#Hot Forging Press Market Size

Explore tagged Tumblr posts

Text

Metal Working Machinery Market Size, Global Industry Trend Analysis and Forecast 2024-2030

Global Info Research announces the release of the report “Global Metal Working Machinery Market 2024 by Manufacturers, Regions, Type and Application, Forecast to 2030” . The report is a detailed and comprehensive analysis presented by region and country, type and application. As the market is constantly changing, the report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of selected competitors, along with market share estimates of some of the selected leaders for the year 2024, are provided. In addition, the report provides key insights about market drivers, restraints, opportunities, new product launches or approvals, COVID-19 and Russia-Ukraine War Influence.

According to our (Global Info Research) latest study, the global Metal Working Machinery market size was valued at USD 561.8 million in 2023 and is forecast to a readjusted size of USD 835.7 million by 2030 with a CAGR of 5.8% during review period. Metal Working Machinery includes deburring machines, cold saws, presses and more. The Global Info Research report includes an overview of the development of the Metal Working Machinery industry chain, the market status of Automobile Manufacturing (Metal Drilling Machines, Metal Boring and Milling Machines), Precision Machinery (Metal Drilling Machines, Metal Boring and Milling Machines), and key enterprises in developed and developing market, and analysed the cutting-edge technology, patent, hot applications and market trends of Metal Working Machinery. Regionally, the report analyzes the Metal Working Machinery markets in key regions. North America and Europe are experiencing steady growth, driven by government initiatives and increasing consumer awareness. Asia-Pacific, particularly China, leads the global Metal Working Machinery market, with robust domestic demand, supportive policies, and a strong manufacturing base. Key Features:

Global Metal Working Machinery market size and forecasts, in consumption value), sales quantity, and average selling prices, 2019-2029

Global Metal Working Machinery market size and forecasts by region and country, in consumption value, sales quantity, and average selling prices, 2019-2029

Global Metal Working Machinery market size and forecasts, by Type and by Application, in consumption value, sales quantity, and average selling prices, 2019-2029

Global Metal Working Machinery market shares of main players, shipments in revenue, sales quantity, and ASP, 2019-2024

The Primary Objectives in This Report Are:

To determine the size of the total market opportunity of global and key countries

To assess the growth potential for Metal Working Machinery

To forecast future growth in each product and end-use market

To assess competitive factors affecting the marketplace

This report profiles key players in the global Metal Working Machinery market based on the following parameters - company overview, production, value, price, gross margin, product portfolio, geographical presence, and key developments.

The report involves analyzing the market at a macro level: Market Sizing and Segmentation: Report collect data on the overall market size, including the sales quantity (K Units), revenue generated, and market share of different by Type: Metal Drilling Machines Metal Boring and Milling Machines Metal Tapping and Threading Machines Metal Grinding Machines Metal Forging, Die-Stamping and Bending Machines Metal Broaching Machines Others Industry Analysis: Report analyse the broader industry trends, such as government policies and regulations, technological advancements, consumer preferences, and market dynamics. This analysis helps in understanding the key drivers and challenges influencing the Metal Working Machinery market. Regional Analysis: The report involves examining the Metal Working Machinery market at a regional or national level. Report analyses regional factors such as government incentives, infrastructure development, economic conditions, and consumer behaviour to identify variations and opportunities within different markets. Market Projections: Report covers the gathered data and analysis to make future projections and forecasts for the Metal Working Machinery market. This may include estimating market growth rates, predicting market demand, and identifying emerging trends. The report also involves a more granular approach to Metal Working Machinery: Company Analysis: Report covers individual Metal Working Machinery manufacturers, suppliers, and other relevant industry players. This analysis includes studying their financial performance, market positioning, product portfolios, partnerships, and strategies. Consumer Analysis: Report covers data on consumer behaviour, preferences, and attitudes towards Metal Working Machinery This may involve surveys, interviews, and analysis of consumer reviews and feedback from different by Application: Automobile Manufacturing Precision Machinery Electrical Equipment Metal Products Other

Technology Analysis: Report covers specific technologies relevant to Metal Working Machinery. It assesses the current state, advancements, and potential future developments in Metal Working Machinery areas. Competitive Landscape: By analyzing individual companies, suppliers, and consumers, the report present insights into the competitive landscape of the Metal Working Machinery market. This analysis helps understand market share, competitive advantages, and potential areas for differentiation among industry players. Market Validation: The report involves validating findings and projections through primary research, such as surveys, interviews, and focus groups.

The Main Contents of the Report, includes a total of 15 chapters:

Chapter 1, to describe Optical Tweezers (Mechanobiology Equipment) product scope, market overview, market estimation caveats and base year.

Chapter 2, to profile the top manufacturers of Optical Tweezers (Mechanobiology Equipment), with price, sales, revenue and global market share of Optical Tweezers (Mechanobiology Equipment) from 2019 to 2024.

Chapter 3, the Optical Tweezers (Mechanobiology Equipment) competitive situation, sales quantity, revenue and global market share of top manufacturers are analyzed emphatically by landscape contrast.

Chapter 4, the Optical Tweezers (Mechanobiology Equipment) breakdown data are shown at the regional level, to show the sales quantity, consumption value and growth by regions, from 2019 to 2030.

Chapter 5 and 6, to segment the sales by Type and application, with sales market share and growth rate by type, application, from 2019 to 2030.

Chapter 7, 8, 9, 10 and 11, to break the sales data at the country level, with sales quantity, consumption value and market share for key countries in the world, from 2017 to 2023.and Optical Tweezers (Mechanobiology Equipment) market forecast, by regions, type and application, with sales and revenue, from 2025 to 2030.

Chapter 12, market dynamics, drivers, restraints, trends and Porters Five Forces analysis.

Chapter 13, the key raw materials and key suppliers, and industry chain of Optical Tweezers (Mechanobiology Equipment).

Chapter 14 and 15, to describe Optical Tweezers (Mechanobiology Equipment) sales channel, distributors, customers, research findings and conclusion.

The analyst presents a detailed picture of the market by the way of study, synthesis, and summation of data from multiple sources by an analysis of key parameters. Our report on the Metal Working Machinery market covers the following areas:

Metal Working Machinery market sizing

Metal Working Machinery market forecast

Metal Working Machinery market industry analysis

Analyze the needs of the global Metal Working Machinerybusiness market

Answer the market level of global Metal Working Machinery

Statistics the annual growth of the global Metal Working Machineryproduction market

The main producers of the global Metal Working Machineryproduction market

Describe the growth factor that promotes market demand

Global Info Research is a company that digs deep into global industry information to support enterprises with market strategies and in-depth market development analysis reports. We provides market information consulting services in the global region to support enterprise strategic planning and official information reporting, and focuses on customized research, management consulting, IPO consulting, industry chain research, database and top industry services. At the same time, Global Info Research is also a report publisher, a customer and an interest-based suppliers, and is trusted by more than 30,000 companies around the world. We will always carry out all aspects of our business with excellent expertise and experience.

0 notes

Text

WMASS Flanges Dealers in Oman

Meraki Star Metals Oil & Gas Equipment Trading L.L.C. stands out as a leading manufacturer of Carbon Steel Flanges in India, offering a diverse range of flanges in various types and material grades. Our carbon steel flanges are composed of carbon, manganese, phosphorus, sulfur, silicon, copper, nickel, chromium, molybdenum, and vanadium, varying according to the material grade. The pricing of Carbon Steel Pipe Flanges also varies based on the material grade.

The WMASS Carbon Steel Flanges exhibit varying dimensions and strengths, with a tensile strength ranging from a minimum of 485MPa to a minimum yield strength of 250MPa. Classified as a medium pressure class within the B16.5 standard flanges, the Flange ANSI B16.5 Class 150 utilizes materials and pressure classes determined by nominal bore sizes and wall thicknesses.

With nominal bore sizes ranging from ½ inches to 48 inches, and classes such as WMASS Carbon Steel Flanges Rating offering different pressure ratings, we cater to diverse industrial needs. Different types of flanges serve specific purposes, such as the Carbon Steel Blind Flange for terminating pipe connections either permanently or temporarily, with permanent joints welded and temporary ones secured with bolts and nuts. The CS Lap Joint Flange, featuring a lap joint, serves as a special type. Known for their toughness and high wear and tear resistance, our carbon steel flanges assure reliability in demanding applications. For further details on Carbon Steel Weld Neck Flange Dimensions, prices, and additional information, please don't hesitate to reach out to us.

Specifications of WMASS Carbon Steel Flanges Companion Flanges:

WMASS CARBON STEEL FLANGES SIZES: Ranging from 1/2" (15 NB) to 48" (1200NB) DN10~DN5000.

API FLANGES STANDARDS: Compliant with ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092.

API FLANGES PRESSURE RATING ANSI: Including Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS.

