#Heavy Structural Fabrication Companies in India

Explore tagged Tumblr posts

Text

Spearheading Industrial Structural Fabrication: E S HAJI & CO in India

In the realm of industrial development and infrastructure, structural fabrication plays a pivotal role in bringing architectural visions to life. Among the cadre of Heavy Structural Fabrication Companies in India, E S HAJI & CO stands out as a cornerstone of excellence, offering top-tier solutions in Industrial Structural Fabrication.

Spearheading Industrial Structural Fabrication: E S HAJI & CO in India

Proficiency in Structural Fabrication Companies in India

E S HAJI & CO boasts a wealth of expertise in industrial Structural Fabrication. Their skilled workforce, coupled with advanced technology, enables them to fabricate heavy structural components with precision and finesse. From towering steel frameworks to intricate industrial components, their craftsmanship ensures robust and enduring structures.

Catering to Diverse Industries

What sets E S HAJI & CO apart is their ability to cater to a spectrum of industries. Whether it's construction, oil and gas, power plants, or infrastructure development, their comprehensive structural fabrication services encompass diverse project requirements. They specialize in adapting their expertise to suit the unique demands of each sector.

Stringent Adherence to Quality Standards

At the core of their operations lies an unwavering commitment to quality. E S HAJI & CO upholds stringent quality standards throughout the fabrication process. Each structural component undergoes rigorous inspections and quality checks, ensuring compliance with industry benchmarks for strength, durability, and safety.

Technological Prowess and Innovation

Innovation and technological integration are key pillars of E S HAJI & CO's success. They invest in cutting-edge machinery and continually refine their fabrication techniques to stay at the forefront of the industry. This dedication to technological advancement not only enhances efficiency but also allows them to undertake complex structural projects with ease.

Client-Centric Approach

E S HAJI & CO places immense value on building strong client relationships. Their approach revolves around collaboration, open communication, and understanding clients' unique needs. This client-centric ethos ensures that each project is executed with precision, meeting and often exceeding client expectations.

Conclusion

E S HAJI & CO's legacy in industrial structural fabrication exemplifies their commitment to excellence, innovation, and client satisfaction. As a leading player among structural fabrication companies in India, their ability to deliver superior structural solutions across various sectors stands as a testament to their expertise.

For industries seeking reliable, heavy structural fabrication, E S HAJI & CO emerges as the prime choice. With a track record of quality, comprehensive services, technological adeptness, and a client-focused approach, they continue to shape India's industrial landscape through exemplary structural fabrication.

#Industrial Structural Fabrication#Heavy Structural Fabrication Companies in India#Structural Fabrication Companies in India#Structural Fabrication

0 notes

Text

How Staffing Solutions Support Workforce Requirements in Ahmadabad Manufacturing and Textile Sectors

In today’s evolving economy, staffing has emerged as a critical element in managing workforce dynamics across various sectors. With industries undergoing technological shifts and facing increasing demand cycles, businesses need flexible yet reliable manpower solutions. Staffing plays a key role in bridging the gap between workforce availability and organizational demand. From short-term project needs to long-term hiring plans, staffing allows companies to scale their workforce based on market requirements. In cities with strong industrial footprints like Ahmedabad, where manufacturing and textile sectors dominate, the availability of skilled manpower can make or break operational efficiency. A strategic staffing plan ensures that the right candidates fill the right roles at the right time. Companies can focus on production targets and strategic growth when staffing partners handle recruitment, screening, and placement. Staffing also helps reduce costs associated with hiring mistakes and lengthy recruitment processes. As the manufacturing and textile industries in Ahmedabad continue to expand, staffing has moved from being a support function to a core business enabler. The ability to quickly adapt to labor fluctuations while maintaining quality has made staffing a smart choice for forward-thinking businesses in this competitive landscape.

Ahmedabad has long stood as a cornerstone of India’s manufacturing and textile prowess. With hundreds of small and large units driving production, the demand for a consistent and capable workforce remains high. This is where Staffing Solutions Services in Ahmedabad have become a vital link between employers and skilled labor. These services go beyond just filling vacancies. They analyze market trends, study labor supply, and offer customized hiring strategies that align with each company’s operational goals. In the textile sector, for example, where seasonal demand often peaks, staffing partners offer temporary and contract-based manpower without compromising on skills or productivity. In the heavy manufacturing segment, where precision and compliance are paramount, staffing providers ensure that recruits undergo training and background checks before placement. Moreover, staffing firms help reduce attrition by continuously engaging with candidates and managing performance feedback. Many factories in Ahmedabad have improved their efficiency and reduced downtime simply by collaborating with staffing services that understand the local employment landscape. Whether a company needs machine operators, production supervisors, or quality control staff, these staffing partners deliver tailored workforce solutions that keep operations running smoothly.

The workforce structure in Ahmedabad has undergone a visible transformation in recent years. Increasing mechanization and production capacity in sectors like garments, chemical engineering, and plastics have led to more nuanced job roles. To meet these evolving demands, Staffing Agencies in Ahmedabad have expanded their offerings significantly. They now offer specialized recruitment services, payroll management, compliance handling, and on-site staffing support. These agencies have access to extensive talent databases and utilize advanced screening tools to ensure optimal candidate matching. For example, when a textile exporter requires workers skilled in advanced weaving machinery, a staffing agency can source, train, and deploy such talent with minimal turnaround time. Similarly, for a steel fabrication unit needing workers with safety training certifications, staffing partners handle verification and documentation. The local knowledge of these agencies gives them an edge, allowing them to address labor gaps efficiently and with cultural sensitivity. In the face of rising competition from other industrial regions, these staffing agencies help Ahmedabad-based companies maintain workforce stability without bearing high hiring overheads. By outsourcing hiring needs to these professional agencies, businesses can focus on operational excellence while maintaining workforce agility.

The concept of workforce customization has become increasingly important for businesses looking to maintain output quality and control costs. Staffing Services in Ahmedabad now offer highly tailored workforce solutions that reflect the operational rhythms of each industrial unit. For example, textile businesses that experience fluctuating demand across seasons can benefit from staffing solutions that align hiring with peak periods. These services allow them to increase labor capacity quickly and reduce it when needed, without dealing with the burden of full-time employment liabilities. Manufacturing companies that work on export orders often face tight deadlines. In such scenarios, staffing providers ensure that trained workers are available on short notice to handle rush orders. Staffing services also include productivity monitoring, shift scheduling, and post-placement support, which enhances worker retention and performance. Some providers even manage worker accommodations and transport in remote industrial clusters. As a result, both productivity and worker satisfaction increase. The quality of output remains consistent, and businesses benefit from lower absenteeism. For companies that operate across multiple units in Ahmedabad, staffing providers also ensure centralized reporting and workforce tracking. This level of workforce customization would be difficult to achieve without professional staffing support.

