without chemicals.

Recycled Glass or Ceramic: Gives new life to old materials and adds a unique, artistic touch.

Stoneware with Eco-Glazes: Offers a rustic feel with modern sustainability.

These materials are commonly featured in collections that offer the best dinner plates without compromising the health of the planet.

3. Styles That Match Sustainability with Sophistication

Eco-friendly doesn’t mean plain or boring. In fact, sustainable luxury dinner set options often come with artistic flair:

Earth-toned palettes: Greens, browns, creams, and soft greys for natural warmth.

Textured surfaces: For an organic, handmade aesthetic.

Matte finishes: Soft, contemporary elegance that fits minimalist and modern homes.

Unique shapes: Asymmetrical designs that break away from factory-made perfection.

These sets can be proudly displayed on your open shelves or laid out for eco-conscious dinner parties.

4. Where to Shop for Sustainable Dinnerware

Looking for eco-friendly best dinner plates and bowls? Try:

Local artisan markets for handmade, small-batch collections.

Sustainable lifestyle brands that specialize in bamboo, palm leaf, or recycled materials.

Online platforms like Etsy, Amazon, and West Elm, which now offer curated eco-friendly kitchenware sections.

Always look for product details like compostable, dishwasher-safe, food-grade certified, and chemical-free labels when browsing.

Conclusion: Make a Statement with Eco-Conscious Dining

Sustainability doesn’t stop at what’s on your plate—it extends to what you serve it on. Investing in eco-friendly plates and bowls is a simple yet impactful way to make your kitchen greener and more responsible. You can still enjoy the elegance of a luxury dinner set without harming the environment. In fact, many eco-conscious collections now feature the best dinner plates that rival traditional designs in both quality and style.

0 notes

Text

Eco-Friendly Plates and Bowls Sets for a Greener Kitchen

Sustainability starts at home—and what better place to begin than in your kitchen? With the growing demand for conscious living, many homeowners are now choosing eco-friendly alternatives that are stylish, functional, and kind to the planet. From biodegradable materials to artisanal handmade designs, eco-conscious luxury dinner set options are now more accessible than ever. And if you're in the market for the best dinner plates that align with your green lifestyle, you're in the right place.

Not only do these sets elevate your everyday dining, but they also contribute to reducing environmental impact. Whether you're curating a rustic kitchen or a sleek modern setup, there's an eco-friendly luxury dinner set that fits your style while offering the best dinner plates made from sustainable, non-toxic materials.

1. Why Choose Eco-Friendly Dinnerware?

Sustainable dinnerware is more than a trend—it's a responsible choice. Here’s why eco-friendly options matter:

Reduce plastic waste: Many biodegradable plates are made from bamboo, palm leaf, or wheat straw.

Non-toxic and safe: Free from harmful chemicals like BPA and lead.

Stylish and unique: Often handcrafted or minimally designed for natural elegance.

Durable and reusable: Unlike disposable plates, these are built to last without harming the environment.

Choosing sustainable sets also means supporting ethical production and small artisans who prioritize eco-conscious craftsmanship.

2. Top Eco-Friendly Materials for Plates and Bowls

Here are some of the best sustainable materials you’ll find in today’s green luxury dinner set collections:

Bamboo: Lightweight, durable, and fast-growing—making it highly renewable.

Areca Palm Leaf: Naturally fallen palm leaves, molded into plates without chemicals.

Recycled Glass or Ceramic: Gives new life to old materials and adds a unique, artistic touch.

Stoneware with Eco-Glazes: Offers a rustic feel with modern sustainability.

These materials are commonly featured in collections that offer the best dinner plates without compromising the health of the planet.

3. Styles That Match Sustainability with Sophistication

Eco-friendly doesn’t mean plain or boring. In fact, sustainable luxury dinner set options often come with artistic flair:

Earth-toned palettes: Greens, browns, creams, and soft greys for natural warmth.

Textured surfaces: For an organic, handmade aesthetic.

Matte finishes: Soft, contemporary elegance that fits minimalist and modern homes.

Unique shapes: Asymmetrical designs that break away from factory-made perfection.

These sets can be proudly displayed on your open shelves or laid out for eco-conscious dinner parties.

4. Where to Shop for Sustainable Dinnerware

Looking for eco-friendly best dinner plates and bowls? Try:

Local artisan markets for handmade, small-batch collections.

Sustainable lifestyle brands that specialize in bamboo, palm leaf, or recycled materials.

Online platforms like Etsy, Amazon, and West Elm, which now offer curated eco-friendly kitchenware sections.

