#I Shape Silicon Plastic Mould Manufacturer

Explore tagged Tumblr posts

Text

https://mstilesmachinery.com/

We are Interlocking Mould and Tiles Manufacturer, Paving Tiles Making Machine Manufacturer, Mini Concrete Mixers Manufacturer, Concrete Mixture Manufacturer, 3 HP Concrete Mixture Machine Manufacturer, Best Tiles Machinery Manufacturer etc… contact us : Phone: +91-8510893237, Email: [email protected].

#Tiles Machine Manufacture in Jahidabad#I Shape Silicon Plastic Mould Machine in Jahidabad#2 HP Interlocking Tiles Making Machine Manufacturer in Sorkha#2 HP Interlocking machine Manufacture in sorkha#2 HP Interlocking machine in sorkha#2 HP Interlocking in sorkha#2 HP Interlocking in Noida Uttar Pradesh#2 HP Interlocking in Noida#2 HP Interlocking in Delhi#2 HP Interlocking in Greater Noida#2 HP Interlocking in Pari chowk#2 HP Interlocking in Ghaziabad#2 HP Interlocking in Vaishali#I Shape Silicon Plastic Mould Machine in Ghaziabad#I Shape Silicon Plastic Mould Machine in Noida#I Shape Silicon Plastic Mould Machine Greater Noida#interlocking machine in jahidabad#interlocking machine in Noida#interlocking machine in greater noida#interlocking machine in ghaziabad#interlocking machine in sikandarabad#interlocking machine in sorkha#Industrial Interlocking Machine Manufacturer in Jahidabad#Industrial Interlocking Manufacturer in sorkha Jahidabad#Industrial Interlocking Manufacturer in ghaziabad#2 HP Interlocking Tiles Making Manufacturer Sorkha#Industrial Interlocking Machine Manufacturer machine in ghaziabad#2 HP Interlocking in Pari Chowk#I Shape Silicon Plastic Mould Machine in Sorkha#Jahidabad

0 notes

Text

Contextual Analysis

I chose the kitchen utensil as a significant object because I love talking about ergonomics and functionality of objects and it’s the best way to read an object.

So I am identifying this as a serving spoon as it’s not the right shape for a ladle nor stirring spoon. It’s made from two types of plastic.

The spoon head and body are made from polypropylene (pp) which is a foodgrade standard plastic. This means this plastic is safe to use in kitchens or near anywhere with food prep.

It has a chemical resistance which makes it foodgrade standard. It has a very good fatigue resistance which means that if it comes into contact with heat or hot water which it inevitably will, it won’t melt or go flimsy or bend.

Polypropylene is in a category of plastics called thermoplastics this means it has a high tolerance to heat which in the kitchen is important. Though my spoon has got a burn mark where the plastic has started to bubble.

This is because my flatmate once held a lighter under it.

The handle has a black silicon grip over it, this means that if your hands are wet or there is a lot of moisture in your hands would slip and drop the spoon.

Silicone is very similar to thermoplastic which means it won’t melt or heat up.

It’s also watertight and where the silicone moulds around the handle it keeps a watertight seal preventing any buildup of bacteria thus keeping it food safe. The silicone has been made in black, identifying it as a point of contact for the user, it seems like it would already be self-explanatory that that is where you hold it but everything is designed like that. Bosch tools are always designed in green and red.

The red is used on buttons, triggers and changeable parts identifying them as user contact points.

The spoon has been designed with a foot to keep the spoon head (which has remanence of food) off the countertop surface preventing mess. I actually didn’t realise this till now.

The spoon has been mass manufactured by injection forming. I know that’s because on the bottom of the spoon it has remnants of the injection pin from the machine. So the spoons are being produced on a mass rate. I think the spoon probably came from IKEA like most things in the flat did. So given the popularity and affordability of IKEA the manufacture has to be quick and cheap.

Injection forming is the best process while also being compatible with polypropylene.

Injection forming can produce one spoon in approximately 15 to 60 seconds. So say it’s 60 seconds, that’s 60 units per hour and because it’s a machine and does not require humans it can be left running for long periods with little to no assistance. This zero requirement of humans also means that manufacturers don’t have to pay wages therefore cutting a lot of overhead costs and keeping IKEA affordable.

Obviously there are running costs and start-up cost can be quite high.

So it’s likely this spoon was manufactured in the last five years. That doesn’t mean to say it was designed in the last five years but given its modern considerations it’s definitely been designed in the last 10 years.

So after hours of looking at spoons online I bloody fond the exact one. It was hard to trace its manufacturing roots because it had no factory mark on the spoon.

The spoon was manufactured in Australia in a factory called KG electronic who manufacture anything from ovens earphones to clothes. They manufacture for leading brands in Australia. Lemon+Lime is the brand of the spoon. Lemon+Lime is an Australian cookware brand.

No idea how we ended up with the spoon in Scotland. I still can’t find the date or year of the manufacturer but I have the product code which is 68076_4PK. I might phone them tomorrow and ask for more details. What I can find out though is the history of polypropylene.

Commercial production of polypropylene began to circulate in 1957 after a few years of refining by a German chemist called Karl Ziegler and perfected by an Italian professor called Giulio Nattain. Ziegler won the Nobel Prize for chemistry in 1963.

In reality this is the shittest spoon I’ve ever used. I choose it as a significant object because it annoys me every time I look at it.

It’s the worst designed spoon because it’s so top-heavy which means it always falls out of the pan or bowl splashing food 🤬 everywhere so the idea of the foot rest to eliminate food mess is pointless. After the drawing task it’s being immediately replaced. I 🤬 hate it.

0 notes

Text

A Purchased Concrete Paver Molds Production

He provides that he finished far rapidly than he expected and that the stroll maker is easy to scrub afterward. A reviewer also states that the concrete path kind works exceptionally well and that he made a 400 ft patio with it without encountering any issues. He extremely recommends it as the best stroll maker obtainable. If you're searching for a method to make a stone path rapidly, you may contemplate this stroll maker offered by Quikrete. Users love the standard of the mildew, however some do notice that the form arrived broken. The Kenley authentic path maker measures 17” x 17” x 1.6”, and it contains a weight of 2.9 kilos, 9-stone patterns for patios and driveways, and a PP resin development see the full article.

You can play with this by including water to help mute the colour. Blend these colors into the stone and into one another the means in which you might with a watercolor painting. If your pigment is a powder, then combine some water in with it. In addition, for every colour you've, you should also have one cup of water, plus you may discover it useful to have another further cup of water. Round them somewhat, and push them inward to create extra of a curve if you'd like. Now go ahead and add the charcoal colorant to the remaining mix you had separated and blend it in nicely.

Creates an effect of cracked concrete paver molds ice on concrete paving slabs. Choose a concrete combination best suited for replica of your stepping stone and properly combine it. We had some SureCrete Xtreme Concrete Mix laying around our store, so we used it for the purposes of this demonstration. Carefully pour the rubber into one corner of the mould box and permit it to flow across the mannequin. Pour rubber into rubber; avoid pouring rubber instantly onto the model. Do not scrape the edges of the bucket as you pour as unmixed materials tends to cling the sides of the blending container.

A purchaser also states that the Kenley mould is made from high quality materials and that it works perfectly. However, some prospects have complained that the Quikrete mold is overpriced and that it’s messy to use it. Some customers additionally noted that an eighty lb bag of concrete was too much and they advise that you simply use a 60 lb combine.

Though we now have many forms of concrete molds, can also produce it by your requirement. Creates a cobble design in 4 rows of 4 on concrete paving slabs. Creates a small cobble design in 5 rows of 5 on concrete paving slabs. Creates a crazy paving design on concrete paving slabs. Creates a diamond cobble design on concrete paving slabs.

Shop a wide selection of mold making materials, including latex, silicone, and more. One reviewer advised us that they added coloring and mortar mix in order that the completed patio would have enhanced traction- and even supplemented with some glass beads for a sparkling appearance. The producers say that you do not actually must lubricate the mold previous to pouring in cement, in contradiction to other reviewers who've ceaselessly suggested that that is the case. However, some clients have complained that it’s not very straightforward to use the random path for and that it’s onerous to maneuver.

Of course, you don’t should make concrete stepping stones that look natural. You can comply with much of this tutorial and make regular round stones, using the same stepping stone mold I used for these. If you make a concrete stepping stone mildew after which install them separately you’re going to should level the bottom first. This is because the underside of the mould would have been flat.

