#HDPE Bottle Market Factors

Explore tagged Tumblr posts

Text

HDPE Bottle Market Size Expected to Expand with Growing Demand for Sustainable Packaging

The global HDPE Bottle Market research report, published by Value Market Research, is designed to offer various market framework such as market size, portion, trends, growth path, value and factors that impact the current market dynamics over the forecast period 2024-2032. Most importantly, this report also provides the latest significant strategies adopted by major players along with their market share.

The report also covers detailed competitive landscape including company profiles of key players operating in the global market. The key players in the HDPE bottle market include All American Containers, Alpha Packaging, CL Smith, Fisherbrand, Graham Blowpack Pvt. ltd., Kaufman Container, Maynard & Harris Plastics, O.BERK COMPANY, LLC, Parker Plastics and Vivek Polymer India. An in-depth view of the competitive outlook includes future capacities, key mergers & acquisitions, financial overview, partnerships, collaborations, new product launches, new product developments and other developments with information in terms of H.Q.

Get more information on "Global HDPE Bottle Market Research Report" by requesting FREE Sample Copy at https://www.valuemarketresearch.com/contact/hdpe-bottle-market/download-sample

Market Dynamics

The market is majorly driven owing to rising demand from residential sector for domestic purpose. Owing to better durability, excellent impact resistance, and moisture barrier properties has widened its application in chemical, cosmetic, pharmaceutical and other end-use industries. Also, strict regulation imposed by government regarding plastic recycling is pushing the market growth uphill. However, volatile price of raw material (petroleum) is likely to impact the market growth.

This detailed market study is centered on the data obtained from multiple sources and is analyzed using numerous tools including porter’s five forces analysis, market attractiveness analysis and value chain analysis. These tools are employed to gain insights of the potential value of the market facilitating the business strategists with the latest growth opportunities. Additionally, these tools also provide a detailed analysis of each application/product segment in the global market of HDPE bottle.

Browse Global HDPE Bottle Market Research Report with detailed TOC at https://www.valuemarketresearch.com/report/hdpe-bottle-market

Market Segmentation

The broad HDPE bottle market has been sub-grouped into end- user and channel sales. The report studies these subsets with respect to the geographical segmentation. The strategists can gain a detailed insight and devise appropriate strategies to target specific market. This detail will lead to a focused approach leading to identification of better opportunities.

By Barrier Types

Low-barrier Bottles

High-barrier Bottles (Ethylene Vinyl Alcohol (EVOH) Layer Bottles, Polyamide (PA) Layer Bottles, Fluorinated Bottle)

By End-users

Homecare & Toiletries

Personal Care & Cosmetics

Pharmaceuticals

Specialty Chemicals

Chemicals (Lubricants & Petrochemicals, Industrial Chemicals, Agro Chemicals, Food & Beverages, Juices, Dairy Products, Others)

Regional Analysis

Furthermore, the report comprises of the geographical segmentation, which mainly focuses on current and forecast demand for HDPE bottle in North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. The report further focuses on demand for individual application segments in all the regions.

Purchase complete Global HDPE Bottle Market Research Report at https://www.valuemarketresearch.com/contact/hdpe-bottle-market/buy-now

About Us:

Value Market Research was established with the vision to ease decision making and empower the strategists by providing them with holistic market information.

We facilitate clients with syndicate research reports and customized research reports on 25+ industries with global as well as regional coverage.

Contact:

Value Market Research

UG-203, Gera Imperium Rise,

Wipro Circle Metro Station, Hinjawadi, Pune - 411057

Maharashtra, INDIA.

Tel: +1-888-294-1147

Email: [email protected]

Website: https://www.valuemarketresearch.com

#HDPE Bottle Market Size#HDPE Bottle Market Share#HDPE Bottle Market Trends#HDPE Bottle Market Growth#HDPE Bottle Market Forecast#HDPE Bottle Market Segments#HDPE Bottle Market Dynamics#HDPE Bottle Market Factors

0 notes

Text

Inverted Squeeze Bottle Market Insight | Outlook | Growth Analysis Report 2030

Inverted Squeeze Bottle Market Report has recently added by Value Market Research, this surveillance report establishing the facts based on current scenarios, historical records from 2022 to future forecast upto 2030. This report explicit data of various outlook such as market share, size, growth rates, and industry opportunities and offering an economical advantage for business success. It furnish the 360-degree overview of the competitive landscape of the global industries. Porter’s Five Forces Model analysis has been used to understand the industry’s structure, strength, weaknesses, opportunities, threats and challenges in front of the businesses. Moreover, the report also highlights a sudden occurrence of COVID 19 impact on Inverted Squeeze Bottle market to improve future capacities and other developments.

The research report also covers the comprehensive profiles of the key players in the market and an in-depth view of the competitive landscape worldwide. The major players in the inverted squeeze bottle market include Genesis Industries, Inc., IonWays, LLC, Midland Manufacturing Company, Inc., Kyoraku Co., Ltd., The Original Squeeze Company, Suzhou Innovation Packaging Materials Co.,Ltd, Illing Company, Inc., Kaufman Container Company etc. This section consists of a holistic view of the competitive landscape that includes various strategic developments such as key mergers & acquisitions, future capacities, partnerships, financial overviews, collaborations, new product developments, new product launches, and other developments.

Get more information on "Global Inverted Squeeze Bottle Market Research Report" by requesting FREE Sample Copy at https://www.valuemarketresearch.com/contact/inverted-squeeze-bottle-market/download-sample

Market Dynamics

The growing utilization of squeeze bottles in several industries such as food, drinks, healthcare, and personal care, pharmaceuticals, and so on is the major factor driving the inverted squeeze bottle market. The huge benefits are associated with squeeze bottles, such as it leaves less waste, Better control of food quantity, Easy fit into refrigerator door shelves, and require less space in the refrigerator, which might create high market demand in the coming years across the food industry. The rising popularity of fast food and Italian food like pasta and pizza among consumers across the globe is positively impacting the inverted squeeze bottle market’s growth. Moreover, the rapidly growing food and beverage industry across the globe is likely to create lucrative growth opportunities for key players of the Inverted squeeze bottle market in the coming years.

The research report covers Porter’s Five Forces Model, Market Attractiveness Analysis, and Value Chain analysis. These tools help to get a clear picture of the industry’s structure and evaluate the competition attractiveness at a global level. Additionally, these tools also give an inclusive assessment of each segment in the global market of inverted squeeze bottle. The growth and trends of inverted squeeze bottle industry provide a holistic approach to this study.

Browse Global Inverted Squeeze Bottle Market Research Report with detailed TOC at https://www.valuemarketresearch.com/report/inverted-squeeze-bottle-market

Market Segmentation

This section of the inverted squeeze bottle market report provides detailed data on the segments at country and regional level, thereby assisting the strategist in identifying the target demographics for the respective product or services with the upcoming opportunities.

By Closure Type

Flip Top Cap

Plug Orifice Cap

Screw Cap

Others

By Material Type

Polyethylene Terephthalate (Pet)

Polypropylene (Pp)

High Density Polyethylene (Hdpe)

Others

By Capacity

Up To 100 Ml

100 Ml To 250 Ml

250 Ml To 500 Ml

500 Ml To 750 Ml

Above 750 Ml

By End Use Industry

Food & Beverages

Automobile

Personal Care & Hygiene

Healthcare & Pharmaceutical

Chemicals

Others

Regional Analysis

This section covers the regional outlook, which accentuates current and future demand for the Inverted Squeeze Bottle market across North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. Further, the report focuses on demand, estimation, and forecast for individual application segments across all the prominent regions.

Purchase Complete Global Inverted Squeeze Bottle Market Research Report at https://www.valuemarketresearch.com/contact/inverted-squeeze-bottle-market/buy-now

About Us:

Value Market Research was established with the vision to ease decision making and empower the strategists by providing them with holistic market information.

