#IBC Spill Containment

Explore tagged Tumblr posts

Text

Choosing the Right Spill Containment Solution: Industrial Safety and Supply’s Expert Tips

Most businesses don’t think about spill containment until a disaster strikes. Mishandled spills result in fines, safety concerns, or environmental damage. Choosing dependable is a wise decision, one that is also necessary. Industrial Safety and Supply provides expertise and tools meant to meet these demands directly. Every product from this company reflects years of industry knowledge and a dedication to safety.

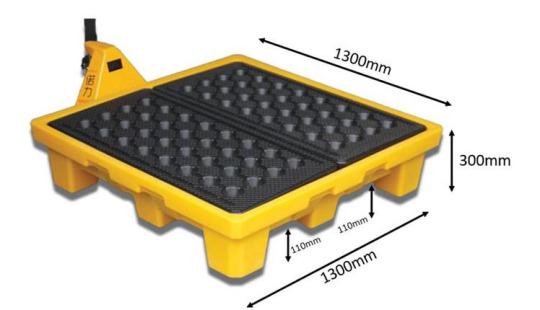

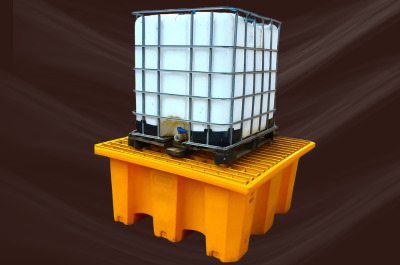

Needs for Containment of Spills Every sector struggles with its puzzle of containment. Federal regulations have strict guidelines for the storage of chemicals. This is where excellent tools like the Ultra IBC Spill Pallet or Ultra-Twin IBC Hard Top can help. These products are made from sturdy polyethylene, providing complete compatibility with most chemicals and resistive qualities that prevent rust and corrosion. These characteristics help companies comply with strict regulations and prevent operational interruption brought on by equipment breakdown. Rain complicates matters in outdoor operations. Units with roll-top covers, like the Ultra-Twin, protect contents against storms and help to support large loads. Uneven weight distribution is not a problem with this tool because steel plates distribute the weight equally. These careful designs provide operational effectiveness even in demanding surroundings. What Defines a Good Spill Solution? For a good spill solution, you want tools for handling spills, rain, and rough handling without breaking a sweat. Open units like the Ultra IBC Spill Containment Pallet can be good indoors but struggle outdoors. Including self-bailing systems or choosing enclosed models fixes this. Also important is flexible design. Products with UV-resistant materials, reinforced bases, and removable grates are going to be good for every circumstance. Good spill control reduces environmental hazards as well. They enable companies to follow sustainable practices. Regardless of the arrangement, following local rules and EPA regulations is still absolutely essential. Ignoring rules runs the risk of fines, as well as the danger of long-term client trust and reputation damage for a business. Why Industrial Safety and Supply Leads the Pack The commitment of this company goes very deep. Years of working with top producers have shown how its products surpass expectations. Simple operations with reasonable pricing of IBC spill containment pallet makes sure that premium equipment is within reach of every business out there. Support is fundamentally strong. They can help you understand complex configurations and make sure your order meets your exact requirements, all with a team that provides unparalleled customer service. Expert consultation supports every order and gives companies confidence in their investments. Find out the ideal product for your needs by visiting https://industrialandsafetysupply.com/ Original Source: https://bit.ly/3OVdxaU

0 notes

Text

IBC Spill Pallet | Spill Containment

Top-quality Spill Prevention at Ocean Safety Supplies!

Discover top-quality spill prevention at Ocean Safety Supplies!

Introducing our IBC spill pallet – your ultimate solution for containing leaks and protecting the environment.

Trust us for reliable, eco-friendly spill solutions.

#Spill Pallet#IBC Spill Pallet#Ocean Safety Supplies#Spill Kit#Spill Containment#Oil Spill Kit#Oil Absorbent Pads

2 notes

·

View notes

Text

IBC Spill Containment Pallets: Best Practices for Use and Benefits

Ensuring spill control and safety is crucial in businesses handling huge amounts of hazardous liquids. These liquids are frequently transported and stored in intermediate bulk containers (IBCs), yet there is a chance of spilling. IBC spill containment pallets are useful in this situation. Because these pallets are designed to reduce environmental damage and increase worker safety, These pallets are crucial for following the safety standards and protecting your business.

In this blog, we will discuss the use and benefits of IBC spill containment pallets.

Understanding IBC Spill Containment Pallets

Pallets designed for IBC spill containment are made especially to store liquids and stop leaks or spills. A containment basin in robust construction collects and holds spills. This prevents them from spilling into the surrounding space. It also stops spills from reaching the floor. The robust materials used to manufacture these pallets like polyethylene, which is resistant to chemicals ensure long-term usage and durability.

Proper Placement and Setup

Where to place: To ensure the best results with your IBC spill containment pallet, carefully place it on a flat, stable surface. Make sure the area around it is free from any obstructions and has easy handling and movement of your IBCs.

Leveling: Make sure the pallet is level to avoid spills brought on by tilting and uneven liquid distribution in the IBC.

Load Bearing Limits: Stick to the weight limits set by the pallet manufacturer. Overloading can compromise its integrity, resulting in spillage.

Handling and Transport

Proper Lifting: Forklifts or pallet jacks are suitable lifting equipment to use while moving IBCs onto and off the spill containment pallet. IBCs should not be dragged or dropped since this could harm the pallet as well as the container.

Secure Positioning: Make sure the IBC is steady and firmly positioned when it has been placed on the pallet. To prevent movement during handling or transportation, use straps or other fastening techniques as needed.

Load Management

Weight Limits: Observe the weight restrictions for the pallets as indicated by the manufacturer. Pallet overloading increases the chance of spills and can harm the structure.

Proper Loading: Position IBCs centrally on the pallets to ensure even weight distribution and stability. Avoid putting multiple IBCs on the same pallet unless it has been designed to handle such weights.

Benefits of Using IBC Spill Containment Pallets

1. Enhanced Safety

Swift’s IBC spill containment pallets are a game-changer for workplace safety. They offer a secure platform to store hazardous materials, giving you peace of mind. With their advanced secondary containment feature, any spills are contained, preventing them from spreading. This means a safer environment, less risk of accidents, and reduced exposure to dangerous chemicals.

