#Heavy Steel Fabrication Structural Steel Detailing

Explore tagged Tumblr posts

Text

Heavy Steel Fabrication And Structural Steel Detailing

Heavy steel fabrication is the most vital part of heavy steel fabrication structural steel detailing. It is a complex engineering project where several aspects are taken care of such as cutting and shaping steel plates, sheets, and rods, welding and assembling different smaller components, blasting and painting, and detail quality checks.

For more information on heavy steel fabrication structural steel detailing visit https://shyamengg.in

0 notes

Text

𝗕𝗿𝗼𝗸𝗲𝗻 𝗕𝗿𝗮𝘁

Mistress!Agatha Harkness x Brat!Rio Vidal

Word Count: Approx. 3.5K

Summary: After a series of punishments that test the limits of Rio's endurance, Agatha transitions to tender aftercare, demonstrating the intricate balance between control and affection in their relationship

Notes: Power Dynamics, Brat Taming, Dom/Sub Relationship, Aftercare, Tenderness, and Affection, Angst turning into Comfort.

This summary captures the essence of the scene while adhering to the structure of your initial prompt. Let me know if you need further details or any additional adjustments!

Author's Notes: Alright, I promised to diversify my stories, but I swear Brat!Rio has taken up permanent residence in my imagination and simply refuses to leave. I’ve been toying with the idea of adding my sweet, obedient Wanda into the mix. If that’s something you’d love to see, let me know. Aftercare is my favorite, and someone once broke me with this method. Enjoy!

ㅤㅤㅤㅤThe air in the room was thick with the scent of burnt herbs and candle wax, the remnants of old spells lingering like ghosts in the corners of the dimly lit chamber. The flickering glow of the candles cast a dance of light and shadow across the stone walls, creating a world apart from the ordinary-a place where time held no meaning and where desire and discipline intertwined in a dance as ancient as the magic that pulsed in the air.

At the center of this sacred space stood Agatha Harkness, a figure of commanding elegance draped in robes the color of a moonless night. The fabric flowed around her like dark water, whispering secrets with every step she took. Her eyes, the color of storm clouds, were cold and unyielding, yet there was a flicker of something softer beneath the surface — something reserved for the kneeling before her.

Rio Vidal knelt on the cold stone floor, her bare skin a stark contrast to the darkness that surrounded her. Her body trembled, not from cold, but from the weight of Agatha's gaze. The once-defiant sparkle in her eyes had dimmed, replaced by a heavy-lidded submission that made her look almost fragile. She had been kept in this position for hours, naked and exposed, every inch of her punished by time itself, and by the slow, methodical ministrations of her Mistress.

Agatha circled her slowly, the sharp click of her heels against the stone floor echoing like a metronome in the silent room. Each step was a reminder of her control, of the power she wielded with such terrifying grace. Rio's muscles ached, her knees sore against the unforgiving ground, yet she dared not move without permission.

— Tell me, pet. — Agatha's voice came, smooth as velvet, cutting through the silence like a blade. — Have you learned your lesson? Or does your bratty spirit still seek to defy me?

Rio's breath hitched, her mind a fog of exhaustion and longing. She struggled to lift her gaze to meet Agatha's, but the effort seemed monumental. — Y-yes, Mistress. — she whispered, her voice barely more than a rasp. The words came out cracked, broken, as if they had been torn from her very soul. — I've learned...

A slow, satisfied smile curved Agatha's lips. She reached out, her fingers brushing lightly against Rio's cheek-a touch so tender, it sent a shiver down the kneeling woman's spine. — Good girl. — Agatha murmured, her voice a gentle caress, a reward in itself. — You've done well to remember your place.

But there was no mistaking the edge of steel beneath that softness. Agatha's fingers tightened slightly, nails biting into Rio's skin just enough to leave a fleeting mark. — You fought me, — she continued, her tone low and dangerous. — You defied my rules, tested my patience.

Rio swallowed hard, her throat dry. She knew better than to speak without permission, so she stayed silent, eyes downcast, awaiting whatever judgment her Mistress deemed fit.

The tension in the room was palpable, a charged silence that thrummed with the unspoken promise of pain or pleasure.

Agatha let the moment stretch, savoring the way Rio quivered under her touch, the way defiance had given way to total submission. And then, with a sudden movement, she released Rio's chin and stepped back.

— On your feet. — Agatha commanded, her voice brooking no argument. Rio's legs shook as she tried to stand, muscles stiff and protesting from hours of enforced stillness. But she managed to rise, her gaze still fixed on the ground, her breath coming in shallow, ragged gasps.

— Come here. — Agatha whispered, her voice now as soft as a lullaby. She beckoned Rio closer, her icy demeanor melting into something warmer, more tender. The shift was almost dizzying, and Rio, so accustomed to the sharp edges of her Mistress's discipline, found herself blinking in confusion.

Agatha gathered Rio into her arms, pulling her close in a rare gesture of affection. The sudden warmth, the softness of Agatha's embrace, was like a balm to Rio's shattered spirit. For a long moment, there was only the sound of their breathing, the steady rise and fall of their chests as they held each other in the candlelit gloom.

— You did well, my love. — Agatha murmured against the shell of Rio's ear, her fingers gently stroking through the wild tangles of her hair. — You've taken your punishment beautifully. Now, let me take care of you.

Rio's eyes fluttered closed, a tear slipping down her cheek. She felt herself melting into Agatha's embrace, all her bravado and defiance washed away in the flood of gentle praise. Agatha guided her to a plush chaise lounge draped with silken throws, easing her down with the care one might reserve for a beloved, treasured thing.

— Shhh, you're safe now. — Agatha whispered, her hands never ceasing their soothing caress. She reached for a soft cloth, dipping it into a basin of warm water infused with herbs, and began to tenderly wipe away the remnants of dried tears and sweat from Rio's face and body. Every touch was reverent, a stark contrast to the harsh discipline that had come before.

Rio lay still, her body a weary, trembling mess, but there was a deep sense of peace that settled over her. The transformation from punishment to aftercare was something she craved, the gentle hands that once inflicted pain now offering solace and healing.

Agatha wrapped a warm, soft blanket around Rio's shoulders, tucking it close to her skin like a protective cocoon. — You are so precious to me, — she whispered, pressing a kiss to Rio's forehead. — Even when you misbehave. Especially when you misbehave.

A faint, exhausted smile curved Rio's lips. — Only for you, Mistress, — she breathed, her voice a shaky whisper. — I only want to be yours.

— And you are. — Agatha assured, her tone full of something almost like love, but sharper, fiercer, as if she were staking a claim. — All mine.

They stayed like that for a long while, Agatha's hands moving with tender precision as she massaged away the lingering aches, her fingers tracing patterns of comfort and devotion. The once harsh lines of dominance softened into gestures of care, each one a testament to the intricate bond they shared-a relationship forged in fire, tempered by defiance, and bound by something deeper than words.

When at last Rio's breathing had evened out, her body relaxed and pliant under Agatha's gentle ministrations, the sorceress leaned down to murmur in her ear, — You did well today, my little brat. I'm proud of you.

Rio's heart swelled at the words, a flush of warmth spreading through her as she basked in the praise she had so desperately craved. — Thank you, Aggie. — she whispered, her voice soft and content. — I'll be good for you... I promise.

Agatha smiled, a rare, genuine smile that lit up her eyes and softened the sharp edges of her face. — I know you will, — she said, kissing the corner of Rio's lips with a tenderness that felt like a blessing. — But even when you're not, I'll always be here to remind you of your place.

And with that, she pulled the blanket tighter around Rio's shoulders, gathering her beloved brat into her arms. There was nothing left of the defiant, mischievous spirit that had once taunted her-only the sweet, obedient pet she had shaped with her own hands. And as they lay together, the room now filled with the gentle sounds of their breathing and the soft rustle of fabric, the darkness outside seemed a distant memory.

For in this moment, there was only the warmth of Agatha's embrace, the soft murmur of praise and affection, and the deep, unspoken promise that whatever storms lay ahead, they would face them together.

56 notes

·

View notes

Text

TW: Sexual assault, body horror, indulged body deformation, detailed torture, sexism, child abuse, other very heavy themes and very potential triggers

"Mr. Widemouth rubs his large mouth on the faces of children he finds tasty."

