#IEC 61158

Explore tagged Tumblr posts

Text

BLIIoT EtherCAT EdgeIO Distributed IO Module BL200EC

1. What is EtherCAT protocol?

Brief introduction

EtherCAT (Ethernet for Control Automation Technology) is an Ethernet-based fieldbus system invented by Beckhoff Automation. The protocol is standardized in IEC 61158 and is suitable for both hard and soft real-time computing requirements in automation technology.

The goal during development of EtherCAT was to apply Ethernet for automation applications requiring short data update times (also called cycle times; ≤ 100 μs) with low communication jitter (for precise synchronization purposes; ≤ 1 μs) and reduced hardware costs.

Protocol

The EtherCAT protocol is optimized for process data and is transported directly within the standard IEEE 802.3 Ethernet frame using Ethertype 0x88a4. It may consist of several sub-telegrams, each serving a particular memory area of the logical process images that can be up to 4 gigabytes in size. The data sequence is independent of the physical order of the nodes in the network; addressing can be in any order. Broadcast, multicast and communication between slaves is possible, but must be initiated by the master device. If IP routing is required, the EtherCAT protocol can be inserted into UDP/IP datagrams. This also enables any control with Ethernet protocol stack to address EtherCAT systems.

2. EtherCAT Edge Distributed IO Module BL200EC

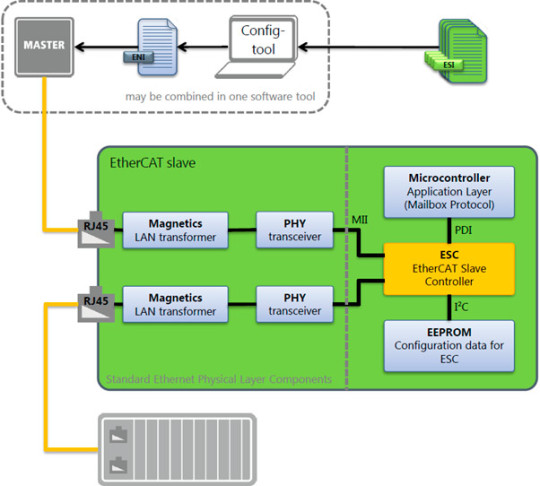

The BL200EC coupler supports the standard EtherCat protocol access, the coupler supports the maximum input 1024 byte, the maximum output of 1024 byte, and the number of supported IO modules is 32.

EtherCAT I/O Coupler BL200EC designed for Industrial Real-Time Ethernet, it adopts embedded Linux system, equips with Real-Time Ethernet interface chip and a dual-port memory,supports two communication channels for Real-Time Ethernet equipped with PHY or fieldbus,compatible with EtherCAT,fast SPI host interface with Read/Write functions.

3. Typical applications

Typical application fields for EtherCAT are machine controls (e.g. semiconductor tools, metal forming, packaging, injection molding, assembly systems, printing machines, robotics). Remote controlled hump yard facilities used in the railroad industry.

Control and Adjustment

For the control and adjustment of the physical process, high data integrity, data security and synchronization are needed. Ethercat is designed for such applications to meet all the needs of rapid control.

Measuring System

The characteristics of modern measurement systems are multi -channel, synchronization and accuracy. Due to EtherCat's advanced protocol characteristics, it ensures high -efficiency synchronous data throughput. Based on the Ethernet network characteristics, the measurement network has a distributed measurement module.

The BL200EC coupler is used as EtherCat from the station. It is connected to the Ethercat main station based on Ethernet through the ETH 1 interface. ETH 1 can also connect to the EtherCat main station through the switch. ETH2 is used to connect other nodes that need to access Ethernet. Essence The BL200EC couplet does not have a separate webpage configuration interface.

4. Features

Maximum 32 I/O modules can be connected;

Support a variety of industrial communication EtherCAT protocols.

Support access to Alibaba Cloud, Huawei Cloud, AWS Cloud, Thingsboard, Ignition, etc.;

Built-in programmable logic control, edge computing;

The field side, the system side and the bus side are electrically isolated from each other;

Support 2 X RJ45 interface, integrate switch function, can establish line topology, save switch or hub; The dual network ports adopt the MAC layer data exchange technology to realize the cascade between modules, and the downtime of the middle module will not affect the data transmission of the following equipment.

Convenient wiring connection technology, screw-free installation.