We facilitate clients with syndicate research reports and customized research reports on 25+ industries with global as well as regional coverage.

Contact:

Value Market Research

401/402, TFM, Nagras Road, Aundh, Pune-7.

Maharashtra, INDIA.

Tel: +1-888-294-1147

Email: [email protected]

Website: https://www.valuemarketresearch.com

#Inverted Squeeze Bottle Market#Inverted Squeeze Bottle Market Report#Inverted Squeeze Bottle Industry#Inverted Squeeze Bottle Industry Report

2 notes

·

View notes

Text

High Density Polyethylene (HDPE) Prices Trend | Pricing | News | Database | Chart

High-Density Polyethylene (HDPE) is one of the most widely used thermoplastic polymers, prized for its strength, durability, and versatility. It finds applications in a wide range of industries, from packaging to construction, automotive to consumer goods. As a key polymer in global markets, HDPE prices are subject to fluctuation, influenced by a variety of factors such as raw material costs, production capacities, supply and demand dynamics, and geopolitical events. Over the years, HDPE pricing has seen considerable volatility, which can impact production costs, profitability, and the final pricing of goods across sectors. The price trends of HDPE are of particular interest to manufacturers, suppliers, and buyers looking to optimize costs and make informed purchasing decisions.

One of the primary factors driving the prices of HDPE is the cost of its raw material: ethylene. Ethylene, which is primarily derived from natural gas or petroleum, is the building block for HDPE production. As such, fluctuations in global oil prices or changes in the availability of natural gas can significantly affect the cost of producing HDPE. In periods when crude oil prices rise due to geopolitical tensions, supply disruptions, or changes in global demand, the price of ethylene also increases, which, in turn, raises the price of HDPE. Conversely, when crude oil prices decrease, manufacturers may see lower HDPE production costs, leading to more favorable pricing in the market.

Get Real Time Prices for High-Density Polyethylene (HDPE) : https://www.chemanalyst.com/Pricing-data/hdpe-7

Another factor influencing HDPE prices is the global supply and demand balance. Demand for HDPE is strong in many sectors, including packaging, construction, agriculture, and automotive, as its chemical properties make it resistant to moisture, chemicals, and impact. It is used in a wide array of products, such as plastic bottles, pipes, and containers, as well as plastic films and liners. Any fluctuations in demand from these key industries can lead to price changes. For example, during periods of increased consumer demand for packaging or construction materials, the demand for HDPE can outstrip supply, leading to price hikes. Conversely, during periods of slower economic growth or reduced demand from key markets, prices may stabilize or fall.

The production capacity of HDPE manufacturers also plays a key role in determining price fluctuations. Overcapacity in the production of HDPE can lead to lower prices, as manufacturers compete to sell their products. However, when production is limited or reduced due to maintenance, plant closures, or capacity restrictions, the reduced supply of HDPE can cause prices to rise. In addition, factors such as the availability of feedstock, transportation costs, and infrastructure limitations can also influence the production costs associated with HDPE, thus affecting overall pricing trends.

Geopolitical factors and trade policies can further impact HDPE pricing, as these can affect the availability of raw materials, the cost of production, and the price of shipping. Trade tariffs and sanctions, for example, can increase the cost of importing or exporting HDPE, leading to higher prices in certain regions. Additionally, political instability in key HDPE-producing regions can disrupt supply chains, resulting in price hikes due to supply shortages. On the other hand, trade agreements and favorable policies may help stabilize prices by improving access to resources and reducing trade barriers.

Regional variations in HDPE prices are another important consideration. While the global price of HDPE can be influenced by many of the aforementioned factors, local market conditions can cause price differences in different regions. For example, regions with higher production capacities may see lower prices due to a more abundant supply, while regions with limited access to raw materials or production facilities may experience higher costs. The cost of labor, energy, and logistics in different regions also plays a role in determining local pricing trends. These regional disparities highlight the importance of keeping track of both global and local market developments when assessing the price of HDPE.

The rising demand for sustainable and eco-friendly materials has also impacted the pricing of HDPE in recent years. As environmental regulations tighten and consumer preferences shift toward more sustainable products, the cost of recycling HDPE and producing eco-friendly alternatives can drive prices up. The demand for recycled HDPE (rHDPE), in particular, has grown, as it is seen as an environmentally responsible alternative to virgin HDPE. However, the cost of processing and recycling HDPE can be higher, which can result in price increases for rHDPE products.

In addition to these fundamental factors, market speculation and trading in commodity markets can also contribute to short-term price fluctuations. Investors and speculators who trade HDPE futures contracts may drive prices higher or lower based on anticipated supply and demand conditions, geopolitical events, or broader economic trends. While these price swings are typically short-term in nature, they can still have a significant impact on the day-to-day pricing of HDPE in global markets.

For businesses that rely on HDPE as a key material in their production processes, staying informed about price trends is essential for making informed purchasing decisions. By closely monitoring market developments, raw material prices, and production capacities, companies can better anticipate price movements and adjust their purchasing strategies accordingly. Strategic sourcing, long-term contracts, and hedging strategies can all help mitigate the impact of price fluctuations and secure stable pricing for HDPE.

In conclusion, the prices of High-Density Polyethylene are influenced by a complex interplay of factors, including raw material costs, production capacities, supply and demand dynamics, geopolitical events, and regional market conditions. As a vital material used in a variety of industries, HDPE pricing can experience significant volatility, which affects the cost structure of many products. Understanding the factors that drive HDPE prices is crucial for businesses and consumers looking to navigate the ever-changing landscape of this essential polymer.

Welcome to ChemAnalyst App: https://www.chemanalyst.com/ChemAnalyst/ChemAnalystApp

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#HDPE Price#HDPE Prices#HDPE Pricing#High Density Polyethylene Price Monitor#High Density Polyethylene Price

0 notes

Text

High Density Polyethylene (HDPE) Bottles Market : Technology Advancements, Industry Insights, Trends And Forecast 2033

The high density polyethylene (hdpe) bottles global market report 2024 from The Business Research Company provides comprehensive market statistics, including global market size, regional shares, competitor market share, detailed segments, trends, and opportunities. This report offers an in-depth analysis of current and future industry scenarios, delivering a complete perspective for thriving in the industrial automation software market.

High Density Polyethylene (HDPE) Bottles Market, 2024 report by The Business Research Company offers comprehensive insights into the current state of the market and highlights future growth opportunities.

Market Size -

The high density polyethylene (HDPE) bottle market size has grown steadily in recent years. It will grow from $51.96 billion in 2023 to $54.37 billion in 2024 at a compound annual growth rate (CAGR) of 4.6%. The growth in the historic period can be attributed to advancements in plastic manufacturing, expansion of fast-moving consumer goods, economic factors driving cost efficiency, demand for pharmaceuticals and personal care products, globalization, and supply chain optimization.

The high density polyethylene (HDPE) bottle market size is expected to see steady growth in the next few years. It will grow to $65.53 billion in 2028 at a compound annual growth rate (CAGR) of 4.8%. The growth in the forecast period can be attributed to a focus on sustainability, innovations in recycling processes, a shift towards lightweight packaging, e-commerce growth, urbanization, and changing lifestyles. Major trends in the forecast period include regulatory support for safe packaging, adoption of smart packaging solutions, customization and personalization, shift towards lightweight packaging, and expansion of recycled content.

Order your report now for swift delivery @

The Business Research Company's reports encompass a wide range of information, including:

1. Market Size (Historic and Forecast): Analysis of the market's historical performance and projections for future growth.

