#High-quality fasteners 1/2 inch

Explore tagged Tumblr posts

Text

Parts of a Chinese Sword: The Jian and Dao Anatomy

Chinese swords are very beautiful and dangerous weapons that have played an important role in Chinese history and culture for thousands of years. Their intricate design and construction are a testament to centuries of Chinese swordmaking tradition.

One must be familiar with the complex workings of Chinese swords to fully appreciate their lethality and beauty and use them more effectively in Wushu or Kung Fu Chinese martial arts. In this article, we’ll introduce you to the various components of the Dao or Jian, the traditional Chinese swords, and their use.

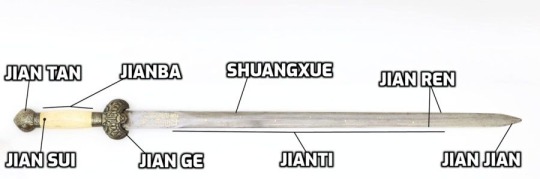

Parts of the Jian / Straigh Double Edge

The Parts of a Jian Sword – Credits: Mandarin Mansion Antiques

The Jian is a type of ancient Chinese straight, double-edged sword that has been valued for over a thousand years. Its blade is long and narrow, while the handle is straight and slim. Soldiers, martial artists, and academics employed the sword in ancient China and surrounding regions. Together with the staff, spear, and Dao swords, it is one of the four key weapons in Chinese martial arts.

1. Jiantan – Pommel

The Chinese word for the pommel of a Jian sword is Jiantan, and it is there that the sword begins. It’s a metal weight at the end of the handle, and its purpose is to balance the blade so the user can have a firm hold. First only available in ring pommels, Jian pommels eventually evolved into more complex designs like the metal cap, ball, or teardrop shapes and the common disk pommel known today.

2. Jian Sui – Tassel

A Jian sword’s tassel is a decorative accessory that can be fastened to the pommel or scabbard. The Chinese sword tassel is often constructed from silk. This sheath beautifies the Jian and adds a few features that may or may not improve the sword’s effectiveness in battle.

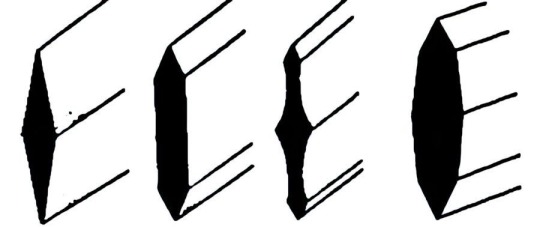

3. Jianba – Handle

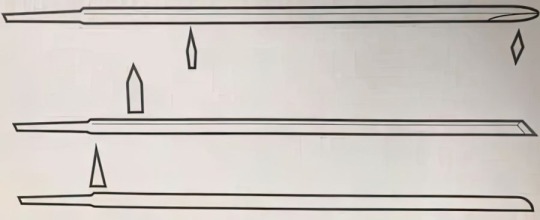

The different possible edge features on the Jian sword – Credits: Sword Buyers Guide

The Jianba is the sword’s handle, and it is always straight and slim, measuring somewhere between 6 and 10 inches (15 and 25 cm) in length. For ceremonial and combat purposes, it may be crafted from various materials, including bone, wood, horn, and even jade. The majority of Jianbas have a shorter handle designed for use with one hand, although there are also longer versions used with both.

4. Jian Ge – Guard

Traditional Jian sword guards are thin, tapered pieces of metal that can be angled in either direction relative to the blade and handle. In some cases, it can be round or square that goes between the blade and the handle. Its purpose is to shield the user’s hand from the oncoming blade and to stop the enemy’s weapon from sliding down the blade onto the hand. In some cases, it only serves as a beautiful ornamental piece.

5. Shaungxue – Hamon

A hamon is the visible line on the Jian sword that is sometimes on the blade but not always. It is a result of the differential hardening used throughout history to make the edges of the blade sharper by using clay. It is a feature most known today on the Japanese Katana.

6. Jianti – Blade

The blade of a Jian sword is narrow and long, normally measuring 23 to 31 inches (60 to 80 cm) but reaching as high as 47 inches (1.2 meters), and always tapers into a sharp blade tip. It is the only straight Chinese sword, one of just a few in the arsenal of Chinese swords, with no curving variant. The blade is forged from bronze, then iron, and finally, high-quality steel, and it is optimized for speed and accuracy when cutting.

7. Jian Ren – Edge

The straight Jian scabbard –

The sharp edges on both sides of the Jian’s blade are called Jian Ren. This Jian Ren has three sections and parts, mostly seen in the combat or martial arts type of Jian sword.

Top – razor sharp and used primarily for hacking, slashing, thrusting, but not blocking

Middle – semi-sharpened part of the blade but much thicker, which is used for slashing and blocking

Bottom – very thick, sturdy, and usually unsharpened for defensive or unorthodox offensive movements

8. Jian Jian – Blade Tip

The very point of the Jian sword is called Jian Jian. It is sharpened on both sides and made to be deadly when used for thrusting and piercing, but it can also be used for slashing.

9. Jianqiao – Scabbard

When not in use, a Jian sword is stored safely in its scabbard, called the Jianqiao. It’s usually crafted from wood and covered in luxurious materials like silk or leather. Metal fittings and tassels are two examples of possible embellishments for the scabbard.

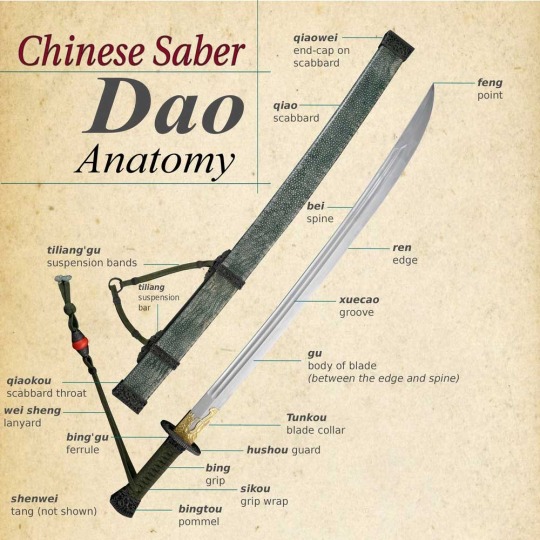

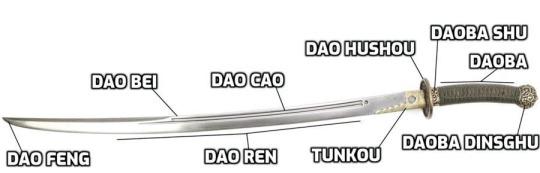

Parts of the Dao Sword (Knife/ Saber)

The Parts of a Dao Sword – Credits: Mandarin Mansion Antiques

The Dao sword, often called the Chinese broadsword, is a renowned blade that has served Chinese warriors for millennia. Its defining feature is a single-edged blade, which can be straight or slightly curved and may be gripped in one or both hands thanks to the long, slim grip. The Dao sword has a long history of use in numerous Chinese martial arts traditions, but it was primarily a sword of the soldier thanks to its ease of use and simpler design.

1. Daoba Dingshu – Pommel

Usually, the Dao sword has a smaller metal cap of a pommel which can be ring type, as seen in the 20th-century use of the Dadao. However, the most common type is a round or wider disc shape. It serves as a back support to the user’s hand as well as a possible blunt attack tool.

2. Lanyard and Tassel

Like the Jian has the traditional Chinese tassel, so does the Dao. But most of the time, the Dao swords have a lanyard, which is meant to have a better grip on the sword and make this curved blade more effective in mounted attacks.

3. Daoba – Handle

The handle of the Dao, which can be as small as a person’s hand or the size of the blade itself, is called the Daoba. Its most common length is 8 to 13 inches (20 to 35 cm), and it can be used with one or two hands for powerful slashing attacks.