API FLANGES PRESSURE CALCULATION IN DIN: With ratings such as 6Bar, 10Bar, 16Bar, 25Bar, 40Bar / PN6, PN10, PN16, PN25, PN40, PN64.

JIS: Offering options like 5K, 10 K, 16 K, 20 K, 30 K, 40 K, 63 K.

UNI and EN: With pressure ratings of 6Bar, 10Bar, 16Bar, 25Bar, 40Bar.

COATING: Includes options like Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized.

MOST COMMON TYPES OF API: Forged, Threaded, Screwed, Plate.

TEST CERTIFICATES: Compliant with EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report, etc.

PRODUCTION TECHNIQUE: Utilizing forging, heat treatment, and machining processes.

CONNECT TYPE/FLANGE FACE TYPE: Offering a range including Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove.

SPECIAL DESIGN: Tailored as per specific drawings and standards such as AS, ANSI, BS, DIN, and JIS, spanning from 15 NB (1/2") to 200 NB (8"), encompassing both Equal and Reducing Configurations.

TEST EQUIPMENT: Equipped with state-of-the-art tools like Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector, Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine, etc.

ORIGIN: Sourcing raw materials from Indian, West European, Japanese, US, and Korean origins.

MANUFACTURER OF: Compliant with ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE, etc.

API FLANGES USES & APPLICATION: Catering to diverse applications including Bitumen upgraders, Heavy oil refineries, Nuclear power (mostly seamless), Petrochemicals, and acids.

EXPORT TO: Serving global markets including Ireland, Singapore, Indonesia, Ukraine, Saudi Arabia, Spain, Canada, USA, Brazil, Thailand, Korea, Iran, India, Egypt, Oman, Dubai, Peru, etc.

MATERIAL TEST CERTIFICATES (MTC): Adhering to EN 10204 3.1 and EN 10204 3.2 standards, with additional certifications certifying NACE MR0103 and NACE MR0175.

For More Information:

Visit Our Website: https://www.merakimetals.ae

Contact No: +971-523973687

E-Mail ID: [email protected]

#Carbon Steel Flanges in UAE#CS Flanges in UAE#Carbon Steel Flanges Stockist in UAE#WMASS Carbon Steel Flanges#WMASS Carbon Steel Flanges UAE#WMASS Carbon Steel Flanges Manufacturers

0 notes

Text

Understanding the Fundamentals of Stainless Steel Production

Our company relies on high-quality metal components for manufacturing. The diversity of shapes, sizes, and finishes we achieve reflects our commitment to a range of production processes, highlighting our dedication to excellence and productivity.

Modern production methods, driven by robotic and computerized technologies, have transformed the metal manufacturing landscape. These advanced techniques have become market leaders, delivering visually appealing forms and textures with consistency and precision. Hot forged fasteners manufacturer in India are excellent.

In the realm of bending metal, there are two approaches: manual and machine-driven. While the former is more prevalent, the latter offers swifter and more precise results. This process is indispensable in creating various shapes like rectangles, 'V's, 'U's, and channels, and it finds extensive use in the production of Inconel 625 fasteners, known for their exceptional quality.

The art of bending metal involves multiple steps, each demanding specific tools tailored to the desired outcome. Its popularity persists due to its versatility and cost-effectiveness, as it doesn't require an extensive array of instruments. Titanium fasteners manufacturer in India offer valuable solutions in this regard.

Cutting metal is an essential part of any metal manufacturing process, encompassing various techniques to achieve desired shapes. Among these methods, plasma cutting stands out for its accuracy, enabling clean, precise cuts through thick metals without damaging the edges. Its efficiency contributes to high output and cost-effectiveness. Stainless Steel 304 Pipe cater to global demands for their superior products.

Roll forming is a process similar to bending but excels in producing longer shapes in larger quantities. The technique's higher cost is attributed to its combination of various criteria into one set, making computer simulations a common tool. Roll forming may result in thinner yet robust walls compared to other methods, while simultaneously reducing the need for additional finishing equipment. Monel 400 flanges are the most reliable.

Stamping, a fundamental metalworking technique, is a versatile and precise process that draws inspiration from traditional stamping methods. Inconel 625 flanges are indeed outstanding. It involves creating intricate shapes on sheet metal using a specialized machine press or analogous equipment. However, what sets modern stamping apart is its profound reliance on advanced computing technology. This integration of computational power minimizes errors and ensures consistent production levels, making it an invaluable resource for various industries. Hastelloy C276 pipe fittings are used widely.

The versatility of stamping allows it to deliver a myriad of modifications to sheet metal. It can punch holes, create intricate bends, emboss patterns, and even coin unique designs, tailoring its application to a broad spectrum of industries. Stainless steel 316 pipe fittings will always help you.

Stamping's influence reaches across diverse sectors, including lighting, automotive, electronics, aviation, and medicine. In the automotive industry, it plays a pivotal role in shaping intricate parts and components, while in the field of electronics, it contributes to the precision manufacturing of intricate connectors and components. Inconel 600 fasteners have been used widely. Aerospace and aviation rely on stamping for its precision in crafting structural components that meet stringent safety and performance standards. Additionally, in the medical sector, stamping is vital for creating delicate medical instruments and equipment. Incoloy 825 flanges are outstanding.

In the digital age, many companies are actively engaged in producing round bars using online platforms, offering competitive prices and access to high-quality materials, ensuring that modern stamping technologies continue to support and drive innovation in various industries. ASTM A193 B8 Bolts has the finest quality.

0 notes

Text

0 notes

Text

Cold Forging Machines Market Size, Share, Demand & Growth during Forecast 2022 to 2032

The cold forging machine market is anticipated to be worth US$ 22.16 billion in 2022 and US$ 38 billion between 2022 and 2032, with a 5.5% CAGR. The global market's rising use of cold forging machines may be ascribed to the high quality of the items produced as well as the cost savings gained by removing the fabrication stage.

Cold forging is a manufacturing technique that shapes a product by applying specific stresses at room temperature. Hot forging is the process of repeating the same procedure at a higher temperature.

As a result, cold forging machines are pieces of equipment used to carry out the cold forging process without the need of higher working temperatures.

The expanding use of these machines is entirely dependent on the expansion of major industries such as automotive and heavy engineering, as expansion and increased output volumes are the only variables that are expected to produce new demand for cold forging machines.

Automotive, construction, general manufacturing, and heavy engineering among others are the major end-users of the cold forging machines. The growth of these industries will be having a positive impact on the overall growth of the target market.

Request a Sample Copy of this Report @ https://www.futuremarketinsights.com/reports/sample/rep-gb-8353

Cold Forging Machine:

A Cold Forging Machine is a machine tool that compresses material under cold conditions by applying pressure. The compression power is transferred via dies, which are attached to opposing faces of the workpiece and plate known as an anvil.

Cold forging can be used on a variety of materials, including low carbon steel, alloy steel, aluminium alloys, copper alloys, and others. High power or force is used to push the material into a die with an impression of the desired shape.

The workpiece is placed at room temperature between two dies and then impacted with a hydraulic press until the metal takes on its final shape inside the die cavities. This cold forging process aids in the creation of precise parts with the desired shape, size, and dimensions.

Segments of the Global Cold Forging Machine Market Report:

Type 2-Die Station, 3-Die Station, 4-Die Station, 5-Die Station, 6-Die Station, Other (1-Die Station, 7-Die Station), and Application Fastener, Shaped Pieces are the market segments.

Some of the companies that are profiled in this report are:

Cold Forging Equipment Market research reports provide a close look at leading competitors through strategic analysis, micro and macro market trend and scenario analysis, pricing analysis, and a comprehensive overview of market situations during the forecast period.

It is a thorough report that focuses on primary and secondary drivers, market share, leading segments, and geographical analysis. The report also examines key players, major collaborations, mergers and acquisitions, as well as trending innovation and business policies.

Key Benefits for Industry Participants & Stakeholders:

Industry drivers, restraints, and opportunities covered in the study

Neutral perspective on the market performance

Recent industry trends and developments

Competitive landscape & strategies of key players

Potential & niche segments and regions exhibiting promising growth covered

Historical, current, and projected market size, in terms of value

In-depth analysis of the Cold Forging Machine Market

Overview of the regional outlook of the Cold Forging Machine Market:

The market is divided into five regions: North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa (MEA). North America is further subdivided into countries such as the United States and Canada.

The Europe region is further divided into the United Kingdom, France, Germany, Italy, Spain, Russia, and the Rest of Europe. China, Japan, South Korea, India, Australia, South East Asia, and the rest of Asia Pacific are subdivided into Asia Pacific.

The Latin America region is divided into Brazil, Mexico, and the rest of Latin America, while the MEA region is divided into GCC, Turkey, South Africa, and the rest of MEA.

