#High pressure Ball valve manufacturer in india

Explore tagged Tumblr posts

Text

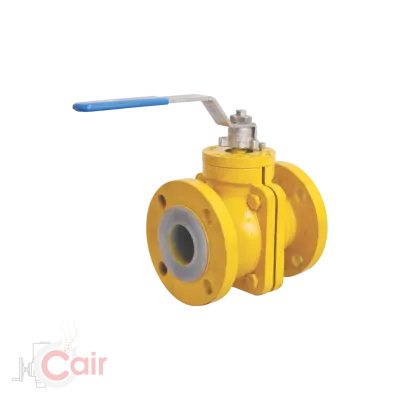

High pressure Ball valve manufacturer in india

Extreme pressure systems employ High Pressure Ball Valve Manufacturer in Ahmedabad, Vadodara, Mumbai, Delhi, Chennai, Bangalore, Ghaziabad, Rajasthan, Gujarat India to regulate fluid flow dynamics. Materials used in high pressure ball valves can endure high temperatures. A ball having a hole that can enable fluid to flow is part of the high pressure valve. The ball is attached to a stem, which is then attached to a hand wheel. You can choose an electric or manual hand wheel for ball valve from us. High-sensitive applications for automation makes use of the high pressure electric actuated ball valve. We produce high pressure ball valves in a range of sizes, from 1/8 inches to 4 inches. Two-way valves and high-pressure three-way valves are both available with Payal Engineering under the brand name Ped Lock.

Visit Website:

#High pressure Ball valve manufacturer in india#High Pressure Ball Valve Manufacturer in Ahmedabad#Vadodara#Mumbai#Delhi#Chennai#Bangalore#Ghaziabad#Rajasthan#Gujarat

0 notes

Text

High Pressure Ball Valve in India | High Pressure Ball Valve Mexico | Ball Valves Manufacturers Indonesia

Baxcell is a leading manufacturer and supplier of high-pressure ball valves in India, designed to handle extreme conditions with efficiency and reliability. Our valves are engineered for industries like oil and gas, petrochemicals, and process engineering, ensuring superior performance and durability

0 notes

Text

#needle valve manufacturer in India#High pressure Ball valve manufacturer in India#SS Check valve manufacturer in India

0 notes

Text

Valves Market is Estimated to Witness High Growth

Valves Market is Estimated to Witness High Growth Owing to Rising Constructional and Infrastructure Development Activities The valves market comprises products such as gate valves, globe valves, check valves, butterfly valves, ball valves and pressure regulating valves which are used to control the flow, pressure and direction of fluids. Valves are extensively used in power plants, refineries, oil & gas, water & wastewater and construction activities. These products play a key role in fluid transportation and management which makes them an integral component across various industrial sectors. Rising infrastructure development projects across both developed and developing nations are augmenting the demand for valves. Moreover, growing pipeline networks for oil & gas transportation is also favoring market growth. The Global valves market is estimated to be valued at US$ 83 Mn in 2024 and is expected to exhibit a CAGR of 3.5% over the forecast period 2024 To 2031. Key Takeaways Key players operating in the valves market are Tyson Foods, Inc., JBS S.A., Pilgrim's Pride Corporation, Wens Foodstuff Group Co. Ltd., BRF S.A., Perdue Farms, Sanderson Farms, Baiada Poultry, Bates Turkey Farm, and Amrit Group. The major players are focusing on capacity expansion plans and mergers & acquisitions to gain market share. Rising population and changing diets are expected to fuel the growth of the poultry sector which presents significant opportunities for valve manufacturers. With the growing poultry industry, demand for processing equipment including valves is also projected to rise substantially over the forecast period. The global valves market is estimated to witness growth across key regions such as North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. This can be attributed to surging investments in oil & gas, water & wastewater infrastructure, and industrial development projects worldwide. Emerging economies with high urbanization rates like China and India also offer lucrative prospects for market expansion. Market Drivers The key driver behind the Valves Market Demand is the increasing constructional and infrastructure development activities worldwide. There is huge government focus as well as private investments toward projects such as roadways, railways, metro stations, power generation, water supply, etc. which involves extensive use of valves in various process applications. Further, the rising need for energy and growing focus on rural electrification has boosted investments in power transmission and distribution sector augmenting valves demand.

PEST Analysis

Political: The valves market is regulated by laws pertaining to safety, environmental protection and quality standards. New regulations regarding emissions could impact demand patterns. Economic: Changes in the global and regional economic conditions directly impact spending on industries like oil & gas, energy & power, and water & wastewater management which influences Valves demand. Social: Growing population and urbanization is increasing requirements for water, energy and other infrastructure development which boost the usage of valves. Technological: Advancements in materials and designs of valves are improving efficiency, lowering costs and enabling usage in newer applications. Digitalization is also aiding remote monitoring of industrial valves. The regions concentrating maximum valves market share in terms of Valves Market Size and Trends include North America, Europe and Asia Pacific. North America accounts for a major portion owing to strong presence of end-use industries like oil & gas and significant infrastructure spending. Europe and Asia Pacific are also sizable markets led by Germany, China, India respectively. The fastest growing regional market for valves is expected to be Asia Pacific led by increasing investments in water & wastewater management, power projects and industrial activities in China and India. Rising standards of living and initiatives to improve urban infrastructure will further drive the demand across developing nations in the region.

Get more insights Valves Market

Discover the Report for More Insights, Tailored to Your Language.