2. Drivers: Examination of the key factors propelling market growth.

3. Trends: Identification of emerging trends and patterns shaping the market landscape.

4. Key Segments: Breakdown of the market into its primary segments and their respective performance.

5. Focus Regions and Geographies: Insight into the most critical regions and geographical areas influencing the market.

6. Macro Economic Factors: Assessment of broader economic elements impacting the market.

Market Drivers -

The increasing pharmaceutical and healthcare industries are expected to propel the growth of the high density polyethylene (HDPE) bottle market going forward. The pharmaceutical and healthcare industry encompasses the development, production, and distribution of drugs, medical devices, and services aimed at improving health and treating diseases. The increasing demand for medications, medical devices, and health services, driven by an aging population and rising chronic diseases, is fueling the growth of the pharmaceutical and healthcare industries. High-density polyethylene bottles are required in the pharmaceutical and healthcare industries due to their excellent chemical resistance, durability, and ability to maintain product integrity and safety for various medications and healthcare products. For instance, in December 2022, according to a report published by Statistics Canada, a Canada-based government agency, the personal and household goods subsector saw sales increase by 2.8% for the third consecutive month in October 2022, amounting to $11.6 billion in total sales. Leading this growth was the pharmaceuticals and pharmacy supplies industry, which experienced a 3.9% increase, reaching $6.4 billion, marking its highest level since January 2022. Therefore, the increasing pharmaceutical and healthcare industries are driving the growth of the high density polyethylene (HDPE) bottle market.

Market Trends -

Major companies operating in the high density polyethylene (HDPE) bottle market are focusing on developing technologically advanced solutions, such as carbon-optimized prototype solutions, to reduce waste, conserve resources, and decrease the environmental impact associated with plastic production. A carbon-optimized prototype solution aims to minimize carbon emissions throughout its lifecycle, from production to end-use, by integrating efficient design, sustainable materials, and renewable energy sources. For instance, in December 2022, Alpla Group, an Austria-based manufacturer of plastic packaging, launched the recycled HDPE bottle for beauty product brands. The Canupak beauty care packaging by Alpla highlights its commitment to global sustainability by significantly reducing emissions and carbon footprints. These bottles, made from recycled HDPE, boast approximately 71% less carbon consumption compared to similar packaging, ensuring complete recyclability of both bottle and cap.

The high density polyethylene (HDPE) bottles market covered in this report is segmented –

1) By Cap Type: Screw Closures, Snap Closures, Push-Pull Closures, Disc Top Closures, Spray Closures, Dispensers, Dropper

2) By Bottle Capacity: Less Than 30 Ml, 31 Ml – 100 Ml, 101 Ml – 500 Ml, 501 Ml – 1Lt, Above 1Lt

3) By Visibility: Translucent, Opaque

4) By Manufacturing Process: Gas Phase Process, Slurry Process, Solution Process

5) By End User: Food And Beverages, Pharmaceutical, Chemical, Homecare And Toiletries, Other End Users

Get an inside scoop of the high density polyethylene (hdpe) bottles market, Request now for Sample Report @

Regional Insights -

North America was the largest region in the high density polyethylene (HDPE) bottle market in 2023. Asia-Pacific is expected to be the fastest-growing region in the forecast period. The regions covered in the high density polyethylene (hdpe) bottles market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

Key Companies -

Major companies operating in the high density polyethylene (HDPE) bottles market are Indorama Ventures Public Co. Ltd., Nampac Limited, Amcor Plc, Berry Global Inc., Silgan Holding Inc., ALPLA Group, Berlin Packaging, Plastipak Holdings Inc., Gerreshemier AG, RPC Group Plc, Graham Packaging Company LP, O.Berk Company LLC, Parker Plastics Inc., MJS Packaging, Kaufman Container Corporate, Canyon Plastics Inc., Werner And Mertz GmbH, Meredith-Springfield Associates Inc., JSK Industries Pvt. Ltd., Green Bay Plastics Inc., Mai animal health, APEX Plastics, Teknobyte India Pvt. Ltd., Sangam Plastic Industries Pvt. Ltd., Containers Plus

Table of Contents

1. Executive Summary

2. High Density Polyethylene (HDPE) Bottles Market Report Structure

3. High Density Polyethylene (HDPE) Bottles Market Trends And Strategies

4. High Density Polyethylene (HDPE) Bottles Market – Macro Economic Scenario

5. High Density Polyethylene (HDPE) Bottles Market Size And Growth

…..

27. High Density Polyethylene (HDPE) Bottles Market Competitor Landscape And Company Profiles

28. Key Mergers And Acquisitions

29. Future Outlook and Potential Analysis

30. Appendix

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Pharmaceutical Packaging Market Challenges, Strategies And Forecast Report 2024 - 2030

The global pharmaceutical packaging market size was valued at USD 139.37 billion in 2023 and is expected to grow a compound annual growth rate (CAGR) of 9.7% from 2024 to 2030.

The enormous growth of the pharmaceutical sector is one of the primary growth factors for the pharmaceutical packaging sector. The pharmaceutical business has been expanding quickly in recent years due to scientific and technological advancements, and this trend is predicted to continue over the projection period, particularly in developing nations like China, India, Saudi Arabia, and Brazil.

The U.S. accounted for the largest pharmaceutical market worldwide. Large healthcare system, high per capita income, and large investments in drug development in the country are some of the key factors driving the U.S. market. Furthermore, growing importance of generic drugs and access to better healthcare services are anticipated to provide lucrative opportunities for pharmaceutical packaging in the coming years. The 21st Century Cures Act (Cures Act) was signed on December 13, 2016, in the U.S. and is designed to accelerate medical product development. The law is expected to drive new innovations in product developments in pharmaceutical industry. This is expected to drive the demand for pharmaceutical packaging in U.S.

Gather more insights about the market drivers, restrains and growth of the Pharmaceutical Packaging Market

Pharmaceutical Packaging Market Report Highlights

• Asia Pacific is expected to register the fastest CAGR of more than 12% from 2024 to 2030. This growth is due to the rapidly expanding pharmaceutical market, particularly in China & India, and rising cases of various diseases, such as cancer and heart problems

• In terms of material, the glass segment is projected to ascend at the highest CAGR of 10.3% over the forecast period. Strong chemical resistance to various medicinal products and the ability to withstand heating treatment during the sterilization process is expected to expand the penetration of glass packaging

• Pharma manufacturing is the key end-use segment that accounted for the highest share of 49.9% in 2023 and is expected to witness strong growth from 2024 to 2030. This is owing to the increasing demand for medicines.

• In April 2022, Amcor has launched new and more sustainable High Shield laminates to its pharmaceutical packaging portfolio. This is low carbon, recycle-ready, and moisture resistant packaging solution, thus end use companies’ recyclability agendas

Browse through Grand View Research's Plastics, Polymers & Resins Industry Research Reports.

• The global flexible paper packaging market size was estimated at USD 50.35 billion in 2023 and is projected to grow at a CAGR of 4.2% from 2024 to 2030.

• The global seaweed packaging market size was valued at USD 699.23 million in 2023 and is expected to expand at a CAGR of 6.6% from 2024 to 2030.

Pharmaceutical Packaging Market Segmentation

Grand View Research has segmented the pharmaceutical packaging market on the basis of on material, product, drug delivery mode, end-use, and region:

Pharmaceutical Packaging Material Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

• Plastics & Polymers

o Polyvinyl Chloride (PVC)

o Polypropylene (PP)

o Homo

o Random

o Polyethylene Terephthalate (PET)

o Polyethylene (PE)

o HDPE

o LDPE

o LLDPE

o Polystyrene (PS)

o Others

• Paper & Paperboard

• Glass

• Aluminium Foil

• Others

Pharmaceutical Packaging Product Outlook (Revenue, USD Million, 2018 - 2030)

• Primary

o Plastic Bottles

o Caps & Closures

o Parenteral Containers

o Syringes

o Vials & Ampoules

o Others

o Blister Packs

o Prefillable Inhalers

o Pouches

o Medication Tubes

o Others

• Secondary

o Prescription Containers

o Pharmaceutical Packaging Accessories

• Tertiary

Pharmaceutical Packaging Drug Delivery Mode Outlook (Revenue, USD Million, 2018 - 2030)

• Oral Drugs

• Injectables

• Topical

• Ocular/ Ophthalmic

• Nasal

• Pulmonary

• Transdermal

• IV Drugs

• Others

Pharmaceutical Packaging End-use Outlook (Revenue, USD Million, 2018 - 2030)

• Pharma Manufacturing

• Contract Packaging

• Retail Pharmacy

• Institutional Pharmacy

Pharmaceutical Packaging Regional Outlook (Revenue, USD Million, 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o Germany

o UK

o France

o Italy

o Spain

o Russia

o Turkey

• Asia Pacific

o China

o India

o Japan

o South Korea

o Australia

o Southeast Asia

• Central & South America

o Brazil

o Argentina

• Middle East & Africa

o Saudi Arabia

o UAE

o South Africa

o Egypt

Order a free sample PDF of the Pharmaceutical Packaging Market Intelligence Study, published by Grand View Research.