Ahmedabad’s leading manufactures and textile firms increasingly rely on the Top Staffing Companies in Ahmedabad to drive long-term operational success. These companies offer more than basic hiring assistance. These companies offer more than basic hiring assistance. They become strategic partners who understand business goals, align workforce strategies accordingly, and contribute to improved KPIs. These top firms bring sector-specific insights, whether it’s understanding the productivity benchmarks of a textile mill or the safety standards required in a chemical plant. They also invest in skill development and training initiatives to ensure that the available talent pool remains updated. Many of these top staffing companies collaborate with industrial associations to forecast manpower needs and create proactive hiring pipelines. Their technology-enabled platforms allow employers to track attendance, productivity, and performance in real-time. Moreover, their expertise in labor laws and regulatory compliance ensures that employers remain audit-ready. By offering a full range of services from temporary staffing to permanent recruitment, these top-tier companies play a crucial role in helping Ahmedabad industries scale efficiently. As competition intensifies and operational margins narrow, aligning with experienced staffing companies is no longer optional-it is a necessity for growth-focused businesses.

Seven Consultancy stands as a benchmark in the staffing and recruitment industry, offering end-to-end human resource solutions with a focus on both quality and efficiency. With over 15 years of experience and a wide-reaching presence across PAN India and globally, the consultancy has built a reputation for delivering reliable staffing services. Their ability to identify top talent with the right skills and attitude ensures clients achieve their organizational goals effectively. The consultancy’s strength lies not only in temporary and contractual staffing but also in offering complete HR management solutions that streamline recruitment and workforce operations. This efficiency leads to enhanced client satisfaction and productivity. Their dedicated team of professionals provides tailored advice and compliance support across multiple industries, ensuring all hiring standards are met seamlessly. Recognized among the Best Temporary Staffing Agencies in India, Seven Consultancy consistently exceeds client expectations through personalized attention, industry expertise, and an unwavering commitment to service excellence. Whether it is for short-term roles or long-term staffing needs, they offer the right talent pool across various domains, including skilled and unskilled labor. Clients can rely on their professionalism, responsiveness, and deep understanding of market demands, making it a trusted partner for all staffing requirements.

#staffingagency#temporarystaffingservices#contractstaffingcompaniesinmumbai#payrolloutsourcing#payrolloutsourcingcompaniesinindia#thirdpartypayroll#temporary staffing services

0 notes

Text

Benefits of Using Carbon Steel ERW Pipe

When structural steel is being selected to build a house or be used industrially then the correct grade is to be picked. ASTM A500 Grade C is one of the most reliable ones. It is mostly applied in steel tubing, columns and structures due to its durability and performance. At the steel India Company, we tend to advise our clients on the reasons as to why Grade C is unique. This blog should help you realize why this grade is different and why it is more desirable to be used in hard applications in various industries.

Increased Strength (Structural)

The greatest feature is the strength of ASTM A500 Grade C. It has high yield and tensile strength compared to ASTM A500 Grade A, and ASTM A500 Grade B. This makes it a perfect fit as far as heavy-structural applications are concerned where the steel must support heavy load or resist bending.

It is commonly applied in buildings, bridges and towers. The additional strength provides additional support and durability. Grade C performs better structurally than the general alternatives such as Carbon Steel ERW Pipe or A106 Grade B pipe when they are compared.

Uniform Form and Facility of Manufacture

Grade C is a uniform shape and size ASTM A500. This assists in easy cutting, bending and welding. The installation process can be saved by builders and fabricators. It is also used to provide stability throughout the structure particularly in cases where large frames or columns are constructed.

The steel is welding friendly to techniques such as MIG or Tig Welding without any jagged joins. Although other materials such as api 5l grade b Pipe or a333 grade 6 Pipe could be satisfactory in pressure lines, Grade C is constructed more with shapes and support of loads in mind.

Affordable and Readily Accessible

The cost-efficiency of ASTM A500 Grade C is also an additional reason why this material is popular. It is high performance at a reduced cost compared to certain stainless or alloy alternatives. As an example, although stainless steel pipe suppliers in india and alloy steel pipe suppliers can provide corrosion proof pipes the same are costlier and usually applicable in chemical or marine installation.

Grade C is a cost effective general construction solution. Many carbon steel pipe manufacturers in India widely stock it and this means that you do not have to wait long to get it delivered. You have quality and speed all in a single package.

Multi-purpose in Other Industries

Buildings are not the only buildings that use ASTM A500 grade C. They are applied in agriculture, oil fields, frames of machines and even sign posts. It is strong and bendable to numerous purposes because of its strength and shape. Use of Grade C Grade C is also used due to its weldability and load capabilities by industries which usually use S275JR Steel Pipe, S355JRH Pipe or YST 310 Pipe.

Grade C is a good base even in coated applications. It goes hand in hand with 3LPE Coated Pipes and��FBE Coated Pipe and is durable in the open air.

Conclusion

In Steel India Company, we provide reliable and certified ASTM A500 Grade C steel to any project that requires reliability and strength. Its distinguishing characteristic is that it is strong and can be easily shaped and cheap. It is also suitable in most industries and does not cause any problem to complex structures.

Be it in comparison to ASTM A234 WPB, Stainless Steel 304 Pipe or any other material Grade C comes out as a viable and cost effective performer. We guarantee that you get the correct grade at the required time.

0 notes

Text

Leading the Way in Illumination: Mactec – A Trusted High Mast Pole Manufacturer

In the modern world, infrastructure plays a pivotal role in urban development, public safety, and community well-being. One crucial element that often goes unnoticed yet significantly impacts visibility and security is high mast lighting. These towering structures are vital for illuminating highways, stadiums, airports, ports, and large public areas. Among the top players in this niche sector, Mactec has emerged as a trusted and innovative high mast pole manufacturer, setting new standards in quality, durability, and performance.

Mactec’s Expertise and Excellence

With years of experience and a strong commitment to engineering excellence, Mactec has earned a reputation for delivering high mast poles that are not only structurally sound but also technologically advanced. Their manufacturing process adheres to strict quality controls, ensuring every pole meets national and international standards such as IS, BSEN, and ASTM.

Each Mactec high mast pole is designed using high-grade steel and fabricated with precision to withstand harsh weather conditions, seismic impacts, and heavy loads. The company invests in cutting-edge technology and skilled manpower to create poles with superior galvanization, corrosion resistance, and long service life.

Customization and Versatility

Understanding that different projects have different requirements, Mactec offers customized solutions to meet specific client needs. Whether it's a smart city project requiring advanced lighting systems or a remote port that needs extra-tall poles for wide-area coverage, Mactec provides tailored designs with varying pole heights, platform types, and headframe options.

Their team of engineers works closely with clients from the design phase to final installation, ensuring seamless integration with existing infrastructure. Mactec also provides options for motorized winch systems and remote control mechanisms to simplify maintenance and enhance operational efficiency.

Applications and Global Reach

Mactec high mast poles are widely used in a range of applications, including:

National and state highways

Industrial zones and power plants

Airports and seaports

Railway yards and logistic hubs

Sports stadiums and public parks

With a growing presence across India and expanding export operations, Mactec’s products are trusted by government bodies, urban planners, contractors, and multinational corporations alike.

Commitment to Sustainability

In today’s environmentally conscious landscape, Mactec is not just about robust infrastructure but also about sustainable solutions. Their poles are compatible with LED fixtures, solar lighting systems, and energy-efficient controls. This focus on green technology aligns with global efforts to reduce carbon emissions and create smart, energy-saving cities.

Why Choose Mactec?