French German Italian Russian Japanese Chinese Korean Portuguese

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

#Coherent Market Insights#Valves Market#Control Valves#Globe Valves#Plug Valves#Gate Valves#Ball Valves#Butterfly Valves

2 notes

·

View notes

Text

Hydraulic Manifold valve manufacturer in india by hydrofittings

In addition, an Air Manifold With Valves allows the set up of more than one solenoid valves in a centralized vicinity. A unmarried air deliver and port are shared by means of numerous valves. Manifold take a look at Valve acts as a primary distribution point for aircraft that have dual dry air pumps. If one pump of Manifold Pneumatic fails it’s miles designed to isolate the failed pump and provide continuous airflow from the operating pump. Water Manifold With Valves is designed to distribute water and has built-in ports in a section of pipe. They act as manage facilities of water distribution within the house. Solenoid Valve Manifold has a most preferred stress of 6000 psi at a hundred ranges F and has a mounting hollow that enables inside the self-supporting software. Hydraulic Valve Manifold Has a stainless steel pin that forestalls the bonnet from detaching itself from the frame due to vibration. Ball Valve Manifold has a burr-loose thread that reduces inner floor leaks accordingly offering accurate transmitter read. No O-ring is used bonnet to body pressure Transmitter Manifold seal. It is a steel-to-metallic seal. Hydraulic Valve Manifold Block has the choice of panel mounting. There are one of a kind sorts of Manifold Valves to be had within the market but the maximum typically used ones are the two valve, three valve, and 5 valve assemblies. Swagelok Manifold is designed mainly for liquid stage, static stress, and differential stress packages. Smc Valve Manifold has a blended isolating and venting in a single valve that eliminates the want for tubing and fitting. Festo Valve Manifold is simple to gather and set up and is dependable. They’ve dirt caps fitted on them that comprise stem lubricant and save you the ingress of contaminants. Rosemount 305 Manifold gets rid of the need for a flange because it suits immediately to the patented Rosemount. Why to choose hydrofittings ? About us – The briefcase of our company consists of numerous additions which include, – clever hydraulics, engineering, and digital answers. With the guide of 80 personnel, our company works like a well-oiled system to deliver most effective the very best fine product to our buyers. Proper from the responsibly sourced product by way of our procurement team to our nice manage team, many agencies have lauded our work. And that they admire the fact that we’re transparent in all our dealings. With a properly-mounted channel of communique, our customers can connect with us anytime. Our control and our body of workers, together form a competent and ambitious crew. The readability and high stage of performance make us one of the most modern but sought after manufacturers. And because we fee initiative behavior, we adore to have our studies and development crew collaborate with the opposite teams to recognize the current requirements of the hour. We frequently have checking out and great exams to maintain brilliant requirements.

An global provider of

TO KNOW MORE ABOUTS US VISITE OUR WEBSITE www.hydrofittings.com

3 notes

·

View notes

Text

Apex Ball Valve Trusted Supplier in Kerala

Apex Ball Valve Trusted Supplier in Kerala, RPVC Apex Ball Valve, UPVC Apex Ball Valve. Rigid PVC Ball Valves. KANA Valves Pvt. Ltd. is the Leading Manufacturer of Rigid PVC ball Valve, P.P Ball Valve, PVC Ball Valve, UPVC Ball Valve, CPVC Ball Valve, RPVC Apex Ball Valve, UPVC Apex Ball Valve, CPVC & Upvc pipes & Fittings, PVC taps & PTMT Taps and other plumbing and irrigation product Trusted Supplier in Kerala over 15 years, Our Manufacturing unit is Located at Kuha, Ahmedabad, Gujarat, India. Overview of Apex Ball Valve: We engineer the Apex Ball Valve as a high-performance valve for efficient and reliable fluid flow control across applications. Manufactured using durable materials, Apex Ball Valves offer excellent resistance to corrosion, chemicals, and temperature fluctuations, making them ideal for both residential and industrial use. The valve features a precision-crafted ball mechanism that ensures smooth operation and tight sealing, reducing leakage while maximizing durability. What are some alternative names commonly used for Apex Ball Valve products? RPVC Apex Ball Valve UPVC Apex Ball Valve RIGID PVC Ball Valve Apple Cut Ball Valve Pressure Ratings for Various Types of Apex Ball Valve: RPVC Apex Ball Valves: Rated up to 150 PSI at room temperature. Certain models can handle higher pressures based on size and construction. UPVC Apex Ball Valves: Generally rated up to 150 PSI, with some variants capable of handling pressures up to 200 PSI for applications requiring greater strength. Available in various sizes ½" to 2" (DN15 to DN50) in ANSI & DIN Standard and configurations, the Apex Ball Valve is easy to install and operate. Its ergonomic handle allows quick and effortless opening and closing, clearly indicating the valve's position. The Apex Ball Valve guarantees robust performance and long-lasting reliability, whether used in plumbing, irrigation, industrial processes, or water treatment systems. Types of Apex Ball Valve Available at KANA Valves Pvt. Ltd.: RPVC Apex Ball Valve, UPVC Apex Ball Valve. Features of Apex Ball Valve: Precision Ball Design: Ensures quick and precise on/off operation, minimizing pressure drop and maximizing flow efficiency. Wide Range of Applications: Suitable for plumbing, chemical processing, HVAC systems, irrigation, and water treatment. Ergonomic Lever Handle: Provides easy operation and allows quick adjustments even in tight spaces. Temperature and Pressure Resilience: Designed to handle a wide range of temperatures and pressures, ensuring reliable operation across different applications. Leak-Proof Seals: High-quality seals maintain system integrity and prevent fluid loss. Minimal Upkeep: Apex Ball Valves are built to require little maintenance, providing long-lasting reliability. Ease of Installation: Lightweight compared to metal alternatives, making them easier to handle and install. Apex Ball Valve Applications: We design Apex Ball Valves to be versatile, using them across various industries and settings, including: Plumbing Systems Irrigation Systems Industrial Processes Water Treatment Marine Applications KANA Valves Pvt. Ltd. is an Apex Ball Valve Trusted Supplier in Kerala including locations Alappuzha, Ernakulam, Idukki, Kannur, Kasaragod, Kollam, Kottayam, Kozhikode, Malappuram, Palakkad, Pathanamthitta, and Thrissur. For more information, inquiries, or to place an order for Apex Ball Valve, feel free to contact KANA Valves Pvt. Ltd. today! View Product: Click here Read the full article