More information: https://www.iot-solution.com/ethercat-io-module-p00349p1.html

0 notes

Text

마이크로칩, 시간민감네트워크(TSN) 지원 이더넷 스위치 출시

마이크로칩, 시간민감네트워크(TSN) 지원 이더넷 스위치 출시

LAN9668 TSN 스위칭 디바이스 제품군 마이크로칩테크놀로지(아시아 총괄 및 한국대표: 한병돈)가 산업자동화 현장에서 실시간 제조 공정을 수행할 수 있도록 시간민감네트워크(TSN)을 지원하는 새로운 산업용 이더넷 스위치인 ‘LAN9668 TSN 스위칭 디바이스 제품군’을 출시했다고 밝혔다. 이 제품군은 업계 최초의 스위칭 솔루션에서 IEEE 표준 호환 기능을 제공하여 데이터 트래픽 지연을 줄이고 클럭 정확도를 높여준다. 특히 이번 LAN9668x는 마이크로칩의 LAN8814 4포트 기가비트 이더넷 PHY(Physical Layer) 트랜시버를 추가함으로써 성능 실현을 구현했다. 마이크로칩의 LAN9668-I/9MX 및 LAN9668-9MX 디바이스는 각각 Arm® Cortex®-A7 CPU(중앙 처리…

View On WordPress

0 notes

Text

LAN Line (04/05/2021)

Der Stand der Dinge bei Single Pair Ethernet

... Dieser Ansatz findet sich in einem speziellen Technischen Report wieder, den die ISO/IEC JTC 1 SC 25/WG 3 im Auftrag der Industrie-Anwender entwickelt und publiziert. Der Report heißt ISO/IEC 11801.

1 note

·

View note

Text

Bus Cable Manufacturers in India

Bus Cable or modern correspondence links are utilized for the advanced sign transmission among sensors and the comparing show units. Because of the great transmission rate and information stream, standard information links are not adequate longer. For applications concerning model package transport lines, arranging units in reusing plants and waste glass arranging an extremely speedy transmission, evaluation and response are of most noteworthy significance. We produce links for practically all standard transport systems concerning model Interbus-S and circle,

In the accompanying outline, we might want to provide you with an overview of transport and ethernet links for the different transport systems that are frequently utilized for modern applications. On the off chance that you don't observe a suitable link for your transport framework kindly reach out to our link specialists. As a main unique link producer, we can plan and deliver a modern correspondence link that meets your necessities.

Bus Cable Manufacturers in India-igus

Interbus has been created for the sensor/actuator correspondence in the mechanization strategy. 61158 and 61784. For the principle application fields different link types are characterized: remote transport link, establishment remote transport link, S-line, and circle.

Utilizations of Interbus-Loop links

The two-guide Interbus-Loop link is to be applied as an information transmission link as well concerning the inventory of sensors. The three-guide Interbus-Loop links are applied for the supply of actuators. These links are likewise reasonable for Interbus-Loop 2.

Utilizations of CAN-Bus links

Links for a Controller Area Network have been normalized for various application fields. The biggest spreading has the fast kind acc. to ISO 11898-2. The transport is streamlined for a band proficient advanced data trade on the regulator level.

Uses of DeviceNet™ links

In light of CAN structures, DeviceNet was created for the modern interaction robotization on the North American landmass. This framework is isolated into the Trunk and Drop link.

Bus Cable Manufacturers in India-igus

igus systems are particularly made for process computerization (PA). igus is normalized acc. to IEC 61158 which implies the best interoperability of parts from various makers. The secluded fringe development (DP: decentralized outskirts) of the transport framework works on establishment and support. The igus type An is by and large utilized in current frameworks, links of igus type B are just utilized for substitution reasons in previously existing frameworks.

These links generally have a spiral symmetric development. This empowers the utilization of extraordinary stripping apparatuses that make conceivable a faster and simpler bridling and establishment.

SafetyBUS is an open transport framework that has been particularly enhanced for the transmission of information as to machine wellbeing: the consistency of information concerning time and items have the most elevated need. SafetyBUS satisfies an assortment of best expectations to ensure the security of people and merchandise during creation.

Igus manufactures the best such as

chainflex® transport link CF888

For adaptable focusing on the limit, PVC external coat, safeguarded, fire-resistant

chainflex® transport link CF898

For adaptable focusing on the limit, iguPUR external coat, oil-safe, safeguarded, fire-resistant

chainflex® transport link CFBUS

For incredibly uncompromising use, TPE external coat is protected, impervious to oil/natural oil, fire-resistant, hydrolysis-safe, and organism safe.

0 notes

Link

0 notes

Text

Ethernet Controller Market is Estimated To Expand At a Healthy CAGR in The Upcoming Forecast 2025

The ethernet controller market is expected to register a CAGR of 6.1% during the forecast period 2020-2025. As Ethernet controller controls Ethernet communications, the trend towards industrial Ethernet physical layer (PHY) products to help manufacturers addressing key Industry 4.0 and smart factory communication challenges surrounding data integration, synchronization, edge connectivity, and system interoperability is highly being adopted. The ADIN1300, for example, is a low-power, single-port Ethernet transceiver designed for time-critical industrial Ethernet applications up to Gigabit speeds and designed to operate reliably in harsh industrial conditions over extended ambient temperature ranges. It is the latest technology developed for the company’s ADI Chronous portfolio of industrial Ethernet solutions. - Adoption of EtherCat for the real-time network for machine control drives the market. EtherCAT uses the implementation of on-board Ethernet controller integrated via Direct Memory Access (DMA), so no CPU capacity is required for the data transfer between the master device and the network providing higher orders of magnitude faster than Profibus, DeviceNet, and ModbusTCP. Automation equipment manufacturers can use EtherCAT on their own device implementations to improve performance and flexibility, while end-users and automation system designers can implement their own EtherCAT-compliant devices. Further, EtherCAT is part of several IEC Standards (61158, 61784, 61800), ISO 15745, and is also a SEMI standard (E54.20).

