#Heat Pump Market Research

Explore tagged Tumblr posts

Text

#Heat Pump Market#Heat Pump Market Trends#Heat Pump Market Growth#Heat Pump Market Industry#Heat Pump Market Research

0 notes

Text

#Heat Pump Market Market#Heat Pump Market Market Share#Heat Pump Market Market Size#Heat Pump Market Market Research#Heat Pump Market Industry#What is Heat Pump Market?

0 notes

Text

"The man who has called climate change a “hoax” also can be expected to wreak havoc on federal agencies central to understanding, and combating, climate change. But plenty of climate action would be very difficult for a second Trump administration to unravel, and the 47th president won’t be able to stop the inevitable economy-wide shift from fossil fuels to renewables.

“This is bad for the climate, full stop,” said Gernot Wagner, a climate economist at the Columbia Business School. “That said, this will be yet another wall that never gets built. Fundamental market forces are at play.”

A core irony of climate change is that markets incentivized the wide-scale burning of fossil fuels beginning in the Industrial Revolution, creating the mess humanity is mired in, and now those markets are driving a renewables revolution that will help fix it. Coal, oil, and gas are commodities whose prices fluctuate. As natural resources that humans pull from the ground, there’s really no improving on them — engineers can’t engineer new versions of coal.

By contrast, solar panels, wind turbines, and appliances like induction stoves only get better — more efficient and cheaper — with time. Energy experts believe solar power, the price of which fell 90 percent between 2010 and 2020, will continue to proliferate across the landscape. (Last year, the United States added three times as much solar capacity as natural gas.) Heat pumps now outsell gas furnaces in the U.S., due in part to government incentives. Last year, Maine announced it had reached its goal of installing 100,000 heat pumps two years ahead of schedule, in part thanks to state rebates. So if the Trump administration cut off the funding for heat pumps that the IRA provides, states could pick up the slack.

Local utilities are also finding novel ways to use heat pumps. Over in Massachusetts, for example, the utility Eversource Energy is experimenting with “networked geothermal,” in which the homes within a given neighborhood tap into water pumped from underground. Heat pumps use that water to heat or cool a space, which is vastly more efficient than burning natural gas. Eversource and two dozen other utilities, representing about half of the country’s natural gas customers, have formed a coalition to deploy more networked geothermal systems.

Beyond being more efficient, green tech is simply cheaper to adopt. Consider Texas, which long ago divorced its electrical grid from the national grid so it could skirt federal regulation. The Lone Star State is the nation’s biggest oil and gas producer, but it gets 40 percent of its total energy from carbon-free sources. “Texas has the most solar and wind of any state, not because Republicans in Texas love renewables, but because it’s the cheapest form of electricity there,” said Zeke Hausfather, a research scientist at Berkeley Earth, a climate research nonprofit. The next top three states for producing wind power — Iowa, Oklahoma, and Kansas — are red, too.

State regulators are also pressuring utilities to slash emissions, further driving the adoption of wind and solar power. As part of California’s goal of decarbonizing its power by 2045, the state increased battery storage by 757 percent between 2019 and 2023. Even electric cars and electric school buses can provide backup power for the grid. That allows utilities to load up on bountiful solar energy during the day, then drain those batteries at night — essential for weaning off fossil fuel power plants. Trump could slap tariffs on imported solar panels and thereby increase their price, but that would likely boost domestic manufacturing of those panels, helping the fledgling photovoltaic manufacturing industry in red states like Georgia and Texas.

The irony of Biden’s signature climate bill is states that overwhelmingly support Trump are some of the largest recipients of its funding. That means tampering with the IRA could land a Trump administration in political peril even with Republican control of the Senate, if not Congress. In addition to providing incentives to households (last year alone, 3.4 million American families claimed more than $8 billion in tax credits for home energy improvements), the legislation has so far resulted in $150 billion of new investment in the green economy since it was passed in 2022, boosting the manufacturing of technologies like batteries and solar panels. According to Atlas Public Policy, a research group, that could eventually create 160,000 jobs. “Something like 66 percent of all of the spending in the IRA has gone to red states,” Hausfather said. “There certainly is a contingency in the Republican party now that’s going to support keeping some of those subsidies around.”

Before Biden’s climate legislation passed, much more progress was happening at a state and local level. New York, for instance, set a goal to reduce its greenhouse gas emissions from 1990 levels by 40 percent by 2030, and 85 percent by 2050. Colorado, too, is aiming to slash emissions by at least 90 percent by 2050. The automaker Stellantis has signed an agreement with the state of California promising to meet the state’s zero-emissions vehicle mandate even if a judicial or federal action overturns it. It then sells those same cars in other states.

“State governments are going to be the clearest counterbalance to the direction that Donald Trump will take the country on environmental policy,” said Thad Kousser, co-director of the Yankelovich Center for Social Science Research at the University of California, San Diego. “California and the states that ally with it are going to try to adhere to tighter standards if the Trump administration lowers national standards.”

[Note: One of the obscure but great things about how emissions regulations/markets work in the US is that automakers generally all follow California's emissions standards, and those standards are substantially higher than federal standards. Source]

Last week, 62 percent of Washington state voters soundly rejected a ballot initiative seeking to repeal a landmark law that raised funds to fight climate change. “Donald Trump’s going to learn something that our opponents in our initiative battle learned: Once people have a benefit, you can’t take it away,” Washington Governor Jay Inslee said in a press call Friday. “He is going to lose in his efforts to repeal the Inflation Reduction Act, because governors, mayors of both parties, are going to say, ‘This belongs to me, and you’re not going to get your grubby hands on it.’”

Even without federal funding, states regularly embark on their own large-scale projects to adapt to climate change. California voters, for instance, just overwhelmingly approved a $10 billion bond to fund water, climate, and wildfire prevention projects. “That will be an example,” said Saharnaz Mirzazad, executive director of the U.S. branch of ICLEI-Local Governments for Sustainability. “You can use that on a state level or local level to have [more of] these types of bonds. You can help build some infrastructure that is more resilient.”

Urban areas, too, have been major drivers of climate action: In 2021, 130 U.S. cities signed a U.N.-backed pledge to accelerate their decarbonization. “Having an unsupportive federal government, to say the least, will be not helpful,” said David Miller, managing director at the Centre for Urban Climate Policy and Economy at C40, a global network of mayors fighting climate change. “It doesn’t mean at all that climate action will stop. It won’t, and we’ve already seen that twice in recent U.S. history, when Republican administrations pulled out of international agreements. Cities step to the fore.”

And not in isolation, because mayors talk: Cities share information about how to write legislation, such as laws that reduce carbon emissions in buildings and ensure that new developments are connected to public transportation. They transform their food systems to grow more crops locally, providing jobs and reducing emissions associated with shipping produce from afar. “If anything,” Miller said, “having to push against an administration, like that we imagine is coming, will redouble the efforts to push at the local level.”