0 notes

Text

What Is a Ball Valve? A Complete Guide to Its Function and Uses

Ball valves are one of the most commonly used types of valves in industries worldwide. Their design and versatility make them ideal for controlling the flow of various fluids and gases. This comprehensive guide will explore what a ball valve is, how it functions, and its various applications, along with insights into the ball valve manufacturing industry in India.

What is a Ball Valve?

A ball valve is a type of valve that uses a spherical ball to control the flow of media (liquids, gases, or slurries) through a pipe or system. The ball has a hole or port through the center, which aligns with the flow path when the valve is open. When the valve is closed, the ball rotates 90 degrees, blocking the flow path and preventing the passage of the media.

The simplicity of this design allows for quick and efficient operation. Ball valves are known for their durability, reliability, and ability to maintain a tight seal even after long periods of use.

How Does a Ball Valve Work?

A ball valve consists of several key components, including the body, the ball, the stem, and the handle or actuator. The ball is mounted inside the valve body, with the hole or port aligned with the flow path when the valve is open. When the valve handle is turned, the stem rotates the ball, either opening or closing the valve.

The flow direction and the valve's status (open or closed) are determined by the orientation of the ball. In the open position, the flow passes through the hole in the ball, allowing the fluid or gas to move through the valve. In the closed position, the ball rotates 90 degrees, blocking the flow entirely.

One of the key features of ball valves is their ability to create a tight seal. The design ensures minimal leakage, even in high-pressure applications, making them highly reliable in various industries.

Types of Ball Valves

There are different types of ball valves, each suited for specific applications. The most common types include:

Standard Ball Valve: This is the most basic type of ball valve, ideal for simple on/off applications.

V-Port Ball Valve: This valve has a V-shaped ball, which allows for precise flow control, making it suitable for throttling applications.

Multi-Port Ball Valve: These valves have multiple ports, allowing for directional flow control and bypassing multiple channels. They are used when more complex flow control is needed.

Trunnion Ball Valve: A trunnion ball valve has a ball that is supported by bearings, allowing for larger sizes and higher-pressure applications.

Uses of Ball Valves

Ball valves are widely used across different industries due to their efficiency and reliability. Some of the key applications include:

Oil and Gas: Ball valves are essential in oil and gas systems for controlling the flow of crude oil, natural gas, and other fluids. Their ability to withstand high pressures and temperatures makes them ideal for this industry.

Water Treatment: In water treatment plants, ball valves are used to control the flow of water and chemicals. They are often found in filtration systems, distribution lines, and pumping stations.

Chemical Processing: Chemical plants use ball valves to manage the flow of various chemicals, ensuring safe and controlled operations. The tight seal offered by ball valves minimizes leaks and contamination.

HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, ball valves regulate the flow of fluids used for heating and cooling purposes.

Food and Beverage: In the food and beverage industry, ball valves ensure the smooth flow of ingredients, liquids, and gases, as well as maintain hygienic conditions.

Pharmaceuticals: Ball valves are also critical in the pharmaceutical industry, where cleanliness and precise flow control are required for producing medicines and vaccines.

Why Choose Ball Valves?

There are several reasons why ball valves are favored in various industries:

Durability: Ball valves are highly durable and can withstand harsh operating conditions, such as extreme temperatures and high pressures.

Leak-Proof Performance: Ball valves are designed to provide a tight seal, preventing leaks even in demanding applications.

Ease of Operation: With a simple 90-degree turn, ball valves are easy to operate and provide quick response times.

Versatility: They can be used for a wide range of applications, from small-scale systems to large industrial plants.

Low Maintenance: Due to their robust design and minimal moving parts, ball valves require little maintenance compared to other types of valves.

India has become a significant player in the global valve manufacturing industry, with many reputable ball valve manufacturers producing high-quality valves. A ball valve manufacturer in India is equipped with advanced technology and expertise to meet the growing demand for industrial valves in various sectors.

These manufacturers use state-of-the-art materials and rigorous quality control processes to ensure that their products meet international standards. As a result, India's ball valve manufacturers are well-positioned to cater to both domestic and international markets, offering products that are durable, reliable, and cost-effective.

Conclusion

Ball valves are essential components in many industries, offering excellent control and reliability in fluid and gas handling systems. Their simple design, combined with a tight seal, makes them an ideal choice for various applications. Whether in oil and gas, water treatment, or pharmaceuticals, ball valves continue to play a crucial role in ensuring smooth and safe operations. As the demand for high-quality valves grows, ball valve manufacturers in India are playing a crucial role in supplying the global market with reliable and durable valves to meet diverse industry needs.