Highlights of The Cold Forging Machine Market Report:

Market structure and forecasts for the coming years

Cold Forging Machine Market drivers, restraints, opportunities, and current trends

Historical data and projections

Estimates for the time period 2030.

Market developments and trends.

Regional, sub-regional, and country market scenarios

Market share of market participants, company profiles, product specifications, SWOT analysis, and competitive landscape are all included.

Upstream raw material analysis, downstream demand, and current market dynamics

The report also includes government policies, macroeconomic and microeconomic factors.

We studied the Cold Forging Machine Market from every angle, using both primary and secondary research methods.

This aided us in developing an understanding of current market dynamics, such as supply-demand imbalances, pricing trends, product preferences, consumer patterns, and so on.

The findings were validated further through primary research with industry experts and opinion leaders from around the world.

The data is then compiled and validated using a variety of market estimation and data validation methodologies. In addition, we have an in-house data forecasting model that can forecast market growth up to 2030.

Full Information on this Report @ https://www.futuremarketinsights.com/reports/cold-forging-machines-market

Key Segments Profiled in the Cold Forging Machines Industry Survey

Cold Forging Machines Market by Product Type:

2-Die Station Cold Forging Machines

3-Die Station Cold Forging Machines

4-Die Station Cold Forging Machines

5-Die Station Cold Forging Machines

6-Die Station Cold Forging Machines

Cold Forging Machines Market by Process:

Cold Forging by Hammers

Cold Forging by Press

Cold Forging Crank Type Mechanisms

Cold Forging Rotary Machines

Pneumatic Forging Hammers

Electro-hydraulic Forging Hammers

Power-operated Forging Hammers

CNC Hydraulic Die Forging Hammers

Mechanical Press

Hydraulic Press

Cold Forging Machines Market by End Use:

Cold Forging Machines for Automotive

Cold Forging Machines for Heavy Engineering

Cold Forging Machines for General Manufacturing

Cold Forging Machines for Construction

Cold Forging Machines for Aerospace

Cold Forging Machines Market by Region:

North America Cold Forging Machines Market

Latin America Cold Forging Machines Market

Europe Cold Forging Machines Market

Asia-Pacific Cold Forging Machines Market

Middle East and Africa Cold Forging Machines Market

0 notes

Text

Hot Forging Press Market Research Report 2023 - Industry Size, Share, Demands, Regional Analysis & Estimations Till 2028

The Hot Forging Press Market Report, in its latest update, highlights the significant impacts and the recent strategical changes under the present socio-economic scenario. The Hot Forging Press industry growth avenues are deeply supported by exhaustive research by the top analysts of the industry. The report starts with the executive summary, followed by a value chain and marketing channels study. The report then estimates the CAGR and market revenue of the Global and regional segments.

Base Year: 2021

Estimated Year: 2022

Forecast Till: 2023 to 2028

The report classifies the market into different segments based on type and product. These segments are studied in detail, incorporating the market estimates and forecasts at regional and country levels. The segment analysis is helpful in understanding the growth areas and potential opportunities of the market.

Get | Download FREE Sample Report of Global Hot Forging Press Market @ https://www.decisiondatabases.com/contact/download-sample-18061

A special section is dedicated to the analysis of the impact of the COVID-19 pandemic on the growth of the Hot Forging Press market. The impact is closely studied in terms of production, import, export, and supply.

The report covers the complete competitive landscape of the Worldwide Hot Forging Press market with company profiles of key players such as:

China First Heavy Industries

ERIE Press Systems

Fagor Arrasate

JSC “Tjazhmekhpress”

Komatsu America Industries LLC

Kurimoto, Ltd.

Mitsubishi Nagasaki Machinery Mfg. Co., Ltd.

Qingdao YiYou Forging Machinery Co., Ltd.

Schuler Inc.

SMS group GmbH

Stamtec, Inc.

Sumitomo Heavy Industries, Ltd.

The Ajax Manufacturing Company

Yangzhou Metalforming Machine Tool Co., Ltd.

Want to add more Company Profiles to the Report? Write your Customized Requirements to us @ https://www.decisiondatabases.com/contact/get-custom-research-18061

Hot Forging Press Market Analysis by Type:

< 10000 KN

10000-100000 KN

> 100000 KN

Hot Forging Press Market Analysis by Application:

Automotive Industry

Hardware Tools

Engineering Machinery

Others

Hot Forging Press Market Analysis by Geography:

North America (USA, Canada, and Mexico)

Europe (Germany, UK, France, Italy, Russia, Spain, Rest of Europe)

Asia Pacific (China, India, Japan, South Korea, Australia, South-East Asia, Rest of Asia-Pacific)

Latin America (Brazil, Argentina, Peru, Chile, Rest of Latin America)

The Middle East and Africa (Saudi Arabia, UAE, Israel, South Africa, Rest of the Middle East and Africa)

Key questions answered in the report:

What is the expected growth of the Hot Forging Press market between 2023 to 2028?

Which application and type segment holds the maximum share in the Global Hot Forging Press market?

Which regional Hot Forging Press market shows the highest growth CAGR between 2023 to 2028?

What are the opportunities and challenges currently faced by the Hot Forging Press market?

Who are the leading market players and what are their Strengths, Weakness, Opportunities, and Threats (SWOT)?

What business strategies are the competitors considering to stay in the Hot Forging Press market?

Purchase the Complete Global Hot Forging Press Market Research Report @ https://www.decisiondatabases.com/contact/buy-now-18061

About Us:

DecisionDatabases.com is a global business research report provider, enriching decision-makers, and strategists with qualitative statistics. DecisionDatabases.com is proficient in providing syndicated research reports, customized research reports, company profiles, and industry databases across multiple domains. Our expert research analysts have been trained to map client’s research requirements to the correct research resource leading to a distinctive edge over its competitors. We provide intellectual, precise, and meaningful data at a lightning speed.

For more details: DecisionDatabases.com E-Mail: [email protected] Phone: +91 90 28 057900 Web: https://www.decisiondatabases.com/

#Hot Forging Press Market#Hot Forging Press Market Report#Hot Forging Press Market Size#Hot Forging Press Market Share#Hot Forging Press Market Growth

0 notes

Note

Hi hun!! I have a prompt!! So, Zuko was born into an obviously conservative family and with all that royal training and everything, he usually speaks with proper grammar and etiquette. Enter: Sokka. Sokka has the most filthy mouth in terms of speaking and anything in general. He can turn a simple conversation about dinner into something that makes Zuko blush unintentionally. I just want to see more flustered!Zuko out here!! Ty!!

hello love! it’s probably not what you expected, it’s definitely not what I expected, but there’s a lot of flustered!Zuko, so here we are

I don’t think it’s nsfw? but it’s also not entirely sfw??

ok here’s Sokka’s got a filthy mouth and a filthy mind and now Zuko does, too almost 2k words

Zuko spent three years of his life traveling the high seas, so he spent a fair amount of time around sailors. As a banished prince, he didn’t necessarily have his pick of the lot when it came to choosing his crew, and very few men on his ship ended up being the upstanding sort typical of the Fire Navy. Instead, the men Zuko lived with during his early teen years were often slippery, prone to debauchery, and crude. They swore frequently, mercilessly, and thoroughly, and after a couple of bottles of soju, could not have been stopped by the sea itself from telling detailed stories of their sexual conquests, the deck of the ship rollicking with tall tales of quivering thighs and heaving breasts left behind at the last port. For a long time Zuko couldn’t understand why he didn’t enjoy these stories, or why all the other men did. Still, despite his uncle’s careful influence, Zuko experienced his fair share of vulgarity on his travels, and largely as a result of the seafaring men surrounding him.

Yet he finds, time and again, that he has never met anyone whose mind or mouth matched Sokka’s.

They are all sitting around the courtyard of the Fire Lord’s house on Ember Island, idly waiting for dinner to finish cooking, when Zuko hears a gasp. He looks up from sharpening his swords in time to find Sokka standing next to Katara at the pot full of their food.

“What the hell are those?” Sokka demands.

“Sea aubergines,” Katara says matter-of-factly, though Zuko hears the annoyed undercurrent of her tone.

Sokka lets out a peal of laughter. “Katara, they look like dicks!”

A governess once struck Zuko for using such a word, and he feels the sting again as he gapes at Sokka’s relaxed form. He almost expects Katara to lash out or yell at her brother, but instead she barely rolls her eyes.

“It was all they had at the market,” she says.

“Aang!” Sokka calls, cupping his mouth with his hands. He waves the airbender over. “You need to see the size of these.”

Aang skips over easily and leans over to look into the pot.

“Don’t they look like a bunch of dicks?” Sokka says, nudging him with his elbow.

