#High-Performance Actuators

Explore tagged Tumblr posts

Note

Something I'm curious on (And definitely not having fanfic writing problems *cough*) is how Mobius would react to people talking badly about or reacting badly to Loki when they have reason to. Like the Hawkeye duo or Coulson or Fury. Loki, I imagine, would probably be neutral towards or just accept their hatred/anger and move on. But how would Mobius react to it? He has been shown to try to defend Loki to others, but he also recognizes the fact that Loki was a dick. Your opinion?

From one fanfic writer (*cough* currently on hiatus *cough**cough*) to another, I'm so honored to be the recipient of this question!

If we're talking about how Mobius would respond internally, I don't think he would be offended. Maybe a bit tired of hearing the same response over and over again, but his patience is his second greatest strength after empathy. I think he would only get truly pissed (which we know is scary to bear witness to) if Loki has proven himself trustworthy in front of everyone repeatedly and he is still treated like crap. Oh, man ... now that you got me started on this, I think an angry Mobius, defensive on Loki's behalf, would dig REALLY deep into the person's insecurities and biggest flaws, slowly pull it out like disembowelment, and force feed it back to the person as poisonous truth and expose their hypocrisy. Mobius has the capacity to do that, but the threshold to get there is pretty high. Loki would need to be visibly distraught.

If we're talking about how Mobius would respond verbally, on first meeting, we should remember Mobius is an Analyst. He chooses how to act and what to say based on what he knows about the individual he is talking to and the current emotional state they're in. I don't think he would have a one-size fits all response. I think he would use the angle of highest benefit and interest of the person negatively affected by Loki's presence, then drill down into his Loki's value in increments.

He does this with Ravonna first by arguing Loki would be a useful tool to the TVA, then proving his argument is sound by explaining Loki's apocalypse theory is correct, and Loki should therefore be brought out into the field. Mobius feeds two birds with one hand in doing this: he gives Ravonna what he wants and he gives Loki an environment in which he can be himself and thrive. His selfish desires are rewarded for his efforts as well: he gets to spend time with Loki.

This is highly utilitarian, I know, but it's smart. Mobius knows what most people think about Loki. They don't care about him as a person, only his potential usefulness. Trying to make a humanitarian case is not going to work, at least not in the beginning. He knows it's more effective to go through the motions of proving, with a benefit to the affected person as a bargaining chip for Loki's immediate safety.

I am convinced that if Loki hadn't chased after Sylvie (and let's be honest, in the long run it was a VERY good thing for everyone involved that he did), Mobius would have presented the case to Ravonna that they shouldn't prune Loki once Sylvie is captured. He would argue: He's reformed. He's a good person. He's my friend. The humanitarian argument would then come out alongside the utilitarian argument to move the listener closer to compassion for Loki while also giving them a tangible benefit outside Loki's personhood. Eventually, Mobius would be able to drop the utilitarian aspect. Mobius is very cunning in this way and has the patience to play the long game for the big picture.

If time is an issue because of high stakes, then I would say that Mobius and Loki would mutually agree to have Loki restrained while Mobius performs a mini TVA infodump, which may include a crucial event about the timeline that is nearing actuation and how to best respond to it. The proving of his claim will verify the TVA infodump as truthful and his claim that Loki is good likely.

Now, if the issue is not immediate plot conflict but immediate emotional conflict, I think Mobius would be more subtle in how he gets people to pause before listening to him. No one can touch Loki without being harmed, at least that's the wisdom people have with pre-TVA Loki. Mobius might touch Loki's elbow, his shoulder, his back--points of contact that are casually intimate and normal for him and Loki, but shocking to anyone not-in-the-know given who is being touched. In that moment of shock, Mobius might say, with a sigh, "Y'know, we've heard this all before. We're not gonna argue with you. We get it. But do you really want to waste time going through three hours of backstory, or do you want to focus on figuring out how to deal with the bigger problem right now? Because I'll be honest with you: you dont have a lot of time. We've seen it."

The follow up to any of these initial responses would likely be a private moment between the character and Mobius, with Mobius hinting at or outright sharing the true nature of their relationship, and why he's stuck by Loki's side so long.

I hope this helpful, anon! Thank you for your question!

47 notes

·

View notes

Text

Study identifies high-performance alternative to conventional ferroelectrics

Lighting a gas grill, getting an ultrasound, using an ultrasonic toothbrush—these actions involve the use of materials that can translate an electric voltage into a change in shape and vice versa. Known as piezoelectricity, the ability to trade between mechanical stress and electric charge can be harnessed widely in capacitors, actuators, transducers and sensors like accelerometers and gyroscopes for next-generation electronics. However, integrating these materials into miniaturized systems has been difficult due to the tendency of electromechanically active materials to—at the submicrometer scale, when the thickness is just a few millionths of an inch—get "clamped" down by the material they are attached to, which significantly dials down their performance. Rice University researchers and collaborators at the University of California, Berkeley have found that a class of electromechanically active materials called antiferroelectrics may hold the key to overcoming performance limitations due to clamping in miniaturized electromechanical systems.

Read more.

#Materials Science#Science#Ferroelectrics#Piezoelectric#Electronics#Antiferroelectric#Thin films#Rice University

13 notes

·

View notes

Text

Telescope for NASA’s Roman Mission complete, delivered to Goddard

NASA’s Nancy Grace Roman Space Telescope is one giant step closer to unlocking the mysteries of the universe. The mission has now received its final major delivery: the Optical Telescope Assembly, which includes a 7.9-foot (2.4-meter) primary mirror, nine additional mirrors, and supporting structures and electronics. The assembly was delivered Nov. 7. to the largest clean room at NASA’s Goddard Space Flight Center in Greenbelt, Maryland, where the observatory is being built.

The telescope will focus cosmic light and send it to Roman’s instruments, revealing many billions of objects strewn throughout space and time. Using the mission’s Wide Field Instrument, a 300-megapixel infrared camera, astronomers will survey the cosmos all the way from the outskirts of our solar system toward the edge of the observable universe. Scientists will use Roman’s Coronagraph Instrument to test new technologies for dimming host stars to image planets and dusty disks around them in far better detail than ever before.

“We have a top-notch telescope that’s well aligned and has great optical performance at the cold temperatures it will see in space,” said Bente Eegholm, optics lead for Roman’s Optical Telescope Assembly at NASA Goddard. “I am now looking forward to the next phase where the telescope and instruments will be put together to form the Roman observatory.”

Designed and built by L3Harris Technologies in Rochester, New York, the assembly incorporates key optics (including the primary mirror) that were made available to NASA by the National Reconnaissance Office. The team at L3Harris then reshaped the mirror and built upon the inherited hardware to ensure it would meet Roman’s specifications for expansive, sensitive infrared observations.

“The telescope will be the foundation of all of the science Roman will do, so its design and performance are among the largest factors in the mission’s survey capability,” said Josh Abel, lead Optical Telescope Assembly systems engineer at NASA Goddard.