0 notes

Text

Functions and applications of non return valves

Non-return valves, commonly referred to as check valves, are essential components in various industrial systems and equipment. These valves are specifically designed to prevent the backflow of fluids and gases, ensuring the safety, efficiency, and reliability of the system they are integrated into.

Types of Non-Return Valves

Non-return valves come in different types, each with unique features and capabilities tailored to specific applications. Some of the most common types include:

Swing Check Valves: Utilize a hinged disc mechanism to prevent backflow. Ideal for low-pressure systems.

Lift Check Valves: Employ a spring and poppet design, making them suitable for high-pressure applications.

Ball Check Valves: Use a ball to block backflow, often found in applications requiring compact and simple valve designs.

Non-Return Valves

Applications of Non-Return Valves

Non-return valves are widely used across various industries, including:

Oil and Gas: Ensuring unidirectional flow in pipelines and storage systems.

Water and Wastewater: Preventing contamination and maintaining flow direction in treatment plants and sewage systems.

Pharmaceuticals: Maintaining sterility and preventing contamination in drug production processes.

Food Industry: Ensuring hygiene and preventing backflow in food processing lines.

Non-Return Valves in the Food Industry

In the food industry, maintaining hygiene and process integrity is paramount. Non-return valves play a critical role in preventing the backflow of fluids, ensuring that production processes meet strict health and safety standards. These valves are often employed in applications such as:

Dairy Processing: Preventing cross-contamination between raw and pasteurized milk.

Beverage Production: Maintaining the purity of ingredients during blending and bottling.

Food Packaging: Ensuring unidirectional flow in filling lines to uphold product quality.

The robust construction and easy maintenance of these valves make them indispensable in food production environments.

Non-Return Valves in Pharmaceuticals

In the pharmaceutical sector, the prevention of backflow is crucial for ensuring the safe handling of sensitive and potentially hazardous materials. Non-return valves provide the following benefits:

Drug Manufacturing: Preventing liquid backflow to ensure precise ingredient proportions and maintain process consistency.

Hazardous Material Management: Avoiding gas backflow, which helps preserve material integrity and system safety.

Non-return valves are integral to maintaining compliance with stringent regulatory standards in pharmaceutical production.

Why Choose Parth Valve and Hoses LLP?

Parth Valve and Hoses LLP stands out as a leading manufacturer and supplier of high-quality non-return valves in India. Their products are known for their durability, efficiency, and ease of maintenance. Catering to both industrial and commercial needs, the company offers:

A wide variety of non-return valves suitable for diverse applications.

Timely delivery and exceptional customer service.

Solutions tailored to industry-specific requirements, ensuring optimal performance.

Conclusion

Non-return valves are vital for preventing fluid and gas backflow in various industrial applications. Their role in ensuring the safe and efficient operation of systems cannot be overstated. Industries such as food, pharmaceuticals, oil and gas, and water treatment rely heavily on these valves for maintaining process integrity.

Parth Valve and Hoses LLP, with its commitment to quality and reliability, has established itself as India’s top supplier of non-return valves. Whether for the food industry, pharmaceuticals, or other sectors, their products deliver unmatched performance and longevity, making them the preferred choice for businesses nationwide.

Visit Us- https://parthvalve.com/pressure-valve/

Email Us- [email protected]

Call At- (+91)8600034431

0 notes

Text

Industrial Valve Supplier in Telangana

Keshar Bhawani Metal & Tubes Pvt. Ltd is a leading provider Industrial Valve Supplier in Telangana, India. Our manufacturing unit is in Mumbai, Maharashtra, India. Industrial valves are essential components in controlling the flow of liquids, gases, or slurries within pipelines. These valves regulate pressure, volume, and flow rates in various systems across multiple industries. Keshar Bhawani Metal & Tubes Pvt. Ltd. is a renowned manufacturer, supplier, and exporter of high-quality industrial valves, offering a wide range of products to suit the needs of diverse applications. We design our industrial valves for durability, reliability, and efficiency in industries such as oil and gas, chemicals, pharmaceuticals, power generation, and more. Whether you are working with fluids in a chemical plant or controlling pressure in a power station, our industrial valves provide optimal performance, ensuring smooth operations and long-term reliability. Specifications: Size: 2” to 24” (DN 50 to DN 600) Pressure Rating: ASME 150 to 2500 Design Standard: BS 1873, API 623 Pressure / Temperature Rating: ASME B 16.34 Media: Water, Air, Gas Automation Grade: Automatic Usage/Application: Industrial FAQs: What types of industrial valves do you offer? We offer ball valves, gate valves, globe valves, check valves, butterfly valves, pressure relief valves, control valves, and needle valves. Are your industrial valves customizable? Yes, we offer customized industrial valves in different sizes, materials, and configurations to meet specific requirements. What materials are used to make industrial valves? Our industrial valves are made from high-quality materials such as stainless steel, carbon steel, alloy steel, and brass. Keshar Bhawani Metal & Tubes Pvt. Ltd is an Industrial Valve Supplier in Telangana, India Including Adilabad, Bhadradri-Kothagudem, Hyderabad, Jagtial, Jangaon, Jayashankar, Bhoopalpally, Jogulamba-Gadwal, Kamareddy, Karimnagar, Khammam, Komaram Bheem Asifabad, Mahabubabad, Mahabubnagar, Mancherial, Medchal, Medak, Nagarkurnool, Nalgonda. Nirmal, Nizamabad, Peddapalle, Rajanna Sircilla, Ranga Reddy, Sangareddy, Siddipet, Suryapet, Vikarabad, Wanaparthy, Warangal, Yadadri-Bhuvanagiri. Contact us today to discuss your requirements or get a quote. View Product: Click Here Read the full article