Federal funding — like how the U.S. Forest Service has been handing out $1.5 billion for planting trees in urban areas, made possible by the IRA — might dry up for many local projects, but city governments, community groups, and philanthropies will still be there. “You picture a web, and we’re taking scissors or a machete or something, and chopping one part of that web out,” said Elizabeth Sawin, the director of the Multisolving Institute, a Washington, D.C.-based nonprofit that promotes climate solutions. “There’s this resilience of having all these layers of partners.”

All told, climate progress has been unfolding on so many fronts for so many years — often without enough support from the federal government — that it will persist regardless of who occupies the White House. “This too shall pass, and hopefully we will be in a more favorable policy environment in four years,” Hausfather said. “In the meantime, we’ll have to keep trying to make clean energy cheap and hope that it wins on its merits.”"

-via Grist, November 11, 2024. A timely reminder.

#climate change#climate action#climate anxiety#climate hope#united states#us politics#donald trump#fuck trump#inflation reduction act#clean energy#solar power#wind power#renewables#good news#hope

2K notes

·

View notes

Link

0 notes

Text

Excerpt from this story from Canary Media:

Colorado just got a big boost to help slash planet-warming emissions from commercial buildings.

Last week, the U.S. Department of Energy (DOE) announced the state was selected to receive a $20 million grant to help implement its building performance standards — ambitious rules that limit the amount of carbon pollution big buildings can emit. Colorado adopted the policy, which applies to edifices 50,000 square feet or greater, last year.

The funding will be used to help buildings in marginalized communities, whose owners may be less able to afford deep carbon-cutting measures like insulation and heat pumps, meet the state’s building decarbonization targets.

“We’re really excited about this DOE award to ensure the success of Colorado’s building performance standard,” Dominique Gómez, deputy director of the Colorado Energy Office, told Canary Media.

The Colorado award was the largest among the 19 grants to state and local governments announced last week as part of a broader $1 billion Inflation Reduction Act effort to clean up the U.S. building stock. The vast majority of the new round of funding went to helping cities and states design or implement performance standards for buildings, a means of tackling emissions that’s taking root around the country. From New York City’s pioneering Local Law 97 to Seattle’s Building Emissions Performance Standards, these policies set emissions or energy-use intensity caps per square foot in large structures that become more stringent over time.

Building owners have flexibility in figuring out how to meet these standards, whether that’s switching to LED light bulbs, weatherizing, electrifying heating or all of the above. If they fall short, owners face hefty penalties that are designed to exceed retrofit costs, according to Paulina Torres, research manager at global real-estate services firm JLL.

Performance standards are sticks to the policy carrots incentivizing energy efficiency upgrades that, on their own, largely haven’t worked to reduce building sector emissions, said Marshall Duer-Balkind, policy director at the building decarbonization nonprofit Institute for Market Transformation (IMT).

Unlike building energy codes, which generally target new construction, performance standards tackle emissions from existing buildings — a massive source of climate pollution. When you include the electricity they consume, buildings are the largest source of carbon emissions in the country — more than transportation, agriculture, or industry (excluding its buildings), according to the DOE.

4 notes

·

View notes

Text

Zero Friction Coatings Market: Charting the Course for Enhanced Performance and Sustainable Solutions

The global zero friction coatings market size is estimated to reach USD 1,346.00 million by 2030 according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 5.6% from 2022 to 2030. Growth can be attributed to the fact that these coatings reduce friction and wear resulting in low fuel consumption and less heat generation. According to the European Automobile Manufacturers' Association, 79.1 million motor vehicles were produced across the globe in 2021 which was up by 1.3% as compared to 2020. Zero friction coatings can extend the time between component maintenance and replacement, especially for machine parts that are expensive to manufacture.

Zero Friction Coatings Market Report Highlights

In 2021, molybdenum disulfide emerged as the dominant type segment by contributing around 50% of the revenue share. This is attributed to its properties such as low coefficient of friction at high loads, electrical insulation, and wide temperature range

The automobile & transportation was the dominating end-use segment accounting for a revenue share of more than 35% in 2021 due to the rapid growth of the automotive industry across the globe

The energy end-use segment is anticipated to grow at a CAGR of 5.7% in terms of revenue by 2030, owing to the excessive wear on the drill stem assembly and the well casing during the drilling operations in the oil and gas sector

In Asia Pacific, the market is projected to witness the highest CAGR of 5.8% over the predicted years owing to the presence of car manufacturing industries in the countries such as Japan, South Korea, and China

For More Details or Sample Copy please visit link @: Zero Friction Coatings Market Report

Several applications in the automobile industry use wear-resistant plastic seals that require zero tolerance for failure and lifetime service confidence. Increasing demand for the product from the automotive industry across the globe for various applications including fuel pumps, automatic transmissions, oil pumps, braking systems, and others is expected to drive its demand over the forecast period.

Low friction coatings can be used in extreme environments comprising high pressure, temperatures, and vacuums. These coatings can provide improved service life and performance thereby eliminating the need for wet lubricants in environments that require chemicals, heat, or clean room conditions. The product containing molybdenum disulfide (MoS2) are suitable for reinforced plastics while those free from MoS2 are suitable for non-reinforced plastics.

Zero friction coatings are paint-like products containing submicron-sized particles of solid lubricants dispersed through resin blends and solvents. The product can be applied using conventional painting techniques such as dipping, spraying, or brushing. The thickness of the film has a considerable influence on the anti-corrosion properties, coefficient of friction, and service life of the product. Its thickness should be greater than the surface roughness of the mating surfaces.

ZeroFrictionCoatingsMarket #FrictionlessTechnology #CoatingInnovations #IndustrialEfficiency #ZeroFrictionSolutions #AdvancedMaterials #SurfaceCoatings #ManufacturingAdvancements #GlobalIndustryTrends #InnovativeCoatings #PerformanceOptimization #MechanicalSystems #SustainableTechnology #IndustrialApplications #FutureTech #InnovationInMaterials #EfficiencySolutions #ZeroFrictionMarket #TechnologyInnovation #EngineeringMaterials

#Zero Friction Coatings Market#Frictionless Technology#Coating Innovations#Industrial Efficiency#Zero Friction Solutions#Advanced Materials#Surface Coatings#Manufacturing Advancements#Global Industry Trends#Innovative Coatings#Performance Optimization#Mechanical Systems#Sustainable Technology#Industrial Applications#Future Tech#Innovation In Materials#Efficiency Solutions#Zero Friction Market#Technology Innovation#Engineering Materials

2 notes

·

View notes

Text

North America HVAC System Market Overview, Top Key Players, Market Growth Analysis by Forecast to 2030

The North America HVAC system market was valued at US$ 90,492.1 million in 2022 and is expected to reach US$ 2,02,793.85 million by 2030; it is estimated to grow at a CAGR of 10.6% from 2022 to 2030.