The team at Goddard worked closely with L3Harris to ensure these stringent requirements were met and that the telescope assembly will integrate smoothly into the rest of the Roman observatory.

The assembly’s design and performance will largely determine the quality of the mission’s results, so the manufacturing and testing processes were extremely rigorous. Each optical component was tested individually prior to being assembled and assessed together earlier this year. The tests helped ensure that the alignment of the telescope’s mirrors will change as expected when the telescope reaches its operating temperature in space.

Then, the telescope was put through tests simulating the extreme shaking and intense sound waves associated with launch. Engineers also made sure that tiny components called actuators, which will adjust some of the mirrors in space, move as predicted. And the team measured gases released from the assembly as it transitioned from normal air pressure to a vacuum –– the same phenomenon that has led astronauts to report that space smells gunpowdery or metallic. If not carefully controlled, these gases could contaminate the telescope or instruments.

Finally, the telescope underwent a month-long thermal vacuum test to ensure it will withstand the temperature and pressure environment of space. The team closely monitored it during cold operating conditions to ensure the telescope’s temperature will remain constant to within a fraction of a degree. Holding the temperature constant allows the telescope to remain in stable focus, making Roman’s high-resolution images consistently sharp. Nearly 100 heaters on the telescope will help keep all parts of it at a very stable temperature.

“It is very difficult to design and build a system to hold temperatures to such a tight stability, and the telescope performed exceptionally,” said Christine Cottingham, thermal lead for Roman’s Optical Telescope Assembly at NASA Goddard.

Now that the assembly has arrived at Goddard, it will be installed onto Roman’s Instrument Carrier, a structure that will keep the telescope and Roman’s two instruments optically aligned. The assembly’s electronics box –– essentially the telescope’s brain –– will be mounted within the spacecraft along with Roman’s other electronics.

With this milestone, Roman remains on track for launch by May 2027.

“Congratulations to the team on this stellar accomplishment!” said J. Scott Smith, the assembly’s telescope manager at NASA Goddard. “The completion of the telescope marks the end of an epoch and incredible journey for this team, and yet only a chapter in building Roman. The team’s efforts have advanced technology and ignited the imaginations of those who dream of exploring the stars.”

TOP IMAGE: Upon arrival at NASA's Goddard Space Flight Center, the Optical Telescope Assembly for the agency's Nancy Grace Roman Space Telescope was lifted out of the shipping fixture and placed with other mission hardware in Goddard's largest clean room. Now, it will be installed onto Roman's Instrument Carrier, a structure that will keep the telescope and Roman's two instruments optically aligned. The assembly's electronics box –– essentially the telescope's brain –– will be mounted within the spacecraft along with Roman's other electronics. Credit NASA/Chris Gunn

CENTRE IMAGE: In this photo, optical engineer Bente Eegholm inspects the surface of the primary mirror for NASA's Nancy Grace Roman Space Telescope. This 7.9-foot (2.4-meter) mirror is a major component of the Optical Telescope Assembly, which also contains nine additional mirrors and supporting structures and electronics. Credit NASA/Chris Gunn

BOTTOM IMAGE: This photo shows the Optical Telescope Assembly for NASA's Nancy Grace Roman Space Telescope, which was recently delivered to the largest clean room at the agency's Goddard Space Flight Center in Greenbelt, Md. Credit NASA/Chris Gunn

3 notes

·

View notes

Text

Automated Armor Suit Fitting System (AASF System)

The Automated Armor Suit Fitting System (AASF System) represents the latest advancement in the seamless integration of advanced full-body armor suits onto cadets. Designed for efficiency and precision, the AASF System eliminates the need for manual fitting, ensuring a perfect fit for each cadet in minimal time. This system underscores a pragmatic approach to uniformity and control, reflecting the reality of modern military training environments.

Design and Features

Robotic Chamber: The AASF System consists of a fully automated robotic chamber equipped with high-precision actuators and sensors. The chamber is designed to accommodate a wide range of body sizes and shapes, ensuring each cadet receives a tailored fit.

3D Scanning Technology: The system employs advanced 3D scanning technology to capture the cadet’s exact body dimensions. This data is used to adjust the armor suit in real-time, ensuring a snug and secure fit that maximizes protection and mobility.

Robotic Servo Arms: The fitting process utilizes robotic servo arms to install the suits onto the conscripts' bodies. These arms handle the suit components with precision, attaching each part securely while the conscript remains passive. This automation ensures consistency and accuracy, reducing the risk of human error.

Precision Fitting: Using a combination of hydraulic and pneumatic systems, the chamber adjusts the suit’s various components—torso, limbs, helmet, and integrated chastity/underwear/diaper component—to fit the cadet’s body perfectly. The process ensures that all joints and seals are aligned correctly, minimizing potential points of failure or discomfort.

Biometric Integration: The system integrates biometric monitoring to track the cadet’s vital signs during the fitting process. This includes heart rate, respiration, and stress levels, ensuring the process is conducted safely and efficiently.

Automated Fastening: Once the suit components are in place, the AASF System employs automated fastening mechanisms to secure the suit. This includes the activation of locking mechanisms, sealing of joints, and integration of the internal waste management system.

Calibration and Adjustment: The system performs final calibration and adjustment checks, ensuring that all suit functions—such as the servos, waste management, and communication systems—are operational and correctly configured. This stage also includes a diagnostic check to identify and rectify any potential issues.

Fitting Procedure

Initial Positioning: Cadets enter the fitting chamber nude except for their Standard Chastity/Underwear/Diaper Component. The chamber’s docking mechanism arm clasps them from behind, fixing them in place securely. This initial docking provides the first point of stabilization.

Boot Installation: Robotic servo arms install the boots onto the cadets' feet. These boots are the foundation of the armor, providing additional strap points to stabilize the cadets during the subsequent steps.

Torso Protector: The next step involves the application of the torso protector. The servo arms carefully align and attach the torso segment, ensuring it fits snugly and securely around the cadet’s upper body.

Hips and Legs Armor: Following the torso protector, the hips and legs armor components are attached. These segments are aligned with the boots and torso protector, creating a seamless protective layer over the cadet’s lower body.

Arm Armor: The servo arms then attach the arm segments, ensuring each piece aligns with the torso protector and the shoulder joints. This step includes both the upper arm and forearm components.

Gauntlet-Style Gloves: The final armor components to be attached are the gauntlet-style gloves. These gloves are carefully aligned with the forearm segments, completing the protective suit.

Helmet: Although not specified in the initial sequence, the helmet is typically the final piece, providing comprehensive protection and integrating with the suit’s communication and sensory systems.

Final Checks and Adjustments: The system performs a series of checks to ensure all components are securely fastened and properly aligned. The cadet's biometrics are continuously monitored, and any necessary adjustments are made to ensure comfort and functionality.

