#High-Density Polyethylene Mats

Explore tagged Tumblr posts

Text

Exploring the Importance of Underground Warning Tapes, Geotextiles, and Geomembranes in Modern Infrastructure

Infrastructure development is a cornerstone of modern civilization, with advancements in technology and materials continuously improving the efficiency, safety, and longevity of these projects. Three key materials that have proven essential in ensuring both safety and sustainability in construction are Underground Warning Tape, geotextiles, and geomembranes. These materials, each serving specific functions, work together to support a wide range of infrastructure projects, from roadways and pipelines to environmental protection systems. In this article, we will delve into the role of these materials, their applications, and their benefits in construction and engineering projects.

The Role of Underground Warning Tape in Enhancing Safety

Underground warning tapes are essential tools in preventing accidental damage to underground utilities such as gas lines, electrical cables, and communication networks. These tapes are made from durable plastic materials, often polyethylene or polypropylene, and are buried just below the surface during the installation of underground infrastructure. Their primary purpose is to act as a visual marker that alerts workers and operators about the presence of vital underground utilities, reducing the risk of damage during excavation or maintenance work.

One of the most significant advantages of underground warning tape is its ability to prevent costly and dangerous accidents. Excavation without knowledge of existing underground utilities can result in ruptured gas lines, severed communication cables, or electrical outages. These types of accidents not only pose serious safety risks but can also lead to expensive repair costs and project delays. By marking the location of buried utilities, underground warning tape serves as a proactive measure, ensuring that work crews are aware of the dangers beneath the surface before they begin digging.

Moreover, these tapes are color-coded according to the type of utility they are marking, following standardized regulations. For example, red tapes are used for electric power lines, yellow for gas, oil, or steam lines, blue for potable water, and green for sewer systems. This color-coding system ensures that utility workers can quickly and easily identify the type of infrastructure they are dealing with, further enhancing safety and efficiency.

In modern construction projects, underground warning tapes play a crucial role in ensuring compliance with safety regulations and preventing unnecessary damage. Their use is essential in any project involving underground installations, providing peace of mind to construction crews and project managers alike.

Geotextiles: Strengthening the Foundation of Construction

While underground warning tapes are essential for safety, geotextiles are a key material in enhancing the stability and durability of infrastructure projects. Geotextiles And Geomembranes are synthetic fabrics, usually made from polyester or polypropylene, that are designed to perform various functions in construction, including separation, filtration, drainage, reinforcement, and erosion control. These materials are used extensively in civil engineering, particularly in road construction, retaining walls, landfills, and drainage systems.

One of the primary functions of geotextiles is soil stabilization. In construction, different layers of materials, such as soil, gravel, and sand, must often be combined to create a stable foundation. However, these layers can shift or mix over time, leading to a loss of stability. Geotextiles act as a barrier between different layers, preventing them from mixing and thus maintaining the integrity of the foundation. This is particularly important in road construction, where the constant weight of vehicles can cause soil to shift, leading to uneven surfaces and potholes. By reinforcing the layers, geotextiles improve the longevity of roads and reduce maintenance costs.

Another crucial function of geotextiles is in drainage and filtration. In projects such as landfills, retaining walls, or embankments, managing water flow is essential to prevent erosion or structural failure. Geotextiles allow water to pass through while blocking the movement of fine soil particles, effectively preventing erosion while maintaining soil stability. This filtration capability makes geotextiles invaluable in projects that require long-term drainage solutions, such as agricultural fields, roadways, and embankments.

Additionally, geotextiles are commonly used in environmental protection projects, particularly in preventing soil erosion. By covering slopes, riverbanks, or other vulnerable areas with geotextiles, engineers can significantly reduce the impact of wind and water erosion, ensuring the long-term sustainability of the project. As such, geotextiles have become an indispensable tool in modern construction, contributing to both the safety and durability of a wide range of infrastructure projects.

Geomembranes and High-Density Polyethylene Mats: The Future of Environmental Protection

In the latter stages of many infrastructure projects, environmental protection becomes a key concern. This is where geomembranes and high-density polyethylene (HDPE) mats come into play. Geomembranes are impermeable barriers made from synthetic materials like high-density polyethylene, which are used to prevent the leakage of hazardous substances into the surrounding environment. They are most commonly used in applications such as landfills, mining operations, wastewater treatment plants, and containment systems for hazardous materials.

Geomembranes are especially important in projects involving the storage or disposal of potentially harmful substances. For example, in landfills, geomembranes are installed as liners to prevent leachate (a toxic liquid formed when waste decomposes) from contaminating the groundwater. In mining operations, geomembranes are used to line tailings ponds, ensuring that harmful chemicals do not seep into the surrounding environment. Similarly, in wastewater treatment plants, geomembranes are used to create impermeable barriers that prevent the leakage of untreated sewage or industrial waste.

The use of high-density polyethylene mats in construction and environmental protection is another growing trend. HDPE mats are durable, flexible, and resistant to chemicals, making them ideal for a wide range of applications. In construction, HDPE mats are often used as temporary roadways or ground protection mats, providing stability in areas with soft or unstable soils. These mats can support heavy machinery and vehicles, ensuring that construction work can proceed without damaging the underlying ground.

Moreover, HDPE mats are also used in environmental protection projects to prevent soil contamination or erosion. For example, in oil and gas operations, HDPE mats are used to create a barrier between the ground and potential contaminants, ensuring that spills or leaks do not harm the surrounding environment. The flexibility and strength of HDPE mats make them a versatile solution for both construction and environmental protection.

The combination of geomembranes and HDPE mats represents a significant advancement in environmental protection technology. By providing durable, impermeable barriers that prevent contamination, these materials are helping to ensure the long-term sustainability of infrastructure projects while minimizing their environmental impact.

Conclusion

In conclusion, the integration of modern materials such as underground warning tapes, geotextiles, geomembranes, and High-Density Polyethylene Mats has revolutionized the construction and engineering industry. These materials not only enhance the safety and stability of infrastructure projects but also play a critical role in environmental protection. Underground warning tapes serve as essential tools for preventing accidental damage to underground utilities, while geotextiles strengthen the foundation of construction projects by stabilizing soil and improving drainage. Meanwhile, geomembranes and HDPE mats provide an impermeable barrier that prevents harmful substances from contaminating the environment.

As infrastructure development continues to evolve, the use of these materials will become even more critical. By incorporating them into construction and engineering projects, we can ensure safer, more durable, and environmentally friendly infrastructure for the future.

FAQs

Q1: What are the benefits of using underground warning tape in construction? A1: Underground warning tape helps prevent accidental damage to underground utilities by marking their location. This reduces the risk of injury, project delays, and costly repairs during excavation work.

Q2: How do geotextiles improve road construction? A2: Geotextiles stabilize soil layers in road construction, preventing them from shifting under heavy traffic. They also aid in drainage, reducing erosion and extending the lifespan of roadways.

Q3: Why are geomembranes important in environmental protection? A3: Geomembranes act as impermeable barriers that prevent harmful substances from leaking into the surrounding environment, making them essential for projects involving landfills, mining, and wastewater management.

0 notes

Text

Forecasting the Future of the Ground Protection Mat Market to 2035

In industries where heavy equipment and foot traffic are part of daily operations, safeguarding the ground below becomes critical. From construction and oil & gas to outdoor events and utility work, ground protection mats are essential for preserving sensitive surfaces, enhancing safety, and maintaining access across uneven or soft terrain. As demand grows across various sectors, the global ground protection mat market is poised for steady expansion in the coming years.

According to recent data, the ground protection mat industry was valued at US$ 3.0 Bn in 2024. The market is projected to grow at a CAGR of 4.6% from 2025 to 2035, reaching approximately US$ 5.0 Bn by the end of 2035. This steady growth trajectory is supported by increased infrastructure development, a greater focus on environmental sustainability, and rising adoption of temporary access solutions in heavy-duty applications.