Click Here to Download Sample Report >> https://www.sdki.jp/sample-request-86056 - In April 2020, Renesas Electronics Corporation announced the RX72N Group and RX66N Group of 32-bit microcontrollers (MCUs), new additions to the RX Family that combines equipment control and networking function on a single chip with EtherCAT support.

- The adoption of USB Ethernet controllers drives the market. There are various protocols for Ethernet-style networking over USB. The main function of these protocols is to allow the application-independent exchange of data with USB devices, instead of specialized protocols such as video or MTP. Even though USB is not a physical Ethernet, the networking stacks of all major operating systems are set up to transport IEEE 802.3 frames.

- For instance, implementing the KL5KUSB121 10/100 Base-T USB-Ethernet controller provides highly integrated 16-bit RISC CPU, mask ROM, and RAM buffer coupled with serial, external memory, and SPORT interfaces. It easily converts USB to Ethernet. The chip's internal processor enables a remote network device interface specification that provides compatibility with next-generation operating systems and faster data transfers and is well suited for LAN, Home Area Network, cable modem, set-top boxes, or mobile networking applications.

- The impact of COVID-19 has provided the restraints to market growth. There is nearly an 80% chance for significant contraction in worldwide semiconductor revenues in 2020, which also affects the market of ethernet controllers due to the massive slowdown of the supply chain. A player such as Arista, Cisco, Juniper, and many others in the 400GbE ecosystem planned to demonstrate interoperability and the growing volume of 400GbE wares at OFC (Optical Fiber Communication Conference and Exhibition) 2020 and the major networking vendors working on 400GbE were reported some degree of 400G implementation, but the players have decided to manufacture in the first half of 2021, and currently, the production has been stopped. - Further, as the epidemic has caused the manufacturing industry to slow down, the requirement of EtherCAT in the industry is most vital as it provides real-time, deterministic, high performance, and open industrial Ethernet network protocol and can ensure the data transmission certainty and real-time. In April 2020, ASIX Electronics Corporation announced to supply EtherCAT Slave Controller SoC in China and other parts of the world, which caters to the significant assistance in the market growth. But overall, the growth is restrained due to negligible demand from all the sectors. Key Market Trends Gigabit Ethernet to Witness Growth in Data Centers - Data-intensive applications such as big data and cloud computing continue to grow at an accelerating rate. Multiple terabits of data travel to and from the data center each second. Moving such massive data around the data center requires a robust infrastructure that is capable of handling high bandwidth data delivery having high IP traffic to and from storage endpoints, servers, top-of-rack (TOR) switches, and core switches. This penetrates the demand of an ethernet controller, which connects devices using media access control (MAC) addresses. - Players such as Marvell Ethernet Network Adapters and Controllers are purpose-built to accelerate and simplify data center, PC and workstation networking. Marvell Ethernet controllers deliver Ethernet connectivity speeds ranging from NBASE-T for Workstations to data center-class 10/25/50/100GbE for high-volume software-defined datacenters. - Further, rising power consumption and costs related to continuous growth in data are bringing data centers to face the challenges of delivering greater storage bandwidth and capacity. To address such issues, in April 2020, Marvell’s MRVL QLogic Fibre Channel and FastLinQ Ethernet adapter solutions will now enable NVMe over Fabrics (NVMe-oF) technology in VMwarevSphere 7.0, displaying its continued efforts to strengthen its end-to-end Ethernet storage and bandwidth capabilities. - Further, with an increasing demand for networking speed and throughput performance within the data center and high-performance computing clusters, in April 2020, the newly rebranded Ethernet Technology Consortium has announced a new 800 Gigabit Ethernet technology for data center replacing the 400 Gigabit Ethernet. The 800 B base-R specification (or 800 GbE) will need new definitions for media access control (MAC) and physical coding sublayer (PCS). This further benefits hyperscale datacenter networks that span a large number of nodes and require multiple hops. - Furthermore, in April 2020, Tyan has officially announced its support for the new chips on selecting models of their Transport HX barebones servers, which are designed for high-performance computing and server data-driven workflows. It includes Transport HX TN83-B8251, TS75A-B8252, and the TS75-B8252, where on the motherboard, there is an Intel X550-AT2 dual 10 G Ethernet controller, with a dedicated Realtek IPMI Ethernet port, and an Aspeed AST2500 BMC. Each model has offered its own benefits for the server, data center, and high-frequency trading systems.

- Moreover, as the demand for public cloud services continues to grow, hyper-scale data centers and cloud providers increasingly rely on multicore SmartNIC solutions to offload infrastructure services and workloads to maximize server utilization. In March 2020, Broadcom Inc. announced that its Stingray adapter, the industry’s first 100G SmartNIC (integrated NetXtreme Ethernet Controller), is powering Baidu Cloud with unprecedented levels of performance. The Stingray adapter’s exceptional levels of integration, includes eight ARM A72 CPU cores running at 3GHz, 300G of memory bandwidth.