2. Cost Savings

Spill and leak control may save you a lot of money. Spills can result in costly cleaning operations, penalties, and damage to equipment and the workplace. Investing in IBC spill containment pallets reduces the multiple costs.

3. Versatility

IBC spill containment pallets have many uses and show up in different industries such as food and drink processing, and chemical production. They can adapt to different needs, which makes them a key tool for any business working with liquids and chemicals. These pallets help keep people safe and make handling these materials more effective.

4. Easy Maintenance

These pallets are built to last and require minimal maintenance. Regular inspections and cleaning assure its longevity and efficacy, giving a long-term spill containment solution.

Conclusion

You may extend the life and efficacy of these pallets by being aware of their design and function, making sure they are positioned and set up correctly, and following safe handling and transportation procedures.

IBC spill containment pallets have many advantages, such as improved worker safety, cost savings from spill prevention, industry adaptability, and ease of maintenance. We at Swift Technoplast are dedicated to offering IBC spill containment pallets of the finest quality that meet industry standards and support the safety of your business.

Swift's products are made to provide 100% Environmentally friendly, sturdy, dependable containment solutions that guarantee worker safety. Invest in Swift Technoplast IBC spill containment pallets to enhance the safety and efficiency of your facility.

#Spill Pallets#Spill Containment Pallet#Spillage Pallet#Drum Spill Containment Pallets#ibc spill pallets#ibc spill containment pallet#ibc pallet#IBC Plastic Pallet#IBC Container Pallet#Intermediate Bulk Container Pallet#IBC Pallet Supplier#IBC Pallet Cost#oil containment pallet

0 notes

Text

Latest Update on RAAH IBC Lifter: Transforming Industrial Material Handling

Industrial operations often demand innovative solutions for safe and efficient handling of heavy containers such as Intermediate Bulk Containers (IBCs). The RAAH IBC Lifter is the ultimate tool designed to meet this challenge. Recently updated with cutting-edge features, this lifter enhances safety, productivity, and convenience for industries that handle IBCs regularly.

Key Updates to the RAAH IBC Lifter

1. Improved Load Capacity

The latest update boosts the lifter's load-bearing capabilities, allowing it to handle heavier IBCs with ease. This feature caters to industries dealing with larger volumes of materials.

2. Advanced Locking Mechanism

The new locking system ensures that IBCs remain securely in place during lifting and transportation. This reduces the risk of accidents and product loss.

3. Enhanced Ergonomic Design

The lifter now features an ergonomic design for better operator control. This minimizes physical strain and ensures smooth operation.

4. Durable Construction

Manufactured with high-grade materials, the updated RAAH IBC Lifter is built to withstand challenging industrial environments while maintaining its performance.

5. Compatibility with Various IBC Types

The lifter is now compatible with a wider range of IBC designs, making it a versatile solution for diverse industrial needs.

Importance of the RAAH IBC Lifter for Industrial Use

1. Ensures Workplace Safety

Handling heavy IBCs manually can lead to injuries and accidents. The RAAH IBC Lifter eliminates these risks by providing a secure and efficient lifting mechanism.

2. Boosts Efficiency

With its enhanced features, the lifter allows for quick and seamless transportation of IBCs, reducing downtime and improving operational flow.

3. Protects Materials

The advanced locking system prevents accidental spills or damages to the IBC’s contents, ensuring the integrity of stored materials.

4. Enhances Compliance

The RAAH IBC Lifter helps businesses adhere to safety regulations by minimizing workplace hazards and improving material handling standards.

5. Reduces Labor Costs

By automating the lifting process, the lifter reduces the need for additional manpower, translating into significant cost savings over time.

Applications of the RAAH IBC Lifter

1. Manufacturing

Ideal for moving raw materials or finished products stored in IBCs across the production floor.

2. Chemical Processing

Ensures the safe handling of hazardous chemicals stored in bulk containers.

3. Food and Beverage Industry

Facilitates the transportation of liquids and food ingredients stored in IBCs, ensuring hygiene and safety.

4. Warehousing and Logistics

Streamlines the loading and unloading of IBCs during transportation and storage processes.

5. Construction

Assists in handling construction materials stored in IBCs, improving site efficiency.

Key Features of the RAAH IBC Lifter

High Load Capacity: Handles heavy IBCs with ease.

Secure Locking Mechanism: Keeps containers safe during transport.

Ergonomic Design: Easy to operate, minimizing worker fatigue.

Versatile Compatibility: Suitable for various IBC types.

Robust Construction: Built for durability and long-term use.

Compact and Lightweight: Allows for easy maneuverability and storage.

Why Choose the RAAH IBC Lifter?

Safety Assurance: Reduces workplace injuries and enhances operational safety.

Cost-Effective: Minimizes labor requirements and material losses.

Productivity Booster: Accelerates the process of handling IBCs.

Trusted Solution: Manufactured by a reliable brand known for quality and innovation.

Conclusion: Revolutionize Your Material Handling Operations

The updated RAAH IBC Lifter is an essential tool for industries that prioritize safety, efficiency, and productivity. Its innovative design and enhanced features make it a game-changer in the handling of Intermediate Bulk Containers.

Whether you’re in manufacturing, logistics, or any industry requiring the movement of bulk materials, the RAAH IBC Lifter is the perfect solution to streamline your operations and elevate workplace safety standards.

👉 Explore the RAAH IBC Lifter here and take your industrial operations to the next level!

0 notes

Text

IBC Tank Decontamination | Gulshan IBC Group

Gulshan IBC Group excels in providing IBC Tank Decontamination Services in Gujarat, addressing the needs of industries that utilize Intermediate Bulk Containers (IBCs) for storing and transporting hazardous substances. These tanks, if not properly decontaminated, can pose severe risks, including chemical spills, contamination, and legal non-compliance.

0 notes

Text

Latest Update on RAAH IBC Lifter: Transforming Industrial Material Handling

Industrial operations often demand innovative solutions for safe and efficient handling of heavy containers such as Intermediate Bulk Containers (IBCs). The RAAH IBC Lifter is the ultimate tool designed to meet this challenge. Recently updated with cutting-edge features, this lifter enhances safety, productivity, and convenience for industries that handle IBCs regularly.