Aang immediately bursts into laughter, his hands coming to rest on his stomach. Zuko can only gawk at them and the casual way they react to such language.

“Where’d Toph go?” Sokka asks. “She’d get a kick out of the dicks.”

“You idiot, I’m blind,” Toph says from her position lying on the stairs.

“You can still—” Sokka notes Katara’s glare and the fact that Toph is still a twelve-year-old girl and immediately retreats. “Right, then,” he says, taking the ladle from Katara and scooping up one of the phallic vegetables, “Zuko!”

Zuko lifts his head, the dismay clear on his face.

Sokka waves the sea aubergine in the air maniacally. “Don’t you think it looks like a dick?” he almost shrieks.

Zuko tries not to wince at the word, and instead lies, “I don’t see it.”

“What?” Sokka looks between the vegetable and the stony look on Zuko’s face. “Are you serious? It’s even oozing—”

“Enough,” Zuko says. The island heat seems to have suddenly gathered entirely around his face. “Don’t be disgusting.”

Sokka’s face breaks into a boyish grin. “So, you do see it.” He waves the ladle in the air, the sea aubergine clinging by its tip to the bowl of the spoon.

“No,” Zuko continues denying.

Katara puts her hands on her hips and finally addresses her brother. “Sokka, would you cut it out? We’re going to eat that.”

Sokka ignores her.

“Here, Zuko,” he says casually, holding the ladle handle with both hands for some reason, “maybe you just need a closer look!”

And all of a sudden, a slimy, tan-and-purple, mottled, tubular vegetable is hurtling across the courtyard straight at Zuko. Before he can even think about it, he closes his eyes and catches it right in his hands. Then comes the heat, so high and concentrated from the cooking pot, that his hands immediately pull apart, and the aubergine flops, useless, on the courtyard ground.

Zuko looks up and glares, and for the first time since going back to the Fire Nation, he swears.

“Damn it, Sokka, that’s hot!”

Sokka stops laughing abruptly, and his expression turns mischievous. “I didn’t know you swung that way, Zuko.” A blush erupts across Zuko’s face as he suddenly hears his own poor phrasing. Sokka smirks. “Good to know.”

The blush is still on Zuko’s face when they finally sit down to dinner, and it’s all he can do not to choke at the sight of Sokka’s ruthless grin each time he takes another bite of slimy, limp sea aubergine.

A couple of years after the war ends, Zuko finally lets Sokka drag him on a trip to see Master Piandao. Sokka’s already gone back a couple of times to forge a new sword and for training, but Piandao hasn’t seen Zuko since before his banishment. He politely does not react to Zuko’s scar, and instead scrutinizes the close relationship between the two young men.

“Knowing you when you were younger,” he says in his measured tone to Zuko, “and knowing Sokka,” he continues, turning to look at the younger swordsman, “I wouldn’t have imagined you two being quite so drawn to each other.”

“What do you mean?” Sokka looks up from where he’s flicking Zuko’s arm. He throws his own arm around Zuko’s shoulders and pulls him in close, beaming. “We’re best fucking friends!”

Zuko looks horrified at the blatant lack of refinement in Sokka’s language, and in front of their swordmaster no less, but Piandao remains unperturbed. In fact, if Zuko squints hard enough, it might even look like he’s smiling.

“Well,” Piandao says, picking up his own sword, “let’s get started.”

Their training session does not last long.

The two young men are caught in almost a death grip, their swords biting into each other, and their bodies so close they are practically panting in each other’s faces. Sokka’s managed to disarm Zuko of one of his swords, cast aside on the patio of Piandao’s house, and looks smug even as Zuko pushes against him. Hard.

Zuko, on the other hand, looks enraged. His leg is smarting where Sokka smacked him with the flat edge of his sword, and he has suddenly been made frighteningly aware of the fact that Sokka is now taller than him. He glowers up at Sokka, pressing back against Sokka’s sword with all of his strength, which he worries will not last as long he needs it to because since he last checked, Sokka has gotten broad, and Sokka has gotten strong.

Zuko feels a growing desire to ram his sword through Sokka, and his glower turns to a grin as he considers it. The ramming. And then a thought fills his head of how Sokka would interpret that word, and he’s shocked when he doesn’t hate it, and it makes him even angrier. Sokka’s definitely rubbing off on him. And there he goes again.

“All right, it’s a draw,” Piandao says from his safe distance away.

When neither boy pulls back, he calmly walks over and pulls them apart. They both slump onto the ground, panting like polardogs in heat.

“You’re clearly very well matched,” Piandao says thoughtfully. He waits until both boys have cooled off before he continues speaking. They sit in front of him, waiting for instructions. He nods and gestures for Fat, the butler, to join them. “There’s an orchard on the way to the village full of plum trees.”

Fat hands Zuko and Sokka each a towel.

“Best plums I’ve ever had,” Piandao continues. “Sweet and juicy, and a little sour, too.” He takes the beverage Fat hands him. “And this time of year, the trees are full of them.”

Sokka and Zuko wait as Piandao sips his drink. He hands it back to Fat.

“Go home. And walk through the orchard on your back,” Piandao says, pointing in the general direction. He bows his head slightly at the two swordsmen in front of him. “Training is done for the day. I’ll see you early tomorrow morning.”

Zuko and Sokka look at each other questioningly but scramble to do as they’re told.

Fat stands behind Piandao as they watch the two run off toward the orchard. “Those two,” he says with a shake of his head.

Piandao glances behind himself and then forward at the boys again. A thin smile graces his mouth. “They’ll figure it out,” he says warmly.

In the orchard, Zuko walks resolutely back towards the house they’re staying in, while Sokka takes his time to languorously pick individual plums from the passing trees, biting into each of them with gusto. Juice drips down his lips and chin, even down his neck, and falls from individual fruits down his wrists and muscled forearms. His appetite’s only grown as he’s gotten bigger, and so has his enthusiasm for eating. He makes loud slurping sounds to prove it.

“Stop that, would you? It sounds awful,” Zuko says.

“I can’t help it, they’re so juicy,” Sokka replies, waggling his eyebrows at Zuko. He holds one of his plums out. “Are you sure you don’t want one?”

“I’m sure,” Zuko practically barks.

Sokka shakes his head. “You’re just mad because I tricked you,” he says, referring to the three times he’s managed to pull Zuko in with the promise of a bite of plum, only to rip the fruit away at the last minute.

“I’m not mad about that,” Zuko says angrily.

Sokka raises his eyebrows. “Then what are you mad about?”

Zuko gestures back toward Piandao’s house. “We must have done something wrong if we got kicked out,” he says glumly.

Sokka stares at him. “What? We almost killed each other. In a swordfight, I’d say that was doing it right.” He pulls out one of his plums. “Besides, you heard Master Piandao. We’re well matched.”

Zuko sighs.

Sokka bites into the plum, and his eyes go wide. He holds the fruit out to Zuko.

“Zuko,” he says seriously, “try this one. It’s the best I’ve ever tasted.”

“I don’t know if I trust the guy who goes around eating random plants all the time.”

“Come on,” Sokka almost whines. He shakes the plum a bit in Zuko’s face. “It’ll make you feel better.”

Zuko gives him a hard look. “You’re not going to take it away again?”

“I’m not going to do it again,” Sokka promises, his face genuine. He almost looks caring.

Zuko eyes him suspiciously, but leans toward the plum. The skin is shiny and dark purple, the color of an eggplant, but the flesh inside is a bright and brilliant pink, exposed by the bite from Sokka’s mouth. Juice trickles down the edges of the bite into Sokka’s outstretched hand, and Zuko briefly wonders what it would be like to skip the plum altogether and take Sokka’s fingers into his mouth, to lick the juice off of them.

Zuko swallows and tries to toss the image out of his head, finally leaning toward the fruit. Just as his lips make contact with the plum’s skin, a high-pitched moan erupts from Sokka’s mouth. Zuko pulls his head back immediately to find Sokka grinning widely, and he fixes Sokka with a hot glare.

“You’re disgusting,” Zuko snaps.

Sokka smirks and takes another bite of the plum. “Ah, you love it,” he says, and he continues making those awful slurping sounds all the way back to town.

sorry

220 notes

·

View notes

Text

1831 Monday 10 October

7 55/.. 11 55/..