Diy Driveway Garden Pavement Brick Mildew Cellular Paving Stone Mildew

Concrete Success options a extensive variety of mildew shapes to create interlocking patio stones as nicely as stones for backyard paths. With so many molds to choose from, you are certain to search out one which matches your backyard. Since adding stones and pavers takes time and effort, and the outcomes aren't simply moved as quickly as they're put in, take your time to pick out the proper appear and feel on your garden. In right now's world of huge field home and backyard shops and smaller specialty garden centers, you may marvel why utilizing a mold to make concrete pavers is better than shopping for ready-made pavers.

As properly, when you solely want to use one square part of the mold, you'll have the ability to add the concrete simply to that using a small carton like a espresso can. A professional contractor informed us that after the entire concrete has set, it's a good suggestion to do some stress washing on the finished stone patio and apply some semi-transparent stain. You'll wish to fill-in any gaps and crevices between the stones with sand and use some black weed block previous to laying within the concrete to guarantee that weeds do not become a nuisance. Concrete is porous and is vulnerable to stains like leaf stains.

If you feel a reference price is inaccurate or deceptive please report it with the URL for the listing to report- Whether you need a driveway cutter, hydraulic side skirts, adjustable side partitions, or even changing profiles, Miller Formless can design a mildew to swimsuit your slipforming needs. These molds can be utilized tons of of occasions if cared for per instructions.

Tap the mildew together with your hand to eliminate any air bubbles.

In most situations, controlling the moisture, rather than the mud, is much extra desirable.

The path was already there however was coated in pebbles, so I shoveled all the unfastened pebbles out the areas I would be placing the stones.

Color the concrete and mould it into the form of actual fieldstones or flagstones. [newline]A main side to the manufacturing of concrete pavers or blocks would be the durability of the mildew being used.

Immediately after pouring, spray Pol-Ease 2300 Release Agent throughout the floor of the liquid rubber to assist take away surface air bubbles.

The distinctive mould manufacturing technology utilized by Lammers leads to concrete molds which last longer and constantly produce the highest quality products. The most likely place to make use of concrete pavers is the garden pathway. Choosing pavers for walkways provides a sublime contact to backyard pathways. Depending on what sizes, shapes and colors of stepping stones and pavers you choose, you probably can add an air of ritual or nation charm to the backyard path.

For an attractive natural-stone stroll, do this DIY information exhibiting you the means to build a bluestone path. Watch along here as Roger walks you thru developing a brick patio. For most of his patio design ideas, This Old House landscaping contractor Roger Cook favors 1 ½- to 2-inch-thick bluestone, a tough sandstone quarried in New York, Pennsylvania and Vermont. Mankind has called the hearth home for the centuries, it's true, but today persons are going ultra-retro and getting their warmth from stone-walled pits set into the earth. On cool summer time nights, you presumably can soften marshmallows and nibble s'mores when you lounge in an Adirondack chair, ft propped up on the rock ledge.

Established in 2000, PIM plastic mildew firm provides design of plastics, contract plastic mildew making, and customized injection molding service. It employed 15 people with a 500 sq. meters plant in Huangyan, a so-called Chinese mold town with over three thousand Chinese plastics firms and manufacturer. The final reusable concrete walk mold we examined is the Scepter Pathmate mildew. It supplies a random sample engineered to allow contractors and amateurs alike the power to shortly layout attractive-looking pathways, guaranteeing random designs for curved walkway paths.

Keep the trowel at a slight angle and just sweep it backwards and forwards. If this is easiest for you then go forward and simply pour it directly into the mould. It will most likely be best should you combine what you suppose you’ll need for the entire stone, but separate a piece that would be the prime ½”.

Our High Pick: The Quikrete Walkmaker

The Pathmate Paving Stone Mold provides an ideal approach to mold a walkway in a yard with pace and effectivity. It's constructed of a plastic material that is out there in black colour. This paving stone mildew options various shapes and sizes so you will get artistic together with your pavers. It can be reused after cleaning so you could make as many as you need. This concrete paver mould permits you to design your own path with numerous colors and designs.

The concrete paving mildew measures 17.12” x 17.12” x 1.57”, and it features heavy-duty, plastic development. This nation stone sample stroll maker is a Chinese-made choice designed to create engaging patios, courtroom yards, and walks. All you should do is fill the mould with a concrete combine, easy the floor and then remove mould. Such as plastic paving molds, plastics grass brick molds, curb stone molds, slope safety molds, concrete slat molds and so forth.

Paver Molds For Concrete, Lot Of 14 Interlocking Octagon Patio,walkway,Backyard

Suzerain Ltd is a provider of high-density polypropylene paver moulds and accessories used for paver brick manufacturing. Allow the concrete to set for a maximum of five minutes, then rigorously take away the mould. For the following stretch, rotate the mildew a quarter-turn and place it beside the paver simply accomplished, angling barely when you're creating a curving pathway.

To simplify my quantities, I figured I had the equivalent of 9 giant stepping stones. The strategies are actually fairly easy, however since the concrete is heavy to cope with and this project would require a lot of crouching and squatting on the ground. If you’re not satisfied about making your personal stepping stones, then take a glance at my article discussing all the pros and cons of constructing stepping stones vs. buying them and having them put in. A reference value is supplied by the seller of the item . Percentage off and financial savings amounts are primarily based on the vendor's reference price. The reference value can give you an indication of the worth of the product butsome shops might promote the item for lower than the reference value.

As we previously mentioned- when you have a large project to do, you may wish to rent a cement mixer quite than hand-mixing the concrete. Buyers advise to purchase multiple of these walker maker molds at a time to make the job go easier- laying out multiple molds at a time. So the subsequent most efficient method of blending the concrete combine is to make use of a bucket and a drill with a particular concrete mixing bit. The info on the bag of the concrete mix should provide this info, but when not, you probably can often find that info on the manufacturer’s website. And be sure you do a check patch first to ensure it doesn’t change the color or darken the concrete stones in any undesired means.

In general, customers are extraordinarily happy with the functionality and usefulness of the Pathmate random stone mold. A purchaser feedback that he made a 16 ft path very quickly and that you have to wait only two minutes earlier than eradicating the frame. He also says that the form is sturdy and light-weight, and he recommends that you buy two for comfort.

Our paving stone molds are made out of the liquid rubber that hardens to mould and recreate all pure stone texture and grain detail. The first stepping stone mould we study is manufactured by Quikrete- it is a Chinese made walker maker designed to build out patios, walks and courtyards. All you want to do is fill the mold in with a concrete mix, smooth surface, after which remove the walker maker mold.

In addition to being highly sturdy, stamped concrete doesn’t include any gaps or grooves that pesky weeds can development by way of, making your path safer and more aesthetically pleasing. Stamped concrete walkways are relatively maintenance-free, only requiring sealing every few years to take care of the color and texture of the walkway. Stamped concrete is also significantly less prone than other materials to the frost freeze cycle widespread in colder climates. We use actual stone molds to give your walkways the same look and texture solely present in nature, and can customized colorize to your choice. Stamped Ashlar Pattern Walkway with Brick Stamped decorative concrete patterns pair properly with other hardscapes, such as brick, and can be colored to enrich your exteriors.

Instead of wearing a path into the grass, join spaces purposefully with a stone walkway. Watch TOH landscaper Roger Cook work with a home owner to make a flagstone walkway in a day’s time. For a patio well price the view, let a fence, hedge, or facade function a wall, and a pergola, tree cover, or wide umbrella as a roof. Then furnish your outdoor room for eating, entertaining, or gathering around a fire. With all the brilliant thing about a well-manicured garden however without the maintenance, a stone patio makes a sublime addition to any home.

It may be washed off with water after the mold making course of. If you've a very porous mannequin, like the one in this tutorial, you may have to use a couple of coat of Poly PVA Solution. We applied two coats of this sealer, waiting for it to dry (~ 1 hour) in between coats and earlier than transferring on to the next steps.