#Adilabad#Ahmedabad#Bhadradri-Kothagudem#Bhoopalpally#Exporter#ExporterofIndustrialValve#Gujarat#Hyderabad#India#IndustrialValve#IndustrialValveExporter#IndustrialValveExporterinTelangana#IndustrialValveinAhmedabad#IndustrialValveinGujarat#IndustrialValveinIndia#IndustrialValveinTelangana#IndustrialValveManufacturer#IndustrialValveManufacturerinTelangana#IndustrialValveSupplier#IndustrialValveSupplierinTelangana#Jagtial#Jangaon#Jayashankar#Jogulamba-Gadwal#Kamareddy#Karimnagar#Khammam#KomaramBheemAsifabad#Mahabubabad#Mahabubnagar

0 notes

Text

Ball Valves, 3-Way Valves, Needle Valves Manufacturer in Indonesia & India

Baxcell is a leading manufacturer and supplier of high-quality valve solutions, serving Indonesia, Italy, Mexico, and India. We specialize in producing durable ball valves, including 3-way ball valves (3-piece) and high-pressure ball valves designed for precision and reliability in industrial applications.

#SuperDuplexValves#StainlessSteelFittings#IndustrialValves#OilAndGasEquipment#CorrosionResistant#Baxcell

0 notes

Text

Choosing the Right Industrial Valve Exporter from India for Your Business

When it comes to sourcing industrial valves, choosing the right exporter can have a significant impact on the success of your business. India, with its vast industrial landscape and growing manufacturing capabilities, has emerged as one of the leading exporters of industrial valves.

However, with so many options available, finding the right industrial valve exporter from India for your specific needs can be challenging. This article will guide you through the essential factors to consider when selecting an industrial valve exporter, ensuring that you make an informed decision that will benefit your business in the long run.

Quality of Products

The most crucial factor when selecting an industrial valve exporter is the quality of their products. Industrial valves are critical components used in various sectors, including oil and gas, chemicals, water treatment, and power generation. A malfunctioning or low-quality valve can lead to costly downtime, safety hazards, and operational inefficiencies. Therefore, ensure that the exporter you choose adheres to international standards and certifications for quality assurance.

India is home to several manufacturers that specialize in producing high-quality industrial valves. Be sure to inquire about the materials used, the manufacturing process, and whether the valves undergo rigorous testing to meet the required specifications. Look for an exporter who can provide you with the technical data and test reports of the valves you intend to purchase.

Experience and Expertise

An experienced exporter understands the nuances of the industry and can provide valuable insights into your specific needs. Choose a company with a proven track record in supplying industrial valves for the sectors you operate in. Experienced exporters can guide you in selecting the right valve for your requirements, whether it’s a ball valve, gate valve, globe valve, or butterfly valve.

Additionally, exporters with industry expertise are likely to have better after-sales support and customer service, ensuring that any issues are addressed quickly and effectively. It is also beneficial to choose an exporter who has a deep understanding of the technical aspects of valves, such as pressure ratings, material compatibility, and temperature resistance.

Customization Options

Each business has its own set of requirements when it comes to industrial valves. Some industries need valves with specific features, such as corrosion resistance, high-temperature tolerance, or specific sealing mechanisms. The right industrial valve exporter from India should be able to offer customized solutions to meet these specific needs.

Look for exporters who provide customization options, whether it's valve size, material, or specific technical features. A flexible exporter who is willing to tailor solutions to your needs will ensure that your valves function efficiently within your system and environment.

Timely Delivery and Shipping

When sourcing industrial valves, timely delivery is crucial. Delays in valve shipments can disrupt production schedules and lead to costly downtimes. Therefore, it is essential to choose an industrial valve exporter who can deliver on time. A reliable exporter will have a streamlined logistics process in place and will communicate any potential delays well in advance.

India’s well-established export infrastructure allows for efficient shipping across the globe. Be sure to discuss delivery timelines with the exporter and clarify their shipping policies, including potential customs clearance issues, shipping costs, and transportation methods.

Customer Service and After-Sales Support

A reliable industrial valve exporter should offer excellent customer service and after-sales support. Whether you need assistance with product selection, installation, or troubleshooting, a responsive and knowledgeable customer service team can help resolve any issues swiftly. Additionally, inquire about warranty policies and technical support services that the exporter offers.

Good after-sales support can also ensure that you can access spare parts and maintenance services if needed, keeping your valves operating optimally for longer periods.

Conclusion

Choosing the right industrial valve exporter from India is a crucial decision that will impact the efficiency and safety of your operations. By considering factors such as product quality, experience, customization options, timely delivery, pricing, and customer service, you can ensure that your business sources high-quality valves that meet your specific requirements.

Mayur Valves System Private Limited, based in Ahmedabad, stands out as a trusted partner for companies seeking reliable and high-quality industrial valves. With their extensive experience in the industry and commitment to customer satisfaction, they are equipped to meet the diverse needs of businesses worldwide.

0 notes

Text

Industrial Valves Manufacturer in India: Delivering Quality and Reliability

India has emerged as a global hub for industrial valve manufacturing, catering to a diverse range of industries, including oil and gas, petrochemical, water treatment, power generation, and more. The country is home to numerous reputed industrial valves manufacturer in India known for their innovative designs, robust engineering, and commitment to quality.

Why Choose Indian Manufacturers for Industrial Valves?