4. Daoba Shu – Ferrule

The small metal piece just under and between the guard and the handle is called the Daoba Shu. These are often circular metal rings made for extra joining and fastening of the handle and sealing and reinforcing the wrapping material.

5. Dao Hushou – Guard

The metal piece that protects the user’s hand between the blade and the handle is the Dao Hushou. The most common type of guard seen on a Dao sword is round or disc-shaped. It offers protection to the user’s hand but is fairly limited. It makes for an excellent marching or cavalry type of guard. However, It is also featured in the parts of a Katana known as tsuba.

6. Dao Cao – Groove

The early types of Dao Ren on the straight Dao swords, which curved with time – Credits: The Scholar General

The Dao Cao translates to saber groove and can be found in almost all types of Chinese Dao. They are sometimes referred to as blood grooves, but their real purpose is to lessen the weight of the blade so that it can increase the saber’s handling and speed. In addition, they make eye-pleasing aesthetics.

7. Dao Ren – Blade (Edge)

The sharpened side of the Dao swords, which makes them single-edged, is called the Dao Ren, which sets it apart from the Jian. This edge makes for an effective slashing tool that benefited from the curve added onto the later Dao types of swords. Thanks to the Dao Ren, these blades were easier to master and cheaper to produce, but still very effective in combat and became the main type of military sword for Chinese soldiers.

8. Dao Bei – Spine

The sturdy part of the Dao sword, which can hold off the flexibility of the edge, is called Dao Bei. This isn’t a sharpened part and can be either straight or curved based on the type of sword and can be used for defensive purposes too. Sometimes the blade can be made broader and wider, and there are instances of a spike on some Dao Beis.

9. Blade Rings

There are some cases of Chinese swords with rings placed on the Dao Bei or the blade’s spine. They are mostly for entertainment and ornamental reasons, but some say they are also beneficial in combat.

10. Tunkou – Blade Collar

An unsharpened piece of metal, usually on top of the guard of Dao swords, is called a Tunkou, which is a blade collar. This is placed for decorative purposes, mostly with traditional Chinese elements, but it also holds the blade tightly inside the scabbard, keeping it safe from the elements.

11. Dao Feng – Blade Tip

The very end of the blade is called the Dao Feng, the blade’s sharpened tip. There are cases where only one side is sharpened, but on some Dao swords, the tip is double-edged, making it ideal for both slashing and thrusting.

12. Daoqiao – Scabbard

The P-shape curved scabbard of the Dao sword – Credits: Mandarin Mansion Antiques

The Daoqiao, or the scabbard for the Dao blade, has the same features and materials as the Jian, except that it is curved. It protects the blade from outside elements and is a nice resting piece for carrying the Dao around.

13. Dao Shu Liang – Scabbard Suspension

The Dao Shu Liang is how the scabbard is different from the Jian. This tradition came from Persian influence on the west during the Tang Dynasty and is basically two ropes swinging from the blade that hold the swords in a horizontal fashion

#sifu kisu#atlab#northern shaolin#lok#northern shaolim#kung fu#jian#baguazhang#atlab lok#piandao#Jian Shu#Chinese sword fighting

75 notes

·

View notes

Text

CHDS

STEADY manufactures over a thousands different types of blind rivet nut in steel,aluminium and stainless steel,thread size from M3-M16 in metric and UNC #6-32 to UNC 1/2-13 in inch. High advantage in stainless steel blind rivets both for open and sealed type, mutigrip,monobolt and other structural rivets. We focus on "one stop shopping" and with advantage of large production capacity , consistent quality, competitive prices, punctual delivery and goods serverices before and after sales, STEADY has become one of the leading blind fasteners manufacuture & supplier in Asia.

Add:No. 1598, Huayu Road, Xiuzhou District, Jiaxing City, Zhejiang Province, China

Tel:(86)-133 8863 9264(86)-0573 82192537

E-Mail:[email protected]

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] [ MATERIALS ] Made of stretchable resistant neoprene. SPYKART Armband case easily bends, flexes, twists, and folds without warping. Comfort-grip keeps the band firmly on your arm during workouts and running.[ SAFETY STRIP ] Imagine you are on a track early morning or late afternoon, the environment can be dark or less visible, thinking of this while manufacturing the Armband we have installed the white stripes in a rectangular shape which glow in that condition (dark or less visible).[ TOUCH SCREEN COMPATIBLE ] Enjoy the easy access of your phone through the protective screen cover on the armband with fully touch compatible, easily answer calls, manage your playlist, or activate your stopwatch without removing the phone.[ MULTIPLE HEADPHONE JACK CUTOUTS ] Multiple port holes allow it to work with any device. There are 6 cutouts to accommodate any type of phone.[ EXTRA SPACE ] Built-in key pocket; secret compartment stores your house key while exercising. Integrated key slot keeps your key safe.[ UNIVERSAL SIZING ] The SPYKART armband features two arm strap slots for big and small arm sizes. Multi-slot Adjustable Velcro Armband Will Fit Almost Any Arm Size.[ NON SKID VELCRO ] Comfort-grip keeps the band firmly on your arm during workouts and running. 1.【Environmental Material More Comfortable】Highly quality breathable fiber environmental spandex material easier absorbing sweat and comfortable for wearing, prevent for cellphone slip. The Velcro fastening is adjustable, base on your body shape, between with 9.5”-14” 2.【Dual Pockets & Dual Zipper Heads】Dual pockets and zipper heads designed for closure safer and storage spaces larger for our cellphone, earphones,cable, charger, keys, ID cards,cash, and other accessories, prevent scratch for us phone. 3.【Perfect for All Activities】 The running armband case can be a gift for men or women, if he or she like exercise, when they in gym, high intensity workouts, extreme exercise, fitness, yoga, casual walking, running, cycling, hiking, fishing, cross training, mountaineering, camping, travelling, daily leisure, etc 4.【Fit for All Upto 6 inch Cellphone】 The running arm phone holder fit iPhone 7 plus/7(5.5")/6/6s (4.7"), iPhone 5/5s/5c, Samsung s8 s7 s6 s5 s4, s3, s2, Moto,Google, Oneplus, ZTX and any phone with a screen up to 6 inches cellphone for our running. 5.【Earphone Port Design】Special earphone port designed for our enjoying the music conveniently, provide more pleasure during your running. We will offer guarantee within 30days, If you have any question, please contact with us in your first time,we will help you soon. [ad_2]

0 notes

Text

Step-by-Step Guide to Standing Seam Metal Roof Installation

Introduction

When it comes to roofing solutions, standing seam metal roofs have emerged as one of the most durable, efficient, and aesthetically pleasing options available on the market today. This guide aims to provide a comprehensive overview of the Step-by-Step Guide to Standing Seam Metal Roof Installation, covering everything from materials needed to installation techniques, as well as maintenance tips that will help you maximize the lifespan of your new roof.

Understanding Standing Seam Metal Roofs What is a Standing Seam Metal Roof?

A standing seam metal roof consists of vertical panels that are seamed together at the top. These seams stand above the level of Austin roofing professionals the flat portion of each panel. This design is not only visually striking but also provides several advantages in terms of durability and weather resistance.

Advantages of Standing Seam Metal Roofing Durability: Made from high-quality metals such as aluminum or steel, these roofs can withstand severe weather conditions. Energy Efficiency: Reflective properties can significantly reduce cooling costs. Low Maintenance: Unlike other roofing types, standing seam metal roofs require minimal upkeep. Longevity: With proper installation, they can last 50 years or more. Preparation for Installation Choosing the Right Materials

Before you begin your installation journey, it's crucial to select the right materials:

Metal Panels: Available in various metals such as galvanized steel or aluminum. Underlayment: A vital component for moisture protection—choose between synthetic or felt underlayment. Fasteners: Make sure you select appropriate fasteners designed for metal roofing systems. Gathering Tools and Equipment

You'll need several tools to ensure a successful installation:

Measuring tape Snips Drill with bits Safety gear (gloves, goggles) Level Hammer Step-by-Step Guide to Standing Seam Metal Roof Installation Step 1: Inspect Your Roof Structure

Before any installation begins, it's austin roofing essential to evaluate your existing roof structure. Ensure that it is sound and capable of supporting a new metal roof system.