What Are Ground Protection Mats?

Ground protection mats are durable, portable panels made from materials like high-density polyethylene (HDPE), composite plastic, rubber, or aluminum. These mats are designed to provide a stable, non-slip surface that distributes weight and prevents ruts, compaction, or erosion on natural terrain.

Request Sample Copy of this report- https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=74116

They are widely used in:

Construction and civil engineering

Renewable energy projects

Event staging and outdoor festivals

Utilities and telecom maintenance

Military and aviation sectors

Market Drivers and Trends

Several global trends are converging to push the ground protection mat market forward:

1. Surge in Infrastructure and Construction Projects

Rapid urbanization and infrastructure expansion, especially in emerging economies, are driving demand for ground access systems. Ground protection mats are vital for maintaining site safety and protecting the environment during large-scale construction and utility projects.

2. Environmental Regulations and Sustainability

As governments and industries emphasize soil preservation and eco-friendly practices, reusable ground mats offer an effective solution. They reduce ground disturbance, prevent cross-contamination, and minimize long-term environmental damage.

3. Expansion of Renewable Energy and Utility Sectors

Wind and solar farms often require remote site access for heavy equipment. Ground protection mats enable stable pathways without costly permanent roads, making them ideal for temporary and semi-permanent access needs in these sectors.

4. Event and Entertainment Industry Demand

Outdoor events, film shoots, and festivals increasingly use ground mats to protect lawns and provide safe access routes. Lightweight, modular mats allow for quick setup and dismantling with minimal surface impact.

Key Developments in the Ground Protection Mat Market

Innovation and product line expansion continue to define the competitive landscape. Notable recent developments include:

In 2024, ArborMats™ introduced new additions to its product portfolio, including the AlturnaMAT® and VersaMAT® ground protection mats. The AlturnaMAT® is engineered to handle loads up to 120 tons with a diamond plate tread for optimal traction. In contrast, the VersaMAT® offers a dual-sided tread design suited for pedestrian and vehicle use, supporting up to 60 tons—ideal for mixed-use applications.

In 2024, Checkers Safety Group launched the Hi-Viz Aircraft Wheel Chocks with SafeRay™ Technology, utilizing fluorescent materials to boost visibility and safety in aviation operations. While not a ground mat, this innovation highlights the company’s broader commitment to surface safety and rugged design.

In 2025, Myers Industries, Inc. focused on strengthening its e-commerce presence, notably through Amazon. This move aims to increase visibility and boost sales of key product lines—including ground protection solutions—by reaching a broader, digitally connected customer base.

These strategic developments show that leading players are not only enhancing product performance but also embracing new distribution channels and market outreach strategies.

Analysis of Key Players in the Ground Protection Mat Market

The competitive landscape of the ground protection mat market is defined by innovation, material advancements, and a growing focus on sustainable practices. Several key players dominate the global market, offering a broad range of solutions across industries and geographies.

Top companies operating in the market include:

DuraDeck

TuffTrak

MegaDeck HD

AlturnaMATS

Matrax

Checkers Safety Group

Signature Systems Group

Newpark Mats & Integrated Services

Ground-Guards Ltd.

Quality Mat Company

These manufacturers are actively focused on product durability, load-bearing capacity, traction optimization, and easy transportation. Composite materials, engineered treads, and interlocking mechanisms are becoming key differentiators in product design.

Each of these companies has been profiled in the ground protection mat market report based on the following parameters:

Company overview

Business strategies

Financial performance

Business segments

Product portfolio

Recent innovations

This in-depth profiling provides insights into competitive dynamics, helping industry stakeholders make informed decisions on partnerships, investments, and market positioning.

Regional Market Insights

North America

The U.S. and Canada dominate the North American ground protection mat market due to high construction activity, well-established event industries, and stringent environmental compliance. The oil & gas and utility sectors also contribute significantly to regional demand.

Europe

In Europe, the market is driven by a strong focus on soil protection and temporary access needs in urban and rural projects. EU regulations regarding environmental safety encourage the adoption of non-invasive ground protection technologies.

Asia Pacific

Rising investments in construction, infrastructure, and renewable energy projects in China, India, and Southeast Asia are expected to spur substantial demand in the region. Local production and rising awareness of temporary access solutions offer promising growth opportunities.

Opportunities and Challenges

Opportunities:

Rising investment in smart cities and urban infrastructure

Expansion of the events and entertainment industry post-pandemic

Growing awareness of the environmental benefits of reusable ground mats

Integration of smart tracking (RFID/GPS) for asset management

Challenges:

High cost of advanced composite mats may limit adoption in price-sensitive markets

Maintenance and storage requirements for large-scale operations

Need for customized solutions across diverse terrain types

Conclusion

The global ground protection mat market is on a solid growth trajectory, underpinned by rising infrastructure activity, sustainability goals, and the need for robust ground access solutions. As industries recognize the cost-efficiency and environmental advantages of reusable mats, manufacturers are responding with innovative products and digital marketing strategies.

With market value set to reach US$ 5.0 Bn by 2035, the sector presents compelling opportunities for manufacturers, suppliers, and investors alike. The path forward is clear—ground protection solutions are not just a construction site accessory but a strategic asset in today’s infrastructure-driven world.

0 notes

Text

A Complete Review on Weed Mat Purchase and Utilization for Effective Ground Cover

Introduction to Weed Mat and the Reason Why It Is Needed

Weed mats are an indispensable product for anyone who wants to preserve the cleanliness and health of their garden or farm. Weed mats inhibit invasive weed development but do not prevent the soil underneath it from breathing. Made from polypropylene or polyethylene, weed mats are a cover-up that prevents weeds from getting sunlight and nutrients.

Regardless of whether your garden consists of fruiting plants, flowers, or vegetables, a weed-free environment promotes productivity and health of the plants. Weed mats not only provide simplicity in installation but also reduce the application of chemical herbicides, hence more environmentally friendly.

Types of Weed Mats

Weed mats are produced in various types, each utilized to perform a specific task. The most utilized ones are:

1. Woven Weed Mat: Made of tightly woven fabric with water and air penetrability, best for garden beds and landscaped lawns. 2. Non-Woven Weed Mat: Durable and best suited for long-term application for extensive areas like plantations. 3. Plastic Weed Mat: Harder in weed resistance but may limit water and air penetrability.

The type to use should be based on your application area, usage period, and density of weed growth.

Benefits in Garden and Agricultural Use

Weed mat installation has several benefits aside from weed suppression.

1. Improved Soil Moisture: Weed mats reduce evaporation, keeping soil moisture for longer periods. 2. Time-Saving: With weeds minimized, you’ll spend significantly less time on maintenance. 3. Eco-Friendly: Minimizes the use of herbicides, keeping your soil and plants safe. 4. Temperature control: They control soil temperature to make root growth better.

Applying weed mat regularly can greatly enhance your farm productivity and yields.

Best Weed Barrier in Gujarat for Farming

Gujarat is diverse in terms of its agriculture and requires adequate weed control as, where the weed growth is dense, it does not come under regulation. The Best weed barrier in Gujarat would generally be woven polypropylene mat UV-stabilized. They are most widely applied as they can withstand extremely high temperatures, are wear-and-tear proof, and will retain their shape even in severe field conditions.

Heavy-duty weed mat with excellent GSM rating is the favorite among Gujarat farmers as it is more durable and cannot be torn easily. Regular checking at proper utilization makes the weed mat able to last long and utilize multiple growing seasons effectively.

Black Plastic Weed Barrier for Intensive Weed Control

Where additional weight of weed control is needed, especially where high-nutrient or high-moisture zones exist, Black plastic weed barrier is an intelligent choice. These are usually non-woven with a high-density polyethylene foundation and have strong resistance to invasive, perennial weeds.

