#Henan Huaxing Cable

Explore tagged Tumblr posts

Text

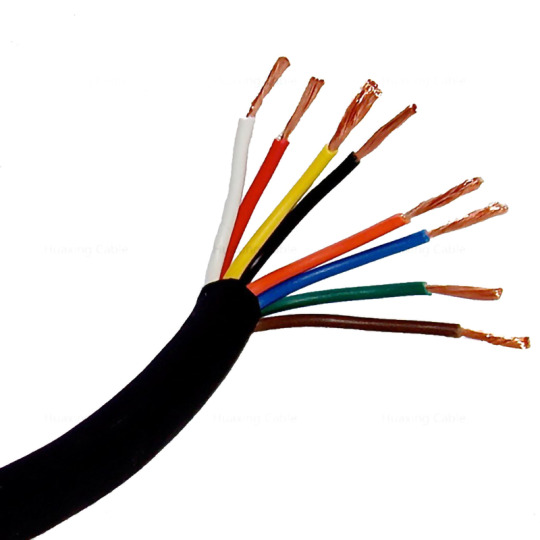

The main products of Huaxing Cable are AAC/AAAC/ACSR/ACAR Conductor, overhead bunched cable (ABC cable),Control cable, concentric cable, low voltage and medium voltage power cable, plastic wire, solar power cable, protection cable, etc.

We have also passed ISO9001 quality system, ISO14001 environment system, OHSAS18001 occupational health system, CCC national product certification. And so on; We can also produce wire and cable products according to IEC, ASTM, BS, DIN, AS, CSA, JIS, KS and other standards to meet the specific needs of customers.tection cable, etc.

0 notes

Text

What Should Be Paid Attention To During The Cable Laying Process?

Power cables are also referred to as cables in broad sense. Cables in a narrow sense refer to insulated cables, which can be defined as: a collection of the following parts; one or more insulated cores, and their respective coatings , The total protective layer and the outer protective layer, the cable can also have additional conductors without insulation. The main characteristics of Henan Huaxing Wires and Cables production of this type of products are: pure conductor metal, no insulation and sheath, such as steel core aluminum stranded wire(ACSR), copper aluminum busbar, electric locomotive wire, etc.; the processing technology is mainly pressure processing, such as Smelting, calendering, drawing, stranding/squeezing stranding, etc.; products are mainly used in suburbs, rural areas, user main lines, switch cabinets, etc. Wire products used to transmit electrical (magnetic) energy, information and realize electromagnetic energy conversion.

1. Special personnel should be assigned to manage and command unified leadership when laying cables. Before the job, the person in charge of the job technology or the commander-in-chief shall explain the job environment requirements, contact signals and safety precautions to all student job designers in the enterprise. Operation staff should have a clearer division of labor, collaborate with each other, and be dedicated to their responsibilities. When working in residential areas and near the development of highways and railways, special personnel are required to supervise and supervise the operations. The wells shall be set up with signs of “construction ahead, vehicles bypassing”, and red lights shall be set at night.

2. When laying cables, choose a hard and flat ground to support the cable shaft. The screw jack bracket used should be flexible, strong, safe and reliable to rotate, and ensure that the end face of the cable shaft is vertical and the reel is horizontal when the cable shaft is raised and lowered. After removing the cable shaft protection plate, keep it in a centralized manner to prevent nails from hurting people's feet.

3. When the cable is laid in the trench, the operator should pull the cable to the bottom of the trench by hand or shoulder. At the bend, the operator must stand on the outside of the cable to avoid being lifted by the cable, and keep his hands away from the upper mouth to avoid touching his fingers. Gloves must be worn when laying cables.

4. When laying cables, ensure that the bending radius of the cable is within the allowable range at all times.

5. When laying cables in the ditch, the debris in the ditch should be cleaned up first. Hard and sharp objects are not allowed in the sand; when laying along the wall or overhead, it must be firmer, more stable and reliable. Overhead laying should follow the overhead and line design and construction Relevant information security management regulations.such as laying overhead ACSR cable 336.4MCM.

6. The number of cable tunnels laid in the same trench. This is the running project that needs to be moved on the cable. In addition to the approval of the person in charge of the electrical appliances, on-site safety measures and hand orders must be formulated. The length of the moving cable should not exceed 100 Micrometers. 10kV and charging cable movement is prohibited from above. During the movement, the bending radius of the cable must be guaranteed within the allowable range.

7. When working with cable heads, use blowtorch or open flame heating system should have a fire prevention management measure. Flammables, chemical learning materials and oil should be properly kept and kept away from major heat sources.

8. When handling cable glue during operation, protective gloves should be worn; when handling heated cable glue, use a barrel with a mouth and a lid, and care should be taken not to splash or tip over the glue when transferring it. In addition to wearing sleeves, Wear long-sleeved overalls, shoe covers, and masks when necessary.

9. When filling the cable glue at a high place, we are not allowed to stand below, and the operation management personnel should wear protective glasses. When heating control cable glue or molten lead, you should wear masks, gloves and shoe covers, and stand on the windy side of the world. Measures should be taken on site to prevent the occurrence of water droplets in the cable glue; when taking molten lead liquid with a spoon , The spoon should be preheated first to avoid splashing lead liquid.

10. The plastic cable that must melt slowly is warm, and violent fire is prohibited. It cannot be heated into a container by brazing. The mouth of the container should be covered to avoid overflow.

11. In the production of epoxy cable heads, when drying the quartz powder, you must wear a mask, and you must wear protective management glasses and medical data gloves when preparing the pharmaceutical liquid. The on-site construction ventilation system must be good and operated on the wind side of the market. When the skin can come into contact with the amine curing agent, it should be wiped off with water, rinse and alcohol immediately. If you find that you are dizzy or tired, you should immediately start to leave the company site and rest in a ventilated place.

0 notes

Text

As a representative of the wire and cable industry in the field of photovoltaic power equipment, Henan Huaxing Wire and Cable Co., Ltd. participated in this exhibition and brought the company's core product - a new material aluminum alloy Solar Cable. This is a high-end new material alloy photovoltaic cable integrating technology research and development, professional certification, production and processing, green energy saving, and 5G digital intelligent system application. Through the unique heat treatment technology, the elongation rate of the product can reach 25%, which is far higher than the 10% elongation rate standard required by UL in the United States. The comprehensive performance has a leading advantage in the country and even in the world.

0 notes