#Heavy Duty Panel Rack

Explore tagged Tumblr posts

Text

#rack manufacturers#pallet rack manufacturers#pallet rack wholesalers#rack suppliers#pallet rack#rack wholesalers#pallet rack suppliers#rack#storage rack manufacturers in delhi#storage rack in delhi#Heavy Duty Panel Rack#Heavy Duty Panel Rack Manufacturers in Delhi#Rack Manufacturers in Delhi#Panel Rack Manufacturers in Delhi#Mild Steel Heavy Duty Panel Racks Suppliers in India#Mild Steel Heavy Duty Panel Racks#Heavy Duty Rack#Warehouse FIFO Rack#Warehouse FIFO Rack in Delhi#Heavy Duty Beam Rack in Delhi#Heavy Duty Beam Rack#Material Handling Racks#Storage Systems#Industrial Racking System#Industrial Racking System MANUFACTURES in Delhi

0 notes

Text

Heavy Duty Rack: Heavy Duty Pallet Rack Manufacturers Delhi -

Mex Storage System Pvt Ltd is the best Heavy Duty Rack Manufacture industry in Delhi, Noida, and Gurgaon. Heavy Duty Rack is one of the best-selling products in this company. Its material is mild steel and it has 3 layers per rack. Per rack load capacity is 1000-1200 kg. Due to its versatility, it become the foremost choice for warehouse manager

For further information visit our site - www.mexstorage.in

#Heavy Duty Rack Manufacturers#Heavy Duty Pallet Rack#Cantilever Racks Suppliers#Heavy Duty Storage Rack#Heavy Duty Panel Rack#Light Duty Storage Rack#Mobile Compactor

0 notes

Text

#Heavy Duty Racks in Delhi#Cable Tray in Delhi#Display Rack in Delhi#Heavy Duty Racks Manufacturers in Delhi#Cable Tray Manufacturers in Delhi#Heavy Duty Racks Suppliers in Delhi#Display Rack Suppliers in Delhi#Heavy Duty Racks Exporters in Delhi#Display Rack Exporters in Delhi#Section Panel Rack in Delhi#Section Panel Rack Manufacturers in Delhi#Section Panel Rack Suppliers in Delhi#Section Panel Rack Exporters in Delhi

0 notes

Text

#mild steel heavy duty panel racks in delhi#mild steel ms mezzanine floor suppliers in delhi#heavy duty panel rack suppliers in delhi#heavy duty panel rack manufacturers in delhi#modular mezzanine floor in delhi#best heavy duty panel rack exporters in delhi#modular mezzanine floor suppliers in delhi#heavy duty panel rack in delhi

0 notes

Text

Heavy Duty Panel Rack Manufacturers in Noida

Looking for Heavy Duty Panel Rack Manufacturers in Noida? Discover Beeco Storage, a trusted manufacturer offering durable and customizable storage solutions

