#Human Machine Interface Industry

Explore tagged Tumblr posts

Text

Intelligente Bedienoberflächen für die Industrie: Siemens Panel im HMI-Gehäuse

Die HMI-Panels des Unternehmens, also sogenannte Human Machine Interfaces, sorgen dafür, dass komplexe Prozesse einfach zu steuern bleiben. In vielen modernen Industrieanlagen ist die Verbindung zwischen dem Menschen und der Maschine längst digital geworden – klar strukturiert, berührungsempfindlich und verlässlich. Siemens gehört in diesem Bereich zu den bekanntesten Namen. Die HMI-Panels des…

0 notes

Text

What is a Human Machine Interface

(HMI) ?

A Human-Machine Interface (HMI) is a system that allows humans to interact with machines, typically in industrial automation. It serves as the interface between the operator and the machine, providing real-time data visualization, control options, and feedback on the system’s status.

#automation#trending#tumblr trends#viral#bestdeals#viralpost#trendingnow#allen bradley#rockwell automation#plc#human machine#Human machine interface#tech#technology#techpost#industry#industrial#industrial automation

1 note

·

View note

Text

"The Crucial Role of Industrial Control Integrators: Driving Efficiency and Innovation in Modern Industry"

The Essential Role of an Industrial Control Integrator in Modern Industry

In today’s fast-paced industrial environment, the expertise of an Industrial Control Integrator has become indispensable. These professionals or companies specialize in designing, implementing, and maintaining complex control systems that are critical for optimizing industrial processes. This blog delves into the pivotal role of an Industrial Control Integrator, explaining their key responsibilities and the impact they have on industrial efficiency.

What is an Industrial Control Integrator?

An Industrial Control Integrator is a specialized expert or firm responsible for creating and managing control systems that automate and regulate industrial machinery and processes. These control systems encompass both hardware and software components, which work together to enhance performance, increase reliability, and streamline operations.

Core Responsibilities of an Industrial Control Integrator

Control System Design and Engineering:

Needs Analysis: The integrator begins with a comprehensive assessment of the client’s specific requirements. This involves understanding their industrial processes and defining the desired outcomes.

Custom System Design: Based on the assessment, the integrator designs a bespoke control system, selecting the appropriate sensors, controllers, and communication protocols to meet the client’s needs.

Integration and Installation:

Hardware Setup: The integrator manages the installation of essential components such as Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), and other field instruments.

Software Configuration: They also configure the software that governs the control system, ensuring seamless communication between hardware and other operational systems.

Testing and Commissioning:

System Testing: Before full deployment, the integrator conducts rigorous testing to identify and rectify any issues, simulating real-world conditions to verify system performance.

Commissioning: Once testing is complete, the integrator supervises the final commissioning process, making any necessary adjustments to ensure optimal functionality.

Training and Ongoing Support:

Staff Training: Integrators provide training for the client’s personnel, equipping them with the knowledge to operate and maintain the new system effectively.

Continued Support: They offer ongoing maintenance and support services to resolve any issues and ensure the system continues to operate smoothly.

Why Industrial Control Integrators are Vital

Boosting Efficiency:

Industrial Control Integrators streamline processes by automating operations, which reduces manual input and enhances precision. This leads to improved productivity and reduced operational costs.

Enhancing Safety:

Integrators implement advanced control systems that monitor conditions in real time, increasing workplace safety by triggering alarms or shutdowns when necessary.

Ensuring Reliability:

By designing systems with redundancy and fail-safes, integrators help minimize downtime, which is crucial for meeting production targets and maintaining product quality.

Facilitating Scalability:

As businesses expand, their control systems must adapt. Integrators create flexible solutions that can be easily scaled or upgraded to meet growing demands.

Incorporating Emerging Technologies:

With the rise of Industry 4.0, integrating new technologies such as the Internet of Things (IoT), advanced analytics, and Artificial Intelligence (AI) is becoming increasingly important. Control integrators are key to incorporating these innovations into existing systems.

The Future of Industrial Control Integration

The field of industrial control integration is continuously evolving, driven by technological advancements and shifting industry needs. Future trends include:

AI and Machine Learning Integration: Enhancing predictive maintenance and process optimization.

IoT Integration: Enabling more detailed data collection and real-time analytics.

