#Green Automotive Fluids Sector

Explore tagged Tumblr posts

Text

Global Electric Vehicle Fluids Market Forecast to 2030: Engine Oil and Coolants Lead Product Demand

The Electric Vehicle Fluids market is projected to reach USD 8,644 million by 2030, at a CAGR of 31.2% from USD 749 million in 2021. The major factor driving the demand for electric vehicle fluids is an increase in electric vehicle production. With the growing concern over tailpipe emissions and their harmful effects on the environment, stringent standards for carbon dioxide and pollutants such…

#Electric Vehicle Battery Fluids Segment#Electric Vehicle Fluids Market#Electric Vehicle Fluids market share#Electric Vehicle Fluids market trends#EV Coolant Industry#EV Transmission Fluids Market#Green Automotive Fluids Sector#Sustainable Automotive Fluids Market

0 notes

Text

The Strategic Role of Lubricant Plants in Global Industrial Growth

In the industrial world, where efficiency and reliability are paramount, lubricant plants serve as a cornerstone for smooth operations. These facilities are designed to produce high-quality lubricants that minimize friction, protect machinery, and support industrial growth. The role of a lubricant plant manufacturer in India is particularly vital, as the country emerges as a global hub for manufacturing and sustainable solutions. Among the notable players in this field, Advance Biofuel has established itself as a leader in delivering cutting-edge lubricant plants.

The Purpose of Lubricant Plants

At the heart of industrial productivity lies the critical function of lubrication. Lubricant plants are responsible for creating products that ensure machinery operates efficiently, reducing wear and tear while enhancing durability. These plants produce a variety of lubricants, including oils, greases, and specialty fluids, tailored to meet diverse industrial demands.

Key operations of lubricant plants include:

Blending Technology: Crafting precise formulations by combining base oils with performance-enhancing additives.

Quality Control: Ensuring that every batch meets stringent performance standards for reliability.

Sustainable Practices: Adopting eco-conscious methods to minimize waste and emissions during production.

These facilities are indispensable in industries such as automotive, aerospace, manufacturing, and energy, where the reliability of machinery directly impacts productivity.

The Significance of Lubricant Plant Manufacturers in India

India's manufacturing sector has grown rapidly, supported by innovative technologies and skilled professionals. A lubricant plant manufacturer in India caters to the increasing demand for high-performance lubricants, addressing challenges faced by both domestic and international industries.

Indian manufacturers bring value through:

Advanced Infrastructure: Utilizing state-of-the-art technology to produce efficient and reliable plants.

Cost-Effective Solutions: Providing world-class products at competitive prices, making India a preferred destination for industrial buyers.

Environmental Responsibility: Aligning with global sustainability goals by integrating green practices into their processes.

Advance Biofuel: A Trusted Name in Lubricant Plant Manufacturing

Among the leading lubricant plant manufacturers in India, Advance Biofuel has earned a reputation for excellence. The company specializes in developing and supplying top-tier lubricant plants that cater to the evolving needs of industries worldwide.

What Sets Advance Biofuel Apart?

Custom Solutions: Advance Biofuel designs plants tailored to specific industrial applications, ensuring optimal performance.

Energy Efficiency: Their plants are built with energy-saving technologies that reduce operational costs.

Eco-Friendly Operations: From recycling systems to renewable energy integration, sustainability is at the core of their manufacturing processes.

Global Standards: Adhering to international benchmarks, their plants ensure reliability and superior output.

Advance Biofuel’s dedication to quality and innovation has positioned it as a trusted partner for industries seeking efficient lubricant production solutions.

How Lubricants Drive Industrial Growth

Lubricants produced by these plants are essential for maintaining the efficiency and longevity of industrial equipment. They deliver several critical benefits:

Reduced FrictionBy minimizing friction between moving parts, lubricants prevent wear, ensuring machinery operates smoothly.

Heat ManagementLubricants help dissipate heat generated during operations, maintaining optimal temperatures and preventing damage.

Extended Equipment LifeRegular lubrication protects machinery from corrosion and wear, reducing the need for frequent repairs or replacements.

Energy ConservationBy reducing resistance, lubricants improve energy efficiency, lowering operational costs.