#Pharmaceutical Packaging Market#Pharmaceutical Packaging Market size#Pharmaceutical Packaging Market share#Pharmaceutical Packaging Market analysis#Pharmaceutical Packaging Industry

0 notes

Text

Why Soft-Touch HDPE Bottles Are Revolutionizing the Personal Care Industry

Soft-Touch HDPE bottles are making a significant impact on various packaging innovations. These bottles are transforming how consumers perceive and experience products. In this blog, we’ll explore why Soft-Touch HDPE bottles are revolutionizing the personal care industry and what sets them apart from traditional packaging options.

Understanding Soft-Touch HDPE Bottles

Definition and Composition

Soft-Touch HDPE Bottles: These bottles are made from High-Density Polyethylene (HDPE) with a soft-touch finish, offering a unique tactile experience.

HDPE Properties: Known for its strength, durability, and resistance to impact and chemicals, HDPE is a preferred choice for packaging. The soft-touch coating enhances these properties by adding a premium feel.

Manufacturing Process

Production: Soft-Touch HDPE bottles are produced using advanced molding techniques that incorporate a special coating to achieve a velvety, smooth finish.

Difference from Traditional HDPE: While traditional HDPE bottles are functional and durable, they lack the sensory appeal provided by the soft-touch finish, which elevates the overall product experience.

Benefits of Soft-Touch HDPE Bottles in the Personal Care Industry

Enhanced Aesthetic Appeal

Tactile and Visual Appeal: The soft-touch finish gives the bottle a luxurious look and feel, which can make a product stand out on the shelf.

Influence on Consumer Perception: The premium feel of Soft-Touch bottles can enhance the perceived value of the product, helping brands attract and retain customers.

Improved User Experience

Ergonomic Benefits: The soft-touch surface provides a comfortable grip, making the bottle easier to handle and use.

Impact on Satisfaction: A positive tactile experience can lead to higher consumer satisfaction and more enjoyable product usage.

Durability and Safety

Comparison with Other Materials: Soft-Touch HDPE bottles are robust and resistant to breaking, compared to alternatives like glass or less durable plastics.

Safety Features: These bottles can withstand the rigors of daily use, ensuring that the product remains safe and intact throughout its lifespan.

Eco-Friendly Attributes

Recycled Content: Many Soft-Touch HDPE bottles are made from recycled materials, supporting sustainability efforts.

Recyclability: HDPE is widely recyclable, making these bottles an environmentally friendly option compared to non-recyclable materials.

Case Studies and Examples

Industry Adoption

Successful Brands: Leading personal care brands have adopted Soft-Touch HDPE bottles to enhance their product offerings. For example, high-end skincare and cosmetic brands use these bottles to convey luxury and quality.

Impact on Sales: Brands that have integrated Soft-Touch HDPE bottles report increased consumer interest and improved brand loyalty due to the enhanced product presentation and user experience.

Consumer Feedback

Positive Reviews: Consumers appreciate the comfortable grip and elegant appearance of Soft-Touch bottles. Many reviews highlight the added value and premium feel that these bottles bring to their personal care routines.

Shaping Trends: Consumer preferences for more engaging and tactile packaging are driving the trend toward Soft-Touch HDPE bottles.

Future Trends and Innovations

Emerging Technologies

Innovations in Manufacturing: Advances in coating technology are enabling even more refined and diverse textures for Soft-Touch HDPE bottles, offering brands new ways to differentiate their products.

Future Trends: As sustainability and consumer experience continue to be top priorities, Soft-Touch HDPE bottles are likely to see increased adoption across various personal care segments.

Potential Market Growth

Growth Predictions: The market for Soft-Touch HDPE bottles is expected to grow as more brands recognize their benefits and incorporate them into their packaging strategies.

Driving Factors: Increased consumer demand for premium and eco-friendly packaging solutions is a key factor driving this growth.

Conclusion

Soft-Touch HDPE bottles are more than just a packaging trend; they are a revolution in how personal care products are presented and experienced. With their enhanced aesthetic appeal, improved user experience, durability, and eco-friendly attributes, these bottles are setting new standards in the industry. As brands continue to seek ways to stand out and connect with consumers, Soft-Touch HDPE bottles offer a compelling solution.

At Regent Plast, we specialize in crafting high-quality HDPE bottles, including our innovative Soft-Touch range. Our Soft-Touch HDPE bottles combine durability with a premium tactile experience, making them the perfect choice for personal care brands looking to elevate their packaging. Contact Regent Plast today to discover how our Soft-Touch HDPE bottles can enhance your product’s appeal and contribute to your brand’s success

Read More:- https://regentplast.com/why-soft-touch-hdpe-bottles-are-revolutionizing-the-personal-care-industry/

0 notes

Text

Marketing through Packaging: The Impact of Design on Consumer Choices

1.What kind of plastic is used for packaging?

Various types of plastics are utilized in packaging, each selected for its unique properties and suitability for specific applications. Among these, Polyethylene (PE) stands out as the most used plastic, prized for its remarkable flexibility and excellent moisture resistance. This versatility makes it an ideal material for a wide range of applications, including shopping bags, food wraps, and protective films. Its ability to be produced in various densities, such as low-density polyethylene (LDPE) and high-density polyethylene (HDPE), allows manufacturers to tailor its properties for specific needs. For instance, LDPE is typically used for thinner, more flexible products, while HDPE is known for its strength and is often used in more robust packaging solutions such as milk jugs and detergent bottles. In contrast, Polypropylene (PP) is favoured for its greater rigidity and higher heat resistance, making it particularly suitable for applications such as containers, automotive parts, and food packaging that requires sterilization. Polyethylene Terephthalate (PET) has gained immense popularity, especially in the beverage industry, due to its remarkable strength, transparency, and recyclability, allowing for a circular economy in bottle usage. Meanwhile, Polystyrene (PS) is commonly used for disposable items such as cutlery, plates, and food containers, valued for its lightweight nature and ease of production. Polyvinyl Chloride (PVC) is often found in cling films and other flexible packaging due to its excellent barrier properties. However, the choice of plastic not only influences the functionality and durability of the packaging but also raises important considerations regarding environmental sustainability. As awareness of plastic pollution grows, the industry is increasingly tasked with finding solutions that balance performance with eco-friendly practices, leading to innovations in bioplastics and enhanced recycling methods.

2. What is the purpose of packaging design?

Packaging design serves a multifaceted purpose that extends well beyond mere aesthetics. At its core, the primary function of packaging is to safeguard the product during transportation and storage, ensuring that it arrives at the consumer in optimal condition. This protective layer is essential in preventing damage from external elements, which can include anything from physical shocks to environmental factors like moisture and temperature fluctuations. However, effective packaging does not stop at protection; it also plays a crucial role in enhancing brand identity. In a competitive market laden with alternatives, well-designed packaging helps differentiate products, making them more recognizable and memorable to consumers. This differentiation fosters brand loyalty, as consumers are more likely to repurchase products that they find visually appealing and aligned with their personal values and preferences. Moreover, effective packaging design serves as a vital communication tool that conveys essential information to the consumer. It informs users about usage instructions, nutritional content, and other pertinent details that aid in their purchasing decision. In this context, packaging can evoke emotions, tapping into consumers' values and aspirations, which can significantly influence their buying behaviour. As environmental concerns become increasingly prominent, sustainable packaging solutions have emerged as a critical component of modern design strategies. Consumers are now more aware of the ecological impact of their purchases, and they often prefer brands that prioritize sustainability in their packaging choices. Ultimately, successful packaging design seamlessly integrates functionality, branding, and sustainability, creating a compelling first impression that not only attracts consumers but also fosters long-term loyalty and satisfaction.