Step 2: Remove Existing Roofing Material

If you're replacing an old roof, you'll need to strip away all existing materials down to the decking. This includes shingles, tiles, or even felt paper.

Step 3: Install Underlayment

Lay down your chosen underlayment across the entire roof surface. Overlap seams by at least six inches and secure them with staples or nails.

Step 4: Install Drip Edge Flashing

This step involves installing drip edge flashing along all eaves and rakes. This ensures that water drains properly off your new roof.

Step 5: Measure and Cut Metal Panels

Using your measuring tape and snips, measure each panel needed for your specific roof layout and cut accordingly.

S

0 notes

Text

Drywall Screws : Benefits, Types, and How to Install Them

Drywall screws have become a very essential part of the modern construction process, applied extensively to fasten drywall panels on wooden or metal studs. Due to their strength and efficiency in use, the screw has become one of the most widely used tools by professional builders and individuals during construction projects. In India, one of the renowned manufacturers of high-quality international-standard drywall screws is Landmark Crafts Limited.

What Are Drywall Screws?

Drywall screws are special fasteners that are used to hold drywall sheets in place without damaging the material. Unlike traditional nails, drywall screws have a bugle-shaped head that allows for flush installation, so the drywall surface does not crack or break. Their threaded design ensures a tight grip, making them ideal for creating sturdy and smooth walls and ceilings.

Benefits of Drywall Screws

Drywall screws have several benefits:

1. Durability: Made of high-grade steel, these screws resist corrosion and offer long performance.

2. Ease of Use: Their sharp point and threaded shaft make them easy to drive into drywall and studs, even for beginners.

3. Clean Finish: The bugle head design sits flush with the drywall surface for a seamless finish.

4. Versatility: They work well with both wood and metal frames, making them suitable for various applications.

5. Cost-Effective: Their durability reduces the need for frequent replacements, offering excellent value for money.

Types of Drywall Screws

Drywall screws come in several types, each suited for specific applications:

1. Coarse-Thread Drywall Screws:

These screws feature wide, spaced threads, making them ideal for fastening drywall to wooden studs. The coarse thread provides a strong grip in softer materials.

2. Fine-Thread Drywall Screws:

Fine-thread screws are good for securing drywall to metal studs as they are specifically designed to penetrate metal easily but hold securely.

3. Self-Drilling Drywall Screws:

These screws don't need pre-drilling. They are very time and effort-saving when used with metal studs or hard surfaces.

4. Coated Drywall Screws:

Coated screws resist rust and corrosion. That is why they can be used in moisture-prone areas like bathrooms for basements.

Installation Tips for Drywall Screws

Proper installation will ensure that your drywall project is durable and aesthetically pleasing. Here's how to do it step by step:

1. Select the Right Screw:

Choose a screw type depending on the material of the frame. For wood, use coarse-thread screws, and for metal, use fine-thread screws.

2. Use the Right Tools:

A power drill with a Phillips head bit is ideal for driving screws quickly and efficiently.

3. Space, it matters:

There should be at least 12 to 16 inches screw along the stud space. This way, a screw driven to just below the surface of the drywall does not tear the paper layer on its way into the drywall.

4. Check screw pops:

Do not overtighten screws that could reduce the holding capability of screws in some cases that are termed "screw pop later".

Landmark Crafts Limited: A Trusted Manufacturer in India

Amongst all the Drywall Screw manufacturers in India, Landmark Crafts Limited is a leading company. With a promise of quality and innovation, it offers drywall screws in various varieties, suitable for all types of constructions. All their products are made of premium material and are subjected to high standards of quality checks so that they could be relied on and deliver performance.

Conclusion

Drywall Screws are an absolute must in pursuit of robust, finish-free drywall installations. Their benefits and different kinds and installation procedures ensure that you undertake successful construction or renovation works. For the best in drywall screws in India contact Landmark Crafts Limited.

Source URL: https://medium.com/@draywellscrew/drywall-screws-benefits-types-and-how-to-install-them-ec1ad8a90bbd

#drywallscrew#drywallcsrewmanufacturerinindia#drywallscrewmanufacturers#drywallscrewmanufacturingcompanyinindia#bestdrywallscrewmanufacturer

0 notes

Text

Why are Bath Towels Important?

Visit www.dzeehome.com to learn more about home bedding.

Towels are definitely not something you think much about till you’re in the shower and you’ve forgotten to bring one in with you. Now, you don’t have a towel and that means you need to put on your clothes while being wet or wait for someone to push them through the door. Then there is the quality of the towels that no one thinks about till the towels have scratched them or caused skin irritation. DZEE Home offers high-quality cotton bath towels that prevent skin issues and ensure a safe showering experience for you. Understanding the reasoning behind why are bath towels important help us invest in the best bath towels for home use.

Luxury Bath Towels Usage

When investing in cotton bath towels you need to understand the different usages it has in your life. As a family, you need multiple big bath towels to ensure everyone is taken care of. A bath towel is important in your household because:

1. Post Shower Drying

After a nice and relaxing shower, all you need is a soft towel to dry you up by absorbing the majority of the water from your body. If you don’t invest in the best bath towel in terms of quality and absorption ability; you will not be able to dry yourself enough to wear your clothes without making them completely wet. We aim to provide complete user satisfaction. Investing in a big bath towel means that they cover your entire body and you’re able to completely dry the majority of your body without any issue.

2. Cover Up

Not everyone purchasing luxury bath towels immediately dries off and wears their clothes. A soft cotton bath towel needs to be big in size to completely cover you; so that they can wrap around and walk from the bathroom to their room. At times, people don’t choose what they want to wear before they shower so they do it while wrapped up in a towel. Many people first do their hair and makeup before wearing clothes, and a big towel definitely plays a significant role in keeping you covered while you get things done. If the towels don’t cover up enough and are not comfortable, users will have an issue.

3. A Hair Wrap

Drying off your body is one thing but your hair is an entirely different story altogether. Hair absorbs much more water which takes longer to dry off; especially when you have long and thick hair. Many people prefer wrapping it around their heads and waiting for the towels to absorb the maximum amount of water. It fastens up the hair drying process making it easier for everyone to get their hairstyles in a short while. If the towel doesn’t completely cover all your hair, you will have many loose strands which just kills the purpose of using it as a hair wrap. You may have been in a situation where you forgot your bath towels and the hand towel wasn’t able to dry your hair enough to comfortably put on your clothes.

Why are Big Bath Towels Sizes Important?

Once you understand why are bath linen important you also get an idea of the importance of towel size. After discussing the importance of investing in luxury bath towels you also need to understand the best bath towel sizes available.

Our cotton bath towel size is 27-inch x 54 inches which are big enough to serve the purpose for which each towel has been bought. If you don’t invest in a big enough towel, they will not feel comfortable while in use. It is always better to check the sizes before making a purchase. At DZEE Home we provide the best bath towels which can be used by families without any issue. Each towel has a specific size to serve its individual purpose for the best results and user comfort.

Home users may not put much thought into the towels they’re purchasing but knowing the best choice always helps you make the right decision for your home. When you’re investing an amount in luxury bath towels you want the best use from them for your family. Big sizes bath towels provide the right comfort for everyone.

Conclusion

Each DZEE Home cotton bath towel is manufactured after considerable research and uses state-of-the-art technology. We aim to equip your household with soft and durable big bath towels for maximum user satisfaction. You can easily make the purchase on our website and see whether they are the right choice for you or not. Once you make the right purchase for your household, you will understand why a bath towel is important; and why we are stressing about you making smart choices for your home.

Investing in the best bath towels in terms of material and size such as cotton bath towels and big bath towels; helps your family with an enhanced post-shower experience. Why do you think luxury bath towels are an important investment for a family? Let us know in the comments below.