Always look for product details like compostable, dishwasher-safe, food-grade certified, and chemical-free labels when browsing.

Conclusion: Make a Statement with Eco-Conscious Dining

Sustainability doesn’t stop at what’s on your plate—it extends to what you serve it on. Investing in eco-friendly plates and bowls is a simple yet impactful way to make your kitchen greener and more responsible. You can still enjoy the elegance of a luxury dinner set without harming the environment. In fact, many eco-conscious collections now feature the best dinner plates that rival traditional designs in both quality and style.

0 notes

Text

Bottling Line Manufacturers in India: Streamlining Beverage Production with PEB-Integrated Solutions

Bottling Line Manufacturers in India: Streamlining Beverage Production with PEB-Integrated Solutions

India’s beverage and liquid packaging industry is expanding rapidly, driven by rising consumer demand, increasing urbanization, and the growth of sectors like FMCG, pharmaceuticals, and bottled water. At the heart of this growth are bottling line manufacturers—engineering specialists who design and install automated systems for filling, sealing, labeling, and packaging liquids. As modern factories demand faster deployment and scalable infrastructure, the collaboration between bottling line manufacturers and PEB (Pre-Engineered Building) manufacturers is proving to be a game-changer in industrial development.

What Is a Bottling Line?

A bottling line is a sequence of machinery used in the packaging process for liquids such as water, soft drinks, juices, dairy products, edible oils, and pharmaceuticals. These lines include various components like rinsers, fillers, cappers, labelers, conveyors, and shrink-wrapping units, all designed to work in sync for efficient, high-speed production.

Today’s bottling lines are highly automated, requiring hygienic, vibration-free, and dust-controlled environments—making them ideal for installation inside PEB-based industrial facilities.

The Role of Bottling Line Manufacturers

Bottling line manufacturers are not just machine fabricators—they offer complete turnkey solutions. Their responsibilities include:

Designing customized production lines based on the type of liquid and bottle/container size

Integrating advanced technologies like servo control, touch-screen interfaces, and IoT sensors

Installing and commissioning the line within tight deadlines

Offering maintenance, training, and post-sales support

When combined with PEB construction, these manufacturers can help clients set up full-fledged bottling plants within weeks rather than months, enabling faster time-to-market.

Why PEB Structures Are Ideal for Bottling Plants

Pre-Engineered Buildings (PEBs) offer numerous advantages that align perfectly with the needs of modern bottling plants:

Quick Construction: Reduces build time, allowing faster commissioning of bottling lines

Customizable Design: Open floor plans accommodate machinery layouts and conveyor systems

Thermal Efficiency: With insulated cladding and roofing, ideal conditions are maintained inside

Durability and Cleanability: Steel structures resist corrosion and are easy to sanitize

Future Expansion Ready: Additional bays or areas can be added without disrupting operations

Leading PEB manufacturers often partner with bottling line equipment suppliers to deliver end-to-end plant infrastructure, especially for startups and fast-scaling beverage brands.

Applications Across Industries

Bottling line manufacturers in India cater to a wide range of sectors:

Packaged Drinking Water

Carbonated Soft Drinks (CSD)

Fruit Juice and Flavored Beverages

Pharmaceutical Syrups and Liquids

Milk, Buttermilk, and Dairy Products

Liquor and Spirits

Edible Oil and Vinegar

Each industry has unique technical and regulatory needs, and manufacturers offer tailored solutions with options like PET blow molding, hot filling, and cleanroom-compatible packaging systems—often installed inside PEB structures for speed and efficiency.

Growth Drivers and Market Trends

India’s bottling equipment market is on an upward trajectory due to several key trends:

Surge in Packaged Water Consumption

Growing Urban Beverage Demand

Emergence of Health and Functional Drinks

Export Opportunities for Indian Beverage Brands

Government Support for Food Processing and MSMEs

With this growth, there is increasing demand for modular, quickly deployable bottling units—a need perfectly fulfilled by the synergy between bottling line manufacturers and PEB suppliers.

Many bottling equipment providers now offer plug-and-play lines that are installed inside PEB buildings, reducing infrastructure costs and project timelines significantly.

Future Outlook

As automation, sustainability, and digital monitoring become standard in the packaging sector, bottling line manufacturers will need to invest in smarter, cleaner technologies. Integration with solar-ready PEB buildings, energy-efficient layouts, and IoT-enabled production systems is likely to become the new norm.

Additionally, export-driven production facilities and third-party bottling units will increasingly demand faster setup—further boosting demand for PEB-integrated manufacturing solutions.