3. How is PVC used in packaging?

Polyvinyl chloride (PVC) has established itself as a predominant choice in the packaging industry, primarily due to its exceptional versatility and durability. This synthetic polymer is adept at serving a multitude of packaging needs, including the production of rigid containers, blister packs, and flexible film wraps. One of the key attributes of PVC is its ability to offer robust protection against various external factors, such as moisture, chemicals, and physical damage, ensuring the integrity of the products contained within. Moreover, the inherent transparency of PVC allows consumers to visually assess the product without compromising packaging quality, thereby enhancing consumer appeal. The lightweight nature of PVC not only facilitates easier handling and storage but also contributes to reduced transportation costs, ultimately leading to a lower overall environmental impact associated with logistics. Despite the numerous advantages that PVC offers, growing sustainability concerns have prompted the packaging industry to reevaluate its reliance on traditional materials. As a response, there is a concerted effort to explore innovative recycling options and sustainable alternatives that can mitigate the environmental footprint associated with PVC usage. Efforts are underway to develop eco-friendly packaging solutions that harness the beneficial properties of PVC while addressing the material's ecological implications. This dual approach not only fosters advancements in sustainable practices but also highlights the potential for PVC to adapt and evolve in a market increasingly driven by environmental consciousness. By leveraging its inherent advantages while embracing responsible manufacturing processes, the packaging industry can continue to rely on PVC as a valuable material while contributing positively to global sustainability goals.

4. What is packaging design in business?

Packaging design in business is a multifaceted discipline that encompasses the strategic creation and development of product packaging to fulfill various essential functions. At its core, packaging serves as a protective barrier for products, ensuring they remain intact during transportation and storage. However, it extends far beyond mere protection. Effective packaging design involves a meticulous selection of materials, shapes, colors, and graphics that work together to form a cohesive visual identity. This identity must resonate with the target consumer demographic, creating an immediate connection that can influence their purchasing behavior. By carefully considering these elements, businesses can craft packaging that not only safeguards the product but also captivates the consumer's eye on store shelves or online platforms. Moreover, effective packaging design plays a crucial role in the broader context of marketing strategy. It serves as a powerful communication tool, conveying essential information about a product’s features, benefits, and usage instructions. Thoughtful packaging can enhance shelf appeal, making products stand out in a crowded marketplace, while also fostering brand loyalty through consistent and recognizable design elements. By aligning packaging with overall marketing strategies, businesses can effectively differentiate their offerings from competitors, thereby driving sales and increasing market share. In today's consumer-driven environment, where first impressions count, a well-executed packaging design is not merely an accessory; it is a fundamental component of successful product marketing that can significantly influence a brand's trajectory in the marketplace.

5. What is a packaging business?

A packaging business is a vital player in the supply chain, specializing in the design, production, and distribution of packaging materials and solutions tailored to protect and promote a wide array of products. This industry encompasses a diverse range of materials, including cardboard, plastic, glass, and metal, each selected based on the specific needs of various sectors such as food and beverage, pharmaceuticals, and consumer goods. Companies within this sector prioritize the development of innovative, sustainable, and cost-effective packaging solutions that not only enhance product visibility but also ensure safety during transportation and storage. By adhering to regulatory standards and industry best practices, packaging businesses help minimize risks associated with product damage, spoilage, and contamination, thereby adding significant value to the overall supply chain. Furthermore, packaging serves as a critical component of branding and marketing strategies for businesses. Packaging companies work closely with their clients to create customized packaging options that reflect the company’s identity, values, and market positioning. This bespoke approach not only contributes to aesthetic appeal but also enhances consumer experience by making products more accessible and engaging. Effective packaging design can significantly influence consumer perception and purchasing decisions, fostering brand loyalty and satisfaction. In today’s competitive marketplace, where sustainability and eco-friendliness are increasingly prioritized, packaging businesses are also committed to developing environmentally responsible solutions that reduce waste and promote recycling, ensuring that they meet the evolving expectations of consumers and regulatory bodies alike.

0 notes

Text

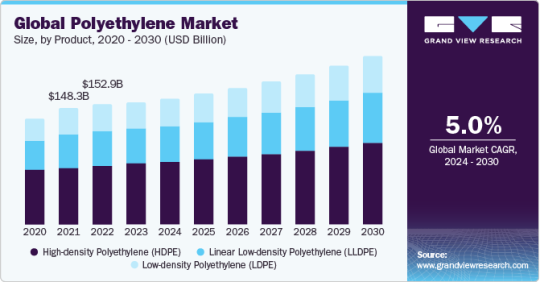

Polyethylene Market Size To Reach USD 213.77 Billion By 2030

Polyethylene Market Growth & Trends

The global polyethylene market size is anticipated to reach USD 213.77 billion by 2030, growing at a CAGR of 5.0% during the forecast period, according to a new report by Grand View Research, Inc. The market growth is driven by the increasing consumption of plastics in the automotive, medical, construction, and electrical & electronics industries. Moreover, the increasing demand for lightweight materials in the automotive industry contributes to industry growth. Polyethylene (PE) is commonly used for manufacturing lightweight plastics, films, and foams used in vehicles.

The emphasis of the automotive industry on enhancing the fuel efficiency of vehicles by reducing their weight leads to the adoption of PE in this industry. As recycling technologies advance, the PE market adapts to integrate more recycled content into its products, contributing to a more circular and resource-efficient approach. Government policies and regulations supporting sustainable practices further bolster the demand for recycled PE. The circular economy encourages the collection, separation, and reprocessing of used PE products, diverting them from landfills.

One of the major challenges faced by the market includes fluctuations in raw material prices. The global crude oil prices have witnessed severe fluctuations in the past few years. Social disruption in key crude oil-producing regions, such as Venezuela, Libya, Iran, Nigeria, and Iraq has hampered crude oil supply, generating inelasticity in the supply-demand balance. These factors are short-lived in the market causing immediate fall and rise in prices, thus impacting market growth.

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/polyethylene-pe-market

Key Polyethylene Company Insights

Key companies are adopting several organic and inorganic growth strategies, such as new product development, mergers & acquisitions, and joint ventures, to maintain and expand their market share.

In November 2023, Dow announced an investment in the Fort Saskatchewan Path2Zero project in Alberta, Canada, with an investment of USD 6.5 billion, as part of the company's goal to achieve carbon neutrality by 2050. The project involves the construction of a new ethylene plant and expanding polyethylene capacity by 2 million metric tons annually. The construction is scheduled to commence in 2024, and the increased capacity is set to be implemented in stages, with the initial phase anticipated to begin in 2027

In October 2023, Borealis AG and TotalEnergies SE announced plans to construct a USD 1.4 billion Borstar PE unit within their Baystar joint venture. This PE unit, boasting a capacity of 625,000 metric tons annually, marks a significant increase, doubling the current production capabilities at the Baystar site including two existing PE production units

In August 2023, Dow partnered with Mengniu, a dairy company, to launch a PE yogurt pouch, specifically designed for recyclability. This joint effort signifies a significant step for both companies in reinforcing their dedication to promoting a circular economy in China. The partnership with Mengniu enables both brands to take the lead in pioneering recyclable all-PE dairy packaging in the Chinese market.