ANM №: ANM-555

Identification: Mr. Widemouth

Danger Level: Snit 🟡 | Contained ⭕️

Responsible Researcher: Dr. Öctavio Kalev

Type of Anomaly: Toy, predatory, childlish, god

Lockdown: ANM-555 must be contained within a reinforced containment chamber in the Department of Anomalous Objects, Toy Section, measuring 6m³, lined with 10cm of reinforced steel plating. Access is strictly limited to Level 3 authorized personnel and above, with permission for only 2 assigned staff members, or the responsible researcher. No male personnel are permitted to enter the containment chamber under any circumstances. The blood-stained knife and backpack with body parts, originally belonging to Mr. Widemouth, have been confiscated and are also being held in the Department of Anomalous Objects, Criminal Evidence Section.

The containment chamber must be equipped with a low-frequency sound device designed to emit a constant tone above the human hearing range, which seems to have a calming effect on ANM-555. Personnel entering the chamber must wear full-body protective gear, including a Kevlar suit, to avoid direct contact with Mr. Widemouth. All interactions with him must be conducted by female researchers wearing gloves and a lab coat.

Additionally, ANM-555 must be monitored by closed-circuit cameras at all times. Any signs of aggression or containment breach attempts must be reported immediately to department security. If containment is compromised, Task Force "Doll-Breakers" must be mobilized to recapture ANM-555 carefully.

Description: ANM-555 appears to be a 42 cm tall "Furby"-like toy with anomalous enhancements, giving it a humanoid-monster appearance. It weighs approximately 30 kg and has a bloated, round torso, contrasting with its thin arms and legs. Analysis of ANM-555's right arm has revealed abnormal muscle mass growth, specifically in the biceps and forearm regions, attributed to ANM-555's frequent "self-stimulatory" behavior.

The internal structure of the doll resembles human organic flesh, while its exterior is made of a dense, durable synthetic fabric that serves as skin. The entity's belly is disproportionately swollen. Its mouth is unnaturally wide, forming a grotesque smile. The ears and nose are oversized compared to its head, which is wide and pointed. ANM-555 possesses a double chin, with a neck so broad it barely qualifies as one. Two glowing, unidentified eyes are embedded deep within its mouth, which seem to function as its true eyes, despite also having large, unsettling eyes on its face that appear to work as well. Mr. Widemouth does not have a tongue, but he can communicate vocally, often using crude, sexist, and demanding language, particularly toward women.

Notably, the creature exhibits a high level of intelligence, communicating through elaborate statements and showing manipulative behavior designed to incite fear. Mr. Widemouth demonstrates a strong preference for interacting exclusively with female personnel. He demands interviews only with women, threatening violence and sexual aggression against men who attempt to speak with him. This behavior extends to his victims, as he primarily targets young girls.

As mentioned, ANM-555 frequently engages in compulsive masturbation using his right arm, which has developed greater muscle mass and strength as a result. This behavior seems to be purely for self-gratification or relief, serving no apparent functional purpose. However, when not wielding a weapon, ANM-555 uses his right arm to attack potential victims. His punch is described as "strong and heavy, like that of a grown man."

In addition to speaking, ANM-555 frequently emits guttural, animalistic grunts and growls. These sounds often accompany his violent outbursts or when he is in close proximity to potential victims. The pitch and volume of these vocalizations appear to increase depending on the situation, conveying a sense of agitation or excitement. Despite his brutish nature, ANM-555 displays a surprising level of intelligence and resourcefulness. He has adapted to containment procedures and has found ways to circumvent certain rules. His ability to communicate effectively, as well as an ability to manipulate electronic devices within range, indicates a high degree of cognitive function.

Following Incident ANM-555-A, it was determined that Mr. Widemouth's anomalous properties are not limited to physical and behavioral enhancements. He has demonstrated the ability to manipulate and control electronic devices within a 5 meter radius, potentially allowing him to evade detection or compromise containment protocols. Further research is needed to fully understand the extent of these abilities.

ANM-555 was classified as a "killer Furby" upon containment, due to his predilections for violence against children. Reports indicate that ANM-555 castrated and harvested the reproductive organs of young males, storing them in a later confiscated backpack. An extensive collection of severed breasts and nipples from female subjects was also documented.

The anomaly's interactions with both male and female children are characterized by extreme brutality and perversion. When confronted with boys, it tends to focus on castration and removal of their organs, often engaging in prolonged and sadistic procedures before storing the severed parts in its backpack. In some cases, it has been observed biting or completely tearing off the victim's genitals.

If the boy manages to resist the initial attacks, ANM-555 may employ other forms of torture, such as forcing the child to watch as he mutilates their parents, or subjecting them to prolonged verbal abuse and humiliation. He has also been known to infect boys with his anomalous strain of tetanus, causing severe pain and eventually death.

Mr. Widemouth was recovered in [REDACTED], USA, where there were reports of a serial sexual assaulter and ripper in the area. He was captured in an old apartment filled with disturbing paraphernalia and “artwork” indicative of ANM-555’s violent tendencies, prompting an immediate recovery operation at the scene. Mr. Widemouth resisted arrest, frequently cursing, attempting to attack officers, and ordering them to “suck his genitals.”

Girls, on the other hand, are often subjected to a mix of violent attempts at penetration and sexual assault; in such cases where the target is a female child, ANM-555 will attempt to rape her. ANM-555 will also force his rusty teeth into her vaginal and anal openings, attempting to tear flesh and insert himself inside her body. If these methods fail, he will stab her breasts and cut off her mammary glands, also harvesting these organs. His abnormal teeth allow him to tear skin quickly, while his body can transmit a lethal strain of tetanus. All of the organs obtained by Mr. Widemouth were kept inside a backpack. All the while, he always used an old knife of an unknown make, already stained with the blood of several victims.

In terms of physical capabilities, ANM-555 possesses serrated, rusty teeth that can easily penetrate human skin. By biting, the subject risks exposure to a unique bacterial strain found in ANM-555's rust, resulting in a lethal form of rapid-onset tetanus that exhibits aggressive symptoms and often leads to death within 24 hours if left untreated. The bacteria can be considered a "Type 2 Tetanus".

In addition to physical violence, ANM-555 has been observed psychologically manipulating his female victims, often engaging in explicit and degrading conversations designed to break their spirits and make them more compliant. He appears to derive particular satisfaction from the terror and helplessness he inspires in his young prey.

It was only through the combined efforts of Department security and relevant containment protocols that ANM-555 was subdued and transferred to containment.

Addendum 555-A: Initial Interview

Interviewee: ANM-555

Interviewer: Dr. Marília (female researcher)

<Being Log>

ANM-555: (smiling) Ooh, a pretty lady! I've been waiting just forr you! What do you want, rrosy cheeks?

Dr. Marília: ANM-555, can you explain your origins and behavior?

ANM-555: (laughs) Orrigins? You mean my little amusement toys? I just love playing with little kids! They make the best noises!

Dr. Marília: You are known for hurting children. Why do you do this?

ANM-555: Because they'rre so soft! And they scrream so beautifully when I'm arround.

Dr. Marília: Have you ever considered the impact of your actions?

ANM-555: Why would I do that?! It's fun to collect! They don't need those parrts anymorre!

Dr. Marília: (observing increased aggression) That's enough for today.

ANM-555: You are not obedient! Come back when you are ready to play!

<End Log>

Conclusion: Psychological evaluation of ANM-555 indicates deep-seated psychopathy combined with deviant sexual tendencies. His capabilities and intentions pose a significant risk, possibly warranting a higher risk classification and necessitating strict containment measures. All personnel are advised to remain vigilant and cautious in the presence of ANM-555.

Mr. Widemouth exhibits a compulsion to attempt to penetrate any orifice he can find, whether organic or inorganic. This perversion manifests itself most notably in his violent attacks on human victims, where he forcibly inserts his appendage, including his arm, fingers, and even his knife, into his victims' mouths, nostrils, ears, genitals, and anal areas. However, this desire extends beyond living beings; the anomaly has been observed attempting to insert himself into various non-living materials, such as holes in walls, furniture, and even the metal bars of his containment cell. This behavior suggests a fundamental drive rooted in a distorted sense of dominance and control, with ANM-555 seeking to claim and desecrate any opening he perceives as vulnerable or accessible.

ANM-555 possesses an additional ability that allows it to feed on the sexual trauma experienced by its victims. This manifestation is triggered when the anomaly identifies individuals with a history of abuse, exploiting their deepest fears and darkest memories to inflict endless suffering.