Click Here to Download Sample Report >> https://www.sdki.jp/sample-request-86056 North America Accounts for Significant Share - North America accounts for a significant share. With the increase in the development of technology along with the adoption of a high rate of consumer electronics such as gaming consoles, etc., the demand for the ethernet controller is growing in this region.

- For instance, in April 2020, Killer announced the Killer E3100 Ethernet controller is improving the internet performance by prioritizing gaming and rescuing up CPU power and PC memory. It reaches speeds up to 2.5Gbps and can combine with Killer Wi-Fi products to reach up to 4.9 Gbps of theoretical throughput. The Killer 3100 is available in systems from Acer and MSI, including the newly announced MSI Creator 17 and MSI GE66 Raider.

- Further, as the automotive industry increasingly adopts Ethernet in-vehicle networks for mainstream models, the number of related ports is expected to grow at a 62% annualized growth trajectory, from 53 million in 2018 to 367 million by 2022, according to Marvell Technology Group. Moreover, in September 2019, Marvell Technology Group completed the acquisition of Aquantia Corporation to expand the market in automotive solutions. - The acquisition of Aquantia complements Marvell’s portfolio of copper and optical, physical layer product offerings, and extends its position in the Multi-Gig 2.5G/5G/10G Ethernet segments. In particular, Aquantia’s innovative Multi-gig automotive PHYs, coupled with Marvell’s gigabit PHY and secure switch products, creates a broad range of high-speed in-car networking solutions. - Further, in November 2019, Astronics Ballard announced to embed an open architecture with a 64-bit processing foundation and Ethernet backbone across its next generation of NG avionics input/output (I/O) computers. Inside the next generation, boxes are simple converters capable of supporting Ethernet, MIL-STD-1553 and ARINC 429 among other data bus protocols, and the processing is capable of enabling advanced distributed control and mission computing on fighter jets, drones, and helicopters. - To support the instance, in January 2019, U.S. Air Force, Army, and Navy officials signed a memorandum agreeing that future acquisitions of new aircraft technologies will focus on using the Modular Open Systems Approach (MOSA). In addition to MOSA, the NG computers also meet the design requirements for DoD’s Open Mission Systems (OMS) standard. This enhances the demand for the market in this sector.

Competitive Landscape The ethernet controller market is fragmented in nature due to high competition. Despite the fragmentation, the market is largely tied by the regulatory requirements for establishment and operation. Further, with increasing innovation, acquisitions, and partnerships, the rivalry in the market tends to be increasing in the future. Key players are Intel Corporation and Broadcom Inc. Recent developments in the market are - - March 2020 - Ethernity Networks introduced its ENET-D, an add-on Ethernet Controller technology to its ACE-NIC100 SmartNIC that efficiently processes millions of data flows and offers performance acceleration for networking and security appliances. ENET-D is an Ethernet adapter and DMA (direct memory access) engine that eliminates the need for proprietary hardware on a network interface card. By fitting into various FPGAs and enabling customers to further avoid ASIC-based components, ENET-D advances complete disaggregation at the edge of the network. The dynamic nature of business environment in the current global economy is raising the need amongst business professionals to update themselves with current situations in the market. To cater such needs, Shibuya Data Count provides market research reports to various business professionals across different industry verticals, such as healthcare & pharmaceutical, IT & telecom, chemicals and advanced materials, consumer goods & food, energy & power, manufacturing & construction, industrial automation & equipment and agriculture & allied activities amongst others.

For more information, please contact:

Hina Miyazu

Shibuya Data Count Email: [email protected] Tel: + 81 3 45720790

0 notes

Photo

#roboteq #nidec #robotics #tech #engineering #motorcontrollers #ethercat

EtherCAT (IEC 61158) is an Ethernet-based fieldbus system that is ideally suited for multi-axis robotics applications thanks to its microsecond-level synchronization between drives. EtherCAT is available in a growing selection of RoboteQ controllers. See more on our website (link in bio)

0 notes

Text

How PROFINET was developed?

How #PROFINET was developed?

An innovative open standard for an industrial Ethernet that was developed by Siemens and the Profibus User Organization (PNO) is defined as PROFINET. The solutions for factory and process automation can be implemented with PROFINET such as for safety applications or for clock synchronization motion which is for the drive technology of an entire range. The standard for PROFINET is IEC 61158 and…

View On WordPress

0 notes

Text

Download Engineering Standard | SAES-J-904

Download Engineering Standard | SAES-J-904

FOUNDATION Fieldbus (FF) Systems

This standard defines the requirement for design, specification, installation, configuration, commissioning and maintenance for FOUNDATION™ Fieldbus based control systems. This specification will only discuss the voltage mode (parallel coupling) 100 ohm medium attachment unit, as defined in IEC 61158- 2, operating at a signal speed of 31.25 kilobits per second…

View On WordPress

0 notes

Text

Industrial Fieldbus Solution Market Expected To Create Lucrative Opportunities For The Global Market

Industries have started adopting technologically-advanced solution to increase the efficiency of plants and decrease downtime. Industrial fieldbus solution are a part of this advancement. In order to stay ahead of their competitors, industries and other manufacturing plants are soon adopting advanced automation to provide good quality products to their customers as well as maximize their profits and productivity. Industrial fieldbus solution are a part of this advanced automation. Industrial fieldbus solution are a part of industrial communication networks that are connecting factories to the smart factory techniques.