Dark color is sun-conductive and heats the soil, hence "burning out" the weeds at seed stage. It is most effective in flowerbeds, walks, and vegetable beds. It slightly decreases water permeability more than fabric mats but gives great weed resistance where susceptibility is high.

Installation Tips for Long-Term Effectiveness

In its best performance as a weed mat, installation is key.

1. Clear the Area: Clear weed, debris, and level the ground near the area. 2. Measure and Cut: Lay out your garden bed and cut the mat to the required size accordingly. 3. Anchor It Down: Tackling the mat down by pinning down with U-shaped pins or landscape staples. 4. Slit for Plants: In planting, cut the "X" at planting location. 5. Edging: Edging should be covered with mulch or soil to prevent fraying and provide a neater appearance.

Well-laid weed mat will last 5 years or more based on material used and exposure.

Weed Barrier Fabric India: Growing Demand in Contemporary Gardening

Weed barrier fabric India demand grew at a very high rate with the low-maintenance and green gardening trend. The fabric, usually woven jute-polypropylene mix, is produced to the extent that it must have the best possible air permeability against weeds.

Indian gardeners, small-scale farmers, and garden nurseries also employ fabric weed mats above plain plastic sheets. They are convenient to work with, light in weight, and even biodegradable ones are available, which is a hit among environment-friendly consumers.

Secondly, coming in different strengths of GSM makes customers opt for fabric depending on usage intensity. Balcony gardens to medium-sized agri-farms, weed barrier fabric is making Indians garden smart, not hard.

Cost-Saving and Eco-Friendly Solution

Weed mats are nothing special in appearance, but they are money-saving over the long term. Compared to chemical weed killers that must be purchased year in and year out, a good quality weed mat is an investment which will last several seasons. Also, by conserving weeding and chemicals, it is a sustainable agricultural practice. This is especially relevant to areas that are trying to balance productivity and sustainability.

Tips on Storage and Maintenance

For being able to long last, some easy maintenance practices need to be followed:

1. Regular Check-up: Inspect for tears or frayed ends, and repair immediately. 2. Clean Surfaces: Sweep the material or leaves that can accumulate on top. 3. Seasonal Storage: Roll up the mat and keep it in a dry clean place for use in the season. Maintenance ensures your weed mat lasts longer and works at its optimal level every season.

Conclusion

Weed mats provide a rugged, eco-friendly, and affordable method of dealing with undesirable weeds in farms and gardens. Based on your location and application Best weed barrier in Gujarat, Black plastic weed barrier for maximum control, or Weed barrier fabric India for breathable and biodegradable application—you can simply lessen maintenance tasks and encourage healthier plants.

Weed mats are not just a weed barrier; they're an investment any farmer or gardener can utilize to their benefit in their farm or gardening enterprise. Simple to install and even quicker to maintain, they pay long-term dividends together with weed protection.

Frequently Asked Questions (FAQs)

1. How long do weed mats last? Most good quality weed mats have a life span of between 3 to 5 years, depending on the type of material used, weather exposure, and how well they are cared for.

2. Can I plant directly into a weed mat? Yes, you can slit or cut an "X" in the weed mat so that you would be able to plant your seed or sapling. This won't stop the plant from growing but will inhibit the growth of weeds around it.

3. Who is the largest manufacturer of Weed mat? Although there are several foreign manufacturers of weed matting products, India's biggest name is probably Singhal Industries Pvt. Ltd. They specialize in strong, UV-stabilized plastic weed mats that ensure effective weed control. Their guaranteed quality, flexibility in customizing based on sizes, and dependable delivery systems ensure that they are one of the most reliable and biggest manufacturers in India.

0 notes

Text

Role of Accredited Labs in Verifying Agro Textiles for Crop Protection

In the world of modern agriculture, the demand for crop protection solutions that are efficient, eco-friendly, and cost-effective has never been higher. Agro textiles—such as shade nets, insect-proof screens, mulch mats, and greenhouse covers—have emerged as essential tools for improving crop yield, protecting plants from pests, regulating climate, and conserving water. However, the effectiveness of these materials depends significantly on their quality and performance under field conditions. This is where Agro Textiles Testing by accredited laboratories becomes indispensable.

This blog explores how accredited labs play a critical role in verifying agro textiles to ensure they meet crop protection requirements and comply with industry standards.

What are Agro Textiles?

Agro textiles are specially designed technical fabrics used in agriculture and horticulture for various protective and enhancement purposes. These textiles are primarily made from synthetic polymers like polypropylene (PP), polyethylene (PE), and polyester. Key applications include:

Shading crops from excessive sunlight

Preventing insect and bird intrusion

Reducing weed growth

Retaining soil moisture

Controlling temperature and humidity in greenhouses

Given their continuous exposure to sun, wind, chemicals, and mechanical stress, the performance and reliability of agro textiles must be verified through rigorous testing.

Importance of Agro Textiles Testing for Crop Protection

Agro textiles are designed to offer physical protection, microclimate control, and pest resistance. Their failure due to poor material quality or improper installation can lead to:

Reduced crop yields

Increased pest infestations

Soil degradation

Economic losses for farmers

To prevent such issues, agro textiles must be tested for:

UV stability and light filtration

Tensile and tear strength

Air and water permeability

Thermal aging and durability

Chemical resistance to fertilizers and pesticides

Only accredited labs have the infrastructure and certification to carry out these tests using standardized methodologies.

Who are Accredited Labs?

An accredited laboratory is a testing facility that meets the requirements of international quality standards, such as ISO/IEC 17025. Accreditation is granted by authorized bodies such as:

NABL (National Accreditation Board for Testing and Calibration Laboratories) – India

UKAS (United Kingdom Accreditation Service) – UK

A2LA (American Association for Laboratory Accreditation) – USA

DAkkS (German Accreditation Body) – Germany

Accredited labs ensure that their results are accurate, reproducible, and recognized globally. Their role in verifying agro textiles includes testing, certification, and sometimes, product development support.

Role of Accredited Labs in Verifying Agro Textiles

1. Conducting Standardized Tests

Accredited labs use globally accepted testing methods such as:

ISO 13934-1: Tensile strength of woven fabrics

ISO 4892-2: UV resistance through accelerated weathering

ASTM D5035: Grab test for fabric strength

IS 16008: Indian standards for shade nets and mulch mats

These standardized procedures ensure that the agro textiles are tested under controlled and repeatable conditions.

2. Evaluating Material Durability

Accredited labs simulate long-term usage of agro textiles by exposing them to:

UV light to test degradation

High and low temperatures to assess thermal aging

Mechanical stress to test wear and tear

This helps determine if a material can withstand multiple crop cycles without failing.

3. Verifying Crop-Specific Protection

Different crops have different environmental needs. For example:

Tomatoes require 30–50% shade nets

Lettuce may need insect-proof nets with specific mesh sizes

Grapes benefit from reflective ground covers for light management

Accredited labs test agro textiles for light transmission, air flow, permeability, and mesh density to match the textile’s performance to the crop’s requirements.

4. Ensuring Chemical Safety

Agro textiles may come into contact with fertilizers, pesticides, and herbicides. Accredited labs evaluate:

Resistance to chemical degradation

Leaching of harmful substances

Effect of cleaning agents and sprays

This ensures that the textiles do not degrade prematurely or harm the soil and crops.

5. Compliance with Export and Regulatory Standards

For manufacturers and exporters, accredited testing is essential for meeting:

REACH compliance in Europe

IS 16008 and BIS standards in India

OEKO-TEX certification for textiles near food products

GMP and GAP certifications for organic and high-value crops

Accredited labs issue valid certificates that are accepted by government bodies, buyers, and international markets.