0 notes

Text

The Complete Ipe Decking Installation Guide: From Planning to Perfection

If you're aiming to enhance your home's value with an outdoor area that combines durability with visual appeal, ipe decking installation might be just what you need. It is very durable, easy to maintain, and resistant to rot and decay. But before you start planning your ipe wood decking project, let's go over the basics.

Handling and storage

Ipe wood needs time to acclimate to its environment before installation. Since it's often delivered partially dried, it should be stored in a shaded area and allowed to adjust to the local humidity for at least 7 to 14 days. This helps prevent issues like warping, cupping, or excessive shrinking after the deck is installed.

Joint spacing

Follow the recommended spacing guidelines for boards: 16 inches for 1 x 4 and 1 x 6, and 32 inches for thicker boards like 2 x 6. This will allow for proper ventilation and prevent cupping or warping.

Pitch

To allow for proper water drainage, install your Ipe decking with a slight slope. Aim for a slope of at least 1/4 inch for every 10 feet of decking if you're using standard Ipe lumber. If you’re working with tongue and groove boards, increase the slope to 1/4 inch for each foot to ensure effective water runoff.

Placement

Do not install hardwood decking directly over concrete, as it can retain moisture and cause cupping or bending upwards.

Gap

Maintain a 3/32-inch gap between Ipe boards for ventilation and to account for expansion and contraction with temperature changes.

Airflow

Make sure there’s at least 18 inches of space below the deck to allow air to move through and help the wood stay stable. Cross-ventilation is important too, as it will reduce movement in the wood caused by moisture.

Water drainage

Prevent water from pooling under or on the deck by sloping the ground for drainage and avoiding construction over concrete slabs.

Sealing

Ipe wood usually comes with End Seal on the ends to keep it from cracking. If you cut the wood, make sure to seal the ends the same day to prevent end checking.

Fastening

Ipe wood is incredibly hard, so you’ll need to pre-drill holes before installing screws or fasteners to avoid splitting the wood. It’s also important to use only stainless steel fasteners for Ipe decking installation. If you use screws that are MCQ compliant, Ipe can develop tannin weep, which can cause unsightly stains on the deck's surface. Stainless steel prevents this issue and ensures a clean, long-lasting finish.

And that's it!Ipe decking installation is not a difficult process, but it does require careful planning and proper handling. For professional guidance and high-quality Ipe wood, always consult a reputable supplier or contractor.

ABS WOOD, for example, has been a trusted source of Ipe decking and other hardwood products for years. With their expertise and top-of-the-line materials, you can confidently create the perfect deck for your home. Visit their website today at www.abswood.com to learn more.

0 notes

Text

Hex Bolts Manufacturers, Suppliers & Exporters: Complete Guide

Hex bolts are the most important fasteners utilized in many industries due to their durability, strength and flexibility. Ananka Group manufacture top-quality hex bolts that are in line with internationally-respected standards. If you require hex bolts for automotive, construction or engineering purposes there is a wide variety of options to choose from and all are available to be shipped out and distributed worldwide. In this article, we'll explore the specifications of hex bolts, their dimensions, sizes and specifications, and all you must be aware of DIN 934 Hex Bolts, which come with nuts with weight charts as well as specifications.

What Are Hex Bolts?

Hex bolts are a type of fastener that has hexagonal heads that is designed to work with a socket or wrench. The hexagonal shape gives greater grip and torque applications, making them an ideal choice to secure parts in a variety of machines and structures. These bolts are commonly used in construction, automotive, machinery, and other heavy-duty applications.

Hex Bolts Manufacturers & Suppliers

We are a leading Hex Bolts Manufacturer, Supplier, and Exporter, offering a wide selection of high-quality hex bolt fasteners. Our products are made from high-end raw materials to ensure that they are of superior strength and long-lasting. We respect international standards like ISO, DIN, ASTM and BS and ASTM, which makes our hex bolts suited for use in all areas of the world. We keep a stock of different hex bolt sizes and specifications that are available for immediately export or supply.

Hex Bolts Specifications

Hex bolts can be found in various types, grades and coatings that satisfy various industrial needs. Here are the main specifications:

Material: Hex bolts can be found in stainless steel, carbon steel, alloy steel as well as other materials that are specialized.

Coatings: We offer Hex bolts coated with zinc hot-dip galvanizing, black oxide coating and more to provide long-lasting durability and resistance to corrosion.

Grades: The most common hex bolt grades include Grade 2, Grade 5, Grade 8 as well as stainless steel grade such as A2 as well as A4. with various levels of strength.

Threads: Bolts with hex threads can be found in fine, coarse and fully threaded choices depending on the specific requirements.

Hex Bolts Dimensions

Hex bolts come in a variety of sizes to satisfy a variety of requirements. The dimensions are:

Diameter: Hex bolts usually are M4-M64 in metric sizes. They also range between 1/4 inch and 2 1/2 inches in imperial sizes.

Length: Hex bolts' length can range between 10mm and 300 millimeters or more, dependent on the use.

Thread Pitch: The pitch varies based on the diameter and specification of the hex bolt.

We offer hex bolts with specific dimensions to meet specific needs. Our products comply with global standards like DIN, ISO, and ANSI, ensuring that you receive a precise fit and performance for your application.

Hex Bolts Sizes & Standards

When selecting hex bolts it is crucial to select the correct size and standard to meet the requirements of the application. We have hex bolts available in various sizes and conforming to a variety of international standards, which include:

DIN standards: DIN 933, DIN 931 along with DIN 934 Hex Bolts with nuts.

ISO Standards: ISO 4014, ISO 4017 for bolts for hex.

ANSI/ASME Standards: ASME B18.2.1, providing imperial sizes.

These standards specify dimension, thread types and other specifications, making sure that the bolts work with other components made worldwide.

DIN 934 Hex Bolts with Nuts

It is the standard DIN 934 Hex Bolts with Nuts are extensively used due to their reliability and precision. It is the DIN 934 standard defines hexagonal nuts to be used with Hex bolts. When used together they provide a strong and secure fastening system that is ideal for applications that require heavy-duty in a variety of industries.

We provide DIN 934 hexagonal bolts that come with nuts made of various materials which include carbon steel, stainless steel and alloy steel with the option of galvanization, zinc plating and various other treatments for the surface. This bolt and the nuts work to be used in the automotive, construction machinery, as well as other engineering applications.

Weight Chart for DIN 934 Hex Bolts

Hex bolt weight can be an important aspect in a wide range of situations, particularly for engineering and construction tasks where calculations of load are vital. We offer a complete DIN 934 Hex Bolts Weight Chart that provides information on the various sizes and materials. It will help you pick the appropriate bolt to meet your requirements. The chart provides:

Bolt diameter (in millimeters and inches)

The length of the bolt

The weight per piece is 100 or per kilogram

This weight chart can assist in the planning of transport installation, as well as load management for large-scale construction projects.

Hex Bolts Exporter

As a reputable Hex Bolts exporter We have an international presence, and we deliver our products to clients in different regions which include North America, Europe, Asia and Asia, the Middle East, and Africa. We keep a vast inventory of hex bolts, in a variety of dimensions and sizes, assuring rapid delivery times and competitive prices.

Why Choose Us for Hex Bolts?

Quality Assurance: We strictly adhere to quality control measures to ensure that every hex bolt we sell meets the standards of the industry.

Wide Variety Our vast assortment includes a variety of sizes of hex bolts, the coatings, and materials.

global reach With stock on hand as well as efficient logistical support, we can supply as well as export Hex Bolts for customers around the world.

Customization We provide tailored solutions, which include specific dimensions and specifications that are according to your project's requirements.

Conclusion

Hex bolts are versatile and vital fasteners in a variety of industries. Choosing the right manufacturer, supplier, and exporter ensures the reliability and longevity of your projects. Hex bolts of high-end quality, offered in a variety of sizes and specifications, such as DIN 934 Hex Bolts are made to meet the global needs. Contact us now for your hex bolt requirements, and we'll provide you with the ideal solutions for your industrial needs.