Conclusion

Bottling line manufacturers in India are playing a pivotal role in accelerating the growth of the beverage and liquid packaging industry. Their collaboration with PEB manufacturers ensures faster factory setup, operational efficiency, and scalability—making it easier for brands to meet rising market demand.

Together, these manufacturers are reshaping how bottling plants are built and operated—combining engineering precision with construction speed to deliver world-class packaging facilities for the next generation of Indian industries.

Visit:- https://www.liquorbottlingplants.com/bottling-line.html

0 notes

Text

Ultimate Guide to Wholesale Putty & Slime Toys for Children

Let’s face it, kids love to get their hands messy. And what better way to satisfy that urge than with colorful, squishy, and stretchy toys like slime and putty? These tactile wonders are more than just a trend. They're sensory tools, creative outlets, and, honestly, a whole lot of fun. In this ultimate guide, we’re diving deep into everything you need to know about wholesale putty and slime toys, how to source the best bulk slime and putty toys, and why every toy store, classroom, or party planner should stock up.

Why Kids (and Parents) Love Slime and Putty

Before we talk in bulk, let’s talk about benefits. Slime and putty are more than just good. They're playtime essentials that check all the boxes.

Sensory play: Kids improve their fine motor skills by squishing, stretching, and molding.

Stress relief: Yes, even kids need a stress ball. Slime works wonders for calming nerves.

Creativity booster: With glitter, colors, and scents, kids customize their gooey masterpieces.

These toys have quickly become must-haves, and for good reason. If you're considering jumping into the slime putty toy market, now's the perfect time.

Types of Slime and Putty That Sell Fast

Understanding your product range is key to standing out in the wholesale toy world. Here’s a breakdown of high-demand types you should consider stocking:

- Glow-in-the-dark slime

- Scented putty

- Metallic or glitter slime

- Color-changing slime

- Magnetic putty

The more variety you offer in your wholesale putty and slime toys, the more attractive your collection becomes to retailers and consumers.

Who Should Buy Bulk Slime and Putty Toys?

Let’s explore some key buyers who can benefit from buying affordable bulk slime and putty toys:

Retail stores – Whether you run a physical toy store or an online shop, slime and putty are fast movers.

Schools and daycare centers – Educators love using slime in sensory activities and classroom rewards.

Event organizers – Think birthday parties, kids’ fairs, and corporate family events.

Subscription boxes – Add some gooey delight to your monthly deliveries.

Party supply businesses – Slime is a party bag staple now!

By targeting these segments, you're tapping into a consistent demand that only continues to grow.

What to Look for When Buying Wholesale Putty & Slime Toys

Now, you’re convinced it’s a great idea. But how do you choose the right supplier or product?

Safety standards – Always opt for non-toxic, BPA-free options.

Packaging appeal – Kids (and their parents) love eye-catching packaging.

Variety and customization – Offer unique textures, colors, and scents.

Shelf life – High-quality slime doesn’t dry out fast.

Reliable suppliers – Avoid slow shipping and inconsistent stock. Choose a trusted wholesaler.

Investing in affordable wholesale putty and slime toys only works if you’re getting consistent, safe, and engaging products.

Top Benefits of Buying in Bulk

Why should you go the wholesale route? Here’s the math (and logic) behind it:

Cost savings – Bulk pricing drastically reduces your cost per unit.

Better inventory control – Avoid frequent reordering with large shipments.

Higher margins – Reselling provides you with the flexibility to offer competitive deals while still generating a profit.

Customization opportunities – Larger orders sometimes allow for private labeling or exclusive designs.

Bulk buying means you’re running your operation smarter, not harder.

How to Display Slime and Putty Toys to Maximize Sales

Let’s talk about merchandising. Even the best product won’t move without the right setup.

- Use clear bins or open jars so customers can easily see and touch the samples.

- Create a “slime station” with testers at events or in-store.

- Group items by theme, such as glitter slime, seasonal slime, etc.

- Add signage highlighting features like “non-toxic” or “glow in the dark.”

Remember, impulse buys thrive on fun, visual, and sensory cues. Sell the experience, not just the product.

Trending Slime Putty Toy Ideas for 2025

Want to stay ahead of the game? These trends are shaping the future of slime:

Eco-friendly slime – Made with biodegradable ingredients

DIY slime kits – Encourage kids to mix and match their goo

Jewel or crystal slime – Eye-catching and Instagram-worthy

Science-themed putty – With magnetic or color-shifting elements

Jumping on these trends early can position your inventory as a top-tier offering in the wholesale putty and slime toys category.