6. Product Labeling and Quality Assurance

Based on the results from accredited labs, manufacturers can confidently label their products with:

Shade percentage (e.g., 50% or 75% shade net)

Lifespan (e.g., UV-stabilized for 5 years)

Mesh size (e.g., 40-mesh insect net)

Tensile and tear strength ratings

This transparency builds trust among buyers and farmers, and reduces the risk of field failure.

Benefits of Using Accredited Labs for Agro Textiles Testing

Benefit

Impact

Reliable Results

High accuracy and reproducibility in testing data

Global Recognition

Test reports accepted by international buyers and regulators

Quality Validation

Helps manufacturers differentiate their products

Reduced Crop Loss

Verified textiles reduce the risk of product failure in field

Regulatory Compliance

Ensures agro textiles meet mandatory government and export standards

Real-World Applications

✅ Greenhouses

Accredited labs test films for light transmission, thermal insulation, and anti-drip properties—ensuring optimal plant growth conditions year-round.

✅ Shade Net Houses

Shade nets undergo testing for shade factor, UV stability, and wind resistance to prevent crop burn and storm damage.

✅ Open Field Mulching

Mulch mats are tested for water permeability, weed resistance, and biodegradability to enhance soil health and moisture retention.

✅ Insect-Proof Farming

Labs test insect nets for mesh density, strength, and air circulation to safeguard crops from pests without using harmful chemicals.

How to Choose the Right Accredited Lab

When selecting a lab for agro textiles testing, consider:

ISO/IEC 17025 accreditation status

Experience with polymer and textile materials

Capability to test under national and international standards

Quick turnaround and detailed test reports

Client support and consultation services

Working with a reliable lab ensures accurate verification and adds value to your agro textile products.

Conclusion

Agro textiles are indispensable tools in modern, sustainable agriculture—but only if they perform as expected under real-world conditions. The role of accredited labs in verifying these materials is critical for ensuring crop protection, regulatory compliance, and long-term agricultural success.

By performing rigorous, standardized tests on shade nets, greenhouse films, insect screens, and mulch mats, accredited labs help manufacturers create reliable products and assist farmers in choosing the best tools for their fields. In the ever-evolving agri-tech landscape, agro textiles testing by accredited labs is the foundation of quality assurance and crop protection.

0 notes

Text

Plastic Membrane for Waterproofing: A Smart, Reliable Choice for Modern Construction

In today’s construction landscape, waterproofing is more than just a protective measure; it's a fundamental requirement for long-term structural health. One of the most effective and dependable solutions is the use of a plastic membrane for waterproofing. These synthetic layers act as a durable barrier against water intrusion, offering lasting protection for a variety of projects, from residential basements to large-scale infrastructure. With their flexibility, strength, and easy installation, plastic membranes have become a go-to choice in the industry.

What Is a Plastic Waterproofing Membrane?

Plastic waterproofing membranes are made from durable polymer materials such as HDPE (high-density polyethylene), PVC (polyvinyl chloride), and other high-performance plastics. Supplied in rolls, they can be applied to surfaces using heat welding, adhesive bonding, or mechanical fastening.

Designed to serve as a water protection sheet, these membranes form an uninterrupted waterproof layer that effectively blocks water seepage. This helps prevent common issues like mold growth, rust, concrete decay, and other moisture-related damage that can undermine the integrity of a structure.

Advantages of Using Plastic Membranes

1. Superior Water Resistance These membranes are engineered to provide excellent water-blocking capabilities. Their impermeable nature makes them ideal for both above-ground and below-ground waterproofing applications.

2. Resistance to UV and Chemicals Plastic membranes, especially HDPE-based variants, are highly resistant to chemical exposure and UV radiation, making them suitable for tough environments and outdoor applications.

3. Flexibility Their ability to stretch and conform to structural movements without cracking makes plastic membranes ideal for irregular surfaces or areas prone to slight shifts and vibrations.

4. Long-Lasting Performance When properly installed, plastic waterproofing membranes can last for decades with minimal maintenance, offering a cost-effective and reliable solution.

Where Plastic Membranes Are Used

Plastic membranes are incredibly versatile and are used in a wide range of construction and civil engineering projects:

Foundations and basement walls

Roofs and terraces

Tunnels and bridge decks

Water tanks, pools, and reservoirs

Landfills and canals

A growing innovation in this field is the use of plastic laminated plywood. This combines the structural strength of plywood with a laminated plastic layer, creating a moisture-resistant solution perfect for temporary structures, formwork, and modular buildings.

Boosting Durability with Geo Plastic Sheet Lamination

For large infrastructure or environmental projects, geo plastic sheet lamination is a valuable enhancement. This technique fuses plastic membranes with geotextiles or geogrids to boost their mechanical properties, making them more tear-resistant and durable.

In projects such as landfill liners or canal linings, laminated geo plastic sheets not only prevent leaks but also provide reinforcement against soil pressure and movement—delivering both waterproofing and structural strength in one solution.

Best Practices for Installation

Proper installation is critical to the performance of any waterproofing system. Here are some key considerations:

Surface Preparation: The surface should be clean, level, and free from debris or sharp edges.

Seam Sealing: Joints must be properly sealed—via heat welding or adhesives to prevent leaks.

Protective Covering: A layer of plastic laminated plywood or concrete screed can shield the membrane from mechanical damage.

Drainage Planning: Installing drainage boards or mats helps relieve hydrostatic pressure and directs water away from the structure.

Final Thoughts

As construction practices evolve, so does the demand for advanced, long-lasting waterproofing solutions. The plastic membrane for waterproofing stands out as a proven, practical choice for protecting modern structures against moisture damage. When paired with innovations like plastic-laminated plywood and enhanced with geo-plastic sheet lamination, these membranes provide an extra layer of security and sustainability.

Whether you're working on a home, commercial property, or civil project, choosing the right water protection sheet can make all the difference. With plastic membranes, you're not just preventing leaks; you are building smarter for the future.

0 notes

Text

Cricket Turf Manufacturer: Crafting the Perfect Playing Surface

A pitch is more than a piece of grass; it dictates the rhythm of play, ensures player safety, and heightens supporter amusement. A premium cricket turf manufacturer like OSMS Turf delivers expert advice on every fit-out, with circumstances determining ball bounce and roll under controlled conditions. By the development of a man-made playing surface consisting of superior quality polyethylene fibers, UV protection, and accurate tufting, OSMS Turf provides an even playing surface under any weather conditions or usage rate. The incorporation of infill material, such as calibrated combinations of silica sand and rubber granules, also provides shock absorption and traction for bowlers and batsmen. Exremes of weather, from monsoon rain to scorching sun, push natural grass pitches to the limit, producing uneven bounce and maintenance purgatory. OSMS Turf's advanced drainage systems and damp-proof coatings outsmart these issues at their own game, delivering a firm sub-base that drains water quickly and resists microbial growth. For schools, stadiums, and clubs that want to minimize downtime and maintenance costs, having a veteran cricket turf manufacturer means less repair, equal playability, and longer turf life. By mimicking the natural look and feel of grass but excelling in its durability in every test, OSMS Turf lets groundskeepers focus on game strategy rather than patchwork, so each match is played on a brilliant surface quality.