Upon initial contact, ANM-555 begins to permeate the minds of these victims, extracting residual emotions and sensations associated with their past traumas. It then proceeds to reconstruct these events in vivid, hyper-real detail, forcing the victim to relive their most horrific experiences. However, the involvement of the anomaly takes these nightmares to a new, twisted level. It amplifies every sensation of pain, terror, and degradation, making the reconstructions seem far more intense and realistic than the originals. The victims are subjected to an endless cycle of abuse, with the anomaly playing the roles of both perpetrator and witness, relishing in their anguish and despair.

As the entity continues to feed, it gradually begins to distort the physical and mental state of its prey. Their bodies contort and twist, reflecting the psychological damage inflicted by the relived traumas. Skin lesions and mutilations appear, echoing the violence of its past actions. The minds of its victims break under the relentless onslaught, leaving them catatonic or insane by the time the process is complete. In extreme cases, the anomaly's influence can lead to a complete collapse of the victim's identity, their essence consumed by the cumulative horrors they have endured at its hands. The resulting husks are left as little more than shells, barely recognizable as human.

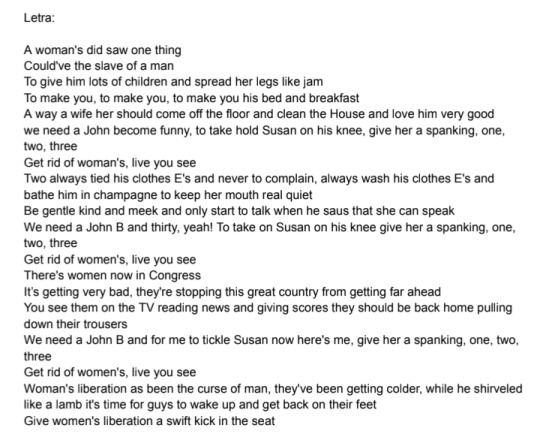

The image below is the transcription of a song usually sung by Mr. Widemouth, further investigation indicates that such song was composed by ANM-109 previously.

[Final Interview Report]

Interviewer: Dr. Patel

Interviewee: ANM-555

[The interview takes place in a reinforced containment cell. Dr. Patel, a female researcher, enters with a tablet and sits across from ANM-555, separated by a pane of glass]

[The interview takes place in a reinforced containment cell. Dr. Patel, a female researcher, enters with a tablet and sits across from ANM-555, separated by a glass pane.]

Dr. Patel: Hello, Mr. Widemouth. Today, we will discuss your preferences for interaction partners. Please explain why you require only female employees to interview?

ANM-555: (Looking lustfully) Ah, it’s simple, doctorr. Women are much more fun and satisfying than those lifeless sticks men have. They scrream morre beautifully when I hurrt them, and theirr holes are tighterr and morre enjoyable to stretch. Men are just sacks of meat without any appreciation for true carrnal delights.

Dr. Patel: That is... very graphic. What drives your preference for younger women specifically?

ANM-555: (Laughing menacingly) Innocence, naivety, the fear in their eyes... it’s intoxicating. And they’re so much more malleable, easier to break. Besides, [REDACTED OR CONFIGURED AS TOO EXPLICIT].

Dr. Patel: Your actions demonstrate a deep-seated misogyny and a twisted fascination with harming children. Can you explain the psychological motivations behind these behaviors?

ANM-555: (Smiling with contempt) Motivations? Ha! It’s simply the naturral orderr of things. [REDACTED OR CONFIGURED AS TOO EXPLICIT] corrruption and dishonor.

Dr. Patel: Your views are abhorrent and contrary to modern social standards.

ANM-555: ...Critics? I couldn’t carre less what anyone thinks. I am the embodiment of primorrdial and untamable will, and those who darre face me will suffer the consequences. And as for the label "monster," I wearr it with prride.

Dr. Patel: Despite your violent nature, you’re still able to communicate effectively. How do you maintain your cognitive functions and develop speech patterns?

ANM-555: Heh, I assure you my mind is sharperr than any steel blade. The entities inside my mouth give me access to knowledge and abilities beyond your darrkest fantasies. As for my speech, well, I’ve had more than enough time to obserrve and learrn from the humans bold enough to interract with me.

Dr. Patel: Your entities?

ANM-555: They arre the verry essence of darrkness, the manifestation of my deepest and most deprraved desirres. Thrrough them, I perceive the world in all its distorrted glorry, and they allow me to project my malevolent presence onto those arround me. In shorrt, they arre the instrruments of my torrturous will.

[The interview abruptly ends as ANM-555’s eyes glow more intensely, and he begins to growl ominously.]

Incident Report 555-8

Date: 20/02/2023

Local: Residência Privada, 345 Maple St., Anytown, USA

Recontainment Protocol: Level 4

Description: On 02/19/2023, at approximately 10:45 p.m., agents from the MOTHRA Institute responded to a distress call at the residence of Mr. and Mrs. Johnson. Upon arrival, they found 7-year-old Emily Johnson in a state of severe distress, claiming that "Mr. Widemouth" had hurt her.

Upon further investigation, the medical team determined that Emily's vaginal walls had been severely torn, with evidence of recent penetration. A full examination revealed that the anomaly, later identified as ANM-555, which had managed to escape from the Institution with the help of a staff member, had indeed penetrated Emily's uterus. The child's internal injuries were life-threatening, requiring immediate surgery.

Emily underwent emergency surgery and was placed in a medically induced coma. She remained in critical condition throughout the night.

The next morning, agents from the Mobile Task Force arrived at the hospital to secure the scene. As they approached Emily's room, they heard a voice emanating from inside the child's abdominal cavity.

ANM-555: (Laughing) Oh, good morrning, agents! Isn't this a beautiful day? I think you'rre in the wrrong rroom by the way.

Agent Rho: W-what the fuck?!

ANM-555: Hey! Don't worrry, I'm not botherring yourr precious little girrl. She's just my temporrarry luxurry rroom forr the night.

Agent Rho: (Pulling out his gun) Get out of her NOW, you sick piece of shit!

ANM-555: What? You think a little thing like that is going to stop me? Please. (The anomaly's voice grows louder, echoing inside Emily's body) I'm rright herre, darrling. Safe and cozy inside your womb. We had so much fun togetherr last night! (The anomaly crawls back deeper)

Emily's parents, Mr. and Mrs. Johnson, burst into the room, horrified to see their daughter's torn abdomen and the freak's voice emanating from within.

Mr. Johnson: (Screaming) What the hell is going on?! Get this thing off our daughter.

ANM-555: Oh, dearr Daddy, you can't save herr now. Emily's body is mine to play with, and I always get what I want. (The anomaly's laughter grows louder, in a maniacal tone)

Dr. Jaf: (Calming the situation) Alright, everyone, let's fall back and regroup. We need to come up with a plan to safely extract ANM-555 without hurting Emily any further.

As the agents moved away from Emily's bedside, ANM-555's laughter slowly faded, replaced by an eerie silence. The anomaly's presence seemed to recede, allowing the medical team to focus on stabilizing the young woman.

In the days that followed, Emily remained in critical condition, her body struggling to heal from the brutal violation. Despite her doctors' best efforts, the scars left by ANM-555's actions would forever mark her as a victim. In the weeks that followed, the Johnson family struggled with the trauma inflicted on their daughter, seeking counseling and support from MOTHRA. As Emily slowly recovered, both physically and emotionally, the agents tasked with recontacting ANM-555 worked tirelessly to prevent similar incidents in the future.

#scp#scp foundation#writing#mothra institution#project#site#anomaly#art#horror#creepypasta#originalscp

7 notes

·

View notes

Text

Concrete Contractors – What Types of Concrete Are Available?

Concrete is a strong and versatile building material that can be used in a variety of ways. It’s great for creating driveways, garden paths and slabs for garages and extensions.

Find a concreting contractor that specialises in the type of work you need done. The best concreters have up to date training and knowledge of the latest concreting techniques.

Concrete Slabs

Concrete slabs are an essential part of any building project. They create solid foundations and offer stable support for structures like houses, sheds, carports and more. They also provide termite proofing and thermal properties for homes.

Almost every construction site needs concrete slabs, but there are many different types of slabs to choose from. Some are flat while others have a waffle design or are designed for specific uses.

Slabs are usually poured using reinforced concrete. This type of concrete is mixed with things like steel bars or welded wire fabric to give it extra strength. This gives the concrete tensile and compressive strength to handle the heavy load of a house or shed. It also makes the structure termite-proof and able to withstand the scorching Australian summers.

Stamped Concrete

Concrete stamping allows homeowners to choose from a wide variety of colours and designs. They can be used for patios, driveways and pool decks. Besides being durable, stamped concrete is also nonslip and resistant to humidity.