Psychological Component

The AASF System is designed not only for physical integration but also for psychological conditioning. The process of being fitted by robotic servo arms, without any active participation, instills a sense of helplessness in the conscripts. This experience reinforces their acceptance of being encased in the suits, effectively making them acknowledge and adapt to their place within the system. The feeling of being physically and psychologically enveloped by the suit contributes to a deeper integration into the regimented environment of the academy.

4 notes

·

View notes

Photo

SSC Tuatara (1 of 100).

The jet fighter inspired teardrop canopy, which is suspended within the dynamic fuselage body, is complemented by vertical stabilizing fins at the rear, revealing the cars stunning speed capabilities. The streamlined design has been tuned to produce a near perfect front to rear aero balance, incredible thermal efficiency to ensure stability at all speeds up to its terminal ground velocity along with unrivaled high speed acceleration. The design of the Tuatara goes further than visual appearance. The intentional design of the body was meticulously crafted to carry the car through the air with unprecedented ease. Boasting an industry leading coefficient of drag of 0.279, the Tuatara is well balanced between unmatched aerodynamics and precision downforce at top speed.Rear static winglets, side mounted buttresses, forward static wing, and a rear active wing manipulate the smooth flowing air to distribute precision down force on the wheels. Air is also diverted to intakes that efficiently cool the powerful drive train, then expelled through perforations in the body to sustain the deliberate airflow. Downforce is systematically applied across the hypercar, providing perfect balance at all speeds.The heart of the Tuatara is an engineering masterpiece in and of itself. Years of meticulous design and engineering at SSC North America culminated into unadulterated power generated from an engine built from the ground up exclusively for the Tuatara. The smooth, balanced power produced offers both incredible performance and a unique hypercar experience. To ensure the engine met the standards of quality, performance, and durability that the hypercar market demands, SSC North America partnered with Nelson Racing Engines to fabricate and manufacture the V8 engine that powers this next generation hypercar.The Tuatara’s unprecedented power is transferred to a CIMA 7 speed transmission, integrated with a state-of-the-art Automac AMT system that operates the engagement and selection of movement in the gearbox. The system includes hydraulic driven components and sensors to produce high force engagement, position accuracy, and load control within milliseconds. The clutch and gear selection actuation are electrically operated, providing high precision and strategic operation. The core of the system is powered by a powerful automotive microprocessor, ensuring exceptional safety and performance.

47 notes

·

View notes

Text

Agilex 3 FPGAs: Next-Gen Edge-To-Cloud Technology At Altera

Agilex 3 FPGA

Today, Altera, an Intel company, launched a line of FPGA hardware, software, and development tools to expand the market and use cases for its programmable solutions. Altera unveiled new development kits and software support for its Agilex 5 FPGAs at its annual developer’s conference, along with fresh information on its next-generation, cost-and power-optimized Agilex 3 FPGA.

Altera

Why It Matters

Altera is the sole independent provider of FPGAs, offering complete stack solutions designed for next-generation communications infrastructure, intelligent edge applications, and high-performance accelerated computing systems. Customers can get adaptable hardware from the company that quickly adjusts to shifting market demands brought about by the era of intelligent computing thanks to its extensive FPGA range. With Agilex FPGAs loaded with AI Tensor Blocks and the Altera FPGA AI Suite, which speeds up FPGA development for AI inference using well-liked frameworks like TensorFlow, PyTorch, and OpenVINO toolkit and tested FPGA development flows, Altera is leading the industry in the use of FPGAs in AI inference workload

Intel Agilex 3

What Agilex 3 FPGAs Offer

Designed to satisfy the power, performance, and size needs of embedded and intelligent edge applications, Altera today revealed additional product details for its Agilex 3 FPGA. Agilex 3 FPGAs, with densities ranging from 25K-135K logic elements, offer faster performance, improved security, and higher degrees of integration in a smaller box than its predecessors.

An on-chip twin Cortex A55 ARM hard processor subsystem with a programmable fabric enhanced with artificial intelligence capabilities is a feature of the FPGA family. Real-time computation for time-sensitive applications such as industrial Internet of Things (IoT) and driverless cars is made possible by the FPGA for intelligent edge applications. Agilex 3 FPGAs give sensors, drivers, actuators, and machine learning algorithms a smooth integration for smart factory automation technologies including robotics and machine vision.

Agilex 3 FPGAs provide numerous major security advancements over the previous generation, such as bitstream encryption, authentication, and physical anti-tamper detection, to fulfill the needs of both defense and commercial projects. Critical applications in industrial automation and other fields benefit from these capabilities, which guarantee dependable and secure performance.

Agilex 3 FPGAs offer a 1.9×1 boost in performance over the previous generation by utilizing Altera’s HyperFlex architecture. By extending the HyperFlex design to Agilex 3 FPGAs, high clock frequencies can be achieved in an FPGA that is optimized for both cost and power. Added support for LPDDR4X Memory and integrated high-speed transceivers capable of up to 12.5 Gbps allow for increased system performance.

Agilex 3 FPGA software support is scheduled to begin in Q1 2025, with development kits and production shipments following in the middle of the year.

How FPGA Software Tools Speed Market Entry

Quartus Prime Pro

The Latest Features of Altera’s Quartus Prime Pro software, which gives developers industry-leading compilation times, enhanced designer productivity, and expedited time-to-market, are another way that FPGA software tools accelerate time-to-market. With the impending Quartus Prime Pro 24.3 release, enhanced support for embedded applications and access to additional Agilex devices are made possible.

Agilex 5 FPGA D-series, which targets an even wider range of use cases than Agilex 5 FPGA E-series, which are optimized to enable efficient computing in edge applications, can be designed by customers using this forthcoming release. In order to help lower entry barriers for its mid-range FPGA family, Altera provides software support for its Agilex 5 FPGA E-series through a free license in the Quartus Prime Software.

Support for embedded applications that use Altera’s RISC-V solution, the Nios V soft-core processor that may be instantiated in the FPGA fabric, or an integrated hard-processor subsystem is also included in this software release. Agilex 5 FPGA design examples that highlight Nios V features like lockstep, complete ECC, and branch prediction are now available to customers. The most recent versions of Linux, VxWorks, and Zephyr provide new OS and RTOS support for the Agilex 5 SoC FPGA-based hard processor subsystem.

How to Begin for Developers

In addition to the extensive range of Agilex 5 and Agilex 7 FPGAs-based solutions available to assist developers in getting started, Altera and its ecosystem partners announced the release of 11 additional Agilex 5 FPGA-based development kits and system-on-modules (SoMs).

Developers may quickly transition to full-volume production, gain firsthand knowledge of the features and advantages Agilex FPGAs can offer, and easily and affordably access Altera hardware with FPGA development kits.

Kits are available for a wide range of application cases and all geographical locations. To find out how to buy, go to Altera’s Partner Showcase website.