0 notes

Text

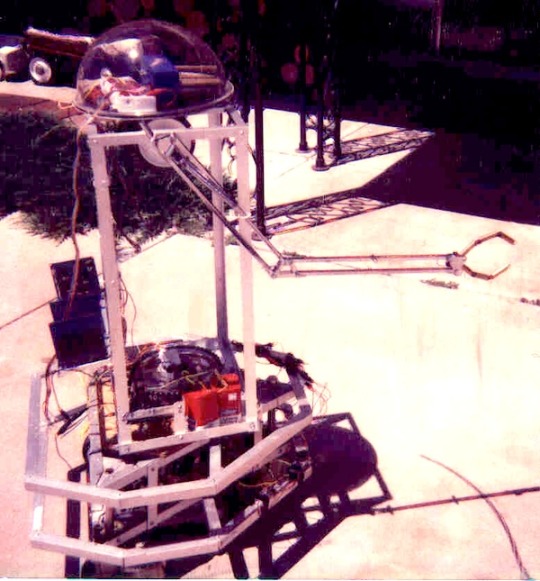

S.A.M by "Bill" (1978). "S.A.M (Short for "Sentient, Autonomous Mechanism" or "Smart Ass Machine", depending on his (and my) mood on a given day, was one of my first real robot projects, started in 1978 when I was around 15. His "brain" was a single-board Z-80 computer (the big square object in the middle of his "back" in this picture), with many bits of TTL I/O, a couple of serial ports, a bunch of counter-timers, and several D/A & A/D channels. The base was taken from the book "How to Build a Computer Controlled Robot" by Todd Loofbourrow - I had built the robot in the book, and had used my KIM-1 to control it. Later, I decided that just a little platform was kind of boring, so I added the upper torso shown here. The torso (mounted on a "lazy-susan" turntable bearing) is rotated by a heavy-duty gear motor driving a chain and sprocket assembly from a bicycle. The base is powered by two of the (apparently no longer available, which is sad) all-metal rubber-tired "motorized wheel" assemblies that Herbach & Rademan used to sell, with a large rubber-tired caster in front. The head platform (mounted on a small "lazy-susan" bearing) was originally rotated by a surplus gearbox from a Mattel "Big Trak" with some rubber-tired wheels mounted on the output shafts. This arrangement was later replaced by a small gear-head motor driving a large gear mounted to the center of the turntable. The device in the head with the tubes sticking out the front is a directional light tracking device. Each tube has a CDS photocell at the bottom, and is painted flat black inside. A comparator circuit tells the computer which direction the brightest light is coming from. This device could also tilt up and down with a small gear-head motor, to track light sources vertically. Most of the circuitry was installed on small plug-boards from Radio Shack, mounted in a card rack below the CPU card. This rack could be tipped back 90 degrees to facilitate easier access for testing. In addition to motor driver circuits, there was a "Sweet Talker" speech synthesizer board so he could talk. Power came from a large "gel-cell" marine battery (for powering trolling motors on boats), which was slung near the ground in the center of the base. Two 6V lantern batteries (later replaced by a 12V motorcycle battery) provided separate power for the electronics. All motors were isolated from the electronics via relays and/or opto-isolators. After these pictures were taken, a set of metal panels was installed on the "facets" of the base, with lever switches behind them for collision sensing. A Polaroid sonar range-finder was also added later. If you check out the other photos of S.A.M., you will notice an "arm" sticking out the front. This was a prototype made from an old swing-arm desk lamp and some "fingers" from a robot hand design using brass tubing, bicycle chain, and 1/16" steel cable to allow natural bending of each finger. It was later replaced with a much heavier duty aluminum framework arm operated by two 12VDC linear actuators." – My Home Robot Projects, by Bill.

25 notes

·

View notes

Text

Campsite Taco Bar (Makes 6 Servings)

We bring you this recipe from our panel, “Anime Foodies: Laid-Back Camp The Movie”.

As the movie opens, our characters are enjoying a group camping trip during their high school years on a lake shore near Mt. Fuji. For their supper, they create a taco bar that allows everyone to customize the final product to their tastes. While some components of the taco bar are familiar, the centerpiece – a whole chicken roasted in a Dutch oven over coals – is a showcase for their camping adventure.

Roasted Chicken:

1 Whole 5-6 Pound – Chicken

1 4 oz. Stick – Unsalted Butter

1 ½ TSP – Kosher Salt

1 TSP – Black Pepper

1 ½ TSP – Juniper Berries

4 Springs – Rosemary

1 – Orange

2 Small – Russet Potatoes

3 Medium – Carrots

Allow the butter to come to room temperature, mix in the salt and pepper, and set aside.

Cut 4 large slices off the orange and eat the rest.

Roll a large length of heavy-duty aluminum foil into a ring and place it into the bottom of your Dutch oven.

Line the base of the Dutch oven above the foil ring with two layers of heavy-duty aluminum foil and line the lid with another layer of foil.

Remove your chicken from its packaging and dry it off with some paper towels.

Working from the back of the bird, carefully reach in and separate the chicken skin from the meat without tearing it across as much of the bird as possible.

Once the skin is lose, take ½ of the seasoned butter and stuff it into the space you’ve made between the meat and skin of the chicken, spreading it evenly.

Stuff the cavity of the chicken with two slices of orange, 2 springs of rosemary, and ½ TSP of juniper berries and then truss the bird.

Peel the carrots, scrub the potatoes, chop them both into large chunks, and place the few of the smallest of your carrot pieces down in the middle of the Dutch oven.

Take some of the additional butter and smear it over the outside skin of the bird before tucking in the wings and setting it into the middle of the Dutch oven on top of the small portions of carrots.