How to Price Bulk Slime & Putty Toys for Resale

Finding the sweet spot between value and profit is key. Here’s a basic formula:

Retail Price = Wholesale Cost × 2.5 to 3

If you're selling high-end variants or custom slime jars, the markup can go higher. Make sure to:

- Offer bundle discounts (e.g., 3 for $10)

- Use tiered pricing for larger orders

- Include free slime with orders above a certain value

Smart pricing helps push volume and builds customer loyalty.

Marketing Your Slime & Putty Collection

Now that you’ve stocked up, let’s move the product. Use these strategies:

Social Media Teasers – Videos of kids playing with slime are gold!

Email Blasts – Announce new colors, themes, or discounts

Unboxing Experiences – Slime is a visual experience. Lean into that with bright packaging and wow moments.

Collaborate with influencers – Kids follow toy influencers. Get your slime featured!

Don’t forget: even though these are bulk items, your marketing should make them feel personal and exciting.

Mistakes to Avoid When Buying Wholesale Putty & Slime Toys

Even seasoned retailers slip up. Here’s what to avoid:

- Buying from unverified sources

- Choosing only one style of slime

- Ignoring safety certifications

- Neglecting seasonal trends

- Underestimating packaging appeal

Play it smart by balancing variety, safety, and sourcing strategy. That’s how you build a slime empire.

Where to Buy Affordable Wholesale Putty & Slime Toys

While we won’t name names, a trusted wholesaler will always offer:

- Clear MOQs (minimum order quantities)

- Transparent pricing and shipping details

- Regular inventory updates

- Responsiveness to custom orders

If your wholesaler ticks all these boxes, you're on the right path to buying affordable wholesale putty and slime toys that sell.

The Future of Slime and Putty Toys

Think slime is just a fad? Think again. These toys are evolving.

Expect to see more:

- STEM-focused slime for educational kits

- Licensed character slimes (think superhero goo!)

- Therapeutic putties for kids with sensory needs

The market isn’t slowing down; it’s diversifying. This makes it the ideal time to expand your offerings with premium slime putty toys in bulk.

Final Thoughts: Make Slime a Business Win

Wholesale Putty & Slime Toys are more than just gooey fun; they're powerful tools for creativity, sensory development, and pure joy. By choosing Affordable Wholesale Putty & Slime Toys, offering diverse options, and adding value through engaging packaging and thoughtful customer support, you're not just selling products; you're building experiences that stick.

At Luna Bella, we believe every child deserves a little magic in their hands. Our carefully curated collection of Bulk Slime and Putty Toys is designed to spark imagination, inspire laughter, and bring delight to every occasion. Whether you're a retailer, party planner, teacher, or parent, we're here to help you make slime-tastic memories that last.

Let Luna Bella be your trusted partner in bringing bright colors, playful textures, and joyful moments to kids everywhere.

For More Info-

https://shorturl.at/uNx0G

#wholesale lollipop kids toys#wholesale assorted toys#Bulk Slime and Putty Toys#Wholesale Putty & Slime Toys

0 notes

Text

How to Choose the Right Silicone Oil Manufacturer in India: Key Factors to Consider

Silicone oil is a versatile, high-performance fluid used across a wide spectrum of industries—ranging from pharmaceuticals, personal care, and food processing to automotive, textiles, and industrial lubricants. As demand for specialty silicones continues to grow, India has emerged as a significant hub for silicone oil manufacturing due to its cost-effective production, skilled workforce, and strong chemical industry base.

However, with numerous manufacturers in the market, selecting the right partner requires careful evaluation. Whether you're sourcing for export, OEM production, or local use, here are the key factors to consider when choosing a silicone oil manufacturer in India.

1. Product Grade and Application Compatibility

Silicone oil isn’t a one-size-fits-all product. It comes in various viscosities, formulations, and purity levels depending on the application:

Medical-grade: For ophthalmic use (e.g., retinal detachment treatment) or pharmaceutical excipients

Cosmetic-grade: For skincare, hair care, and personal hygiene products

Industrial-grade: For mold release, lubricants, dielectric fluids, and thermal stability

Choose a manufacturer that specializes in the grade relevant to your application and provides technical data sheets (TDS) and material safety data sheets (MSDS) to validate product suitability.

2. Certifications and Regulatory Compliance

Regulatory compliance is critical, especially if you're sourcing silicone oil for export or use in regulated industries like pharma, food, or cosmetics.