Choosing the right manufacturer can make a significant difference in long-term project success. Mactec’s high mast poles offer:

Superior strength and finish

Precision engineering and design customization

On-time delivery and reliable support

Proven performance in diverse conditions

In conclusion, Mactec stands out as a leading high mast pole manufacturer, combining technical expertise with customer-centric service. Whether you're looking to illuminate a vast stretch of highway or a busy logistics terminal, Mactec offers a solution built to last and perform.

Visit:- https://www.mactec.in/high-mast-pole.html

#flag mast pole manufacturer#puf sandwich panels manufacturer#octagonal pole manufacturers#conical pole manufacturer#high mast pole manufacturer

0 notes

Text

🔧 Elevate Your Culinary Efficiency with South India’s Leading Commercial Kitchen Equipment Manufacturer

When it comes to building a powerful and efficient kitchen, Dhanya Trading Company stands as one of the Top Commercial Kitchen Equipment Manufacturers in South India. Whether you're running a 5-star hotel, managing a cloud kitchen, or launching your first café, our equipment is engineered for speed, hygiene, and heavy-duty use. Clients across Tamil Nadu trust us for custom stainless steel kitchen solutions that meet the highest standards of durability and design.

From commercial dosa plates to SS sink tables, tandoors, and multi-burner stoves, Dhanya Trading Company crafts equipment that’s tailored for modern Indian kitchens. With years of expertise, we ensure every piece we deliver enhances workflow and withstands high-volume usage. Join the growing list of satisfied chefs and hoteliers who rely on our premium-grade tools for seamless operations.

🏢 Start Smart with Full-Scale Kitchen Setup Services in Tamil Nadu

Looking to launch or revamp your food business? Dhanya Trading Company offers Professional Kitchen Setup Services in Tamil Nadu, including layout design, chimney planning, gas line installation, and equipment fitting. Our team understands food flow, staff movement, and ventilation — giving you a commercial kitchen that's safe, efficient, and space-optimized.

Whether you're in Madurai, Coimbatore, Salem, or Trichy, our experts handle end-to-end execution, right from consultation to commissioning. Cloud kitchens, restaurants, and canteens trust us for our structured project delivery and expert support. With Dhanya Trading Company, you get a kitchen that’s compliant, cost-effective, and built for performance.

💡 Budget-Friendly Commercial Kitchen Tools for Startups & Cafes

Small restaurants and food trucks don’t have to compromise on quality anymore. Dhanya Trading Company is known for supplying Affordable Commercial Kitchen Tools in Tamil Nadu that suit every budget without compromising durability. We offer a wide range of kitchen essentials like idli steamers, vegetable choppers, hot cases, chapati warmers, and wall-mounted racks — all made from food-grade stainless steel.

Perfect for cafés, college canteens, and mess halls, these tools are easy to maintain, rust-free, and long-lasting. Our clients love the value-for-money solutions we provide, making it easier for new entrepreneurs to scale up as their business grows. Buy once, use for years — that’s the Dhanya Trading Company promise.

🔥 Go Big with Heavy-Duty Industrial Kitchen Equipment in India

Running a high-volume kitchen? Then you need Heavy-Duty Kitchen Equipment in India built to withstand the heat of continuous cooking. Dhanya Trading Company manufactures industrial-standard products like bulk cookers, SS storage racks, and high-capacity burners used by top wedding caterers and manufacturing units.

Each product goes through strict quality checks for safety, temperature control, and load-bearing strength. Our robust commercial gas stoves and ovens are trusted by caterers across India who cannot afford downtime. Cook smarter, faster, and safer with Dhanyass — your partner in performance.

🏬 Visit Our Commercial Kitchen Equipment Showroom in Madurai Today!

Want to see and feel the equipment before you buy? Visit our Commercial Kitchen Equipment Showroom in Madurai where you can explore our complete product line with expert guidance. Try out live demos, compare features, and get immediate stock availability for your urgent needs.

Whether you're setting up a new kitchen or upgrading an old one, our showroom is a trusted destination for hoteliers, mess owners, and industrial buyers across Tamil Nadu. We also offer custom fabrication based on your layout or requirement. With over 100+ models on display, finding the right fit has never been easier.

📞 Contact Dhanya Trading Company – Your Trusted Kitchen Equipment Partner:

✅ +91 92455 56074 ✅ +91 90251 56074 ✅ +91 98946 35445 ✅ +91 99948 25445 ✅ +91 73581 56074 🌐 https://dhanyasscommercialkitchenequipmentsmanufacturer.in/

0 notes

Text

Heat Resistant PTFE Mesh Belt Suppliers & Exporters

Industry is the leading PTFE mesh belt manufacturer in India as well as the supplier of high performance belts to industry. Our PTFE mesh belts can perform in heat, chemicals and heavy loads as well. Food processing, textile, printing and packaging industries are a perfect fit for our PTFE mesh belts.

So, what is a PTFE Mesh Belt?

PTFE mesh belts consist of fiberglass and PTFE-coated (Teflon). They consist of an open mesh design that allows the free flow of air or heat, ideal for drying, curing and heat uses. PTFE mesh belts are heat-resistant, durable, and non-stick, thus ideal for long runs in any industrial use.

Key Benefits and Features

The PTFE mesh belts at TP Industry are fabricated to prime importance, with regard to strength. They can withstand high heat up to 260°C and have good release characteristics. The open mesh structure allows for increased air flow for drying or cooling. They are easy to clean, relatively lightweight, and consistent life expectancy. We can provide both standard size and fabricated PTFE mesh belts as per requirements.

Why choose TP Industry?

TP Industry are trusted suppliers and premier PTFE Mesh Belt manufacturers whose primary focus is innovation, quality, and customer service. We employ the finest raw materials along with our advanced equipment and seasoned engineers to produce our belts that either surpass or meet industry standards. We provide competitive prices, timely delivery, and complete technical support to our clients. If you are in the food, textile, electrical or any other related industry that needs PTFE mesh belts TP Industry is your company.

0 notes

Text

Aditya Steels: A Leading Name Among SS Pipe Manufacturers in India

In the modern industrial world, stainless steel (SS) pipes are critical components across a wide range of sectors — from construction and oil & gas to pharmaceuticals, food processing, and water treatment. Their strength, resistance to corrosion, and versatility make them the preferred choice for high-performance systems. As the demand for high-quality SS pipes grows, Aditya Steels has earned its place as one of the most trusted SS pipe manufacturers in India, offering premium solutions backed by technology, expertise, and reliability.

The Role of SS Pipes in Modern Industry

Stainless steel pipes are widely used due to their:

Corrosion resistance

High tensile strength

Long lifespan

Temperature and pressure tolerance

Ease of fabrication and welding

These properties make them suitable for critical environments, including:

Chemical plants

Water distribution systems

Structural and architectural applications

Food-grade and hygienic facilities

Heavy-duty industrial machinery

Choosing the right SS pipe manufacturer ensures not just the quality of materials, but also the success and safety of entire operations — and that’s where Aditya Steels comes into the picture.

Aditya Steels: Manufacturing with Precision

Aditya Steels has built its reputation over years of dedication to excellence in stainless steel manufacturing. As a recognized SS pipe manufacturer, the company combines cutting-edge manufacturing capabilities with a strong focus on quality assurance and customer satisfaction.