Spread the remaining root vegetables along the outside of the chicken and dollop the additional butter over these.

Place the other two slices of orange, 2 springs of rosemary, and the remaining TSP of juniper berries over the top of the chicken and then place the lid of the Dutch oven on (making sure it fits tightly to prevent any ash getting in).

Prepare your coals and set 1/3 of them evenly underneath the Dutch oven and the other 2/3 evenly across the lid.

Allow to cook for 1 hour and 30 minutes and then carefully remove the lid, set it aside, and check the temperature with a thermometer (allow to cook for additional 10 minute intervals as required).

Once ready, place a piece of foil loosely over the chicken and allow to rest for 15 minutes before slicing or pulling for tacos as desired.

Optional/Notes:

If you’re not up to roasting an entire chicken with potatoes and carrots for your taco bar, feel free to pick up a rotisserie chicken from your favorite grocery store as a much simpler alternative.

If you have a small cooking rack or something else to keep the chicken from sitting right on the bottom of the Dutch oven, that will also work in lieu of the foil ring. This and the thinner pieces of carrot being under the bird is meant to mitigate the bottom of the chicken from burning while the rest of it roasts.

The juniper, orange, and rosemary mostly function to scent rather than flavor the chicken and can be omitted, if necessary.

When separating the chicken skin from the meat and adding the butter under the skin, emphasize the breast portion of the bird as this portion is most at risk of drying out during the cooking process.

No need to be fancy with your trussing. As long as it keeps the legs together and the back cavity of the bird closed, it will be fine.

For our coals, we were unable to get binchotan like they used in the show. We instead used a similar looking hardwood charcoal we found locally: Blue Hog – Hog Logs. We used 18 in total with 6 on the bottom of the Dutch oven and 12 on the top. These did not require a change, but if you’ll be using smaller lump charcoal or briquettes, check about halfway through the cooking process as additional coals need to be added.

Taco Meat:

1 ¼ Pound – Lean Ground Beef (Ground Turkey)

1 TBSP – Worcestershire Sauce

1 TBSP – Ketchup

½ TBSP – Sake

½ TBSP – Mirin

2 TSP – Chili Powder

½ TSP – Paprika

½ TSP – Garlic Powder

Heat a pan over medium heat and add the ground beef.

Brown the ground beef while breaking up any large chunks.

Add the remaining ingredients, stir to combine everything, and raise the heat to medium high.

Cook, stirring as necessary, until the liquid has almost entirely boiled away.

Optional/Notes:

Lean ground beef (93/7) is done to mitigate the need to drain any fat from the pan. You can use fattier ground beef, but you may need to add an additional step of draining the fat.

Ground turkey can also function as a good substitute and typically does not require fat to be drained.

A classic stateside taco seasoning mix can be used in place of the Japanese version presented here if desired.

Taco Shrimp:

1 ¼ Pound Medium, Peeled – Shrimp

1 TBSP – Worcestershire Sauce

1 TBSP – Ketchup

½ TBSP – Sake

½ TBSP – Mirin

1 TSP – Chili Powder

½ TSP – Paprika

½ TSP – Garlic Powder

Take all the ingredients, mix them together, and allow the shrimp to marinate for 30 minutes to an hour in the cooler.

When ready to cook, heat a pan over medium heat and add the shrimp with its marinade.

Cook for 4-6 minutes or until the shrimp are cooked through.

Salsa:

2 Medium – Red Tomatoes

½ – Green Bell Pepper (Any Mild Green Pepper)

¼ Medium – White Onion

1 – Lime

2 Pinches – Kosher Salt

Dice the tomatoes, green pepper, and onions and add them to a serving bowl.

Add the juice of the lime and the salt and stir.

Remaining Taco Bar Ingredients:

1 Head – Red Leaf Lettuce (Romaine Lettuce)

2 – Lime

2 Medium – Red Tomatoes

½ Medium – White Onion

8 oz. Block – Jack Cheese

1 – Avocado

2 Packs, Taco-Size – Flour Tortillas

1 Small Bottle – Tabasco Sauce (Any Preferred Hot Sauce)

Wash your lettuce, separate the leaves, and set aside.

Slice the limes into wedges, the onion into thin half-moons, and the tomatoes into slightly thicker half-moons.

Shred your block of cheese and keep it in the cooler until ready to serve.