For further information or questions for more information, feel free to contact us. Our team of experts is ready to help you with any inquiries or details you require. FAQ

1. What are hexagon bolts and where can they be used?

Hex bolts can be described as fasteners featuring an hexagonal head that can be utilized by a socket or wrench. They are used extensively in the automotive, construction machinery, machinery, and other heavy-duty jobs because of their durability and strength.

2. What are the components Hex bolts made from? Hex bolts are made of diverse materials, such as stainless steel, carbon steel, alloy steel as well as other materials that are specialized. These choices offer different strengths and levels of corrosion resistance that can be used for specific purposes.

3. Do you have different types of coatings for hex bolts? Yes, we offer Hex bolts that have various coatings, including zinc plating, hot dip galvanizing and black oxide coating to improve resistance to corrosion and prolong the fasteners longevity.

4. What dimensions and standards do you provide for bolts for hex? Hex bolts are available with a range of sizes, ranging from M4-M64 (metric) as well as 1/4-inch to 2-1/2 inches (imperial). Hex bolts we offer are compliant with several international standards like DIN, ISO, ANSI and ASTM to ensure the highest quality and compatibility for international applications.

0 notes

Text

Upgrade Your 4x4 with a DIY Drawer System for Better Organisation

Imagine you’re out on a rugged adventure and need that one essential tool buried somewhere in the chaos of your vehicle. Frustration mounts as you dig through a disorganised mess, wasting precious time and energy. Now, picture having everything neatly organised and easily accessible right where you need it. Sounds like a dream, right? With a DIY drawer system, that dream can become a reality.

In this blog, you’ll learn how to build your own 4x4 drawer systems to improve organisation and efficiency.

Why Opt for a DIY Drawer System?

1. Tailored to Your Needs

When you build your own 4x4 drawer systems, you can customise the setup to fit your needs. Whether you’re an off-road enthusiast with a ton of gear or a casual adventurer who needs more organisation, a DIY system lets you create compartments and features that cater to your requirements. You’re in control of the design, ensuring that every inch of space is used efficiently.

2. Cost-Effective Solution

Why spend a fortune on pre-made drawer systems when you can build your own 4x4 drawer systems for a fraction of the cost? A DIY project allows you to select materials and tools that fit your budget while achieving high-quality results. Plus, the satisfaction of building something yourself adds value that no store-bought system can match.

3. Flexibility and Creativity

One of the best parts of 4wd drawer systems is the creative freedom it offers. You can choose various materials, finishes, and designs to match your style and preferences. Want a sleek, modern look? Go for it. Do you prefer a rugged, industrial design? That’s totally within your reach. The possibilities are endless, and you get to enjoy bringing your vision to life.

Steps to Build Your Own 4x4 Drawer System

1. Plan and Design

Design your drawer system before starting the project. Measure the 4x4's interior and sketch the design, including the number, size, and features, to ensure a perfect fit.

2. Gather Materials and Tools

Prepare your design, gather materials and tools like plywood, metal brackets, screws, handles, saw, drill, and sandpaper. Seek advice at hardware stores or watch tutorial videos.

3. Assemble the Drawers

Start precisely assembling your drawers, following design plans and measurements, ensuring smooth operation and secure fastening for a visually appealing and functional system.

4. Install the System

Install the assembled drawers in your 4x4, secure them with screws and brackets, test for smooth operation, and make adjustments for a perfect fit.

Enjoy the Benefits

1. Increased Organisation

A well-designed DIY drawer system transforms your 4x4 into an organised haven. No more digging through piles of gear or tools. Everything has its place, making finding what you need quickly and efficiently easier. This enhanced organisation saves time and reduces stress during your adventures.

2. Enhanced Functionality

Build your own 4x4 drawer systems functionality by creating dedicated spaces for tools, camping gear, and first aid kits. Removable bins or modular compartments allow for versatility.

3. Personal Satisfaction

Building your system provides enormous joy and pride since it enhances your vehicle and adventures by personalising them to your requirements.

Conclusion

Upgrading your 4x4 with a DIY drawer system is a game-changer for organisation and functionality. Build your own 4x4 drawer systems; you can create a setup that fits your needs while saving money and adding a personal touch. So roll up your sleeves, grab your tools, and start building a drawer system to make your adventures smoother and more enjoyable. Your well-organized 4x4 awaits!

0 notes

Text

Common Egress Window Installation Mistakes and How to Avoid Them

Installing egress windows is a crucial upgrade for ensuring safety and compliance with building codes, but it’s a task that requires precision and attention to detail. Avoiding common mistakes during the installation process can save you time, money, and ensure that the installation meets safety and regulatory standards. Here’s a guide to common egress window installation mistakes and how to avoid them:

1. Ignoring Local Building Codes

Mistake: Not adhering to local building codes and regulations can result in unsafe installations and may require costly modifications.

How to Avoid:

Research Regulations: Before starting the installation, thoroughly research North Dakota’s building codes for egress windows. This includes size requirements, height from the floor, and window well dimensions.

Obtain Permits: Ensure you have the necessary permits from your local building authority. This helps ensure that the egress windows installation in North Dakota meets all regulatory requirements.

2. Incorrect Window Size and Placement

Mistake: Installing a window that does not meet the minimum size or placement requirements can compromise safety and functionality.

How to Avoid:

Measure Accurately: Double-check the dimensions of the window and the opening to ensure it meets the minimum size requirements for clear opening (typically at least 5.7 square feet).

Follow Guidelines: Ensure that the bottom of the window is no more than 44 inches above the floor and that the window well provides adequate space for egress.

3. Poor Weather Sealing

Mistake: Inadequate sealing around the window can lead to drafts, water infiltration, and energy loss.

How to Avoid:

Use Quality Materials: Apply high-quality weatherstripping and caulking around the window frame to create a tight seal.

Install Flashing Properly: Ensure that flashing is correctly installed to direct water away from the window and prevent leaks.

4. Inadequate Window Well Construction

Mistake: Installing a window well that is too shallow or poorly constructed can lead to drainage problems and limit the effectiveness of the egress window.

How to Avoid:

Choose Durable Materials: Select window wells made from rust-resistant materials such as galvanized steel or heavy-duty plastic.

Ensure Proper Depth: Make sure the window well is deep enough to handle snow accumulation and provides sufficient space for safe egress.

Install a Cover: Use a sturdy cover to keep debris and snow out of the well, but ensure it is easily removable for emergency egress.

5. Improper Excavation and Cutting

Mistake: Incorrect excavation or cutting of the foundation wall can damage the structure and affect the window’s fit and function.

How to Avoid:

Plan Carefully: Mark the area for cutting accurately and ensure that you have the correct tools and equipment.

Hire Professionals: If you’re not experienced, consider hiring a professional to handle excavation and cutting to avoid damaging the foundation.

6. Incorrect Window Installation

Mistake: Installing the window incorrectly can lead to poor performance, security issues, and potential safety hazards.

How to Avoid:

Level and Plumb: Ensure that the window is installed level and plumb to guarantee proper operation and a secure fit.

Secure Properly: Use appropriate fasteners and techniques to secure the window frame to the foundation. Check that the window opens and closes smoothly.

7. Neglecting to Test the Installation

Mistake: Failing to test the window and Egress Windows Installation In North Dakota thoroughly can result in overlooked issues that may compromise safety.

How to Avoid:

Functionality Test: Open and close the window to ensure it operates smoothly and provides the required clear opening.

Inspect Seals: Check all weather seals and insulation for proper installation and functionality.

8. Overlooking Maintenance Needs

Mistake: Neglecting regular maintenance can lead to issues such as window degradation, poor performance, and safety concerns.

How to Avoid:

Regular Inspections: Periodically inspect the window and window well for signs of wear, damage, or blockages.

Clean and Maintain: Keep the window and window well clean and ensure that drainage systems are functioning properly.

9. Failing to Address Drainage Issues

Mistake: Poor drainage around the window well can lead to water accumulation, leaks, and potential damage to the foundation.