0 notes

Text

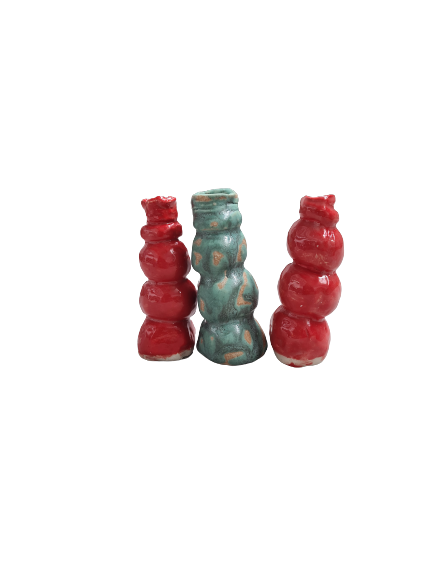

Ceramics Memory in the mould .

The st mags goblets .

The queen's gambit.

2020/21

Ceramics 2021 Memory

In this project we are asked to look at various techniques to create multiples of our chosen objects. A timetable been useful to stay on track to complete a selection of samples as the firing schedules will need to be taken into account often 2 or 3 firings are needed to finish a piece. Research should include artists and recorded analysis, evaluation and sampling ideas for chosen theme. Mould making using different techniques and materials.

A full evaluation report can be uploaded to personal blogs or in sketch book formats.

My chosen object and my interpretation of memory takes into account the actual process of taking a mould which gives a lasting imprint of the object of how it was in that moment. No matter what happens to the original the memory of its former self is kept intact.

I decided to look at various bottles including my teenage son’s aftershave bottles, as they have grown that beautiful baby scent of baby powder has disappeared, new memories are being made and no doubt the overbearing smell of designer aftershaves will forever be with me. (Definitely better than their bedroom). The techniques I have chosen to work with are creating plaster moulds, scratch and slip, slip cast and press moulds. Since being in lockdown learning I learned a lot about the need to make lasting memories with the children, spending quality time with them and finding balance between work and home life, sampling will include found items from outside as well as interesting items in the home. I also intend to look over older projects previously unfinished. The piece was originally designed using a pre made mould and clay taken straight from the ground of my daughter’s primary school. These pieces will give me the opportunity to look further into alternative firing techniques. Given that the clay is reclaimed I see it as a memory of what it was and what it is now.

Artist Research

https://madelena.com/majolica-pottery-3-types.php

I found myself looking at interesting decorative finishes from around the world. Interesting articles and imagery have been recorded by Pinterest board.

https://pin.it/6Py6LO7 Pin boards reference

Main Considerations.

Choosing the best object.

Plastic

Glass

Cardboard

Lino

Wood has to be coated beforehand

Breakages will require more time to recreate or can be fixed together before casting.

I used cobalt oxide which is highly toxic and the use of masks is necessary.

Creating Moulds

The best way for me is to create large clay walls around object to pour in plaster which has to be at correct consistency, if when mixing the plaster starts to feel warm it is drying up. It is important to think about quantity of plaster required. Any clay that has plaster could crack in kiln.

Mindful of wastage. Clay walls can be reused only to build boundary walls and must be completely sealed. I also find it more efficient if leaks do occur as blocking and reducing spillage is quicker and less likely to cause any major issues.

I also looked at the process of making my own silicone moulds using water, fairy liquid and silicone which is relatively easy and cheap creating some interesting moulds I found this particularly

Satisfying when mixing the texture when silicone with soap. After creating a mould around the object allow the silicone to rest and set, the opening of the sealed piece is better to be slit in a jagged cut to allow the mould to be put back together it’s important to only cut down sides and leave the bottom sealed completely. Melted wax works very well with the silicone open the top with a hole and pouring the melted wax through a funnel easily made with a piece of acetate and tape as seen above.

The silicone moulds are very useful when working with mixed media and materials and can be used for multidisciplinary practices. Wax, resin, plaster, slip, soap. These moulds and materials can then be used in jewellery design, glass art and sculpture. I look forward to learning how to cast glass from wax from a chosen silicone mould.

Technical notes

Slip cast is the process of pouring the clay slip into a mould however I found this to be too thin in line with the pieces I was trying to create.

The mixture has to be poured in evenly and left to form a successful piece.

Press moulds can be flat or 3d and cast as two halves, I prefer this method as I have more control over the weight, thickness and the joins. Joining the two pieces is done by scratch and slip method which helps to ensure a bonded seal that is less likely to cause any cracks when fired.

The first firing is the bisque process raising the temperature slowly to drive out any water and carbon content. It is a good idea to dry out your clay to at least bone-dry state before putting into the kiln.

Top temperature is between 1000 and 1100 °c, the piece can then be decorated with coloured or transparent glazes. Glazes also come in matt finish it is best practice to follow manufacturer instructions this is also best when using decals to decorate ceramic and glass.

Slip cast 1st attempts Sometimes it goes perfectly wrong.

The queen’s gambit.

Decorative finishes, Oxide, Glazing and brush strokes

Reclaimed clay

Oxides with transparent glaze 1060°c

These goblets were bisque fired natural clay, using clay tool I tried to create a Japanese style of blossoms using thin lines. After the initial firing I decided to look at alternative options and used cobalt oxide which I rubbed into the cracks and washed off however I felt that I would like to define the strokes more so used a thin brush to paint the Oxide on to the surface. Afterwards I decided to look at various Glazing options and found myself experimenting using transparent glaze and rubbing it off I used a couple of thin layers just to test how this would look and see if it would create a crackle look to give the impression of aging. The results were really interesting and I fell in love with this piece not just its colours but the texture and the imperfections created something really exciting. The techniques used in layers and the adding and taking away of glazes also gave me a sense of palimpsest. This soon became increasingly interesting and I began to look at alternative ways of making multiples from a mould that would be completely identical in shape, material and form, fired at the same time yet creating completely different colours and random decorative pattern, the art of design vs chance. The process of raku interests me and with this in mind I have started to look into building an alternative kiln to create multiples of randomised decorative pots ,pans and goblets. To do this I will need to look at pit and barrel firing techniques and build one safely. The project was definitely an enjoyable experience and I intend to explore the industry and alternative options in my future practices.

Overall, I believe that I used my time, materials and resources including lectures online and in work shop effectively and created unique personal interpretation of the brief and found the techniques enjoyable.

1 note

·

View note

Text

Beginners guide to building a plastic mold

We get asked all the time about how to make molds of things that you create. So we are plastic moulding manufacturers in india teaming up with The Plastic Surgery Workshop to give a little advice on some other ways for doing this!

1 - Mold Making Process:

- A mold is a negative impression used in the process of casting to produce, form or shape an object.

-The term 'mold' can be used for any material that creates this kind of pattern and we call it our "Master Model". An example would be using Sculpey clay as your Master Model (as I do).

- You want to start off with a simple 3D design such as coins or bunnies like my examples because they are easy shapes without undercuts which means you'll have less work. when you cast them into resin later on.

- Use minimal cut outs and limbs 10mm from the body so that when assembling your model, there will not be much leftover resin.

2 - Beginners Guide for Mold Making:

Squares are easy to use - you can make them as thick or thin (depending on the effect desired) and they're perfect for crafting a variety of objects, including jewelry boxes!

Cups save silicone material - there's no need to cut out squares from an expensive sheet of molding materials when these cups will do just fine with less waste all around!

They're readily available in supermarkets which makes it easier than ever before to get your hands on this wonderful product that is so useful at parties too where we want lots of people having fun.

The best way to make your own silicone mold is by using a master model. You can pour mixed silicone into the cup which makes the tool, and place it inside of an opening in the center with a small dab of super glue on its base. Once you have placed everything together be sure that there's at least 10 mm worth material over all parts so they don't move around when casting liquid resin later! Thinking about the cup make sure you have a good flat surface.

3 -Building a custom mold:

Silicone tool cases can be a great way to start shaping large shapes and you have the option of making your mold as big or small as you choose. I recommend leaving around 10 mm all the ways around on both sides, but feel free to make it whatever size is best for your Master Model. Both methods are good places to get started with silicone casting and will produce similar effects in the end product!

Read More: Reasons why your business should be using thermosetting material

0 notes

Text

If you are just managed to get an Nintendo Switch for the upcoming holiday, or you are looking to get some accessories for your device, a carrying case could be one of the items on your shopping list. There are abundance of options in the internet marketplace like Amazon, either game-themed or not. But you may agree that the most commonly seen types of carrying case include hard-shell case, silicone case, fibre zipper pouch, as well as leather pouch.