Growth in Government Regulatory Policies for Energy Saving and Conservation Fuel the North America HVAC System Market

📚 𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐒𝐚𝐦𝐩𝐥𝐞 𝐏𝐃𝐅 𝐂𝐨𝐩𝐲@ https://www.businessmarketinsights.com/sample/BMIRE00026926

Governments across the world are using a variety of strategies to encourage energy saving and conservation. They are including sizable line items for energy costs in their yearly operational budgets. In addition, they are saving a lot of money on energy costs incurred in public buildings and are exhibiting energy and environmental leadership by investing in energy efficiency.

📚𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭 𝐋𝐢𝐧𝐤 @ https://www.businessmarketinsights.com/reports/north-america-hvac-system-market

Other than the increase in the efficiency of both new and existing facilities, many governments are including energy efficiency standards in their decisions of product purchases. The main energy consumers in municipal level operations are often the water and wastewater treatment facilities. High-quality HVAC systems can be employed at water and wastewater facilities to decrease energy costs and greenhouse gas emissions. Through energy data management and evaluation, energy efficiency standards for public buildings, uptake of retrofit programs for already-existing public buildings, acquisition of energy-efficient appliances and equipment, and establishment of energy-efficient operations and maintenance procedures, state and local governments are promoting energy efficiency programs and policies for public facilities, equipment, and government operations.

𝐓𝐡𝐞 𝐋𝐢𝐬𝐭 𝐨𝐟 𝐂𝐨𝐦𝐩𝐚𝐧𝐢𝐞𝐬

Mitsubishi Electric Corp

Blue Star Ltd

Hitachi Ltd

Daikin Industries Ltd

Emerson Electric Co

Honeywell International Inc

LG Electric Inc

Carrier Global Corp

Johnson Controls Inca

Regulatory factors are significantly influencing the HVAC market. Stringent energy efficiency standards, such as those set by government agencies and building codes, are driving the development of more efficient HVAC systems. Regulations aimed at phasing down the use of high-GWP refrigerants are also reshaping the market landscape. The increasing focus on indoor air quality is leading to stricter regulations on ventilation and filtration requirements. Furthermore, policies promoting renewable energy integration are encouraging the adoption of heat pumps and other electric-powered HVAC systems.

𝐀𝐛𝐨𝐮𝐭 𝐔𝐬: Business Market Insights is a market research platform that provides subscription service for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductor; Aerospace & Defense; Automotive & Transportation; Energy & Power; Healthcare; Manufacturing & Construction; Food & Beverages; Chemicals & Materials; and Technology, Media, & Telecommunications

𝐀𝐮𝐭𝐡𝐨𝐫’𝐬 𝐁𝐢𝐨: 𝐀𝐤𝐚𝐬𝐡𝐚 𝐆𝐡𝐚𝐫𝐠𝐞 𝐒𝐞𝐧𝐢𝐨𝐫 𝐌𝐚𝐫𝐤𝐞𝐭 𝐑𝐞𝐬𝐞𝐚𝐫𝐜𝐡 𝐄𝐱𝐩𝐞𝐫𝐭

0 notes

Text

Top Forging Manufacturers in India: Innovation & Excellence

India has become a global hub for manufacturing across various industries, and forging is no exception. The country is home to a wide range of forging manufacturers that cater to both domestic and international markets. With a rich industrial heritage, skilled labor force, and an expanding manufacturing sector, India is rapidly gaining prominence in the global forging industry. In this article, we’ll explore the key aspects of forging manufacturers in India, their capabilities, and why they are gaining international recognition.

What is Forging? Forging is a manufacturing process where metal is shaped by applying compressive forces, usually through the use of a hammer or press. This process is widely used for creating strong, durable, and high-performance components that are used in various sectors such as automotive, aerospace, construction, agriculture, and oil and gas. The forging process involves heating the metal to high temperatures and shaping it under controlled conditions to ensure the final product has enhanced strength, reliability, and structural integrity.

Types of Forging There are several types of forging processes that manufacturers in India specialize in:

Open Die Forging: This is one of the oldest and most common forms of forging, where the metal is shaped between two flat dies. Open die forging is used to create large and heavy parts for industries such as aerospace and defense.

Closed Die Forging: In this process, metal is placed in a die that completely encloses the material. The shape of the finished product is more intricate and precise. Closed die forging is often used for automotive parts, such as gears, shafts, and pistons.

Ring Rolling: This is a specialized forging process used to create round parts like rings and discs. This technique is commonly used in industries like aerospace, automotive, and energy.

Upset Forging: This method involves increasing the diameter of a specific area of the material to create components like bolts, nuts, and fasteners used in engineering applications.

Forging Manufacturers in India: Capabilities and Services State-of-the-Art Technology Many forging manufacturers in India invest in advanced forging technologies such as hydraulic presses, automated forging lines, and CNC (Computer Numerical Control) machines. These technological advancements enable manufacturers to produce high-quality components with greater precision, faster lead times, and at competitive prices.

Versatility Across Industries India’s forging manufacturers serve a wide array of industries, each with its unique needs. These include:

Automotive Industry: India’s forging sector plays a vital role in supplying components like crankshafts, axles, suspension parts, and engine blocks for the automotive industry, both domestically and for export. Aerospace and Defense: Forging is essential in aerospace and defense applications where precision and strength are paramount. Manufacturers in India produce critical components like turbine blades, landing gear parts, and structural elements for aircraft. Construction and Infrastructure: Large-scale forgings such as beams, girders, and custom-designed parts are used in construction and infrastructure development. Energy and Oil & Gas: India’s forging manufacturers produce components that are used in power generation plants, oil rigs, and pipelines, including valves, flanges, and pumps. Customization and R&D Capabilities Leading forging manufacturers in India often provide customized solutions tailored to the specific needs of their clients. Whether it’s a unique material, shape, or size, manufacturers can work closely with clients to deliver precisely what is required. Additionally, many of these manufacturers invest in research and development (R&D) to innovate and stay ahead in terms of material strength, lightweight options, and cost efficiency.

Competitive Pricing and Quality India has established itself as a global leader in cost-effective manufacturing, and the forging sector is no exception. By leveraging low labor costs, efficient production processes, and economies of scale, Indian forging manufacturers are able to offer competitive pricing without compromising on quality. This combination of quality and cost-effectiveness has made India an attractive outsourcing destination for forging needs worldwide.

Export Potential India’s forging industry is increasingly looking to cater to global markets. As a result, many manufacturers have obtained international certifications such as ISO, AS9100, and TS16949, ensuring they meet global quality standards. Countries in North America, Europe, and the Middle East have become key export markets for Indian forging manufacturers, with demand growing steadily.