Are you a start-up willing to make it big in the business? Grab an exclusive PDF Brochure of this report

Market Overview:

Industrial fieldbus solution are standardized as IEC 61158 and find use in real-time distributed control system applications. Industrial fieldbus solution represent a group of industrial computer network protocols. Manufacturing assembly lines require distributed control system wherein industrial fieldbus solution are applied. In distributed control systems, there is a Human Machine Interface (HMI) at the top. Then, there is a Programmable Logic Controller (PLC) in the middle layer connected to the top layer via Ethernet. The bottom layer consists of a fieldbus that links the PLC to the components such as contactors, valves, switches, electric motors, actuators and sensors that do the actual work. Basically, industrial fieldbus solution provide ways to connect instruments in industries or manufacturing plants. Industrial fieldbus solution work on networks that allow a variety of topologies such as tree, star, daisy-chain, branch and ring topologies.

Market Dynamics:

Earlier, RS-232 connectors were used to connect computers. But, only two devices can communicate via RS-232 connectors. RS_2322 connectors operate in a very similar manner to the currently used 4-20 mA schemes for communication. In the 4-20 mA schemes for communication, at the controller level, each device needs to have its own communication point. Industrial fieldbus solution are exactly opposite to the above-mentioned technologies and very similar to LAN-type connections used in homes and offices. In industrial fieldbus solution, a single communication point is required at the controller level such that hundreds of industrial equipment can be connected to each-other. This factor greatly reduces the amount of cabling that was required earlier because the same set of cables are shared in a multi-drop style. Industrialists are now shifting to industrial fieldbus solution and replacing the older similar technologies. Requirement for optimized plant asset management is another factor that is driving the growth of the Industrial Fieldbus Solution market. Industrial fieldbus solution help operators communicate with sensors and other plant assets in real-time in such a way that operators are able to check the status of the plant assets. This helps in increasing productivity of plant. The integration of IIoT with the industrial fieldbus solution for application in the process industries is enhancing the demand for industrial fieldbus solution in the market. Integration of IIoT with the industrial fieldbus solution provides high performance, better connectivity, security, and safety.

0 notes

Text

Industrial Fieldbus Solution Market - Global Industry Analysis, Size, Share

Industries have started adopting technologically-advanced solution to increase the efficiency of plants and decrease downtime. Industrial fieldbus solution are a part of this advancement. In order to stay ahead of their competitors, industries and other manufacturing plants are soon adopting advanced automation to provide good quality products to their customers as well as maximize their profits and productivity. Industrial fieldbus solution are a part of this advanced automation. Industrial fieldbus solution are a part of industrial communication networks that are connecting factories to the smart factory techniques.

Market Overview:

Industrial fieldbus solution are standardized as IEC 61158 and find use in real-time distributed control system applications. Industrial fieldbus solution represent a group of industrial computer network protocols. Manufacturing assembly lines require distributed control system wherein industrial fieldbus solution are applied. In distributed control systems, there is a Human Machine Interface (HMI) at the top. Then, there is a Programmable Logic Controller (PLC) in the middle layer connected to the top layer via Ethernet. The bottom layer consists of a fieldbus that links the PLC to the components such as contactors, valves, switches, electric motors, actuators and sensors that do the actual work. Basically, industrial fieldbus solution provide ways to connect instruments in industries or manufacturing plants. Industrial fieldbus solution work on networks that allow a variety of topologies such as tree, star, daisy-chain, branch and ring topologies.

Market Dynamics:

Earlier, RS-232 connectors were used to connect computers. But, only two devices can communicate via RS-232 connectors. RS_2322 connectors operate in a very similar manner to the currently used 4-20 mA schemes for communication. In the 4-20 mA schemes for communication, at the controller level, each device needs to have its own communication point. Industrial fieldbus solution are exactly opposite to the above-mentioned technologies and very similar to LAN-type connections used in homes and offices. In industrial fieldbus solution, a single communication point is required at the controller level such that hundreds of industrial equipment can be connected to each-other. This factor greatly reduces the amount of cabling that was required earlier because the same set of cables are shared in a multi-drop style. Industrialists are now shifting to industrial fieldbus solution and replacing the older similar technologies. Requirement for optimized plant asset management is another factor that is driving the growth of the Industrial Fieldbus Solution market. Industrial fieldbus solution help operators communicate with sensors and other plant assets in real-time in such a way that operators are able to check the status of the plant assets. This helps in increasing productivity of plant. The integration of IIoT with the industrial fieldbus solution for application in the process industries is enhancing the demand for industrial fieldbus solution in the market. Integration of IIoT with the industrial fieldbus solution provides high performance, better connectivity, security, and safety.