World-Class Quality Standards Indian industrial valve manufacturers adhere to international quality standards such as API, ASME, BS, and DIN. With state-of-the-art manufacturing facilities and stringent quality checks, they ensure that the valves meet the demanding requirements of industries worldwide.

Diverse Product Range From gate valves and globe valves to butterfly valves, ball valves, and check valves, Indian manufacturers offer a wide variety of valves suitable for various applications. They also provide customized solutions to meet specific client needs, ensuring maximum efficiency and durability.

Cost-Effective Solutions One of the significant advantages of sourcing industrial valves from India is cost-effectiveness. Indian manufacturers leverage advanced technology and efficient production processes to deliver high-quality products at competitive prices, making them a preferred choice globally.

Focus on Innovation Indian valve manufacturers invest in research and development to stay ahead in the competitive market. They continuously innovate to produce eco-friendly and energy-efficient valves, catering to the growing demand for sustainable solutions.

Experienced Workforce The Indian industrial valve sector is supported by a skilled workforce with expertise in design, manufacturing, and quality assurance. Their dedication and technical know-how contribute significantly to the production of reliable and high-performing valves.

Applications of Industrial Valves

Industrial valves play a crucial role in controlling the flow of liquids, gases, and slurries across various industries. Key sectors utilizing industrial valves include:

Oil and Gas Industry: Valves are essential for managing upstream, midstream, and downstream operations, ensuring safe and efficient flow control.

Power Generation: Power plants rely on industrial valves for handling steam, water, and gas flows, contributing to optimal energy production.

Water Treatment: Valves regulate water flow in treatment plants, aiding in purification, desalination, and distribution processes.

Chemical and Petrochemical Industry: These industries require valves resistant to high pressure and corrosive materials to ensure smooth operations.

Leading Industrial Valve Manufacturers in India

India is home to several top-notch industrial valve manufacturers known for their exceptional products and services. Some of the prominent names include:

L&T Valves: Renowned for their innovative designs and reliability, L&T Valves offers a comprehensive range of industrial valves catering to diverse industries.

Kirloskar Brothers Limited: With decades of expertise, Kirloskar provides high-quality valves designed for various applications, ensuring efficiency and durability.

CRI Valves: Known for their precision engineering, CRI Valves specializes in manufacturing durable and eco-friendly valve solutions.

BHEL (Bharat Heavy Electricals Limited): A leader in industrial valve manufacturing, BHEL produces robust valves for power generation and other critical sectors.

Choosing the Right Manufacturer

When selecting an industrial valve manufacturer in India, consider the following factors:

Quality Assurance: Ensure the manufacturer complies with international quality standards and certifications.

Experience: Look for manufacturers with a proven track record and extensive industry experience.

Product Range: Opt for a company offering a wide variety of valves to meet your specific needs.

After-Sales Support: Reliable after-sales service is crucial for maintaining the performance and longevity of industrial valves.

Conclusion

Indian industrial valve manufacturers are at the forefront of delivering high-quality, cost-effective, and innovative valve solutions to industries worldwide. Their commitment to excellence and focus on sustainability make them a trusted choice for businesses seeking reliable flow control solutions. Whether you’re in the oil and gas sector, power generation, or water treatment, Indian manufacturers provide the expertise and technology you need to enhance operational efficiency and ensure safety.

For industries looking for dependable industrial valve solutions, partnering with an Indian manufacturer is a decision that guarantees quality, durability, and value.

For more information, visit us: -

Flow Diversion Valves Manufacturer

Plug Valve Manufacturer in India

Stainless Steel Sampling Valve Manufacturer

0 notes

Text

Industrial Valve Manufacturers in India

Speciality Valve is the largest Industrial valve manufacturers in India produces a wide range of valves used in various sectors like oil and gas, chemical, water treatment, power generation, and more. Valves are crucial components in controlling the flow of liquids, gases, and slurries within pipelines, tanks, and other systems. Manufacturers design and produce valves according to specific industry needs, ensuring they meet high-quality standards for durability, efficiency, and safety.

How it Works:

Valves control the flow and pressure of fluids through pipes by opening, closing, or regulating the flow based on the desired output. Depending on the design, they can be operated manually or automatically through electric, pneumatic, or hydraulic actuators. The basic operation involves a valve body, an inlet, an outlet, and a closure mechanism (such as a ball, gate, or globe). The valve’s internal components, such as seals, stem, and actuator, work together to ensure precise control.

Types of Industrial Valve

Gate Valve

Globe Valve

Ball Valve

Check Valve

Butterfly Valve

Pressure Relief Valve

Benefits:

Flow Control: Valves are integral to maintaining optimal flow in industrial systems, ensuring processes run efficiently.

Safety: Valves can help prevent overpressure, leaks, or contamination, offering safety in hazardous environments.

Energy Efficiency: Proper flow regulation reduces energy consumption and operating costs.

Customization: Manufacturers in India offer valves tailored to specific needs, allowing for versatility across industries.

Types of Industries

1. Oil and Gas Industries

2. Water and Wastewater Industries

3. Chemical Processing Industries

4. HVAC

5. Power Generation Industries

6. Marine and Shipbuilding Industries

7. Pulp and Paper Industries

8. Metallurgy and Mining industries

9. Automotive industries

Main Components:

Valve Body: The main structure that houses all internal components.

Bonnet: Covers the valve’s body and houses the stem and actuator.

Stem: Connects the actuator to the valve plug or disc, controlling the opening or closing of the valve.

Seat: The surface that seals against the valve plug to prevent leaks.