Key Updates to the RAAH IBC Lifter

1. Improved Load Capacity

The latest update boosts the lifter's load-bearing capabilities, allowing it to handle heavier IBCs with ease. This feature caters to industries dealing with larger volumes of materials.

2. Advanced Locking Mechanism

The new locking system ensures that IBCs remain securely in place during lifting and transportation. This reduces the risk of accidents and product loss.

3. Enhanced Ergonomic Design

The lifter now features an ergonomic design for better operator control. This minimizes physical strain and ensures smooth operation.

4. Durable Construction

Manufactured with high-grade materials, the updated RAAH IBC Lifter is built to withstand challenging industrial environments while maintaining its performance.

5. Compatibility with Various IBC Types

The lifter is now compatible with a wider range of IBC designs, making it a versatile solution for diverse industrial needs.

Importance of the RAAH IBC Lifter for Industrial Use

1. Ensures Workplace Safety

Handling heavy IBCs manually can lead to injuries and accidents. The RAAH IBC Lifter eliminates these risks by providing a secure and efficient lifting mechanism.

2. Boosts Efficiency

With its enhanced features, the lifter allows for quick and seamless transportation of IBCs, reducing downtime and improving operational flow.

3. Protects Materials

The advanced locking system prevents accidental spills or damages to the IBC’s contents, ensuring the integrity of stored materials.

4. Enhances Compliance

The RAAH IBC Lifter helps businesses adhere to safety regulations by minimizing workplace hazards and improving material handling standards.

5. Reduces Labor Costs

By automating the lifting process, the lifter reduces the need for additional manpower, translating into significant cost savings over time.

Applications of the RAAH IBC Lifter

1. Manufacturing

Ideal for moving raw materials or finished products stored in IBCs across the production floor.

2. Chemical Processing

Ensures the safe handling of hazardous chemicals stored in bulk containers.

3. Food and Beverage Industry

Facilitates the transportation of liquids and food ingredients stored in IBCs, ensuring hygiene and safety.

4. Warehousing and Logistics

Streamlines the loading and unloading of IBCs during transportation and storage processes.

5. Construction

Assists in handling construction materials stored in IBCs, improving site efficiency.

Key Features of the RAAH IBC Lifter

High Load Capacity: Handles heavy IBCs with ease.

Secure Locking Mechanism: Keeps containers safe during transport.

Ergonomic Design: Easy to operate, minimizing worker fatigue.

Versatile Compatibility: Suitable for various IBC types.

Robust Construction: Built for durability and long-term use.

Compact and Lightweight: Allows for easy maneuverability and storage.

Why Choose the RAAH IBC Lifter?

Safety Assurance: Reduces workplace injuries and enhances operational safety.

Cost-Effective: Minimizes labor requirements and material losses.

Productivity Booster: Accelerates the process of handling IBCs.

Trusted Solution: Manufactured by a reliable brand known for quality and innovation.

Conclusion: Revolutionize Your Material Handling Operations

The updated RAAH IBC Lifter is an essential tool for industries that prioritize safety, efficiency, and productivity. Its innovative design and enhanced features make it a game-changer in the handling of Intermediate Bulk Containers.

Whether you’re in manufacturing, logistics, or any industry requiring the movement of bulk materials, the RAAH IBC Lifter is the perfect solution to streamline your operations and elevate workplace safety standards.

👉 Explore the RAAH IBC Lifter here and take your industrial operations to the next level!

0 notes

Text

Griffith Feed & Grain Warehouse & Offices

Griffith Feed & Grain engaged Asset Building Systems (ABS) in late 2015 with a vision to build a state-of-the-art commercial building/trading premises where the company could operate and sell its broad range of animal feeds & supplements, saddlery & equine supplies, pet food & equipment and clothing & footwear lines in Griffith, NSW.

Working collaboratively with ABS, the final design was a 25m x 12m x 6m commercial warehouse for grain storage with internal offices and front-of-house.

The building consisted of a galvanised portal frame, insulation for climate control, and a premium powder-coated steel exterior, which gives the grain storage warehouse building a modern aesthetic.

Asset Building’s turn-key construction process began with excavation and removal of excess soil, then construction and pouring of footings and concrete slab, along with the construction of the main frame, cladding, roof sheeting and stormwater connection.

Asset Building Systems also managed the construction of the offices inside the shed. We set up the shed for commercial operations including with data points, plumbing and electrical – ready for trading upon completion.

Were there any modifications or changes made at any stage of the project?

During construction, it was identified by the client that a containment bund or embankment surrounding the chemical storage area was going to be a critical addition to the commercial warehouse given Griffith Feed & Grain operated a regional depot to store and distribute chemical, fertiliser and seed.

The modern warehouse facility was created with space for up to 520 pallets and IBCs to meet the Australian regulations in case of chemical spill. In Australia, the requirements are that bunding capacity must be at least 110% of the largest container or 25% of the total stored within the bund – whichever is greater.

Asset Building Systems worked proactively to design and construct a safety chemical containment bund that houses and protects, and separates the chemical storage area from spoiling other inventory in the industrial warehouse.

Why was Asset Building Systems Selected for the Project?

As a local company with in-house custom fabrication capabilities and a long-standing reputation as the most trusted warehouse contractor NSW, Asset Building Systems was the first choice of Industrial Shed Builder for the client.

Offering end-to-end support, including design expertise, and in-house fabrication, with the agility of a local contractor and the ability of a state-wide leader in industrial shed construction.

Client Feedback

“Excellent job – the shed’s gold. I’ve received a lot of positive comments about it.”

– Richard, Griffith Feed & Grain

GET A FREE ESTIMATE

Work with Asset Building Systems Today. We’d love to be a part of your next project. Contact us here for a tight budget estimate.

Book Your Discovery Call Today

During our discovery call, we’ll discuss your business needs and your desired shed construction purpose, your unique preferences or specifications, and other important information.

Learn more about NSW’s Best Warehouse Contractor and Commercial Shed Builder – Asset Building Systems.