Look for manufacturers with:

ISO 9001/14001 certification for quality and environmental management

GMP certification for pharmaceutical and cosmetic-grade products

REACH and RoHS compliance for exports to the EU

FDA or USDMF filing (for medical-grade applications)

These certifications reflect a manufacturer's commitment to consistency, traceability, and global safety standards.

3. Customization and Product Range

An experienced silicone oil manufacturer in India should offer a broad viscosity range (commonly from 5 cSt to 1,000,000 cSt) and the ability to custom-blend or formulate silicone oils based on client requirements—whether for enhanced thermal stability, better spreadability, or food-grade safety.

If your product requires niche properties—like volatile silicones, amino-functional silicones, or emulsified silicones—ensure the manufacturer has R&D capabilities and formulation expertise.

4. Manufacturing Infrastructure and Capacity

A supplier’s infrastructure says a lot about their ability to deliver high-quality silicone oil at scale. Evaluate:

Batch vs. continuous processing systems

Cleanroom facilities for pharma and cosmetic production

On-site analytical labs for quality control and testing

In-house packaging and labeling for B2B or OEM branding

Also, consider their production capacity and whether they can scale with your growing demand without compromising lead time or quality.

5. Logistics, Delivery, and Packaging Options

Choose a manufacturer that offers reliable and timely delivery, both domestically and internationally. Ask about:

Shipping capabilities (road, sea, air)

Lead times and inventory availability

Packaging options (HDPE drums, IBC tanks, small containers)

Safety measures in packaging to prevent contamination or leakage

Efficient logistics support is particularly important if you need Just-In-Time (JIT) deliveries or handle sensitive applications.

6. Client References and Market Reputation

Before finalizing a partnership, review the manufacturer’s reputation:

Request references from clients in your industry

Check online reviews, case studies, or testimonials

Assess how long they’ve been operating in silicone oil manufacturing

Look for signs of long-term partnerships and repeat business

A reputable manufacturer will be transparent about past projects and happy to share success stories.

Conclusion

Choosing the right silicone oil manufacturer in India is a strategic decision that can impact your product quality, brand reputation, and supply chain efficiency. By evaluating factors such as product grade, certifications, customization capabilities, infrastructure, and delivery reliability, you can ensure a strong, compliant, and scalable partnership.

India’s growing silicone oil sector offers a competitive landscape—but with due diligence, you can find a manufacturer that not only meets your technical requirements but also aligns with your long-term business goals.

0 notes

Text

Starter Culture Market: Driving Innovation in Food Fermentation

United States of America – June 26, 2025 – The Insight Partners is delighted to announce the publication of its newest report, “Starter Culture Market: In-depth Analysis and Forecast.” This comprehensive report examines the dynamic starter culture market, highlighting key trends, applications, and technological advancements driving growth across the food fermentation industry.

Overview of the Starter Culture Market

The starter culture market is witnessing consistent growth fueled by increasing demand for fermented food products with improved taste, texture, and nutritional benefits. Starter cultures such as molds/fungi, yeast, and bacteria are essential for producing a wide variety of dairy products, meat and seafood items, and beverages. The rising popularity of natural and probiotic foods continues to encourage market expansion worldwide.

Technological innovations in microbial strain development and fermentation processes are enhancing the quality and efficiency of starter cultures, contributing to broader application and adoption.

Key Market Insights

Growth Drivers:

Growing consumer preference for fermented and probiotic-rich foods.

Expansion of dairy and meat processing industries globally.

Advancements in starter culture technologies improving fermentation outcomes.

Rising interest in functional beverages containing yeast and bacterial cultures.

Market Segmentation

The report categorizes the starter culture market into:

By Type:

Mold/Fungi

Yeast

Bacteria

By Application:

Dairy Products

Meat and Seafood

Beverages

This segmentation highlights the diverse range of cultures and their varied applications across food sectors.

Emerging Trends

Introduction of multi-strain and hybrid starter cultures enhancing fermentation quality.

Increased demand for clean-label and natural starter culture solutions.

Growing use of starter cultures in innovative beverage segments like kombucha.

Expansion into plant-based and alternative protein products leveraging fermentation technology.

Growth Opportunities

Key opportunities include:

Development of novel microbial strains with targeted functional benefits.

Penetration into emerging markets with increasing demand for fermented foods.

Collaborations between culture producers and food manufacturers for customized solutions.

Adoption of sustainable production methods aligning with consumer preferences.

Conclusion

The Starter Culture Market: Global Industry Trends, Share, Size, Growth, Opportunity, and Forecast 2023-2031 report provides much-needed insight for a company willing to set up its operations in the Starter Culture Market. Since an in-depth analysis of competitive dynamics, the environment, and probable growth path are given in the report, a stakeholder can move ahead with fact-based decision-making in favor of market achievements and enhancement of business opportunities.