Actuator: Mechanism that operates the valve (manual, pneumatic, hydraulic, or electric).

so whenever you want connect with us as Industrial valve manufacturers in India making products that are essential in a variety of industrial applications

visit now - https://www.specialityvalve.com/

1 note

·

View note

Text

Pioneering Excellence in Industrial Valve Manufacturing Since 1977

Introduction

Prime Industrial Valves Mfg. Co., established in 1977, is a premier manufacturer of industrial valves, headquartered in Ahmedabad, India. Over the years, the company has emerged as a leader in the industrial valve sector, known for its commitment to quality, innovation, and customer satisfaction. With a robust infrastructure, dedicated R&D capabilities, and a highly skilled workforce, Prime Industrial Valves Mfg. Co. continues to set benchmarks in the industry.

Vision and Mission

Vision: To be a globally recognized leader in the industrial valve manufacturing industry, delivering innovative solutions tailored to the evolving needs of our clients.

Mission: To provide high-quality, cost-effective, and timely solutions while ensuring superior customer satisfaction and environmental sustainability.

Infrastructure and Certifications

Prime Industrial Valves Mfg. Co. operates a state-of-the-art manufacturing facility in Ahmedabad, equipped with cutting-edge technology. The facility boasts an in-house casting unit renowned for its precision and excellence. A dedicated R&D unit drives innovation and continuous improvement, enabling the company to stay ahead in the competitive market.

The company’s commitment to quality and efficiency is validated by prestigious certifications, including:

ISO 9001: For adhering to international quality management standards.

NSIC Certification: Demonstrating our capabilities as a trusted MSME partner.

IBR Certification: Ensuring compliance with the Indian Boiler Regulations.

Product Portfolio

Prime Industrial Valves Mfg. Co. offers a comprehensive range of valves and related products, tailored to meet the diverse needs of industries worldwide. Each product is manufactured from high-quality materials such as Forged Steel, Alloy Steel, Stainless Steel Valve, and Duplex Steel. Here’s an overview of the product range:

1. Gate Valves

Used in water and sewage systems, oil and gas industries, and various industrial processes, gate valves ensure reliable flow control.

2. Globe Valves

Ideal for water and wastewater systems, chemical processing, oil and gas applications, and power plants. Globe valves are designed to regulate flow effectively and withstand challenging environments.

3. Ball Valves

Widely used in water and wastewater treatment, HVAC systems, oil and gas industries, and chemical processing, Ball valves offer durability and precise control. With advanced sealing technologies, they ensure leak-proof operation.

4. Butterfly Valves

Designed for water and wastewater treatment, industrial processes, and pipelines, Butterfly Valves provide efficient flow regulation and are available in various configurations to meet specific needs.

5. Check Valves

Preventing backflow, Check valves are essential for water distribution systems, pumping stations, and fire protection systems. Their robust design ensures long-term reliability.

6. Strainers

Used in water systems, HVAC systems, industrial processes, marine applications, and petrochemicals, strainers ensure the removal of debris and particles, protecting downstream equipment.

7. Needle Valves

Perfect for laboratories, hydraulic systems, fuel systems, and aerospace industries, needle valves provide precise flow control, ensuring accuracy in critical operations.

8. Piston Valves

Used in hydraulic and pneumatic systems, chemical processing, and water treatment, Piston valves are known for their reliability and ability to handle high-pressure environments.

9. Pressure Reducing Valves

Designed for water, gas, steam, and hydraulic systems, Pressure Reducing valves regulate pressure effectively, enhancing system efficiency and safety.

10. Knife Edge Gate Valves

Ideal for wastewater treatment, mining, pulp and paper, and chemical processing, Knife Edge Gate Valves are built for rugged environments and can handle slurry and viscous media efficiently.

11. Specialized Products

Moisture Separators: For steam systems and compressed air applications, ensuring dryness and efficiency.

Blow Down Valves: For boilers and pressure vessels, helping in the effective removal of impurities.

Flush Bottom Valves: Facilitating cleaning and maintenance in industrial processes, ideal for reactors and tanks.

Steam Traps: Enhancing efficiency in heating systems, steam boilers, and autoclaves.

2-3 Way Motorized, Cylinder & Pneumatic Control Valves: Offering precision control in automation systems, designed for advanced industrial needs.

Industries Served

Prime Industrial Valves Mfg. Co. caters to a wide array of industries, ensuring customized solutions for each sector’s unique requirements. Key industries include:

Oil and Gas: Valves designed to handle high pressure and corrosive environments.

Chemical Processing: Specialized valves for handling aggressive chemicals and high temperatures.

Water and Wastewater: Solutions for efficient water management and distribution systems.

Power Generation: High-performance valves for power plants and energy systems.

HVAC Systems: Components ensuring optimal flow and temperature control.

Food and Beverage: Hygienic and durable valves for stringent industry standards.

Marine and Petrochemicals: Robust valves designed for challenging environments.

Operational Philosophy

Prime Industrial Valves Mfg. Co. operates on the philosophy of "QUALITY, COST, and DELIVERY." This ensures that every product not only meets stringent quality standards but is also cost-efficient and delivered on time to exceed customer expectations. The focus on maintaining high standards across all operations has solidified the company’s reputation for excellence.

Research and Development

Innovation is the cornerstone of Prime Industrial Valves Mfg. Co. The R&D unit is equipped with the latest technology and software tools, enabling the design and development of advanced valve solutions. Recent innovations include high-efficiency sealing systems, corrosion-resistant materials, and automation-compatible valves. Continuous research helps the company introduce new products and improve existing ones, ensuring alignment with global industry trends.

Commitment to Sustainability

As a socially responsible organization, Prime Industrial Valves Mfg. Co. is committed to environmental sustainability. The company employs eco-friendly manufacturing practices and materials, minimizing its environmental footprint while maximizing operational efficiency. Initiatives such as energy-efficient production processes and recycling programs reflect the company’s dedication to a greener future.

Global Reach and Export Capabilities

Prime Industrial Valves Mfg. Co. has established a strong presence in both domestic and international markets. Key export regions include the Middle East, Southeast Asia, Africa, and Europe. By maintaining high-quality standards and offering competitive pricing, the company has successfully built lasting relationships with clients worldwide. Customized solutions and efficient logistics ensure timely delivery, enhancing customer satisfaction.

Conclusion

Prime Industrial Valves Mfg. Co. stands as a testament to excellence in the industrial valve manufacturing industry. With a legacy of over four decades, the company has consistently demonstrated its expertise in delivering high-quality, innovative, and cost-effective solutions. Guided by its core values of quality, efficiency, and customer focus, Prime Industrial Valves Mfg. Co. is poised to continue its journey of excellence and innovation in the years to come.

youtube

0 notes

Text

CPVC Ball Valve Trusted Exporter in Nepal

KANA Valves Pvt. Ltd. is a trusted manufacturer and Exporter of CPVC Ball Valve in Nepal. KANA Valves Pvt. Ltd. is a Leading Manufacturer and Exporter of CPVC Ball Valve, UPVC Ball Valve, PVC Ball Vales & Pipe fittings products from Ahmedabad, Gujarat India. CPVC ball valves provide superior performance in fluid control, offering excellent resistance to corrosion, chemicals, and extreme conditions. These valves feature a spherical disc that ensures quick and reliable flow control with a simple quarter-turn operation, making them highly effective for a range of residential, commercial, and industrial applications. Why Choose KANA Valves Pvt. Ltd. for CPVC Ball Valve in Nepal? High Durability: Made from CPVC Ball Valve is resistant to corrosion, chemicals, and environmental wear, ensuring long-lasting performance. Efficient Fluid Control: The spherical design of CPVC Ball Valve offers quick on/off flow control, minimizing pressure loss and optimizing fluid movement. Wide Application Range: CPVC ball valves serve industries like agriculture, HVAC, aquaculture, swimming pools, and wastewater management with reliable solutions. Low Maintenance: CPVC Ball Valve are lightweight, easy to install, and require minimal maintenance, making them cost-effective over time. CPVC Ball Valve Features: Corrosion & Chemical Resistance: Manufactured using CPVC, these valves offer high resistance to corrosion and chemicals, providing long-term reliability in harsh environments. Lightweight & Easy to Install: CPVC ball valves are significantly lighter than metal alternatives, which simplifies transportation, installation, and handling. Minimal Maintenance: With their robust design, CPVC ball valves require little to no maintenance, helping reduce overall operational costs. Leak-Proof Operation: Equipped with high-quality seals and O-rings, these valves ensure a tight, leak-proof seal, preventing system leaks and damage. Affordable Solution: CPVC ball valves offer excellent value, providing a cost-effective alternative to metal valves without sacrificing quality and performance. How Does a CPVC Ball Valve Work? CPVC ball valves work by utilizing a spherical ball with a hole through its center. Turning the valve handle rotates the ball, opening or closing the flow path to regulate fluid movement. When the valve is closed, the spherical ball creates a tight seal, ensuring there is no leakage, and when open, it allows for maximum fluid flow. FAQs. Q1: What pressure ratings do CPVC ball valves have? A1: Most CPVC ball valves are rated for a pressure of up to PN10 (150 psi). However, the pressure rating can vary depending on the valve's size and design. Q2: What is the lifespan of CPVC ball valves? A2: CPVC ball valves typically last between 10 to 20 years, depending on usage and maintenance. Proper care and installation can significantly extend the life of these valves. Q3: Can CPVC ball valves be used with hot water? A3: CPVC ball valves can handle a wide range of temperatures, typically up to 93°C For higher temperatures, materials like CPVC or metal valves may be more suitable. KANA Valves Pvt. Ltd. is a CPVC Ball Valve Trusted Exporter in Nepal and including locations Kathmandu, Pokhara, Patan, Biratnagar, Birganj, Dharan, Bharatpur, Janakpur, Dhangadhi, Butwal, Mahendranagar, Hetauda, Madhyapur Thimi, Triyuga, Inaruwa, Nepalgunj, Siddharthanagar, Gulariya, Titahari, Panauti, Tikapur, Kirtipur, Tulsipur, Rajbiraj, Lahan, Birendranagar, Panauti, Gaur, Siraha, Tansen, Jaleshwar, Dipayal, Baglung, Khanbari, Dhankuta, Walin, Dailekh, Malangawa, Bhadrapur, Dadeldhura, Darchula, Banepa, Dhulikhel, Kankrabari Dovan, Hari Bdr Tamang House, Jumla, Lobujya, Bhattarai Danda, Besisahar. Contact us today to get a quote or discuss your project requirements! View Product: Click here Read the full article

0 notes

Text

Two Valve Manifold Supplier In Mexico

Baxcell is a trusted global supplier and manufacturer of valve solutions, offering two-valve manifolds, five-valve manifolds, and high-pressure ball valves. With operations in Mexico, Indonesia, Italy, and India, we provide durable, high-performance products designed for industrial applications.

0 notes