0 notes

Text

The Hazardous Chemicals Packaging Market is projected to grow from USD 11335 million in 2024 to an estimated USD 18066.26 million by 2032, with a compound annual growth rate (CAGR) of 6% from 2024 to 2032. The hazardous chemicals packaging market is a critical component of the global supply chain, ensuring the safe transport, storage, and handling of potentially dangerous substances. As industries such as pharmaceuticals, agriculture, petrochemicals, and manufacturing continue to expand, the demand for robust and compliant packaging solutions has grown exponentially.

Browse the full report at https://www.credenceresearch.com/report/hazardous-chemicals-packaging-market

Market Overview

Hazardous chemicals packaging encompasses a wide range of containers, including drums, Intermediate Bulk Containers (IBCs), pails, and cylinders, designed to contain substances that pose risks to health, safety, or the environment. The primary objective of this packaging is to prevent leaks, spills, and contamination, while complying with stringent regulations set forth by authorities like the United Nations, the U.S. Department of Transportation (DOT), and the European Union’s ADR (Agreement Concerning the International Carriage of Dangerous Goods by Road).

The market’s growth is being driven by industrialization, globalization of trade, and the increasing focus on safety and environmental sustainability. In 2022, the global hazardous chemicals packaging market was valued at approximately $15 billion and is projected to reach $25 billion by 2030, growing at a compound annual growth rate (CAGR) of 6%.

Key Market Drivers

Regulatory Compliance: Strict regulations for the packaging and transportation of hazardous materials are a significant driver. Packaging must meet rigorous testing standards to ensure it can withstand shocks, pressure changes, and corrosive materials.

Growth in End-Use Industries: Industries such as chemicals, pharmaceuticals, and agriculture are witnessing rapid growth. These sectors rely heavily on hazardous chemicals, necessitating robust packaging solutions.

Focus on Sustainability: Increasing environmental awareness is pushing manufacturers to adopt sustainable packaging solutions. Recyclable materials, reusable containers, and innovative designs are gaining traction.

Global Trade Expansion: The globalization of trade has led to the increased movement of hazardous chemicals across borders, driving the need for standardized and compliant packaging solutions.

Challenges in the Market

Stringent Regulatory Frameworks: While regulations drive the market, they also pose challenges for manufacturers. Compliance requires constant updates to packaging designs and materials, increasing costs and time-to-market.

Material Costs: The cost of high-quality, durable materials such as stainless steel, high-density polyethylene (HDPE), and composite materials can be prohibitive for smaller manufacturers.

Complex Supply Chains: Ensuring the safe and compliant transportation of hazardous chemicals across global supply chains is logistically challenging, especially in regions with varying regulatory requirements.

Environmental Concerns: Balancing the need for durable, leak-proof packaging with environmental sustainability is a significant hurdle. Non-biodegradable materials continue to dominate the market, raising concerns about their long-term environmental impact.

Emerging Trends

Smart Packaging: IoT-enabled packaging solutions are being developed to monitor temperature, pressure, and other parameters during transportation. These innovations improve safety and reduce losses.

Customization: Manufacturers are offering tailored solutions to meet specific industry requirements, ensuring compliance and enhancing operational efficiency.

Lightweight and Durable Materials: Advances in material science are leading to the development of lightweight yet durable materials, reducing transportation costs and environmental impact.

Recyclable and Reusable Packaging: With the push for a circular economy, manufacturers are increasingly focusing on recyclable and reusable packaging solutions that minimize waste.

Future Outlook

The hazardous chemicals packaging market is poised for significant growth, driven by advancements in technology, regulatory evolution, and the increasing focus on sustainability. Emerging economies in Asia-Pacific and Latin America are expected to play a pivotal role, given their expanding industrial base and rising trade activities.

However, the market’s growth will depend on the industry’s ability to innovate while addressing environmental concerns and adhering to stringent regulations. Collaboration between manufacturers, regulatory bodies, and end-users will be crucial in shaping the future of this critical sector.

Key Player Analysis:

BASF SE

Berry Global Inc.

EnviroTech Custom Injection Molders, Inc.

Greif Inc.

Grief Flexible Products & Services

Hawman Container Services

International Paper

Mauser Packaging Solutions

Precision IBC

Schütz GmbH & Co. KGaA

Thielmann Group

Time Technoplast Ltd.

Segmentation:

By Product Type

Drums

Steel Drums

Plastic Drums

Intermediate Bulk Containers (IBCs)

Rigid IBCs

Flexible IBCs

Bottles & Cans

Cartons & Boxes

Pails

By Material

Plastic

High-Density Polyethylene (HDPE)

Polyethylene Terephthalate (PET)

Metal

Steel

Aluminum

Composite Materials

Paperboard

By End-Use Industry

Chemical Industry

Pharmaceuticals

Oil and Gas

Agriculture

Automotive

Paints and Coatings

Food and Beverage (Specialized Chemicals)

By Distribution Channel

Direct Sales

Distributors

By Region

North America

U.S.

Canada

Mexico

Europe

Germany

France

U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/hazardous-chemicals-packaging-market

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

0 notes

Text

Why Every Center Requirements an IBC Tote Mixer: Enhancing Quality and Consistency

Introduction

In today's fast-paced industrial landscape, keeping quality and consistency in items is critical. Whether you remain in the food and drink sector, pharmaceuticals, or any manufacturing market, the importance of efficient blending can not be overemphasized. One buying a drum bung tool that has transformed Installing Drum Bung this process is the IBC lug mixer As we look into the important reasons why every facility requires an IBC carry mixer, we'll check out how it improves quality and consistency in operations.

Why Every Facility Requirements an IBC Tote Mixer: Enhancing Quality and Consistency

An IBC lug mixer is designed specifically to mix large quantities of liquids or slurries stored in Intermediate Bulk Containers (IBCs). The need for such a device occurs from numerous vital factors:

Uniformity of Mixtures: With time, parts can settle or separate within storage containers. An IBC lug mixer guarantees a homogenous mix, reducing item variability.

Efficiency: Mixing large volumes by hand can be labor-intensive and time-consuming. With an automated blending solution like a tote mixer, centers can streamline operations.

Quality Control: Constant item output causes much better quality control, decreasing waste and guaranteeing consumer satisfaction.