Challenges and Opportunities for Forging Manufacturers in India Challenges:

Rising Raw Material Costs: The cost of raw materials like steel and aluminum can fluctuate, impacting production costs. Manufacturers need to manage these price variations effectively. Skill Development: Although India has a large labor force, there is a constant need to train workers in advanced forging techniques and technologies to stay competitive in the global market. Opportunities:

Technological Advancements: The adoption of Industry 4.0 technologies, including automation, AI, and IoT, presents an opportunity for manufacturers to further improve efficiency and product quality. Sustainability Initiatives: Growing global emphasis on sustainability is encouraging manufacturers to develop eco-friendly practices and explore the use of recycled materials in forging. Expanding Markets: With global demand for high-quality forged products on the rise, Indian manufacturers have the opportunity to penetrate more markets and build long-term relationships with international clients. Conclusion Forging manufacturers in India are playing a crucial role in meeting the global demand for high-quality, durable, and precisely engineered components. With a strong focus on technology, quality control, and customization, Indian manufacturers are making their mark across various industries. As the country continues to invest in infrastructure, research, and skill development, India’s forging sector is poised for further growth and innovation, offering immense potential for both domestic and international customers.

0 notes

Text

Emerging Markets in Immersion Cooling: Opportunities and Challenges

Immersion Cooling Market Introduction 2022-2030

Immersion Cooling Market Growth was valued at approximately USD 164.5 million in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 22.5% during the forecast period.

An IT approach called immersion cooling, which entails immersing a big power distribution component in a thermally conductive dielectric fluid, is used to cool the component. Electronic servers and transformers are frequently cooled using this technique. The coolant, which is non-conductive and non-capacitive, completely submerges the components during the procedure, guaranteeing that the electronics are not at risk. In order to effectively transfer heat from the electrical components into the fluid, fans keep running and slowly circulate the oil over heat sinks. Conventional cooling elements including heat sinks, sheet metal, fans, shrouds, and interface materials are no longer required with this method. Low electrical conductivity and superior insulating qualities are essential for the coolant.

Request Sample Report of https://wemarketresearch.com/reports/request-free-sample-pdf/immersion-cooling-market/593

Market Dynamics:

Driver: Growth in Cryptocurrency Mining and Blockchain Adoption

The rise of cryptocurrency mining and blockchain adoption is fuelling the immersion cooling market. Mining generates significant heat, making efficient cooling essential. Immersion cooling improves energy efficiency, extends hardware lifespan, and enhances mining performance, driving renewed investment in the sector.

Restraint: Risk of Leakage

Leakage remains a key challenge in immersion cooling. While offering benefits like reduced water use and superior heat dissipation, systems—especially those using fluorocarbon-based coolants—are still prone to leaks, affecting reliability. Limited awareness and technical expertise further hinder market growth.

Opportunity: Rising Adoption of Low-Density Data Servers

The increasing use of low-density data servers presents an opportunity for immersion cooling. These servers enable higher hardware density, optimize space, and reduce energy consumption. As demand for data processing grows with IoT, AI, and blockchain, this synergy is set to shape future data centres.

Challenge: High Infrastructure Costs

High initial investment remains a barrier to adoption. Implementing immersion cooling requires costly components and facility modifications, making it challenging for enterprises with existing air-cooled infrastructure to transition without operational disruptions.

Market Growth and Trends

Rising Data Center Demand – Cloud computing, AI, and IoT are fueling the need for energy-efficient cooling solutions.

Energy Efficiency & Sustainability – Immersion cooling lowers power usage effectiveness (PUE) to 1.03, cutting costs and carbon footprints.

Crypto Mining Growth – Helps manage heat, extend hardware life, and reduce energy expenses.

HPC Adoption – Supports high-performance computing in AI, finance, and research by preventing overheating.

Dielectric Fluid Innovations – New biodegradable, non-toxic fluids enhance cooling efficiency.

Get Customized Report https://wemarketresearch.com/customization/immersion-cooling-market/593

Types of Immersion Cooling

Single-phase Immersion Cooling: In this system, hardware is submerged in a dielectric liquid that remains in its liquid form while absorbing heat. The heated fluid is then pumped to a heat exchanger for cooling before being recirculated.

Two-phase Immersion Cooling: This method utilizes a dielectric fluid with a lower boiling point, which turns into vapor when it absorbs heat. The vapor then condenses back into liquid form, releasing heat in the process.

Market Segments:

Based on Product

Single-phase

Two-phase

Based on Application

High-performance Computing

Edge Computing

Cryptocurrency Mining

Artificial Intelligence

Others

Based on Cooling Liquid

Mineral Oil

Fluorocarbon-based Fluids

Deionized Water

Others

Key Benefits for Stakeholders

Comprehensive Analysis: Covers market segments, trends, forecasts, and dynamics (2022–2030) to identify growth opportunities.

Market Drivers & Challenges: Highlights key factors influencing growth for informed decision-making.

Strategic Insights: Porter's five forces analysis aids in optimizing supply chain and profitability.

Segment Evaluation: Identifies high-potential segments and investment opportunities.

Regional Insights: Maps key countries based on revenue contribution and market potential.

Competitive Benchmarking: Assesses industry players' positioning for strategic advantage.

Holistic Overview: Provides a global and regional market perspective, key players, and growth strategies.

Top Leading Key Companies Profiled this report

Green revolution Cooling Inc.

Summer Technologies

Fujitsu Limited

Allied Control Ltd

Midas Green Technologies

Asperities

DCX–The Liquid Cooling Company

Isotope Technologies Ltd

Liquid Cool Solutions Inc.

and Exascale Inc.

Market Regional Analysis:

North America led the market in 2021, with Europe coming in second. Over the course of the forecast period, North America is anticipated to continue to lead the worldwide immersion cooling market in terms of revenue. The huge concentration of hyperscale data centers in the United States and Canada, which greatly boost the region's revenue, is what propels its strong position in the business. Interestingly, 40% of the world's hyperscale facilities are located in the United States alone.

Possibilities for the Future

Initial Investment Costs: Compared to more conventional cooling systems, immersion cooling may have a greater upfront cost.

Compatibility Issues: Some hardware parts need unique solutions or design changes because they are not all designed for immersion cooling.

Industry Adoption Barriers: Because of a lack of knowledge and uniformity, many companies are still reluctant to make the switch.

Commonly Asked Questions?

Q1. What is the immersion cooling market report's entire market value?

Q2. What time frame would the market report forecast?

Q3. How much will the immersion cooling market be worth in 2022?

Q4. In the immersion cooling market study, which base year is used?

Q5. Which leading businesses control the majority of the market for immersion cooling?

Conclusion

The immersion cooling market is set to revolutionize thermal management across various industries, from data centres to blockchain and AI. As organizations prioritize energy efficiency and sustainability, immersion cooling will play a critical role in shaping the future of cooling technology. Businesses looking to stay ahead in the digital era should consider investing in this innovative solution to reduce costs, improve performance, and contribute to a greener planet.