Nowadays, industrial fieldbus solution providers are incorporating devices such that controller does not have to perform the processing task as well. PID control, a type of control scheme is increasingly being installed with the industrial fieldbus solution.

Request PDF Brochure: https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=32753

Market Segmentation:

Industrial Fieldbus Solution market is segmented into three types based on product type, end-user type, and by region.

Based on the product type, Industrial Fieldbus Solution market is segmented into Foundation fieldbus Profibus, SERCOS, Modbus, AS-I, and DeviceNet.

Based on the application type, Industrial Fieldbus Solution market is segmented into power generation, flowmeters, hydrocarbon processing, pressure transmitters, control valves, and other measurement devices.

Based on the region type, Industrial Fieldbus Solution market is segmented into- Latin America, North America, Asia-Pacific Except Japan (APEJ), Western Europe, Eastern Europe, Middle-East and Africa (MEA) and Japan.

North America holds the highest market share in the Industrial Fieldbus Solution market. Oil and gas industry, in particular, is seeing tremendous demand for the industrial fieldbus solution. Oil and gas plants require industrial fieldbus solution for secure and robust communication that ensure efficient plant operation.

Key Players:

The industrial fieldbus solution market is well-versed with the presence of a lot of vendors in the market. The players in the market are competing with each-other on the parameters such as technological advancements, service support, price, distribution channels, and quality.

Some of the players operating in the Industrial Fieldbus Solution market include - Schneider Electric, Yokogawa Electric, ABB, SAMSON, Emerson Electric, Pepperl+Fuchs, Endress+Hauser, Metso, Siemens, Krohne Group, Azbil Corporation, and Eaton Corporation.

Simatic PDM Maintenance Station V2.0 is a technology created by Siemens. Simatic PDM Maintenance Station V2.0 efficiently monitors the status of the intelligent field devices independent of the control system and automation used. Simatic PDM Maintenance Station V2.0 is used in a variety of applications such as monitoring of intelligent field components and field devices, project engineering, and parameterization.

With the world heading towards automation at a fast pace, industries are not staying behind. Smart factory technologies such as industrial fieldbus solution are not only helping the industries increase efficiency and productivity of the plants but also helping in ensuring the safety of the plants. Owing to these factors, the Industrial Fieldbus Solution market is estimated to grow at a high CAGR during the forecast period from 2017 to 2027.

0 notes

Text

Industrial Fieldbus Solution Market To 2025 Anticipated To Predict A Promising Growth Rate During The Forecast Period

Industries have started adopting technologically-advanced solution to increase the efficiency of plants and decrease downtime. Industrial fieldbus solution are a part of this advancement. In order to stay ahead of their competitors, industries and other manufacturing plants are soon adopting advanced automation to provide good quality products to their customers as well as maximize their profits and productivity. Industrial fieldbus solution are a part of this advanced automation. Industrial fieldbus solution are a part of industrial communication networks that are connecting factories to the smart factory techniques.

Market Overview:

Industrial fieldbus solution are standardized as IEC 61158 and find use in real-time distributed control system applications. Industrial fieldbus solution represent a group of industrial computer network protocols. Manufacturing assembly lines require distributed control system wherein industrial fieldbus solution are applied. In distributed control systems, there is a Human Machine Interface (HMI) at the top. Then, there is a Programmable Logic Controller (PLC) in the middle layer connected to the top layer via Ethernet. The bottom layer consists of a fieldbus that links the PLC to the components such as contactors, valves, switches, electric motors, actuators and sensors that do the actual work. Basically, industrial fieldbus solution provide ways to connect instruments in industries or manufacturing plants. Industrial fieldbus solution work on networks that allow a variety of topologies such as tree, star, daisy-chain, branch and ring topologies.

Planning To Lay Down Future Strategy? Request Sample https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=32753

Market Dynamics:

Earlier, RS-232 connectors were used to connect computers. But, only two devices can communicate via RS-232 connectors. RS_2322 connectors operate in a very similar manner to the currently used 4-20 mA schemes for communication. In the 4-20 mA schemes for communication, at the controller level, each device needs to have its own communication point. Industrial fieldbus solution are exactly opposite to the above-mentioned technologies and very similar to LAN-type connections used in homes and offices. In industrial fieldbus solution, a single communication point is required at the controller level such that hundreds of industrial equipment can be connected to each-other. This factor greatly reduces the amount of cabling that was required earlier because the same set of cables are shared in a multi-drop style.

Industrialists are now shifting to industrial fieldbus solution and replacing the older similar technologies. Requirement for optimized plant asset management is another factor that is driving the growth of the Industrial Fieldbus Solution market. Industrial fieldbus solution help operators communicate with sensors and other plant assets in real-time in such a way that operators are able to check the status of the plant assets. This helps in increasing productivity of plant. The integration of IIoT with the industrial fieldbus solution for application in the process industries is enhancing the demand for industrial fieldbus solution in the market. Integration of IIoT with the industrial fieldbus solution provides high performance, better connectivity, security, and safety.