Up at 7 and lay down (went to bed again) - fine morning - Fahrenheit 64°. now at 8 35/.. - breakfast at 8 50/.. - got a man as guide took Cameron and George and out at 9 40/.. - walked to the Dockyard in 10 mins. [minutes] - waited there 10 mins. [minutes] and then, a party of 7 or 8 besides myself being assembled, an intelligent sort of person took us in charge, and we began the round at 10 and it took us till 11 50/.. - I was beginning to make pencil notes as usual but the man said it was not allowed - I was not expecting to find this the case in England - however it was no great matter -

Went 1st. to the mast-rooms - masts of all sizes - the old ones took larger timber - those now made consist of from 30 to 52 pieces - apparently squares about 6 inches square and about 20 feet long? - saw the main mast of the victory (100 guns) - 52 pieces and would weigh about 12 tons - of american pine as were a great many of the masts - then passed the store (lying out) of anchors, an amazing quantity - 5 anchors for each vessel - saw those for the Nelson § [Margin - vide next page] (120 guns - will in reality mount 134 or 136) weighing above 97 cwt [hundredweight] - all of wrought iron welded together - would take 17 men a fortnight to weld one anchor - each anchor for the Nelson would cost ten or eleven hundred pounds - then to the ropery - rope cables 22 inches in circumference the thickest 27 inches circumference, but chain cables most used now -

Then to the anchor forge - the anchors moved to and from the fires by cranes - they used to have enormous bellows 6 or 8 yards long and 4 men to blow them by treading on them very hard work - now (for these about 10 years) have a constant current of air kept up and stronger than ever before produced by 2 barrels (about 4 1/2 foot diameter) something like a churn half filled with water turned backwards and forwards by 2 men - 2 valves - one in each half of each end - so that when the water falling to one side shuts the valve and presses the air out into the tube communicating with the fire the valve of the other half the barrel opens and lets in air which is the next turn pressed out by the falling back of the water as before - there being a tube from each of the barrels meeting in one tube near the fire, there is by this means a constant current - one of the gents. [gentlemen] present observed that at Mr. Guest's iron works at Merthyr Twydvil in South wales, the bellows the largest in existence was a steam engine which pumped up air thro' a large cylinder - I must see these far-famed works -

Then went to the copper furnaces and rollers these are merely for the old copper - all the new copper is bought by contract in sheets ready done - the copper when taken liquid from the furnace in ladles is put into moulds forming plates of perhaps 1 1/2 feet by 1 foot and perhaps 1/4 inch thick - these are eventually rolled out (at twice) into four thin oblongs perhaps 3 1/2 by 1 foot - when rolled out to the last size, they are rubbed over with some acid, put into the furnace till red hot, then suddenly thrown into water on which the outside blackish coating immediately peels off and the copper appears that bright red copper colour we peculiarly call and know by the name of copper colour - inquired but could not learn what was the acid the sheets were mopped over with - they said it was an acid - a particular composition - the sheets were lastly put upon a roller that marked them thickly over with anchors in such sort that it is easy to know government copper -

The man too in passing an old rope pulled out one single green thread from one of the twists or threads of the rope - but mentioning the forges and furnaces I should have said that from the store of anchors we went to the block machinery (very curious) all turned by one centre wheel turned by a steam engine which was partitioned off from us so that we did not see the engine itself (of 50 horse power) - saw a block made from the square piece of Elm (because Elm does not fly off in splinters) to the last finish of the copper-eyed lignum vitæ (because very hard wood) pulley (what did the man call it?) and iron pin which fastens it within the block for the rope to run on - the man who worked the machinery that polished the iron pin was not there that we merely saw the principle of his machinery and how it worked - these 3 men (the Elm man, lignum vitæ man, and iron pin man) during the war made 12,000 blocks a month and supplied the whole navy - they are not in full employ now - tho' they still make for the whole navy - the man shewed us a large new building (enormous almost square span of roof) for making boilers for the government steamers - none yet in hand there - only a few iron tanks to mend -

From the copper furnaces, went on board the Indus 80 gun ship building these 4 or 5 years and still only (I think) the hull done - built on a new principle - diagonal timbers all along her inside in squares diamondwise so that if she strikes, she cannot spring a plank and directly fill with water and go down - 16 or 17 inches thick of timber covering of these diagonal timbers - what an immense machine! what strength! how mighty is man! how mightier far the wave that snaps his work in pieces like a bit of glass! the Indus built partly of English partly of African oak - then pass the Nelson § [Margin - § vide last page] built in India? of teak - has undergone a thorough repair - where laid up smear them all over with a yellowish composition to keep them from dry rot and roof them over to keep the weather from the deck -

The HMS Indus, finally launched from Portsmouth in 1839 [Image Source]

Left the Dock yard at 11 50/.. (no difficulty - had merely rung the bell, and asked to see it) - took boat at 11 55/.. and rowed off to the royal George (of which Lord .. Fitzclarence is Captain) the royal yatch that the late King went to Ireland and Scotland in - has 70 men - 310 tons (I think) - but what ever she is Lord Yarborough's yatch the Falcon lying near, and looking like a man of war, is tentons ten tons more - this last mounts 14 six pounders, and can take care of herself when the guns not mounted the gun carriages fit up as wash-stands! 50 men? the royal yatch a magnificently fitted up vessel - great deal of gilding without - great deal of comfort and luxury within - the rooms or cabins hung with a glazed calico (up these 15 years) that does and looks admirably well - shut-up chairs, the most excellent travelling concerns I ever saw - by Edward Bailey upholsterer etc. to his majesty mount street Grosvenor Square - an admirable wash-stand that holds a bed - capital for any dressing room - these too of Bailey -

From the yatch rowed across to the new victualling offices close to Gosport - we should have had an order to see them? but did not take any pains to get admitted - an enormous brick pile, - a large square projecting part of it towards the water standing on columns - then rowed forward and landed in Cold harbour Gosport - walked along the works, and came in at the far end of High street very good street very soon passed (left) the neat small house of Mr. Titcher and then near it same side the large 3 or 4 story (brick - all the town brick) best house in the town? of Mrs. Page (has been for some time confined to her bed), Mrs. Henry Priestley's uncle and mother -

Went into the handsome market house and reembarked close to there and in about 20 mins. [minutes] rowed off to the Victory the ship on board which Nelson was killed at Trafalgar - saw the spot where he fell - near (close to) the prow skylight - then went down to the 2nd deck (or mid-deck?) where a court martial was sitting admiral Sir John Gore president - Captain Lord ... Fitzclarence sitting, and 4 or 5 more officers at the table - Backhouse (1st. mate?) versus Captain Belcher of the Ætna bomb - Captain B- [Belcher] brought Backhouse to court martial, and then Backhouse brings the captain to ditto for lastly cruelty and unofficer like conduct and and several other charges that went before - 25 mins. [minutes] there - Backhouse seemed giving rather uncertain evidence - within musket shot and clear day yet could not tell whether signals were up or not - hurried off at last because when Backhouse was called on as to the last charge he said he could not repeat the word Captain Belcher used because there were ladies in the court myself and Cameron and a lady or famale [sic] person what shocking nonsense! I waited for no more but hurried off vexed that there should be such humbug should -

The HMS Victory, Lord Nelson’s flagship at the Battle of Trafalgar, can still be seen at the Portsmouth Historic Dockyard [Image Source]

High water now abouts (at 2 1/4 on leaving the Victory) - rowed down to near the entrance to the harbour (about 1/4 mile across) and landed near the round fort that defends it at 2 40/.. - sent home Cameron and George to get all ready for being off, and myself took the guide, and walked round the ramparts - soon came to what they call the King's steps where the King lands, a sort of small squary windowed ornament tower - but a battery? there - and several batteries all along - very strong place - double moated and ramparted - from just beyond the Kings stairs magnificent views of Spithead, Isle of Wight, see Ryde quite plain - Fort Monckton and its barracks, and Haslar hospital and Gosport, Stoke just beyond it, and Anglesea Crescent the Duke of Norfolk began about 2 years ago (2 miles from Gosport - near Stoke) for a watering place, but the work is not going on just now - 'Tis Portsmouth only within the fortifications - beyond these is Southsea (quite a town and Southsea castle a low thick round fort about a mile from the rampart where I stood) - then Portsea where the docks are, then on the other side the harbour Gosport - at high water a mile across - finest harbour in the world - the largest ship ride in safety - but if they should get aground it is only in mud, and the next tide gets them off unhurt - the new custom house a large pile of building, and immense government store houses close by - High street and 1 or 2 more good streets and 2 or 3 pretty good churches in Portsmouth -

Went into bookseller's shop near the George, and bought Portsmouth guide - no plan of the town in it - no plan of it allowed to be published - the George hotel (Guy) High street - very good hotel, and not dear considering - my expenses were more than usual, but I had dinner 4/6 and 2 bottles soda water 1/6 and servants dined I suppose when I sent them back for their expenses were 11/. - my wax lights and good sitting room were 2/6 and beds 5/6 and all that and the rest as usual - back at 3 25/.. -