Read more on govindhtech.com

#Agilex3FPGA#NextGen#CloudTechnology#TensorFlow#Agilex5FPGA#OpenVINO#IntelAgilex3#artificialintelligence#InternetThings#IoT#FPGA#LPDDR4XMemory#Agilex5FPGAEseries#technology#Agilex7FPGAs#QuartusPrimePro#technews#news#govindhtech

2 notes

·

View notes

Text

Ball Valves: Types, Sizes, and Applications

Ball valves are integral components in fluid systems, known for their efficiency, durability, and ease of use. This article delves into various types of ball valves, including specialty and electric options, and covers sizes from 1/2 inch to 4 inches. We will also highlight specific product options and their applications to help you choose the best valve for your needs.

What is a Ball Valve?

A ball valve is a valve that controls fluid flow through a pipeline using a spherical ball with a hole through its center. The ball is mounted on a shaft and rotates to open or close the flow. When the valve is open, the hole in the ball aligns with the pipe, allowing fluid to pass. When closed, the ball rotates to block the flow completely. Ball valves are celebrated for their simple design, reliable performance, and versatility.

Types of Ball Valves

1. Standard Ball Valves: These are the most common type, suitable for general applications. They come in various sizes, including 1/2 inch, 3/4 inch, and 4 inch ball valves, providing flexibility for different systems.

2. 3-Way Ball Valves: Designed for more complex flow control, 3-way ball valves allow you to direct flow between three different paths. They are ideal for systems that require flow diversion or mixing.

3. Electric Ball Valves: These valves are equipped with electric actuators, enabling automated operation. They are perfect for applications requiring remote or programmable control.

4. Apollo Ball Valves: Known for their high quality and reliability, Apollo ball valves are designed for demanding applications. They offer robust performance and durability in various industrial settings.

Available Sizes and Products

1. 1/2 Inch Ball Valve: Suitable for small pipelines and applications where precise control is needed. Check out our 1/2 Inch Ball Valve for detailed specifications.

2. 3/4 Inch Ball Valve: Ideal for medium-sized pipes, offering a balance between performance and space. Explore our 3/4 Inch Ball Valve for more information.

3. 4 Inch Ball Valve: Perfect for larger systems requiring higher flow capacities. Visit our Valves Category for options.

4. 3-Way Ball Valve: Designed to manage flow between three paths, ideal for complex systems. Learn more about our 3-way ball valve options here.

5. Electric Ball Valve: For automated control, our electric ball valves offer convenience and precision. Check out our range of electric ball valves at Udhhyog.

6. Apollo Ball Valves: High-quality Apollo ball valves are available for rigorous applications. Discover Apollo options in our Valves Category.

Choosing the Right Ball Valve

Consider the following factors when selecting a ball valve:

Pipeline Size: Match the valve size to your pipeline dimensions. Available sizes include 1/2 inch, 3/4 inch, and 4 inch ball valves.

Application Requirements: Determine if you need a standard valve, a 3-way valve, or an electric valve based on your system’s needs.

Material and Construction: Select a valve made from materials compatible with your fluids and environmental conditions.

4 notes

·

View notes

Text

Explore a wide selection of high-quality valve limit switches and monitors at Valworx. Our reliable and durable products are designed to provide precise valve position feedback for a variety of industrial applications. Ensure optimal performance and control with our easy-to-install and maintain solutions. Shop now for competitive prices and excellent customer support.

2 notes

·

View notes

Text

Arduino Due vs. Mega: A Comprehensive Comparison

What is Arduino Due and Mega?

The Arduino platform has revolutionized the world of DIY electronics, providing hobbyists and professionals alike with versatile and powerful microcontroller boards. Among the myriad of options, the Arduino Due and Arduino Mega stand out for their advanced features and robust performance. The Arduino Due, introduced in 2012, is the first Arduino board based on a 32-bit ARM core microcontroller, the Atmel SAM3X8E. In contrast, the Arduino Mega, built around the 8-bit ATmega2560 microcontroller, is known for its abundant I/O pins and memory. Understanding the differences between these two boards can help in selecting the right one for specific projects, enhancing both functionality and efficiency.

Processing Power and Performance

The processing capabilities of the Arduino Due and Mega are distinctly different, primarily due to their core microcontrollers. The Arduino Due, with its 32-bit ARM Cortex-M3 processor running at 84 MHz, offers significantly higher processing power compared to the Arduino Mega's 8-bit ATmega2560, which operates at 16 MHz. This difference in architecture and clock speed means that the Due can handle more complex calculations and tasks faster and more efficiently than the Mega. For projects requiring high computational power, such as real-time data processing or handling multiple sensors simultaneously, the Due is the superior choice. However, for simpler tasks, the Mega's processing power may suffice.

Memory and Storage Capabilities

Memory is another critical aspect where the Arduino Due and Mega diverge. The Arduino Due is equipped with 512 KB of flash memory for code storage and 96 KB of SRAM for data. On the other hand, the Arduino Mega has 256 KB of flash memory and 8 KB of SRAM. Additionally, the Due features a Direct Memory Access (DMA) controller, which allows for efficient memory operations, freeing up the CPU to handle other tasks. These memory enhancements make the Due more suitable for applications requiring large codebases and significant data handling, such as advanced robotics or sophisticated control systems. The Mega, with its more modest memory, is ideal for less demanding applications.

Input/Output Capabilities and Expansion

Both the Arduino Due and Mega are renowned for their extensive input/output (I/O) capabilities, yet they cater to different needs. The Mega boasts a whopping 54 digital I/O pins, 16 analog inputs, and 4 UARTs, making it ideal for projects that require multiple sensors, actuators, or communication interfaces. The Due, while offering fewer digital I/O pins at 54, includes 12 analog inputs and 4 UARTs, along with additional features like two DAC outputs for analog signal generation and enhanced PWM capabilities. These features provide the Due with superior analog output capabilities, making it suitable for applications like audio processing or advanced signal generation.

Power Consumption and Compatibility

Power consumption and compatibility are practical considerations when choosing between the Arduino Due and Mega. The Due operates at 3.3V logic levels, which makes it more power-efficient than the Mega, which uses 5V logic levels. This lower voltage operation is beneficial for battery-powered projects where energy efficiency is crucial. However, the 3.3V logic also means that the Due is not directly compatible with 5V components without level shifters. The Mega, with its 5V logic, offers broader compatibility with existing Arduino shields and components, making it a versatile choice for a wide range of projects. Understanding these power and compatibility nuances can help in making an informed decision based on the project's specific requirements.