Polyethylene Market Report Highlights

High-density Polyethylene (HDPE) dominated the product segment with more than 49.0% share in 2023. The demand for efficient and long-lasting solutions in water infrastructure and agriculture enhances the growth prospects of the HDPE segment

The Linear Low-density Polyethylene (LLDPE) type segment is expected to grow at the fastest CAGR of 5.5% over the forecast period

The bottles & containers application segment held a substantial market share in 2023. The sustainability trend in the packaging industry contributes to the growth of this segment

The use of recyclable materials is growing due to environmental concerns. The recyclability and compatibility of PE with recycling processes are essential for eco-conscious industries and consumers

Asia Pacific dominated the global market in 2023. The growing manufacturing industry in Asia Pacific is anticipated to drive the demand for PE

In October 2023, Borealis AG and TotalEnergies SE announced plans to construct a USD 1.4 billion Borstar PE unit within their Baystar joint venture. This PE unit, boasting a capacity of 625,000 metric tons annually, marks a significant increase, doubling the current production capabilities at the Baystar site including two existing PE production units

Regional Insights

The North America Polyethylene Market accounted for a significant revenue share of 19.2% in 2023. The shale gas boom in North America has transformed the regional PE market. The abundant and easy availability of cost-effective feedstocks derived from shale gas, particularly ethane, has given PE producers, based in North America, a significant competitive advantage.

U.S. Polyethylene Market Trends

The Polyethylene Market in the U.S.is expected to grow over the forecast period. The U.S. energy landscape, specifically the abundant availability of shale gas, is a critical driver for the PE market growth in the country. Shale gas serves as a primary feedstock for ethylene production, which is a key building block for PE. The accessibility and the cost competitiveness of shale gas contribute to the expansion of ethylene production capacities in the U.S., thereby supporting market growth.

Asia Pacific Polyethylene Market Trends

The Asia Pacific Polyethylene Market dominated the global industry in 2023 with a share of over 50.3%. Asia Pacific is a diverse market for PE owing to the growing automotive and construction industries in the region that are key consumers of this material. The growing manufacturing industry in Asia Pacific is anticipated to drive the requirement for PE.

The Polyethylene Market in China held a significant share in the Asia Pacific region. The market is anticipated to register a CAGR of 5.3% over the forecast period. Government initiatives for infrastructure development projects are driving market growth in China. The ambitious infrastructure development plans of the country, including the Belt and Road Initiative, stimulate the demand for PE in construction and related activities.

Polyethylene Market Segmentation

Grand View Research has segmented the global polyethylene market on the basis of product, application, end-use, and region:

PE Product Outlook (Volume, Kilotons, Revenue; USD Million, 2018 - 2030)

Low-density Polyethylene (LDPE)

High-density Polyethylene (HDPE)

Linear Low-density Polyethylene (LLDPE)

PE Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Bottles & Containers

Films & Sheets

Bags & Sacks

Pipes & Fittings

Other Applications

PE End-use Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Packaging

Construction

Automotive

Agriculture

Consumer Electronics

Other End-uses

PE Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

North America

Europe

Asia Pacific

Central & South America

Middle East & Africa

List of Key Players in the Polyethylene Market

BASF SE

Borealis AG

Braskem

Dow

Exxon Mobil Corporation

Formosa Plastics

INEOS Group

LG Chem

LyondellBasell Industries Holdings B.V.

Mitsubishi Chemical Corporation

MOL Group

SABIC

China Petrochemical Corporation (Sinopec)

Browse Full Report: https://www.grandviewresearch.com/industry-analysis/polyethylene-pe-market

#Polyethylene Market#Polyethylene Market Size#Polyethylene Market Share#Polyethylene Market Trends#Polyethylene Market Growth

0 notes

Text

Flat Black Shampoo Bottles Manufacturers & Suppliers in India | Singh Enterprise

In current rapid-paced global, non-public care and grooming product have turn out to be essential. Among these products, shampoos play a critical feature in retaining hair fitness and hygiene. However, the efficacy of shampoo isn't quite a whole lot the additives in the bottle; the packaging plays an equally huge role. The name for aesthetically fascinating, useful, and strong shampoo bottles is rising, especially in India, in which the non-public care organization is boosting. This blog delves into the place of Flat Black Shampoo Bottles Manufacturers and Suppliers in India, exploring the nuances of the market, the importance of nice packaging, and the critical factor game enthusiasts in the industry.

The Growing Market for Shampoo Bottles in India

The Indian non-public care market has visible exponential boost in contemporary years, driven through a growing populace, developing disposable earning, and a developing attention to private grooming. This increase has spurred the call for first-rate bottles for shampoo that are not handiest useful but additionally align with the branding goals of diverse agencies.

Shampoo bottles are available in numerous shapes, sizes, and colorations, with the flat black variant gaining reputation for its smooth and modern enchantment. These bottles are in particular favored with the beneficial aid of top price manufacturers that need to deliver an experience of luxury and sophistication. The flat design gives a minimalist appearance, while the black color provides a detail of beauty. Moreover, the one's bottles are often selected for his or her potential to protect the contents from publicity to moderate, thereby retaining the integrity of the product.

Importance of Quality in Shampoo Bottles

When it comes to bottles for shampoo, excellent is paramount. The bottle no longer needs to look particular but additionally be long lasting and useful. An exceptional shampoo bottle ensures that the product inner is covered from external factors collectively with air, moisture, and moderation that may degrade the satisfaction of the shampoo through the years.

Moreover, the bottle has to be leak-proof, clean to use, and handy for the client. A poorly designed bottle can motivate spillage, wastage, and a terrible character enjoyment. Therefore, producers of shampoo bottles want to stick to strict remarkable standards, ensuring that every bottle that leaves the producing line meets the favored specs.

Materials Used in Shampoo Bottles

The desire for fabric is an essential problem within the manufacturing of shampoo bottles. The maximum typically used substances encompass:

Plastic (PET, HDPE, LDPE): Plastic is the maximum notably used material for bottles for shampoo due to its durability, mild-weight nature, and fee-effectiveness. PET (Polyethylene Terephthalate) is specifically famous for its immoderate electricity and resistance to moisture. HDPE (High-Density Polyethylene) and LDPE (Low-Density Polyethylene) are also used for his or her flexibility and durability.

Glass: While a first-rate deal is a good deal less common than plastic, glass is used by some pinnacle rate manufacturers for its high-priced experience and environmental benefits. Glass shampoo bottles are regularly decided on for inexperienced product lines, in spite of the fact that they'll be greater fragile and heavier than plastic.

Aluminum: Aluminum bottles are gaining reputation due to their sustainability and present day aesthetic. They are lightweight, durable, and recyclable, making them a superb desire for manufacturers that prioritize environmental duty.

The Manufacturing Process of Shampoo Bottles

Manufacturing shampoo bottles consists of several steps, every requiring precision and adherence to superb necessities. The tool typically consists of:

Design and Molding: The first step in production bottles for shampoo is designing the mildew. The format needs to bear in mind the shape, period, and potential of the bottle, further to any branding factors together with trademarks or embossing. Once the design is finalized, a mildew is created that lets in you for use to form the bottles.

Blow Molding: For plastic bottles, blow molding is the maximum not unusual manufacturing manner. In this manner, a heated plastic preform is placed within the mold, and air is blown into it, forcing the plastic to take the shape of the mildew. The bottle is then cooled and ejected from the mold.

Injection Molding: Injection molding is every different approach used to manufacture shampoo bottles. In this gadget, molten plastic is injected right right right into a mold beneath high strain. Once the plastic cools and solidifies, the mildew is opened, and the bottle is eliminated.

Labeling and Finishing: After the bottles are molded, they'll be categorized and finished. This can consist of an emblem, printing product statistics, or using an ornamental end. The final step is to study the bottles for any defects and make certain they meet the required awesome necessities.