About The Insight Partners

The Insight Partners is among the leading market research and consulting firms in the world. We take pride in delivering exclusive reports along with sophisticated strategic and tactical insights into the industry. Reports are generated through a combination of primary and secondary research, solely aimed at giving our clientele a knowledge-based insight into the market and domain. This is done to assist clients in making wiser business decisions. A holistic perspective in every study undertaken forms an integral part of our research methodology and makes the report unique and reliable.

To know more and get access to Sample reports. https://www.theinsightpartners.com/sample/TIPRE00009065

#starter culture#fermentation#molds#fungi#yeast#bacteria#dairy products#meat processing#seafood#beverages#probiotics#natural food

0 notes

Text

Blue Cheese Market: Growth Trends 2034

Blue Cheese Market is poised for steady growth, expected to increase from $2.5 billion in 2024 to $4.3 billion by 2034, reflecting a CAGR of approximately 5.6%. Blue cheese, distinguished by its blue veins formed by Penicillium mold, includes iconic varieties such as Roquefort, Gorgonzola, and Stilton. As consumer interest grows in bold flavors, artisanal craftsmanship, and gourmet culinary experiences, blue cheese is no longer a niche luxury — it’s becoming a mainstream staple in retail shelves and fine dining menus alike.

A surge in specialty cheese consumption, fueled by a rising appreciation for regional authenticity and health-conscious choices, continues to reshape the market. Cow milk-based blue cheese remains the dominant product, while goat and sheep milk variants are gaining ground due to their unique taste and nutritional benefits. The diversity in forms — crumbles, wedges, spreads, and even powdered options — caters to a wide range of consumer applications.

Click to Request a Sample of this Report for Additional Market Insights: https://www.globalinsightservices.com/request-sample/?id=GIS31534

Market Dynamics

The market dynamics surrounding blue cheese are evolving with changing dietary habits, culinary trends, and global food culture. Urban consumers, especially millennials and Gen Z, are seeking premium, organic, and locally sourced cheeses, prompting a boom in the artisanal segment, which now commands 45% of the market. Meanwhile, the industrial segment contributes 35%, thanks to its efficiency in mass production and global distribution.

Technological advancements in dairy processing are enabling producers to meet increasing demand while maintaining traditional flavor profiles. However, challenges persist. Rising plant-based diets and concerns about saturated fat content present barriers, compelling producers to innovate with healthier formulations or even plant-based blue cheese alternatives. Additionally, supply chain disruptions and regulatory hurdles related to food safety and labeling can strain operations and inflate costs.

Key Players Analysis

The blue cheese industry is rich with tradition and innovation, comprising heritage producers and emerging artisans alike. Leading players include Roquefort Société, Castello Cheese, Point Reyes Farmstead, Maytag Dairy Farms, and Gorgonzola Producers. These companies are recognized for maintaining high standards in cheese aging, flavor complexity, and sustainable practices.

On the other hand, rising stars like Blue Horizon Creamery, Whispering Pines Creamery, and Rustic Wheel Cheesemakers are gaining popularity through direct-to-consumer models and organic product lines. These newer entrants are nimble, adapting quickly to market trends such as clean labeling, eco-friendly packaging, and e-commerce retailing, enabling them to appeal to younger, environmentally conscious consumers.

Regional Analysis

Europe remains the heart of the blue cheese market, led by France, Italy, and the United Kingdom. These regions uphold a strong cultural heritage and regulatory framework that supports artisanal cheese production. Europe also benefits from a deeply rooted consumer base that values traditional cheeses as part of everyday meals.

In North America, particularly the United States, growing appreciation for gourmet dining and fusion cuisine drives demand. Blue cheese is becoming more popular as a topping on burgers, salads, pizzas, and charcuterie boards. With robust retail and foodservice networks, the U.S. offers ample growth potential.

Asia-Pacific is an emerging region for blue cheese, especially in countries like Japan, South Korea, and China, where Western dietary patterns are gradually being embraced. As income levels rise and food preferences become more adventurous, blue cheese consumption is expected to increase. Meanwhile, Latin America, the Middle East, and Africa represent smaller but expanding markets, driven by urbanization and a growing middle class.

Recent News & Developments

The blue cheese landscape is buzzing with innovations. Price points now range between $15 to $50 per pound, depending on origin and aging process. Recently, there has been a marked rise in demand for organic and sustainable cheeses, especially among health-conscious consumers. Producers are responding with cleaner ingredients and greener practices.