How to Avoid:

Install Proper Drainage: Ensure that the window well has an effective drainage system, such as gravel at the bottom and a connected drain pipe.

Check for Blockages: Regularly check and clear any debris or blockages from the drainage system to prevent water buildup.

10. Not Considering Energy Efficiency

Mistake: Ignoring energy efficiency can lead to increased heating and cooling costs and reduced comfort.

How to Avoid:

Choose Energy-Efficient Windows: Opt for windows with double or triple glazing and low-E coatings to improve insulation and reduce energy costs.

Insulate Properly: Ensure that any gaps around the window frame are properly insulated to maintain energy efficiency.

Conclusion

Avoiding common egress window installation mistakes requires careful planning, adherence to local building codes, and attention to detail. By understanding and addressing these potential pitfalls, you can ensure a successful installation that enhances the safety, functionality, and energy efficiency of your home. Whether you handle the installation yourself or hire professionals, following these tips will help you achieve a well-executed egress window project.

#Basement Window Installation Near Me#Egress Windows Installation In North Dakota#Egress Window Well Installation

0 notes

Text

Steel UK standard Reduce Head Round Body Plain Rivet open type Nut

STEADY manufactures over a thousands different types of blind rivet nut in steel,aluminium and stainless steel,thread size from M3-M16 in metric and UNC #6-32 to UNC 1/2-13 in inch. High advantage in stainless steel blind rivets both for open and sealed type, mutigrip,monobolt and other structural rivets. We focus on "one stop shopping" and with advantage of large production capacity , consistent quality, competitive prices, punctual delivery and goods serverices before and after sales, STEADY has become one of the leading blind fasteners manufacuture & supplier in Asia.

Add: No. 1598, Huayu Road, Xiuzhou District, Jiaxing City, Zhejiang Province, China

Tel: (86)-133 8863 9264 (86)-0573 82192537

E-Mail: [email protected]

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] [FABRIC & STITCHING – 100% Made in India] - Autofy Pro-Fit, now comes as a pack of 2, is Highest quality thick 240 GSM Nylon Spandex (stretchable) stitched with Flat Seam technology to make sure that stitches don’t cause skin irritation even during excess sweat situations. 240 GSM fabric ensures less loosening during daily use hence lasts longer compared to other brands. [FITING] – can be used by Men, Women, Boys, Girls & Children (from age 10 & above). If you have thin/medium arms (8 – 15-inch biceps) OR strong muscular built with 16+ inch biceps Autofy Pro-Fit arm sleeves will fit easily because of the elastic on biceps. Snug fit at wrist. Fitting (loose/skin tight) can vary based on arm size. 1 Packet – has 2 sleeves for Left & Right Hands. [FEATURES] – Tight fit enables COMPRESSION to enhance blood flow in the body (very good for health) to deliver high performance & fasten muscle recovery, Quick Sweat Absorption (dry-fit) – controls body temperature during sweating, UV Protection Rating = 50; cuts 99% UV rays to safeguard skin from burns, tanning etc. (choose light color for summers & dark for winters), heavy yet breathable fabric. [USAGE] – Compression technology increases blood flow to boost performance hence best product for all indoor & outdoor activities like Cricket, Basketball, Hockey, Badminton, Cycling, Running, Bike Motorcycle Riding, Shooting, Golf etc. Protects you from UV rays, absorbs sweat hence lowers fatigue rate & you can perform for longer time. [SEASONS & WASH CARE] – use dark colors in winters to keep warm during bike driving, playing & use light color to reflect UV rays to stay cool in summers. Even if sleeves don’t fit tight, Doctors recommend to wear it because it saves you from harmful rays – tanning, burns etc. & keeps you warm in winters to balance your body temperature. WASH gently with hands/machine and hang to dry. [ad_2]

0 notes

Text

The Benefits of Slipcover Books: Enhanced Protection and Visual Appeal

1.What is an adhesive book cover?

An adhesive book cover serves as an essential protective layer designed to guard books against the inevitable wear and tear that comes with regular use. Constructed from high-quality, durable materials such as plastic or vinyl, these covers are specifically engineered to adhere seamlessly to the book's surface through a self-adhesive backing. This innovative design ensures a secure fit that eliminates the need for additional fasteners, which can sometimes detract from the book's appearance. Available in a diverse array of sizes, colors, and finishes, adhesive book covers allow for a degree of customization that caters to both the aesthetic preferences of the user and the design elements of the book itself. Beyond their primary function of protection, adhesive book covers offer significant advantages in terms of personalization and branding, particularly within educational and professional environments. By safeguarding books from dust, moisture, and potential physical damage, these covers play a crucial role in preserving the integrity and longevity of valuable texts. Additionally, their customizable nature enables institutions and organizations to effectively promote their brand or identity with tailored designs and logos. As such, adhesive book covers not only enhance the visual appeal of books but also serve as a practical solution for maintaining their condition, ultimately contributing to a more organized and professional presentation of literature.

2. How many types of book covers are there?

Book covers are not merely protective layers for the pages within; they serve as the first point of contact between a reader and a literary work, significantly influencing a potential reader's decision to engage with the text. The design of a book cover plays a pivotal role in the marketing strategy for literature, as it encapsulates the essence of the story while simultaneously appealing to the target audience. There are several distinct types of books covers that cater to varying preferences and contexts, including hardcover, paperback, and digital formats. Each of these primary categories has its own unique attributes and benefits. For instance, hardcover editions often come with dust jackets that not only provide additional protection but also allow for more intricate and captivating designs, while paperback versions can range from trade paperbacks, which are typically larger and of higher quality, to mass-market paperbacks, which are more affordable and accessible to a broader audience. Within these categories, there exist numerous design variations that enhance the visual appeal and marketability of a book. Illustrated covers, for example, can evoke a sense of whimsy or adventure, drawing in readers who are attracted to artistic representations of themes or characters. Minimalist styles often communicate sophistication and elegance, appealing to readers who appreciate simplicity and modern design. Photographic imagery, on the other hand, can create a striking and immediate connection to the subject matter, particularly in genres such as memoirs or thrillers. Each type of book cover is meticulously crafted with the intention of targeting specific audiences and genres, reflecting both artistic expression and strategic marketing considerations. As a result, the diversity of book covers not only showcases the creativity of designers and authors but also serves as a crucial component in the broader narrative of how literature is presented and perceived in a competitive marketplace.

3. What are popular book cover sizes?

Book cover sizes play a crucial role in the publishing industry, varying significantly across different genres and formats to cater to the preferences and expectations of readers. For trade paperbacks, the most common dimensions are 6 x 9 inches, which strikes an ideal balance between readability and portability. This size is particularly favored for fiction and non-fiction works alike, allowing for a comfortable reading experience while remaining easy to handle and carry. On the other hand, mass market paperbacks, typically measuring 4.25 x 7 inches, aim to attract consumers who prioritize affordability and convenience This compact format is often seen in genres such as romance and mystery, where impulse purchases are common. The smaller size not only reduces production costs but also makes these books highly accessible to a wider audience, further driving sales in competitive markets. In contrast, hardcover editions frequently adopt larger dimensions, such as 6 x 9 inches or 7 x 10 inches, which enhance both the visual appeal and durability of the publication. These sizes are particularly well-suited for illustrated books, coffee table books, and certain literary genres that benefit from a more substantial presentation. The robust nature of hardcover bindings also makes them a popular choice for gift-giving and collectors, adding to their desirability. Furthermore, the rise of digital formats has introduced a new dimension to book cover sizes, with e-books being optimized for various screen dimensions across devices such as tablets, e-readers, and smartphones. In this evolving landscape, the choice of cover size is not merely a design consideration; it significantly influences marketing strategies and consumer engagement, impacting how readers perceive and interact with the content.