Versatility: IBC mixers are versatile to different markets, making them ideal for different applications-- from chemicals to food products.

Cost-Effective: By improving mixing efficiency, organizations can save on material costs and minimize the likelihood of rework due to inconsistencies.

Improved Safety: Automated mixing minimizes manual handling of materials, lessening risks associated with spills or accidents.

With these advantages in mind, let's more check out the benefits of having an IBC lug mixer in your facility.

Understanding the Parts of an IBC Lug Mixer What is an IBC?

Intermediate Bulk Containers (IBCs) are big containers typically used for storing bulk liquids or granulated compounds. They come in different sizes-- usually varying from 275 gallons to 330 gallons-- and are created for transport and storage efficiency.

youtube

Key Features of an IBC Carry Mixer

An effective IBC lug mixer will have several key functions:

Powerful Motor: Guarantees sufficient torque to mix even the most thick materials. Variable Speed Controls: Allows operators to adjust speeds based on material needs. Durable Construction: Made from materials resistant to deterioration and wear. Safety Features: Emergency shut-off switches and protective guards are necessary for safe operation. Types of Mixers Utilized with IBCs Drum Mixers Designed particularly for 55-gallon drums. Good for smaller sized batches but less effective than carry mixers for bigger volumes. Larger Tank Mixers Suitable for large quantities however not always useful for basic IBC sizes. Port

0 notes

Text

Spill Pallets for Every Industry: A Guide to Choosing the Right Type

Choose the right spill pallets for your industry. Learn how to enhance safety, prevent spills, and ensure compliance with the best containment solutions. This article defines spill pallets, highlights their importance, and explains how they help ensure safety and regulatory compliance within your organization for storing oils, chemicals, and managing leaks, drips, and spills. Drum spill pallets, for instance, provide a safe storage solution. First, let’s understand what spill pallets are.

Contaminated pallets, also known as spill containment pallets are specialized platforms used to contain a spillage of liquids. It is designed as a strong platform with a depressed section to collect any spillages from vessels resting on it. These pallets vary in size and shape to accommodate different containers such as barrels and IBCs. The containers are fitted above a grate, and should there be a spillage, it maximally goes through the grate which is contained within the pallet base. Best Spill pallets by Allwin are also fitted with drainage plugs for easy draining and recovery of the liquids collected.

Keep reading to continue:- Spill Pallets for Every Industry: A Guide to Choosing the Right Type

0 notes

Text

Flexitank Containers - A Cost-Effective Alternative to Tanks & Barrels

Fluid Flexitanks understands the challenges you face in the bulk liquid transportation industry. Keeping costs down while ensuring safe and efficient delivery is paramount. That's why we created high-quality flexitank containers – a revolutionary solution designed to significantly reduce your shipping expenses. In this blog, we'll delve into how flexitanks from Fluid Flexitanks can be your game-changer for cost-effective bulk liquid transportation. We'll compare them to traditional methods like drums and ISO tanks, highlighting the cost-saving advantages you can leverage with our innovative flexitank containers. Why Flexitanks? Maximizing Efficiency and Minimizing Costs Flexitanks are durable, single-use containers made from robust, multi-layered materials. Designed to fit snugly within a standard 20-foot shipping container, they offer a plethora of advantages that translate to substantial cost savings:

Increased Payload Capacity: A single flexitank container from Fluid Flexitanks can hold up to 24,000 litres of non-hazardous liquids. This impressive capacity surpasses that of drums and IBC totes, allowing you to ship more product per container. Imagine the cost reduction achieved by shipping fewer containers

Reduced Labour Costs: Loading and unloading flexitanks is a streamlined process. Unlike drums, which require significant manual handling, flexitanks can be efficiently filled and discharged using pumps. This indicates lower labour costs and faster turnaround times. Elimination of Storage Hassles: Empty flexitanks fold compactly, requiring minimal storage space compared to bulky drums and IBC totes. This frees up valuable warehouse space and eliminates storage costs.

Single-Use Simplicity: Flexitanks are disposable, eliminating the need for cleaning and maintenance associated with reusable containers. This translates to significant cost savings and simplifies your logistics.

Eco-Friendly Advantage: Flexitanks from Fluid Flexitanks are recyclable, making them an environmentally friendly choice. It enhances your brand image and potentially lead to cost savings through participation in green initiatives.

Here's a quick comparison to illustrate the cost-saving benefits:

Flexitanks vs. Drums: A single flexitank can hold the equivalent of 85 drums, significantly reducing the number of containers needed for shipment. This translates to lower freight costs and minimized handling expenses.

Flexitanks vs. ISO Tanks: While ISO tanks offer higher capacity, they come with hefty rental or purchase costs. Flexitanks provide a more cost-effective option for medium-sized shipments, particularly for one-way journeys.

The Fluid Flexitanks Difference: At Fluid Flexitanks, we go beyond just providing flexitank container.

Unmatched Quality: Our flexitanks are manufactured using the highest quality materials along with rigorous quality control processes. This ensures maximum durability and leak-proof performance, protecting your valuable cargo and at the same time minimizes the risk of costly spills.

Expert Support: Our team of experienced professionals is here to guide you every step of the way. We'll help you choose the right flexitank for your specific needs.

Global Network: Fluid Flexitanks ensures seamless delivery and support wherever you require them.

Are Flexitank Containers Right for You? Flexitank containers are ideal for transporting a wide range of non-hazardous liquids, including:

Wines and juices

Edible oils

Chemicals

Pharmaceuticals

Resins and latex

Key factors to consider when deciding if flexitanks are the right choice for you:

The type of liquid you're shipping: Flexitanks are ideal for non-hazardous liquids.

Volume of your shipment: Flexitanks are perfect for medium-sized bulk shipments.

Cost-effectiveness: If reducing shipping costs is a priority, flexitanks offer significant advantages.

Cost-Effective Future of Bulk Liquid Shipping By incorporating Fluid Flexitanks' innovative flexitank container into your shipping strategy, you can unlock a world of cost-saving benefits. From maximizing payload capacity to streamlining logistics, flexitanks offer a compelling solution for efficient and cost-effective bulk liquid transportation.