Additionally, the rise of online retail and specialty e-commerce platforms has opened new channels for distribution, helping small-scale artisanal makers reach global audiences. Technological integrations in packaging and storage are also improving shelf-life and transport logistics. Collaborations between traditional cheesemakers and food tech companies are driving product innovation — particularly in vegan blue cheese, now gaining traction.

Browse Full Report : https://www.globalinsightservices.com/reports/blue-cheese-market/

Scope of the Report

This report offers comprehensive insights into the blue cheese market, covering various dimensions including type, application, end-user, packaging, milk source, and distribution channels. It provides an in-depth analysis of market drivers, trends, restraints, opportunities, and competitive dynamics.

From evaluating PESTLE and SWOT analyses to tracking key events and innovation trends, this research aims to empower businesses with actionable intelligence. The scope also includes import-export analysis, local market evaluations, regulatory assessments, and segmentation reviews. With the global consumption of blue cheese projected to hit 600,000 metric tons by 2028, stakeholders in this industry are well-positioned to seize growth through innovation, authenticity, and consumer engagement.

#bluecheesemarket #artisanalcheese #gourmetdairy #cheeselovers #organiccheese #cheesetrends #culinaryinnovation #foodservicegrowth #ecommercefood #cheesemarketinsights

Discover Additional Market Insights from Global Insight Services:

Algae Fats Market : https://www.globalinsightservices.com/reports/algae-fats-market/

Aluminum-free Natural Food Colour Market : https://www.globalinsightservices.com/reports/aluminum-free-natural-food-colour-market/

Animal Feed Additives Market : https://www.globalinsightservices.com/reports/animal-feed-additives-market/

Antifreeze Proteins Market : https://www.globalinsightservices.com/reports/antifreeze-proteins-market/

Aquafeed Market ; https://www.globalinsightservices.com/reports/aquafeed-market/

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1–833–761–1700 Website: https://www.globalinsightservices.com/

0 notes

Text

Mixer Power Cords by Concord Industries: Trusted Solutions for Reliable Kitchen Performance

Concord Industries: High-Quality Mixer Power Cords Designed for Safe and Efficient Kitchen Use

In every modern kitchen — from family homes to commercial setups — the mixer is a fundamental appliance used for grinding, blending, and preparing food with speed and precision. But one often overlooked component that ensures a mixer functions safely and efficiently is the power cord. At Concord Industries, a leading name in electrical accessory manufacturing in India, we specialize in producing high-quality mixer power cords engineered for durability, flexibility, and performance.

With decades of experience in designing appliance-ready electrical components, Concord is the trusted choice for appliance manufacturers, OEMs, and bulk suppliers across India and abroad.

Why Mixer Power Cords Need Specialized Design

Mixer power cords are subject to unique challenges in the kitchen:

Exposure to moisture, heat, and oil

Frequent plugging and unplugging

Continuous bending and handling during operation

High-speed motor demands requiring stable voltage

A mixer’s performance, lifespan, and safety largely depend on the quality of its power cord. That’s why Concord Industries creates mixer cords that are resilient, heat-resistant, and made with precision to ensure consistent and long-lasting appliance operation.

Key Features of Concord Mixer Power Cords

High-Purity Copper Wires Ensures efficient power flow with minimal heat buildup and energy loss.

Flexible, Heat-Resistant Insulation Made with premium PVC or rubber sheathing to resist heat, oil, and kitchen spills.

Flame-Retardant Design Enhances safety by minimizing fire risk even during prolonged use.

Durable and Long-Lasting Built to withstand constant bending and coiling without cracking or fraying.

ISI and RoHS Certified All products are compliant with Indian safety standards and international environmental regulations.

Custom Plug Options Available in both 2-pin and 3-pin designs for different appliance specifications.

Applications Across Industries

Concord’s mixer power cords are widely used in:

Household mixer grinders and food processors

Commercial kitchen appliances in hotels and restaurants

Appliance manufacturing and OEM supply chains

Retail markets and spare parts distribution

Their versatility and reliability make them ideal for both consumer and professional applications.

Customization for Appliance Brands and OEMs

Concord Industries understands that different brands have different technical and design requirements. We offer full customization options, including:

Cable lengths

Outer sheath colors and materials

Plug configurations (angled, straight, etc.)

Brand labeling and retail packaging

Bulk supply for assembly lines or distribution

Our ability to deliver tailor-made solutions with strict quality assurance makes us a preferred supplier to appliance manufacturers across India.