The Nintendo Switch is my third game console in life after PlayStation 1 and the earliest monochrome Game Boy, and I love the Switch a lot. As it is a fairly expensive toy for me, in order to better protect it when I carry it around, I have been using a hard-shell carrying case since day one I got my Nintendo Switch in April. It has been performing very well especially when I take it with me during travels aboard. The case gets my Switch covered with full protection. I do sometimes also swap the case with the official Zelda-themed Zipper Pouch (as shown above) when I do not feel like carrying other accessories with me, such as the USB-C charging cable and the earphone, as the pouch itself does not have any storage slots for this purpose.

Recently, I look into getting a leather pouch as I think it is aesthetically more classic and matches with my usual outfit and leather accessories, such as Apple Watch straps.

This is how I come up with an idea to write this post to share with you my opinions on using both leather pouch and hard-shell case that I picked and purchased from the ocean of choices, putting them for a side-by-side comparison. If you are undecided on which one to pick up, I hope your will find the following details informative and useful.

Design and dimensions

Certainly the overall design for a hard-shell carrying case is very different from a leather pouch. Despite that the compartments are sealed by zippers surrounded by fabric, how you open the case is a completely different story. You will need to flip over hard-shell cases while you can simply unzip the leather pouch and take out your Switch. It can be somehow easier and more handy than hard-shell cases that you need to flip the cover over. And this may be a more secure way to take out the console if you are on mobile rather than sitting down near a desk.

Basic hard-shell carrying cases generally look minimal, or boring in most cases. Unless your get some special editions for certain games or from designers, the outer shell designs are pretty homogenous across affordable options. However, you can easily get a more stylish look, classy colors, beautiful stitching work on a leather pouch. Aesthetically, in my personal opinion, a leather pouch definitely stands out as a beautiful contrast to the common hard-shell ones.

In terms of dimension, it quite depends on the design of each type of cases and pouches and how the brands design on their product. Generally speaking, it may not deviate a lot between the two as the size of the Nintendo Switch is there and manufacturers can simply design around it. Usually leather pouch measures smaller in size but mine is an exception. And the only major difference I can guess for most of the case will be the thickness and it depends on the material being used and the internal structure of the case or pouch.

Material, internal structure and protection

As I mentioned earlier, the major build material for a carrying case would be plastic hard-shell, silicone, fabric cloth, leather, carbon fibre or even metal, such as HORI AlumiCase. Undoubtedly, the hard-shell ones offer highest level of protection against scratches and most general circumstances that you will not feel guilty when you throw it into the bottom of your backpack right away.

It is true that leather surface is more vulnerable to scratches and damage by shape edges comparing with hard-shell cases. For genuine leather, it will grow over time with all the histories engraved on the surface on how you used and experienced with it, which is not something for everyone. However, leather wins over flexibility as it is more elastic. In addition, it may come to your surprise that a leather pouch, at least the one I owned and showed right now, provides excellent protection against accidental drop at a reasonable handheld height, thanks to the thickness and elasticity of the leather itself and the cushion inside the pouch.

Internally, the hard-shell case is very different from a leather pouch. In my case, I have the very early generation of hard-shell case. On one side two short elastic nylon straps to hold the two corners of the console, which is incredibly insecure when opening up the case. In the middle, there are only 5 cartridge slots. Lastly a pocket on the other side for minimal amount of essential accessories. The major issue for using this kind of nylon rubber straps or velcro straps is that it will age quickly over time as it is being used pretty frequently in case of a Nintendo Switch. Users will not just put it away but rather taking it in and out from time to time. However, from manufacturing cost and user-friendliness perspectives, they are the best options that we have to deal with it when they ever age.

On another hand, the leather pouch I have is just like a traveller wallet. There is no nylon or velcro straps to hold the console but instead just slide it in the pocket and it is pretty secure thanks to the friction against the fluffy inner surface, which also serves as a very good cushion against drops. On the next compartment, I can put away some accessories. However, it turns out to be a bit too tight that I need to take the headphone out from its pouch to release some space. On the outer surface, there is a zipped pocket that I can put 5 cartridges inside but there is no way to expand, unlike the hard-shell case that manufacturers can stitch more slots on the flip side of the middle flap. And again, it is quite tight when the console is insider which I can hardly put in or take out any cartridge.

For minimal cases or pouches like the above, the size is just about right fit for a Switch console and a few small accessories, such as headphone, charging cable, micro-fibre cleaning cloth or maximum one more joy-con. Do not expect that you can put a good amount of stuffs such as two more joy-cons, powerbanks or having your Switch covered with additional protective sleeve.

Stuffing any of these too much will result in pressing on joy-con analog sticks, buttons or the screen that may potential damage the parts or console, or if the device is on, consume excessive battery while the device is not in use. Most likely this will happen on a hard-shell case as it is moulded with fixed dimensions, but I have the same experience with my leather pouch as well.

One more important point to note is that despite the fact leather is more elastic and you can stretch it and put more stuff inside the pocket, beware with the nylon around the zipper that the stitching may break or things along may come off if it is being stretched too much.

Buying options

As a disclaimer, this review is not sponsored by any sellers. I purchased both hard-shell case (~US$3) and leather pouch (~US$15) from Taobao, the major e-marketplace in China, at my own cost. For hard-shell cases, there are tons of options you can find on Amazon. I researched some top-rated similar ones without breaking the bank:

Promotional image from Orzly on Amazon

AmazonBasics Carrying Case for Nintendo Switch (US$13.99)

Orzly Carry Case for Nintendo Switch (US$14.91)

Ortz Nintendo Switch Carrying Case (US$16.99)

Hestia Goods Switch Carrying Case (US$18.99)

For leather pouch, as there is no one-to-one design, I could only find a few similar alternatives on Amazon simply by looking at the promotional pictures. As usual and as a smart customer, you may wish to check the reviews under each product before you purchase, and at your own risk that I will not be responsible for any unsatisfactory buying experience:

GARUNK Leather Carrying Bag (US$11.99)

iVAPO PU Leather Bag – Beige (US$13.99)

iVAPO PU Leather Bag – Black (US$13.99)

I am no affiliate to the sellers below but there are a few more premium options you may wish to check out if you have some extra cash to splash during the holidays:

Promotional image from Waterfield

SkinzNhydez Leather Zelda-themed carrying case (US$225)

Waterfield Pouch for Nintendo Switch (US$49+)

Waterfield CityClicker for Nintendo Switch (US$79+)

Conclusions

Overall speaking, in terms of value for money, if you have ever come across any hard-shell carrying case that offers basics such as accessories and cartridge slots for around US$10, and you are not looking for something extremely fancy but just get the job done, it is definitely worth the money. Certainly there are more expensive options for Nintendo Switch hard-shell cases that offer better specifications, such as better case material, quality velcro straps and more slots for game cartridges. And if you love a game so much, you may either opt for game-theme silicone or fibre cases, there are quite a few good options with Mario and Zelda signatures.

However, if you are neither the above and looking to get something more stylish on top of practicality, provided that you do not mind spending a bit more for fancier case for your beloved Nintendo Switch console, a leather pouch a pretty good options that comes with a fashion-ascent. One thing to note will be the dimensions of the pouch, number and types of compartments the pouch has. If it is too small, it may have the possibility that the joy-con analog sticks will be pressed when the pouch is sealed, or you simply cannot stuff other accessories in the pouch.

Again, I do hope this little guide will help you out when making a buying decision on this particular accessory. For those who have already got one of the carrying cases for your Nintendo Switch, what is your pick so far and which one is the best? I would love hearing your experience down in the comments section. If you have any questions that you may think I can help on, please feel free to drop me a message and I am happy to answer at best of my knowledge as a gadget reviewer, or simply a Nintendo Switch fan and leisure gamer.

If you like the contents here, feel free to check out more posts around, subscribe to the blog, follow us on Instagram or consider being a Patreon for as little as $1 a month to support the future contents.

Detailed Comparison: Nintendo Switch Leather Pouch vs. Hardshell Carrying Case If you are just managed to get an Nintendo Switch for the upcoming holiday, or you are looking to get some accessories for your device, a carrying case could be one of the items on your shopping list.

#Game#gamer#gaming#nintendo#nintendo switch#nintendo switch carrying case#nintendo switch case#nintendo switch review

1 note

·

View note

Text

What is borosilicate glass and why it is better?

What is Borosilicate Glass?

Most people don’t realise is that not all glass is created equally. Borosilicate glass is a special kind of glass which incorporates two chemicals in high concentration: boron trioxide and silica. These safe and environmentally-friendly chemicals make borosilicate glass more heat resistant than other forms of glass on the market.