Ready to experience the Fluid Flexitanks difference? Contact us today for a free consultation and discover how our high-quality flexitank containers, manufactured by a leading Flexitank manufacturer in India, can revolutionize your bulk liquid shipping operations.

0 notes

Text

Why Spilled Compounds and Chemicals Have Been a Dire Matter?

One of the concerns prevalently encountered by industries is chemical spills. The problem intensifies when workers try to control the spill. The issue seemed to have no solution until innovators introduced IBC spill containment products. These products helped manage these dire circumstances by eliminating risks and consequences.

Spilled Chemicals and Compounds:

Industrial sectors have gone through extreme situations due to chemical spills. Many companies have suffered severe life and asset losses. As a result, these industries needed a solution to prevent chemical and compound spills. The aim is to control spills from damaging surfaces, lives, etc., directly and indirectly.

Consequences of Spilled Chemicals and Compounds:

Surface Damage:

Chemicals are reactive compounds and elements that can damage surfaces, air, etc. Spilled chemicals need quick containment to control the damage. For example, it can impact walls, floors, machinery, and everything else in contact. Therefore, it is essential to handle these chemicals and compounds well to reduce spill possibility.

Product Loss:

Industries order chemicals and compounds to proceed with the next step. It can be essential to manufacture products, repairs, installations, constructions, etc. Chemical and compound spills will result in product loss. As a result, it will impact further steps of the process, delaying it more.

Casualties:

Highly reactive chemicals and compounds are the worst. They can easily impact human lives. Spilled chemicals could easily burn skin. These chemicals can react to elements present in the air and release harmful fumes into the environment. So, when workers and other people breathe in such a polluted environment, they develop respiratory and other health conditions.

A Preventive Measure:

Industries mandatorily need IBC spill containment pallet, berms, etc. These spill containment solutions can help prevent minor and major chemical spills. Even if the container bursts or is manhandled, the spilled chemical and compound will not be widespread.

Industrial safety products are the best way to safeguard the premises. Industrial operations are increasingly secure with these products. Safety product suppliers aid industries in improving their procedures and operations with required solutions. Therefore, these suppliers hold a valuable position in the market.

About Industrial Safety and Supply:

Industrial Safety and Supply is among the top safety product suppliers. The brand offers solutions by Ultratech and many other safety product manufacturers. It provides everything from spill containment solutions to surface mounts and berms. Industries can trust this service and get every single solution needed to upgrade safety standards.

Check out more at https://industrialandsafetysupply.com/

Original Source: https://bit.ly/3Vua4E4

0 notes

Text

Ramp for Spill Pallet | IBC Pallet

Backed by Our 3 Year Guarantee

A heavy duty ramp manufactured form 100% polythene to provide toughness and durability.

Its features grip runners and raised sides for additional stability.

#Spill Pallet#Spill Pallet Containment#IBC Pallet#Ramp for Spill Pallet#Drum Spill Pallet#Containment Pallet

1 note

·

View note

Text

IBC Spill Containment Pallets: Best Practices for Use and Benefits

Ensuring spill control and safety is crucial in businesses handling huge amounts of hazardous liquids. These liquids are frequently transported and stored in intermediate bulk containers (IBCs), yet there is a chance of spilling. Consequently, IBC spill containment pallets are useful in this situation. Because these pallets are designed to reduce environmental damage and increase worker safety, they are crucial for following safety standards and protecting your business.

In this blog, we will discuss the use and benefits of IBC spill containment pallets. Understanding IBC Spill Containment Pallets Pallets designed for IBC spill containment are made especially to store liquids and stop leaks or spills. Additionally, a containment basin in robust construction collects and holds spills. This prevents them from spilling into the surrounding space and stops spills from reaching the floor. Moreover, the robust materials used to manufacture these pallets, like polyethylene, which is resistant to chemicals, ensure long-term usage and durability.

Proper Placement and Setup

Where to place: To ensure the best results with your IBC spill containment pallet, carefully place it on a flat, stable surface. Additionally, make sure the area around it is free from any obstructions and allows for easy handling and movement of your IBCs.

Leveling: Make sure the pallet is level to avoid spills brought on by tilting and uneven liquid distribution in the IBC.

Load Bearing Limits: Stick to the weight limits set by the pallet manufacturer. Overloading can compromise its integrity, resulting in spillage.

Handling and Transport

Proper Lifting: Forklifts or pallet jacks are suitable lifting equipment to use while moving IBCs onto and off the spill containment pallet. IBCs should not be dragged or dropped since this could harm the pallet as well as the container.

Secure Positioning: Make sure the IBC is steady and firmly positioned when it has been placed on the pallet. To prevent movement during handling or transportation, use straps or other fastening techniques as needed.

Load Management

Weight Limits: Observe the weight restrictions for the pallets as indicated by the manufacturer. Pallet overloading increases the chance of spills and can harm the structure.

Proper Loading: Position IBCs centrally on the pallets to ensure even weight distribution and stability. Avoid putting multiple IBCs on the same pallet unless it has been designed to handle such weights.

Benefits of Using IBC Spill Containment Pallets 1. Enhanced Safety Swift’s IBC spill containment pallets are a game-changer for workplace safety. They offer a secure platform to store hazardous materials, giving you peace of mind. With their advanced secondary containment feature, any spills are contained, preventing them from spreading. This means a safer environment, less risk of accidents, and reduced exposure to dangerous chemicals.

2. Cost Savings Spill and leak control may save you a lot of money. After all, spills can result in costly cleaning operations, penalties, and damage to equipment and the workplace. Therefore, investing in IBC spill containment pallets reduces these multiple costs.

3. Versatility IBC pallets have many uses and show up in different industries such as food and drink processing, and chemical production. They can adapt to different needs, which makes them a key tool for any business working with liquids and chemicals. These pallets help keep people safe and make handling these materials more effective.

4. Easy Maintenance These pallets are built to last and require minimal maintenance. Moreover, regular inspections and cleaning assure their longevity and efficacy, giving a long-term spill containment solution.