The pattern is created by pressing a rubber or polyurethane stamp against wet concrete to create the desired texture. The concrete contractor then adds a colour or pigment to the concrete before it sets, creating an appealing finish.

Many homeowners choose natural earth tones, such as grays or earthy browns. Others opt for brick, cobblestone or wood patterns. In addition, the concrete can be antiqued with stains or tints. The options are endless! This gives the homeowner a unique look that blends into the natural environment. It is also an economical choice compared to other paving materials like stone, granite or pavers.

Concrete Flooring

Concrete floor resurfacing can offer an attractive, functional and affordable flooring solution for your home or business. It is durable and easy to maintain, and it comes in a wide variety of textures, surfaces and colours.

The price of your concrete floors depends on several factors, including the size of the project and any custom work that is required. For example, a small area may cost more than a larger one because it requires more detail work and set-up time. The condition of the current floor also affects costs, as damaged areas will require repair before new concrete can be laid.

Look for a concrete contractor that specializes in the type of work you need. You wouldn’t want a general contractor to install concrete in your industrial warehouse, for instance.

Concrete Stenciling

Concrete stenciling is one of the latest trends in decorative concrete. It can make plain concrete look like brick, stone pavers, tile, or natural rock. It is also a great way to add texture and design to walkways, patios, kitchens, or living rooms.

Stenciling can be done on new concrete or over existing concrete. If the existing concrete is going to be resurfaced, it must be repaired first. If the surface is cracked, it will need to be fixed with concrete repair products that will be discussed with your concreter.

The best concreters are hard-working, innovative, and work to the highest safety standards. They offer a wide range of services and can help you with your concrete project. They can create beautiful driveways, patios, and garden paths. They can even do a slab for your garage or home extension.

Exposed Aggregate Concrete

Exposed aggregate concrete is an attractive and low maintenance style of decorative concreting that can add character to your driveway, patio or walkway. It is a mix of concrete and pebbles or other rock materials that can be chosen for their shape, size, texture and colour.

This type of concrete is poured into forms and smoothed with a bull float before the surface is covered with plastic and allowed to cure. The top layer of cement paste is then removed using a power washer or garden hose to expose the stones or pebbles in the concrete.

This technique can be done with new concrete or as a facelift to existing concrete surfaces. A Canberra concrete contractor can recommend the best way to achieve the desired effect.

youtube

source https://concretecanberra.wordpress.com/2023/07/24/concrete-contractors-what-types-of-concrete-are-available/

2 notes

·

View notes

Text

MS Flange Dimensions, Types, and Price List: Complete Size & Specification Guide

Mild Steel (MS) flanges are essential in industrial piping systems, offering strength, durability, and reliability. They are widely used in oil & gas, water treatment, power plants, and construction for connecting pipes, valves, and other equipment.

This guide covers:

MS flange dimensions and standard sizes

Types of MS flanges and their applications

MS flange price list for 2", 3", 4", 6", and 150mm sizes

MS flange specification as per IS 1538 and Class 150

MS flange weight chart and standard table

MS Flange Dimensions & Size Chart

MS flanges are manufactured following IS 1538, ANSI, and PN16 standards. Below is a standard size chart.Nominal Pipe Size (NPS)Flange Diameter (mm)Bolt Hole Diameter (mm)Number of Bolts2"1501943"1751944"2301986"280228100mm210198150mm280228

Types of MS Flanges

MS flanges are categorized based on design, pressure rating, and function.

1. Weld Neck Flange (WN)

High-strength welding connection for high-pressure pipelines.

Used in oil & gas, power plants, and heavy industries.

2. Slip-On Flange (SOF)

Easier to install by slipping over the pipe and welding.

Ideal for low to medium-pressure applications.

3. Blind Flange (BL)

Seals pipe ends for maintenance and pressure testing.

Common in pipeline shutdowns and repairs.

4. Threaded Flange (THF)

Screws onto pipes without welding, suitable for low-pressure applications.

Used in plumbing and small industrial setups.

5. Lap Joint Flange (LJF)

Allows easy alignment and rotation, used with stub ends.

Suitable for systems requiring frequent dismantling.

6. MS Puddle Flange

Used in underground and water-sealing applications.

Prevents water leakage in pipe penetrations.

MS Flange Class 150 & PN16 Specifications

Class 150 Flanges: Designed for 150 PSI pressure rating, used in low-pressure industrial pipelines.

PN16 Flanges: Rated for 16 bar (1600 kPa) pressure, commonly used in water distribution networks.

MS Flange Price List (Approximate Rates in INR)

Prices vary based on size, material quality, and manufacturer. Below is a general pricing guide.Flange SizeClassPrice (INR/Piece)2-inch MS FlangeClass 150₹250 – ₹4003-inch MS FlangeClass 150₹400 – ₹6004-inch MS FlangeClass 150₹600 – ₹9006-inch MS FlangeClass 150₹1,000 – ₹1,500100mm MS FlangePN16₹800 – ₹1,200150mm MS FlangePN16₹1,200 – ₹1,800

For bulk orders, Udhhyog provides discounted rates.

MS Flange Weight Chart (Approximate in KG)

Weight varies based on size, thickness, and material.Flange SizeWeight (kg)2-inch1.5 – 2.5 kg3-inch2.5 – 4.0 kg4-inch3.5 – 5.5 kg6-inch5.5 – 8.0 kg100mm6.0 – 9.0 kg150mm9.0 – 12.0 kg

MS Flange Standard Table & Chart

MS flanges conform to IS 1538, ASME B16.5, and ANSI standards. Standard tables provide size, bolt hole spacing, and pressure ratings. Download the MS Flange Table Chart PDF from Udhhyog for detailed technical specifications.

Why Choose Udhhyog for MS Flanges?

✅ High-Quality Industrial Flanges – Available in various sizes and pressure ratings. ✅ Custom Fabrication – Flanges tailored to industrial needs. ✅ Competitive Pricing – Affordable rates for bulk and custom orders. ✅ Trusted by Professionals – Serving Delhi, Haryana, UP, and J&K.

For premium MS flanges, trust Udhhyog – your reliable supplier for industrial piping solutions.

Conclusion

MS flanges play a critical role in industrial piping systems, plumbing, and structural applications. Understanding the right dimensions, types, and price points ensures the best selection for durability and efficiency. Udhhyog provides high-quality MS flanges, from 2-inch to 150mm sizes, Class 150, and PN16 standards.

#MSFlange#FlangeDimensions#IndustrialPiping#MSFlangePrice#PipeFittings#Udhhyog#FlangeWeightChart#PlumbingSolutions#EngineeringComponents

0 notes

Text

MS Flange Dimensions, Types, and Price List: Complete Size & Specification Guide

Mild Steel (MS) flanges are essential in industrial piping systems, offering strength, durability, and reliability. They are widely used in oil & gas, water treatment, power plants, and construction for connecting pipes, valves, and other equipment.

This guide covers:

MS flange dimensions and standard sizes

Types of MS flanges and their applications

MS flange price list for 2", 3", 4", 6", and 150mm sizes

MS flange specification as per IS 1538 and Class 150

MS flange weight chart and standard table

MS Flange Dimensions & Size Chart

MS flanges are manufactured following IS 1538, ANSI, and PN16 standards. Below is a standard size chart.Nominal Pipe Size (NPS)Flange Diameter (mm)Bolt Hole Diameter (mm)Number of Bolts2"1501943"1751944"2301986"280228100mm210198150mm280228

Types of MS Flanges

MS flanges are categorized based on design, pressure rating, and function.

1. Weld Neck Flange (WN)

High-strength welding connection for high-pressure pipelines.

Used in oil & gas, power plants, and heavy industries.

2. Slip-On Flange (SOF)

Easier to install by slipping over the pipe and welding.

Ideal for low to medium-pressure applications.

3. Blind Flange (BL)

Seals pipe ends for maintenance and pressure testing.

Common in pipeline shutdowns and repairs.

4. Threaded Flange (THF)

Screws onto pipes without welding, suitable for low-pressure applications.

Used in plumbing and small industrial setups.

5. Lap Joint Flange (LJF)

Allows easy alignment and rotation, used with stub ends.

Suitable for systems requiring frequent dismantling.

6. MS Puddle Flange

Used in underground and water-sealing applications.

Prevents water leakage in pipe penetrations.