Top Manufacturers and Suppliers of Shampoo Bottles in India

India is home to several reputed producers and providers of bottles for shampoo. These agencies have set up themselves as leaders inside the corporation, supplying a good sized sort of shampoo bottles to satisfy the diverse needs of the market. Below are a number of the pinnacle producers and vendors in the world:

1. Singh Enterprises

Singh Enterprises is a first-rate producer and dealer of shampoo bottles in India, known for its big style of first rate packaging answers. The corporation makes a speciality of producing flat black shampoo bottles which may be popular amongst top elegance manufacturers. Singh Enterprises is committed to terrific innovation, making sure that its product meets the top notch enterprise requirements.

With a modern production facility and a group of expert experts, they have carved a gap within the market. The business employer gives loads of bottles for shampoo, which includes custom designs that cater to the suitable needs of its clients. Whether you're looking for famous shampoo bottles or particular, customized packaging answers, they have you protected.

2. Kripa Plastic Industries

Kripa Plastic Industries is a distinguished player within the Indian marketplace, presenting a big variety of shampoo bottles in numerous shapes, sizes, and colors. The employer prides itself on its willpower to sustainability, the use of inexperienced materials and techniques to manufacture its product.

Kripa Plastic Industries gives flat black shampoo bottles which might be each elegant and useful, making them a well-known choice among manufacturers looking to make a declaration. The commercial enterprise agency's bottles are recounted for his or her sturdiness, leak-evidence layout, and simplicity of use, making sure a pleasing enjoyment for customers.

3. Dhanlaxmi Plastic

Dhanlaxmi Plastic is a main provider of bottles for shampoo in India, catering to domestic and worldwide markets. The employer gives a wide type of packaging solutions, which incorporates flat black shampoo bottles that are tremendous for top rate manufacturers.

Dhanlaxmi Plastic makes use of the modern-day generation and substances to provide amazing shampoo bottles that meet the stringent requirements of the personal care employer. The employer moreover offers customization alternatives, permitting producers to create specific packaging that displays their identification and values.

Why Choose Flat Black Shampoo Bottles?

Flat black shampoo bottles have end up more and more famous amongst manufacturers for numerous reasons:

Aesthetics: The easy and current format of flat black bottles for shampoo affords a touch of beauty to any product. The minimalist appearance appeals to customers who decide on a clean and complicated appearance.

Branding: Black is frequently associated with steeply-priced, making it an excellent desire for top elegance manufacturers. Flat black shampoo bottles provide a splendid canvas for branding, allowing groups to create packaging that stands out at the cabinets.

Protection: The black coloration of these bottles gives safety in the path of mild, that could degrade the fantastic of the shampoo over the years. This is specifically crucial for formulations that include mild-sensitive components.

Versatility: Flat black shampoo bottles are bendy and can be used for numerous products, which includes shampoos, conditioners, and frame washes. Their regular attraction makes them a famous desire throughout precise segments of the non-public care market.

Customization Options for Shampoo Bottles

One of the important blessings of operating with principal manufacturers and vendors of bottles for shampoo in India is the functionality to customize the packaging consistent with specific logo necessities. Customization options may additionally moreover encompass:

Shape and Size: Manufacturers can create shampoo bottles in several sizes and patterns, counting on the product's goals. Whether it is a swish and slender layout or a higher and strong bottle, the alternatives are limitless.

Material: While plastic remains the maximum common material for bottles for shampoo, manufacturers can offer alternatives collectively with glass or aluminum for manufacturers searching to differentiate themselves in the market.

Color and Finish: In addition to the famous flat black choice, producers can produce shampoo bottles in quite a whole lot of sun shades and finishes. This permits manufacturers to create packaging that aligns with their visible identity.

Labeling and Decoration: Custom labeling and decoration options, which consist of embossing, debossing, and show screen printing, allow brands to create unique and first-rate shampoo bottles that resonate with their target market.

The Future of Shampoo Bottles in India

The destiny of shampoo bottles in India seems promising, with continued boost anticipated within the non-public care marketplace. As customers end up discerning, the selection for top notch, aesthetically captivating, and practical bottles for shampoo will most effectively increase.

Manufacturers and providers in India are well-located to meet this name for, imparting innovative packaging answers that cater to the evolving goals of the market. The popularity of sustainability will also strengthen the development of green shampoo bottles, as manufacturers are searching out ways to lessen their environmental footprint.

Conclusion

In the aggressive global world of private care products, the packaging is virtually as critical due to the reality of the product itself. Shampoo bottles play a crucial role in defending the contents, improving the character enjoyment, and conveying the brand's identification. Flat black bottles for shampoo have emerged as a famous preference for top price manufacturers, imparting a sleek, cutting-edge, and sensible packaging answer.

India is home to several top-notch manufacturers and suppliers of shampoo bottles, which incorporates them, which is famend for its self-control to exquisite innovation. By choosing the proper shampoo bottles, producers can make certain their products stand out in the crowded market and meet the expectations of their discerning customers.

If you are searching out dependable and fantastic bottles for shampoo in India, Singh Enterprises is your circulate-to supply. With a good sized form of alternatives and customization talents, they will let you create the proper packaging method for your brand.

0 notes

Text

High Density Polyethylene (HDPE) Resins Market: Current Analysis and Forecast (2022-2028)

According to a new report published by UnivDatos Markets Insights, the High Density Polyethylene (HDPE) Resins Market was valued at more than USD 52000 million in 2020 and is expected to grow at a CAGR of around 5% from 2022-2028. The analysis has been segmented into Type (Adhesive Type HDPE Resin, Coating Type HDPE Resin); Drive Application (Films & Sheets, Injection Coatings, Blow Molding, Others); End User (Packaging, Agriculture, Building & Construction, Automotive, Others); Region/Country.

The high density polyethylene (HDPE) resins market report has been aggregated by collecting informative data on various dynamics such as market drivers, restraints, and opportunities. This innovative report makes use of several analyses to get a closer outlook on the high density polyethylene (HDPE) resins market. The high density polyethylene (HDPE) resins market report offers a detailed analysis of the latest industry developments and trending factors in the market that are influencing the market growth. Furthermore, this statistical market research repository examines and estimates the high density polyethylene (HDPE) resins market at the global and regional levels.

Market Overview

HDPE resins are high-density polyethylene plastics that are used to make products such as milk jugs, detergent bottles, and garbage bags. HDPE is strong and tough, making it an ideal material for products that need to be durable. The market for high density polyethylene (HDPE) resins is anticipated to increase as a result of the strong demand from the food and beverage industry. In keeping with this, it is anticipated that the easy accessibility of inexpensive raw materials and the high demand for multiple-use plastics worldwide because of strengthening regulations on single-use plastic will also play a significant role in promoting the growth of the high density polyethylene (HDPE) resins market. The market for high-density polyethylene (HDPE) resins is predicted to increase favorably as a result of the rising use in the manufacture of films and the growing emphasis on extending the shelf life of edible goods. For instance, in November 2020, INEOS Olefins and Polymers USA announced it had agreed on principle terms to acquire Sasol’s 50% membership interest in Gemini HDPE LLC and, thereby, to become the 100% owner of the asset. Gemini is a toll manufacturer of bimodal high-density polyethylene products.

Some of the major players operating in the market include Dow, LG Chem, LyondellBasell Industries Holdings B.V., SABIC, Exxon Mobil Corporation, BASF SE, Chevron Phillips Chemical Company LLC, Braskem, Formosa Plastics Corporation, Qatar Petrochemical Company (QAPCO) Q.P.J.S.C.

COVID-19 Impact

The recent covid-19 pandemic has disrupted the world and has brought a state of shock to the global economy. The global pandemic has impacted industries and has transformed the way packaging is delivered. The high density polyethylene (HDPE) resins market has been significantly affected during these times owing to the delay in product packaging during the pandemic.

The global high density polyethylene (HDPE) resins market report is studied thoroughly with several aspects that would help stakeholders in making their decisions more curated.