What is Borosilicate Glass made of?

Borosilicate glass is made by combining boron trioxide with silica sand, soda ash, and alumina. Because of the different melting points of the various components, it took manufacturers a considerable amount of time to figure out how to make the glass. Even today, they use a range of methods, including moulding, tube drawing and floating.

What is the difference between borosilicate glass and soda-lime glass?

Soda-lime glass is the most common kind of glass. You find it in all sorts of applications, from window panes to glass jars. Soda-lime glass accounts for around 90 per cent of all glass manufactured in the world.

The main difference between soda-lime glass and borosilicate glass is their silicon dioxide and boron trioxide content. Soda-lime glass typically contains 69 per cent silicon dioxide compared to 80.6 for borosilicate glass. It also contains far less boron trioxide: just 1 per cent compared to 13 per cent in borosilicate.

Four factors differentiate borosilicate glass from its regular soda-lime counterpart. As discussed above, it is thermal shock resistant, meaning you can pour boiling water into a borosilicate glass jug and it won’t crack. It’s also harder than regular glass, can be moulded into more complex shapes and is more resistant to acid erosion (which is why you commonly find it used in chemistry labs).

Is Borosilicate Glass safe or toxic?

Just like regular glass, borosilicate glass is completely non-toxic. Companies like Pyrex use it as a safe material to make heat-resistant glass jugs, glass bottles, and cookware. Food and drink from borosilicate containers often taste better because the material does not leach out, as it does in plastic bottles and other BPA-containing packaging.

Is Borosilicate Glass BPA free?

Borosilicate glass itself is BPA-free. However, some products which use borosilicate may have other components made from BPA plastic. When choosing borosilicate products, check to see the chemical composition of any plastic products. All pure borosilicate glass products (like baking dishes) are 100 per cent BPA-free.

Is Borosilicate Glass safe to drink from?

Borosilicate glass is safe to drink from, just like regular glass. Borosilicate glass helps you to improve sustainability and keep plastic waste out of the landfill, which is good news for the environment. Plastic pollution is a significant concern, so using a reusable jug or bottle made of borosilicate glass can help enormously.

What is Borosilicate Glass used for?

Borosilicate glass is used for all kinds of things.

Research and chemistry labs. Researchers and chemists love borosilicate glass for its ability to resistant both extremes of acid and heat. Borosilicate glass will not crack or break down when it comes into contact with the kind of compounds that you might find in a chemistry lab.

Cookware. Pyrex is famous for its use of borosilicate glass in cookware. Borosilicate glass does not crack at high temperatures found in ovens. It’s ideal, therefore, for the casserole dishes.

Water Jugs/Bottles. More durable than Soda-lime glass, strong enough to compete with plastic.

Wine glasses. Some wine glasses are made of borosilicate glass. Manufacturers make them in this way to enhance strength and durability.

Industrial applications. Borosilicate glass is much stronger than traditional soda-lime glass. Many industrial manufacturers prefer to use it across a variety of heavy-duty applications, such as panels on consoles or for viewing machinery.

Is Borosilicate Glass durable?

Borosilicate glass is highly durable. In fact, that’s what makes it so famous and sought-after.

Borosilicate glass requires higher temperatures to make than regular soda-lime glass. The higher manufacturing temperatures are what confers its heat resistance. You need to apply more heat to change the glass’s chemical structure.

The higher manufacturing temperatures also make the glass much stronger. You can drop borosilicate glass on the floor, and it won’t shatter like regular glass. Often you can pick it back up again and continue to use it. Of course, when dropped from high enough, it will crack, but you can often get away with dropping it on the floor from a regular height.

Why is Borosilicate Glass better?

Borosilicate glass is better than regular glass for a wide variety of reasons.

First, borosilicate glass expands by only half the amount of regular soda-lime glass when exposed to heat. It's low coefficient of thermal expansion means that it is far less liable to crack than regular glass.

Second, borosilicate glass is much harder and stronger than soda-lime glass. This feature makes it an ideal water container to take with you while you travel. Even if you drop it, it shouldn’t break.

Third, borosilicate glass is much more malleable than regular glass, allowing you to make more complex shapes. Some manufacturers turn borosilicate glass into vacuum insulated vessels that will keep your drinks warm or cold. Just as before, this feature makes borosilicate glass the ideal material for making sustainable glass bottles. These bottles are long-lasting and don’t contain any BPA which could damage your health.

Fourth, borosilicate glass is resistant to acid, while the soda-lime glass is much less so. Beers have an acidity of the pH scale of 3.3, meaning that it’s probably better to put them in a borosilicate glass than ordinary glass.

Should I switch to a Borosilicate Glass water jug/bottle?

The great thing about borosilicate is that it gives you all of the advantages of glass, but with none of the drawbacks. From an environmental perspective, borosilicate is a godsend. It has enough strength to compete with plastic, but it doesn’t contain any of the harming toxins, like phthalates or BPA.

Is it worth the money?

For the vast majority of people, borosilicate is worth spending the extra money. As discussed, you get a host of benefits, with few of the downsides. Ecobud’s stylish Gentoo Glass Water Jug body is made of hand-blown borosilicate glass. It’s highly durable and will stand the test of time while preventing any nasty chemicals from leaching into your crystal clear drinking water. It is reusable and recyclable.

https://bit.ly/2uUJF9r

#betterhealth#borosilicateglass#bottles#BPA#breakable#cleanwater#coefficient#contaminants#decompose#disposableplastic#durability#energy#environment#expansion#expensive#healthyfamily#filteredwater#glass#glassbottle#healthylifestyle#heatresistant#hydration#improvements#kiutchenware#leach#landfill#lifetime#recycle#pollution#long-lasting

0 notes

Text

Concrete Paver Molds For Garden Stepping Stones

The final reusable concrete walk mold we examined is the Scepter Pathmate mould. It provides a random sample engineered to permit contractors and amateurs alike the ability to rapidly format attractive-looking pathways, guaranteeing random designs for curved walkway paths https://columbiamachine.com/concrete-molds/.

Another reviewer advises that instead of lifting the entire walker maker mildew up without delay, that as an alternative you should lift one facet at a time to prevent concrete from sticking to it.

FREE directions and email assist are included with each purchase.

Home owners additionally advise to purchase/rent a concrete mixer somewhat than doing it by hand- manual-mixing can turn into incredibly grueling .

to the cement combine, too, but at all times 'over-darken' it, as a result of as quickly as it dries it shall be considerably lighter.

Rain on newly poured concrete dilutes it too much and might stop it from hardening.

Learn the method to make concrete molds for pavers, patio blocks, and walkways.

Miller Formless will custom construct concrete curb and gutter molds and median barrier wall molds to satisfy all concrete paver molds specs.

You might attempt your hand at completely different shapes corresponding to rectangles or hexagons. But keep in mind that the molds for each paver ought to be equivalent, else you could face a problem whereas laying them. • Assemble the mould in a square, and insert screw into the concrete paver molds holes. While the unique Mold Inspection and Repair Station limited swiveling of the mildew bottom only, the second generation MIRS allows for tilting the mildew head into various positions.

This process describes tips on how to make concrete molds for patio or walkway blocks. Laying sand earlier than laying your brick paver is essential. It determines the outlook of your patio paver after set up.

How To Make A Concrete Stepping Stone Mould With Bender Boards

With the lowest prices online, low cost delivery rates and native assortment choices, you can also make an even bigger saving. Some gardeners may be intimidated on the considered making their very own concrete pavers. If you can make a cake, you might make concrete pavers and stepping stones. Here are some useful hints for using molds to make stones and pavers. The stone path mildew is reusable, and also you only want a concrete mixer and a trowel to make your own distinctive pathways or patios. Another nice feature of the Scepter stone mould is the design which permits you to create a steady path in any path and make turns and curves.

Product Catalog Our hardworking molds set the standard within the business by producing excellent products for countless cycles. Online Mold Parts Ordering A personalized on-line store provides a fast and intuitive approach to order the parts you should keep your plant up and running. With our process, you can make one tile or stone per day, per mildew. If you've a big project, you could want to consider ordering a quantity of molds based mostly on the number of tiles or stone wanted, and your work schedule. As an example…it would take you ten days to provide a hundred sq. feet of tile, utilizing 10 molds, 20 days using 5 molds, etc.