4. What is the best cloth for book covers?

When selecting the optimal cloth for book covers, it is essential to consider a combination of durability, aesthetic appeal, and tactile quality. Fabrics such as cotton canvas and linen are particularly favored for their strength and versatility, as they provide a robust barrier against wear and damage. These materials not only contribute to the longevity of the book but also enhance its aesthetic value, making it a visually appealing addition to any collection. Additionally, polyester blends have gained popularity due to their enhanced resistance to moisture and fading, ensuring that the book can withstand various environmental conditions. This makes them suitable for both hardcover and softcover applications, appealing to publishers and designers seeking a reliable option without compromising on style.

For those looking to create a more luxurious finish, fabrics such as silk and velvet can be employed, although these materials necessitate more careful maintenance due to their delicate nature. Such luxurious options can elevate the perceived value of a book, making it an ideal choice for special editions or high-end publications. Ultimately, the choice of fabric should align with the book's intended use and target audience. It is vital to strike a balance between functionality and visual allure, ensuring that the cover not only protects the contents within but also leaves a lasting impression on potential readers. A thoughtfully selected fabric can transform a simple book into a treasured object, enhancing its overall appeal and desirability.

5. What is a slipcover book?

A slipcover book, often referred to as a slipcase book, is a distinguished type of hardcover publication that is encased in a protective slipcover or slipcase. This design serves a dual purpose: enhancing the aesthetic appeal of the book while simultaneously providing a layer of durability that safeguards the contents within. Typically constructed from sturdy materials such as cardboard or high-quality paper, the slipcover acts as a barrier against dust, wear, and various forms of environmental damage. This thoughtful design not only preserves the physical condition of the book but also opens opportunities for intricate illustrations, elaborate designs, or thematic artwork that enhances the overall visual experience for readers. Slipcover books are particularly prevalent among special edition releases, collector's items, and literary works that necessitate an additional layer of protection and elegance. They are meticulously crafted to cater to the tastes of bibliophiles and collectors who appreciate the artistry and craftsmanship that goes into book presentation. The added slipcover elevates the perceived value of the book, making it an attractive addition to any library or personal collection. Furthermore, the presence of a slipcase can enhance the book's functionality, as it makes storage easier and keeps the book in pristine condition, ensuring that it can be enjoyed for years to come. In this way, slipcover books not only serve as vessels for literary content but also as beautiful artifacts that reflect a commitment to quality and aesthetics in publishing.

0 notes

Text

Inconel 600 or Monel Fasteners: Choosing the Best Alloy for Your Application

Choosing the right fastener material is crucial for ensuring longevity and affects your project's overall performance. When it comes to high-performance applications that demand resistance to corrosion, high temperatures, and harsh environments, two alloys stand out: Inconel 600 and Monel.

With This blog let’s help you make the right decision for your project: Inconel 600 or Monel fasteners

Let’s begin with understanding both these alloy types and their ideal industry applications:

Inconel 600

Inconel 600 is a nickel-chromium-iron superalloy known for its exceptional strength and resistance to oxidation, creep rupture, and carburization. Its high nickel content makes it highly resistant to corrosion in a wide range of environments, including oxidizing, reducing, and acidic conditions. Here at Online Fittings, we offer a variety of Inconel 600 fasteners, including bolts, nuts, washers, and screws, in various sizes and thread types to meet your specific needs.

Inconel 600 is the ideal choice for applications requiring exceptional high-temperature strength, oxidation resistance, and resistance to creep rupture. Its ability to withstand harsh environments makes it suitable for use in:

1. Jet engines 2. Nuclear reactors 3. Chemical processing equipment 4. Gas turbines 5. Heat exchangers 6. Furnace components 7. Cryogenic applications (at limited temperatures)

Monel

Monel is a nickel-copper alloy that offers excellent resistance to various corrosive media, including seawater, sulfuric acid, and hydrofluoric acid. It also boasts superior mechanical properties at both high and cryogenic temperatures. You have the liberty to choose from our online vast selection of Monel fasteners, including hex cap screws, square neck bolts, U-bolts, and coupling nuts, ensuring you have the right fastener for your application.

Monel is ideally used in industries that demand superior resistance to saltwater corrosion, sulfuric acid, and hydrofluoric acid. Its good strength at both high and low temperatures makes it a versatile option for:

1. Marine equipment 2. Offshore oil and gas rigs 3. Chemical processing plants 4. Pulp and paper mills 5. Pickling tanks 6. Desalination plants

Key Factors to Consider When Choosing Between Inconel 600 and Monel Fasteners

Here’s a breakdown of key factors to consider whilst deciding between Inconel 600 and Monel fasteners:

Property Inconel 600 Monel

Maximum Service Temperature, 1600°F (871°C), 800°F (427°C)

Strength

Higher, Lower

Oxidation Resistance

Excellent, Excellent

Chloride Stress Cracking

Good, Excellent

Cost

Higher, Lower

Additional pointers to consider:

1. Size and thread type: Ensure the fasteners are the correct size and thread type for your application. Look for an alloy fastener manufacturer who can customize each inch for your requirements.

2. Head style: The head style of the fastener (e.g., hex head, socket head) should be compatible with the installation tools and space constraints of your application.

3. Surface finish: Consider the desired surface finish (e.g., plain, zinc-plated) for factors like corrosion resistance and aesthetics.

Why Choose Online Fittings for Your Inconel 600 and Monel Fastener Needs?

At Online Fittings, we are committed to providing our customers with the highest quality Inconel 600 and Monel fasteners. We offer a comprehensive selection of fasteners in various sizes, thread types, and head styles to meet the demands of your project.

The experts at Online Fittings are always here to help you select the right fasteners to ensure the success of your project.

Let Online Fittings be your one-stop shop for all your Inconel 600 and Monel fastener needs. Contact us today to discuss your project requirements and receive a custom quote quote.

0 notes

Text

Installation Techniques for Wood Sound Panels: Best Practices in Homes

Wood sound panels are not only aesthetically pleasing but also serve a crucial role in improving acoustics within residential spaces. Whether you're enhancing the sound quality of a home theater, reducing noise in a bedroom, or creating a more productive home office environment, proper installation of wood sound panels is essential. This article delves into the best practices for installing wood sound panels in homes, covering everything from preparation and planning to mounting methods and maintenance.

Understanding Wood Sound Panels

Wood sound panels are designed to absorb sound waves effectively, reducing echoes and reverberations within a room. They are typically constructed from various types of wood, each with its own acoustic properties and aesthetic characteristics. These panels not only enhance sound quality but also add warmth and visual appeal to interiors, making them a popular choice for homeowners seeking both functionality and style.

Planning and Preparation

Before diving into the installation process, thorough planning and preparation are key to achieving optimal results with wood sound panels.

Assessing Acoustic Needs: Begin by evaluating the acoustic requirements of the space. Determine whether sound absorption, diffusion, or a combination of both is needed based on the room's purpose (e.g., home theater, music room, living room).

Selecting the Right Panels: Choose wood sound panels that match your aesthetic preferences and acoustic goals. Consider factors such as panel size, thickness, wood type (e.g., oak, maple, walnut), and finish (e.g., natural, stained, painted).

Measuring the Space: Accurate measurements of the installation area are crucial. Measure the height and width of the walls or ceiling where the panels will be installed to determine the quantity and size of panels required.

Calculating Coverage: Calculate the total surface area to be covered by the wood sound panels to ensure sufficient coverage for effective sound treatment. This calculation will also help in determining the spacing between panels for uniform sound absorption.

Installation Steps

Once you have planned and prepared adequately, follow these steps for successful installation of wood sound panels:

Step 1: Surface Preparation

Clean the Surface: Ensure that the walls or ceiling where the panels will be mounted are clean and free of dust, dirt, and debris. Use a dry cloth or vacuum cleaner to remove any particles that could affect adhesion.

Surface Inspection: Check for any imperfections or irregularities in the surface that may need to be addressed before installation. Smooth out bumps or fill in gaps as necessary to ensure a flat and even mounting surface.

Step 2: Panel Placement and Layout

Mock Installation: Before mounting the panels permanently, perform a mock installation by placing the panels against the wall or ceiling in the desired configuration. This allows you to visualize the layout and make adjustments if needed.