Just prior to serving, split and pit the avocado, scoop the flesh out of each half in one piece, and slice into half-moons.

Heat a pan over medium heat and toast the tortillas one at a time for 30 seconds to a minute on each side.

As the tortillas finish, place them on a plate under a towel to keep warm until it is time to serve.

Optional/Notes:

Any long leaf lettuce will work fine.

You can skip the process of shredding your own cheese by buying a standard pack of pre-shredded cheese that you enjoy with tacos.

#anime#anime food#nos anime#anime foodies#camping#camping food#food#laid back camp#yuru camp#yurucamp#laid back camp the movie

7 notes

·

View notes

Text

Industrial Mezzanine Floor

Spanglesteel one of India's largest industrial rack manufacturers, provides high-quality storage solutions, including Slotted Angle Racks, Heavy Duty Racks, Section Panel Racks, and Industrial Mezzanine Floor. Designed for durability and efficiency, our racks optimize space utilization for warehouses, factories, and commercial facilities, ensuring superior organization and accessibility.

1 note

·

View note

Text

Cantilever Racking: The Perfect Storage Solution for Long & Heavy Items!

Storing long, bulky, and irregularly shaped items can be a challenge in traditional warehouse setups. Cantilever racking provides the ideal solution for pipes, lumber, steel bars, furniture, and other oversized materials that don't fit in standard racking systems.

This guide explores why cantilever racking is essential, its key advantages, and how to choose the right system for your storage needs.

1️⃣ What is Cantilever Racking?

Cantilever racking is a specialized storage system designed to hold long, heavy, and awkwardly shaped items. It features:

✔ Horizontal arms extending from a vertical frame, providing open storage. ✔ No front columns, ensuring easy loading and retrieval. ✔ Adjustable arms to accommodate various item sizes. ✔ Heavy-duty steel construction for maximum durability.

2️⃣ Key Benefits of Cantilever Racking

✅ Ideal for Long & Bulky Items

✔ Perfect for pipes, steel bars, wood planks, and furniture. ✔ Provides unrestricted horizontal space for easy storage. ✔ Eliminates the risk of damaged goods due to improper stacking.

✅ Maximizes Warehouse Space

✔ Utilizes vertical storage to save floor space. ✔ Can be installed against walls or as freestanding units. ✔ Available in single-sided or double-sided configurations for efficiency.

✅ Easy Access & Handling

✔ No front columns allow for quick loading and unloading. ✔ Compatible with forklifts, cranes, and manual handling. ✔ Reduces labor time and improves workflow efficiency.

✅ Heavy-Duty & Customizable

✔ Built to withstand heavy loads and high-impact environments. ✔ Arms can be adjusted or removed for flexible storage configurations. ✔ Suitable for indoor and outdoor storage.

3️⃣ Industries That Benefit from Cantilever Racking

Cantilever racking is widely used in:

✔ Lumber & Timber Yards – Storing wood planks, plywood sheets, and beams. ✔ Steel & Metal Fabrication – Organizing pipes, steel bars, and heavy metals. ✔ Furniture Warehouses – Keeping sofas, cabinets, and other large items safe. ✔ Construction & Building Materials – Storing drywall, roofing sheets, and concrete molds.

4️⃣ Types of Cantilever Racking

🟠 Light-Duty Cantilever Racking

✔ Suitable for lighter materials like plastic pipes and aluminum profiles. ✔ Commonly used in retail and small workshops.

🔵 Medium-Duty Cantilever Racking

✔ Ideal for moderate-weight materials like furniture and construction panels. ✔ Can be used in manufacturing and distribution centers.

��� Heavy-Duty Cantilever Racking

✔ Built for massive loads like steel beams, lumber, and concrete slabs. ✔ Designed for industrial warehouses and outdoor storage yards.

5️⃣ How to Choose the Right Cantilever Racking System

When selecting a cantilever racking system, consider:

✔ Weight Capacity – Ensure the system can handle your heaviest inventory. ✔ Arm Length & Strength – Choose arms that support various product sizes. ✔ Warehouse Space – Optimize vertical and horizontal layout for efficiency. ✔ Environmental Factors – Select galvanized steel for outdoor use.

Conclusion

A cantilever racking system is the ultimate storage solution for long and bulky items, offering easy access, durability, and space optimization. By investing in a high-quality cantilever rack, businesses can streamline storage, reduce damage, and improve operational efficiency.