Nowadays, industrial fieldbus solution providers are incorporating devices such that controller does not have to perform the processing task as well. PID control, a type of control scheme is increasingly being installed with the industrial fieldbus solution.

Request For COVID19 Impact Analysis Across Industries And Markets - Industrial Fieldbus Solution Market

Key Players:

The industrial fieldbus solution market is well-versed with the presence of a lot of vendors in the market. The players in the market are competing with each-other on the parameters such as technological advancements, service support, price, distribution channels, and quality.

Some of the players operating in the Industrial Fieldbus Solution market include - Schneider Electric, Yokogawa Electric, ABB, SAMSON, Emerson Electric, Pepperl+Fuchs, Endress+Hauser, Metso, Siemens, Krohne Group, Azbil Corporation, and Eaton Corporation.

Simatic PDM Maintenance Station V2.0 is a technology created by Siemens. Simatic PDM Maintenance Station V2.0 efficiently monitors the status of the intelligent field devices independent of the control system and automation used. Simatic PDM Maintenance Station V2.0 is used in a variety of applications such as monitoring of intelligent field components and field devices, project engineering, and parameterization.

With the world heading towards automation at a fast pace, industries are not staying behind. Smart factory technologies such as industrial fieldbus solution are not only helping the industries increase efficiency and productivity of the plants but also helping in ensuring the safety of the plants. Owing to these factors, the Industrial Fieldbus Solution market is estimated to grow at a high CAGR during the forecast period from 2017 to 2027.

More Trending Reports by Transparency Market Research –

Bakery Processing Equipment Market https://www.globenewswire.com/news-release/2019/04/11/1802882/0/en/Bakery-Processing-Equipment-Market-to-Reach-US-23-441-7-Mn-by-2026-Owing-to-Rising-Consumption-of-Baked-Products-Noted-TMR.html

Smart Camera System Market https://www.prnewswire.com/news-releases/smart-camera-system-market-to-ride-the-wave-of-internet-of-things-from-2019-to-2027-transparency-market-research---concludes-a-tmr-study-301004424.html

0 notes

Text

국제 표준 기술 특허 주도권 확보 시급하다

국제 표준 기술 특허 주도권 확보 시급하다

스마트그리드, 국제 표준 특허 현황 분석

국제표준이 기업의 글로벌 경쟁력 강화를 위한 핵심수단으로 자리잡음에 따라 국제표준특허 창출을 위한 기업간 경쟁이 치열해지고 있다. 이러한 흐름은 주요 5대 표준화기구에 선언된 표준특허 건수가 2009년 29,649건에서 2013년 44,256건으로 1.5배 증가한 것에서도 확인할 수 있다. 국제 표준 기술 특허 주도권을 초기에 적극 확보하는 것이 시급하다.

표준특허는 표준 규격을 기술적으로 구현하는 과정에서 침해할 수밖에 없는 특허를 말한다. 표준특허는 특허침해를 폭넓고 쉽게 주장할 수 있고, 회피설계도 어려워 상당한 로열티 수입을 가져다준다. 이러한 이유로 스마트그리드 산업에서도 다국적 기업들은 표준특허 확보에 전력을 다하고 있으며, 표준특허가 시장을 선점하기…

View On WordPress

#icnweb#IEC 61158#IEC 61850#IEC 62439#top#로크웰오토메이션#변전자동화#사물인터넷#슈나이더일렉트릭#스마트그리드#스마트제조#시스코#아이씨엔#오승모#오토메이션#필드버스

0 notes

Text

Elcano Royal Institute (15/01/2019)

Hacia la fusión entre la ciberseguridad industrial y los sistemas de información corporativos

… Entre las áreas clave figura la ciberseguridad, para la cual el comité técnico ISO/TC 292/WG 2 elabora los estándares sobre continuidad y resiliencia; el comité ISO/IEC JTC 1/SC 27, sobre técnicas de seguridad para tecnologías de la información, y el comité IEC/SC 65C/WG13, sobre redes industriales (series IEC 61158 e IEC 61784).

El grupo de trabajo ISO/IEC JTC 1/WG 10 elabora modelos de referencia para aplicaciones del IoT y el ISO/IEC JTC 1/WG 7 se centra en la interoperatividad de redes de sensores IoT. Otras áreas clave son la estandarización y arquitectura de referencia del Big Data (ISO/IEC JTC 1/WG 9); la impresión 3D y la fabricación aditiva (ISO TC 261 y CEN/TC 438); la robótica avanzada (ISO/10218 e ISO/TS 15066), o la computación en la nube y las plataformas distribuidas (ISO/IEC JTC 1/SC 38).