Our Production Process

OSMS Turf manufacturing combines stringent material selection and top-of-the-line equipment to produce cricket turfs to international standards. It begins with purchasing polyethylene and polypropylene fibers that have passed tensile strength and colorfastness tests to ensure every batch is wear and UV-fading resistant due to prolonged UV exposure. They are then fed into premium tufting machines where professionals manually position pile height, usually 25 to 30 millimeters for cricket, to ensure player grip and ball roll. The backing layer consists of a double-weave cloth, which is fitted with a proprietary latex coating that waterproofs the turf, preventing water entry and bacterial and fungal growth. This process is vital in maintaining turf integrity during wet weather or heavy‑use environments. Once tufted and coated, the turf also goes through quality control inspections for stitch consistency and even density, and any variations are corrected at the same time. The final step is the infill application, wherein a custom‑made blend of rubber granules and silica sand is poured and brushed onto the fibers to activate shock‑absorbing properties. Finally, grooming finishes off the job, brushing fibers upwards and placing infill to develop an even, hard-wearing surface. Having control over all of these phases—from fiber chemistry to tufting tension OSMS Turf, being a world-leader in producing cricket turf, produces a product which repeatedly meets the exacting requirements of club, academy, and international standard cricket pitches.

Products, Installation, and Maintenance

As a multi-purpose cricket turf manufacturer, OSMS Turf manufactures a variety of products to meet different playing needs, from world-class international pitches to transportable practice mats. All product lines are built on the same basic principles of performance, longevity, and low maintenance. International standard pitches replicate the conditions required by the International Cricket Council, with real bounce and unbroken ball flight. Club and academy fields focus on high-traffic resistance, with daily training sessions appearing unworn. For backyard recreation and development at a grassroots level, transportable mats provide the benefit of being able to drill anywhere, with turf segments built for easy mounting and storing. Hybrid systems incorporate natural grass root structures and synthetic reinforcement, resulting in a true-grass sensation and all-year-round use. Installation is completely controlled from end to end, starting with an extensive site survey to determine soil type, drainage needs, and sun aspects. OSMS Turf's professional installers dredge sub-base material with graded stone, roll and stabilize it, and place the turf to laser-leveled accuracy. Three to six weeks is the typical duration, depending on the scale and complexity of the site. Following installation, maintenance of OSMS Turf involves site visits every three months to brush fibers, Decompact infill, and replenish materials as necessary to maintain the best performance of the turf. Regular inspections and training sessions for staff provide grounds staff with best practice, allowing the synthetic surface to maintain its structure and playing characteristics for more than ten years.

Why Choose OSMS Turf as Your Cricket Turf Manufacturer

The proper choice of cricket turf supplier is central to the success of centers wanting to offer world‑class playing experiences. OSMS Turf has been in operation for more than 15 years and throughout more than 25 countries, with a capacity to show flexibility in design to suit different climates and usage patterns. Sustainability is the basis of each product: eco-friendly latex coatings reduce chemical runoff, and completely recyclable turf products reduce long-term environmental impacts. The company's end-to-end service model includes CAD-driven design, logistics, installation, and after-sales service, ending in a 10-year industry-leading warranty. One specific instance was the Riverside Cricket Club's total makeover from waterlogged, patchy outfield to world-class ground in just four weeks.

Conclusion

Cricket Turf Manufacturers like OSMS Turf are extremely detail-oriented to guarantee that all your measurement of play for your ground, from the selection of material and exact engineering to skilled installation and regular upkeep, is accomplished with professionalism and respectfulness. OSMS Turf's artificial turf replicates the playing conditions of natural grass but with enhanced durability, reliability of ball action, and lower maintenance needs. From upgrading an overseas stadium, constructing a club-level practice facility, or installing a backyard pitch, our end-to-end service model that includes site survey, CAD-driven design, certified installation, and full maintenance service provides a turnkey solution that is specifically customized to meet the needs of your venue.

0 notes

Text

Unlocking the Power of XLPE Sheets: Aerolam’s Cutting-Edge Insulation for Every Industry

In the evolving world of sustainable design and efficient construction, insulation is no longer a luxury—it's a necessity. One material that’s redefining insulation standards across industries is the XLPE Sheet. With its superior durability, thermal performance, and adaptability, XLPE Sheets have earned their place as a go-to solution for applications in construction, HVAC, automotive, packaging, and even sports gear.

Leading the charge in this space is Aerolam, a global innovator in advanced insulation materials, offering high-performance XLPE Sheets tailored to modern energy and safety needs.

What Are XLPE Sheets and Why Are They Unique?

XLPE Sheets—short for Cross-Linked Polyethylene Sheets—are made through a specialized process that chemically links polymer chains, enhancing strength, elasticity, and thermal resistance. Despite being lightweight, these sheets deliver robust mechanical properties, including high tensile strength and impressive shock absorption.

Their closed-cell structure ensures resistance to moisture, heat, and noise, making them incredibly versatile for various insulation and cushioning needs.

Standout Features of Aerolam XLPE Sheets

Superior Thermal Insulation Minimizes heat transfer to maintain indoor comfort and lower energy bills.

Waterproof & Mold-Resistant Closed-cell foam prevents moisture absorption—even in humid environments.

Noise Reduction Acts as an acoustic barrier in buildings, vehicles, and machinery.

Resilient Under Pressure Withstands impact, wear, chemicals, and UV exposure.

Lightweight Yet Tough Flexible, easy to cut or mold, and ideal for complex installations.

Real-World Applications of XLPE Sheets Across Industries

🏗️ Construction & Architecture

Used for roof, wall, and floor insulation

Improves building energy efficiency and indoor climate control

Helps in LEED certification for green buildings

🌬️ HVAC Systems

Wraps ducts, pipes, and mechanical systems

Reduces thermal loss and suppresses equipment noise

🚗 Automotive Interiors

Enhances soundproofing and temperature regulation

Damps vibration for smoother rides

📦 Industrial & Protective Packaging

Cushions delicate products during transportation

Maintains shape and structure under pressure

🏋️ Sports & Fitness Equipment

Found in yoga mats, gym flooring, and sports pads

Delivers comfort, flexibility, and shock resistance

Why Choose Aerolam for XLPE Sheets?

Aerolam stands as a trusted name in insulation, offering XLPE Sheets engineered with precision and sustainability in mind. With a proven track record and global reach, Aerolam combines innovation with reliability.

What Makes Aerolam the Industry Leader?

✅ State-of-the-Art Production Consistent quality through advanced manufacturing processes

✅ Sustainable Innovation Eco-friendly materials designed to reduce environmental impact

✅ Tailored to Your Needs Available in a variety of thicknesses, densities, and sizes

✅ Responsive Customer Support Dedicated professionals to help you find the perfect solution

✅ Global Delivery Quick access to products across continents

Key Benefits of Using Aerolam’s XLPE Sheets

✔️ Increased energy efficiency for buildings and facilities ✔️ Enhanced acoustic comfort in noisy environments ✔️ Fire-retardant options for safety-critical projects ✔️ Long-term performance in extreme conditions ✔️ Quick, easy installation with minimal upkeep

Final Word: Elevate Insulation with Aerolam XLPE Sheets

From homes to heavy industries, XLPE Sheets deliver unbeatable performance in insulation, safety, and energy savings. As businesses and builders strive to meet modern standards of comfort and efficiency, Aerolam provides the materials to get them there.

Ready to upgrade your insulation strategy? Choose Aerolam’s XLPE Sheets for a smart, future-ready solution—and experience the difference that innovation and quality can make.

0 notes

Text

HDPE Ground Protection Mats: The Essential Solution for Safe and Efficient Ground Protection

HDPE ground protection mats are made from high-density polyethylene, a type of plastic known for its exceptional strength, durability, and resistance to environmental factors. These mats are used to create a protective layer over natural or artificial ground surfaces to prevent damage from heavy machinery, equipment, and foot traffic. They are designed to withstand the weight of construction equipment, trucks, cranes, and other heavy vehicles, preventing ruts, compaction, and soil erosion.

HDPE Ground Protection Mats: The Essential Solution for Safe and Efficient Ground Protection

0 notes

Text

Water Park Manufacturing: Creating World-Class Aquatic Attractions

Water parks are a source of fun and excitement for people of all ages. Behind every thrilling slide, wave pool, and lazy river is a meticulous process of water park manufacturing. High-quality materials,Water Park manufacturing innovative designs, and strict safety standards are essential in creating a successful water park. This blog explores the key aspects of water park manufacturing, including design considerations, construction processes, safety measures, and future trends.