Upgrade Your Storage with Cantilever Racking & Maximize Your Warehouse Potential Today! 🏗️📦

0 notes

Text

#Heavy Duty Panel Rack in Delhi#Mild Steel Heavy Duty Panel Racks in Delhi#Heavy Duty Panel Racks in Delhi#Heavy Duty Panel Rack Manufacturers in Delhi#Mild Steel Heavy Duty Panel Racks Manufacturers in Delhi#Heavy Duty Panel Racks Manufacturers in Delhi#Heavy Duty Panel Rack Suppliers in Delhi#Mild Steel Heavy Duty Panel Racks Suppliers in Delhi#Heavy Duty Panel Rack Wholesalers in Delhi#Mild Steel Heavy Duty Panel Racks Wholesalers in Delhi#rack manufacturers#rack wholesalers#pallet rack#rack suppliers#storage rack manufacturers in delhi#pallet rack suppliers

0 notes

Text

Modular Mezzanine Floor Manufacturers

Spanglesteel Products is a trusted manufacturer and supplier of high-quality storage solutions, including slotted angle racks, section panel racks, light and heavy-duty racks, and modular mezzanine floors. Our durable and customizable designs optimize space utilization, catering to diverse industrial and commercial needs with efficiency, strength, and long-lasting performance.

1 note

·

View note

Text

Roof Racks Car: The Ultimate Guide to Enhancing Your Vehicle with Galaxy Auto

When it comes to enhancing your vehicle's functionality and versatility, roof racks car accessories are indispensable. At Galaxy Auto, we recognize the diverse needs of automotive enthusiasts and offer a comprehensive range of products designed to elevate your driving experience. From roof racks to tri-fold tonneau covers, towing mirrors, and front bumpers, our selection ensures your vehicle is equipped for any adventure.

Roof Racks Car: Expand Your Vehicle's Horizons

Roof racks are essential for maximizing your vehicle's cargo capacity. Whether you're planning a family road trip, an outdoor adventure, or simply need extra space for luggage, Galaxy Auto's roof racks provide the perfect solution. Our collection includes versatile options designed to fit various vehicle models, ensuring durability and easy installation.

For instance, our Full-Size Contractors Rack is ideal for canopy and camper setups, offering robust support for heavy loads. Similarly, our Roof Ladder Racks cater to vans with or without rain gutters, providing flexibility for different vehicle types. Each roof rack is constructed with high-quality materials to withstand diverse weather conditions, ensuring longevity and reliability.

Tri-Fold Tonneau Covers: Secure and Stylish

Protecting your truck bed while maintaining a sleek appearance is made easy with our tri fold tonneau cover. Galaxy Auto offers both hard and soft tri-fold options, catering to various preferences and needs. Our hard tri-fold tonneau covers are constructed from industry-leading 18mm thick heavy-duty aluminum panels, providing exceptional durability and security. These covers are designed for easy installation without the need for drilling, allowing you to safeguard your cargo efficiently.

For those seeking a more flexible solution, our soft tri-fold tonneau covers are made from marine-grade double-sided 24oz vinyl with heavy-duty aluminum framing. This combination ensures a lightweight yet sturdy cover that offers protection against the elements while enhancing your vehicle's aesthetic appeal.

Towing Mirrors: Enhanced Visibility for Safer Towing

Towing requires enhanced visibility to ensure safety on the road. Galaxy Auto's towing mirrors are designed to provide a broader field of view, reducing blind spots and making lane changes or reversing with a trailer more manageable.

Our towing mirrors are compatible with various vehicle models and are crafted to withstand the rigors of frequent towing. With easy installation and adjustable features, these mirrors are a practical addition for anyone who regularly tows trailers, boats, or caravans.

Front Bumpers: Robust Protection and Aesthetic Appeal

Front bumpers serve as the first line of defense against collisions and obstacles. Beyond protection, they also contribute significantly to your vehicle's overall look. Galaxy Auto offers a range of front bumpers designed to provide robust protection while enhancing your vehicle's aesthetic appeal.

Constructed from high-quality materials, our front bumpers are engineered to absorb impact and prevent damage to critical components of your vehicle. Whether you're navigating off-road terrains or urban environments, these bumpers offer the resilience and style your vehicle demands.