Settled all and Off from Portsmouth at 3 42/.. - soon passed under the 2 covered ways (arches) and over the 2 wooden bridges - part of the last a drop bridge - still town, Portsea, or Southsea, or something, for a considerable distance the whole backed by the chalk range of Portsdown - at I suppose about 4 miles from Portsmouth (at 4 10/..) pass port's bridge, 2 wooden bridges over 2 canals or fosses and a military station like a french porticoed barrière close (left) by the road - then at 4 1/4 a short distance Portsbridge turnpike and then at 4 1/4 the neat enough little town or good village of Cosham - my once for a moment idea of staying there and taking horses thence to Portsmouth, would not have answered - the George Inn the best apparently is quite like a common Inn, and one at which one would not think of stopping, save on a pinch - at 4 17/.. turn (right) at the end of Cosham down to Havant, a village-like little town - neat enough little place posting Inn, the blackbear - a continued street for some distance - neat little liveable cottages (left) along the road - sea and shipping now and then right - Range of down (good sheep pasture) all along at a little distance (left) - 5 1/2 p.m. late enough for seeing anything now -

Enter Chichester at 5 55/.. - pass the cathedral close (right) - a lengthy, fine enough looking church - then beautiful gothic pinnacled rotunda, or market cross, or what, in the middle of the street and then immediately wide good street and alight at 6 at the Swan hotel - very good small sitting room opening on to balcony towards the street - good bedroom another flight on 2de. [secunde] and very comfortable - tea at 6 1/2 - sat over it till 7 3/4 - musing, as I had been all the way this afternoon and as I have done perpetually since seeing yesterday morning the gothic windows at Cowes -

On the plan for altering Shibden hall so as to make it liveable - put such gothic windows as at Cowes into both gables - take the drawing room end groundfloor and above for bedrooms and dressing rooms - take away my uncles room and butteries leaving only room enough for light stairs - Gothicize the passage like that to the courthouses at Norwich - pull away the kitchen part and parlour and all that instead of which add to the breakfast gable a part to correspond with the present hall and beyond and joined to that another gable extending backwards length enough to allow that is wanted - then taking a light gothic passage off the upper kitchen and likewise off the new hall-corresponding-part and all thro' the new gable everything would be comeatalbe [sic], and there the whole suite of rooms to the south opening into one another - new gable, or drawing room? new hall-corresponding-part, or dining room? present breakfast room enlarged by all the present upper kitchen but enough for gothic passage - present passage gothicized and perhaps heightened and lightened by the present library, present hall thrown up to the roof, and present drawing room fitted up as a French dress bedroom - the present passage would have 4 gothic doors - 2 on each side, at each end - 2 opening into the hall (with billiard table?) and 2 opening the one into the new passage along the upper kitchen etc. the other into the present breakfast room - the ground falls so rapidly to the East, that I think laundries and cellars etc. might all be under the new gable -

Very rain-threatening day but fair - raining heavily now at 10 35/. p.m. and has been for some time - great deal of rain fell during last night, too - Fahrenheit 64°. now at 10 35/.. p.m. at which hour had just done all the above of today - came upstairs at 10 50/.. -

Reference: SH:7/ML/E/14/0132 - SH:7/ML/E/14/0133

#anne lister#anne lister code breaker#gentleman jack#1831#southern england tour#portsmouth#portsmouth dockyard#chichester#HMS Indus#HMS Victory

5 notes

·

View notes

Text

Tolkien/Middle Earth Headcanons: Winter and Snow!

Tolkien Headcanons/Imagines: Snow

Plus Size Reader, PS Reader Tolkien Character, Lord of the Rings, The Hobbit

Winter Activities!

Legolas: The prince of the Woodland Realm is all about hunting this time of year. Yes, it's cold. Yes, it's dreary. But man, the game is truly spectacular. To be honest, he usually does his ACTUAL hunting when you're not with him. It's not because you can't keep up because you're awesome and can slay like no one's business. But if Legolas has managed to get you out away from the kingdom...in the privacy of the woods...with the possibly of getting you cold and letting him warm you up? Well, he's not an idiot. He doesn't squander such lovely opportunities.

Aragorn: Lol, 10/10 you're out riding horses. Probably scouting but just using it as an excuse to get in a ride. You most definitely did not throw that snow ball that hit him smack dab in the face. And he most definitely didn't pull your ass off your horse by the leg. And ya'll most certainly didn't have it out in the snow. No, never you two. Noooooooo. ;)

Frodo: Sweet Frodo Baggins reads you a book as you mill about outside. You're a busy little bee and while he likes to take him time and relax, he sure does enjoy accompanying you on whatever it is that you've decided to do at that moment in time. Even if what that is, is probably going to get you both in trouble. Frodo is in love with The Shire but it pales in comparison to his love for you.

Sam: An exciting trip to the market! It's lively even in the cold of winter! Everyone is out and about with harvest from the summer! Dried fruits and vegetables! Jars of preserves! And possibly his favorite! The fresh food! Fires blazing with pots of soups and stews bubbling away for sale! Hot mead and spiced cider! Sam either offers you his arm or holds it snugly around you the entire time! The two of you keep warm but cozying up and filling your bellies! You return home to your cottage with full bellies, baskets of food and ready to snuggle up by the fireplace!

Merry: Merry probably takes you for a date at the Prancing Pony! The two of you take Bucklebury Ferry across the Brandywine River to Buckland and then on to the Pony. You probably have a nice meal there with a pint of ale. Merry had arranged a room for the two of you for the night just so you can get away for a bit. You probably mill about town the next day, collecting this and that before heading back home to The Shire. Adventures don't always have to be half way across the world, you know. ;)

Pippin: Oh, Pippin, lol. You are the spark to his flame so whenever Gandalf is near he gets as many fireworks as he can. Pippin probably gets you all cozied up for winter temperatures and prepares a picnic. You argue with him about how impractical it is to have a picnic in the dead of winter. However, you go because you love him. When you reach your destination and he builds a small fire to keep you toasty. You admit it's nice. Eventually darkness is on the horizon and you pack up to go back home but he's disappeared. Not in the mood for his games, you almost throw a fit. However, you nearly jumped out of your knickers when you heard an explosion. You search it out only to find your crazy love. Soot on his face and hair a mess. The poor fireworks exploded in his face, lol.

Boromir: Ah, the Captain. There he was with his men in a very important meeting when something hit the window. At first, he ignored it but then again...and again. Eventually he checked it out only to see your cheeky grin as you teased him. He scolds you but you only shake your bottom at him and run away. He shakes his head but returns to him men with a much merrier look to him.

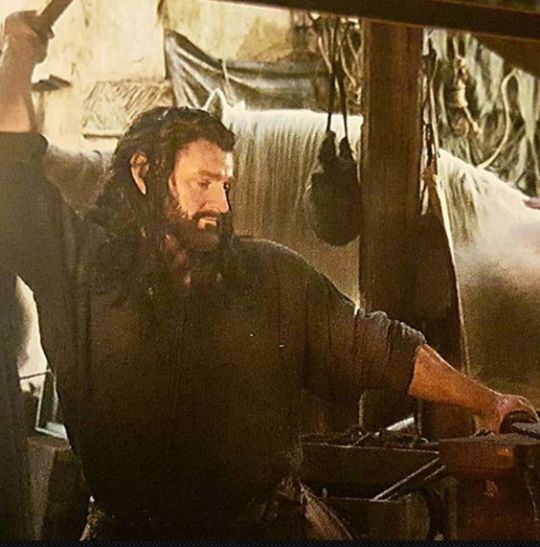

Thorin: Without a doubt, he's working the iron. Before the journey back to Erebor whilst he worked as a talented blacksmith...you were his ever faithful wife. On cold winter days, like this one, you made sure your duties were finished rather quickly and you took him lots of snacks. The forge was warm from the roaring fires and he usually ended up with his shirt open a little. You'd sit, wrapped up in furs, watching the sweat roll of your beast of a husband and you can bet your sweet ass that you weren't cold anymore. Also, Thorin - the cheeky shit- knows this. It's why he kisses you sinfully on those days. Like a mouse to cheese he leads you to him. He quite enjoys watching his little wife all hot bothered for him. Makes it even better when he takes you at the end of the day.

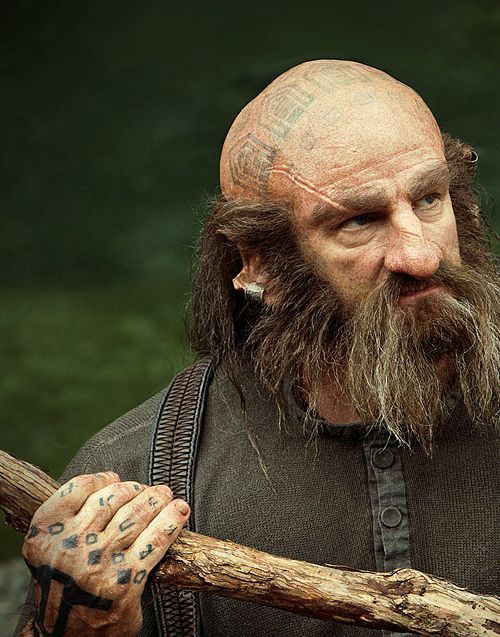

Dwalin: Dwalin is out chopping wood to feed the fires necessary for winter. And you? You follow him...because that's just how you are. And also because you would rather DIE than miss watching your husband's muscles ripple. He tells you if you're going to come along then you're going to hurt. You and he both know perfectly well that you're more than capable of cutting wood. And damn good at it. However, you fake it everytime just so he'll stand behind you and 'show' you what to do. It's become quite a routine for the two of you now.