Get a Purchase of This Report https://wemarketresearch.com/purchase/immersion-cooling-market/593?license=single

About We Market Research:

WE MARKET RESEARCH is an established market analytics and research firm with a domain experience sprawling across different industries. We have been working on multi-county market studies right from our inception. Over the time, from our existence, we have gained laurels for our deep-rooted market studies and insightful analysis of different markets.

Our strategic market analysis and capability to comprehend deep cultural, conceptual and social aspects of various tangled markets has helped us make a mark for ourselves in the industry.

Contact Us:

Mr. Robbin Joseph Corporate Sales, USA We Market Research USA: +1-724-618-3925 Websites: https://wemarketresearch.com/ Email: [email protected]

0 notes

Text

Second Intelligent In-Line Vacuum Glue Potting Machine: a powerful tool to realize high quality and high efficiency gluing

In-line vacuum glue potting machine is a kind of efficient and precise equipment, which is mainly used for vacuum potting of products with glue under vacuum environment. Under the current background of industrial automation, more and more factories start to use vacuum glue potting machine to equip their production.

In front of the extensive market demand, Shenzhen Second Intelligent Equipment Co., Ltd (referred to as Second Intelligent) combines its own precision assembly technology advantages and industry development trend, developed and upgraded the in-line vacuum glue potting machine SEC-S400-ZL which is suitable for automotive electronics, capacitors, new energy motors, high-voltage packages, ignition coils, solenoid coils, motor stators and sensors, and other industries, which is a good solution to the problem of The industry commonly exists in the product of small seams, poor penetration and easy to produce bubbles when filling glue and other issues, and in the stability and performance of the product have a strong industry advantage.

01. Promote the continuous advancement of the vacuum potting machine

With the continuous progress of science and technology and the continuous development of various industries, the demand for gluing equipment grows, the application scenarios also tend to be more diversified. In the glue potting machine market, semi-automatic glue potting machine has been China's largest demand for products, but benefited from the downstream automation degree of enhancement.

Automatic glue potting machine market demand is also growing steadily. The market requirements for the gluing process is also more stringent, high precision, high efficiency, automation and even intelligence is still the direction of modern gluing equipment technology innovation.

Vacuum potting process can effectively improve product quality, production efficiency and automation level. Looking around the world, in-line vacuum glue potting machine is widely used, the market sales show a rapid growth trend. Second Intelligent, which has been ploughing into the fluid application industry for 19 years, has a keen grasp of the user's advanced needs.

Through careful research and judgement of the development trend of the glue filling industry, Second Intelligent believes that no matter from the perspective of market demand or technology, in-line vacuum glue potting machine has a wide range of application prospects.

For this reason, Second Intelligent upgraded the original offline vacuum glue potting machine to achieve the process of automatic entry of the product into the vacuum box, automatic sensing of the positioning of the fixture in place, automatic closing of the door of the vacuum box, automatic vacuum pumping, and automatic potting of the glue according to the gluing procedure, and automatic pressure relief after the completion of gluing, automatic opening of the door, and automatic flow of fixtures out of the process solution.

After the product is assembled in the front section, it can be automatically transported to the internal conveyor line of the vacuum dispenser for positioning through the front receiving table. The preparation unit needs to heat and stir the A/B glue, and defoam and prepare the material under the vacuum environment of -100KPA.

Second Intelligent in-line vacuum glue potting machine has obvious advantages of high performance, reliability and durability, streamlined design, able to adapt to a variety of specifications, and absolute advantages for products with complex internal structure, high bubble requirements, and slow glue penetration.

It adopts industrial control machine + Second Intelligent motion control card integrated with advanced algorithm and Second Intelligent self-developed glue filling software control, equipped with friendly operation software, easy to operate and improve production efficiency.

02.Committed to product and process optimisation

Second Intelligent In-line vacuum glue potting machine perfectly solves the modern user's demand for quality gluing. It is not a pile of technology, but a multi-dimensional integration based on user experience.

Second Intelligent always practices the concept of total quality development, starting from the actual needs of users, and constantly optimises and improves product design, raw material management, process improvement, etc., and constantly advances and polishes multi-dimensionally to practice the original intention. The launch of In-line vacuum glue filling machine products, experienced countless trial and error, invested a lot of time and resources, overcome the complexity of the production process,

devices and other technical problems, to a very high degree of craftsmanship for the user to bring the true meaning of the potting experience.

Thousands of hammers and refinements, keep improving. Second Intelligent not only adhere to the development of technological innovation of the two-component potting product line, but also to further explore the depth of the three-stage vacuum potting machine research and development, to provide equipment for the IGBT industry.

It provides equipment solutions for IGBT industry. In terms of function upgrading, Second Intelligent realizes real-time monitoring of the dynamics of the product to be filled to ensure the accuracy and quality of the filling, and achieves the filling process of vibration while filling, while accelerating the rapid penetration of glue and the discharge of air bubbles to effectively improve efficiency.

In terms of operation optimisation, Second Intelligent ensures the solidity and reliability of the in-line vacuum glue potting machine system through user-friendly operation software, which makes the operation more convenient and easy to start.

Outstanding performance, leading edge, can meet the needs of more areas of application.

In addition to the traditional 3C, semiconductor and other fields, Second Intelligent will further expand the in-line vacuum glue potting machine to automotive electronics, lithium batteries, hydrogen energy, biomedical, aerospace and other fields.

0 notes

Text

#Heat Pump Market Market#Heat Pump Market Market Share#Heat Pump Market Market Size#Heat Pump Market Market Research#Heat Pump Market Industry#What is Heat Pump Market?

0 notes

Text

What’s Driving Growth in the Global Heat Exchangers Market?

The Global Heat Exchangers Market is experiencing significant growth, with projections estimating it will reach USD 25.9 billion by 2030. This represents a robust compound annual growth rate (CAGR) of 5.6% from 2022 to 2030. But what is driving this growth? Let’s take a closer look at the key factors influencing the market dynamics.

Understanding Heat Exchangers and Their Importance

At its core, a heat exchanger is a device designed to transfer heat between two or more fluids. Heat exchangers are vital in various industries, from power plants and oil refineries to residential and commercial buildings. These devices operate on the principle of thermal conductivity and convective heat transfer, allowing one fluid to lose heat while the other absorbs it. Depending on the application, heat exchangers can be compact or non-compact and can come in various designs such as plate & frame, shell & tube, and air-cooled versions.

The market for heat exchangers is vast, as these devices are used in critical applications like power generation, HVAC systems, and chemical processing. The demand for more efficient, high-performance heat exchangers is accelerating due to rising industrial activities, urbanization, and increasing energy consumption worldwide.

For more in-depth insights into the Global Heat Exchangers Market, you can check out detailed market reports on Shingetsu Research.

Key Factors Driving Growth in the Heat Exchangers Market

1. Rising Demand in Construction and Industrial Sectors

One of the primary drivers of the Global Heat Exchangers Market is the boom in construction and industrial activities across both developed and emerging economies. As the global population grows, there is an increasing demand for energy-efficient buildings and factories. Heat exchangers are essential components of HVAC systems, which regulate temperature and air quality in residential and commercial buildings.