Understanding Water Park Manufacturing

Water park manufacturing involves the design, engineering, and construction of water-based attractions. The process requires collaboration between architects, engineers, and manufacturers to ensure each component meets industry standards and provides an exceptional experience for visitors.

Key Components of Water Park Manufacturing

Water Slides

Made from fiberglass or high-density polyethylene (HDPE) for durability.

Designs include body slides, tube slides, mat racers, and drop slides.

Wave Pools

Engineered with powerful water-pumping systems to create artificial waves.

Requires careful design to balance wave intensity and visitor safety.

Lazy Rivers & Rapids

Custom-built with varying flow speeds for different experience levels.

Equipped with water filtration systems to maintain cleanliness.

Interactive Play Structures

Includes tipping buckets, water cannons, and spray zones.

Constructed with child-friendly, non-slip materials.

Filtration and Water Treatment Systems

Essential for maintaining hygiene and water clarity.

Uses chlorine, UV sanitation, or ozone purification for safe water quality.

The Water Park Manufacturing Process

Concept and Planning

Market research and feasibility analysis to determine target audience and budget.

Site selection and land assessment.

Design and Engineering

Creating 3D models and blueprints for attractions.

Collaborating with safety consultants to ensure compliance with regulations.

Material Selection

Choosing high-quality, weather-resistant materials for longevity.

Fiberglass-reinforced plastics (FRP) for slides and corrosion-resistant metals for structures.

Fabrication and Assembly

Manufacturing slide sections, pools, and play elements in specialized factories.

Assembling and testing components before transportation.

On-Site Construction and Installation

Excavation, foundation work, and structural installation.

Connecting water circulation and filtration systems.

Safety Testing and Certification

Inspecting all attractions for stability and functionality.

Ensuring compliance with international safety standards.

Grand Opening and Operation

Final adjustments and staff training.

Implementing maintenance schedules for long-term efficiency.

Safety Considerations in Water Park Manufacturing

Material Durability

Using UV-resistant coatings to prevent fading and degradation.

Ensuring all surfaces are slip-resistant.

Structural Integrity

Conducting stress tests to evaluate weight-bearing capacity.

Reinforcing load-bearing structures for added safety.

Emergency and Rescue Features

Installing lifeguard stations, first-aid zones, and emergency exits.

Implementing water depth markers and safety signage.

Water Quality Management

Using advanced filtration to prevent bacterial growth.

Regular pH level monitoring and chemical balancing.

Trends in Water Park Manufacturing

Sustainable and Eco-Friendly Practices

Solar-powered water heating and LED lighting.

Water recycling and rainwater harvesting systems.

Technology Integration

RFID wristbands for ticketing and cashless transactions.

Augmented reality (AR) and virtual reality (VR) attractions.

Customization and Theming

Unique themes like jungle adventures, pirate coves, or space exploration.

Tailored attractions for different age groups and accessibility needs.

Smart Maintenance Systems

IoT-enabled sensors for real-time equipment monitoring.

Predictive maintenance to reduce downtime and repair costs.

Choosing the Right Water Park Manufacturer

Experience and Reputation

Researching past projects and client testimonials.

Ensuring the company has expertise in various water attractions.

Safety Compliance

Verifying adherence to international safety standards (e.g., ASTM, EN, ISO).

Checking for necessary certifications and insurance coverage.

Innovative Designs

Selecting manufacturers that offer customized solutions.

Ensuring compatibility with evolving trends and technologies.

Cost and ROI Considerations

Evaluating upfront costs vs. long-term operational efficiency.

Choosing durable, low-maintenance materials to maximize return on investment.

Conclusion

Water park manufacturing is a complex yet rewarding industry that brings joy to millions worldwide.Water Park manufacturing From design and construction to safety measures and emerging trends, every aspect plays a crucial role in ensuring a successful and sustainable water park. By choosing experienced manufacturers and implementing modern innovations, businesses can create world-class aquatic attractions that offer fun, safety, and longevity.

0 notes

Text

HDPE Ground Protection Mats for Enhancing Worksite Safety

HDPE (High-Density Polyethylene) ground protection mats are durable, lightweight, and heavy-duty mats used to protect surfaces from damage during construction, transportation, and other industrial processes. Made from high-quality polyethylene, these mats are designed to distribute the weight of heavy equipment and vehicles over a larger surface area, thereby preventing ruts, tire marks, or surface damage that could occur on soft, uneven, or sensitive ground.

0 notes

Text

Comprehensive Guide to IBC Totes: Product Features, Industry Applications & Shipping Guidelines

Comprehensive Guide to IBC Totes: Product Features, Industry Applications & Shipping Guidelines

Introduction: Why Are IBC Totes the Global Standard for Liquid Transportation?

In the global chemical and liquid logistics industries, Intermediate Bulk Containers (IBC Totes) have become the gold standard for transporting liquids and semi-fluids due to their efficiency, safety, and cost-effectiveness. With a decade of expertise in plastic product trading, this 2,000+ word guide provides an in-depth analysis of IBC totes’ core advantages, diverse applications, and critical maritime shipping protocols. By the end, you’ll gain actionable insights to reduce cross-border logistics costs by 30%+ while ensuring compliance and operational excellence.

1. Technical Breakdown of IBC Totes

1.1 Definition & Structural Design

IBC totes feature a triple-layer composite structure:

Outer Frame: Galvanized steel or high-density polyethylene (HDPE) grid (impact resistance ≥10 kJ/m²)

Inner Container: Food-grade HDPE (2.5–3.5 mm thickness, FDA 21 CFR certified)

Base Pallet: Modular design (static load capacity ≥1,500 kg; dynamic load ≥1,000 kg)

(IBC Tote cross-sectional view highlighting layers)

1.2 Technical Specifications Comparison

Parameter

Standard

Anti-Static

Chemical-Grade

Capacity

1,000 L

1,000 L

1,000 L

Temp. Range

-40°C to 60°C

-30°C to 50°C

-20°C to 70°C

Valve Type

Butterfly

Ball valve + grounding

316 stainless steel

UN Certification

UN31HA1/Y

UN31HA2/Y

UN31HA1/X

1.3 Innovative Technologies

Multi-Layer Coextrusion: 3-layer HDPE inner liners improve oxygen barrier efficiency by 40%.

Smart Monitoring: Optional RFID temperature sensors (±0.5°C accuracy).

Quick-Clean Design: 135° discharge port reduces residue to <0.1%.

2. Industry Applications & Case Studies

2.1 Chemical Industry Solutions

Hazardous Material Transport: Compliant with ADR/RID for Class II dangerous goods (e.g., UN 1203 diesel).

Case Study: A global paint manufacturer reduced annual transport losses from 2.3% to 0.7% using anti-static IBC totes.

2.2 Food-Grade Applications

Aseptic Filling: CIP (Clean-in-Place) systems meet ISO 22000 microbial standards.

2.3 Pharmaceutical Compliance

GMP Standards: Inner surface roughness ≤0.8μm (USP <88> Class VI compliant).

Temp. Control: Phase Change Material (PCM) insulation maintains ±2°C for 72 hours.

3. Maritime Shipping Protocols

3.1 Pre-Shipment Checklist

Documentation:

Valid UN Performance Test Report (5-year validity).

Material Safety Data Sheet (MSDS).

CTU Code-compliant container certificate.

Pre-Treatment:

Cleaning: Residuals <10 ppm.

Drying: Internal humidity <15% RH.

Leak Test: 0.3 bar pressure held for 30 minutes.