Columbia’s concrete molds are recognized worldwide for superior high quality, fit and end. We have set the industry normal for years and every member of our team is committed to supplying a superior product. Be positive the concrete is filled to the highest of the shape and is leveled and smoothed. When the concrete is cured, merely take away the shape.

You can select the sort of concrete or different mortar to make the stones, and even add coloring brokers to the mortar to change it from gray to any colour under the sun. Adding rocks, pebbles, or colored stones also can add interest and selection. All of those additions and selections add as a lot as backyard paths lined with concrete pavers which are as distinctive as you may be and add your personal personal stamp to the backyard.

QUIKRETE WalkMaker Forms are reusable plastic molds for creating patterned walks, paths, patios, courtyards, etc. A closeup view of the hole that was left bordering the brick pavers on all 4 sides. I have reduce 2 x 4s to surround each sets of bricks spacing the wooden 1 half inches from the sting of the brick pattern. I decided to show the complete basket weave design the width of the size of four bricks extensive, bordered with working pattern of single bricks as edging. See the alternatives of designs within the above image for different designs that you would possibly like higher.

Every day you’ll discover new, online-only offers, store discounts and the chance to avoid wasting even more by amassing coupons. But you might have to behave fast as this high paver molds is set to turn into one of the sought-after best-sellers very quickly. Think how jealous you’re pals will be if you inform them you got your paver molds on AliExpress.

If you need to do a return or change, please email us your return request, all of the return requests shall be handled inside 2 business days. Not that DIY can't be carried out properly and be price it if somebody has extra time than cash, or just enjoys the process. With expectations measured accordingly, one method is not higher or worse than the opposite. Basically it simply provides the drainage paths under the pavers which is what the gravel did anyway.

Diamond Silicone Wall Molds Concrete Brick Molds Front Room Background Tile Molds

Thus, proper mildew care and upkeep are so as. One cause why you want to opt for patio brick pavers is that they tend to last longer. Some of these options embrace mosaic, flagstone, poured concrete, and gravel. Mosaics are more enticing than pavers however pavers are less expensive. Gravels have a greater drainage function than pavers. Poured concrete could be cheaper than pavers however eradicating them just isn't easy.

Handling equipment added for the Fort Myers plant improve consists of conveyors, elevators, and finger car, as properly as a curing system with 3,456-board capacity. The operation additionally includes a high-speed KVM cubing robot for unloading production boards and forming transport bundles of various merchandise. Plug and play adapters for the robot suit varied product types. Growing demand for unique concrete hardscapes in Florida has sparked production improvements from Tri-Circle Pavers, which operates crops in Fort Myers and Bartow. Over the past 35 years, principals Bill and Daniel de Deugd have established a observe document of high product quality and innovation. They uphold it with the latest installation of new KVM International manufacturing equipment netting varied, finely crafted hardscape units inside an automatic Fort Myers plant environment.

Although this may be a one-time mould, a leftover pizza delivery box can be used to kind a sq. stepping stone. Our Machine Shop has some impressive capabilities including in-house warmth treating, floor grinding, and full concrete mould meeting testing to call a quantity of. The Mold Store carries a extensive variety of molds to make pavers, stepping stones, bricks and extra. They embody easy do-it-yourself instructions on the means to forged pavers utilizing their molds right on the home web page. Many individuals are turning to paver molds to create flooring for patio areas.

Place dry Sand Mix in cracks and sweep in to desired level. Dampen the Sand Mix with a nice mist of water (do not over-wet). • Depending on the peak and dimension of the paver, cut a strip from the wooden. We advocate purchasing bags of ready-to-mix concrete at your local ironmongery store. Once you have these, all you should do is add water and mix.

You obtain FREE directions on tips on how to make the stone, and tips on how to lay it, , with your purchase. This is obviously a simplified version of the process, however it's that simple. FREE directions and e-mail help are included with each buy. From your 4 form pieces that you’ve reduce, kind a square. When assembled, the square must be 12 inches lengthy on each side.

Paint a daring, stunning picture using stones and pavers that is uniquely you. Another residence remodeler suggested new purchasers to rent a concrete mixer if they're working on a large project, as a outcome of hand-mixing cement can turn into an extremely grueling process. A professional contractor advised us that after all of the concrete has set, it is a good idea to do some pressure washing on the finished stone patio and apply some semi-transparent stain. It's finest to ease the form out of the bottom, somewhat than just lifting it up vertically- it helps stop sticking cement.

In today's world of big box house and garden stores and smaller specialty garden facilities, you might marvel why using a mould to make concrete pavers is best than buying ready-made pavers. The fourth choice we examined is the Quikrete sq. and rectangle formed stroll maker. Another reviewer mentions that the plastic is sturdy however versatile and that it’s best for DIY projects. A person provides that he has been utilizing the Scepter stone mould kind for months and that he is very impressed with the heavy-duty quality and the attractive results. In basic, prospects are extraordinarily satisfied with the achieved results, and they don’t have any main complaints relating to the performance and functionality of the Kenly stroll maker.

Homeowners like you will be able to expand your creativity and create numerous design choices on your backyard stepping stones. Bounce the mould to take away any air bubbles and make it stronger. Also, use a trowel to smooth the top of the paver mildew for a uniform end. When the concrete begins to set, use the edging trowel to kind clean, rounded edges on the sides. Give the concrete another hour to set and turn into fully onerous.

Some you may already have round the house, while others could value a number of dollars, but they are all considerably cheaper than buying all-in-one stepping stone kits. We perceive surface textures add breadth and depth to your product line. With today’s software program and scanning technology, we created some of our favorite natural surfaces that allow for a particular texture on the concrete molds and different merchandise you create. In addition to our commonplace textures, send us your design and we are able to rapidly present custom-made floor samples. In addition to sturdiness, the production method used by Lammers ensures the creation of their concrete paver moulds and block molds produce the same end result every time. This, finally, results in a constant end product out of your paver batching plant or block batching plant, every time.

In brief, you don’t have to take our word for it – just listen to our tens of millions of joyful clients. The third pathmaker mildew we examined is manufactured by Kenley, it's the paver walk maker mildew. It contains a nine stone pattern designed for the construction of the decorative driveways, walkways and backyard patio paths, with curves, angles and straight edges built into the mould.

Some customers report that sprinkling sand on the underside of the pans before pouring concrete helps the dried stone come out of the mildew. If you are a gardener, you might already have a set of plastic saucers that maintain massive garden pots or indoor planters. If not, they are fairly inexpensive and may be reused to make as many stepping stones as you need. The greatest saucers to use are those with smooth bottoms; those with contours might make it exhausting to remove the dried concrete. There are more options than you think in relation to the molds wanted to kind stepping stones.

While concrete is still in mildew, pat and smooth cavity surface with trowel. After removing the mildew, easy all edges with a trowel until appearance is satisfactory. Place the mildew adjacent to the completed part and continue this course of until your project is completed. Both features increase hardscape unit quality and improved manufacturing efficiency. Concrete can take anywhere from lower than an hour to an entire day to set. Concrete will shrink throughout the drying process, making it easy to release from the mildew.

Here are two different enjoyable tutorials where I used concrete to make a stone shaped planter and likewise to make a rock shaped planter. I had my concrete lined as a end result of it was the height of pollen season and I didn’t want the yellow pollen staining the stones. If you are questioning about needing to cover these with plastic whereas curing, per the concrete representative at Quikrete, it's not needed. I was able to carefully stroll on them after about 24 hours, however you should wait 3-5 days before you allow any foot visitors. Place the bag on your hands and pat the highest of the concrete.

She adds that it’s a child’s play to use the stroll maker and that it took her husband three days to complete a big section of their yard. This walk maker supplied by Quikrete Companies is straightforward to make use of, useful, and suitable for creating cobblestones paths in your garden. Users love the simple design, however some do notice that the mildew is manufactured in China. to the cement mix, too, however all the time 'over-darken' it, as a outcome of once it dries it will be significantly lighter.

Carefully flip the mould over —the concrete continues to be fragile— and raise off the base. On average, it prices about 10 dollars for every square foot. This amount can rise as a lot as 20 dollars or extra depending on the dimensions of the brick. Other factors like materials used and style also influence the fee.