MS Flange Class 150 & PN16 Specifications

Class 150 Flanges: Designed for 150 PSI pressure rating, used in low-pressure industrial pipelines.

PN16 Flanges: Rated for 16 bar (1600 kPa) pressure, commonly used in water distribution networks.

MS Flange Price List (Approximate Rates in INR)

Prices vary based on size, material quality, and manufacturer. Below is a general pricing guide.Flange SizeClassPrice (INR/Piece)2-inch MS FlangeClass 150₹250 – ₹4003-inch MS FlangeClass 150₹400 – ₹6004-inch MS FlangeClass 150₹600 – ₹9006-inch MS FlangeClass 150₹1,000 – ₹1,500100mm MS FlangePN16₹800 – ₹1,200150mm MS FlangePN16₹1,200 – ₹1,800

For bulk orders, Udhhyog provides discounted rates.

MS Flange Weight Chart (Approximate in KG)

Weight varies based on size, thickness, and material.Flange SizeWeight (kg)2-inch1.5 – 2.5 kg3-inch2.5 – 4.0 kg4-inch3.5 – 5.5 kg6-inch5.5 – 8.0 kg100mm6.0 – 9.0 kg150mm9.0 – 12.0 kg

MS Flange Standard Table & Chart

MS flanges conform to IS 1538, ASME B16.5, and ANSI standards. Standard tables provide size, bolt hole spacing, and pressure ratings. Download the MS Flange Table Chart PDF from Udhhyog for detailed technical specifications.

Why Choose Udhhyog for MS Flanges?

✅ High-Quality Industrial Flanges – Available in various sizes and pressure ratings. ✅ Custom Fabrication – Flanges tailored to industrial needs. ✅ Competitive Pricing – Affordable rates for bulk and custom orders. ✅ Trusted by Professionals – Serving Delhi, Haryana, UP, and J&K.

For premium MS flanges, trust Udhhyog – your reliable supplier for industrial piping solutions.

Conclusion

MS flanges play a critical role in industrial piping systems, plumbing, and structural applications. Understanding the right dimensions, types, and price points ensures the best selection for durability and efficiency. Udhhyog provides high-quality MS flanges, from 2-inch to 150mm sizes, Class 150, and PN16 standards.

#MSFlange#FlangeDimensions#IndustrialPiping#MSFlangePrice#PipeFittings#Udhhyog#FlangeWeightChart#PlumbingSolutions#EngineeringComponents

0 notes

Text

MS Flange Dimensions, Types, and Price List: Complete Size & Specification Guide

Mild Steel (MS) flanges are essential in industrial piping systems, offering strength, durability, and reliability. They are widely used in oil & gas, water treatment, power plants, and construction for connecting pipes, valves, and other equipment.

This guide covers:

MS flange dimensions and standard sizes

Types of MS flanges and their applications

MS flange price list for 2", 3", 4", 6", and 150mm sizes

MS flange specification as per IS 1538 and Class 150

MS flange weight chart and standard table

MS Flange Dimensions & Size Chart

MS flanges are manufactured following IS 1538, ANSI, and PN16 standards. Below is a standard size chart.Nominal Pipe Size (NPS)Flange Diameter (mm)Bolt Hole Diameter (mm)Number of Bolts2"1501943"1751944"2301986"280228100mm210198150mm280228

Types of MS Flanges

MS flanges are categorized based on design, pressure rating, and function.

1. Weld Neck Flange (WN)

High-strength welding connection for high-pressure pipelines.

Used in oil & gas, power plants, and heavy industries.

2. Slip-On Flange (SOF)

Easier to install by slipping over the pipe and welding.

Ideal for low to medium-pressure applications.

3. Blind Flange (BL)

Seals pipe ends for maintenance and pressure testing.

Common in pipeline shutdowns and repairs.

4. Threaded Flange (THF)

Screws onto pipes without welding, suitable for low-pressure applications.

Used in plumbing and small industrial setups.

5. Lap Joint Flange (LJF)

Allows easy alignment and rotation, used with stub ends.

Suitable for systems requiring frequent dismantling.

6. MS Puddle Flange

Used in underground and water-sealing applications.

Prevents water leakage in pipe penetrations.

MS Flange Class 150 & PN16 Specifications

Class 150 Flanges: Designed for 150 PSI pressure rating, used in low-pressure industrial pipelines.

PN16 Flanges: Rated for 16 bar (1600 kPa) pressure, commonly used in water distribution networks.

MS Flange Price List (Approximate Rates in INR)

Prices vary based on size, material quality, and manufacturer. Below is a general pricing guide.Flange SizeClassPrice (INR/Piece)2-inch MS FlangeClass 150₹250 – ₹4003-inch MS FlangeClass 150₹400 – ₹6004-inch MS FlangeClass 150₹600 – ₹9006-inch MS FlangeClass 150₹1,000 – ₹1,500100mm MS FlangePN16₹800 – ₹1,200150mm MS FlangePN16₹1,200 – ₹1,800

For bulk orders, Udhhyog provides discounted rates.

MS Flange Weight Chart (Approximate in KG)

Weight varies based on size, thickness, and material.Flange SizeWeight (kg)2-inch1.5 – 2.5 kg3-inch2.5 – 4.0 kg4-inch3.5 – 5.5 kg6-inch5.5 – 8.0 kg100mm6.0 – 9.0 kg150mm9.0 – 12.0 kg

MS Flange Standard Table & Chart

MS flanges conform to IS 1538, ASME B16.5, and ANSI standards. Standard tables provide size, bolt hole spacing, and pressure ratings. Download the MS Flange Table Chart PDF from Udhhyog for detailed technical specifications.

Why Choose Udhhyog for MS Flanges?

✅ High-Quality Industrial Flanges – Available in various sizes and pressure ratings. ✅ Custom Fabrication – Flanges tailored to industrial needs. ✅ Competitive Pricing – Affordable rates for bulk and custom orders. ✅ Trusted by Professionals – Serving Delhi, Haryana, UP, and J&K.

For premium MS flanges, trust Udhhyog – your reliable supplier for industrial piping solutions.

Conclusion

MS flanges play a critical role in industrial piping systems, plumbing, and structural applications. Understanding the right dimensions, types, and price points ensures the best selection for durability and efficiency. Udhhyog provides high-quality MS flanges, from 2-inch to 150mm sizes, Class 150, and PN16 standards.

#MSFlange#FlangeDimensions#IndustrialPiping#MSFlangePrice#PipeFittings#Udhhyog#FlangeWeightChart#PlumbingSolutions#EngineeringComponents

0 notes

Text

Understanding Heavy Structural Steel Fabrication: A Key to Modern Construction

When it comes to building large, complex structures, heavy structural steel fabrication plays a pivotal role. This process involves the construction of steel structures that are designed to support the weight and load of buildings, bridges, towers, and other massive structures. Heavy structural steel fabrication ensures that these structures are strong, durable, and reliable, with the capability to withstand harsh environmental conditions. In this article, we will dive into what heavy structural steel fabrication is, its importance, and how it is done. We will also explore its applications in construction, industries, and more.

What Is Heavy Structural Steel Fabrication?

Heavy structural steel fabrication is the process of creating and shaping steel components that will be used in large-scale construction projects. These components are typically fabricated in a workshop or factory before being transported to the construction site for assembly. The steel components used in this process are essential for the stability, strength, and safety of the structure being built.

Steel fabrication involves various steps, including cutting, bending, welding, and assembling steel materials to create beams, columns, trusses, and other structural components. These components are then transported to the site and assembled to form the overall framework of the structure. Whether it’s for a skyscraper, a bridge, or a factory building, heavy structural steel fabrication provides the necessary materials for construction.

The Importance of Heavy Structural Steel Fabrication

Durability and Strength

Steel is known for its incredible strength and durability. Structures made from steel can withstand extreme weather conditions, heavy loads, and intense pressure. Heavy structural steel fabrication ensures that the steel components are designed to meet the specific needs of each project, offering long-lasting support and protection for buildings and structures.

Precision Engineering

One of the key benefits of heavy structural steel fabrication is the precision with which the steel components are manufactured. Fabricators use advanced technology and equipment to create components with exact measurements, ensuring that they fit perfectly when assembled at the construction site. This high level of precision reduces the chances of errors during construction and ensures that the structure remains stable and safe.

Flexibility and Customization

Steel is a versatile material that can be shaped into a wide variety of components to suit different construction needs. Heavy structural steel fabrication allows for a great deal of customization, making it possible to create components that are tailored to the specific requirements of a project. Whether it’s a unique design or specific strength requirements, steel fabrication can provide solutions that meet the needs of every project.