Cutting-Edge Manufacturing and Quality Control

Our ISO-certified manufacturing units are equipped with advanced machinery for:

Cable extrusion and molding

Plug insertion and sealing

High-voltage and insulation testing

Flame and bend endurance testing

Every mixer power cord undergoes multiple stages of quality inspection to ensure:

Safe electrical performance

Resistance to wear, heat, and moisture

Mechanical durability under frequent use

This process ensures our cords are ready for real-world kitchen environments.

Commitment to Sustainability

Concord Industries is a RoHS-compliant manufacturer, ensuring that:

No hazardous materials like lead or mercury are used

Waste and emissions are minimized

Packaging is recyclable and eco-friendly

We combine product quality with environmental responsibility — a value that defines every Concord product.

Why Choose Concord Industries?

Over 20 years of industry expertise

Trusted by top-tier Indian appliance brands

Capable of high-volume production with consistent quality

Timely delivery and nationwide logistics support

Custom solutions for OEMs and global buyers

Conclusion

The mixer power cord may seem like a small component, but it plays a big role in ensuring kitchen appliances work smoothly and safely. At Concord Industries, we build power cords that are engineered to withstand the demands of everyday use — with safety, flexibility, and durability at the core of our design.

If you're looking for reliable mixer power cords for your appliances or distribution channels, Concord Industries is your trusted manufacturing partner — delivering quality you can plug into with confidence.

Visit:- https://concordindustries.in/mixer-power-cord-manufacturer/

0 notes

Text

Reliable Herbal Medicine Testing Services – India

India, being the global hub of Ayurveda and traditional herbal medicine, ayurvedic medicines testing labs has witnessed an increasing demand for reliable herbal medicine testing services to ensure the safety, quality, and efficacy of products reaching both domestic and international markets.

As the herbal industry grows rapidly with consumers turning toward natural and plant-based remedies, it has become essential for manufacturers, exporters, and healthcare providers to verify their products through scientific testing. Reliable herbal medicine testing

services in India provide comprehensive laboratory support to assess the purity, identity, potency, and safety of raw herbs, extracts, and finished formulations like tablets, capsules, syrups, oils, and powders. These services are critical not only for compliance with national regulations such as AYUSH, FSSAI, and the Drugs and Cosmetics Act but also for meeting global standards laid out by authorities in the USA, Europe, the Middle East, and Southeast Asia. The testing process typically begins with raw material authentication to prevent adulteration and misidentification, a common challenge in herbal sourcing.

This includes microscopic analysis and modern chromatographic techniques like HPTLC and HPLC for identifying active botanical constituents. Reliable labs also carry out detailed physicochemical testing, including pH, ash values, moisture content, extractive values, and solubility, which help establish baseline quality parameters. Ensuring safety is a core aspect of herbal testing.

Accredited labs in India conduct thorough contamination testing for heavy metals (lead, mercury, arsenic, cadmium), pesticide residues, microbial load (such as E. coli, Salmonella, and mold), and aflatoxins. These contaminants, if undetected, can pose serious health risks to consumers and may result in product recalls or export rejections. Therefore, testing ensures that herbal products are not only effective but also safe for human use.

Moreover, stability and shelf-life studies are conducted to determine product longevity and validate label claims regarding expiry dates and storage conditions. India's top herbal testing laboratories are often NABL-accredited and ISO/IEC 17025-compliant, assuring that testing methods, equipment, and technicians meet global

benchmarks for quality and consistency. These labs are equipped with advanced analytical instruments such as Gas Chromatography (GC), Mass Spectrometry (MS), FTIR, UV-Vis spectrophotometers, and Atomic Absorption Spectroscopy (AAS), enabling accurate detection and quantification of ingredients and contaminants.

Many offer end-to-end services, including preparation of Certificates of Analysis (CoA), regulatory documentation, product dossier support, and even guidance on international compliance for herbal exports.

Their services are crucial for Ayurvedic and nutraceutical companies aiming to build trust, expand globally, and differentiate their brand in a competitive marketplace. Reliable herbal medicine testing also helps foster innovation, as R&D teams can scientifically evaluate the effects and composition of new plant-based formulations. In conclusion, India’s reliable herbal medicine testing services provide the essential scientific backbone that supports the ancient wisdom of Ayurveda in the modern world.

These services ensure that consumers receive safe, high-quality, and effective products while enabling herbal businesses to grow with credibility, compliance, and confidence in the global market.

follow more information:

https://isspllab.com/services-ayush-herbal-products/

1 note

·

View note

Text

How to choose a reliable oil seal manufacturer