#Industry 4.0#smart manufacturing#cyber security#IIoT#ISO/IEC JTC 1#cloud computing#big data#industrial iot#IEC 61784#IEC 61158

0 notes

Text

Bus Cable Manufacturers in India

Bus links or mechanical correspondence links are utilized for the advanced sign transmission among sensors and the comparing show units. Because of the great transmission rate and information stream, standard information links are not adequate any more. For applications with respect to model bundle transport lines, arranging units in reusing plants and waste glass arranging a fast transmission , evaluation and response are of most noteworthy significance. We make links for virtually all standard transport frameworks concerning model Interbus-S and circle, CAN BUS, Profibus, Profinet, DeviceNet and Safety Bus.

In the accompanying outline we might want to give you an overview of transport and ethernet links for the distinctive transport frameworks that are regularly utilized for mechanical applications. In the event that you don't track down a fitting link for your transport framework if it's not too much trouble, get in contact with our link specialists. As a main exceptional link maker we can plan and to deliver a modern correspondence link that meets your prerequisites.

Modern correspondence links for various feldbus frameworks

Application and choice

Applications of transport links

Selection table transport links

Products

Remote transport links and wires

Interbus-Loop links and wires

CAN-Bus links

DeviceNet Cables

Profibus-DP links and wires

PROFIBUS PA Cables

SafetyBUS p links and wires

Hybrid field transport links and wires

USB 2.0 links and wires

USB 3.0 Cables and Wires

CATLine links for mechanical ethernet applications

CAT 5 Cables

CAT 5 Ethernet Cables

Industrial Gigabit Ethernet Cables

Single-Pair-Ethernet Cables

Industrial Ethernet Cables for use in Rail Vehicles

Industrial Ethernet links CAT 5e/CAT 6A/CAT 7A links for oceanic use

Harnessed link track links

Applications of INTERBUS-S links • distant transport links • establishment far off transport links

Interbus has been created for the sensor/actuator correspondence in the computerization method. This in fact developed framework has been normalized meanwhile acc. to IEC 61158 and 61784. For the primary application fields distinctive link types are characterized: far off transport link, establishment far off transport link, S-line and circle.

Applications of Interbus-Loop links

The two-conductor Interbus-Loop link is to be applied as an information transmission link just as for the stock of sensors. The three-conductor Interbus-Loop links is applied for supply of actuators. These links are additionally appropriate for Interbus-Loop 2.

Applications of CAN-Bus links

Cables for a Controller Area Network have been normalized for various application fields. The biggest spreading has the high velocity type acc. to ISO 11898-2. The transport is upgraded for a band productive computerized data trade on the regulator level.

Applications of DeviceNet™ links

Based on CAN structures, DeviceNet was created for the mechanical cycle robotization on the North American landmass. This framework is separated into Trunk and Drop link.

Applications of Profibus links

PROFIBUS frameworks are particularly made for measure robotization (PA). PROFIBUS is normalized acc. to IEC 61158 that implies best interoperability of segments from various fabricates. The measured fringe development (DP: decentralized outskirts) of the transport framework improves on establishment and support. The PROFIBUS type An is for the most part utilized in current frameworks, links of PROFIBUS type B are just utilized for substitution reasons in previously existing frameworks.

Fast Connect link development

These links generally have an outspread symmetric development. This empowers the utilization of unique stripping devices that make conceivable a speedier and simpler saddling and establishment.

Applications of SafetyBUS p links

SafetyBUS is an open transport framework that has been particularly streamlined for the transmission of information concerning machine wellbeing: the consistency of information with respect to time and substance have most elevated needs. SafetyBUS satisfies an assortment of best expectations to ensure the assurance of people and merchandise during creation.

Applications of Hybrid field transport links

S 670 and S 671 are adaptable UL perceived, CSA endorsement mixture field transport control links, reasonable for link constant flexing with optical fiber and copper conveyors. The link S 670 with its polyurethane external coat has a generally excellent obstruction against acids, alkalines, solvents, water driven fluids and oil.

Applications of USB 2.0 and USB 3.0 links

The SAB robot link USB 2.0 and USB 3.0 was produced for high recurrence information transmission in industry. In the business keen picture, preparing frameworks are vital. They are the way to more proficiency, exactness and profitability with the establishment and treatment by robots for the most various applications. Regardless of whether for the distinguishing proof of parts and segments, for visual assessment, welded crease control or for the assortment of scanner tags or type tests; any place a fast and solid assortment and transmission of information from the camera to the modern PC are totally significant. Our exceptionally adaptable robot link USB 2.0 and USB 3.0 was particularly created for this application. It ensures magnificent transmission qualities as it is requested for shrewd picture handling under outrageous mechanical application conditions. The utilization of PC viable parts make conceivable the response to set up guidelines and improves on additional treatment in electronic information preparing frameworks.

0 notes

Text

Control Engineering (11/01/2019)

The significance of industrial networking for the IIoT

… These Institute of Electrical and Electronics Engineers (IEEE) standards define the physical layer and data link layer’s media access control (MAC) of wired Ethernet. A set of common and technology-specific definitions is made available through the International Electrotechnical Commission (IEC) 61158 and IEC 61784-5 series.

0 notes