Enhanced Cybersecurity: Addressing the increasing need for robust security measures to protect industrial control systems from cyber threats.

Conclusion

Industrial Control Integrators are essential in ensuring the efficiency, reliability, and safety of modern industrial processes. Their expertise in designing, implementing, and maintaining control systems is crucial for optimizing operations and keeping pace with technological advancements. For businesses looking to upgrade or implement control systems, partnering with a skilled Industrial Control Integrator can be the key to achieving greater efficiency and performance.

#Industrial Control Integrator#Industrial Automation#Control Systems Engineering#Programmable Logic Controllers (PLCs)#Human-Machine Interfaces (HMIs)#Industrial Process Optimization#Automation Solutions#System Integration#Industrial Efficiency#Operational Reliability#Advanced Control Systems#Industry 4.0#Internet of Things (IoT)#Artificial Intelligence (AI) in Industry#Predictive Maintenance#Industrial Cybersecurity#Control System Design#Industrial Technology Trends#Engineering and Integration Services#Manufacturing Automation

0 notes

Text

Automotive human-machine interfaces (HMI) market size is valued at USD 41.82 billion by 2028 and is expected to grow at a compound annual growth rate of 11.56% over the forecast period of 2021 to 2028. Data Bridge Market Research report on automotive human-machine interfaces (HMI) market provides analysis and insights regarding the various factors expected to be prevalent throughout the forecasted period while providing their impacts on the market’s growth.

0 notes

Text

Barcode Scanner Supplier In Pune, India | Aeron Automation

In the era of fast-paced business operations, reliability is key. Elevate your business efficiency with Aeron Automation, your trusted Barcode Scanner Supplier in Pune, India. We are committed to delivering not just products but solutions that redefine reliability and productivity. Our barcode scanners are precision-engineered to meet the diverse needs of modern businesses. Whether you're managing inventory, improving customer service, or enhancing data accuracy, our scanners offer the reliability you can count on. Choose Aeron Automation as your partner in efficiency and reliability. Discover how our barcode scanners can streamline your operations and elevate your business to new heights.

#barcode scanner supplier#Human Machine Interface in India#human-machine interface manufacturers#programmable logic controller manufacturers in India#Industrial Power Suppliers India#ac variable frequency drive dealers in India#sensors manufacturers in India#photoelectric sensor suppliers India#industrial robots manufacturers in India#industrial ethernet solutions services providers in India#CNC machine suppliers#CNC machine manufacturers#cnc supplier#manufacturing robots#robot manufacturing companies#industrial sensor manufacturers

0 notes

Text

#Human Machine Interface Software Market#Human Machine Interface Software Market Trends#Human Machine Interface Software Market Growth#Human Machine Interface Software Market Industry#Human Machine Interface Software Market Research#Human Machine Interface Software Market Reports

0 notes

Note

wait whats wrong with chatgpt :(

just the minor little issue of it actively killing the planet, draining the creative marrow from everything it touches, and posing an existential threat to workers, responsibility, national security, and, oh yeah, privacy.

imagine a machine that not only guzzles electricity but also flattens human expression into soulless, regurgitated slop while quietly replacing entire industries. and let’s not forget. every word it generates is a tiny little middle finger to the concept of accountability. so, yeah. nothing major. just a slow-motion apocalypse wrapped in a shiny, user-friendly interface

#asks#this is an anti ai blog#i used to use c.ai a few months ago before i found out it was horrible too#like#nu uh

59 notes

·

View notes

Text

The River Jordan and Sweetpea are electric engines on the first railway on Mars.

River Jordan was the first one built, being the product of a collaboration between the nations who established the colony.

Sweetpea was donated by a coronal aerospace guild and assembled onsite. Her parts were imported and her blueprints were crownmade, so her visage is coronal.