Conclusion You may extend the life and efficacy of these pallets by being aware of their design and function, making sure they are positioned and set up correctly, and by following safe handling and transportation procedures. IBC spill containment pallets have many advantages, such as improved worker safety, cost savings from spill prevention, industry adaptability, and ease of maintenance. We at Swift Technoplast are dedicated to offering IBC spill containment pallets of the finest quality that meet industry standards and support the safety of your business. Our products are made to provide 100% Environmentally friendly, sturdy, dependable containment solutions that guarantee worker safety. Invest in Swift Technoplast IBC spill containment pallets to enhance the safety and efficiency of your facility.

#IBC Spill Containment pallet#plastic industry#plasticmanufacturer#plasticproducts#IBC pallet#spill pallets#swifttechnoplastprivatelimited#plastic product manufacturer#plastic product suppliere

0 notes

Text

Latest Update on RAAH IBC Lifter: Transforming Industrial Material Handling

Industrial operations often demand innovative solutions for safe and efficient handling of heavy containers such as Intermediate Bulk Containers (IBCs). The RAAH IBC Lifter is the ultimate tool designed to meet this challenge. Recently updated with cutting-edge features, this lifter enhances safety, productivity, and convenience for industries that handle IBCs regularly.

Key Updates to the RAAH IBC Lifter

1. Improved Load Capacity

The latest update boosts the lifter's load-bearing capabilities, allowing it to handle heavier IBCs with ease. This feature caters to industries dealing with larger volumes of materials.

2. Advanced Locking Mechanism

The new locking system ensures that IBCs remain securely in place during lifting and transportation. This reduces the risk of accidents and product loss.

3. Enhanced Ergonomic Design

The lifter now features an ergonomic design for better operator control. This minimizes physical strain and ensures smooth operation.

4. Durable Construction

Manufactured with high-grade materials, the updated RAAH IBC Lifter is built to withstand challenging industrial environments while maintaining its performance.

5. Compatibility with Various IBC Types

The lifter is now compatible with a wider range of IBC designs, making it a versatile solution for diverse industrial needs.

Importance of the RAAH IBC Lifter for Industrial Use

1. Ensures Workplace Safety

Handling heavy IBCs manually can lead to injuries and accidents. The RAAH IBC Lifter eliminates these risks by providing a secure and efficient lifting mechanism.

2. Boosts Efficiency

With its enhanced features, the lifter allows for quick and seamless transportation of IBCs, reducing downtime and improving operational flow.

3. Protects Materials

The advanced locking system prevents accidental spills or damages to the IBC’s contents, ensuring the integrity of stored materials.

4. Enhances Compliance

The RAAH IBC Lifter helps businesses adhere to safety regulations by minimizing workplace hazards and improving material handling standards.

5. Reduces Labor Costs

By automating the lifting process, the lifter reduces the need for additional manpower, translating into significant cost savings over time.

Applications of the RAAH IBC Lifter

1. Manufacturing

Ideal for moving raw materials or finished products stored in IBCs across the production floor.

2. Chemical Processing

Ensures the safe handling of hazardous chemicals stored in bulk containers.

3. Food and Beverage Industry

Facilitates the transportation of liquids and food ingredients stored in IBCs, ensuring hygiene and safety.

4. Warehousing and Logistics

Streamlines the loading and unloading of IBCs during transportation and storage processes.

5. Construction

Assists in handling construction materials stored in IBCs, improving site efficiency.

Key Features of the RAAH IBC Lifter

High Load Capacity: Handles heavy IBCs with ease.

Secure Locking Mechanism: Keeps containers safe during transport.

Ergonomic Design: Easy to operate, minimizing worker fatigue.

Versatile Compatibility: Suitable for various IBC types.

Robust Construction: Built for durability and long-term use.

Compact and Lightweight: Allows for easy maneuverability and storage.

Why Choose the RAAH IBC Lifter?

Safety Assurance: Reduces workplace injuries and enhances operational safety.

Cost-Effective: Minimizes labor requirements and material losses.

Productivity Booster: Accelerates the process of handling IBCs.

Trusted Solution: Manufactured by a reliable brand known for quality and innovation.

Conclusion: Revolutionize Your Material Handling Operations

The updated RAAH IBC Lifter is an essential tool for industries that prioritize safety, efficiency, and productivity. Its innovative design and enhanced features make it a game-changer in the handling of Intermediate Bulk Containers.

Whether you’re in manufacturing, logistics, or any industry requiring the movement of bulk materials, the RAAH IBC Lifter is the perfect solution to streamline your operations and elevate workplace safety standards.

👉 Explore the RAAH IBC Lifter here and take your industrial operations to the next level!

0 notes

Text

Industrial Bulk Packaging Market Overview: Growth Factors and Future Trends (2023-2032)

The Global Industrial Bulk Packaging market is expected to witness a CAGR of 4.57% during the forecast period. The revenue generated by the global Industrial Bulk Packaging market in 2020 was over USD 20 billion and is expected to generate revenue worth USD 30.42 million in 2027.

The Industrial Bulk Packaging Market is witnessing significant growth driven by the increasing demand across various sectors such as chemicals and petrochemicals, food and beverages, pharmaceuticals, and building and construction. This market encompasses a wide range of packaging solutions including drums, IBCs (Intermediate Bulk Containers), bulk boxes, and sacks designed to transport and store large quantities of materials efficiently and safely. The rise in global industrial activities, coupled with the need for safe and effective packaging solutions, has bolstered the market's expansion.

The shift towards eco-friendly packaging solutions, driven by environmental concerns and regulatory pressures, is encouraging manufacturers to innovate and adopt sustainable practices. Regions such as North America and Europe are leading the market due to their established industrial base and stringent regulatory frameworks, while emerging economies in Asia-Pacific are rapidly catching up, fueled by industrialization and increasing foreign investments. The competitive landscape is characterized by mergers and acquisitions, strategic partnerships, and continuous R&D efforts aimed at product innovation and expansion of production capabilities. As industries continue to evolve and expand, the industrial bulk packaging market is poised for sustained growth, underpinned by the constant need for robust, efficient, and sustainable packaging solutions.

Industrial bulk packaging serves a critical role across various industries by providing efficient, safe, and cost-effective solutions for transporting and storing large quantities of materials.

Here are some key uses of industrial bulk packaging:

Chemical and Petrochemical Industry:

Transportation of Hazardous Materials: Industrial bulk packaging is essential for the safe transportation of hazardous chemicals, ensuring compliance with regulatory standards and preventing leaks or spills.