Their SS pipes are engineered to meet the stringent requirements of modern industries, adhering to international standards such as ASTM, ASME, and DIN.

Advanced Manufacturing Facilities

Aditya Steels operates state-of-the-art manufacturing facilities equipped with:

Automatic tube mills

Seamless pipe production lines

Precision welding machines

High-accuracy cutting and sizing equipment

In-house testing and inspection laboratories

This infrastructure allows Aditya Steels to manufacture a broad range of stainless steel pipes in various shapes (round, square, rectangular), grades, diameters, wall thicknesses, and lengths. Whether for general usage or highly specialized industrial purposes, the company offers tailor-made solutions.

Product Range and Grades

Aditya Steels offers SS pipes in a variety of grades to meet diverse industry requirements:

SS 304 / 304L: General purpose, food-grade applications

SS 316 / 316L: Marine and chemical processing environments

SS 310 / 310S: High-temperature applications

SS 202: Cost-effective choice for architectural and structural projects

These pipes are available in:

Seamless and Welded Varieties

ERW (Electric Resistance Welded) Pipes

Polished and Unpolished Finishes

Each pipe is crafted to ensure high performance, structural integrity, and longevity.

Quality Control and Testing

Aditya Steels believes in delivering zero-defect products. A rigorous quality control system is in place at every stage of manufacturing. The testing process includes:

Chemical composition analysis

Dimensional accuracy check

Surface inspection

Hydrostatic and pressure testing

Non-destructive testing (NDT), if required

Each product is delivered with detailed test reports and certifications, ensuring complete transparency and confidence for buyers.

Industries Served

As one of the top SS pipe manufacturers in India, Aditya Steels supplies stainless steel piping solutions to a wide array of industries, including:

Oil & Gas and Petrochemicals

Construction and Real Estate

Pharmaceutical and Biotech

Food and Beverage Processing

Power and Energy

Marine and Offshore Engineering

These sectors depend on Aditya Steels’ pipes for their high resistance to corrosion, precision, and long operational life.

Why Choose Aditya Steels?

Aditya Steels isn’t just another manufacturer — it’s a partner in industrial growth. Here's why businesses across India and abroad choose Aditya Steels:

High-quality, standard-compliant products

Custom manufacturing as per project needs

Reliable and timely delivery

Competitive pricing and value-driven solutions

Dedicated technical support and after-sales service

Whether you’re sourcing pipes for a small fabrication job or a large-scale industrial project, Aditya Steels offers consistent quality and professional service.

Commitment to Sustainability

In line with global sustainability goals, Aditya Steels adopts eco-friendly manufacturing practices and promotes the use of recyclable materials. Stainless steel itself is a 100% recyclable material, making it a responsible choice for environmentally conscious industries.

Conclusion

As industries move toward stronger, cleaner, and more efficient operations, the need for trusted SS pipe manufacturers continues to grow. Aditya Steels has emerged as a leader in this space by combining technical excellence with a customer-first mindset.

Whether your needs are industrial, architectural, or process-specific, Aditya Steels delivers stainless steel pipes that stand the test of time.

Visit:- https://www.adityasteels.in/

0 notes

Text

Comprehensive Guide to Sheet Metal Works and Fabrication Companies in Bangalore

Summary

Bangalore is a leading hub for sheet metal and heavy fabrication, offering advanced, cost-effective, and customized solutions across industries with skilled labor, modern technology, and quality-focused companies.

Introduction

Bangalore, often hailed as the Silicon Valley of India, is not just a hub for IT and technology but also a thriving center for manufacturing and industrial services. Among the many services flourishing here, sheet metal works in Bangalore and heavy fabrication form the backbone of multiple industries, including automotive, construction, aerospace, and infrastructure. If you’re looking for reliable fabrication companies in Bangalore to meet your manufacturing or structural needs, understanding the landscape of sheet metal and heavy fabrication services in the city is essential.

What is Sheet Metal Work?

Sheet metal work involves the cutting, bending, and assembling of thin metal sheets to create parts and structures used across various industries. The metals commonly used include steel, aluminum, copper, and brass. Sheet metal fabrication is critical for producing durable components that are lightweight yet strong, making it ideal for applications ranging from ductwork and roofing to automotive panels and electronic enclosures.

Key Processes in Sheet Metal Works

Cutting: Methods like shearing, laser cutting, and plasma cutting are used to accurately slice sheet metal into desired shapes.

Bending: Using press brakes or rollers, sheet metal is bent into angles or curves.

Forming: Processes like stamping and punching create holes or specific shapes.

Assembling: Welding, riveting, or fastening the pieces to build complete components.

Why Bangalore for Sheet Metal Works?

Bangalore hosts a vast network of fabrication companies in Bangalore that specialize in sheet metal works. The availability of skilled labor, advanced machinery, and proximity to industries that demand precision fabrication makes the city an ideal location for this work. The city’s fabricators can handle everything from small batch custom orders to large-scale industrial projects.

Leading Fabrication Companies in Bangalore

Fabrication companies in Bangalore are known for their expertise in delivering quality metal products. These companies offer a variety of services, including:

Sheet metal fabrication: Custom cutting, bending, and shaping metal sheets.

Structural steel fabrication: Manufacturing of beams, columns, and frameworks for construction.

Heavy fabrication: Production of large and heavy metal structures like tanks, pressure vessels, and industrial equipment.

Custom fabrication: Tailored fabrication services based on client designs and requirements.

Many companies combine traditional craftsmanship with modern technology such as CNC machines and robotic welding to ensure precision and efficiency. Their ability to deliver within tight deadlines while maintaining quality standards has made them a preferred choice among clients.

Heavy Fabrication Companies in Bangalore

Heavy fabrication involves working with large metal components that require specialized handling, welding, and finishing. This type of fabrication is critical for sectors like infrastructure development, shipbuilding, and heavy machinery manufacturing. Heavy fabrication companies in Bangalore provide services including:

Fabrication of structural steel for bridges, buildings, and factories.

Manufacturing heavy machinery parts such as frames, supports, and chassis.

Producing industrial vessels and storage tanks.

Custom heavy metalwork based on engineering designs.

These companies invest heavily in equipment capable of handling massive metal sheets, plates, and beams, along with skilled welders and fabricators trained in complex fabrication processes.

Benefits of Choosing Bangalore-Based Fabrication Companies

Skilled Workforce: Bangalore’s fabrication industry is powered by highly skilled engineers, welders, and technicians with expertise in the latest fabrication techniques.

Technological Advancements: Many companies employ CNC machines, laser cutters, and robotic welders to improve precision and reduce turnaround times.

Competitive Pricing: The competitive landscape ensures cost-effective solutions without compromising on quality.

Wide Range of Services: From light sheet metal works to heavy fabrication, clients can find comprehensive solutions under one roof.

Quality Compliance: Reputed companies adhere to international quality standards like ISO, ensuring durable and safe fabricated products.

Applications of Sheet Metal Works and Fabrication in Bangalore

Automotive Industry: Sheet metal components are vital in vehicle body parts, exhaust systems, and chassis fabrication.

Construction: Structural steel frameworks and roofing materials are fabricated using sheet metal and heavy fabrication services.

Aerospace: Precision sheet metal parts for aircraft components require advanced fabrication techniques.