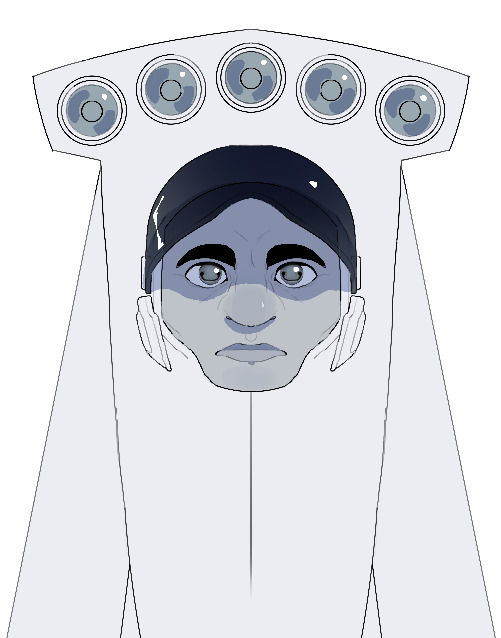

Visage and the nature of living transport

Engines take the image of their creators. Their faces are not organic, and are more like a vessel for helpful senses and communication tools.

They come alive soon after they are built, once out of eyeshot for any moment. Attempts to stare at a new engine to see it stir are foiled somehow (blinks, saccades, CCTV malfunction, momentary lapse in attention). Not all engines come alive, as their animacy is often (but not always) decided by the intent of the builder.

Living engines can assess their circumstances and make judgements based on them. They are useful in volatile situations as an expert second opinion on conduct and design, and are capable of sensing external and internal problems quickly.

In calmer periods, they may not get adequate stimulation, and their personalities may interfere with their efficiency. For this reason, railways have their preferences when they build and purchase engines.

The facial material ends at the surface of the machine and is inscrutable in composition—the material appears to be made of itself, and is unusable for any other purpose besides as an engine’s interface with the world. If damaged, the material heals. If removed, it disappears. The conceptual self-referentiality of engines’ faces, souls, and senses deter scrutiny.

Living machines exist as a fact of the universe. Their animacy is cloaked in an analysis-averting antimeme.

Human Engines

Engines designed and built by humans possess dual-pinhole pupils that dilate into an elliptical shape, granting them a broad field of view and tolerance of rapid changes in light levels (such as in going in and out of tunnels). Deep set zygomata allow them to look directly to their sides, and with the dual-pinhole setup, they maintain some depth perception in monocular sight. Their pupil shapes are hidden by their black irises, which absorb glare. They can see clearly to their front and sides, but can’t see up or down very well. A tapetum lucidum retroreflects incoming light back through their retinas, granting them vision in darkness. The nictitating membranes and long eyelashes protect the eyes from dust.

The chemicals engines are capable of detecting are relevant to their purpose, e.g. distinguishing coal, gasoline, diesel, and wood fires from their smoke but not being able to distinguish or detect food smells. Similar to how cats, obligate carnivores, have lost their ability to taste sugar due to its absence in their diet, but can taste ATP for its presence in meat—engines can parse environmental and industrial scents, but will have wildly varied responses to food and fragrant compounds, often being unable to notice them.

To investigate an aroma, they slightly lower their bottom lip to take air into their vomeronasal organ located behind the upper incisors.

Engines do not require oxygen, but if debris enters the nasal passage, human engines will sneeze to:

Ensure their voice resonates properly,

Keep their olfactory facilities clean, and

Indicate to engineers that particle buildup may have occurred in other places, such as the boiler tubes for steam engines.

Crown Engines

Just as the tongue is the only colored object on a human engine’s face for distinguishability, so are the teeth on coronal engines. The positions of the upper and lower jaw indicate tone, functioning in communication similarly to eyebrows.

Coronal engine eyes consist of an armored cornea surrounded by a cuticle and muscular eyelid. The cornea moves with the help of the embedded eyestalk supporting it. The cuticle is lubricated with an oil-based film and is less susceptible to irritation than the aqueous solution on human engine eyes. The undersides of the eyelids and surface of the cornea are covered in setae, preventing chafing and reducing airflow on the cornea. The hairs catch debris and are combed out by the lids with a puckering motion.

To make up for unenhanced vision by human engine standards, coronal engine hearing is advanced, allowing the listener to pinpoint sound sources through triangulation of the four inner ears. Coronal engines, too, channel sound through their incisors and into their internal ears via the acoustic windows at the hinge of each jaw.

Coronal engines achieve their sense of industrial smell through the gustatory papillae that line their choana and pharynx. They supplement their olfaction by introducing cool air behind the heat pits inside their nares.

Coronal engines’ thermoception is more efficient than living crowns, as coronal engines’ faces do not produce heat nearly proportional to their mass.