2 notes

·

View notes

Text

I have described as a 'magician's bargain' that process whereby man surrenders object after object, and finally himself, to Nature in return for power. And I meant what I said. The fact that the scientist succeeded where the magician failed has put such a wide contrast between them in popular thought that the real story of the birth of Science is misunderstood. You will even find people who write about the sixteenth century as if Magic were a medieval survival and Science the new thing that came to sweep it away. Those who have studied the period know better. There was very little magic in the Middle Ages: the sixteenth and seventeenth centuries were the high noon of magic. The serious magical endeavour and the serious scientific endeavour are twins: one was sickly and died, the other strong and throve. But they were twins. They were born of the same impulse. I will allow that some (certainly not all) of the early scientists were actuated by a pure love of knowledge. But if we consider the temper of that age as a whole we can discern the impulse of which I speak. There is something which unites magic and applied science while separating both from the 'wisdom' of earlier ages. For the wise men of old the cardinal problem had been how to conform the soul to reality, and the solution had been knowledge, self-discipline, and virtue. For magic and applied science alike the problem is how to subdue reality to the wishes of men: the solution is a technique; and both, in the practice of this technique, are ready to do things hitherto regarded as disgusting and impious — such as digging up and mutilating the dead. If we compare the chief trumpeter of the new era (Bacon) with Marlowe's Faustus, the similarity is striking. You will read in some critics that Faustus has a thirst for knowledge. In reality, he hardly mentions it. It is not truth he wants from the devils, but gold and guns and girls. 'All things that move between the quiet poles shall be at his command' and 'a sound magician is a mighty god' [citation]. In the same spirit Bacon condemns those who value knowledge as an end in itself: this, for him, is to use as a mistress for pleasure what ought to be a spouse for fruit [citation]. The true object is to extend Man's power to the performance of all things possible. He rejects magic because it does not work; but his goal is that of the magician. In Paracelsus the characters of magician and scientist are combined. No doubt those who really founded modern science were usually those whose love of truth exceeded their love of power; in every mixed movement the efficacy comes from the good elements, not from the bad. But the presence of bad elements is not irrelevant to the direction the efficacy takes. It might be going too far to say that the modern scientific was tainted from its birth: but I think it would be true to say that it was born in an unhealthy neighborhood at an inauspicious hour. Its triumphs may have been too rapid and purchased at too high a price: reconsideration, and something like repentance, may be required. Is it, then, possible to imagine a new Natural Philosophy, continually conscious that the natural object produced by analysis and abstraction is not reality but only a view, and always correcting the abstraction? [...] The regenerate science I have in mind would not do even to minerals and vegetables what modern science threatens to do to man himself. What it explained it would not explain away. [...] Its followers would not be free with the words only and merely. In a word, it would conquer nature without being at the same time conquered by her and buy knowledge at a lower cost than that of life itself.

C.S. Lewis (The Abolition of Man). Bolded emphases added, italics original.

16 notes

·

View notes

Text

New ferroelectric material could give robots muscles

A new type of ferroelectric polymer that is exceptionally good at converting electrical energy into mechanical strain holds promise as a high-performance motion controller or "actuator" with great potential for applications in medical devices, advanced robotics, and precision positioning systems, according to a team of international researchers led by Penn State. Mechanical strain, how a material changes shape when force is applied, is an important property for an actuator, which is any material that will change or deform when an external force such as electrical energy is applied. Traditionally, these actuator materials were rigid, but soft actuators such as ferrroelectric polymers display higher flexibility and environmental adaptability. The research demonstrated the potential of ferroelectric polymer nanocomposites to overcome the limitations of traditional piezoelectric polymer composites, offering a promising avenue for the development of soft actuators with enhanced strain performance and mechanical energy density. Soft actuators are especially of interest to robotics researchers due to its strength, power and flexibility.

Read more.

8 notes

·

View notes

Text

F-104 Starfighter Veterans on the Ongena Touch-Roll-Touch Maneuver

August 14, 2013 Vintage Aviation News Articles 19

Aircorps Art Dec 2019

youtube

You’ve probably seen this video before, Legendary Belgian Air Force Silvers Aerobatic Team member, William “Bill” Ongena performing a touch-roll-touch in a Lockheed F-104G Starfighter, a plane that was infamously difficult to control at lower speeds. Until Bill actually performed the maneuver, it was said to be impossible, though clearly it wasn’t. Bill was the first of very few pilots to successfully perform it, though many subsequently tried, with some dying in the trying. Bill tragically passed away, in of all things, a car accident, well before his time. We’ll admit to being a little Starfighter-obsessed here at Warbirds News, and having a contact list full of ex-Starfighter pilots, we thought it would be interesting to send them the video and ask them to comment on the maneuver. The response was overwhelming.

Lieutenant Colonel William “Bill” Ongena in an F-104 cockpit.

In order of response to our query:

(on an editorial note, some of these responses were translated, so please assume any errors are ours)

Wolfgang Czaia, a pilot with more than 27,000 hours of flight time began flying gliders while still in high school in his homeland of Germany, progressing through a variety of aircraft, from the L-19, Dol-27, FW-149, T-6, T-37, T-33, T-38 and a Skyfox (a modified T-33), to a MiG-29, an Iskra Polish jet trainer and a Pilatus PT-9. He has served as a test pilot for the Messerschmitt 262 reproduction project at Paine Field in Everett, Washington. Of all of the planes he’s flown, the F-104 Starfighter stands out as his all-time favorite. He has served as a military flight instructor in F-104s, training German, Dutch, Belgian, and Italian NATO pilots at Fighter Weapons School 10 at Jever Air Base.

Wolfgang’s Comment: “This one shows Belgian Air Force pilot Bill Ongena doing the so-called ‘Touch-Roll-Touch’, but other pilots of other air forces have done it as well. He approaches the runway with gear and take-off flaps extended, touches down briefly, applies full power, and pulls up to about 50 feet while initiating a roll on his upward trajectory. Then comes a power reduction, possibly speed brake extension to slow down, and descent to another touch-and-go. With the landing gear down, full aileron travel (20°) is available, producing a sufficiently good rate to complete a 360° roll without the nose dropping dangerously low. (With landing gear up, the aileron throw is only 10°). It was strictly a “show” maneuver to demonstrate the controllability of the airplane and had no practical application. After Belgian pilot Jacobs was killed during a practice flight, the maneuver was prohibited.”

Wolfgang Czaia

US Air Force Captain Harold Alston of the 435th, TFS 479th was the first pilot to fly 100 combat missions in Vietnam flying the F-104C. Harold’s Comment: “The important thing is that the pilot did not actuate the landing gear. When the gear and doors are moving it creates a lot of drag. For us old air show pilots we either do an aileron roll with the gear up or gear down, but not with it transitioning. I was impressed with the demonstration.”

Harold Alston in 1965, at George Air Force Base in Victorville, California, as a newly combat-qualified F-104C pilot.

Howard “Scrappy” Johnson served as a fighter pilot flying over 7,000 hours in fifteen different fighter planes during his career. In 1953, Major Johnson transferred to Hamilton AFB where he had the first opportunity to hear about the Air Force’s newest, fastest airplane, the F-104A. In 1958, with only 30 hours of flight time in the Starfighter, he shattered the World’s Altitude Record zooming to 91,243 feet. In recognition of the record, Vice President Richard Nixon presented him with the Robert J. Collier Trophy for aeronautical achievement. “Scrappy’s” Comment: “When I was an advisor to the West German Air Force, from 1960-1963, one of my fellow advisors did this same thing, landed A/B (After Burner), take off, roll and BAAAM! crashed. His name was Captain Tom Perfilli. This maneuver was then prohibited.”

Test pilots Walt Irwin and Jim Low congratulate “Scrappy” after his record-setting flight.

Ferry Van Der Geest flew the RF104 in the Royal Netherlands Air Force until the last day of F-104 operations. His squadron got the 104 in 1963 and she was replaced in in 1984 by the RF16. He was with the 306 Squadron from September 1983 until May 1987. He only flew the 104 for 1.5 years with a total of around 320 hours. But according to him, as a young fighter pilot, he had enough adventures with the “Spillone” (Italian for Needle) to fill a book.

Ferry’s comment: “This famous touch-roll-touch was only performed in Belgium, one day a pilot had an afterburner (AB) blow-out and he crashed on the second touch, killing himself in the process. It is an extremely dangerous maneuver with no room for error whatsoever. The average touchdown speed is at around 175 knots and the use of AB is totally mandatory. So far no one has ever done something like this afterward.”

Ferry Van Der Geest flying the slot of a four-ship formation

Hans Van Der Werff flew the 104 in the Royal Netherlands Air Force, his total flight time on the F-104 is 2400 hours, though it’s worthwhile to note that the RNAF uses actual flying time instead of block time, so for an apples-to-apples comparison with other pilots from other air forces, adding 10% is in order. Hans flew the 104 from 1968 till 1980, he was instructor-pilot, instrument rating examiner and test-pilot. From 1974 until 1979 he was the official demo pilot for the F-104G for the Royal Netherlands Air Force and he participated in over 100 flying displays.

Hans’ Comment: “I did this maneuver (touch-roll-touch) a couple of times myself during training for my airshow. As you probably know I was the F-104 demo pilot for the Royal Netherlands Air Force from 1974 until 1979. Air staff prohibited me from doing the maneuver after a USAF pilot crashed doing the same thing. Subsequently, I would do a “dirty roll” without touching. To do the maneuver it actually takes as much guts as skill. The low speed/low altitude was the main problem. And then the extended gear made the roll rate a lot less. Also, because the roll was started in a climbing attitude, you had to take care that the roll ended slightly nose down to start the landing within the limits of the runway.”

Hans Van Der Werff in his F-104G at the 65th anniversary commemoration of the founding of the Royal Netherlands Air Force in 1978.

(Image Credit: 916-Starfighter.de)

General Bruno Servadei served with the Italian Air Force flying F-84Fs and F-104Ss. Now retired, he performs in European airshows flying the Fl 100 RGf with the famed Blu Circe Aerobatic Team. General Servadei’s Comment: “I saw Ongena perform this maneuver, live in Turin at Caselle Airport in the 60s, back when I was flying with the F84F. It was amazing, especially for me with piloting the F84F, where Ongena would be able to take off, roll, and land in less distance than it would take my plane to just get its wheels off the ground. On the maneuver itself, it undoubtedly required technical ability but it especially required guts, because the aircraft is flying very close to the ground. I think with a little practicing it could have been done by others, probably with the F-104S variant it would be easier with the plane having 2000lbs of extra thrust. If I were to have attempted the maneuver myself back in the day, the commander on the base would have kicked me out! At the time of Ongena, there was still a free-spiritedness in effect that allowed pilots to do crazy shit like that. In my time I’ve seen many pilots of the 6th Aerobrigata (Now 6 Stormo) doing crazy things. I have seen pilots in the Red Devils (the aerobatic team of the 6 Aerobrigata) flying upside down with their canopy and tails just a few feet from the grass!”

Bruno Servadei in an F-104 back in the day

Dave Skilling spent 3 years as an instructor on the F104 at Luke Air Force Base in Arizona, in the training program for German 104 pilots, and almost 7 years in two separate tours of duty in Europe, flying the 104 with 6 NATO air forces in a strike training role as a part of the NATO Standardization Team for strike wings (the “DOON Team”) for three years.

Dave’s Comments: “First, that sort of maneuver close to the ground takes a lot of practice at that slow speed at a higher altitude, then bringing it down lower and lower until you can do it after a takeoff. I was never in a situation where I could practice sufficiently to make it safe. It takes some unusual yaw “to the top” at the beginning and end, and some zero to negative G’s over the top in order not to lose altitude (I’ve done it at altitude). The US Air Force would ground you for trying such a maneuver after takeoff (except for the Thunderbirds and Blue Angels, who practiced it a lot before their solos did it). By the time I flew in Europe, where it might be more admired, I was a guest pilot at the F-104 bases (even though I was an “inspector”), and wouldn’t have tried such stunts as a guest. I think any 104 pilot who really wanted to do this could have trained in it – but not all would not have wanted to! But few ever got the chance. In my next life, I may be a Thunderbird (and lots of other stuff I didn’t have time for in this life).”

Belgian Air Force F-104 Starfighter at the Kleine-Brogel Air Base.

Because you can never have too many pictures of the Starfighter.

Well there you have it, analysis of one of the most daunting and dangerous maneuvers on record for the F-104 Starfighter by seven men who flew and knew the craft, including one who’s actually performed it and lived to tell the tale. We’d like to thank all those who took the time to contribute by responding to our query, as well as for providing the photos.

@WarbirdNews via X

3 notes

·

View notes

Photo

Bentley Mark VI Majestic Major Hemi V8 Special (one-off).

When you first see a Bentley Mark VI in all of its stately proportions, high-performance isn’t the first thing that comes to mind. The Mark VI is now often used as a wedding car along with its Rolls-Royce stablemate the Silver Wraith, and what they lack in outright speed they make up for with elegance, dignity, and opulence.

For the uninitiated, a Bentley Special is a car that started life as a Bentley, often a Mark VI, that then has its chassis shortened and lowered. A new more sporting body is usually fitted on top, possibly influenced by the Bentley Le Mans racers of the 1920s and 1930s, and new engines and transmissions are frequently fitted for a more sporting driving experience.

In essence, Bentley Specials are hot rods for the kind of people who fare on a first name basis with all the Ritz-Carlton concierges from London to Los Angeles.

When delivered to customers most of the Bentley Mark VIs that were made were fitted with steel coachwork with four doors, and they were powered by either the 4.3 or 4.6 liter straight-six sending power to the rear wheels via a 4-speed manual gearbox.

The Daimler Majestic Major 4.5 V8 engine is perhaps not as well known as it should be. It was designed by legendary British engineer Edward Turner in two forms that look remarkably similar from the outside – the 2.5 V8 and the 4.5 V8.