3.2 Container Loading Optimization

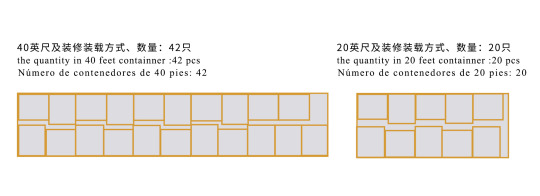

IBC Tote Container Loading

Container Type

20’GP

40’HQ

Units/Layer

20

42

Stacking

2 layers

3 layers

Securing

Cross straps + anti-slip mats

Honeycomb pads + airbags

3.3 Risk Mitigation Strategies

Temp. Monitoring: Refrigerated containers must maintain -5°C to 25°C (±3°C/24h).

Moisture Control: Silica gel desiccants (≥200 g/m³).

Emergency Kits: Include polymer sealants and repair tapes.

Click here for the complete original link of the blog post.

1 note

·

View note

Text

Understanding High-Density Polyethylene Mats, Geomembrane Sheet Prices, and Underground Warning Tape

Introduction to High-Density Polyethylene Mats

High-Density Polyethylene mats are a versatile and highly durable material used in numerous industries. Made from a type of thermoplastic polymer known for its strong resistance to various environmental factors, HDPE mats are popular for construction, environmental protection, and industrial applications. These mats are particularly noted for their excellent chemical resistance, water impermeability, and durability, which make them a preferred choice for projects where longevity and protection are paramount.

One of the primary benefits of HDPE mats is their ability to provide a stable and durable surface in challenging terrains. In industries such as construction, mining, and oil & gas, these mats are often used to create temporary roadways, offering support and preventing vehicles and machinery from sinking into soft or unstable ground. Due to their lightweight nature and ease of transportation, they are also highly efficient in terms of installation and cost-effectiveness. Their durability means that they can be reused multiple times, further lowering the total cost of ownership over time.

Moreover, HDPE mats have a high load-bearing capacity, which ensures they can support heavy machinery without the risk of breaking or becoming damaged. This makes them indispensable in heavy-duty construction environments where the ground needs reinforcement.

Geomembrane Sheet Price and Applications

Moving into the realm of containment and environmental safety, geomembrane sheets are another critical product manufactured using HDPE material. These sheets are thin, flexible barriers often used in various applications that require waterproofing or containment, such as landfill liners, pond liners, and waste containment facilities. The high impermeability of HDPE geomembrane sheets ensures that no contaminants leak into the surrounding environment, thus protecting natural resources.

The price of geomembrane sheets varies widely based on several factors, including thickness, material quality, and the size of the project. On average, Geomembrane Sheet Price can range from a few dollars per square meter to more significant sums for large-scale industrial projects. Customization of thickness is another factor that influences the price, with thicker sheets offering higher durability and protection but at a greater cost. Additionally, the installation process, including welding and securing the geomembrane sheet to ensure there are no leaks, can also affect the overall cost of a project.

It is also important to note that while HDPE geomembrane sheets may have a higher upfront cost compared to alternative materials, their long-term benefits far outweigh the initial investment. HDPE sheets are known for their longevity, typically lasting for several decades without significant wear and tear. Their resistance to UV rays, chemicals, and extreme temperatures ensures that they provide lasting protection in harsh environments.

In construction and environmental protection projects, where maintaining structural integrity and environmental safety is critical, geomembrane sheets provide an essential solution. Their high performance makes them a cost-effective choice despite the varying geomembrane sheet prices. Whether used for lining reservoirs, protecting landfills, or creating containment barriers, they contribute significantly to safeguarding natural ecosystems from potential contamination.

The Importance of Underground Warning Tape

In addition to HDPE mats and geomembrane sheets, another critical element in the construction and utility industries is underground warning tape. This product, while less visible, plays a crucial role in safety and infrastructure management. Underground warning tape is a colored plastic or metallic tape buried above underground utilities such as gas lines, electrical cables, water pipes, and telecommunications infrastructure. Its purpose is to serve as a visual warning for excavation crews and prevent accidental damage to buried utilities.

Underground warning tape is available in different colors, each denoting a specific type of utility. For example, red is typically used for electrical lines, yellow for gas, orange for telecommunications, blue for water, and green for sewage. By providing a clear visual indicator of the location of underground utilities, this tape significantly reduces the risk of damage during excavation activities, which could otherwise lead to service disruptions, environmental hazards, and costly repairs.

The effectiveness of underground warning tape lies in its durability and visibility. Made from high-quality plastic, usually polyethylene, these tapes are resistant to environmental degradation, ensuring that they remain functional for years. The bright colors and printed warnings make it easy for workers to identify the presence of utilities even when buried several feet underground.

The use of underground warning tape is often mandated by law in many regions to ensure public safety and prevent costly accidents. Without this crucial layer of protection, excavators run the risk of hitting gas lines or power cables, which can result in dangerous situations such as explosions, power outages, or contamination of water supplies.

Despite its simple design, underground warning tape is an essential tool in maintaining the safety and functionality of underground utility networks. It serves as the first line of defense in protecting vital infrastructure and ensuring that projects proceed smoothly without unforeseen complications.

Conclusion

High-Density Polyethylene mats, geomembrane sheets, and Underground Warning Tape are indispensable components across various industries. Each product plays a specific role in ensuring safety, efficiency, and environmental protection. Whether it’s the robust support of HDPE mats in construction projects, the environmental safeguarding provided by geomembrane sheets, or the crucial warnings offered by underground tape, these materials are critical to modern industrial practices.

Investing in high-quality HDPE mats ensures long-term durability and reliable performance in challenging terrains, while choosing geomembrane sheets that meet the specific demands of a project offers substantial long-term benefits in terms of environmental safety and containment. Additionally, the use of underground warning tape cannot be overstated, as it directly contributes to the prevention of accidents and costly disruptions.

In essence, the combined use of these materials ensures that industrial projects not only proceed smoothly but also adhere to safety standards and environmental regulations. The effectiveness and cost-efficiency of these products have made them a staple in industries that prioritize safety, protection, and sustainability.

FAQ

What are the advantages of using High-Density Polyethylene mats in construction? HDPE mats provide a durable and stable surface, especially in challenging terrains, supporting heavy machinery and preventing vehicles from sinking. They are lightweight, easy to install, reusable, and highly resistant to chemicals and environmental factors.

How is the price of geomembrane sheets determined? The price of geomembrane sheets is influenced by factors such as thickness, material quality, and the size of the project. Thicker sheets provide more durability but come at a higher cost. Installation costs also play a role in the overall price of geomembrane projects.

Why is underground warning tape important in excavation projects? Underground warning tape acts as a visual warning to prevent accidental damage to buried utilities such as gas lines, water pipes, and electrical cables during excavation activities. It reduces the risk of service disruptions, accidents, and costly repairs.

0 notes

Text

Protect Wetlands During Projects with HDPE Ground Mats

Wetlands are some of the most delicate and valuable ecosystems on our planet. They provide habitats for countless species, act as natural water filters, and help in flood control. However, construction and industrial projects near these sensitive areas pose significant risks to their health and longevity. At Singhal Industries Pvt Ltd, we understand the importance of balancing development with environmental conservation. One of the most effective solutions to protect wetlands during projects is the use of HDPE (High-Density Polyethylene) Ground Mats.