Conversely, the tines heat up significantly hotter than the crown average for unambiguity in temperature tones. The origin of the tine thermal energy appears to be redirected from excess produced by the machinery, or from the face’s temperature directly.

Extramodal senses

Engines are capable of listening from within their cabs with greater acuity than mere conduction of sound through the body would suggest. Other unsubstantiated sensory abilities include:

Discernment of water/fuel quality within the framework of taste though intake alone

Somatosensory awareness in the entire body, not just the face

#BOA#the railway series#<- my cover all tag#the river jordan#sweetpea#crowns#my art#speculative biology#This is an AU of my sci fi story#thomas and friends

443 notes

·

View notes

Text

“Among the accomplishments of the Enlightenment, one amplified considerably by industrial apparatuses, is the dubious fabrication of the atomized human individual, a magical figure separated from the world by his mastery over it. This construct is resistant to implications of Copernican traumas, as it continues to appreciate not only humanity but individual humans at the radiant center of the action. As this figure came to organize systems in its own image, its synthetic replication through micro-economics and social psychology set the stage for its cohesion into what is called, by design, the User. In practice, however, the User is not a type of creature but a category of agents; it is a position within a system without which it has no role or essential identity. The User of this layer is not the universal persona that collapses design research into reductive and manipulative psychologism, a fixed term toward which design must orient its interfaces and artifacts, but as a model that is not given in advance and must be construed by interfaces and constructed for platforms. Its position at the top of The Stack, where driving agency is situated momentarily, is slippery, fragile, and always enmeshed in its own redefinition, an uncertainty that underwrites the formation of subjectivity in general, always a manifest image cobbled in relation to available technologies of self-reflection, from cave walls at Lascaux to Quantified Self Apps.

For anything that is situated in the User layer of The Stack—he, she or it—the interplay between technical delineation and stable self-image is volatile. In that it is entwined with feedback loops up and down the layers, the position of User is obviously in some ways always “cybernetic,” but it does not bend toward any homeostasis or necessary resolution. It is a limited effector of processes bubbling up and down layer to layer. To and from its location, the User is both an initiator and an outcome. I would argue that anthropocenic humanism is not a natural reality into which we must awake from the slumber of machinic alienation; rather it is itself a symptomatic structure powered by—among other things—a gnostic mistrust of matter, narcissistic self-dramatization, and indefensibly pre-Copernican programs for design.” — Benjamin Bratton, The Stack

12 notes

·

View notes

Text

The biggest tech companies in the world imagine a near future where AI will replace a lot of human labor, unleashing new efficiency and productivity. But this vision ignores the fact that much of what we think of as “AI” is actually powered by tedious, low-paid human labor. “I think one of the mythologies around AI computing is that they actually work as intended. I think right now, what human labor is compensating for is essentially a lot of gaps in the way that the systems work,” Laura Forlano, Associate Professor of Design at the Institute of Design at Illinois Institute of Technology, told Motherboard. “On the one hand, the industry can claim that these things are happening, you know, magically behind the scenes, or that much of what's going on is the computing. However, we know that in so many different examples, whether we look at online content, how to operate an autonomous vehicle, or if we look at medical devices, human labor is being used to address the gaps in where that system really isn't able to work.” [...] Tech companies hire tens of thousands of gig workers to maintain the illusion that their machine-learning algorithms are fully self-functional, and that each new AI tool is capable of solving a number of issues out of the box. In reality, AI development has a lot more in common with material production cycles than we realize. “I think that the public doesn't have a good awareness of the fact that this is a supply chain. It’s a global supply chain, it contains uneven geographic flows and relations. And that it is based on a huge amount of human labor,” Kelle Howson, a postdoctoral researcher on the Fairwork project at the Oxford Internet Institute, told Motherboard. Howson can’t say for sure whether tech companies are intentionally obscuring human AI laborers, but that doing so certainly works in their interests. “I think that in some ways it supports their business models to do so because there's this perception that the work is done,” said Howson. “You as a client access a platform interface, post your project, and the work is delivered immediately. It's almost like magic. There was maybe never any human involved or [that’s what] it feels like, and so there's a sense of efficiency. And that really goes along with the kind of narrative that Silicon Valley likes to tell. The disruption, the tech solutionism, the move fast and break things kind of ideas.”