Storage Solutions: Drums, IBCs, and other bulk containers are used to store chemicals and petrochemicals, protecting them from contamination and maintaining their integrity.

Food and Beverage Industry:

Bulk Ingredients Handling: Large quantities of raw materials such as grains, sugars, and liquids are transported and stored using bulk packaging solutions, ensuring hygiene and quality.

Beverage Storage: IBCs and bulk tanks are used for storing and transporting beverages, including wine, juices, and syrups, in large volumes.

Pharmaceutical Industry:

Active Ingredients Transport: Bulk packaging is used to transport active pharmaceutical ingredients (APIs) and other raw materials required for drug manufacturing.

Finished Products Storage: Bulk containers are also employed for the storage of finished pharmaceutical products, ensuring they remain uncontaminated and secure.

Building and Construction:

Bulk Cement and Aggregates: Sacks, bulk bags, and other containers are used for transporting and storing cement, sand, gravel, and other construction materials in large quantities.

Chemical Additives: Packaging solutions for chemical additives used in construction processes help in maintaining product quality and ease of handling.

Agriculture:

Seed and Fertilizer Transport: Bulk packaging is utilized for the efficient transport and storage of seeds, fertilizers, and pesticides, ensuring they remain protected from moisture and pests.

Harvested Crops: Containers and bulk bags are used to store and transport harvested crops, maintaining their quality and freshness.

Manufacturing and Industrial Goods:

Raw Materials Handling: Industrial bulk packaging is employed for transporting and storing raw materials such as plastics, metals, and textiles used in manufacturing processes.

Finished Goods Packaging: Bulk packaging solutions are also used for the storage and transportation of finished industrial goods, providing protection and ease of handling.

Waste Management:

Hazardous Waste Disposal: Industrial bulk packaging is critical for the safe disposal and transport of hazardous waste materials, ensuring they do not pose a risk to the environment or public health.

Recyclable Materials: Bulk containers are used for the collection and transport of recyclable materials, facilitating efficient waste management and recycling processes.

The Industrial Bulk Packaging Market faces several challenges that impact its growth and development. One of the primary challenges is the fluctuation in raw material prices, particularly for plastics and metals, which are fundamental to bulk packaging products. These price variations can affect the overall cost structure and profitability for manufacturers. Additionally, stringent environmental regulations and increasing consumer demand for sustainable packaging solutions put pressure on companies to innovate and adopt eco-friendly materials, which can involve significant research and development investments. The need to comply with diverse regulatory standards across different regions also adds complexity to the market, requiring substantial efforts to ensure compliance and maintain product quality.

Another challenge is the high initial investment required for advanced packaging technologies and machinery, which can be a barrier for small and medium-sized enterprises. Furthermore, the market faces logistical challenges, including the need for efficient transportation and storage solutions to handle large volumes of bulk packaging products. The competitive landscape, marked by the presence of numerous players, drives the need for continuous innovation and cost optimization to maintain market share. Lastly, the market must address issues related to supply chain disruptions, which can affect the timely availability of raw materials and finished products, thereby impacting overall market operations. Addressing these challenges requires strategic planning, investment in sustainable practices, and technological advancements to ensure the market's sustained growth and resilience.

Major Key Players-

Cleveland Steel Container

Peninsula Drums

Hoover Ferguson Group, Inc.

International Paper

Myers Container

Grief

Time Technoplast Ltd.

BWAY Corporation

Composite Containers LLC

Eagle Manufacturing Company

More About Report- https://www.credenceresearch.com/report/industrial-bulk-packaging-market

The Industrial Bulk Packaging Market is driven by several key factors that contribute to its growth and expansion across various sectors:

Growing Industrialization: Rapid industrialization, especially in emerging economies, is a major driver. The expansion of manufacturing and production facilities increases the demand for bulk packaging solutions to transport and store raw materials and finished goods efficiently.

Increasing Demand in Chemical and Petrochemical Industries: The need for safe and reliable packaging for hazardous and non-hazardous chemicals and petrochemicals fuels the demand for industrial bulk packaging. Stringent regulations regarding the transportation and storage of these materials further boost market growth.

Rising Food and Beverage Industry: The food and beverage industry requires bulk packaging solutions for the transportation and storage of large quantities of raw materials and finished products. The growth of this industry, driven by increasing consumer demand, directly impacts the bulk packaging market.

Pharmaceutical Industry Growth: The pharmaceutical industry's expansion, driven by rising healthcare needs and increased drug production, boosts the demand for bulk packaging solutions for the safe and contamination-free transport and storage of pharmaceutical ingredients and products.

Sustainability and Environmental Concerns: The growing emphasis on sustainability and the need for eco-friendly packaging solutions drive innovation in the bulk packaging market. Companies are increasingly adopting sustainable practices and materials to meet regulatory requirements and consumer preferences.

Technological Advancements: Innovations in packaging materials and technologies enhance the durability, efficiency, and sustainability of bulk packaging solutions. These advancements meet the evolving needs of various industries, contributing to market growth.

Global Trade Expansion: The increase in global trade activities necessitates efficient bulk packaging solutions for the safe and secure transportation of goods across borders. The rise in exports and imports, particularly in chemicals, food and beverages, and pharmaceuticals, drives market demand.

Construction Industry Development: The growth of the construction industry, with its need for bulk materials such as cement, sand, and aggregates, drives the demand for bulk packaging solutions. The packaging ensures safe transportation and storage, supporting construction activities.

Economic Growth in Emerging Markets: Economic development in regions like Asia-Pacific and Latin America leads to increased industrial activities and investments, driving the demand for industrial bulk packaging solutions. The growing manufacturing sector in these regions further supports market growth.

Regulatory Compliance: Stringent regulations related to the safe transportation and storage of hazardous materials drive the adoption of high-quality bulk packaging solutions. Compliance with these regulations ensures safety and minimizes environmental impact, fostering market growth.

Browse the full report – https://www.credenceresearch.com/report/industrial-bulk-packaging-market

Browse Our Blog: https://www.linkedin.com/pulse/industrial-bulk-packaging-market-projections-mnuwc

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes