#High Pressure Hydrostatic Pump Manufacturers

Explore tagged Tumblr posts

Text

Powering Performance: Hydrojetenergy's High Pressure Hydrostatic Pump Manufacturers

Hydrojetenergy stands as a premier provider of High Pressure Hydrostatic Pump Manufacturers, offering cutting-edge solutions for various industrial applications. With a focus on innovation and quality, Hydrojetenergy manufactures pumps that excel in delivering powerful performance under demanding conditions.

Their hydrostatic pumps are meticulously designed and engineered to meet the highest standards of efficiency, reliability, and durability. Whether it's for water jet cutting, industrial cleaning, or other high-pressure applications, Hydrojetenergy's pumps are capable of delivering consistent and precise results.

Visit for more info : https://www.hydrojetindia.com/manufacturers/high-pressure-hydrostatic-pump.html

Address : Hydro Jet Energy, 29/2, Parishikhar Cottage Industrial Estate, Near Ramol Toll Plaza, SP Ring road, Ramol, Ahmedabad-382449,Gujarat,India

Mail : [email protected]

Phone no :8686862582

0 notes

Text

From Raw Material to Masterpiece: The Adventure of Stainless Steel Flanges

Stainless steel flanges are vital components in piping systems, providing a secure and leak-proof connection between pipes, valves, pumps, and other equipment. Their journey, from raw material to a finished masterpiece, is a fascinating blend of metallurgical science, advanced manufacturing techniques, and rigorous quality assurance. This article explores the intricate processes and technologies that transform raw stainless steel into high-performance flanges that drive industries worldwide.

The Importance of Stainless Steel Flanges

Versatility Across Industries

Stainless steel flanges are indispensable in industries such as oil and gas, chemical processing, water treatment, and power generation. They ensure seamless connectivity and durability, even under extreme conditions. Their resistance to corrosion, heat, and pressure makes them the preferred choice in demanding environments.

Key Properties That Define Excellence

Corrosion Resistance: The chromium content in stainless steel forms a passive oxide layer, protecting flanges from rust.

Strength and Durability: High tensile strength ensures long-lasting performance.

Hygienic and Low Maintenance: Ideal for food processing and pharmaceutical industries.

Raw Materials: The Foundation of Quality

The production of stainless steel flanges begins with the careful selection of raw materials. Stainless steel, an alloy primarily composed of iron, chromium, nickel, and molybdenum, forms the backbone of flange manufacturing.

Grades of Stainless Steel

304 Stainless Steel: Known for excellent corrosion resistance and affordability.

316 Stainless Steel: Contains molybdenum for superior performance in marine and chemical environments.

Duplex Stainless Steel: A blend of austenitic and ferritic grades for high strength and corrosion resistance.

The Manufacturing Journey of Stainless Steel Flanges

1. Melting and Casting

The process begins in electric arc furnaces where raw materials are melted at temperatures exceeding 1500°C. The molten steel is cast into large billets or slabs, which form the foundation for further processing.

2. Forging: Shaping the Flange

Forging is a critical step that gives stainless steel flanges their basic shape and strength. Using hydraulic presses, the billets are heated and hammered into desired forms. This enhances grain structure, resulting in a stronger and more reliable product.

3. Precision Machining

Once forged, the flange undergoes machining to achieve precise dimensions and surface finish. Advanced CNC (Computer Numerical Control) machines are employed to ensure consistency and accuracy, meeting international standards like ASME, ASTM, and EN.

Design and Engineering Excellence

Types of Stainless Steel Flanges

Weld Neck Flanges: Ideal for high-pressure applications.

Slip-On Flanges: Cost-effective and easy to install.

Blind Flanges: Used to seal pipe ends.

Socket Weld Flanges: Perfect for small-diameter pipes.

Threaded Flanges: Simplify installation without welding.

Each flange type is meticulously designed to serve specific industrial needs, balancing cost, performance, and installation convenience.

Heat Treatment: Enhancing Performance

Heat treatment processes, such as annealing and quenching, improve the mechanical properties of stainless steel flanges. These treatments refine grain structure, enhance corrosion resistance, and relieve internal stresses, ensuring a robust final product.

Surface Finishing: The Final Touch

Surface finishing is an essential step in flange manufacturing. Techniques like pickling, passivation, and polishing not only improve aesthetics but also enhance corrosion resistance. A polished flange is less likely to harbor contaminants, ensuring longevity and hygiene.

Rigorous Quality Control

Inspection and Testing

Stainless steel flanges undergo comprehensive quality checks, including:

Dimensional Inspection: Verifying precise measurements.

Hydrostatic Testing: Ensuring pressure handling capabilities.

Non-Destructive Testing (NDT): Detecting internal flaws without damaging the product.

Certifications and Standards

Compliance with standards like ISO 9001, ASTM A182, and ANSI B16.5 guarantees that flanges meet global benchmarks for performance and safety.

Stainless Steel Flange Manufacturers in India - Trusted Manufacturer

Riddhi Siddhi Metal Impex is a leading name among Stainless Steel Flange Manufacturers in India, known for delivering high-quality products that meet global standards. With years of expertise, we specialize in manufacturing a wide range of stainless steel flanges suitable for various industrial applications. Our dedication to precision and excellence makes us a preferred choice for customers across the globe.

As one of the most trusted SS Flange Manufacturers, we produce flanges that cater to the needs of industries like oil and gas, petrochemicals, power plants, and construction. Each product undergoes stringent quality checks to ensure durability, corrosion resistance, and optimal performance under extreme conditions.

At Riddhi Siddhi Metal Impex, we prioritize customer satisfaction by offering customized solutions to meet specific requirements. Our comprehensive range includes weld neck flanges, slip-on flanges, blind flanges, and more, all crafted using premium-grade stainless steel.

If you’re looking for reliable Stainless Steel Flange Manufacturers, Riddhi Siddhi Metal Impex is your go-to partner for superior products and unmatched service. Trust us for precision engineering, competitive pricing, and timely delivery.

For More Detail

Website: riddhisiddhimetal.com

Product: Stainless Steel Flanges Suppliers in India

Other Product: EIL Approved Pipe Fittings Suppliers in India.

#Stainless Steel Flanges Manufacturer in India#EIL Approved Flanges Manufacturers#Stainless Steel Flanges Manufacturer#Stainless Steel Flanges

0 notes

Photo

Hydrostatic Pump Repair Services in Columbia TN

### Hydrostatic Pump Repair Services in Columbia TN As industries continue to rely heavily on hydraulic systems for various applications, the demand for specialized repair services, like hydraulic valve repair Columbia, has significantly increased. Whether you're involved in agriculture, manufacturing, or construction, understanding where to find reliable hydraulic valve repair Columbia can save time and reduce operational downtime. In Columbia TN, several service providers specialize in hydraulic valve repair Columbia. They offer a range of services from routine maintenance to complete overhaul of hydraulic systems. It's crucial to maintain your equipment regularly and hydraulic valve repair Columbia is a vital component of this maintenance. Hydraulic valves are critical to the operation of any hydraulic system. They control the flow and pressure of the fluid within the system, ensuring everything operates smoothly. When these valves fail, it often results in immediate and sometimes severe consequences. That’s why having access to dependable hydraulic valve repair Columbia is imperative. If you notice any issues with your hydraulic system, the first step should be to seek professional help from technicians skilled in hydraulic valve repair Columbia. These experts have the knowledge and tools needed to diagnose problems quickly and accurately. They understand that every moment your machinery isn't working could mean lost productivity, so they work efficiently to get your hydraulic valve repair Columbia done correctly. Businesses requiring frequent hydraulic valve repair Columbia would benefit from setting up regular service schedules with their chosen provider. This proactive approach not only minimizes the risk of unexpected failures but also extends the life of the equipment. Regularly maintained valves handled through hydraulic valve repair Columbia are less likely to cause major operational disruptions. The process of finding a reliable hydraulic valve repair Columbia includes verifying their credentials and experience in handling similar hydraulic systems. Most providers offering hydraulic valve repair Columbia are well-versed with different types of valves and have a proven track record of solving complex problems related to them. Customer reviews can also guide when searching for quality hydraulic valve repair Columbia. Those who have previously engaged a provider for hydraulic valve repair Columbia can provide insights into the expertise and customer service offered by these experts. This feedback is invaluable in making an informed decision about where to take your business for hydraulic valve repair Columbia. Moreover, consider providers who use high-quality replacement parts for any hydraulic valve repair Columbia. The durability of repaired valves greatly depends on the quality of parts used. Ensuring that your service provider uses the best materials available means that repairs last longer and perform better—something particularly essential in high-stress environments where hydraulic systems are frequently used. In addition to technical capability, excellent customer service is another cornerstone of superior hydraulic valve repair Columbia. Providers that prioritize clear communication, transparent pricing, and timely completion of jobs tend to stand out in the field of hydraulic valve repair Columbia. This trait ensures not only are your valves fixed effectively but also aligns with your expectations and business timelines. Lastly, businesses should not overlook the importance of safety while performing hydraulic valve repair Columbia. Working with high-pressure systems can pose risks if not handled properly. Technicians skilled in hydraulic valve repair Columbia should abide by stringent safety protocols to ensure both their safety and the integrity of your machinery. To sum up, finding reliable hydraulic valve repair Columbia involves research, understanding your needs, and knowing what constitutes high-quality service in the realm of hydraulic services. Whether routine check-ups or emergency repairs, the right provider makes all the difference in maintaining operational efficiency and prolonging equipment lifespan. Remember to count on dependable professionals for your hydraulic services needs, especially focusing on specialized areas such as hydraulic valve repair Columbia. By adhering to these guidelines, businesses in Columbia TN can continue to thrive without being bogged down by mechanical failures or inefficient systems.

hydraulic valve repair Columbia

0 notes

Text

Parker Hydraulic Pumps for Construction Machinery

Parker hydraulic pumps provide machinery, performance, durability, and reliability specially designed for construction machinery. Whether it's powering excavators, cranes, loaders, or other construction equipment, hydraulic systems form the backbone of motion control and force application. In this field, Parker hydraulic pumps have become synonymous with excellence, delivering unparalleled functionality and resilience in even the most demanding industrial and mobile applications.

When choosing a hydraulic pump for construction machinery, it's essential to select one that not only meets but exceeds the demands of the job. Parker's range of hydraulic pumps is engineered to provide maximum efficiency, energy savings, and reliability—ensuring that construction machines remain operational under the toughest conditions.

Why Choose Parker Hydraulic Pumps?

Parker hydraulic pumps are renowned for their robust design and ability to perform under high-pressure, high-demand applications. They are a trusted choice across the construction, agricultural, and manufacturing sectors because of their superior build quality, energy efficiency, and ability to handle various hydraulic fluid types. From large excavators to compact skid steers, Parker has a pump for every machinery type, offering customizable options to meet specific operational needs.

Exceptional Functionality and Durability

Parker hydraulic pumps are designed for long-term performance, withstanding harsh environments often encountered on construction sites. Their high durability reduces downtime, translating into fewer interruptions and a lower total cost of ownership. Whether your equipment is used in demolition, excavation, or material handling, Parker pumps are up to the task.

The rugged design of Parker hydraulic pumps ensures they deliver consistent performance. Designed to handle high loads and operate for extended periods, these pumps are ideal for applications where downtime is costly.

A Versatile Range for Every Application

Parker’s extensive portfolio includes a variety of hydraulic pumps that cater to different machinery needs. These include variable displacement piston pumps, fixed vane pumps, and fixed gear pumps, each optimized for different applications. One of the standout features of Parker’s pumps is their adaptability. For construction machinery operators, this means a solution exists regardless of whether the machinery is mobile or stationary, hydraulic needs are simple or complex, or the operation is continuous or intermittent.

Here's a closer look at Parker’s hydraulic pump offerings:

Hydrostatic GOLD CUP Pumps: These pumps are designed for high-pressure applications and are commonly used in mobile and industrial operations where peak performance is a must. GOLD CUP pumps are known for their robust construction, making them ideal for challenging conditions often found in construction environments.

Piston Pumps: Parker’s piston pump range includes a wide array of models, such as the DCP series, F1 series, F12 series, and many more. These pumps are ideal for construction machinery that demands precision and high efficiency. Piston pumps from Parker are available in both fixed and variable displacement models, allowing for greater control over flow and pressure.

Gerotor Pumps: The PGG / PGG2 series gerotor pumps offer reliable and efficient performance. These pumps are often used in situations where quiet operation is essential, such as in confined spaces or environments where minimizing noise pollution is a priority.

Vane Pumps: The vane pump offerings from Parker, such as the T6 series* and T7 series*, are known for their compact design and reliable operation. Vane pumps are perfect for continuous-duty applications, providing consistent performance while reducing wear on components.

Gear Pumps: Gear pumps, like the PGP300 series, PGP517 series, and GP1 series, are excellent for low-pressure applications where simple, cost-effective solutions are needed. These pumps provide consistent flow, making them ideal for tasks like hydraulic lifting or material handling.

Each pump series is tailored to a specific need, whether for compact machinery or large-scale construction equipment, ensuring that the operator always has the right tool for the job.

Energy Efficiency and Precision Control

In today’s world, energy efficiency is not just a trend—it’s a necessity. Parker hydraulic pumps lead the way with innovative designs that focus on reducing energy consumption while maintaining peak performance. This is particularly important in construction, where fuel costs can quickly add up, and any inefficiencies can have a significant impact on the bottom line.

Parker pumps come with a range of electronic and computer control options, allowing operators to fine-tune their machines for optimal performance. Variable displacement pumps, in particular, offer precise control over flow and pressure, ensuring that hydraulic systems operate efficiently and only when necessary. This results in reduced energy consumption and less heat generation, which prolongs the life of the hydraulic components.

A Trusted Partner for Construction Professionals

Construction is an industry that relies heavily on trust. Contractors need to know that their equipment will work when they need it to, without fail. This is where Parker excels. With decades of engineering expertise and a commitment to innovation, Parker has earned the trust of construction professionals worldwide.

One of the key reasons Parker pumps are so reliable is the rigorous testing and quality control measures that go into their production. Each pump is built to withstand the toughest conditions, ensuring that it can handle everything from extreme temperatures to heavy vibration and shock. In addition, Parker offers comprehensive support and maintenance solutions, so you’re never left without help when you need it most.

NN Hydraulic India: Leading Supplier of Parker Hydraulic Pumps

NN Hydraulic India is a leading supplier of Parker hydraulic pumps. We offer an extensive range of Parker products, ensuring that construction machinery operators have access to the best hydraulic solutions available. Whether you need a specific pump model or a comprehensive hydraulic system for your machinery, NN Hydraulic India is your go-to source for top-quality products and exceptional service.

0 notes

Text

Quality Assurance Practices of Top Vertical Gland Less Pump Manufacturers

Introduction Of Vertical Gland Less Pump

In the industrial world, the reliability and efficiency of pumps are critical to the smooth operation of many processes. Vertical glandless pumps, known for their maintenance-free operation and suitability for corrosive and abrasive environments, have become a popular choice across various industries. Ensuring the highest standards of quality in these pumps is essential to meet the demands of modern industry. Top vertical glandless pump manufacturers have established rigorous quality assurance practices to guarantee that their products perform optimally and reliably under the most challenging conditions.

1. Stringent Material Selection

One of the first steps in quality assurance for vertical glandless pumps is the careful selection of materials. These pumps are often used in environments where they are exposed to harsh chemicals, high temperatures, and abrasive particles. To withstand these conditions, manufacturers use high-grade, corrosion-resistant materials such as stainless steel, Hastelloy, or various high-performance alloys. The choice of material is crucial in determining the pump's durability and longevity, and manufacturers conduct thorough tests to ensure that the materials meet the required standards for resistance to corrosion and wear.

2. Precision Engineering and Design

The design and engineering of vertical glandless pumps are key factors in their performance and reliability. Top vertical gland less pump manufacturers employ advanced computer-aided design (CAD) tools and simulation software to create pump designs that optimize flow dynamics, minimize turbulence, and reduce wear on internal components. Precision engineering ensures that the pumps operate efficiently, with minimal energy loss and reduced maintenance requirements. During the design phase, manufacturers also focus on creating pumps with compact footprints and easy installation features, which are essential for industries with limited space.

3. Rigorous Testing and Validation

Before a vertical glandless pump is released to the market, it undergoes a series of rigorous tests to validate its performance. These tests include hydrostatic pressure testing, where the pump is subjected to pressures higher than its maximum operating pressure to ensure its structural integrity. Manufacturers also perform endurance testing, running the pumps continuously for extended periods to evaluate their reliability and durability. Vibration and noise levels are also monitored, as excessive vibration can indicate potential issues with the pump’s balance or alignment. Only pumps that pass these stringent tests are approved for sale, ensuring that customers receive products of the highest quality.

4. Adherence to International Standards

Top vertical gland less pump manufacturers adhere to internationally recognized standards and certifications to ensure the quality and safety of their products. These standards, such as ISO 9001 for quality management systems and API standards for pump design and construction, provide a framework for consistent manufacturing practices and product quality. Compliance with these standards not only ensures that the pumps meet global benchmarks for performance and safety but also demonstrates the manufacturer’s commitment to delivering reliable products.

5. Continuous Improvement and Innovation

The best manufacturers understand that quality assurance is an ongoing process. They invest in research and development (R&D) to continuously improve their products and introduce innovative solutions that address emerging industry challenges. By staying at the forefront of technology, these manufacturers can offer pumps with enhanced features such as improved efficiency, reduced energy consumption, and longer service life. Continuous improvement programs often involve feedback loops from customers, allowing manufacturers to identify areas for enhancement and implement changes that further elevate the quality of their products.

6. Comprehensive Quality Control in Manufacturing

Quality assurance is deeply integrated into the manufacturing process of vertical glandless pumps. From the initial stages of raw material inspection to the final assembly, manufacturers implement stringent quality control measures at every step. Automated systems and sensors are often used to monitor critical parameters such as temperature, pressure, and flow rates during the manufacturing process. These systems can detect deviations from the desired specifications in real-time, allowing for immediate corrective actions. Additionally, manufacturers employ skilled technicians to perform manual inspections and quality checks, ensuring that every component meets the required standards before it is assembled into the final product.

7. Training and Expertise of Workforce

The expertise and training of the workforce are vital to maintaining high standards of quality in pump manufacturing. Leading manufacturers invest in continuous training programs for their employees, ensuring they are equipped with the latest knowledge and skills in pump design, manufacturing, and quality assurance. Skilled engineers and technicians play a crucial role in identifying potential issues during production and ensuring that each pump is built to exact specifications. A knowledgeable workforce is also better equipped to innovate and optimize processes, contributing to the overall quality of the final product.

8. After-Sales Support and Service

Quality assurance extends beyond the manufacturing process to include after-sales support and service. Top vertical gland less pump manufacturers provide comprehensive after-sales services, including installation support, maintenance, and troubleshooting. They offer detailed documentation, including operation manuals and maintenance guides, to help customers get the most out of their pumps. In addition, manufacturers often provide training to customers on how to operate and maintain their pumps, ensuring that the pumps continue to perform reliably over their lifespan. This commitment to customer support is a key aspect of quality assurance, as it helps prevent operational issues and extends the life of the pumps.

Conclusion

VND Plastico Pumps Pvt. Ltd. is a trusted name among vertical gland less pump manufacturers and process pump manufacturers, delivering reliable, high-performance pumps engineered to handle demanding industrial processes with efficiency and precision. Choose us for superior pump solutions. From material selection and precision engineering to rigorous testing and continuous improvement, every aspect of the manufacturing process is designed to produce pumps that deliver exceptional performance and reliability.

0 notes

Text

STAINLESS STEEL FLANGES MANUFACTURER & EXPORTER IN ABU DHABI

Abu Dhabi, the capital of the United Arab Emirates, is known not only for its oil wealth but also for its growing industrial sector. Among the industries thriving in this dynamic city is the manufacturing and export of stainless steel flanges, which play a significant role in the local economy and the global supply chain.

Why Stainless Steel Flanges?

Stainless steel flanges are essential components used to connect pipes, valves, pumps, and other equipment in a piping system. They provide a reliable means for disassembly and maintenance, ensuring the integrity and efficiency of fluid and gas transport systems. The key advantages of stainless steel flanges include:

Corrosion Resistance: Stainless steel offers excellent resistance to rust and corrosion, making it ideal for harsh environments, including those with high levels of moisture, chemicals, and salinity.

Strength and Durability: Stainless steel flanges are known for their high tensile strength and durability, ensuring a long service life even under high-pressure and high-temperature conditions.

Versatility: Available in various grades and specifications, stainless steel flanges can be customized to meet the specific requirements of different industries, from oil and gas to chemical processing and water treatment.

Leading Manufacturer & Exporter in Abu Dhabi

Abu Dhabi is home to several leading manufacturers and exporters of stainless steel flanges, known for their commitment to quality, innovation, and customer satisfaction. Among these, Metalloys International stands out for its dedication to excellence. The company leverages advanced manufacturing technologies, stringent quality control measures, and a deep understanding of industry standards to produce flanges that meet and exceed client expectations.

Advanced Manufacturing Facilities

Manufacturers like Metalloys International invest in state-of-the-art production facilities equipped with the latest machinery and technology. This enables them to produce a wide range of flanges, including:

Weld Neck Flanges: Designed for high-pressure applications and seamless welding to the pipe.

Slip-On Flanges: Easy to install and suitable for low-pressure applications.

Blind Flanges: Used to seal off the ends of pipes or valve openings.

Socket Weld Flanges: Ideal for small-diameter, high-pressure pipelines.

Threaded Flanges: Used in systems where welding is not feasible.

For more information on advanced manufacturing facilities, visit here.

Quality Assurance

Quality is paramount in the manufacturing of stainless steel flanges. Leading manufacturers like Metalloys International adhere to international standards such as ASTM, ANSI, DIN, and JIS, ensuring their products meet the highest quality benchmarks. Rigorous testing procedures, including non-destructive testing (NDT), hydrostatic testing, and dimensional inspections, are employed to verify the integrity and performance of each flange.

Learn more about quality assurance practices here.

Innovation and Customization

Recognizing the diverse needs of their global clientele, Abu Dhabi-based manufacturers like Metalloys International offer customized solutions tailored to specific project requirements. Whether it's a unique design, a special alloy composition, or a specific surface finish, these manufacturers work closely with clients to deliver flanges that precisely match their needs.

Explore innovation and customization options here.

Global Reach

Abu Dhabi's strategic location and excellent logistical infrastructure make it a hub for international trade. Leading stainless steel flange manufacturers like Metalloys International leverage this advantage to export their products to markets worldwide, including the Middle East, Asia, Europe, and the Americas. They maintain robust supply chains and partnerships with global distributors, ensuring timely delivery and reliable service.

Read more about their global reach here.

Commitment to Sustainability

In line with global trends towards sustainability, manufacturers in Abu Dhabi are also focusing on eco-friendly practices. From sourcing raw materials responsibly to implementing energy-efficient manufacturing processes and recycling waste, these companies are committed to reducing their environmental footprint.

Conclusion

Abu Dhabi's stainless steel flange manufacturers and exporters, including Metalloys International, are at the forefront of delivering high-quality, reliable, and innovative solutions to the global market. With their advanced manufacturing capabilities, stringent quality assurance practices, and commitment to customer satisfaction, they continue to play a vital role in various industries worldwide. As the demand for stainless steel flanges grows, these manufacturers are well-positioned to meet the challenges and opportunities of an evolving market.

By choosing a reputable stainless steel flange manufacturer in Abu Dhabi, businesses can ensure they receive products that not only meet their technical requirements but also contribute to the overall efficiency and success of their operations. For more information, visit Metalloys International.

#SS FLANGES MANUFACTURER IN ABU DHABI#SS 304 / 304L FLANGES SUPPLIER IN ABU DHABI#SS 310 / 310S FLANGES STOCKIST IN ABU DHABI#SS 316 / 316L FLANGES WHOLESALER IN ABU DHABI#SS 316TI FLANGES EXPORTER IN ABU DHABI#SS 317 / 317L FLANGES LEADING MANUFACTURER IN ABU DHABI#SS 321 / 321H FLANGES MANUFACTURER IN ABU DHABI#SS 347 / 347H FLANGES SUPPLIER IN ABU DHABI#SS 446 FLANGES STOCKIST IN ABU DHABI#904L FLANGES STOCKIST IN ABU DHABI#SMO 254 FLANGES STOCKIST IN ABU DHABI#SS FLANGES MANUFACTURER & EXPORTER IN ABU DHABI

0 notes

Text

High Pressure Pumps: Powering Critical Industrial Processes

High pressure pumps are essential tools across various industries, providing the necessary force to move fluids at high pressures. These pumps are designed to handle demanding applications, offering robust performance and reliability. In this blog, we will delve into the features, benefits, and applications of high pressure pumps, with a focus on the premium solutions provided by Raah International.

Understanding High Pressure Pumps

High pressure pumps are designed to move fluids at high pressures, typically exceeding 800 psi (55 bar). These pumps are critical in applications that require the transfer of liquids over long distances or the delivery of fluids at high pressures for specific processes.

Key Features of High Pressure Pumps

Robust Construction:

Made from durable materials such as stainless steel and high-grade alloys to withstand extreme pressures and harsh environments.

High Efficiency:

Engineered to operate efficiently, reducing energy consumption while delivering high performance.

Precision Engineering:

Designed with tight tolerances to ensure accurate and consistent fluid delivery.

Corrosion Resistance:

Constructed with materials that resist corrosion, extending the pump's lifespan and ensuring reliable operation in corrosive environments.

Versatility:

Capable of handling a wide range of fluids, including water, chemicals, and oils, making them suitable for diverse applications.

Types of High Pressure Pumps

Reciprocating High Pressure Pumps:

Features: Utilize a piston or plunger to move fluids, capable of generating very high pressures.

Applications: Ideal for applications such as hydrostatic testing, high-pressure cleaning, and chemical injection.

Centrifugal High Pressure Pumps:

Features: Use a rotating impeller to move fluids, suitable for continuous high-pressure applications.

Applications: Commonly used in boiler feed, reverse osmosis, and high-pressure water supply systems.

Hydraulic High Pressure Pumps:

Features: Employ hydraulic fluid to generate high pressures, offering precise control and high efficiency.

Applications: Used in industrial hydraulic systems, machinery, and equipment testing.

Diaphragm High Pressure Pumps:

Features: Utilize a flexible diaphragm to move fluids, ensuring leak-free operation.

Applications: Suitable for handling aggressive and corrosive fluids in chemical processing and water treatment.

Benefits of Using High Pressure Pumps

Enhanced Performance:

Provide the necessary force to move fluids at high pressures, essential for many industrial processes.

Energy Efficiency:

Designed to operate efficiently, reducing energy costs and improving overall system efficiency.

Durability and Reliability:

Built to withstand extreme conditions, ensuring long-lasting performance and minimal downtime.

Versatile Applications:

Suitable for a wide range of industries, from water treatment and oil and gas to manufacturing and agriculture.

Precision and Control:

Offer precise fluid control, essential for processes that require accurate pressure and flow rates.

Applications of High Pressure Pumps

Water Treatment:

Used in reverse osmosis systems, filtration, and high-pressure cleaning to ensure clean and safe water supply.

Oil and Gas Industry:

Employed in drilling operations, hydraulic fracturing, and chemical injection to enhance production and processing.

Manufacturing:

Used in processes such as cutting, cleaning, and pressure testing to ensure product quality and integrity.

Agriculture:

Essential for irrigation systems, pesticide application, and fertigation to improve crop yield and efficiency.

Automotive and Aerospace:

Utilized in component testing, fuel injection systems, and high-pressure washing to maintain performance and safety standards.

Raah International’s High Pressure Pump Solutions

Raah International offers a comprehensive range of high pressure pumps designed to meet the demanding needs of various industries. Their products are characterized by:

Advanced Technology: Incorporating the latest innovations to ensure superior performance, precision, and durability.

Robust Construction: Engineered for long-lasting reliability in demanding environments.

Custom Solutions: Providing tailored pump solutions to meet specific operational requirements and industry standards.

For more detailed information on Raah International’s high pressure pump offerings and to explore a range of products tailored to your specific needs, visit High Pressure Pump page.

0 notes

Text

High-pressure waterblasting bareshaft pump

2000 series The 2000 Series UNx bareshaft pump is the smallest pump in Jetstream’s now seven-series line. The 2000 Series was developed as a compact option for industrial applications from rig washing, petrochemical cleaning, hydrostatic testing, chemical injection, food processing and more. “The 2000 Series will undoubtedly open doors to a wide range of new applications for our bareshaft pumps,” said Jordan Koster, product and marketing manager for Jetstream of Houston LLP. “We are excited to see the jobs and projects our customers will find for this pump as the versatility and ease of maintenance it offers really is a unique new offering for this market segment.” Compatible with up to 75-horsepower engines, the pump boasts flow capabilities of 6,000 to 15,000 psi and up to 20 gpm. Its triplex plunger design consists of three crankshaft-propelled plungers, offering powerful and smooth operation on the most demanding duty cycles. UNx fluid end technology offers versatility by enabling a quick and easy three-step valve change process in the field to accommodate different pressure and flow requirements for a wide range of applications. Jetstream maximizes uptime with the 2000 Series: The packing, univalves and plungers on the pump can all be changed in the field “in five minutes or less”-so the information of the manufacturer. Operators can also adjust the water lube with a simple-to-use system, lending to optimal wear life. All parts and components are manufactured in-house in the company’s Houston, Texas facility, allowing for exceptional quality and pinpoint consistency. Jetstream prioritizes safety and the 2000 Series is no exception. A standard locking rod box cover protects both the operator and equipment while also boosting serviceability, and dual rupture discs provide pressure relief protection to prevent injury. www.waterblast.com Read the full article

0 notes

Text

Steam turbine oil analysis practices

Introduction:

The market studies done by the various analyst on “Global market analysis on Turbine oil “forecast that the global turbine oil market to grow at a CAGR of 3.498% during the period 2017-2021 and the market size has a potential to grow by 1500.05 K MT during 2020-2024, and its momentum will accelerate during the forecast period. Turbine oil manufacturers are continuously working with OEMs to provide high-performance turbine oils to meets the rising demands globally. Nowadays the industries are more focused on extending the life of both lubricants and the equipment by implementing a robust Reliability lubrication Program.

In this article, we have tried to cover the maximum information about turbine oil which could help the power generation & manufacturing industries to move further with a cost-effective sustainable solution.

Turbine & it's lubrication system:

The turbine which is the heart of the power plant extracts thermal energy from high-pressure steam and converts it into mechanical energy on a rotating output shaft. This mechanical energy is used to drive rotating equipment like pumps, compressors, fan, blower, and ultimately to drive a generator for the production of electricity.

Let’s understand a brief of oil flow along with major component and its function in the lubrication system of the turbine with the following steps:

Oil system which is composed of an oil tank (with a heater for a start-up)

Oil pumps to provide the necessary level of oil pressure

Oil coolers to dissipate the heat from the oil during operation

Oil filters to remove erosional debris from the circulating oil

Pressure control valve to regulate an exact and constant supply oil pressure to the bearings

In addition, one pressure relief valves to protect the pumps from overpressure (usually rotary type)

An accumulator for minimizing pressure surge when any operational change occurs, like switching-over between main and stand-by equipment.

A Temperature Control Valve (TCV) is provided to by-pass the coolers when the oil temperature is low, to ensure correct oil viscosity and efficient lubrication. Sometimes it is done by controlling water flow through oil coolers.

Importance of turbine oil:

In this growing modern world where electricity has become the most important part of our life and spending a day without it could slow down our lifestyle, productivity and overall impacting the global economy; then the generation of electricity indeed became fundamental to us. To meet this ever-increasing demand, power plants are delicately performing to improve their output and reliability. In the Power plants, Turbine is the most crucial machine which is the prime movers for other rotating equipment and hence the generation of electricity. Its reliability and availability critically depend on the turbine oil, which makes the lubricant selection very important part in the reliability program. However, the OEM of the turbine carefully specifies the characteristic of the lubricants, laboratory test for oil analysis and standard references for the best performance of the turbine.

Turbine oil has to undergo through an adverse condition like large temperature fluctuation, heavy load, ingress of contamination, moisture, entrained air, heat and many physical & chemical changes. Important roles of oil are cooling of bearings & journals, flushing contaminants away from rotating parts, preventing in leakage of gases, providing hydrostatic lift for shafts, actuating valves in the hydraulic circuit, and protecting lube-system internals.

Modern technologies in lubrication science show clearly a great advancement in the formulation of the turbine oil. Almost 90-95% of turbine oil is a base oil with additives making up the remaining per cent which includes antioxidants, rust inhibitors, metal deactivators, antifoam agents, demulsifier, pour depressants and antiwear additives.

To learn more visit: www.minimacsystems.com

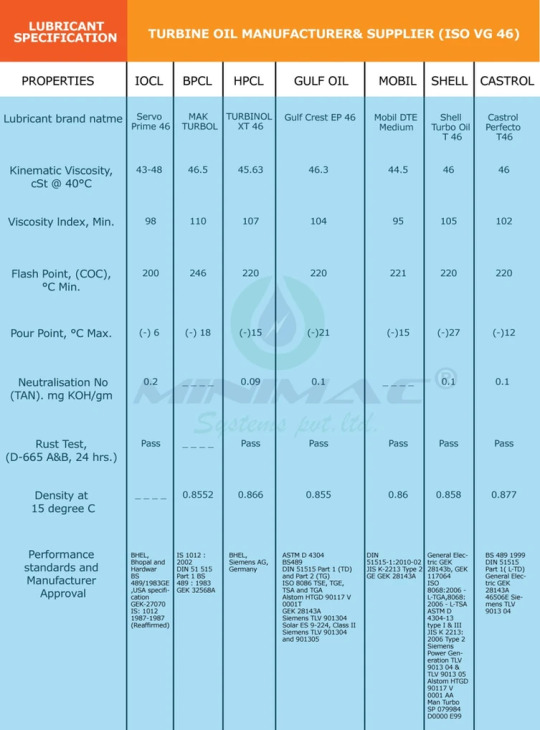

Turbine oil properties, type and brand:

Integral properties of the steam turbine oil are to allow uniform lubricating performance over a wide range of ambient and operating temperatures, to reduce hydrolysis, to reduce the formation of varnish, sludge, emulsion & entrained gas/foam, to prevent rust, minimize acid attack on copper alloy parts, improves lubricity, minimize oxidation, good oil degradation solubility improves filtration, etc. The oil which meets all these mentioned properties is of ISO VG 46.

We at Minimac study your maintenance needs and provide the best solution. We believe in Discern, Design & Deliver.

Lubricant supplier selection and brands:

Selecting a suitable supplier who can meet the performance requirement for the turbine is a vital part of the reliability lubrication program. While finalizing the vendors, many points should be considered like lubricant quality & services, technological advancement, troubleshooting support, emergency preparedness, technical support, laboratory support, price, and delivery capacity.

Turbine oil maintenance (sampling points, testing standards, testing schedule)

Sampling points:

Maximize data density of oil information

Minimize the distortion of information

Designated sampling location of primary points (return line or drain valve, elbow, turbulent area) and secondary points (anywhere on the system to isolate upstream component)

Proper frequency

Proper sampling hardware

Sample when the machine is running at normal operating temperature

Sample after flushing a small quantity of oil (0.5 - 1.0l) through the sampling point

Use only dedicated clean and dry sampling equipment intended for the sampling of used oils.

Samples should be sent to the lab or processed for on-site analysis before 24 hours from the time the sample was extracted.

To avoid leakage, fill the sample bottle to 90% capacity and ensure it is properly sealed before despatch to the laboratory.

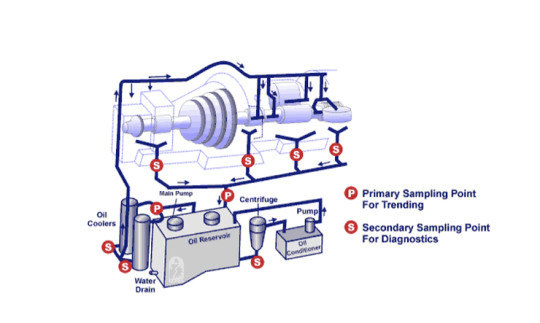

Below images are illustrating both primary sampling points and secondary sampling points of turbine lube oil system:

Primary Sampling Point: Location where regular routine oil samples are taken for monitoring and trending wear metal debris, oil condition, and oil contamination.

Testing Standards:

Power Plant lubrication monitoring is broadly specified under ASTM D4378 and ASTM D6224, and these define almost every test used to qualify lubricants for new and in-service monitoring for power plants. Following are major standards and OEM approval standards

ASTM D4378, "Standard Practice for In-Service Monitoring of Mineral Turbine Oils for Steam, Gas, and Combined Cycle Turbines"

ASTM D6224, "Standard Practice for In-Service Monitoring of Lubricating Oil for Auxiliary Power Plant Equipment", focuses on auxiliary equipment that supports power-generating turbines.

FED-STD-791D (testing method of lubricants, liquid fuels, and related products)

Ahlstom - Gas and Steam - HTGD901117

GE - Gas - GEK 32568f

GE - Steam - GEK 46506D

Solar - ES9-224

MHI - Steam & Gas - MS04-MA- CL001 and CL002

Siemens/ Westinghouse - K-8962-11

Testing schedule with standard reference:

Watch our Low Vacuum Dehydration System video: Click here

Steam turbine breakdown problems:

1. Bearing Failure Bearing & Journal related issues are one of the main causes of turbine generator outages. While faulty design or manufacturing can be occasionally responsible, the most frequent cause of these problems is improper operating conditions. A turbine trip is likely to occur when any bearing/shaft vibration reaches the trip limit. Major operational causes of accelerated wear and failure of turbine generator bearings are:

Improper lubrication (inadequate flow, dirty oil, improper oil temperature)

Excessive load (ie. the force pressing the shaft against the bearing)

Prolonged operation at high vibration levels which can result in fatigue cracking of the bearing lining.

Insufficient oil flow and pressure causes wiping off of babbitt material

Such operating conditions can result in bearing overheating, scoring, or erosion of bearing surfaces by oil contaminants, or fatigue damage.

2. Blade Failure

Turbine blade failure is a nightmare for any power player. It is another major problem and typical operational issues responsible for it are deposits, erosion, corrosion and vibration, fatigue, and manufacturing defect. The most common causes of blade failures are stress corrosion cracking and fatigue cracking due to excessive blade vibration.

Blade failure can cause large scale damage to the turbine. In the worst case, one or more of the long moving blades in an LP turbine may pierce the casing and become turbine missiles. In a less severe case, the broken blade (interfering with the motion of other blades, can shear off or bend some of them. The resultant very high vibration can destroy turbine generator bearings, seals, oil lines, etc. This type of case happened in 2014 at one of the large power generation stations in India where 600 MW LP turbine last stage blade broken at lacing wire area and subsequently damaged 5 more blades. It caused a unit outage of more than 90 days!

The serious consequences of such breakdowns, determination of the causes of bearing failure, and methods of effective repair are of paramount importance. Sublevel maintenance practices or overextending the life of the oil are also important factors for the breakdown of the turbine *A very common myth with lubrication system is that “keeping filters in line with oil circuits will prevent failures due to contamination”. This is the paradox of the situation where emergency oil supply systems bypass all the filters and obstacles in the circuit to fulfill the demand, but contaminants use it as an opportunity to fail the emergency system itself. (Bases on the facts when DC pumps started and failed due to oil contamination).

Turbine bearing failure is not only limited to bearing replacement cost and time but results in rotor damage as well. In 2017, in India, one 300 MW Chinese supplied machine encountered oil starvation during a blackout and resulted in rotor damage which further cost billions of rupee revenue loss to the company.

Consolidated turbine oil care and maintenance points:

Apart from the oil analysis, below lubrication practices should be followed for best performance of Steam Turbine:

Keep oil clean, cool, and dry

Inspect bulk delivery of new oil before acceptance

Maintain proper alignment

Perform regular oil analysis

Install high-capture-efficiency breathers

Inspect for signs of foaming and/or air entrainment

Install primary and secondary sampling points

Routinely inspect sight glasses for level, foam, and water

Keep tank headspace dry using blowers, condensers, or instrument air

Use off-line fluid conditioning for precision contamination control

Regularly inspect for varnish, especially in gas turbines

Analyze the oil periodically

Keep temperature and operation records

Install filter and strainers to retain solid contaminants

Install a multipurpose oil purification unit to prevent solid and liquid contaminants

Check oil filter cartridges or elements periodically

During inspection and overhauls, the turbine oil must be drained from the main oil tank, oil cooler, and the bearing pedestals

Reuse the oil only after ensuring all the parameters within the prescribed limits

Any small change in vibration must be considered on priority

Keep a close view on condition monitoring results and repeat the test in case of any deviation

Call +91 7030901266 for Mechanical Maintenance & Oil Check.

About the Author: Ms. Preeti Prasad associated as Technical Consultant and Business Development Manager with Minimac system Pvt Ltd. She is a chemical engineer with work experience in Oil Refinery and also providing lubrication consultancy services to many companies/sectors. She holds Level I Machine Lubrication Technician(MLT) certification through the International Council for Machinery Lubrication (ICML).

Reference Taken:

Machinery Lubrication India- Noria Corporation Ltd

Monitoring and Optimizing life of Turbine Oil by Analyst, Inc

Troubleshooting bearing and lube oil system problems by Thomas H.McCloseky

BHEL documents on Stem Turbine Maintenance and Turbine oil care maintenance

Turbine Operational Problem (module 234-14)

PDS of mentioned oil manufacturer

#oil flushing#minimac systems#frf#power#minimac#hydraulic oil#oil & gas#lube oil filter#contamination#hydraulic oil filter#lube oil flushing#transformation oil purification#transformers#electrostatics lube cleaner#coalescer separator#metal#mining#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre

1 note

·

View note

Text

Applications of Ebara High-Pressure Pumps

Ebara High-Pressure Pumps are versatile and engineered to excel in a wide array of industrial applications. Their precision and reliability make them indispensable for various fluid handling challenges. Let's explore the diverse applications where Ebara High-Pressure Pumps play a crucial role:

I. Water Treatment:

Reverse Osmosis Systems:

Ebara pumps are instrumental in reverse osmosis processes, efficiently desalinating seawater and purifying water for drinking or industrial use.

Ultrafiltration and Nanofiltration:

High-pressure pumps are utilized in membrane filtration processes, ensuring the effective removal of contaminants in water treatment applications.

Boiler Feedwater Systems:

Ebara pumps play a key role in supplying high-pressure feedwater to boilers in power plants, enhancing energy efficiency and preventing scale buildup.

II. Manufacturing and Processing:

Injection Molding Machines:

High-pressure pumps are used in injection molding processes, providing the required pressure for precise and efficient plastic molding.

Metal Forming and Cutting:

Ebara pumps support metal forming operations by delivering high-pressure coolant for metal cutting and shaping processes.

High-Pressure Cleaning:

In industrial cleaning applications, Ebara pumps excel in providing the high-pressure water needed for effective cleaning of surfaces and equipment.

III. Oil and Gas Industry:

Wellhead Injection:

Ebara pumps contribute to wellhead injection processes, facilitating the injection of chemicals or fluids into oil wells for enhanced recovery.

Hydrostatic Testing:

High-pressure pumps are utilized for hydrostatic testing of pipelines and equipment in the oil and gas industry to ensure structural integrity.

IV. Power Generation:

Steam Generation Systems:

Ebara pumps play a vital role in supplying high-pressure water to steam generation systems in power plants, contributing to efficient power production.

Cooling Water Circulation:

High-pressure pumps assist in circulating cooling water through heat exchangers, ensuring optimal temperature control in power generation facilities.

V. Chemical and Petrochemical Processes:

Chemical Injection Systems:

Ebara pumps are employed in chemical injection systems for precise dosing of chemicals into various processes, ensuring accurate and controlled reactions.

Reactor Cooling:

In petrochemical plants, high-pressure pumps are used for reactor cooling, maintaining optimal temperatures in chemical reactions.

VI. Mining and Minerals Processing:

Slurry Transport:

Ebara pumps are utilized in transporting high-pressure slurry in mining and minerals processing, facilitating efficient ore extraction and processing.

Hydraulic Fracturing (Fracking):

In the oil and gas industry, high-pressure pumps play a role in hydraulic fracturing processes, injecting fluids into reservoirs to enhance oil and gas recovery.

VII. Food and Beverage Industry:

High-Pressure Homogenization:

Ebara pumps contribute to high-pressure homogenization processes in the food and beverage industry, ensuring uniform product quality and texture.

Pasteurization Systems:

High-pressure pumps are employed in pasteurization systems, playing a crucial role in the preservation and safety of food products.

VIII. Research and Development:

Laboratory and Scientific Applications:

Ebara high-pressure pumps find application in laboratories and research facilities, supporting experiments and processes that require precise fluid handling at elevated pressures.

IX. Fire Protection Systems:

High-Pressure Fire Suppression:

Ebara pumps are utilized in high-pressure fire suppression systems, ensuring reliable and efficient delivery of water in emergency situations.

The applications of Ebara High-Pressure Pumps span across a multitude of industries, underscoring their versatility, efficiency, and reliability. From critical processes in water treatment to enhancing productivity in manufacturing, Ebara pumps continue to be indispensable components powering industrial progress. For more info contact Ebara Pump Suppliers in UAE or call us at +971 4 2522966.

0 notes

Text

Rent Triplex Plunger Pumps: Use and Advantage of Renting this Machine

Triplex plunger pumps are powerful and efficient devices used in a wide range of industries for high-pressure fluid transfer applications. Renting Triplex Plunger Pumps is Great option for project owners rather than buying the machine.

In this article, we will explore the various uses of triplex plunger pumps and examine the advantages of renting them instead of buying. By presenting a comparison chart and table, we will help you make an informed decision that aligns with your specific needs and budget.

I. The Uses of Triplex Plunger Pumps:

Triplex plunger pumps are versatile workhorses, offering precise control and delivering high-pressure performance in a wide range of applications.

Oil and gas industry: Well stimulation, pressure testing, and pipeline cleaning.

Manufacturing sector: High-pressure cleaning, hydrostatic testing, and metal forming.

Construction and mining: Concrete pumping, water jetting, and dust suppression.

Agriculture and irrigation: Spraying, fertilizing, and crop irrigation.

Municipal applications: Sewer jetting, street cleaning, and firefighting.

II. Comparison: Renting vs. Buying Triplex Plunger Pumps

Advantages of Renting

Flexibility: Renting allows for easy access to the latest pump models and technologies.

Cost savings: Renting eliminates the need for maintenance, repairs, and storage costs.

Project-specific needs: Renting enables you to select the ideal pump for each project's requirements.

Expert support: Rental providers offer technical assistance and guidance for optimal pump performance.

Scalability: Renting allows you to easily scale up or down based on project demands.

Disadvantages of Buying

Capital investment: Buying a triplex plunger pump requires a significant upfront investment.

Maintenance responsibility: Owning a pump entails maintenance, repairs, and associated expenses.

Limited utilization: If the pump is not regularly used, owning it can be cost-inefficient.

Equipment obsolescence: Owning a pump means bearing the risk of technology advancements making your pump outdated.

Resale challenges: Selling a used pump may be challenging, especially in a competitive market.

III. Renting vs. Buying Comparison Chart:

Conclusion:

Renting a triplex plunger pump offers numerous advantages over buying one. It provides flexibility, cost savings, access to the latest technologies, expert support, and scalability. By renting, you can optimize your pump selection for each project and eliminate the hassles of maintenance, repairs, and equipment obsolescence.

Consider your specific requirements, utilization patterns, and budgetary constraints to make an informed decision that suits your business needs.

Remember to conduct a thorough cost analysis and consult with reputable rental providers to ensure you choose the most suitable option for your high-pressure fluid transfer application

#pinakins#constructionequipment#heavymachinery#heavyequipment#constructionmachinery#Triplex Plunger Pumps

1 note

·

View note

Text

Leading High Pressure Hydrostatic Pump Manufacturers: Amarflourmill

Amarflourmill specializes in being High Pressure Hydrostatic Pump Manufacturers, offering top-of-the-line solutions for various industrial applications. These pumps are meticulously designed and engineered to provide reliable, high-pressure performance in hydrostatic systems.

As leading manufacturers in this field, Amarflourmill prioritizes quality, precision, and durability in their products. Their High Pressure Hydrostatic Pumps are crafted using advanced technology and premium materials to ensure optimal efficiency and long-term reliability.

Visit for more info : https://www.hydrojetindia.com/manufacturers/high-pressure-hydrostatic-pump.html

Address: Hydro Jet Energy, 29/2, Parishikhar Cottage Industrial Estate, Near Ramol Toll Plaza, SP Ring road, Ramol, Ahmedabad-382449,Gujarat,India

Mail: [email protected]

Phone no: 8686862582

0 notes

Text

LPG Bobtail Tank

We want the LPG Bobtail Tank to have the most economical and very durable longevity, as everyone wants it. First of all, of course, we implement the security measures very strictly. All our tanks are subjected to hydrostatic pressure in the best way. Connections of tank accessories are checked and tested. All parts are tested according to manufacturing standards. The truck transport tanker is equipped with a delivery pump. Depending on demand, LPG meter is installed or not. Being a second class tank, it has a production capacity of 10m³-34m³. The products it can carry are: LPG, Propane, Butane. The building material series is made of pressure door steel. Its general height is max 2350mm and width is max 2350. Our tank provides high efficiency and durability.

1 note

·

View note

Text

How to choose best Different Types of Pumps According to Its Usage

The hydrostatic test pumps and equipment are mainly driven by a variety of engines and pressure. These types of pumps are completely portable and are used in order to test the irrigation lines. These pumps are mainly used for boilers, casting parts, pressure vessels, CI mains, gas cylinders, pipes along with tube parts, and are subject to hydro test pressure. The special features of these kinds of pumps include running on an electric motorised driven system, have an entirely enclosed drive mechanism, a heavy-duty precision gear box along with a large air chamber, self-oiling system with quick acting relief valve. This kind of pump is dependable, reliable and ensures a efficient performance. The standard accessories of these pumps are mainly made of stainless steel while the pressure release cock is made of brass metal. The optional accessories that are found with this pump are ware the water tank with water capacity of close to 50 litres made of mild steel metal, a suction hose of about 1 mtr long, a pump trolley with four wheels and a pulley guard made of mild steel.

Also known as hydrodynamic pump or a dynamic pressure pump, a centrifugal pump functions according to the principle of centrifugal force which is easy to install as well as to repair. These kinds of pumps are used in the rubber, textile, chemical, laminate industries and the power stations. These pumps are also in the places where fertilizers and water desalination plants are present. These pumps have versatile shaft sealing arrangements, standard gland packing and the option to use a mechanical seal, comes in three bearing design that offers good results with high productivity, closed impeller to ensure easy removal for inspection and maintenance purposes. The pumps have modular construction, facilities of high interchangeability and fast delivery. The standard pumps are made of grey cast iron cast steel and Hastelloy for the special designs.

An air operated barrel pump is mainly portable in nature and suitable for 200L or 220L, is smaller in size and of light weight. These pumps are mainly used for carrying gasoline, vegetable oil, alcohol, hydraulic oil, acid, engine oil, diesel oil, etc. The major characteristics of these types of pumps include a capacity of one litre output per rotation of 100 litres per minute, net weight of not more than 6 kgs and made with aluminium, zinc plated steel tube. Because of its portability nature, these pumps are suitable for the transfer of low viscosity fluid types such as gasoline and kerosene.

Ceracin is in Gujarat, India base ISO 9001:2008 Certified Company which manufacturing and supplying industrial pumps like Centrifugal Pump supplier, Hydrostatic Test Pump, Barrel Pump Manufacture in Gujarat etc., For more information please call us and mail.

For More Information visit Our social Media Pages:

Facebook

Twitter

Instagram

Linkedin

Google Map Listing

1 note

·

View note

Text

Leading Butterfly Valve Manufacturer: Quality and Durability Guaranteed

Butterfly valves are an essential component in many industrial applications, controlling the flow of liquids and gases with precision and efficiency. As a leading butterfly valve manufacturer, we understand the importance of providing high-quality and durable products that can withstand even the most demanding conditions.

In this blog, we will discuss the features and benefits of our butterfly valves, as well as the manufacturing process that ensures their reliability.

Introduction to Butterfly Valves and Their Importance in Industrial Applications

Butterfly valves are a type of quarter-turn valve that uses a circular disc to regulate the flow of a fluid. The disc is mounted on a shaft that runs through the valve's body, and when the shaft is rotated, the disc either blocks or opens the flow of the fluid. Butterfly valves are known for their simplicity, durability, and cost-effectiveness, making them an ideal choice for a wide range of industrial applications.

Butterfly valves are used in many industries, such as oil and gas, water treatment, power generation, and chemical processing. They are often used in pipeline systems, pump stations, and other equipment that requires precise flow control.

Why Choose Our Butterfly Valves Over Others on the Market

At our company, we pride ourselves on the quality and durability of our butterfly valves. We use only the best materials and manufacturing techniques to ensure our valves meet or exceed industry standards. Our valves are designed to withstand extreme temperatures, pressures, and corrosive environments, making them ideal for use in a wide range of applications.

In addition to their durability, our butterfly valves are also known for their easy maintenance and repair. They are designed with a simple and robust construction, making them easy to disassemble and reassemble, even in the field.

The Manufacturing Process: Ensuring Quality and Durability

We have a strict quality control process that ensures our butterfly valves are manufactured to the highest standards. Our team of experienced engineers and technicians use the latest technology and manufacturing techniques to ensure that each valve meets or exceeds industry standards.

Our manufacturing process begins with the selection of high-quality raw materials, which are then precision machined to ensure they meet our exacting specifications. The valves are then assembled by our skilled technicians, who use the latest welding and brazing techniques to ensure a secure and leak-free connection.

Finally, our valves undergo a thorough testing process to ensure they meet or exceed industry standards for performance and durability. We conduct hydrostatic and pneumatic tests to ensure the valves can withstand the pressures and temperatures they will encounter in the field.

Our Wide Range of Butterfly Valves and Customization Options

We offer a wide range of butterfly valves to meet the needs of any industrial application. Our standard valves are available in a variety of sizes and pressure ratings, and we also offer custom valves that can be tailored to meet the specific requirements of your application.

In addition to our standard and custom valves, we also offer a variety of customization options, such as actuators, limit switches, and positioners. These options allow you to tailor the valve to your specific needs and ensure it performs to your exact specifications.

In conclusion, as a leading butterfly valve manufacturer, we understand the importance of providing high-quality and durable products that can withstand even the most demanding conditions. By using the best materials.

0 notes

Text

Vacuum Truck Operator

The purchase price for a specialised oilfield vacuum truck is dependent upon the scale of its tank, its working capacity, as nicely any further gear it is outfitted with. That is why it's difficult to supply a uniform estimate of how much totally different variants of these trucks would cost without having the required information on the truck itself. Pipeline excavation can be extraordinarily dangerous if not carried out correctly using the most effective methods.

It can be necessary to watch tank temperature gauges and tank pressure gauges . Tank degree indicators must be monitored to avoid overfilling the tank. Our gear breadth, seasoned specialists, and built-in vacuum truck oilfield community of areas across North America collectively deliver superior service and unmatched effectivity to our clients. Dig in at customtruck.com and sustain with us on Facebook, Instagram, and Twitter.

Drive to varied locations, attach hoses to load and unload freshwater, use pump and transport to frac pits and prepare paperwork for billing. YP - The Real Yellow PagesSM - helps you find the best native companies vacuum truck oilfield to fulfill your specific wants. Search results are sorted by a mixture of factors to provide you a set of decisions in response to your search standards.

Whatever your meant use for a vacuum truck, you wish to ensure you buy it from a dependable producer in Houston and the close by area. Curry Supply is here to provide entry to completely different options in your particular necessities. Reach out to us at present and we advise you on the specialized truck to purchase. We have Backhoe companies in our in depth list of oilfield services. Get low pressure in addition to high pressure pumping services from us.

Jimmy was promoted to Project Supervisor prior to accepting the position of Press Vac Sales Representative for KVS Transportation in 1999. Over the following 6 years Jimmy helped create price efficient tank cleaning methods that allowed KVS customers to develop aggressive cleaning schedules which resulted in increased manufacturing. In 2005 after being promoted to Press Vac Department Manager, he decided to observe his ardour of vacuum trucks and accepted a place as Dispatcher. A rising development in North America is the usage of industrial vacuum vans on the construction web site. Hydro excavation trucks and trailers are ideal for precise excavation and underground utility daylighting.

Hydrostatic Oil Tools has a extensive array of apparatus to help in many downhole operations together with drill string accessories, drilling instruments, drilling tubulars, fishing tools, handling instruments and production equipment. Get the results you deserve with this quality providers, specializing in safety, efficiency and respect within vacuum truck oilfield the communities we work. Let our qualified team of professionals convey their experience and know-how with them on every job. Experience what set Tri-State Vacuum & Rental, LLC aside in every means. We have a quantity of frac tanks available to provide liquid and solid storage on your oilfield worksite. By checking this field and clicking the "Send me job offers" button below.

Gloxco offers a variety of quality but inexpensive hose and pipe fittings to fulfill your each want. We sit up for meeting all your oilfield waste elimination and trucking wants. When spills occur, you want an organization you can rely on to reply shortly and deal with the emergency with the eye it deserves. We ship the mandatory gear and instruments to the location of the spill and start the remediation at your instruction. We can safely and effectively recover waste merchandise and remove residual contamination.

0 notes