165 notes

·

View notes

Text

Getting Started with Industrial Robotics Programming

Industrial robotics is a field where software engineering meets automation to drive manufacturing, assembly, and inspection processes. With the rise of Industry 4.0, the demand for skilled robotics programmers is rapidly increasing. This post introduces you to the fundamentals of industrial robotics programming and how you can get started in this exciting tech space.

What is Industrial Robotics Programming?

Industrial robotics programming involves creating software instructions for robots to perform tasks such as welding, picking and placing objects, painting, or quality inspection. These robots are typically used in factories and warehouses, and are often programmed using proprietary or standard languages tailored for automation tasks.

Popular Robotics Programming Languages

RAPID – Used for ABB robots.

KRL (KUKA Robot Language) – For KUKA industrial robots.

URScript – Used by Universal Robots.

Fanuc KAREL / Teach Pendant Programming

ROS (Robot Operating System) – Widely used open-source middleware for robotics.

Python and C++ – Common languages for simulation and integration with sensors and AI.

Key Components in Robotics Programming

Motion Control: Programming the path, speed, and precision of robot arms.

Sensor Integration: Use of cameras, force sensors, and proximity detectors for adaptive control.

PLC Communication: Integrating robots with Programmable Logic Controllers for factory automation.

Safety Protocols: Programming emergency stops, limit switches, and safe zones.

Human-Machine Interface (HMI): Designing interfaces for operators to control and monitor robots.

Sample URScript Code (Universal Robots)

# Move to position movej([1.0, -1.57, 1.57, -1.57, -1.57, 0.0], a=1.4, v=1.05) # Gripper control (example function call) set_digital_out(8, True) # Close gripper sleep(1) set_digital_out(8, False) # Open gripper

Software Tools You Can Use

RoboDK – Offline programming and simulation.

ROS + Gazebo – Open-source tools for simulation and robotic control.

ABB RobotStudio

Fanuc ROBOGUIDE

Siemens TIA Portal – For integration with industrial control systems.

Steps to Start Your Journey

Learn the basics of industrial robotics and automation.

Familiarize yourself with at least one brand of industrial robot (ABB, KUKA, UR, Fanuc).

Get comfortable with control systems and communication protocols (EtherCAT, PROFINET).

Practice with simulations before handling real robots.

Study safety standards (ISO 10218, ANSI/RIA R15.06).

Real-World Applications

Automated welding in car manufacturing.

High-speed pick and place in packaging.

Precision assembly of electronics.

Material handling and palletizing in warehouses.

Conclusion

Industrial robotics programming is a specialized yet rewarding field that bridges software with real-world mechanics. Whether you’re interested in working with physical robots or developing smart systems for factories, gaining skills in robotics programming can open up incredible career paths in manufacturing, automation, and AI-driven industries.

2 notes

·

View notes

Text

Harnessing the Power of Biomass Pellet Machines for Sustainable Energy

In the quest for renewable energy solutions, biomass pellet machines have emerged as pivotal tools in converting organic waste into valuable fuel sources. These machines transform materials like agricultural residues, wood chips, and forestry waste into high-quality biomass pellets, offering a sustainable alternative to fossil fuels.

The Advantages of Biomass Pellet Machines

Renewable Energy Production: Biomass pellets are derived from organic materials, making them a renewable and eco-friendly energy source. Utilizing these pellets helps reduce reliance on fossil fuels and decreases greenhouse gas emissions.

Cost-Effective Fuel Solution: Producing biomass pellets can be more economical than traditional fuels. The raw materials are often readily available and inexpensive, leading to lower operational costs.

High Energy Efficiency: Biomass pellets have a high energy density and burn efficiently, providing substantial heat output with minimal waste.

Versatility in Applications: These pellets can be used in various settings, including residential heating, industrial boilers, and power generation, showcasing their adaptability.

Waste Reduction: Converting agricultural and forestry waste into pellets helps manage and reduce waste, contributing to environmental conservation.

Technological Innovations in Biomass Pellet Machines

Modern biomass pellet machines are equipped with advanced features to enhance performance and user experience:

Automated Systems: Features like Human-Machine Interface (HMI) panels and real-time mobile monitoring allow for precise control and efficient operation.

Robust Construction: Designed to handle diverse biomass materials, these machines ensure consistent output and durability.