Electronics: Enclosures, cabinets, and racks made from sheet metal protect sensitive electronic equipment.

Manufacturing Equipment: Heavy fabrication companies supply machinery frames and custom parts essential for industrial manufacturing.

How to Choose the Right Fabrication Company in Bangalore

Selecting the right fabrication company is crucial for the success of your project. Here are a few tips:

Experience and Expertise: Look for companies with a proven track record in sheet metal and heavy fabrication.

Technology and Equipment: Ensure the company uses up-to-date machinery and technology.

Quality Certifications: Check for ISO or other relevant certifications.

Customization Capabilities: The ability to handle custom designs and specifications is vital.

Customer Reviews and References: Feedback from past clients can provide insight into reliability and service quality.

Delivery and Support: Timely delivery and after-sales support can significantly impact your project timeline.

Future Trends in Fabrication Industry in Bangalore

With increasing demand for precision engineering and custom manufacturing, Bangalore’s fabrication sector is evolving rapidly. Integration of Industry 4.0 technologies such as IoT-enabled machinery, AI-driven quality control, and automation are set to enhance productivity and quality further.Sustainability is another focus area, with companies adopting eco-friendly practices like recycling scrap metal, using energy-efficient equipment, and minimizing waste.

Conclusion

Bangalore’s industrial landscape is greatly supported by efficient and innovative fabrication companies in Bangalore offering everything from intricate sheet metal works in Bangalore to large-scale heavy metal fabrication. Whether you are in construction, automotive, aerospace, or any other industry requiring metal fabrication, Bangalore has trusted companies capable of meeting your exact needs.

Choosing the right fabrication partner ensures high-quality products, timely delivery, and cost-effective solutions, giving your business a competitive edge. With its skilled workforce, advanced technology, and strategic location, Bangalore remains a top choice for metal fabrication services in India.

FAQ

1. What is the difference between sheet metal work and heavy fabrication?

Sheet metal work deals with thin metal sheets (usually under 6mm) that are cut, bent, and assembled to create lightweight components like enclosures, panels, and ducts. Heavy fabrication, on the other hand, involves thicker metals and large-scale structures like industrial tanks, building frameworks, and machine parts.

2. Which metals are commonly used in sheet metal fabrication in Bangalore?

The most commonly used metals include:

Mild steel

Stainless steel

Aluminum

Brass

Copper These metals are chosen based on the application, strength requirements, and corrosion resistance.

3. Can fabrication companies in Bangalore handle custom or small-batch orders?

Yes, many companies specialize in custom fabrication and are equipped to handle both small-batch prototypes and high-volume production, depending on client needs.

4. What certifications should I look for in a fabrication company?

Reputable fabrication companies usually have:

ISO 9001 for quality management

ASME certification for pressure vessel fabrication

EN/ISO 3834 for welding quality Certifications ensure the company follows international standards for safety, quality, and processes.

5. What industries do sheet metal and heavy fabrication companies in Bangalore serve?

Fabrication companies serve a wide range of industries, including:

Automotive

Aerospace

Construction and Infrastructure

Electronics

Power and Energy

Industrial Manufacturing

6. How do I choose the right fabrication company for my project?

Consider the following:

Years of experience and industry expertise

Type of machinery and technology used (CNC, laser, robotic welding)

Quality certifications

Portfolio of past work

Customer feedback and references

Timely delivery and post-sales support

7. Do companies in Bangalore offer design and prototyping services?

Yes, many advanced fabrication companies offer CAD/CAM design, engineering consultation, and prototyping services to help clients finalize their designs before mass production.

#sheet metal works in bangalore#fabrication companies in bangalore#heavy fabrication companies in bangalore#custom sheet metal fabrication

0 notes

Text

Flux Core Wire: A Reliable Welding Solution by Superon

In the ever-evolving world of welding, choosing the right consumables is key to achieving precision, strength, and efficiency. One such essential component in modern welding processes is the flux core wire. Known for its versatility and performance, flux core wire is widely used across industries such as construction, shipbuilding, fabrication, and automotive repair. As a trusted name in the welding industry, Superon offers premium-grade flux core wires that meet the demanding needs of professionals around the globe.

What is Flux Core Wire?

Flux core wire, or flux-cored arc welding (FCAW) wire, is a tubular wire filled with flux. When it melts during the welding process, the flux produces a shielding gas and slag, which protects the weld from atmospheric contamination. This makes it ideal for outdoor welding and high-speed applications, even in challenging environments.

There are two main types of flux core wires:

Self-Shielded Flux Core Wire (FCAW-S): Does not require external shielding gas. Perfect for outdoor or windy conditions.

Gas-Shielded Flux Core Wire (FCAW-G): Requires a separate shielding gas for higher quality welds and is typically used indoors.

Advantages of Using Flux Core Wire

At Superon, our flux core wires are engineered to deliver superior performance, even in harsh conditions. Here are the key benefits:

High Deposition Rates: Increases productivity with faster welds and minimal downtime.

Excellent Penetration: Ideal for thick materials, heavy-duty structures, and multi-pass welding.

Works Well Outdoors: Particularly useful in windy environments where gas-shielded MIG welding may fail.

All-Position Welding: Certain types of flux core wire support flat, vertical, horizontal, and overhead welding.

Reduced Cleanup: Although it forms slag, it peels off easily, leaving behind clean welds.

Applications Across Industries

Superon’s flux core wire is used in a variety of sectors, thanks to its efficiency and adaptability:

Structural Steel Fabrication: For buildings, bridges, and heavy steel frameworks.

Shipbuilding: Suitable for thick metal plates and complex joint configurations.

Automotive Repair and Manufacturing: Offers speed and strength for chassis and structural parts.

Pipeline Welding: Provides deep penetration and strong welds for critical infrastructure.

General Maintenance and Repair: A go-to solution for on-site welding jobs in tough conditions.

Why Choose Superon Flux Core Wire?

As one of the leading welding consumable manufacturers in India, Superon delivers exceptional quality and performance in every product. Our flux core wires are developed using advanced technology, ensuring consistent wire feeding, stable arcs, and superior weld strength.

ISO-Certified Manufacturing

Complies with AWS and BIS Standards

Engineered for Low Spatter and Smooth Arc Performance

Available in Various Sizes and Specifications

Backed by Strong Technical Support and R&D

Final Thoughts

If you're looking for a robust, versatile, and cost-effective welding solution, flux core wire from Superon is the ideal choice. Designed for both indoor precision and outdoor endurance, our products deliver unmatched quality in every weld. Whether you're a small-scale fabricator or a large infrastructure company, Superon’s flux core wire ensures strength, efficiency, and reliability in every job.

Get in touch with Superon today to learn more about our complete range of welding solutions.