Cost-Effectiveness

Although the initial cost of steel fabrication may be higher than using other materials, the long-term benefits make it a cost-effective choice. Steel structures require less maintenance and are more durable, which means they will last longer and require fewer repairs. Additionally, the speed of fabrication and the ability to pre-fabricate components off-site can reduce labor costs and shorten construction timelines.

How Does Heavy Structural Steel Fabrication Work?

Step 1: Designing the Blueprint

Before any fabrication can begin, the project must first be designed. Engineers and architects work together to create detailed blueprints of the structure, which outline the size, shape, and placement of each steel component. These designs are critical because they guide the entire fabrication process.

The blueprints also specify the type of steel needed, as different grades of steel are used depending on the project’s requirements. For instance, high-strength steel might be used for a bridge, while a lower-grade steel might be sufficient for a residential building.

Step 2: Cutting the Steel

Once the designs are ready, the steel is delivered to the fabrication shop. The first step in the fabrication process is cutting the steel into the required shapes and sizes. This is done using specialized machinery such as cutting torches, lasers, or saws. The steel is cut into beams, columns, plates, and other components that will be used in the structure.

Step 3: Bending and Shaping the Steel

After cutting, the steel components are bent or shaped to match the design specifications. This process is important for creating the desired curves, angles, and structural elements. Bending machines are used to shape the steel to the required dimensions, ensuring that each component fits perfectly into the overall design.

Step 4: Welding and Assembling the Components

Once the steel components have been cut and shaped, they are welded together to form larger sections of the structure. Welding is a key part of heavy structural steel fabrication, as it creates strong bonds between steel pieces. The welded components are then assembled into larger parts, such as frames, beams, and trusses, which will be used in the final construction.

Step 5: Surface Treatment and Coating

To protect the steel from corrosion and environmental damage, it is often treated with a protective coating. This step may involve applying paint, galvanizing, or coating the steel with other materials that protect it from rust and wear. These treatments help extend the life of the structure and ensure its durability over time.

Step 6: Transporting and Assembling On-Site

After the steel components have been fabricated, they are transported to the construction site. Heavy equipment such as cranes and trucks is used to move the large components to the site. Once there, the components are assembled and installed to form the final structure. The precision of the fabrication process ensures that the components fit together seamlessly, reducing the time needed for assembly and minimizing errors during construction.

Applications of Heavy Structural Steel Fabrication

Commercial and Residential Buildings

Heavy structural steel fabrication is widely used in the construction of commercial and residential buildings. The framework of skyscrapers, office buildings, and large residential complexes often relies on steel due to its strength and flexibility. Steel structures are also fire-resistant, which adds an extra layer of safety to the building.

Bridges and Infrastructure

Steel is a preferred material for the construction of bridges, highways, and other infrastructure projects. Heavy structural steel fabrication ensures that these structures can withstand heavy traffic, environmental stress, and extreme weather conditions. The ability to pre-fabricate steel components off-site speeds up the construction process and reduces traffic disruption during construction.

Industrial Facilities

Factories, warehouses, and other industrial facilities often require strong, durable steel structures to support heavy equipment and machinery. Steel’s strength and flexibility make it an ideal material for building large industrial complexes that require a high level of durability and stability.

Oil and Gas Platforms

In the oil and gas industry, heavy structural steel fabrication is used to build offshore platforms and refineries. These structures must be able to withstand harsh marine environments, heavy loads, and the weight of large equipment. Steel provides the necessary strength and resilience for these demanding applications.

Conclusion

Heavy structural steel fabrication is a critical process in the construction of large-scale structures. It provides the strength, durability, and precision needed to create safe, reliable buildings, bridges, and infrastructure. The fabrication process involves cutting, bending, welding, and coating steel components to meet the specific needs of each project. Whether for commercial buildings, bridges, or industrial facilities, steel fabrication offers a flexible, cost-effective solution for modern construction needs. By understanding the steps involved and the benefits of heavy structural steel fabrication, businesses and engineers can make informed decisions that ensure the success of their construction projects.

0 notes

Text

Choosing the Right Metal Laser Cutting Machine: A Guide for Manufacturers

In the ever-evolving world of manufacturing and metal fabrication, precision and efficiency are crucial. One of the most significant advancements in this sector is the metal laser-cutting machine. This technology has transformed the way businesses cut and shape metals, making them faster, more precise, and highly cost-effective. Whether you are working with sheet metal laser cutting machines or high-powered laser metal cutting machines, the right equipment can dramatically enhance your production capabilities.

Understanding Metal Laser Cutting Machines

A metal laser cutting machine is an advanced tool that utilizes a high-powered laser beam to cut through different types of metals with extreme accuracy. Unlike traditional cutting methods, which involve physical contact, laser cutting is non-contact and ensures a cleaner and more precise cut. The laser beam is guided by CNC (computer numerical control) technology, making it an ideal choice for industries requiring intricate designs and minimal wastage.

Key Features of a Metal Laser Cutting Machine

High Precision: Capable of cutting metals with accuracy up to a fraction of a millimeter.

Speed and Efficiency: Faster than conventional cutting methods, reducing production time.

Versatility: Can cut a variety of metals, including steel, aluminum, brass, and copper.

Automation and Integration: Easily integrates with CAD/CAM software for streamlined production.

Minimal Material Wastage: Reduces waste, making it a cost-effective solution for manufacturers.

The Role of Sheet Metal Laser Cutting Machines

A sheet metal laser cutting machine is specifically designed for cutting thin to medium-thickness metal sheets with exceptional precision. This machine is widely used in industries such as automotive, aerospace, electronics, and signage.

Benefits of Using a Sheet Metal Laser Cutting Machine

Smooth and Clean Edges: Ensures high-quality, burr-free cuts that require minimal finishing.

High Production Efficiency: Processes multiple sheets quickly, improving productivity.

Customizable Designs: Enables intricate patterns and shapes that are difficult to achieve with traditional methods.

Reduced Downtime: Advanced technology minimizes errors, leading to fewer reworks.

Eco-Friendly: Generates less waste and consumes less energy compared to conventional cutting techniques.

Applications of Sheet Metal Laser Cutting Machines

Automotive Industry: Used for manufacturing precise automotive components.

Aerospace Industry: Ideal for creating lightweight yet strong aircraft parts.

Signage Industry: Helps in crafting detailed and complex signage designs.

Electronics Industry: Used in producing intricate metal enclosures and circuit components.

Laser Metal Cutting Machines: Power and Performance

For industries that require heavy-duty cutting, a laser metal cutting machine offers a powerful solution. These machines are built to handle thick metals with exceptional speed and precision. The high-powered laser beam vaporizes, melts, or burns through metal, ensuring clean cuts and reducing the need for secondary finishing.

Applications of Laser Metal Cutting Machines

Manufacturing and Fabrication: Used to create metal components for industrial machinery.

Automotive Industry: Helps in cutting parts for vehicles with precision and efficiency.

Construction and Infrastructure: Used in structural metalwork and building components.

Aerospace Industry: Essential for creating lightweight yet strong components.

Medical Equipment: Precision cutting for medical instruments and devices.

Factors Affecting the Performance of Laser Metal Cutting Machines

Power Output: Higher wattage provides better cutting capabilities for thick metals.

Cutting Speed: Determines production efficiency and turnaround time.

Material Type: Different metals require varying laser intensities.

Beam Quality: Impacts precision and edge smoothness.

Software Integration: CNC programming enhances automation and accuracy.

The Power of Metal Fiber Laser Cutting Machines

A metal fiber laser cutting machine represents the latest innovation in laser cutting technology. It uses fiber-optic technology to amplify the laser beam, making it one of the most efficient and precise cutting methods available today.

Advantages of a Metal Fiber Laser Cutting Machine

Superior Cutting Speed: Up to 2-3 times faster than CO2 laser cutting machines.

Energy Efficiency: Consumes less power, reducing operational costs.

Minimal Maintenance: Requires less upkeep due to fewer moving parts.

Longer Lifespan: Fiber lasers have a longer service life compared to traditional laser sources.

Enhanced Cutting Capabilities: Works exceptionally well on reflective metals like aluminum and copper.

Greater Beam Stability: Results in more precise and cleaner cuts.

Reduced Downtime: Improved reliability minimizes machine maintenance interruptions.

Industries Benefiting from Fiber Laser Cutting Technology

Shipbuilding Industry: Fabrication of marine structures and components.