In particular, the construction of new infrastructure, including energy plants, chemical plants, and oil refineries, is a significant growth driver. Countries like China, India, and those in Southeast Asia are experiencing rapid industrial expansion, and as a result, they need more heat exchangers to handle the energy demands of these growing economies.

2. HVAC & Refrigeration Applications

Heat exchangers are critical to the efficiency of heating, ventilation, air conditioning, and refrigeration (HVACR) systems. As climate change intensifies, the need for reliable and efficient HVAC systems is rising, especially in regions with extreme weather conditions. The use of microchannel heat exchangers in large refrigerators and freezers is also increasing, primarily in supermarkets and warehouses, which rely on refrigeration.

The Global Heat Exchangers Market is benefiting from advancements in these applications. For example, companies like Gree, Haier, and Midea are implementing microchannel heat exchangers into heat pump water heaters, which are becoming increasingly popular in both residential and commercial settings.

3. Technological Advancements and Efficiency Improvements

Technological advancements in heat exchanger design have played a crucial role in driving the market forward. With increasing awareness about energy conservation, industries are replacing old, inefficient heat exchangers with more compact, high-efficiency models. This transition is particularly visible in sectors like power generation and petrochemicals, where large-scale operations demand highly efficient heat exchangers to minimize energy loss.

For example, shell & tube heat exchangers are commonly used in chemical plants and oil & gas industries because they can manage fluids at high temperatures and pressures. Similarly, plate & frame heat exchangers are valued for their ability to deliver high heat exchange efficiency with a small footprint.

4. Growing Industrialization in Emerging Markets

The rapid industrialization seen in countries such as Brazil, Russia, China, and India is another factor fueling the demand for heat exchangers. These nations have invested heavily in infrastructure projects, including power generation plants, petroleum refineries, and industrial complexes. As energy needs increase, there is a growing demand for heat exchangers that can effectively manage heat transfer and contribute to more energy-efficient operations.

In addition to this, the rise in urbanization is increasing the demand for district heating and cooling systems, which further amplifies the need for efficient heat exchangers.

5. Focus on Renewable Energy Projects

Renewable energy projects, such as wind and solar power plants, are also driving the growth of the Global Heat Exchangers Market. Heat exchangers are crucial components in these plants as they help manage heat generated during energy production processes. For example, wind power plants use heat exchangers to improve the efficiency of cooling systems in turbines, while solar thermal plants rely on heat exchangers to transfer thermal energy to storage systems.

Furthermore, large-scale projects like nuclear power plants and desalination plants also require advanced heat exchangers to ensure optimal performance and energy use. As these projects increase globally, so does the demand for high-quality, durable heat exchangers.

6. Regulatory Pressures and Environmental Concerns

Governments worldwide are implementing stricter regulations on energy efficiency and environmental impact. As a result, industries are being forced to adopt more energy-efficient solutions, such as advanced heat exchangers that reduce heat loss and improve overall system performance. This trend is particularly prominent in the power generation sector, where regulators are pushing for cleaner and more sustainable practices.

The push toward sustainability is not limited to power generation. Industries like oil & gas, food & beverage, and chemicals are also embracing energy-efficient technologies to comply with global environmental standards.

Segment Analysis of the Global Heat Exchangers Market

1. By Type

The Global Heat Exchangers Market is segmented into several types, with shell & tube heat exchangers expected to dominate by 2030. These exchangers are widely used in industries like chemical processing, petrochemicals, and power generation. On the other hand, plate & frame heat exchangers are becoming increasingly popular due to their compactness and high efficiency.

2. By Material

The market can also be segmented based on material. Stainless steel is expected to dominate due to its excellent corrosion resistance, high thermal conductivity, and lightweight properties. Stainless steel heat exchangers are widely used in a variety of industries, including oil & gas, food & beverage, and HVAC systems.

3. By End-User Industry

The demand for heat exchangers varies across different industries. The oil & gas sector is expected to register the highest growth, driven by the need for heat exchangers in upstream and downstream processing. The power generation and HVAC & refrigeration sectors also represent significant growth opportunities in the coming years.

Regional Insights

Geographically, the Asia Pacific region is expected to account for the largest share of the Global Heat Exchangers Market by 2030. Rapid industrialization, government spending on infrastructure, and increasing exploration activities in the oil & gas sector contribute to this growth. Europe and North America are also key players, with high demand for heat exchangers in established industries and the construction of new plants.

Conclusion

The Global Heat Exchangers Market is poised for substantial growth over the next decade. Key factors such as increased industrialization, technological advancements, and regulatory pressures are driving the demand for more efficient heat exchangers. As industries across the globe continue to prioritize energy efficiency and sustainability, heat exchangers will remain at the heart of many industrial operations, from power generation to HVAC systems.

The growth of this market presents significant opportunities for both established companies and newcomers. With continued innovations in heat exchanger technology and increasing demand in emerging markets, the future looks promising for this essential industry.

For detailed market analysis and insights, explore the Global Heat Exchangers Market report available at Shingetsu Research.

0 notes

Link

1 note

·

View note

Text

Excerpt from this New York Times story:

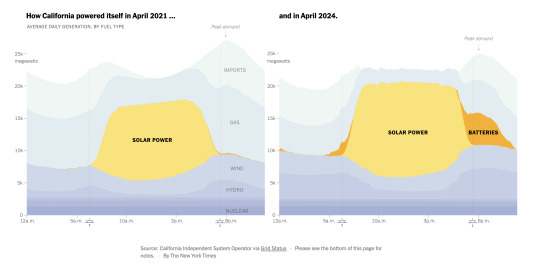

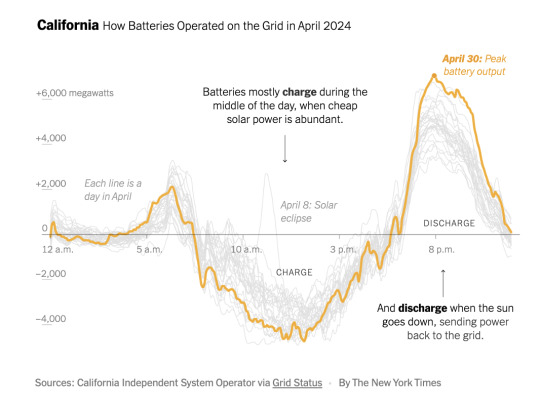

California draws more electricity from the sun than any other state. It also has a timing problem: Solar power is plentiful during the day but disappears by evening, just as people get home from work and electricity demand spikes. To fill the gap, power companies typically burn more fossil fuels like natural gas.

That’s now changing. Since 2020, California has installed more giant batteries than anywhere in the world apart from China. They can soak up excess solar power during the day and store it for use when it gets dark.