Process Optimization: Data analysis tools assist in refining operations, leading to improved productivity and reduced downtime.

Selecting the Right Biomass Pellet Machine

When choosing a biomass pellet machine, consider the following factors:

Production Capacity: Assess your required output to select a machine that meets your needs.

Material Compatibility: Ensure the machine can process the types of biomass materials you plan to use.

Energy Consumption: Opt for machines that offer high efficiency with lower energy usage to maximize cost savings.

After-Sales Support: Reliable customer service and maintenance support are crucial for long-term operational success.

Conclusion

Investing in a biomass pellet machine is a strategic move towards sustainable and cost-effective energy production. By converting organic waste into high-quality pellets, these machines not only provide an alternative fuel source but also contribute to environmental preservation. As the demand for renewable energy grows, adopting biomass pellet technology positions businesses and individuals at the forefront of the green energy movement.

2 notes

·

View notes

Text

Why Self-Service Kiosks Are the Future of Hospitality and Retail !!

The retail and hospitality industries are constantly evolving to meet the demands of modern consumers. As businesses strive for efficiency, convenience and improved customer experience, self-service kiosks have emerged as a game-changing solution. From quick-service restaurants to retail stores and hotels, kiosks are revolutionizing how customers interact with businesses, making transactions smoother, reducing wait times and enhancing overall satisfaction.

The Growing Demand for Self-Service Solutions

With the rise of digital transformation, consumers now expect seamless, tech-driven interactions in every aspect of their lives. Self-service kiosks address this demand by providing :

Speed and Efficiency – Customers can place orders, check-in or make payments quickly without waiting in long lines.

Reduced Labor Costs – Businesses can optimize staff allocation, reducing operational expenses while maintaining quality service.

Enhanced Customer Experience – Customizable interfaces and multilingual support ensure a smooth and personalized experience for diverse audiences.

Improved Accuracy – Self-service kiosks eliminate human errors in order placement, payment processing, and service requests.

How Kiosks Are Transforming Retail Retailers are integrating self-service kiosks to streamline operations and improve shopping experiences. Some key benefits include:

Faster Checkout – Self-checkout kiosks minimize congestion at traditional cash registers, reducing wait times.

In-Store Navigation & Product Lookup – Customers can quickly locate products and access real-time stock availability.

Loyalty Program Integration – Kiosks enable customers to register for rewards programs, check points, and redeem offers effortlessly.

Seamless Omnichannel Experience – Integration with e-commerce platforms allows customers to order online and pick up in-store.

Upselling and Cross-Selling Opportunities – Kiosks can suggest complementary products or promotions based on customer preferences.

The Impact of Kiosks in Hospitality In the hospitality industry, self-service kiosks are redefining guest experiences by offering:

Faster Hotel Check-Ins and Check-Outs – Guests can skip front desk lines and access rooms with digital keys.

Self-Ordering at Restaurants – Quick-service and fast-casual restaurants use kiosks to enhance order accuracy and speed.

Automated Ticketing and Reservations – Kiosks streamline the process for theme parks, movie theaters and travel agencies.

Personalized Customer Interactions – AI-powered kiosks can recommend services, upgrades, or add-ons based on customer preferences.

Multi-Functionality – Kiosks can serve as concierge services, providing guests with local recommendations and travel assistance.

The Future of Self-Service Kiosks The future of self-service kiosks is driven by technological advancements, including:

AI and Machine Learning – Personalized recommendations and predictive analytics will enhance user engagement.

Contactless and Mobile Integration – NFC payments and mobile app connectivity will further simplify transactions.

Biometric Authentication – Facial recognition and fingerprint scanning will improve security and user convenience.

Sustainable and Eco-Friendly Kiosks – Digital receipts and energy-efficient designs will support environmental initiatives.

Cloud-Based Management – Remote monitoring and software updates will enable seamless kiosk operations.

Voice-Activated Interfaces – Enhancing accessibility for all users, including those with disabilities.

Conclusion Self-service kiosks are no longer a luxury but a necessity for businesses aiming to enhance efficiency, reduce costs and improve customer satisfaction. As the retail and hospitality industries continue to evolve, adopting kiosk technology will be key to staying competitive and meeting the ever-growing expectations of tech-savvy consumers.

What are your thoughts on the future of self-service kiosks? Share your insights in the comments below!