If you want to know more about HDPE Ground Mats, then please visit - Protect Wetlands During Projects with HDPE Ground Mats

0 notes

Text

HDPE Ground Mat: The Ultimate Solution for Durable and Safe Ground

HDPE Ground Mats are durable, lightweight, and high-strength solutions for protecting surfaces in construction, landscaping, and industrial sites. Made from high-density polyethylene, they provide superior traction, prevent soil damage, and support heavy loads. Weather-resistant and reusable, these mats ensure stability on uneven terrain, making them ideal for temporary roadways, work platforms, and outdoor events. Read more: HDPE Ground Mat: The Ultimate Solution for Durable and Safe Ground

0 notes

Text

Get AXP Racing Skid Plates for Robust Protection in the UK

Get AXP Racing Skid Plates for Robust Protection in the UK If you’re into motorbikes and love hitting the open road—or the rough trails—then you know how important it is to protect your pride and joy. That’s where AXP Racing skid plates come in. They’re tough, lightweight, and ready to take on whatever The UK’s roads and trails throw at them. From rocky paths to wet, muddy routes, these skid plates are the ultimate armour for your motorbike.

Why AXP Racing Skid Plates Are the Talk of The UK Let’s be real—nobody wants a busted engine or a damaged frame just because they hit a stray rock or went too hard on a trail. Riders across The UK swear by AXP Racing skid plates because they’re made from high-density polyethylene. That’s just a fancy way of saying they’re ridiculously strong without being heavy. Plus, they don’t rust, which is a win for anyone dealing with The UK’s famously unpredictable weather.

Built to Take a Beating The territory in The UK can go from smooth to savage in a matter of seconds. Whether you're cruising down country paths or handling rough terrain tracks, these skid plates are ready for the situation. They absorb impact like an old pro, keeping your motorbike's motor, exhaust, and edge protected from terrible hits.

Fit It Yourself — No Fuss, No Drama You needn't bother with to be a technician to fit an AXP Racing skid plate plate. These bad boys are intended to be as simple to introduce as some tea is to make. With pre-drilled holes and an ideal fit, you'll have your motorbike kitted out and prepared for experience in the blink of an eye.

Why Riders in The UK Love AXP Racing Skid Plates 1. Strong Yet Lightweight: Made from polyethylene, these plates are solid without adding unnecessary weight. 2. Rust-Free Protection: Metal might look fancy, but it doesn’t like The UK’s rain. These plates? No rust worries. 3. Silent Defender: Fail to remember the clanging noise you get with metal plates — these are quite peaceful. 4. Serious Shielding: Stones, trash, tree roots — nothing's breaking through to your motorbike's fundamental pieces.

Perfect for The UK’s Riders Whether you're an off-road adventurer or just somebody who enjoys in a Sunday ride through The UK's open country, AXP Racing skid plates are an easy decision. They’re not just practical; they look good too. Because who says protection can’t have a bit of style?

Tested and Loved All Over The UK These skid plates aren’t just for show—they’ve been put through their paces by riders all across The UK. From harsh mountain trails to muddy backroads, they’ve proved their worth time and again. You can ride with confidence, knowing your motorbike is safe from whatever the road—or lack of it—throws at you.

Fits Pretty Much Any Motorbike Whether you’ve got a dirt bike, an adventure motorbike, or something in between, there’s an AXP Racing skid plate for you. They’re made to fit a wide range of motorbike models, which is why they’re a hit with riders throughout The UK.

Easy to Maintain, Even Easier to Love After a day of tearing up trails or cruising The UK’s stunning roads, just give your skid plate a quick clean. A bit of water and soap will keep it looking sharp and ready for the next ride. It’s as low-maintenance as it gets.

Why You Need One Without a skid plate, you’re leaving your motorbike’s undercarriage exposed to all sorts of damage. And let’s face it, fixing that stuff isn’t cheap. AXP Racing skid plates give you peace of mind so you can focus on what matters: enjoying the ride.

Gear Up and Ride On AXP Racing skid plates are built for riders who don’t hold back. If you’re ready to explore The UK’s diverse terrain—whether it’s scenic coastal routes or gnarly mountain trails—this is the kit you need. Get one today and give your motorbike the protection it deserves.

Don’t let the road decide the fate of your motorbike. With AXP Racing skid plates, you’re in control, and your motorbike stays safe no matter where in The UK you choose to ride.

#axpracing#skidplates#motorbikeprotection#offroadriding#ukriders#motorbikegear#trailriding#enduroriding#motorbikeparts#theuk

0 notes

Text

Exploring the Versatility of XLPE Sheet: Aerolam’s Advanced Insulation Solutions

In today’s energy-efficient world, choosing the right insulation material can greatly impact performance, safety, and cost savings. One standout material that continues to dominate the insulation landscape is the XLPE sheet (cross-linked polyethylene sheet). Known for its exceptional thermal resistance, moisture control, and durability, the XLPE sheet has become a top choice across industries like construction, HVAC, automotive, packaging, and sports.

At the heart of this innovation is Aerolam, a global leader in manufacturing high-quality XLPE sheet products engineered for both everyday and high-performance applications.

What is an XLPE Sheet?

An XLPE sheet is made from chemically cross-linked polyethylene foam. The cross-linking process enhances the polymer’s structure, resulting in improved mechanical strength, temperature resistance, and flexibility. Despite being lightweight, XLPE sheets are known for their impressive tensile strength, shock-absorbing ability, and long-term resilience in harsh conditions.

These properties make them highly effective in insulation, soundproofing, and protective packaging—offering multifunctional solutions in a single material.

Key Features of an XLPE Sheet

Thermal Efficiency: Reduces heat transfer, making it ideal for use in buildings and HVAC systems.

Water Resistance: Closed-cell construction prevents water absorption and mold formation, even in humid conditions.

Soundproofing Capabilities: Effectively blocks noise, making it suitable for residential, commercial, and industrial applications.

Chemical & UV Resistance: Withstands a wide range of chemicals, oils, and environmental exposure.

Flexibility with Strength: Lightweight, easy to handle, and durable—perfect for curved surfaces or custom fittings.

Applications of XLPE Sheet Across Industries

1. Construction

Used in roofs, walls, and flooring to enhance thermal insulation and improve energy efficiency in residential and commercial buildings.

2. HVAC Systems

Installed around ducts and mechanical systems to provide thermal resistance and reduce operational noise.

3. Automotive Sector

Integrated into car interiors for sound insulation, vibration damping, and maintaining cabin temperature control.

4. Protective Packaging

Cushions fragile items during transit while resisting compression and wear.

5. Sports & Fitness Gear

Used in gym mats, yoga mats, and other sports accessories due to its impact resistance and comfort.

Why Aerolam is the Top Choice for XLPE Sheet Products

Aerolam has built its reputation by consistently delivering innovative insulation solutions backed by quality, performance, and sustainability. Their XLPE sheet offerings are known for reliability across various use cases.

What Sets Aerolam Apart?

✅ Premium Manufacturing: Advanced production technology ensures consistent quality and precision

✅ Eco-Conscious Production: Products designed with a minimal environmental footprint

✅ Customized Solutions: Available in multiple thicknesses, densities, and formats to match exact specifications

✅ Exceptional Customer Service: Support teams guide clients in selecting the right insulation materials

✅ Global Distribution Network: Seamless availability across domestic and international markets

Benefits of Choosing Aerolam’s XLPE Sheet

✔️ Boosts energy efficiency in homes, offices, and industrial facilities

✔️ Reduces noise pollution, enhancing comfort and concentration

✔️ Fire-retardant properties for added safety in critical applications

✔️ Long-lasting performance even under extreme temperatures or mechanical stress

✔️ Cost-effective installation with minimal maintenance

Conclusion: Reliable Insulation Starts with the Right XLPE Sheet

The XLPE sheet is a powerful, multipurpose material that delivers superior insulation, flexibility, and resilience. Its wide range of applications makes it a favorite among engineers, contractors, architects, and business owners alike.

When performance matters, Aerolam rises to the occasion—offering dependable, customizable XLPE sheet solutions that meet modern energy, comfort, and safety demands.

Upgrade your insulation strategy today with Aerolam’s premium XLPE sheets—and experience the difference innovation makes.

0 notes