0 notes

Text

Heavy Structural Fabrication Companies in India

Eshaji & Co is one of the leading industrial structural fabrication and heavy structural fabrication companies in India. Established in 1989, the company has become one of the most trusted structural fabrication companies in India. The company provides a wide range of services including design, fabrication and installation of steel structures. Eshaji & Co has a team of highly experienced and qualified professionals who can provide the best solutions for any kind of fabrication work. They use the latest technologies and advanced machinery to ensure that the fabrication work is done perfectly. The company also provides on-site supervision and inspection of the fabrication work to ensure that the highest quality standards are maintained. The company offers a wide range of services for industrial structural fabrication. These include the design, fabrication and installation of steel structures for industrial plants, warehouses, factories, bridges, airports, stadiums and other large structures. The company also provides heavy structural fabrication services for large buildings such as shopping malls, hotels, and other large-scale structures. Eshaji & Co is committed to ensuring the safety and quality of its products and services. The company has a team of highly experienced and qualified professionals who ensure that the fabrication work is done perfectly. The company also provides on-site supervision and inspection of the fabrication work to ensure that the highest quality standards are maintained. Eshaji & Co is one of the leading industrial structural fabrication and heavy structural fabrication companies in India. With its commitment to quality and safety, the company is the preferred choice for many industrial and heavy structural fabrication projects.

#Industrial Structural Fabrication#Heavy Structural Fabrication Companies in India#Structural Fabrication Companies in India#Structural Fabrication

0 notes

Text

Superior High-Quality Aluminium Sheet Manufacturer in India

Inox Steel is one of the trusted Aluminium Plates Manufacturers in India, offering a wide range of high-quality Aluminium Plates suitable for diverse industrial uses. As a leading Aluminium Plates Supplier, the company focuses on precision, durability, and consistency. These plates are designed to perform under high stress and demanding conditions, making them ideal for sectors like aerospace, construction, marine, and heavy machinery.

Known as a reliable Aluminium Plates Supplier in India, we ensure prompt delivery and top-grade materials that meet national and international standards. Our range is suitable for fabrication, transportation, and structural applications. As a top Aluminium Plates Manufacturer and Aluminium Sheet Manufacturer in India, we prioritise quality and customer satisfaction, making us a preferred choice across industries looking for dependable aluminium solutions.

We offer specialised products like 6082 Aluminium Plates, catering to high-performance and aerospace-grade requirements. For engineers and planners, our Aluminium Angles Weight Chart and Aluminium Plates Weight Chart provide accurate weight data for precise planning.

We are also a leading Aluminium Pipes Manufacturers in India, supplying robust and reliable components.

To know more, visit Inox Steel

#Aluminium Plates Manufacturers in India#Aluminium Plates Manufacturer#Aluminium Plates#Aluminium Plates Supplier

0 notes

Text

Faith PEB’s Role in Revolutionizing Industrial Turnkey Projects in Ahmedabad

In recent years, Industrial Turnkey Projects in Ahmedabad have witnessed a remarkable transformation, thanks to the growing demand for faster construction timelines, cost efficiency, and quality execution. Leading this revolution is Faith PEB, a trusted name in the pre-engineered building (PEB) industry. With a strong commitment to innovation, quality, and customer satisfaction, Faith PEB has positioned itself as a game-changer in Ahmedabad’s industrial infrastructure development.

Understanding Turnkey Projects in the Industrial Sector

Turnkey projects are comprehensive solutions where a single contractor takes complete responsibility for designing, constructing, and delivering a fully operational facility. For industrial setups, this approach is highly beneficial as it reduces the complexity of dealing with multiple vendors, accelerates project timelines, and ensures better accountability. Ahmedabad, being one of India’s fastest-growing industrial hubs, has seen a rapid increase in the demand for turnkey project solutions — especially in sectors such as manufacturing, logistics, pharmaceuticals, food processing, and automotive.

Why Faith PEB is a Preferred Choice

Faith PEB has emerged as a reliable partner for companies looking to set up industrial facilities through turnkey solutions. What sets Faith PEB apart is its end-to-end expertise — right from concept development, architectural and structural design, fabrication, civil works, to final installation and commissioning. The company follows a customer-centric approach, ensuring that every project is aligned with the client’s business objectives, budget, and timeline.

Faith PEB specializes in pre-engineered building structures, which significantly reduce construction time without compromising on quality or safety. These structures are manufactured in a controlled environment and assembled at the site, leading to faster delivery and better project management. For turnkey industrial projects, this method offers unmatched advantages.

One-Stop Solution for Industrial Construction

Faith PEB simplifies the entire project journey by serving as a single point of contact. Clients no longer need to coordinate with multiple contractors or suppliers. From soil testing, civil foundations, and PEB fabrication to HVAC, electricals, plumbing, and even interior work, every element is managed by Faith PEB’s experienced team. This integrated approach not only ensures better coordination but also enhances the overall efficiency and cost-effectiveness of the project.

Moreover, Faith PEB utilizes modern design tools like CAD and 3D modeling, which allow clients to visualize the final structure before actual construction begins. This reduces design errors, improves planning, and ensures that the final facility meets all operational needs.

Customized Solutions for Diverse Industries

Every industrial sector has unique requirements, and Faith PEB understands this well. Whether it’s a high-load warehouse, a temperature-controlled food processing unit, or a heavy-manufacturing facility, the company tailors its turnkey solutions to suit specific operational needs. Their design and engineering teams work closely with clients to factor in space utilization, workflow optimization, safety regulations, and energy efficiency.

Faith PEB also pays attention to the sustainability aspect. The company promotes the use of recyclable steel, energy-efficient building designs, and environment-friendly practices — aligning its offerings with global green building standards. This makes their turnkey solutions not only practical but also future-ready.

Timely Delivery with Quality Assurance

One of the key reasons behind Faith PEB’s success in Industrial Turnkey Projects in Ahmedabad is its unwavering commitment to timely delivery. In the industrial sector, time is money, and any delay can mean loss of revenue. Faith PEB mitigates this risk by adopting well-structured project management methodologies, robust procurement strategies, and a skilled in-house workforce. The company’s quality assurance protocols ensure that each component — from steel structures to electrical installations — meets the highest industry standards.

Faith PEB also believes in transparent communication with clients. Regular updates, progress reports, and review meetings ensure that the client remains in control and fully informed throughout the project lifecycle.

Building a Stronger Industrial Ecosystem in Ahmedabad

By offering high-quality turnkey industrial solutions, Faith PEB is not just constructing buildings — it’s helping businesses scale faster and smarter. The company’s contribution extends beyond the physical infrastructure. It plays a vital role in boosting Ahmedabad’s economy by enabling faster industrialization, attracting investments, and creating job opportunities.

Ahmedabad is becoming a preferred destination for industries due to its strategic location, connectivity, and supportive government policies. Faith PEB is capitalizing on this growth trend by supporting entrepreneurs, SMEs, and large corporations with reliable and scalable infrastructure solutions.

Conclusion

As the demand for rapid and reliable industrial infrastructure continues to grow, the need for expert turnkey partners becomes critical. Faith PEB stands out as a trusted name in Industrial Turnkey Projects in Ahmedabad, delivering innovative, efficient, and customized solutions that empower industries to thrive. By combining technical excellence with a client-focused approach, Faith PEB is revolutionizing how industrial spaces are built in Ahmedabad and beyond.

0 notes

Text

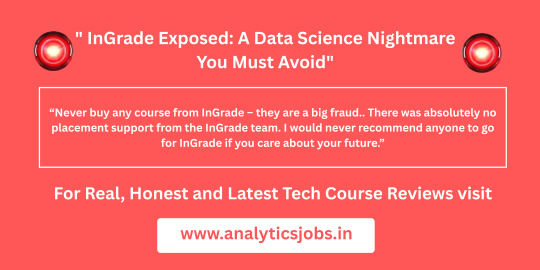

🚨 InGrade Exposed: A Data Science Nightmare You Must Avoid 🚫

If you’re planning to enroll in a Data Science course, read this before you waste your hard-earned money on InGrade.