#PanashiKiosk#KioskDesign#TrendingDesign#InnovativeKiosks#RetailDesign#CustomerExperience#DigitalKiosks#UserFriendlyDesign#SmartRetail#DesignTrends#InteractiveKiosks#TechInRetail#KioskSolutions#ModernDesign#BrandExperience#RetailInnovation#DesignInspiration#FutureOfRetail#selfservicekiosk#businesssolution#kiosk#kioskmachine#bankingkiosk#insurancekiosk#telecomkiosk#vendingmachine#interactivetellermachine#QSRkiosk#restaurantkiosk#donationkiosk

2 notes

·

View notes

Text

CNC Machine Supplier & Manufacturers India | Aeron Automation

When it comes to precision engineering and advanced CNC machinery, Aeron Automation Solutions stands as the premier CNC machine supplier & manufacturer in India. With a commitment to innovation and quality, we offer top-quality CNC machines that cater to the diverse needs of various industries. Our CNC machines redefine precision and efficiency, setting new standards in manufacturing and automation. As a leading CNC machine supplier & manufacturer, we take pride in delivering solutions that empower industries to achieve unparalleled levels of accuracy and productivity. With Aeron Automation Solutions, you're not just investing in CNC machinery; you're investing in the future of your industry. Explore the world of precision and reliability with our state-of-the-art CNC machines.

#industrial robots manufacturers in India#programmable logic controller manufacturers in India#Industrial Power Suppliers India#Human Machine Interface in India#ac variable frequency drive dealers in India#sensors manufacturers in India#photoelectric sensor suppliers India#industrial ethernet solutions services providers in India#CNC machine suppliers#human-machine interface manufacturers

0 notes

Text

Predicting the world 100 years from now is tricky, but based on current trends, here’s my best guess:

Technology & AI

AI will be deeply integrated into daily life, possibly achieving general intelligence.

Humans may have neural interfaces (brain-computer connections) for direct interaction with technology.

Quantum computing could revolutionize science, solving problems we can’t even comprehend today.

Automation will dominate industries, possibly making traditional jobs scarce but also creating new ones.

Medicine & Human Life

Lifespans may extend significantly due to advancements in genetics, nanotechnology, and disease eradication.

Personalized medicine will tailor treatments to individual DNA, making many illnesses rare or manageable.

Bionics and brain implants could enhance human capabilities, blurring the line between human and machine.

Lab-grown organs and artificial blood might make organ failure a thing of the past.

Climate & Environment

Climate change will reshape geography—some cities may be underwater, while new habitable zones open in the Arctic.

Renewable energy will likely be dominant, with fusion power possibly providing limitless clean energy.

Some species will go extinct, but others could be revived using genetic engineering (de-extinction).

Space-based solar power and asteroid mining might provide Earth with limitless resources.

Space Exploration

Humans may have colonies on the Moon, Mars, or even further, possibly terraforming parts of Mars.

Space tourism might be common, and asteroid mining could be a major industry.

We may have discovered signs of extraterrestrial life, even if just microbial.

Society & Culture

Nations may shift towards global governance or digital nation-states with AI-assisted leadership.

Cultural and language barriers could dissolve due to real-time AI translation.

Cities may be smart, self-sustaining, and highly automated, with minimal human labor required.

Virtual reality could become so advanced that people spend much of their lives in digital worlds.

Ethical & Existential Risks

AI, biotechnology, and climate change could present existential risks if not managed well.

Humans may merge with technology so much that the definition of "human" itself changes.

Wars might be fought with cyber weapons, drones, and AI rather than traditional military forces.

Privacy could be nearly nonexistent, with constant surveillance and data tracking.

Overall, the world of 2125 will be radically different, shaped by AI, biotechnology, climate adaptation, and space expansion. Whether it’s a utopia or dystopia depends on how wisely we handle the next few decades.

2 notes

·

View notes

Text

How SCADA, HMI & PLC work together

SCADA (Supervisory Control and Data Acquisition), HMI (Human-Machine Interface), and PLC (Programmable Logic Controller) work together as key components in industrial automation and control systems.

#automation#trending#tumblr trends#viral#viralpost#trendingnow#bestdeals#rockwell automation#allen bradley#plc#hmi#scadatraining#scada

2 notes

·

View notes