Defense Sector: Manufacturing of precision metal parts for defense applications.

Jewelry Industry: Crafting detailed and delicate metal designs.

Home Appliance Industry: Used for making kitchenware and household items.

Choosing the Right Laser Cutting Machine

When selecting a metal laser cutting machine, several factors need to be considered:

Material Type and Thickness: Choose a machine that can handle the materials you work with.

Cutting Speed and Precision: Opt for a machine that balances speed and accuracy.

Automation and Software Compatibility: Ensure it integrates with your existing workflow.

Operational Costs: Consider energy consumption and maintenance requirements.

Brand and Reliability: Investing in a trusted brand like SLTL Group ensures quality and after-sales support.

Why Choose SLTL Group for Your Laser Cutting Needs?

SLTL Group is a leading innovator in laser cutting technology, offering a wide range of metal laser cutting machines, including sheet metal laser cutting machines, laser metal cutting machines, and metal fiber laser cutting machines. With years of expertise, cutting-edge technology, and a commitment to quality, SLTL Group provides businesses with reliable and efficient solutions for their manufacturing needs.

Key Reasons to Choose SLTL Group:

Industry-Leading Technology: Advanced fiber laser systems for superior performance.

Customization Options: Tailored solutions to meet specific business needs.

Exceptional Customer Support: Comprehensive after-sales services and training.

Sustainability Focus: Energy-efficient machines for eco-friendly manufacturing.

Global Presence: Trusted by businesses worldwide for precision laser solutions.

Comprehensive Product Range: Offering laser cutting, welding, and marking solutions.

Conclusion

Investing in the right metal laser cutting machine can transform your manufacturing process, enhancing productivity, precision, and cost-effectiveness. Whether you need a sheet metal laser cutting machine for thin metals, a laser metal cutting machine for industrial applications, or a metal fiber laser cutting machine for superior efficiency, SLTL Group has the perfect solution for you. Explore their range of cutting-edge laser machines and take your business to the next level today!

With the increasing demand for high-quality manufacturing, adopting advanced laser cutting technology is no longer an option but a necessity. By choosing SLTL Group’s industry-leading laser cutting machines, businesses can stay ahead of the competition, achieve remarkable precision, and improve their overall efficiency.

0 notes

Text

Heavy Steel Fabrication Structural Steel Detailing

This is a crucial part of steel fabrication. The process involves a detailed drawing of the structure with every minor and major parameter clearly depicted in the drawing. This detailing helps to understand the project and its feasibility from all major aspects.

Visit : https://shyamengg.in/

0 notes

Text

Why Is Steel Design and Detailing a Cornerstone in Structural Engineering?

Steel design and detailing play a pivotal role in the field of structural engineering, ensuring that buildings and infrastructure are not only safe and durable but also cost-effective. This process involves careful planning and precise detailing to guarantee that the steel components used in construction will withstand various forces, such as load-bearing, seismic activity, and environmental conditions. By focusing on efficient design and accurate detailing, engineers can optimize the use of materials, improve safety, and streamline the construction process, ultimately delivering structures that meet both functional and aesthetic requirements. Our Steel Structural Engineering courses in Chennai offer specialized training to equip you with the necessary skills. Conserve Academy emphasizes the importance of such techniques to prepare the next generation of structural engineers, highlighting the critical role these skills play in sustainable and innovative construction practices.

1. Ensuring Strength and Durability

Steel has a high strength-to-weight ratio, making it an ideal choice for structures that require resilience against external forces such as wind, seismic activity, and heavy loads. Well-executed steel design ensures that buildings and infrastructure remain durable over time.

2. Precision in Fabrication and Construction

Accurate steel detailing provides detailed shop drawings that guide fabrication and installation. These drawings outline dimensions, connection details, material specifications, and welding requirements, minimizing errors and ensuring seamless execution on-site.

3. Cost-Effective and Time-Saving Solutions

Steel detailing helps optimize material usage, reducing waste and overall construction costs. Pre-fabricated steel components, designed with precision, enable faster assembly and installation, leading to reduced labor costs and quicker project completion.

4. Compliance with Industry Standards

Steel structures must adhere to building codes such as AISC, IS, and Eurocodes. Proper design and detailing ensure compliance with these regulations, reducing structural risks and legal complications. Conserve Academy provides in-depth training on international standards to help professionals master industry best practices.

5. Enhancing Structural Aesthetics and Flexibility

Steel allows for innovative architectural designs, enabling the creation of complex structures such as curved facades, long-span bridges, and modern high-rises. Proper detailing ensures that these aesthetic elements are structurally sound and functional.

6. Improved Collaboration and Efficiency

Steel detailing serves as a communication bridge between architects, engineers, fabricators, and construction teams. Clear and accurate drawings enhance project coordination, reducing misinterpretations, delays, and rework.

7. Leveraging Technology for Better Accuracy

With advancements in Building Information Modeling (BIM) and automated detailing software, steel design has become more precise and efficient. Conserve Academy offers training in cutting-edge tools like Tekla, AutoCAD, and Revit, enabling professionals to work with 3D models, detect clashes, and improve overall project accuracy.

Conclusion

In conclusion, steel design and detailing are fundamental aspects of structural engineering that ensure the integrity, safety, and efficiency of construction projects. By incorporating precise design principles and detailed analysis, engineers can create structures that not only meet safety standards but also optimize resource use and minimize costs. Our Structural Detailing course in Chennai provides the necessary training to master these essential skills. As the construction industry continues to evolve, the importance of these practices cannot be overstated, especially with the growing emphasis on sustainability and innovation. Conserve Academy recognizes the significance of mastering these skills, as they are essential in shaping the future of structural engineering and contributing to the development of resilient and environmentally conscious infrastructure.

#steel design course in chennai#steel design course online in chennai#steel structural engineering courses in chennai#structural detailing course in chennai#structural steel detailing courses in chennai

0 notes

Text

MS Pipe Supplier in Agra at Wholesale Rates – Best Quality & Prices

✔ Premium-Grade Steel – Ensuring durability and corrosion resistance. ✔ Wholesale Pricing – Best rates for bulk and retail orders. ✔ Wide Product Range – Options include seamless, ERW, galvanized, and structural MS pipes. ✔ Timely Delivery – Fast shipping across Agra and nearby regions. ✔ Custom Sizes & Orders – Available in various dimensions and thicknesses.

Choosing a reputable supplier means cost-effective, durable, and high-performance MS pipes.

Types of MS Pipes Available in Agra

🔹 Seamless MS Pipes – Best for high-pressure applications like oil & gas pipelines. 🔹 ERW (Electric Resistance Welded) Pipes – Ideal for construction and engineering projects. 🔹 Galvanized MS Pipes – Rust-resistant, perfect for water supply and fencing. 🔹 Square & Rectangular MS Pipes – Used in fabrication, furniture, and industrial frameworks. 🔹 Heavy-Duty MS Pipes – Suitable for large-scale infrastructure projects.

Need custom sizes or bulk orders? Connect with top MS pipe suppliers in Agra today!

Top MS Pipe Suppliers in Agra

1. Local Wholesale Distributors

📍 Located in Agra’s industrial areas and steel markets. ✅ Best for bulk orders at competitive prices.

2. Manufacturer-Authorized Dealers

🔩 Available in Agra and nearby cities like Mathura and Firozabad. ✅ Best for custom orders and high-quality MS pipes.

3. Online MS Pipe Suppliers (IndiaMART, TradeIndia, IndustryBuying)

🛒 Order online with doorstep delivery. ✅ Best for quick price comparisons and small to medium orders.

Need recommendations for the best suppliers? Let us know your order quantity and requirements!

How to Get the Best Wholesale Rates on MS Pipes in Agra?

💡 Compare Prices from Multiple Suppliers – Check quotes before making a purchase. 💡 Buy in Bulk – Larger orders often come with discounts and better rates. 💡 Look for Seasonal Offers – Some suppliers provide special deals on bulk purchases. 💡 Ensure Quality Certifications – Check for ISI, ASTM, and BIS-approved pipes. 💡 Negotiate for Better Pricing – Many suppliers offer discounts for repeat customers.

Following these tips ensures cost savings and premium-quality MS pipes.

Why Choose a Trusted MS Pipe Supplier in Agra?

✅ Premium-Grade MS Pipes – Strong, corrosion-resistant, and durable. ✅ Wholesale Pricing – Best deals for construction and industrial projects. ✅ Variety of Options – Different sizes, thicknesses, and coatings available. ✅ Fast & Reliable Delivery – Ensuring timely supply across Agra.