Sustainability in Lubricant Manufacturing

Modern lubricant plants prioritize sustainability, recognizing the importance of eco-friendly practices in industrial operations. Indian manufacturers, including Advance Biofuel, are at the forefront of these efforts, implementing green technologies to reduce environmental impact.

Key Sustainable Practices:

Bio-Based Lubricants: Using renewable resources to create biodegradable products.

Recycling Systems: Developing processes to recondition and reuse lubricants, minimizing waste.

Energy Optimization: Incorporating efficient technologies to reduce energy consumption during production.

The Global Impact of Lubricant Plants

The contributions of lubricant plants extend far beyond their immediate products. They play a strategic role in driving industrial growth, ensuring the smooth functioning of essential sectors.

Key Contributions:

Enhanced Productivity: Reliable lubrication minimizes downtime, boosting overall productivity.

Economic Impact: The lubricant industry supports job creation, export growth, and technological advancements.

Sustainability Advocacy: Eco-friendly production aligns with global efforts to reduce environmental footprints.

The Road Ahead

The demand for high-performance lubricants continues to grow as industries expand and adopt advanced technologies. The future of lubricant plants will be shaped by innovations in automation, bio-based products, and sustainable practices.

Manufacturers like Advance Biofuel are well-equipped to lead this evolution, offering plants that meet the dynamic needs of modern industries while adhering to strict environmental standards.

Conclusion

Lubricant plants are the backbone of industrial efficiency, enabling machinery to operate reliably while supporting sustainability goals. A lubricant plant manufacturer in India plays a crucial role in addressing the needs of both local and global markets.

Advance Biofuel, with its focus on quality, customization, and environmental responsibility, exemplifies the best of what the industry has to offer. As industries continue to grow and evolve, the strategic role of lubricant plants will remain vital in driving progress and sustainability.

0 notes

Text

Base Oil Market Key Insights: Global Trends and Growth Forecasts by 2031

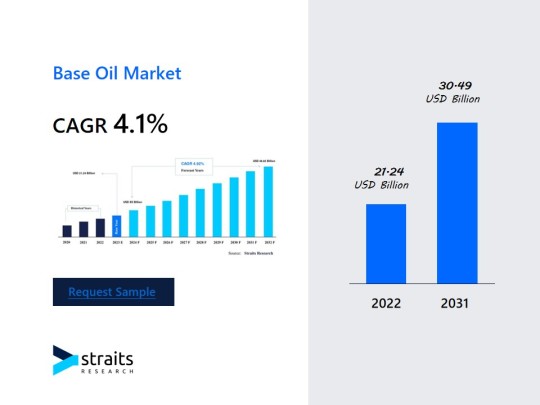

The global base oil market was valued at USD 21.24 billion in 2022. It is projected to grow from USD 22.76 billion in 2023 to USD 48.82 billion by 2031, registering a compound annual growth rate (CAGR) of 4.92% during the forecast period (2023–2031).

Overview of the Base Oil Market

The global base oil market is on a robust growth trajectory, driven by increasing demand for high-performance lubricants across various industries. Base oils, the primary ingredients in lubricants, play a crucial role in the formulation of oils used for automotive, industrial, and metalworking applications. As industrial activity ramps up worldwide and the automotive sector continues its evolution, base oils are expected to experience heightened demand in the coming years.

In 2022, the base oil market was valued at USD 21.24 billion and is forecasted to expand to USD 48.82 billion by 2031, growing at a CAGR of 4.92%. This growth is attributed to the increasing industrialization in emerging markets, rising demand for advanced lubricants, and a greater focus on energy-efficient solutions.

Market Definition

Base oils are refined from crude oil and used as the foundation for creating lubricants, oils, and other products, such as hydraulic fluids, metalworking fluids, and automotive oils. The classification of base oils is determined by their performance properties, with each type offering specific benefits based on application requirements. As key raw materials for a range of applications, base oils are essential to maintaining the smooth operation of machinery and vehicles.

Get a Full PDF Sample Copy of the Report @ https://straitsresearch.com/report/base-oil-market/request-sample

Market Dynamics: Key Trends, Drivers, and Opportunities

Key Trends:

Growing Adoption of Synthetic and High-Performance Oils: There is an increasing shift toward synthetic and high-performance base oils, particularly Group III and Group IV oils, which offer better oxidation stability, improved low-temperature performance, and longer-lasting protection for engines and industrial machinery. This trend is expected to accelerate as consumers and industries alike seek more efficient and durable oils.