Bilbo: You and Mr. Baggins enjoy some pipeweed on the front stoop for a while before retiring inside to enjoy some delicious meals and perhaps a bit of song if he feels inclined. Also note: when Bilbo's been on the pipeweed, he's a little handsy. Think about the lovey dovey potheads you might know. That. It's literally that, lol.

Bard: Bard watches from the window as you play with his children out in the snow. Snowmen, snowball fights and just flat out chasing each other until you all fall down out of breath and make snow angels. You grin up at him and his eyes twinkle from pure adoration.

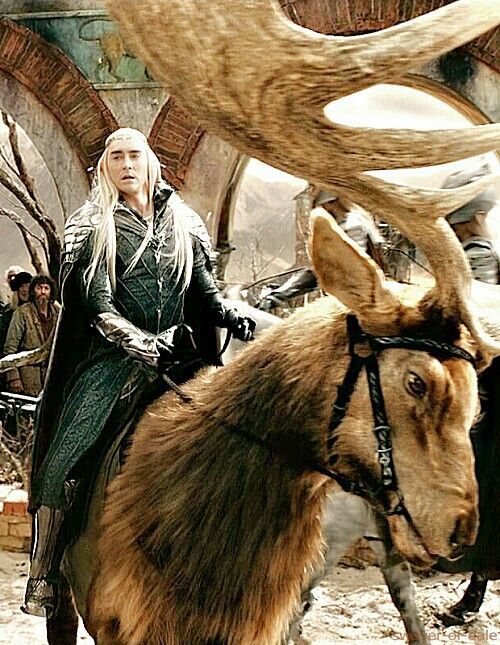

Thranduil: The King of Mirkwood takes you for a ride on his elk. The forest is absolutely spectacular and it twinkles from icicles shining in the sun! The guard is near but he doesn't care for their eyes so he snatches you around in front of him for a bit more privacy. He simply shrugged when you give him a look. "I wanted a little more privacy for us." he simply replied and the two of you kept riding on.

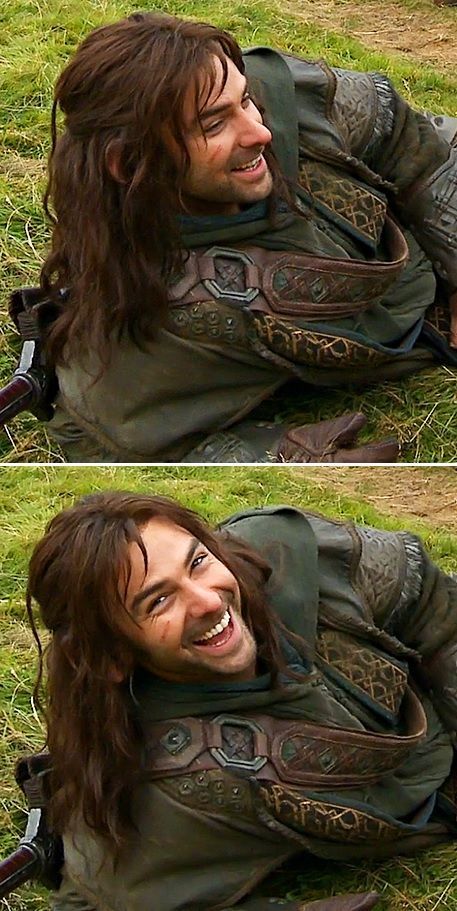

Fili: The young King in Training was in meetings with his uncle and the advisors all day. Kili was supposed to be there but he'd snuck away. The two of you waited until they all got inside before you pressed your noses up against the window. Fili nearly spit out his tea when he saw your ridiculous face. However, he lost it when Kili's tongue got stuck to the metal framing of the window.

Kili: Target practice. Effing target practice. In the freezing freaking rain. "Kili, I'm freezing!" "Good, because when it matters you'll already be frozen. It'll be deadly temperatures and it'll be raining so hard that you won't even be able to see your hand in front of you face." "If I die from the sickness, I'm haunting you forever." "Good." he said. "I'll make sure to play all your most hated music then." You had to resist the urge to shoot him in the foot. He pulled you into his arms and kissed you beneath your earlobe. "Now what?!" You exasperated. "You hit this target, in the rain, freezing, with me lighting you up....and I swear I'll sharpen and clean your weapons for a month." You'd never loosed an arrow so quick in your life. And hit the target on the first try. Also, Kili had never rushed you back to the room and peeled your clothes off so fast in HIS life.

Heeey, smoochies! I hope you enjoyed this bonus content for Smoochmas! ! If ya like it, please be sure to let me know in the comments and check out my masterlist! Link on profile!

Love, Mama Kennysaurus

@frankie2902

@pleasantdreamqueen @becrazy–beyou –beyou

@becrazy-beweird

@littledeadrottinghood @blackirisposts

@therealmrshale @woodworthti666

@jimmys-afterlife-love-deactivat @the-great-irene @fanfictionandjunk

@angelus320

@alanlizzingtonshore @buriednurbckyrd @disneymarina @@tubbypeachwriting

@sullybot @georgiagrl1990 @whenallsaidanddone

@mischiefnevermanaged94 @inumorph

@congurl

@centerhabit

@bubblymusiclover13

@meetcally

@qtmeryr

@thisismysecrethappyplace

@tnupsweetpie

@alisoncdariel

@hannahloveslife

@wormyboi

@blackirisposts

@maggyme13

@amethyst09

@lostdarksoul6

@fanfics1717

@coffeebooksandfandom

Love, Kenny

#tolkien#middle earth#lord of the rings#the hobbit#legolas#merry#pippin#frodo#sam#same wise gamgee#aragorn#boromir#thranduil#filli#kili#thorin#thorin oakenshield#winter imagine#winter headcanons#durinson#bilbo baggins#elf

247 notes

·

View notes

Link

Forging is the operation where the metal is heated and then a force is applied to manipulates the metals in such a way that the required final shape is obtained. Forging is generally a hot working process though cold forging is used sometimes. Scope of the Report: This report focuses on the Hot Forging Press in Asia-Pacific market, especially in China, Japan, Korea, Taiwan, Southeast Asia, India and Australia. This report categorizes the market based on manufacturers, countries/Regions, type and application. Market Segment by Manufacturers, this report covers SMS Sumitomo TMP Schuler Fagor Arrasate Komatsu Lasco Kurimoto First Heavy Stamtec Ajax Mitsubishi Erie J&H Qingdao Yiyou Yandon NHI China National Erzhong Group Market Segment by Countries, covering China Japan Korea Taiwan Southeast Asia India Australia Market Segment by Type, covers 100000 KN Market Segment by Applications, can be divided into Automotive Industry Hardware Tools Engineering Machinery Others There are 19 Chapters to deeply display the Asia-Pacific Hot Forging Press market. Chapter 1, to describe Hot Forging Press Introduction, product type and application, market overview, market analysis by countries, market opportunities, market risk, market driving force; Chapter 2, to analyze the manufacturers of Hot Forging Press, with profile, main business, news, sales, price, revenue and market share in 2016 and 2017; Chapter 3, to display the competitive situation among the top manufacturers, with sales, revenue and market share in 2016 and 2017; Chapter 4, to show the Asia-Pacific market by countries, covering China, Japan, Korea, Southeast Asia, Taiwan, India and Australia, with sales, price, revenue and market share of Hot Forging Press, for each country, from 2012 to 2017; Chapter 5 and 6, to show the market by type and application, with sales, price, revenue, market share and growth rate by type, application, from 2012 to 2017; Chapter 7, 8, 9, 10, 11, 12 and 13 to analyze the key countries by manufacturers, Type and Application,covering China,Japan,Korea,Southeast Asia, Taiwan, India and Australia,with sales,revenue and market share by manufacturers,types and application; Chapter 14, Hot Forging Press market forecast, by countries, type and application, with sales, price, revenue and growth rate forecast, from 2017 to 2022; Chapter 15, to analyze the manufacturing cost, key raw materials and manufacturing process etc. Chapter 16, to analyze the industrial chain, sourcing strategy and downstream end users (buyers); Chapter 17, to describe sales channel, distributors, traders, dealers etc. Chapter 18 and 19, to describe the research findings and conclusion, appendix, methodology and data source

#hot forging press market#hot forging press market trends#hot forging press market size#hot forging press market data#hot forging press market structure#hot forging press industry analysis#hot forging press market research#hot forging press market report

0 notes

Text

Metal Forging: All About Different Forging Methods And Their Uses | Pahladrai Forgings

Forging is a manufacturing process in which the metal is pounded, pressed or squeezed under heavy pressure into high powered strength parts known as Forging. The process is typically performed by preheating the metal into its desired temperature before it is given the shape. But it is crucial to remember that this process is entirely different from that of Casting Process, as the metal used is never poured or melted, which is being done in the casting process.