The 2.5 V8 was produced in far higher numbers as it was fitted to both the Daimler SP250 sports car and the Daimler V8 250 four-door sedan. Surprisingly given the difference in displacement the external dimensions of the two engines are fairly close, the 4.5 is slightly wider, longer, and deeper.

Turner had made a name for himself designing motorcycle engines for Ariel and then Triumph earlier in his career, including the famous Ariel Square Four, the Triumph Speed Twin, the Triumph Thunderbird, and the Triumph T120 Bonneville.

In 1959 he designed the two automotive V8 engines for Daimler, using a very similar design for both engines, which included hemispherical combustion chambers and an overhead valve cylinder head design influenced by his earlier work on high-performance Triumph motorcycle engines.

The V8 has a 90º vee angle, an iron block with sandcast aluminum-alloy heads which contain two valves per cylinder actuated with pushrods from the camshaft which is located high in the block. The design of the engine has been praised by many over the years, including Jay Leno, however the fact that it was most famously fitted to the Daimler SP250 sports car – a vehicle that was not at all well-received – did dampen its reception somewhat. The 4.5 liter version of the V8 was fitted to the Daimler Majestic Major, a large and luxurious four-door sedan with a curb weight north of 4,000 lbs. The engine was said to produce 220 bhp and 283 lb ft of torque however this has been challenged in intervening years as the Daimler dynamometer was somewhat antiquated and was unable to produce readings above 220 bhp.

Whatever the actual power of the engine was it was prodigious, it was capable of propelling the hefty Daimler Majestic Major to a top speed of 120 mph, almost unheard of in such a vehicle at the time, and it gave the car performance that could rival many sports cars of the era.

#Bentley Mark VI#Rolls-Royce#Silver Wraith#Daimler Majestic Major 4.5 V8#Ariel Square Four#Triumph Speed Twin#Triumph Thunderbird#Triumph T120 Bonneville

57 notes

·

View notes

Text

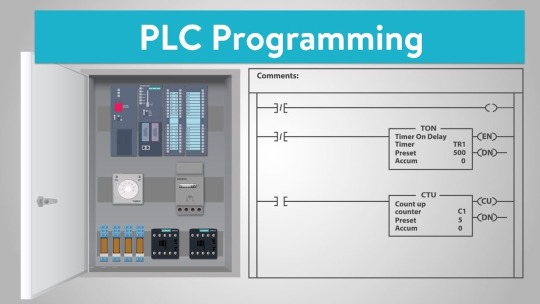

The Basics of PLC Programming: A Comprehensive Guide

If you're interested in the field of industrial automation or looking to enhance your skills in the industry, PLC programming is a crucial skill to possess. Programmable Logic Controllers (PLCs) are widely used in manufacturing and process control systems, and understanding how to program them is essential for ensuring efficient and reliable operation.

In this comprehensive guide, we will explore the basics of PLC programming, covering key concepts and providing valuable insights for beginners in the field.

1. What is PLC Programming?

PLC programming involves creating a set of instructions that control the behavior of a programmable logic controller. PLCs are used to monitor inputs from various sensors, process that data, and execute specific actions based on pre-defined logic. By programming a PLC, you can automate complex industrial processes, making them more efficient and reliable.

2. Why Learn PLC Programming?

PLC programming offers numerous benefits in the industrial automation realm. By acquiring this skill, you can:

Improve productivity: PLCs enable automation, reducing manual labor and increasing overall productivity.

Enhance efficiency: Automation minimizes human error and optimizes processes, resulting in higher efficiency levels.

Facilitate troubleshooting: Understanding PLC programming allows you to diagnose and fix issues efficiently, minimizing downtime.

Expand career opportunities: PLC programming expertise is in high demand, with many industries seeking professionals with these skills.

3. PLC Programming Training Courses:

To learn PLC programming effectively, it's essential to enroll in specialized training courses. These courses provide a structured curriculum, hands-on exercises, and expert guidance. Here are a few key aspects to consider when choosing a PLC programming training institute or center:

Comprehensive curriculum: Look for a training program that covers both theoretical concepts and practical implementation.

Experienced instructors: Ensure that the training institute has qualified instructors with industry experience to guide you effectively.

Hands-on practice: Practical exercises and projects are crucial for gaining proficiency in PLC programming.

Industry relevance: Verify that the training course aligns with current industry standards and practices.

Certification: Opt for courses that offer certifications upon completion, as they enhance your credibility in the job market.

4. Key Concepts in PLC Programming:

Ladder Logic: Ladder Logic is the most commonly used programming language for PLCs. It employs graphical symbols to represent logic functions and control sequences, making it easy to understand and implement.

Inputs and Outputs: PLCs interact with the physical world through inputs (sensors) and outputs (actuators). Understanding how to read inputs and control outputs is fundamental in PLC programming.

Programming Instructions: PLCs execute a set of instructions to perform desired operations. These instructions can include timers, counters, mathematical operations, logic gates, and more.

Program Execution: PLC programs are executed in a cyclical manner. The PLC scans inputs, processes logic, updates outputs, and repeats the cycle continuously.

5. Programming Tools and Software:

PLC programming software provides an interface to create, edit, and debug programs. Familiarize yourself with popular software tools such as Siemens TIA Portal, Allen-Bradley RSLogix, or Schneider Electric Unity Pro, as they are widely used in the industry.

Conclusion:

PLC programming is an essential skill for individuals aspiring to succeed in the field of industrial automation. By learning the basics of PLC programming, you open up a world of opportunities to streamline processes, enhance productivity, and contribute to the advancement of various industries. Enroll in a reputable PLC programming training institute or center, explore the key concepts, and start your journey towards becoming a proficient PLC programmer.

#plc-programming#learn plc programming#plc programming training#plc programming courses#plc training course in india

3 notes

·

View notes

Text

Exploring the Marvel of Piezoelectric Tubes in Modern Engineering

In the realm of advanced engineering and technology, piezoelectric materials stand as exceptional performers, fueling innovative solutions across various industries. Among these fascinating components, piezoelectric tubes hold a special place due to their unique properties and applications.

In this blog post, we will dive into the world of piezoelectric tubes, exploring their working principle, versatile applications, and the profound impact they have on modern engineering.

For More Information Please visit, piezo tube

1. Understanding Piezoelectric Tubes:

Piezoelectric tubes are cylindrical structures made of piezoelectric materials that exhibit the piezoelectric effect. This remarkable property enables them to convert electrical energy into mechanical motion and vice versa, making them highly versatile and sought-after components in the realm of precision engineering.

2. The Working Principle:

When an electric field is applied to a piezoelectric tube, it undergoes dimensional changes, either expanding or contracting. This phenomenon is known as the "d33 effect" and is responsible for the generation of mechanical motion. Conversely, when the piezoelectric tube experiences mechanical stress, it generates an electric charge, known as the "d31 effect."