Spacing Considerations: Determine the optimal spacing between panels to achieve balanced sound absorption throughout the room. Generally, spacing of 1-2 inches between panels is recommended for effective acoustic performance.

Step 3: Mounting Methods

The method of mounting will depend on the type of wood sound panels and the surface they are being installed on (wall or ceiling).

Adhesive Mounting: For lightweight panels, adhesive mounting can be an effective and straightforward method. Use a high-quality construction adhesive suitable for wood and the specific surface material (e.g., drywall, concrete).

Apply the adhesive evenly to the back of the panel in a zigzag pattern or as recommended by the adhesive manufacturer.

Press the panel firmly against the wall or ceiling, ensuring it is level and properly aligned. Use painter's tape or temporary supports to hold the panel in place while the adhesive cures.

Mechanical Fastening: Heavier panels or those requiring more secure attachment may require mechanical fasteners such as screws and anchors.

Pre-drill pilot holes into the panels and the mounting surface to prevent splitting of the wood and facilitate easier installation.

Use screws and appropriate anchors (if needed) to securely fasten the panels to the wall or ceiling. Ensure screws are countersunk to maintain a flush finish.

Step 4: Finishing Touches

Seam Alignment: Pay attention to the alignment of seams between adjacent panels for a professional and cohesive look. Use a level to ensure panels are installed straight and parallel to each other.

Trim and Edging: Install trim or edging around the perimeter of the wood sound panels to provide a finished appearance. This can also help conceal any gaps between panels and the surrounding surfaces.

Step 5: Post-Installation Inspection and Adjustments

Check Stability: Once all panels are installed, gently tap or press on each panel to ensure they are securely attached and there are no loose spots.

Evaluate Acoustic Performance: Conduct a sound test to evaluate the effectiveness of the installed wood sound panels in improving room acoustics. Compare the sound quality before and after installation to assess any noticeable improvements.

Maintenance Tips

To maintain the beauty and functionality of wood sound panels over time, follow these maintenance tips:

Regular Cleaning: Dust panels regularly with a soft cloth or vacuum cleaner attachment to remove surface dust and dirt.

Avoid Moisture: Wood panels should be kept away from excessive moisture or humidity to prevent warping or damage.

Periodic Inspection: Periodically inspect panels for signs of wear or damage. Repair or replace any panels that have become loose or damaged to maintain optimal acoustic performance.

Conclusion

Proper installation of wood sound panels in homes requires careful planning, precise execution, and attention to detail. By following best practices from surface preparation to panel mounting and maintenance, homeowners can achieve enhanced acoustics and a visually appealing environment. Whether you're creating a home theater, music room, or simply improving the comfort of living spaces, wood sound panels offer a versatile solution that combines functionality with timeless elegance.

By investing time and effort into the installation process, homeowners can enjoy the benefits of improved sound quality and aesthetic enhancement that wood sound panels bring to their homes for years to come. For more information on wood sound panels and installation techniques, consult with acoustic specialists or trusted suppliers who can provide expert guidance tailored to your specific needs and preferences.

0 notes

Text

The Art of Making Bags: How Zippers Play Crucial Role in Bag Manufacturing

Bag-making is a complex and intricate process that requires skill, creativity, and attention to detail. One of the most important components in bag manufacturing is the humble zipper. Zippers play a crucial role in both the functionality and aesthetics of bags, transforming them from mere utility items to fashion statements.

The Evolution of Zippers

The history of zippers dates back to 1851 when Elias Howe, Jr., the sewing machine inventor, patented the "Automatic, Continuous Clothing Closure." However, it wasn't until Gideon Sundback's "Separable Fastener" in 1917 that the modern zipper was born. Since then, zippers have evolved from securing money belts and tobacco pouches during World War I to becoming a fashion staple in the 1930s.

Types of Zippers Used in Bag Making

There are several types of zippers commonly used in bag manufacturing, each with its unique characteristics:

1. **Number 3 Zipper (Craft Zipper)**: These zippers are typically used in smaller projects like pouches and wallets. The width of the zipper tape is 1 inch, and the teeth are approximately 3 millimeters wide.

2. **Number 4.5 Zipper (Handbag Zipper)**: Slightly larger than the number 3 zipper, these are commonly used in handbags and other medium-sized projects.

3. **Number 5 Zipper**: The largest of the three, number 5 zippers are often used in heavy-duty bags like duffel bags and luggage.

Choosing the Right Zipper

When selecting a zipper for a bag, several factors must be considered:

- The intended use of the bag (e.g., everyday carry, travel, or fashion)

- The size and weight of the bag

- The overall design and aesthetic of the bag

- The quality and durability of the zipper

High-end brands like Raccagni and YKK are known for their bespoke quality and reliability. Niwar Corner zippers, originating from Central Delhi, India, are synonymous with luxury and are often used by high-end fashion houses. YKK, a Japanese company, is a giant in the zipper industry, supplying about half of all zippers globally.

The Manufacturing Process

Bag manufacturing involves several stages, each of which requires skill and expertise:

1. **Design**: The creative process of incorporating functionality, aesthetics, and ergonomics into the bag design.

2. **Pattern Making**: Creating the templates for the bag pieces based on the design.

3. **Cutting**: Precisely cutting the leather or fabric according to the patterns using specialized tools and machinery.

4. **Stitching**: Carefully stitching the bag pieces together using various techniques to create the bag's structure.

5. **Finishing**: Adding the zipper, hardware, and other finishing touches to the bag.

The Importance of Zippers in Bag Making

Zippers are not just functional components in bag making; they are also an integral part of the design. A well-chosen zipper can enhance the overall appeal of a bag, adding a unique element or drawing attention to specific features.

Moreover, zippers play a crucial role in the durability and longevity of a bag. A high-quality zipper that glides smoothly and exhibits durability is essential for a bag to withstand the test of time.

how do you install an invisible zipper in a bag?

To install an invisible zipper in a bag, follow these steps:

1. **Prepare the Seam Edges**: Finish or serge the joining seam edges where the zipper will be added. Place the joining seam edges side by side, right side up. Mark ¾” from the top edges of both pieces to indicate the placement of the zipper.

2. **Mark the Seam Allowances**: Mark a ⅝” vertical seam allowance where the invisible zipper will be placed.

3. **Prepare the Zipper**: Open up the zipper, rolling and pressing out the curled zipper teeth so they lay slightly flat. This helps you get a closer stitch for a cleaner finish.

4. **Pin the Zipper**: Place the zipper coil right side down along one of the marked ⅝” seam allowances and pin in place. Ensure the fabric is stable; hand-baste if needed.

5. **Sew One Side of the Zipper**: Position the zipper teeth under the proper groove in the invisible zipper foot. Start at the top edge and stitch in place until the foot reaches the zipper stop. Backstitch to lock and remove.

6. **Pin the Other Side of the Zipper**: Ensure the ¾“ markings along the top edge of each pattern piece align perfectly. Adjust and re-pin if necessary.

7. **Sew the Other Side of the Zipper**: Sew the zipper to the other side of the pattern piece, ensuring the zipper coils are flat. Start at the top edge and stitch in place until the foot reaches the zipper stop. Backstitch to lock and remove.

8. **Finish the Seam Below the Zipper**: Close the zipper, place right sides of the fabric together, and move the zipper tails out of the way. Stitch away from the zipper for about 2” using a regular presser foot.

9. **Give a Final Press**: Press the seam over the zipper with a press cloth and low heat. Press the seam allowance open below the zipper with appropriate heat and steam for the fabric.

By following these steps, you can successfully install an invisible zipper in a bag, giving it a professional and polished finish.

Conclusion

In the world of bag making, zippers are more than just fasteners; they are an essential part of the creative process. From the humble craft zipper to the luxurious Raccagni, each type of zipper has its unique role to play in transforming a bag from a functional item to a fashion statement. By carefully selecting the right zipper and incorporating it into the design, bag makers can create products that are not only beautiful but also durable and practical.

0 notes