Based on type, the market is segmented into adhesive type HDPE resin, and coating type HDPE resin. The coating type HDPE resin grows a significant CAGR during the forecast period. High-density polyethylene resin of the coating type is used as a coating material. It offers strong impact resistance and good moisture barrier qualities. Due to its exceptional qualities, coating-type HDPE resin is frequently utilized in the food packaging business.

On the basis of application, the market is segmented into films & sheets, injection coatings, blow molding, and others. Films & sheets grow a significant CAGR during the forecast period. This is mainly due to the increasing use of films & sheets in the packaging industry. Films & sheets have low toughness, stiffness, and strength, and high ductility. This plastic has a high density, sturdy construction, and long life. Hence, they are also used in the manufacturing of tubes, vessels, bubblers, dosing bottles, and molded laboratory equipment due to their property of being opaque. Hence, all these factors are contributing to the growth of the market.

High Density Polyethylene (HDPE) Resins Market Geographical Segmentation Includes:

North America (United States, Canada, and Rest of North America)

Europe (Germany, United Kingdom, Spain, Italy, France, and the Rest of Europe)

Asia-Pacific (China, Japan, India, and the Rest of Asia-Pacific)

Rest of the World

North America held a significant share of the global high density polyethylene (HDPE) resins market. High-density polyethylene resin sales and supply are influenced by the major consumer industries present in the region as well as those found globally. Furthermore, due to rising demand from industries including healthcare, food and beverage, and chemicals, the packaging is the region's largest market. According to the NIST, in 2021, manufacturing contributed $2.3 trillion to U.S. GDP amounting to 12.0 % of total U.S. GDP.

The major players targeting the market include

Dow

LG Chem

LyondellBasell Industries Holdings B.V.

SABIC

Exxon Mobil Corporation

BASF SE

Chevron Phillips Chemical Company LLC

Braskem

Formosa Plastics Corporation

Qatar Petrochemical Company (QAPCO) Q.P.J.S.C.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=35036

Competitive Landscape

The degree of competition among prominent global companies has been elaborated by analyzing several leading key players operating worldwide. The specialist team of research analysts sheds light on various traits such as global market competition, market share, most recent industry advancements, innovative product launches, partnerships, mergers, or acquisitions by leading companies in the High density polyethylene (HDPE) resins market. The major players have been analyzed by using research methodologies for getting insight views on global competition.

Key questions resolved through this analytical market research report include:

• What are the latest trends, new patterns, and technological advancements in the high density polyethylene (HDPE) resins market?

• Which factors are influencing the high density polyethylene (HDPE) resins market over the forecast period?

• What are the global challenges, threats, and risks in the high density polyethylene (HDPE) resins market?

• Which factors are propelling and restraining the high density polyethylene (HDPE) resins market?

• What are the demanding global regions of the high density polyethylene (HDPE) resins market?

• What will be the global market size in the upcoming years?

• What are the crucial market acquisition strategies and policies applied by global companies?

We understand the requirement of different businesses, regions, and countries, we offer customized reports as per your requirements of business nature and geography. Please let us know If you have any custom needs.

About UnivDatos Market Insights (UMI)

Browse Other Related Research Reports from UnivDatos Market Insights

Plastic Resins Market

Thermoplastic Resins Market

Bisphenol A Market

Green Methanol Market

Ethylene Market

About UnivDatos Market Insights

UnivDatos Market Insights (UMI) is a passionate market research firm and a subsidiary of Universal Data Solutions. We believe in delivering insights through Market Intelligence Reports, Customized Business Research, and Primary Research. Our research studies are spread across topics across the world, we cover markets in over 100 countries using smart research techniques and agile methodologies. We offer in-depth studies, detailed analysis, and customized reports that help shape winning business strategies for our clients.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

0 notes

Text

Prestige Plastics: Top Quality Prestige HDPE Selling in Pakistan

Introduction

In the ever-evolving world of industrial materials, high-density polyethylene (HDPE) has emerged as a pivotal element across various sectors. In Pakistan, Prestige Plastics has positioned itself as a leading provider of top-quality HDPE, meeting the diverse needs of industries ranging from packaging to construction.

What is HDPE?

High-density polyethylene (HDPE) is a thermoplastic polymer made from petroleum. Known for its high strength-to-density ratio, HDPE is used in the production of plastic bottles, corrosion-resistant piping, and plastic lumber. It is renowned for its robustness, durability, and versatility.

The Rise of Prestige Plastics

Prestige Plastics has carved a niche for itself in the Pakistani market by consistently delivering high-quality HDPE. The company’s commitment to excellence, innovation, and customer satisfaction has earned it a reputation as a trusted supplier.

Quality Assurance

One of the key factors contributing to the success of Prestige Plastics is its rigorous quality control processes. The company adheres to international standards, ensuring that every batch of HDPE Pipe meets stringent quality criteria. This commitment to quality ensures that customers receive reliable and durable products.

Diverse Applications

Prestige Plastics caters to a wide range of industries, showcasing the versatility of their HDPE products. From packaging materials that require lightweight and durable solutions to construction projects needing robust and resilient piping, Prestige Plastics provides tailored solutions to meet specific industrial needs.

Why Choose Prestige HDPE?

Choosing Prestige HDPE comes with several advantages that make it the preferred choice for many businesses.

Superior Strength and Durability

Prestige HDPE is renowned for its superior strength and durability. This makes it ideal for applications where long-lasting and resilient materials are essential. Whether it’s for industrial piping or heavy-duty packaging, Prestige HDPE stands out for its ability to withstand harsh conditions.

Cost-Effectiveness

While maintaining top-notch quality, Prestige Plastics ensures that its HDPE products are competitively priced. This cost-effectiveness allows businesses to benefit from high-quality materials without straining their budgets.

Eco-Friendly Solutions

In an era where sustainability is paramount, Prestige Plastics is dedicated to providing eco-friendly HDPE solutions. The company’s production processes are designed to minimize environmental impact, and the HDPE products themselves are recyclable, aligning with global sustainability goals.

Customer Testimonials

The reputation of Prestige Plastics is further bolstered by positive feedback from its clients.

Industry Leaders’ Praise

Leading companies across various sectors have lauded Prestige Plastics for its exceptional HDPE products and services. Their testimonials highlight the reliability, quality, and customer-centric approach that Prestige Plastics brings to the table.

Case Studies

Several case studies demonstrate how Prestige HDPE has been instrumental in the success of large-scale projects. From enhancing the efficiency of packaging operations to ensuring the durability of infrastructure, these case studies underscore the real-world benefits of using Prestige HDPE.

Conclusion

Prestige Plastics stands at the forefront of HDPE supply in Pakistan, offering top-quality products that cater to a wide array of industrial needs. Their commitment to quality, cost-effectiveness, and sustainability makes them a preferred choice for businesses looking for reliable HDPE solutions. As industries continue to evolve, Prestige Plastics remains dedicated to providing the materials needed to drive innovation and success.

0 notes

Text

ESG Trends in the Green Packaging Industry

Green packaging or eco-friendly packaging or sustainable packaging is anything that reduces the environmental impact. When it comes to the impact of green packaging on the environment and society, it has a very high negative impact both in terms of environmental and social factors.

Fast-moving consumer goods (FMCG) companies, packaging manufacturers and retailers have taken a giant stride towards a circular economy with investments in green packaging. Consumers’ preferences for sustainable packaging and the repercussions of plastics on the environment have prompted governing bodies to look beyond plastic bans.

Spain introduced Plastic Tax (a special tax on non-reusable plastic packaging) by Law 7/2022 to promote a circular economy and manage waste and contaminated soil; the law came into force on January 1, 2023. In August 2021, the Whitehouse introduced REDUCE (Rewarding Efforts to Decrease Unrecycled Contaminants in Ecosystems) Act to encourage recycling and impose a USD 0.10 per pound fee on virgin plastic resins used for the single-use product, rising up to USD 0.20 per pound in 2024.