Integration of Green and Sustainable Technologies: As environmental concerns continue to rise, there is a growing emphasis on the development of eco-friendly and sustainable base oils. The industry is witnessing innovations in bio-based oils and processes that use renewable feedstocks, reducing the overall carbon footprint of oil production and usage. This shift aligns with global sustainability goals and is likely to enhance market prospects.

Key Market Drivers:

Industrial Growth and Expansion in Emerging Markets: The expansion of industrial activities in emerging markets, particularly in Asia-Pacific, is one of the primary drivers for the base oil market. Rapid infrastructure development, increased manufacturing capacity, and growing demand for automotive lubricants are propelling the need for high-quality base oils. As industrial production ramps up, base oils will continue to be in high demand for applications ranging from hydraulic oils to industrial lubricants.

Technological Advancements in Lubricants and Oils: Advancements in lubricant technology, especially the demand for more energy-efficient and high-performance oils in automotive and industrial applications, are significantly driving the base oil market. Group II and Group III base oils, known for their superior properties, are gaining popularity due to their enhanced performance in high-temperature environments and longer service life.

Key Market Opportunities:

Expanding Automotive Sector and Electric Vehicle Production: As the automotive sector continues to grow, especially in emerging economies, the demand for lubricants is increasing. Additionally, the rise of electric vehicles (EVs) presents a unique opportunity for the base oil market. Even though electric vehicles require fewer oils and lubricants, the growing market for hybrid and electric vehicles will necessitate a shift toward specialized lubricants, creating new opportunities for base oil manufacturers.

Rising Demand for Metalworking Fluids and Hydraulic Oils: Base oils used in metalworking fluids, industrial oils, and hydraulic fluids represent a significant opportunity for market growth. As industries such as construction, mining, and manufacturing expand, the demand for high-performance industrial oils and lubricants is rising, offering strong growth prospects for the base oil market.

Market Segmentation

The base oil market is segmented based on type, application, and end-user industry. This segmentation helps understand the market's diverse needs and the opportunities available across various sectors.

By Type:

Group I

Group II

Group III

Group IV

Group V

By Application:

Hydraulic Oil

Automotive Fluid

Metalworking Fluids

Industrial Oil

Other

By End-User:

Industry

Construction

Automobile

Agriculture

Marine

Other

For more detailed segmentation and insights, visit: https://straitsresearch.com/report/base-oil-market/segmentation

Key Players in the Base Oil Market

The base oil market is highly competitive, with several global players leading the way in product innovation, capacity expansion, and market consolidation. The key players in the market include:

Royal Dutch Shell PLC

Exxon Mobil Corporation

H&R Ölwerke Schindler GmbH

Chevron Corporation

BP plc

Saudi Arabian Oil Co.

Petronas Pvt. Ltd.

Evonik Industries AG

Ergon Inc.

Nynas AB

Total S.A.

SK Lubricants Co. Ltd

S-Oil Corporation

Sinopec Group

Repsol S.A.

PetroChina Company Limited

Neste Oil

MOGoil GmbH

Lotos Oil SP. Z O.O.

GS Caltex Corporation

Calumet Specialty Products Partners Lp

Avista Oil AG

These companies are focusing on expanding their production capabilities, enhancing product quality, and exploring new geographic markets to tap into the growing demand for high-performance base oils.

Regional Analysis

Dominated Region: The Asia-Pacific region is the largest market for base oils, driven by the rapid industrialization in countries like China, India, and Japan. The region's booming automotive and manufacturing sectors, along with increasing infrastructure projects, are fueling the demand for base oils in various applications, such as automotive lubricants, industrial oils, and hydraulic fluids.

Fastest Growing Region: North America is expected to be the fastest-growing region for the base oil market. The U.S. and Canada are focusing on sustainable technologies and improving automotive and industrial production. Additionally, the rising demand for high-performance lubricants and oils is driving market growth in this region.