Those batteries play a pivotal role in California’s electric grid, partially replacing fossil fuels in the evening. Between 7 p.m. and 10 p.m. on April 30, for example, batteries supplied more than one-fifth of California’s electricity and, for a few minutes, pumped out 7,046 megawatts of electricity, akin to the output from seven large nuclear reactors.

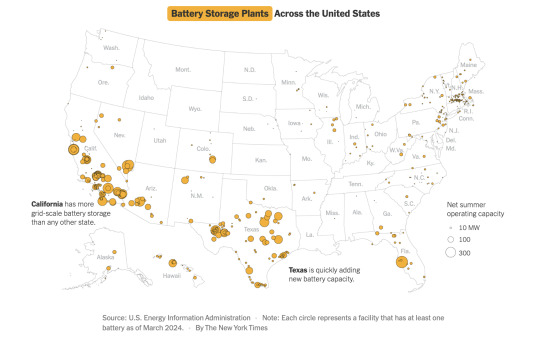

Across the country, power companies are increasingly using giant batteries the size of shipping containers to address renewable energy’s biggest weakness: the fact that the wind and sun aren’t always available.

“What’s happening in California is a glimpse of what could happen to other grids in the future,” said Helen Kou, head of U.S. power analysis at BloombergNEF, a research firm. “Batteries are quickly moving from these niche applications to shifting large amounts of renewable energy toward peak demand periods.”

Over the past three years, battery storage capacity on the nation’s grids has grown tenfold, to 16,000 megawatts. This year, it is expected to nearly double again, with the biggest growth in Texas, California and Arizona.

Most grid batteries use lithium-ion technology, similar to batteries in smartphones or electric cars. As the electric vehicle industry has expanded over the past decade, battery costs have fallen by 80 percent, making them competitive for large-scale power storage. Government mandates and subsidies have also spurred growth.

As batteries have proliferated, power companies are using them in novel ways, such as handling big swings in electricity generation from solar and wind farms, reducing congestion on transmission lines and helping to prevent blackouts during scorching heat waves.

In California, which has set ambitious goals for fighting climate change, policymakers hope grid batteries can help the state get 100 percent of its electricity from carbon-free sources by 2045. While the state remains heavily dependent on natural gas, a significant contributor to global warming, batteries are starting to eat into the market for fossil fuels. State regulators plan to nearly triple battery capacity by 2035.

2 notes

·

View notes

Text

Rooftop panels, EV chargers, and smart thermostats could chip in to boost power grid resilience

New Post has been published on https://sunalei.org/news/rooftop-panels-ev-chargers-and-smart-thermostats-could-chip-in-to-boost-power-grid-resilience/

Rooftop panels, EV chargers, and smart thermostats could chip in to boost power grid resilience

There’s a lot of untapped potential in our homes and vehicles that could be harnessed to reinforce local power grids and make them more resilient to unforeseen outages, a new study shows.

In response to a cyber attack or natural disaster, a backup network of decentralized devices — such as residential solar panels, batteries, electric vehicles, heat pumps, and water heaters — could restore electricity or relieve stress on the grid, MIT engineers say.

Such devices are “grid-edge” resources found close to the consumer rather than near central power plants, substations, or transmission lines. Grid-edge devices can independently generate, store, or tune their consumption of power. In their study, the research team shows how such devices could one day be called upon to either pump power into the grid, or rebalance it by dialing down or delaying their power use.

In a paper appearing this week in the Proceedings of the National Academy of Sciences, the engineers present a blueprint for how grid-edge devices could reinforce the power grid through a “local electricity market.” Owners of grid-edge devices could subscribe to a regional market and essentially loan out their device to be part of a microgrid or a local network of on-call energy resources.

In the event that the main power grid is compromised, an algorithm developed by the researchers would kick in for each local electricity market, to quickly determine which devices in the network are trustworthy. The algorithm would then identify the combination of trustworthy devices that would most effectively mitigate the power failure, by either pumping power into the grid or reducing the power they draw from it, by an amount that the algorithm would calculate and communicate to the relevant subscribers. The subscribers could then be compensated through the market, depending on their participation.

The team illustrated this new framework through a number of grid attack scenarios, in which they considered failures at different levels of a power grid, from various sources such as a cyber attack or a natural disaster. Applying their algorithm, they showed that various networks of grid-edge devices were able to dissolve the various attacks.

The results demonstrate that grid-edge devices such as rooftop solar panels, EV chargers, batteries, and smart thermostats (for HVAC devices or heat pumps) could be tapped to stabilize the power grid in the event of an attack.

“All these small devices can do their little bit in terms of adjusting their consumption,” says study co-author Anu Annaswamy, a research scientist in MIT’s Department of Mechanical Engineering. “If we can harness our smart dishwashers, rooftop panels, and EVs, and put our combined shoulders to the wheel, we can really have a resilient grid.”

The study’s MIT co-authors include lead author Vineet Nair and John Williams, along with collaborators from multiple institutions including the Indian Institute of Technology, the National Renewable Energy Laboratory, and elsewhere.

Power boost

The team’s study is an extension of their broader work in adaptive control theory and designing systems to automatically adapt to changing conditions. Annaswamy, who leads the Active-Adaptive Control Laboratory at MIT, explores ways to boost the reliability of renewable energy sources such as solar power.

“These renewables come with a strong temporal signature, in that we know for sure the sun will set every day, so the solar power will go away,” Annaswamy says. “How do you make up for the shortfall?”

The researchers found the answer could lie in the many grid-edge devices that consumers are increasingly installing in their own homes.

“There are lots of distributed energy resources that are coming up now, closer to the customer rather than near large power plants, and it’s mainly because of individual efforts to decarbonize,” Nair says. “So you have all this capability at the grid edge. Surely we should be able to put them to good use.”

While considering ways to deal with drops in energy from the normal operation of renewable sources, the team also began to look into other causes of power dips, such as from cyber attacks. They wondered, in these malicious instances, whether and how the same grid-edge devices could step in to stabilize the grid following an unforeseen, targeted attack.

Attack mode

In their new work, Annaswamy, Nair, and their colleagues developed a framework for incorporating grid-edge devices, and in particular, internet-of-things (IoT) devices, in a way that would support the larger grid in the event of an attack or disruption. IoT devices are physical objects that contain sensors and software that connect to the internet.

For their new framework, named EUREICA (Efficient, Ultra-REsilient, IoT-Coordinated Assets), the researchers start with the assumption that one day, most grid-edge devices will also be IoT devices, enabling rooftop panels, EV chargers, and smart thermostats to wirelessly connect to a larger network of similarly independent and distributed devices.

The team envisions that for a given region, such as a community of 1,000 homes, there exists a certain number of IoT devices that could potentially be enlisted in the region’s local network, or microgrid. Such a network would be managed by an operator, who would be able to communicate with operators of other nearby microgrids.