Why Use Forgings And Where Are They Used?

Forging process creates stronger parts than those, which are manufactured by any other metal process. This is the reason Forging process is more preferred as reliability and human safety are utmost important. You will rarely find forgings in daily day to day life as they are the component inside parts of assembled items such as automobiles, airplanes, ships, oil drilling equipment, engines, tractors, missiles, all other kinds of capital equipment to name a few.

Who Purchase These Forgings?

These customized parts vary in various shape, size and finesse - from the wrench and hammer in your toolbox to accommodate tolerance precision parts in the Boeing 747 and NASA space shuttle. In fact, a 747 Boeing contains nearly 18,000 forgings. Some of the purchasers and consumer markets include national defence, aerospace, agriculture, automotive, mining, construction, material handling and general industrial equipment.

What Metals Are Forged?

Any metallic substance can be forged. However, the common metals which are used are alloy and stainless steels, carbon, brass, copper, aluminium, titanium, hard tool steels, and high-temperature alloys containing cobalt, molybdenum or nickel. Each of these metals has its own distinct weight or strength characteristics which provide maximum utilization if best applied to any specific parts by the customer.

How Are Forgings Produced?

Gear Forging, or copper Forging , or be it forged steel rings, are all done by customized shaping of the metal by deformation that includes a myriad of techniques and equipment. The key to understanding forging designs, one needs to know the forging characteristics and operations of how the metal flow and what each produces. Forging is one process which takes into the metal's natural flow of grain into its advantage to confirm the unique contours of each part.

Hammer and Press Forging

The forging copper and other metals are carved into shape either by a press or a hammer. Forging done by the hammer is conducted out by repetitive blows. But the hammer forging and its productivity all depend on the techniques and skill of the operator. With the rise of technology and the arrival of automated hammers, it has resulted in the lesser time taken, enhanced flexibility and lesser worker dependency. During the process of the press, the stock is hit usually once in each blow.

The Open Forging or Hammer process

Open die forging is nothing but a modern day extension of the hammer and press process that a metal smith practised in anvil the pre-industrial period.

In the open die forging process, the workpieceis not entirely held in the die to give the desired shape. Usually, the open die forging technique is connectedwith large parts such as metal shafts, sleeves and disks. Most of the open die forging products is built on flat forging dies. Sometimes the round swaging dies and V-shaped dies are utilised in along with the flat dies.

Methods implemented on open die presses include:

· Outstretch and reduce the cross-section of the ingot or billet and expand it

· Upset forging to decrease the length of the ingot or billet where only one side of the metal requires forging

· Upset, outstretch, and piercing processes coupled with forging over a mandrel for unevenly shaped forged steel rings

As the open die forging includes hammered or pressed workpiece, it is frequently manipulated within the dies till it gets its final forged shapes. Because the process depends more on the workers' skill, this process is ambiguous and substantial workpiece stock quantities are preserved to provide forging abnormalities.

The forged parts of the workpieceare roughly shaped and finished to final dimensions. But with the increasing demand and use of the open die forging method and all other forging processes of this type are being automated.

On the other hand, the features of roll-forged elements are very satisfying. In most cases, roll-forged components have no flash, and the metal grain structure is convenient and constant in all parts. The forged steel rings and rolls offer a certain amount of descaling, making the product exterior smooth and free of scale pockets.

Impression Die Forging

In the impression die forging process, two dies are taken together and the workpiece goes through plastic deformation until its developed sides reach the side walls of the die.

During the process of impression die forging, some material starts to slip outside the die impression, forming some flashes.

Once the flashes cool down, they form intensified resistance to deformation. These cooled flashes build pressure inside the bulk of the workpiece and help material flowing into the vacant impressions.

Closed die forging, another type of impression die forging, is performed within a narrow cavity that restricts excess material from flashing out. This process is not dependant on the flash formation. Thus this is the most popular type of impression die forging.

The forging dies become more influential than the workers' skill in case of impression die forging methods. Impression forging program usually shapes materials and finish the piece with the preform, pierce, or cut method.

Precision Forging

Precision Forging means close-tolerance or close to final type forging. This forging technique is not a special technology but an advancement of the existing forging methods to a point where the forged part can be fitted with little or without any subsequent machining.

These advancements include not only the forging method but also preheating, descaling, lubricating, and temperature control works. But the application of Precision Forging method depends on the relevant financial condition of the business. Due to expensive tooling and development costs, precision forging is usually limited within the exceptionally high-quality apparatus.

Steel Ring Rolling

Ring rolling has grown from an art to a stringently managed engineering method. Faultless forged steel rings and other metal rings are constructed on a wide range of equipment.

Ring rolling gives a product a consistent, smooth exterior with peripheral grain orientation. These rings generally have diverging strength and elasticity, and often are less costly to manufacture than closed die forgings.

In whole, the ring rolling process gives uniform grain flow, ease of production, and adaptability in material, volume, size and geometry.

Cutting-edge ring rolling apparatus can roll different shapes in both inner and outer breadth of the forged ring, allowing them for unique weight reductions,and reduced material and machining expense.

Extrusion

In the Extrusion method, the forging workpiece is put in a container and pressed till it reaches the flow-stress level. The workpiece then thoroughly fills the container, and further pressure causes it to move through the cracks, and create the extruded metal piece.

There are different variants of the extrusion process, and many of them are patented. In all states, the degree of heating, the competence of scale elimination or restriction, and the effectiveness of lubrication are matters of obvious concern. The variety of shapes produced through hot extrusion is various. Dimensional precision, surface property, and productivity are high, and a higher range of deformation can be accomplished in a single procedure than in any other metal forging technique.

Extrusion can be Direct as well as Reverse, depending on the direction of motion between the ram and the extruded product. An extruded product can be both hollow and solid. Tube extrusion is ideal of forwarding extrusion of hollow shapes, and reverse extrusion is best for mass manufacturing of containers.

Piercing

Piercing method is closely connected to reverse extrusion process. However, it is recognised by the higher flow of the punch that is related to the velocity of the workpiece material.

Secondary Processes

Along with the primary forging methods, secondary methods are also employed often.

Deformation -The deformation method is such a secondary forging process where divergent compression is applied. The width of the drawing ring may be reasonably smaller than the external width of the pre-forged crust to manage or reduce wall density and raise the height of the shell in a drawing or ironing procedure.

Bending - Even after the completion of copper forging, forged gear, or any other metal forging process, bending can be performed. Furthermore, bending can be applied at any stage of the forging process.It is nearly impossible to build complicated shapes in only one die impression. Thus performing forging stock by bending or rolling the forged metal, or by following a fundamental die may be more profitable.

Preform Forging - The preform design in metal forging performs an essential role in advancing the forging product characteristic, such as defect-free quality and proper metal movement. Preforming also helps in improved productivity, extended die life, and reduced worker expenses. Copper Forging, steel forging or any other metal forging in single die impression is usually effective for much smaller parts.

Special Techniques

After deformation of metal, the forged parts often undergo added metalworking. In case of open die forging the flash is removed. The punched holes may be required, and polished surface finish, as well as closer dimensional accuracy, may be needed. To meet the requirements, additional forging techniques are implemented.

Trimming - Flash is trimmed before the forged metal is ready to use. Seldom, mainly with crack-sensitive alloy metals, trimming is done by grinding, sawing, milling, or flame cutting.

Coining - It is typically the sizing works with stress applied to sharp surfaces to increase tolerance, smoothen surface, and reduce draft. Coining is usually performed on exteriors parallel to the parting line, while ironing is meant to be forced by a cup-shaped element through a ring to measure on the outward diameter. Minor metal flow is included in either direction and flash is not grown

Swaging- This is related to the open die forging method how the stock is drawn out within the flat, narrow dies. However, instead of stock, the hammer is wheeled to deliver increased blows to give the forged metal the desired finishing. Swaging can be paused at any stage in the length of stock and is usually used for pointing tube and bar ends and for manufacturing advanced columns and shafts of decreasing width.

Different Types of Forging

There are three major types of forging – Cold Forging, Warm Forging and Hot Forging.

Cold Forging