Conclusion

The base oil market is poised for significant growth, driven by industrial expansion, technological advancements, and the increasing need for high-performance lubricants. With a projected CAGR of 4.92%, the market is set to reach USD 48.82 billion by 2031. As demand grows across various industries, particularly in emerging markets, base oil manufacturers are well-positioned to capitalize on the opportunities in the automotive, industrial, and metalworking sectors.

For more information or to customize the report before purchasing, visit: https://straitsresearch.com/buy-now/base-oil-market

About Us:

StraitsResearch.com is a leading market research and market intelligence organization, specializing in research, analytics, and advisory services along with providing business insights & market research reports.

Contact Us:

Email: [email protected] Tel: +1 646 905 0080 (U.S.), +44 203 695 0070 (U.K.) Website: https://straitsresearch.com/

0 notes

Text

Cash For Cars: Transforming the Way People Sell Their Vehicles

The Cash For Cars industry has revolutionized the traditional vehicle selling process, offering a streamlined alternative to private sales and dealer trade-ins. This rapidly growing sector provides immediate payment for vehicles of all conditions, creating an efficient marketplace for sellers seeking quick, hassle-free transactions.

Unlike conventional selling methods that often involve lengthy negotiations and uncertain timelines, cash for cars Oahu services typically complete transactions within 24-48 hours. These companies have developed sophisticated valuation systems that consider multiple factors, including make, model, year, condition, mileage, and local market demand, to provide competitive offers quickly.

The process typically begins with an initial assessment, either online or over the phone, where sellers provide basic vehicle information. Modern cars for cash Oahu companies utilize advanced digital tools to generate preliminary offers, often incorporating real-time market data and regional pricing trends. Following this initial step, an in-person inspection confirms the vehicle's condition and finalizes the offer.

One significant advantage of these services is their willingness to purchase vehicles in any condition. Whether dealing with running cars, damaged vehicles, salvage titles, or even complete wrecks, Cash For Cars businesses maintain relationships with various automotive industry sectors, including dealerships, auction houses, and salvage yards, enabling them to profit from vehicles in any state.

Environmental responsibility plays an increasingly important role in the industry. Many Cash For Cars companies participate in green initiatives, ensuring proper disposal of automotive fluids and recycling of materials. This commitment to environmental stewardship has helped improve the industry's reputation and attract environmentally conscious sellers.

The advent of mobile services has further enhanced the convenience factor. Many companies now offer free vehicle pickup, handling all paperwork and transfer requirements at the seller's location. This door-to-door service particularly appeals to sellers with non-operational vehicles or busy schedules.

Competition within the industry has led to service innovations and improved customer experiences. Leading companies now offer price-matching guarantees, same-day payment options, and comprehensive documentation services. Some have expanded into multilingual services to serve diverse communities better.

For sellers, the benefits extend beyond convenience. Cash For Cars services eliminate the risks associated with private sales, such as payment fraud or liability issues. They also handle all DMV paperwork, ensuring proper transfer of ownership and providing sellers with necessary documentation for their records.

The industry has adapted to modern technology, with many companies developing user-friendly mobile apps and online platforms. These digital tools allow sellers to upload vehicle photos, receive instant quotes, and schedule pickups, making the entire process more efficient and transparent.

Market analysis shows that Cash For Cars services often provide competitive offers, particularly for older or damaged vehicles that might be difficult to sell through traditional channels. While prices might be slightly lower than private sale maximums, the convenience and immediacy of payment often outweigh the difference for many sellers.

Looking ahead, the Cash For Cars industry continues to evolve, incorporating new technologies and expanding service offerings. The growing focus on sustainability and the increasing demand for convenient selling options suggest continued growth for this innovative sector of the automotive market. https://www.autozillahawaii.com/

0 notes

Text

The Role of Steel Pipes & Tubes in India’s Infrastructure Development

When it comes to selecting the best steel pipes and tubes manufacturers in India, quality, durability, and industry reputation play pivotal roles. In India, the steel industry has grown exponentially, providing a wide range of products catering to sectors like construction, automotive, oil and gas, and more. One of the leading players in this sector is SMM Industries, known for its exceptional manufacturing standards and customer satisfaction. Their importance can be attributed to their strength, versatility, and durability, which make them ideal for supporting long-term infrastructure projects across the country.