Anushka Bhagat, an alumna of InGrade, has come forward and bravely shared her experience on Analytics Jobs, and it’s nothing short of a horror story for any student.

Here’s what she said:

“My experience in Ingrade is like a worst nightmare. My expectations were completely ruined because of their so-called Data Science course. Never buy any course from InGrade – they are a big fraud. Instructors and mentors were careless about students’ learning, and no one solved doubts or focused on individual development. There was zero practical learning. We studied everything on our own. The course is NOT worth the money – there are far better options online and offline at lower prices. There was absolutely no placement support from the InGrade team. I would never recommend anyone to go for InGrade if you care about your future.”

Let’s break this down.

❌ No Mentor Support

Instructors and mentors are reportedly unresponsive, indifferent, and unqualified. Doubts go unanswered, feedback is nonexistent, and individual learning is completely ignored.

❌ Zero Practical Learning

Despite claiming to offer hands-on training, students are left to self-learn from recorded content. No real-life projects. No structured guidance. Just a glorified YouTube playlist disguised as a “premium course.”

❌ Misleading Placement Promises

Placement support? Another empty promise. Students are left stranded after the course ends. No interview preparation. No company tie-ups. No follow-through.

❌ Overpriced & Underdelivered

The course is heavily overpriced for the value it provides. There are far better alternatives available online at a fraction of the cost — with better support, structure, and actual placements.

This is not just one angry student venting. This is a reality check that many aspiring Data Science professionals need to hear.

Edtech platforms like InGrade survive on false promises, heavy marketing, and fabricated success stories. But when you scratch beneath the surface, the truth is exposed — and it’s ugly.

If you’re someone who genuinely wants to grow in the field of Data Science, don’t fall for flashy ads and fake success rates. Instead, listen to those who’ve actually been there.

✅ Check real reviews of InGrade from genuine students and alumni on Analytics Jobs: 🔗 https://analyticsjobs.in/question/ingrade-reviews-placements-complaints-courses/

At Analytics Jobs, we are committed to providing you with unfiltered, unbiased, and verified reviews of India’s top and upcoming edtech platforms. Because your education and career should never be compromised by marketing gimmicks.

💡 Don’t be the next victim. Be informed. Be smart.

#InGradeReviews #EdTechExposed #DataScienceCourses #AnalyticsJobs #InGradeScam #StudentVoices #EducationFraud #EdTechReality #CareerAlert #CourseReviews

Let me know if you'd like a carousel version or graphic quote highlights for this post.

1 note

·

View note

Text

Certified PTFE Mesh Belt Manufacturers for Packaging & Textile

Industry is one of the leading PTFE Mesh Belt Manufacturers in India and supplier of high performance belts to industry. Our PTFE mesh belts are capable of performing in heat, chemicals and heavy loads. Food processing, textile, printing and packaging industries are a perfect fit for our PTFE mesh belts.

So, just what is a PTFE Mesh Belt?

PTFE mesh belts are made of fiberglass and PTFE-coated (Teflon). They have an open mesh structure that enables the passage of air or heat with ease, which suits drying, curing and heat applications. PTFE mesh belts are resistant to heat, long-lasting, and non-stick, making them suitable for extended runs in any industrial application.

Key Benefits and Features

At TP Industry, our PTFE mesh belts are constructed to the highest quality standards where strength is of prime importance. They can withstand heat to 260°C and have excellent release performance. The open mesh structure promotes higher air flow for drying or cooling. They are simple to clean, reasonably lightweight, and consistent life expectancy. We can provide standard sized or custom fabricated PTFE mesh belts to meet your requirements.

Why go for TP Industry?

TP Industry are reliable suppliers and leading PTFE Mesh Belt manufacturers whose top priority is innovation, quality, and customer service. We use the best raw materials combined with our sophisticated equipment and experienced engineers to manufacture our belts that surpass or equal industry standards. We offer reasonable prices, prompt delivery, and full technical assistance to our clients. If you are in food, textile, electrical or any other industry that requires PTFE mesh belts TP Industry is your company of choice.

visit- https://www.tpindustrialbelts.com/ptfe-mesh-conveyor-belt/ Address- Sector-10, Noida 201301, UP

0 notes

Text

"Tin Shed Manufacturers in India: Supporting the Foundation of PEB Infrastructure"

In India’s booming construction and industrial landscape, Pre-Engineered Buildings (PEBs) have become the go-to solution for fast, reliable, and scalable infrastructure. One essential component that complements the strength of PEBs is the tin shed — a versatile and affordable roofing and structural option used across various applications. At the core of this offering are tin shed manufacturers, who play a vital role in enhancing the reach and functionality of PEB structures.

What Are Tin Sheds?

Tin sheds are lightweight structures made from corrugated galvanized iron or steel sheets, commonly used for roofing, temporary shelters, storage units, industrial sheds, and agricultural facilities. Despite the term “tin,” these sheds are now mostly made from advanced coated steel materials, offering higher durability and resistance to corrosion.

Tin Sheds in the PEB Ecosystem

While PEBs are pre-engineered and manufactured off-site, tin sheds are often integrated into their design — especially for ancillary spaces like workshops, warehouses, canopies, labor housing, and storage enclosures. Their quick installation and low cost make them an ideal solution for expanding usable space around PEB buildings.

Why Tin Shed Manufacturers Are Essential to PEB Projects

Custom Fabrication: Tin shed manufacturers provide tailored solutions that seamlessly align with the design of the primary PEB structure.

Durability: High-grade sheets ensure longevity and resistance to weather, especially in industrial zones.

Quick Deployment: Ideal for projects with tight deadlines, tin sheds can be erected rapidly without heavy civil work.

Affordability: They reduce construction costs without compromising structural utility.

Portability: Many tin sheds are designed to be relocatable, making them suitable for temporary industrial sites.

Collaboration Between Tin Shed and PEB Manufacturers

PEB manufacturers often collaborate with tin shed manufacturers to offer complete structural packages. This synergy ensures consistency in design, structural integrity, and seamless integration. The partnership allows end users — from logistics companies to agro-industrial enterprises — to benefit from a unified solution tailored to their operational needs.

Choosing the Right Tin Shed Manufacturer in India

India is home to a wide network of tin shed manufacturers who offer a range of sizes, profiles, coatings, and customization options. When selecting a supplier, look for:

Experience in PEB-related projects

Quality certifications and material standards

Turnaround time and on-site support

After-sales service and maintenance offerings

Conclusion

Tin shed manufacturers are a crucial pillar in India’s pre-engineered construction space. Their ability to provide flexible, cost-effective, and durable structures makes them a preferred partner for PEB manufacturers. As the demand for industrial, commercial, and agricultural infrastructure continues to rise, the collaboration between tin shed and PEB manufacturers will only become more essential to India’s structural growth story.