Why Choose Galaxy Auto?

At Galaxy Auto, we are committed to providing automotive enthusiasts with top-quality parts and accessories. Our products are designed with precision, ensuring compatibility and longevity. With a focus on customer satisfaction, we offer comprehensive support and guidance to help you select the right accessories for your vehicle. Explore our extensive collection of roof racks car accessories, tri-fold tonneau covers, towing mirrors, front bumpers, and more to enhance your vehicle's functionality and style. Trust Galaxy Auto to equip your vehicle for any journey, ensuring performance, safety, and aesthetic appeal. Follow for more us on Instagram, Facebook, Youtube and linkedin.

0 notes

Text

#mild steel heavy duty panel racks in delhi#mild steel ms mezzanine floor suppliers in delhi#heavy duty panel rack manufacturers in delhi#heavy duty panel rack in delhi#modular mezzanine floor suppliers in delhi#modular mezzanine floor manufacturers in delhi#heavy duty panel rack suppliers in delhi#modular mezzanine floor in delhi#best heavy duty panel rack exporters in delhi#heavy duty panel rack exporters in delhi

0 notes

Link

$359.75 $158.29 SOGA 5 Tier 2 Column White Shoe Rack Organizer Sneaker Footwear Storage Stackable Stand Cabinet Portable Wardrobe with Cover - - ShoeBox94 https://nzdepot.co.nz/product/soga-5-tier-2-column-white-shoe-rack-organizer-sneaker-footwear-storage-stackable-stand-cabinet-portable-wardrobe-with-cover-shoebox94/?feed_id=194712&_unique_id=67a2643143a75 SOGA Shoe Rack Organizer is essential for every home, it keeps your shoes dust-free and neatly organized saving extra space while giving proper space to your shoes and footwear of its own!li> ul> Features:strong> DURABLE AND ECO-FRIENDLY MATERIAL: Constructed from heavy-duty and environmentally friendly PP plastic panels with iron wire connectors, the SOGA Shoe Organizer is durable, tough, and lightweight ensuring long-lasting performance.li> SPACE-SAVING DESIGN: The SOGA Shoe Organizer is designed to save space, requiring minimal floor space while offering maximum storage capacity.li> MULTIFUNCTIONAL STORAGE: Not only is it perfect for storing shoes, but it also provides versatile storage for […] #

0 notes

Text

MEX Storage Systems Pvt. Ltd., based in Noida, is a highly reputable manufacturer of top-quality Heavy Duty Storage Rack. Our range of products includes Heavy Duty Panel Racks, Storage Systems, Slotted Angle Racks, MS Pallet Racks, Drive In Racking Systems, Pallet Racking Systems, and more. Our dedicated team is committed to providing you with exceptional products that meet and exceed your expectations. With a focus on delivering real-time quality, we strive to be your trusted partner for all your storage needs.

#Heavy Duty Storage Rack#Heavy Duty Panel Racks#Storage Systems#Slotted Angle Racks#MS Pallet Racks#Drive In Racking Systems#Pallet Racking Systems

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Product Description INDIAN DECOR MICROWAVE STANDS INDIAN DECOR MICROWAVE STANDS Microwave Rack for Kitchen Organizer Microwave Oven Rack is thick and heavy duty, featuring high load-bearing capacity and matte painted texture. STRONG BEARING CAPACITY Due to the use of heavy carbon steel and iron, The Microwave Oven Rack has a strong load-bearing capacity. Seasonings, cutlery, dishes and even a microwave can be placed at on the top shelf! Material: this Microwave Oven Stand panel material is E1 standard particle wood; metal frame is high-quality powder coated steel. Two tiers design, protect the microwave and at the same top panel can hold some plates,cups,kettles etc. Great for organizing plates, cups, bottles, help to make your kitchen clean and tidy. SAVE YOU LOADS OF SPACE AND TIME- you can put your odds and ends together on the top of the platform more convenient; it’ll be much easier to access your jars, bottles, spoons and such. No need to worry about losing something here and there, since they are at the same place SUIT THE OVEN YOU PLACE BELOW- the 4 stand bases are individually sturdy, allowing you to balance the microwave counter shelf perfectly. Dimension: 22.5"Wx14"Hx22.2"D [ad_2]

0 notes