3. Precision Actuation and Control:

Piezoelectric tubes are renowned for their exceptional precision in motion control. Due to their ability to respond rapidly to electrical signals, they can achieve sub-micrometer level displacements, making them invaluable in applications that require fine adjustments and positioning with unparalleled accuracy.

4. Applications Across Industries:

The versatility of piezoelectric tubes has led to their adoption in various industries and fields, including:

Medical Technology: In ultrasound transducers, piezoelectric tubes facilitate high-resolution imaging, enabling non-invasive medical diagnostics.

Mechanical Engineering: Piezoelectric tubes find applications in precise positioning systems, micro- and nanopositioning stages, and vibration control devices.

Industrial Automation: They are used in ultrasonic cleaning equipment, flow meters, and high-precision pumps, enhancing efficiency and productivity.

Aerospace: Piezoelectric tubes play a vital role in active vibration damping and structural health monitoring of aircraft components.

5. Energy Harvesting and Acoustic Applications:

Piezoelectric tubes are also employed in energy harvesting systems, converting mechanical vibrations into electrical energy. Additionally, they serve as components in acoustic devices like speakers, providing clear and crisp sound reproduction.

6. Miniaturization and Integration:

Due to their compact size and high functionality, piezoelectric tubes are ideal for miniaturized devices and space-constrained applications. Their integration into various systems allows for streamlined designs and improved performance.

7. Advancements in Material Technology:

Continuous research in material science has led to the development of innovative piezoelectric materials, further enhancing the capabilities of piezoelectric tubes. These advancements open up new possibilities for even more efficient and powerful devices in the future.

Conclusion:

Piezoelectric tubes stand as a testament to the wonders of piezoelectricity, offering unparalleled precision and versatility in motion control and sensing applications. As industries continue to evolve, these remarkable components will play an instrumental role in driving technological advancements, paving the way for a more connected, efficient, and innovative future.

2 notes

·

View notes

Text

High-Quality rubber bellows dust boot for Long-Lasting Protection

When hardworking machinery and delicate, sensitive equipment are given protection from dust, dirt, and other elements, rubber bellows dust boots have an essential role to play. These are high-quality products that ensure peak possible performance, low wear and tear, and long life for vital systems. This certainly is a good tip for investing one's resources in addition to having engineering types in other industry sectors, such as automotive and aerospace industrial fields. The right selection can save you time and cost, whereas wasting such. This blog will talk about the features, advantages, and applications of and what to look out for when buying the right rubber bellow manufacturer for your operations.

What Are rubber bellows dust boots?

Rubber bellows Dust boots are specifically designed protective enclosures keeping machinery parts such as shafts, joints, and actuators protected from most harmful elements. A boot of dust is built of tough materials such as nitrile rubber, EPDM, or silicone, so it is flexible while enduring cold and the hardest things it can be found near. That is what channels these protective devices are doing.

Key

The most striking point about them is its unique qualities.

It is long-lasting, it can handle heavy loads, and its wear against wear and tear is commendably high.

Very high elasticity of movement is enabled in users who have some character in their application process.

Operates through a sealed closure, a good seal about contaminants, one can use even in a very contaminated working environment.

The diversity in the material is available in nitrile, EPDM, and silicone, mainly because it possesses diverse properties.

Design variants can be added to accommodate almost all sizes and functions.

Applications

Rubber bellows dust boots are the kind of versatile footwear that is used in a river of industries. These include the following:

Automotive Sector : Guard against dust and moisture in steering systems, suspension parts, and gearboxes, so that everything can run trouble-free.

Industrial Machinery : Protects from dust and corrosive particles to the moving elements of industrial apparatuses, thus promoting the efficiency of the operation.

Aerospace Industry: Protective measures of critical systems aboard aircraft to maintain accuracy and reliability.

Medical Equipment : Prevents contamination of crucial devices and enhances their longevity.

How to Select the Right Rubber Bellows Manufacturer

Choosing the rubber bellows is just as important as choosing the right manufacturer for it. Here are some points that can assist in making a decision:

Experience and Expertise: Seek out a rubber bellow manufacturer that has been in the business for years and has remarkable experience in manufacturing bellows.

Customization Options: A credible industrial bellows manufacturer will provide fully customizable options of different dimensions, shapes, and materials.

Quality Standards: Look for a manufacturer that is up to mark in standard compliance and has the necessary certification for their products.

Innovation and Technology: Many fast advanced manufacturing technologies are used in the production of various products to satisfy most requirements and needs.

Customer Support: Always ensure that the manufacturer has excellent support and assistance for their products.

If there is a well-chosen manufacturer, then a suitable product will be obtained. No more return on such investment.

Advantages of Using High-Quality

Investing in high-quality comes with several advantages:

Enhanced Protection: Seals off contaminants to minimize the chances of spoiling the efficiency of the machines in operation.

Longevity: Saves the cost of replacement, and maintenance, as well as the cost of spare parts for vital machinery and equipment.

Cost Efficiency: Reduces maintenance cost and time spent on fixing damaged components in a production line.

Versatility: Versatile, which makes them useful not only in a certain field but also in a certain use.

Eco-Friendly Options: Most producers incorporate environmentally friendly production materials into their products in support of the green agenda.

Customizable Features: In other words, customized designs mean the absence of a loose fit and, therefore, superior performance. Thus, by putting on rubber bellow seals, you are protecting your equipment against possible harm, which in the long run translates to dispensing with repair and purchase costs.

Customization: Tailored to Fit Your Needs

rubber bellows dust boots are not universal pieces of equipment. The main manufacturers of industrial bellows provide information on different possibilities of customization, which can guarantee a perfect match of the product to its usage.

Material Selection: There is the choice of nitrile, EPDM, silicone, and many others depending on the conditions in which the equipment operates.

Design Modifications: It comes in flanged, tapered, and cylindrical styles for configuration according to the type of setup required.

Size and Thickness: Choose the precise sizes and thicknesses for the best performance. Customization makes it possible to meet the necessary safety, ruggedness, and mobility needed from the dust boots.

Conclusion

Rubber bellows dust boots are a must-have for industries that require a piece of machinery or equipment to run for a very long time without wearing out due to contamination. This versatility and elasticity give them the attribute of impressive resilience and durability, which make them the quintessential primary solution to the goal of long-term optimization of the effectiveness and cost-effectiveness of the processes in the needs. As an Industrial Bellows Manufacturer, we strive to develop high-quality dust boots for the industry that serve various needs. Policies that promote business success, professionalism, creativity, and consumer contentment enable a guarantee of reliability in product performance.

Want to safeguard your equipment? Please contact us today to discuss the complete line of rubber dust boots and our complete line of products to find which will be perfect for your needs.

#rubber-bellows-dust-boot#rubber-bellow-manufacturer#industrial-bellows-manufacturer#rubber-bellow-seal

0 notes