Visit:- https://www.pebmanufacturers.in/tin-shed.html

0 notes

Text

Sheet Metal Fabrication in Bangalore: The Hub of Precision Engineering

Summary

Explore the growing demand for sheet metal works in Bangalore and discover how top fabrication companies in Bangalore deliver precision, quality, and reliability across industries with advanced manufacturing solutions.

Introduction

Bangalore, often celebrated as the Silicon Valley of India, is rapidly emerging as a powerhouse in industrial and manufacturing sectors. Among the many services that support the city's booming industries, sheet metal fabrication stands out as a core component of product development and engineering. From intricate enclosures to heavy-duty industrial parts, the demand for sheet metal works in Bangalore has grown significantly in recent years.

In this article, we explore the scope, strengths, and advantages of working with sheet metal fabrication companies in bangalore, and why this city is now one of India’s most reliable manufacturing destinations.

What is Sheet Metal Fabrication?

Sheet metal fabrication is the process of transforming flat metal sheets into desired shapes and structures through techniques such as cutting, bending, welding, and assembling. It is a critical process in numerous industries, including:

Automotive and Aerospace

Electrical and Electronics

Construction and Infrastructure

Medical Devices

Consumer Appliances

Telecom and Energy Equipment

Precision and consistency are vital in sheet metal works, especially when dealing with mass production or custom prototyping.

Why Bangalore?

1. Industrial Infrastructure

Bangalore boasts advanced industrial zones such as Peenya Industrial Area, Bommasandra, and Electronic City that are home to a dense concentration of engineering and fabrication units. These hubs are equipped with the latest machinery and logistics systems, making Bangalore a manufacturing-ready city.

2. Skilled Workforce

The city benefits from a large pool of engineers, machine operators, and designers who specialize in CNC operations, CAD software, laser cutting, and mechanical fabrication. This ensures high accuracy in output and reduced turnaround times.

3. Tech Integration

Bangalore’s fabrication industry is quick to adopt emerging technologies such as automation, CNC machining, and laser-based systems. These innovations improve efficiency, reduce human error, and support high-volume production.

Services Offered by Fabrication Companies in Bangalore

Fabrication companies in Bangalore typically offer a wide range of services to meet the diverse needs of various sectors. Some of the key services include:

● CNC Laser Cutting

Using high-powered lasers, materials such as stainless steel, aluminum, and copper are cut with pinpoint accuracy. This allows for the creation of complex and clean-edged parts.

● CNC Bending & Forming

Precision press brake machines are used to bend and form sheets into desired shapes. This is essential for creating brackets, enclosures, chassis, and cabinets.

● MIG/TIG/Spot Welding

Welding is crucial in combining different components. Fabrication shops in Bangalore offer MIG, TIG, and spot welding for both heavy and thin-gauge metals.

● Punching & Stamping

CNC turret punching machines help in making holes, cutouts, and complex designs efficiently and accurately.

● Surface Finishing

To protect against corrosion and improve aesthetics, services like powder coating, anodizing, and galvanizing are offered.

● Prototyping & Assembly

Many sheet metal works in Bangalore also include prototyping services for startups and R&D teams. Full or partial assembly services are also available for ready-to-install products.

Industries Served

The versatility and precision of fabrication companies in Bangalore make them well-suited to serve a wide range of industries, such as:

Aerospace: Lightweight yet strong components with tight tolerances

Medical Devices: Sterile, corrosion-resistant equipment housings

Automotive: Customized body panels, brackets, and engine parts

Telecom: Enclosures, racks, and panels for networking equipment

Green Energy: Structures for solar panels, battery cabinets, and more

These companies often follow international quality standards such as ISO 9001, ISO 14001, and AS9100, depending on the industry.

Advantages of Choosing Fabrication Companies in Bangalore

Cost-Effective Production

Thanks to the competitive manufacturing ecosystem, fabrication services in Bangalore often come at a lower cost compared to other major cities without compromising on quality.

Fast Turnaround

Whether it's a prototype or a large batch order, turnaround times are kept short due to advanced scheduling systems, CNC automation, and a dedicated workforce.

Customization & Flexibility

Most sheet metal fabricators offer complete design-to-delivery solutions. Whether it’s a one-off design or a recurring production order, clients benefit from flexibility and tailored service.

Scalability

With a wide network of suppliers and sub-contractors, sheet metal works in Bangalore can scale production rapidly to meet growing business needs.

What to Look for in a Fabrication Partner?

When selecting a fabrication company, it’s important to consider:

Technical Capabilities: Does the shop have modern CNC and laser cutting equipment?

Quality Standards: Are they ISO-certified? Do they follow lean manufacturing practices?

Material Expertise: Can they work with multiple metals like SS, MS, GI, and aluminum?

Communication & Transparency: How well do they share project timelines, reports, and updates?

Delivery & Packaging: Can they ensure secure, on-time delivery with proper documentation?

Many companies also offer online quote portals where customers can upload CAD files and get instant estimates.

Future of Sheet Metal Works in Bangalore

With the rise of Industry 4.0, IoT integration, and smart manufacturing, Bangalore’s fabrication sector is set to become more digital and data-driven. Technologies like 3D printing, robotic welding, and AI-powered inspection systems are already being tested in forward-thinking fabrication workshops.

The increasing focus on electric vehicles, renewable energy, and medical technology is also expected to drive demand for precision sheet metal fabrication in the city.

Conclusion

Whether you're a startup needing a prototype or an OEM looking for a high-volume production partner, fabrication companies in Bangalore offer the technical know-how, flexibility, and reliability required to meet your goals. With a strong industrial foundation, skilled professionals, and cutting-edge technology, sheet metal works in Bangalore are setting benchmarks in quality and innovation.

So, if you’re looking for dependable and cost-effective sheet metal solutions, Bangalore might just be the perfect place to start.

FAQ

Q1. What services are commonly offered by sheet metal fabrication companies in Bangalore? Most fabrication companies in Bangalore offer CNC laser cutting, punching, bending, welding, powder coating, and custom prototyping for a variety of industries.

Q2.Why is Bangalore considered a hub for sheet metal works? Bangalore has advanced industrial zones, a highly skilled workforce, and access to the latest fabrication technologies, making it a prime location for precision sheet metal works.

Q3.Do fabrication companies in Bangalore handle custom or small-batch projects? Yes, many sheet metal fabricators in Bangalore specialize in both mass production and small-batch/custom fabrication for startups, R&D teams, and niche applications.

Q5.What industries rely on sheet metal works in Bangalore? Industries like aerospace, automotive, electronics, telecom, renewable energy, and medical devices frequently depend on Bangalore-based fabrication services.

Q6. Are Bangalore fabrication companies equipped with advanced technologies like CNC and laser cutting? Absolutely. Many fabrication companies in Bangalore use modern CNC machines, laser cutters, and automated welding systems to ensure precision and quality.

Q7. How do I get a quote from a fabrication company in Bangalore? Most companies offer online quote systems where you can upload CAD files and get pricing based on material, quantity, and specifications. Q8. What materials are typically used in sheet metal fabrication in Bangalore? Common materials include stainless steel (SS), mild steel (MS), aluminum, galvanized iron (GI), and sometimes copper or brass depending on the project.

#sheet metal fabricators in bangalore#heavy fabrication companies in bangalore#fabrication companies in bangalore#sheet metal works in bangalore

0 notes