If the main power grid is compromised or attacked, operators would run the researchers’ decision-making algorithm to determine trustworthy devices within the network that can pitch in to help mitigate the attack.

The team tested the algorithm on a number of scenarios, such as a cyber attack in which all smart thermostats made by a certain manufacturer are hacked to raise their setpoints simultaneously to a degree that dramatically alters a region’s energy load and destabilizes the grid. The researchers also considered attacks and weather events that would shut off the transmission of energy at various levels and nodes throughout a power grid.

“In our attacks we consider between 5 and 40 percent of the power being lost. We assume some nodes are attacked, and some are still available and have some IoT resources, whether a battery with energy available or an EV or HVAC device that’s controllable,” Nair explains. “So, our algorithm decides which of those houses can step in to either provide extra power generation to inject into the grid or reduce their demand to meet the shortfall.”

In every scenario that they tested, the team found that the algorithm was able to successfully restabilize the grid and mitigate the attack or power failure. They acknowledge that to put in place such a network of grid-edge devices will require buy-in from customers, policymakers, and local officials, as well as innovations such as advanced power inverters that enable EVs to inject power back into the grid.

“This is just the first of many steps that have to happen in quick succession for this idea of local electricity markets to be implemented and expanded upon,” Annaswamy says. “But we believe it’s a good start.”

This work was supported, in part, by the U.S. Department of Energy and the MIT Energy Initiative.

0 notes

Text

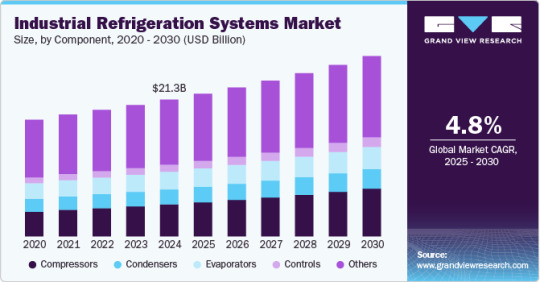

Industrial Refrigeration Systems Market To Reach USD 28.11 Billion By 2030

Industrial Refrigeration Systems Market Growth & Trends

The global Industrial Refrigeration Systems market size is expected to reach USD 28.11 billion by 2030, registering a CAGR of 4.8% from 2025 to 2030, according to a new report by Grand View Research, Inc. The demand for industrial refrigeration is increasing due to the fast-moving consumer goods and retail food which needs efficient storage for perishable edible items. Governments are taking initiatives to support and strengthen the cold chain infrastructure and shifting towards eco-friendly refrigeration systems.

Global warming and climate change have alarmed nations to take the necessary step to curb the crisis. As a result, industrial refrigeration system manufacturing companies have expressed concerns regarding the potential of global warming and ozone depletion of their refrigerants. As a result, companies are focusing on technologies to offer improved cost-effectiveness, lesser toxic refrigerants, lower energy consumption, and less toxic materials.

For instance, DanFoss, a prominent manufacturer of industrial refrigeration systems, introduced Cool selector 2 to help them design and optimize their air conditioning and refrigeration systems. System designers, engineers, and consultants can use the software to make optimum use of energy and HVACR systems. The benefits of using CO2 refrigeration systems are recognized worldwide as CO2 has a GWP (Global Warming Potential) of 1. The new update allows you to calculate components from the standpoint of an application for transcritical high-pressure side systems.

With the advancements in technology, industrial refrigeration systems have shown enhancement in their processes. Innovations have led to the manufacturing of smart and intelligent devices that monitor, set temperature, and notify the person as and when needed. The incorporation of Artificial Intelligence (AI) in the systems became a breakthrough in the market by enhancing productivity and lowering the operational cost for the organizations.

The industry growth in Asia Pacific is anticipated to observe the fastest growth during the forecast period. This expansion is attributed to the rapid growth prospects of cold-chain storage infrastructure in the countries such as Japan, India, and China. For instance, India is the second-largest fruit and vegetable producer, worldwide. The cold storage and handling the refrigeration of this huge vegetable and fruit produce is a challenging job thus fueling the market growth.

Request a free sample copy or view the report summary: https://www.grandviewresearch.com/industry-analysis/industrial-refrigeration-systems-market

Industrial Refrigeration Systems Market Report Highlights

The compressor segment is the largest growing component in the refrigeration system as they are used in commercial as well as industrial refrigeration, heat pumps, and air conditioning applications

Food and beverage applications accounted for the largest market share due to the growing disposable income and the rising population. It has augmented the demand for frozen and processed food products

The 500-1000kW capacity segment led the industrial refrigeration systems market as they helped extend the shelf life and reduce product wastage

Asia Pacific is the highest-growing region in the market due to the maximum number of fruits and vegetable producers and also a requirement for cold-chain storage

Industrial Refrigeration Systems Market Segmentation

Grand View Research has segmented the global industrial refrigeration systems market based on component, capacity, refrigerant, application, and region:

Industrial Refrigeration Systems Component Outlook (Revenue, USD Million, 2018 - 2030)

Compressors

Rotary Screw Compressors

Centrifugal Compressors

Reciprocating Compressors

Others

Condensers

Evaporators

Controls

Others

Industrial Refrigeration Systems Capacity Outlook (Revenue, USD Million, 2018 - 2030)

Less than 100 kW

100-500 kW

500kW-1000kW

1000kW-5000kW

More than 5000 kW

Industrial Refrigeration Systems Refrigerant Outlook (Revenue, USD Million, 2018 - 2030)

Ammonia

Carbon Dioxide

HFC

HCFC

Others

Industrial Refrigeration Systems Application Outlook (Revenue, USD Million, 2018 - 2030)

Refrigerated Warehouse

Food & Beverage

Chemical, Petrochemical, & Pharmaceutical

Refrigerated Transportation

Industrial Refrigeration Systems Regional Outlook (Revenue, USD Million, 2018 - 2030)

North America

U.S.

Canada

Europe

Germany

UK

France

Italy

Spain

Asia Pacific

China

Japan

India

South Korea

Australia

Latin America

Brazil

Mexico

Middle East and Africa

Saudi Arabia

South Africa

Key Industrial Refrigeration Systems Companies:

The following are the leading companies in the industrial refrigeration systems market. These companies collectively hold the largest market share and dictate industry trends.

Johnson Controls

Emerson Electric Co.

Danfoss

GEA Group Aktiengesellschaft

MAYEKAWA MFG Co. Ltd.

BITZER Kuhlmaschinenbau GmbH

DAIKIN Industries Ltd.

EVAPCO Inc.

Guntner GmbH & Co. KG

LU-VE S.p.A

Browse Full Report: https://www.grandviewresearch.com/industry-analysis/industrial-refrigeration-systems-market

#Industrial Refrigeration Systems Market#Industrial Refrigeration Systems Market Size#Industrial Refrigeration Systems Market Share

0 notes