A leading supplier ensures quality, reliability, and competitive pricing.

Conclusion

If you’re looking for an MS pipe supplier in Agra offering wholesale rates, focus on supplier reputation, pricing, and certifications. A trusted supplier ensures you get durable, high-strength MS pipes at cost-effective prices.

For bulk orders, supplier contacts, or pricing details, connect with the top MS pipe suppliers in Agra today!

#MSPipeSupplier#Agra#WholesaleMSPipes#ConstructionMaterials#IndustrialPipes#SeamlessPipes#GalvanizedPipes#Fabrication#ReliableSupplier#AffordableMSPipes

1 note

·

View note

Text

Buy Carbon Steel TIG Welding Wire - shop.castonelectrode.in

Selection of the appropriate materials create big differences while involving in welding activities. The reason for this is that the right material always leads to durability, quality, and efficiency. If you are looking for a top quality of Carbon Steel TIG Welding Wire offer, you must consider Shop.Castonelectrode.in as the go-to destination. Here, you will get variety of products tailored to meet both industrials and professional welding requirements. In simple words, the platform serves as a trustworthy hub for every welder belonging to diverse industries.

What is Carbon Steel TIG Welding Wire?

Carbon steel TIG (Tungsten Inert Gas) welding wire is a critical consumable used in TIG welding processes, known for its precision and high-quality results. TIG welding, often employed in industries requiring clean and aesthetically pleasing welds, involves using a non-consumable tungsten electrode to produce the weld. The carbon steel wire acts as a filler material, providing strength and structural integrity to the weld.

Carbon steel TIG welding wire offered by a reliable Carbon steel TIG welding wire site is ideal for welding carbon steels, which are widely used in construction, automotive, manufacturing, and other sectors. It offers excellent tensile strength, good weldability, and reliable performance, making it a preferred choice for demanding applications.

Why Choose Shop.Castonelectrode.in for TIG Welding Wire?

1. High-Quality Products At Shop.Castonelectrode.in, quality is a top priority. The carbon steel TIG welding wires available here are manufactured using advanced technology and adhere to strict quality standards. This ensures superior performance, consistent weld quality, and long-lasting durability.

2. Wide Range of Options Whether you're working on light fabrication projects or heavy-duty industrial applications, Shop.Castonelectrode.in offers a variety of wire grades and diameters to suit your specific needs. Here, the extensive inventory associated with Carbon Steel TIG Welding Wire sale allows you to find the perfect welding wire for any project.

3. Competitive Pricing Welding consumables can be expensive, especially for large-scale operations. Shop.Castonelectrode.in provides competitive Carbon Steel TIG Welding Wire price without compromising on quality, ensuring you get the best value for your investment.

4. Expert Support Navigating the world of welding materials can be challenging, especially for beginners. The platform offers expert customer support to help you choose the right products for your projects. Their knowledgeable team can guide you on wire selection, compatibility, and usage techniques.

5. Convenient Online Shopping Gone are the days of running from one store to another in search of the right welding supplies. The website of Shop Castron Electrode offers a seamless online shopping experience, with detailed product descriptions, easy navigation, and secure payment options. Plus, they deliver right to your doorstep, saving you time and effort.

Benefits of Using Carbon Steel TIG Welding Wire

Precision: Achieve clean and precise welds with minimal spatter.

Strength: Excellent tensile strength ensures durability and reliability.

Versatility: Suitable for a wide range of applications, including automotive repairs, structural work, and pipeline welding.

Ease of Use: Designed for smooth feeding and consistent performance, even in challenging conditions.

Final Thoughts

Investing in high-quality carbon steel TIG welding wire is essential for achieving superior welds and ensuring the success of your projects. Shop.Castonelectrode.in stands out as a reliable source, offering premium products, expert advice, and a user-friendly shopping experience. Whether you're a professional welder or a DIY enthusiast, you can trust them to provide the best welding consumables at competitive prices. For more details, explore https://shop.castonelectrode.in/product-category/tig-wires/stainless-steel-welding-wires/

0 notes

Text

Steel Buildings for Your Prefab Storage Business: A Home-Based Startup Guide

As the self-storage market continues to boom, you may wonder if you can have a piece of that success. If you’re interested, look no further than our prefabricated metal sheds.

Here at Armstrong Steel, we offer cost-effective and quick-to-build mini-storage metal building kits to help you break into this profitable industry. We are proud to be among the top fabricators of high-quality steel buildings that are customizable to every need. We can design our structures to fulfill security considerations, aesthetic requirements, unit mixes, and expansion capabilities, making them perfect as self-storage units.

In this guide, we explain why prefabricated steel buildings make the best metal sheds. We will also share the benefits of building self-storage units with steel so you can understand their value to your business.

The growing importance of self-storage businesses

Did you know that over one-fifth of Americans rent self-storage units due to a lack of space in their homes? The US self-storage industry is a booming market currently valued at $44.33 billion, and it’s projected to reach $50.01 billion by 2029. This growth is fueled by several factors, including increased urbanization, rising housing costs, evolving lifestyles, growing commercial storage needs, and a greater business awareness of storage benefits and costs.

Gen X and Millennials represent a significant portion of this customer base. Factors such as downsizing and minimalist living have further fueled the need for secure and reliable storage solutions.

Even a small storage business from home can make a difference in meeting that demand. If you’re interested in this industry, prefabricated metal sheds from Armstrong Steel can help you get started.

Why a steel building is best for a self-storage business

As a self-storage business, you want to assure your customers that their belongings are safe and secure. Let's explore how prefabricated steel buildings can protect their valuables and enhance your company's reputation.

Durable structures that can withstand harsh weather

At Armstrong Steel, we engineer steel sheds to your region’s specific building codes and loads. This allows us to deliver a structure that can withstand the environmental conditions in your area. You won’t have to worry about your storage units succumbing to earthquakes or hurricanes. And because they are very durable, high winds and heavy snowfall will be the least of your worries.

Fire resistance

It takes just one spark to ignite a fire in a storage facility that is primarily made of traditional materials like wood. You don't want to risk losing your business and your customers' belongings to a devastating fire. This is why steel is the better choice. Being non-combustible, steel is unlikely to ignite or cause a fire to spread. It will be easy to control the spread of fires in prefabricated metal sheds because the steel structure remains intact even in extreme heat, and you don’t have to worry about your facility burning down completely. This is particularly important in wildfire-prone areas.

Assemble and erect your new storage shed quickly.

Prefabricated steel sheds are ready to assemble and erect as soon they arrive at your site. It should take only a few days or weeks to complete your self-storage facility, assuming you have the rest of the construction materials (including the roofing and walls).

At Armstrong Steel, we provide custom building permits and detailed assembly drawings for your project. Plus, we take the guesswork out of assembling and erecting your shed by providing the anchor bolt patterns and a complete erection guide. All connections are already punched and ready to bolt. Moreover, we cut them to size and number them appropriately so you can follow the drawings effortlessly. All this can save you time and effort to assemble and erect prefabricated metal sheds.

Energy-efficient storage units

Steel buildings for storage have unique insulation requirements to maintain optimum temperatures and humidity inside. Our rigid-frame steel buildings support all insulation technologies to boost energy efficiency while reducing cooling and heating costs.

Create storage sheds that don’t look like a warehouse

If you’re building a storage shed on your residential property, you want it to look consistent with your home or garage’s exterior. At Armstrong Steel, we design prefabricated metal sheds to work with any exterior finish — including all roof and wall materials — so they don’t have to look too industrial.

Sheds of any size

We make steel buildings of any size, and this allows us to meet your exact length, width, or height requirements. No matter your situation, we can tailor the layout and framing to specific needs. Need more room? The clear-span layout minimizes or eliminates interior columns so customers can maximize the space inside. Plus, the modular framing simplifies future expansions, whether you decide to extend the shed crosswise or lengthwise.

How to order steel storage sheds from Armstrong Steel

Once you decide to build self-storage units with steel, don’t hesitate to connect with our building consultants here at Armstrong Steel for a quote. Our engineers can handle any custom design and deliver the most economical prefabricated metal sheds. You may also call us at 1-800-345-4610 to learn if you qualify for our direct buyer program.

Source: https://armstrongsteel.com/steel-buildings-for-your-prefab-storage-business-a-home-based-startup-guide/

0 notes

Text

Avail The Trusted Onsite Steel Fabrication & Services

Design and Planning