Use the mould to breed as many stepping stones as wanted – polyurethane molds can last for many years and might solid hundreds to hundreds of components when nicely taken care of. Apply Pol-Ease® 2300 Release Agent to the stepping stone, mold box walls and mould box bottom board and then brush it out with a dry brush to encourage even coverage. If you plan to put the stepping stone back into its unique position in the walkway, you might think about using a detachable sealing agent, like Poly PVA Solution . It could be washed off with water after the mould making course of. If you have a very porous mannequin, like the one in this tutorial, you may have to apply more than one coat of Poly PVA Solution. We utilized two coats of this sealer, waiting for it to dry (~ 1 hour) in between coats and before transferring on to the next steps.

1 note

·

View note

Text

https://mstilesmachinery.com/

We are Interlocking Mould and Tiles Manufacturer, Paving Tiles Making Machine Manufacturer, Mini Concrete Mixers Manufacturer, Concrete Mixture Manufacturer, 3 HP Concrete Mixture Machine Manufacturer, Best Tiles Machinery Manufacturer etc… contact us : Phone: +91-8510893237, Email: [email protected].

#I Shape Silicon Plastic Mould Machine in Sorkha#Jahidabad#Tiles Manufacture in Sorkha#concrete mixer machine manufacturer in sorkha#Uttar Pradesh#I Shape Silicon Plastic Mould Manufacturer in Noida#I Shape Silicon Plastic Mould Manufacturer in Ghaziabad#interlocking making machine in sorkha#Ghaziabad#I Shape Silicon Plastic Mould Manufacturer in Delhi#I Shape Silicon Plastic Mould Manufacturer in Jahidabad#Best Interlocking Making Machine Manufacturer in Vaishali#Interlocking Making Machine Manufacturer in Vaishali#Paving Tiles Making Machine Manufacturer in Jahidabad#Paving Tiles Making Machine Manufacturer in Sarokha#2 HP Interlocking Tiles Making Machine Manufacturer in Sarokha#Concrete Mixers Machines Manufacturer in Jahidabad#Concrete Mixers Machines Manufacturer in Sarokha#interlocking mould and tiles manufacturer in sorkha#interlocking mould and tiles manufacturer in Jahidabad#Tiles Making Machine Manufacture in delhi#Interlocking Mould and Tiles Manufacturer#Concrete Mixers Manufacturer#Interlocking Making Machine Manufacturer#Concrete Mixture Manufacturer#Mini Concrete Mixers Manufacturer in Noida#3 HP Concrete Mixture Machine Manufacturer in Ghaziabad#Mini Concrete Mixers Manufacturer in Ghaziabad#2 HP Interlocking Tiles Making Machine Manufacturer#Ms Concrete Mixture Manufacturer

0 notes

Text

Create your own art toys

If you don’t know what an art toy is, or you have never seen one, there’s probably a good reason. It’s quite a niche industry, but filled with some of the nicest people and most talented artists in the world. About 10 years ago every man and his dog was talking about it; nowadays it’s quite a steady industry, but one that’s growing in popularity every day.

Art toys are predominately made by artists who have a desire to see their characters come to life in glorious 3D. In many ways, it’s an extension of their character development.

These toys are found at comic conventions worldwide, and are often handmade in low volume runs (as low as 50 or 100 pieces), which can potentially make them much sought-after and valuable. The figures are normally around 8-15 inches, and many artists start small so they can manufacture on a low budget, either by hand resin casting using silicone tools, or in vinyl plastic using rotocast or injection moulding methods (typically done at a factory in China) for larger quantities. This two-part workshop will focus on resin and silicone casting.

Why teaching yourself paper craft could earn you more money

Before you start making your own resin art toys, you need to understand that there are two main methods of production. The first is the basic method of silicone tooling, which uses just one block of silicone to make simple objects and characters. This method is what we will focus on here, because it’s the preferred casting method for beginners.

Split tooling is the more advanced technique, designed to give you greater control over your split lines on each cast while allowing you to produce more complex objects.

Sketching ideas

Turnaround drawings show six projected views of a character. Ideally, it’s best to draw them in Illustrator

In the first part of this workshop, I’ll focus on having a solid idea and producing 2D ‘turnarounds’ (see the image above). Once you have these, you can start to experiment in 3D using plasticine, and then gear up to producing a model using Super Sculpey clay.

You’ll need some paper, pens, a ruler, a computer and printer, and some Super Sculpey clay and plasticine. I’d also recommended you buy yourself a small set of modelling tools.

Before you make anything, though, you need to have a good idea of what you want to make. Your idea can be something new you create just for this project, or something that you’ve been drawing for years and want to see finally brought to life in 3D.

Start by sketching out a few ideas and choose a character that isn’t too complicated. Some things just aren’t suitable for resin casting, such as thin forms like hairs or very long spikes.

The longer and thinner the shapes, the harder it will ultimately be to get resin into these parts and actually pull the resin cast from the mould. Also, the thinner a design element, the longer it will take the resin to harden.

Turnaround drawings

Adding guidelines from the character’s front view helps you to draw the side view in the right proportions

Turnaround drawings are a set of drawings that show six projected views of a character: the front, left side, right side, back side, and if required, the top and bottom too. Ideally, it’s best to draw this up in Illustrator, because you can make adjustments and scale it as you see necessary. You can also use the drawings to see what colour you’d like and how your model will look overall in the final design.

The best way to build up another view is to use one drawing to create another. Draw the front first and then use this drawing to build up the other views. Add guidelines taken from the front view (see image above) to help you work out where to draw the essential details; this will help you establish things like where the top of the head finishes, where the arms finish, and so on.

Once you have your turnaround drawing, print it out for reference at the correct working scale. To keep it clean, I’d recommend putting a layer of clear sticky tape over it, providing a thin protective layer; you can then work on top of these guides directly while using the clay. It’s a great way of making one guide last a long time, and makes model-making easier and quicker.

Start sculpting in 3D

Super Sculpey clay is used to make a master for the art toy

Now build a rough 3D model of your character using plasticine clay. Don’t be precious about how much you use; this is a fun, experimental stage and takes a while to master.

Build lots of models and try out different colours. I normally use my whole hand: the palm for rolling soft shapes like balls, the fingers for rolling out sausage shapes, and fingertips for the fine details. I find I do a lot of fingertip patting down to get really smooth shapes like domes and to reduce the visibility of my own fingerprints. If you need a circle shape in the design, try using a pen lid or the cap of a bottle. Look around you to see what other objects make interesting impressions; plasticine clay takes details really well.

It’s worth taking a moment at this point to refine your design, and you will probably need to retune your turnaround drawings from what you have learnt using clay.

Once you’re comfortable with clay, get out some Super Sculpey. Make sure you knead it well, and have a play to create your model. Super Sculpey can be baked so it goes hard, and you can also sand it and do all sorts of stuff with it.

Next issue, we will be using Super Sculpey to make a master, so in the meantime, please read the instructions on the box you bought and get ready to make a master model in part two.

If you are interested in furthering your knowledge and fancy getting down and dirty with this fun process, check out the Plastik Surgery website and buy a copy of the Plastik Surgery Handbook to get making.

In the second part of this workshop I will reveal how to finish creating your resin art toy.

This article was originally published in Computer Arts magazine issue 262. Buy it here.

Related articles:

11 inspiring design toys for your desk

Inside Etsy’s handmade workspace

15 tips for creating characterful creature art

This post comes from the RSS feed of CreativeBlog, you can find more here!

The post Create your own art toys appeared first on Brenda Gilliam.

from Brenda Gilliam http://brendagilliam.com/create-your-own-art-toys/

0 notes

Text

Interlocking Tiles Making Machine Manufacturer in Ghaziabad

Manufacturer of Interlocking Tiles Moulds offered by Mstiles machinery in Ghaziabad, Uttar Pradesh. We offer these products at reasonable rates and deliver these within the promised time-frame. Best Interlocking Tiles Making Machine Manufacturer in Ghaziabad, Mini Concrete Mixers Manufacturer, Mini Concrete Mixers Manufacture in Navneet Vihar Ghaziabad.

#I Shape Silicon Plastic Mould Machine in Sorkha#Jahidabad#Tiles Manufacture in Sorkha#concrete mixer machine manufacturer in sorkha#Uttar Pradesh#I Shape Silicon Plastic Mould Manufacturer in Noida#I Shape Silicon Plastic Mould Manufacturer in Ghaziabad#interlocking making machine in sorkha#Ghaziabad#I Shape Silicon Plastic Mould Manufacturer in Delhi#I Shape Silicon Plastic Mould Manufacturer in Jahidabad#Best Interlocking Making Machine Manufacturer in Vaishali#Interlocking Making Machine Manufacturer in Vaishali#Paving Tiles Making Machine Manufacturer in Jahidabad#Paving Tiles Making Machine Manufacturer in Sarokha#2 HP Interlocking Tiles Making Machine Manufacturer in Sarokha#Concrete Mixers Machines Manufacturer in Jahidabad#Concrete Mixers Machines Manufacturer in Sarokha#interlocking mould and tiles manufacturer in sorkha#interlocking mould and tiles manufacturer in Jahidabad#Tiles Making Machine Manufacture in delhi#Interlocking Mould and Tiles Manufacturer#Concrete Mixers Manufacturer#Interlocking Making Machine Manufacturer#Concrete Mixture Manufacturer#Mini Concrete Mixers Manufacturer in Noida#3 HP Concrete Mixture Machine Manufacturer in Ghaziabad#Mini Concrete Mixers Manufacturer in Ghaziabad#2 HP Interlocking Tiles Making Machine Manufacturer#Ms Concrete Mixture Manufacturer

0 notes

Text

Manufacturer of Interlocking Tiles Moulds offered by Mstiles machinery in Ghaziabad, Uttar Pradesh. We offer these products at reasonable rates and deliver these within the promised time-frame. Best Interlocking Tiles Making Machine Manufacturer in Ghaziabad, Mini Concrete Mixers Manufacturer, Mini Concrete Mixers Manufacture in Navneet Vihar Ghaziabad.

#I Shape Silicon Plastic Mould Machine in Sorkha#Jahidabad#Tiles Manufacture in Sorkha#concrete mixer machine manufacturer in sorkha#Uttar Pradesh#I Shape Silicon Plastic Mould Manufacturer in Noida#I Shape Silicon Plastic Mould Manufacturer in Ghaziabad#interlocking making machine in sorkha#Ghaziabad#I Shape Silicon Plastic Mould Manufacturer in Delhi#I Shape Silicon Plastic Mould Manufacturer in Jahidabad#Best Interlocking Making Machine Manufacturer in Vaishali#Interlocking Making Machine Manufacturer in Vaishali#Paving Tiles Making Machine Manufacturer in Jahidabad#Paving Tiles Making Machine Manufacturer in Sarokha#2 HP Interlocking Tiles Making Machine Manufacturer in Sarokha#Concrete Mixers Machines Manufacturer in Jahidabad#Concrete Mixers Machines Manufacturer in Sarokha#interlocking mould and tiles manufacturer in sorkha#interlocking mould and tiles manufacturer in Jahidabad#Tiles Making Machine Manufacture in delhi#Interlocking Mould and Tiles Manufacturer#Concrete Mixers Manufacturer#Interlocking Making Machine Manufacturer#Concrete Mixture Manufacturer#Mini Concrete Mixers Manufacturer in Noida#3 HP Concrete Mixture Machine Manufacturer in Ghaziabad#Mini Concrete Mixers Manufacturer in Ghaziabad#2 HP Interlocking Tiles Making Machine Manufacturer#Ms Concrete Mixture Manufacturer

0 notes

Text

https://mstilesmachinery.com/

Manufacturer of Interlocking Tiles Moulds offered by Mstiles machinery in Ghaziabad, Uttar Pradesh. We offer these products at reasonable rates and deliver these within the promised time-frame. Best Interlocking Tiles Making Machine Manufacturer in Ghaziabad, Mini Concrete Mixers Manufacturer, Mini Concrete Mixers Manufacture in Navneet Vihar Ghaziabad.

#I Shape Silicon Plastic Mould Machine in Sorkha#Jahidabad#Tiles Manufacture in Sorkha#concrete mixer machine manufacturer in sorkha#Uttar Pradesh#I Shape Silicon Plastic Mould Manufacturer in Noida#I Shape Silicon Plastic Mould Manufacturer in Ghaziabad#interlocking making machine in sorkha#Ghaziabad#I Shape Silicon Plastic Mould Manufacturer in Delhi#I Shape Silicon Plastic Mould Manufacturer in Jahidabad#Best Interlocking Making Machine Manufacturer in Vaishali#Interlocking Making Machine Manufacturer in Vaishali#Paving Tiles Making Machine Manufacturer in Jahidabad#Paving Tiles Making Machine Manufacturer in Sarokha#2 HP Interlocking Tiles Making Machine Manufacturer in Sarokha#Concrete Mixers Machines Manufacturer in Jahidabad#Concrete Mixers Machines Manufacturer in Sarokha#interlocking mould and tiles manufacturer in sorkha#interlocking mould and tiles manufacturer in Jahidabad#Tiles Making Machine Manufacture in delhi#Interlocking Mould and Tiles Manufacturer#Concrete Mixers Manufacturer#Interlocking Making Machine Manufacturer#Concrete Mixture Manufacturer#Mini Concrete Mixers Manufacturer in Noida#3 HP Concrete Mixture Machine Manufacturer in Ghaziabad#Mini Concrete Mixers Manufacturer in Ghaziabad#2 HP Interlocking Tiles Making Machine Manufacturer#Ms Concrete Mixture Manufacturer

0 notes

Text

Manufacturer of Interlocking Tiles Moulds offered by Mstiles machinery in Ghaziabad, Uttar Pradesh. We offer these products at reasonable rates and deliver these within the promised time-frame. Best Interlocking Tiles Making Machine Manufacturer in Ghaziabad, Mini Concrete Mixers Manufacturer, Mini Concrete Mixers Manufacture in Navneet Vihar Ghaziabad.

#I Shape Silicon Plastic Mould Machine in Sorkha#Jahidabad#Tiles Manufacture in Sorkha#concrete mixer machine manufacturer in sorkha#Uttar Pradesh#I Shape Silicon Plastic Mould Manufacturer in Noida#I Shape Silicon Plastic Mould Manufacturer in Ghaziabad#interlocking making machine in sorkha#Ghaziabad#I Shape Silicon Plastic Mould Manufacturer in Delhi#I Shape Silicon Plastic Mould Manufacturer in Jahidabad#Best Interlocking Making Machine Manufacturer in Vaishali#Interlocking Making Machine Manufacturer in Vaishali#Paving Tiles Making Machine Manufacturer in Jahidabad#Paving Tiles Making Machine Manufacturer in Sarokha#2 HP Interlocking Tiles Making Machine Manufacturer in Sarokha#Concrete Mixers Machines Manufacturer in Jahidabad#Concrete Mixers Machines Manufacturer in Sarokha#interlocking mould and tiles manufacturer in sorkha#interlocking mould and tiles manufacturer in Jahidabad#Tiles Making Machine Manufacture in delhi#Interlocking Mould and Tiles Manufacturer#Concrete Mixers Manufacturer#Interlocking Making Machine Manufacturer#Concrete Mixture Manufacturer#Mini Concrete Mixers Manufacturer in Noida#3 HP Concrete Mixture Machine Manufacturer in Ghaziabad#Mini Concrete Mixers Manufacturer in Ghaziabad#2 HP Interlocking Tiles Making Machine Manufacturer#Ms Concrete Mixture Manufacturer

0 notes

Text

https://mstilesmachinery.com/

#Interlocking Mould and Tiles Manufacturer#Concrete Mixers Manufacturer#Interlocking Making Machine Manufacturer#Concrete Mixture Manufacturer#Mini Concrete Mixers Manufacturer in Noida#I Shape Silicon Plastic Mould Manufacturer in Noida#3 HP Concrete Mixture Machine Manufacturer in Ghaziabad#Mini Concrete Mixers Manufacturer in Ghaziabad#2 HP Interlocking Tiles Making Machine Manufacturer#Ms Concrete Mixture Manufacturer#Interlocking Making Machine Manufacturer in Ghaziabad#Concrete Mixers Machines Manufacturer in Ghaziabad#Concrete Mixers#Interlocking Mould and Tiles#Table Vibrators#Ms Concrete Mixture

0 notes

Text

We are Interlocking Mould and Tiles Manufacturer, Paving Tiles Making Machine Manufacturer, Mini Concrete Mixers Manufacturer, Concrete Mixture Manufacturer, 3 HP Concrete Mixture Machine Manufacturer, Best Tiles Machinery Manufacturer etc… contact us : Phone: +91-8510893237, Email: [email protected].