1. Foundation for Construction Projects

Best steel pipes and tubes manufacturers in India are essential in modern construction, forming the framework for skyscrapers, bridges, and industrial structures. Their high tensile strength ensures that these structures can withstand natural forces such as wind, earthquakes, and heavy loads. In India, where urbanization is rapidly growing, steel provides the backbone for sustainable, high-rise buildings and expansive industrial complexes.

2. Transportation Networks

India’s vast and evolving transportation networks, including railways, highways, and ports, rely heavily on steel pipes and tubes. These materials are used in the construction of railway tracks, bridges, tunnels, and even airports. Steel pipes also contribute to India’s oil and gas pipelines, crucial for transporting energy across the country. Without steel, these transportation systems would lack the durability and efficiency required to meet growing demand.

3. Water Supply and Sanitation

The role of steel in water infrastructure is pivotal, as steel pipes are commonly used for the transportation of water and wastewater. In urban water supply networks, steel pipes ensure the efficient movement of water to homes and industries. In rural areas, they are used in bore wells and irrigation systems, helping to support agriculture. As India continues to work on improving water accessibility and sanitation, steel pipes and tubes remain at the core of this effort.

4. Energy and Power Generation

Steel pipes and tubes are vital components in the power generation sector. They are used in thermal, nuclear, and renewable energy plants to transport fluids and gases at high temperatures and pressures. India’s ambitious energy goals, including an increase in renewable energy capacity, depend on robust and reliable steel infrastructure to ensure the smooth transmission of energy.

5. Sustainability and Longevity

One of the key benefits of best steel pipes and tubes manufacturers in India is their recyclability and long lifespan. As India focuses on sustainable development, steel’s ability to be recycled and reused without losing its quality is a significant advantage. This contributes to the environmental sustainability of infrastructure projects, aligning with India’s push towards green development.

Conclusion

For those seeking top-tier best steel pipes and tubes manufacturers in India, SMM Industries stands out as a trusted partner. With a reputation for quality, innovation, and customer-centric solutions, SMM Industries is a leader in the steel manufacturing space. Whether you’re looking for standard products or customized solutions, they deliver unmatched performance every time.

If you’re interested in learning more about their offerings or want to explore their full product range, feel free to reach out to SMM Industries today!

To Know More https://www.smmindustriesllp.com/the-role-of-steel-pipes-tubes-in-indias-infrastructure-development/

0 notes

Text

What Is Stainless Steel Forged Fittings And Benefits Of Selecting Right Stainless Steel Tube Manufacturers In India

SS forged fittings are taking more and more applications in all the sectors of industries nowadays. This is because they have higher strength, durability, and resistance to corrosion. Among the fittings are elbows, tees, couplings, and flanges. In piping system connections, these fittings are playing a very important role. This is because the interlock of pipes that performs fluid and gas transfer systems requires correct fitting connections.

The Stainless Steel Forged Fittings manufacturing process subjects the metal material to pressurizing that introduces a high tensile property aside from the improvement in resistance generally. This process, in this case, enhances the fitting's strength aside from being exceptional in being under pressure and at high temperatures. This allows use of the product in many industrial applications, such as oil and gas and chemical processing, and construction.

The excellent characteristic of stainless steel is that this material does not easily corrode or rust. This attribute is essential when the temperature condition is extreme and exposure to strong chemicals; hence, such application can reduce maintenance cost and the downtime thereby leading to more efficient operations as a result of stainless steel forged fittings.

Demand for stainless steel forged fittings is growing at a rapid rate in India due to rapid industrialization and infrastructural development in this country. Commitment of this country towards the improvement of manufacturing capabilities has led the increase in local production where more manufacturers are investing in advanced technology and skilled labor for producing high-quality products compatible with international standards.

And hence, if on the line of sustainability, then one buzzword that has of late started coming into industrial practice is the recyclability of stainless steel. It essentially means taking materials back for use without having to compromise with quality-totally environmentally friendly on the producers' and industries' end.

Conclusion It is evident from the above description that stainless steel forgings have formed an integral part of modern industrial application. Strength, durability, and resistance to corrosion have ensured reliable performance in various sectors. Ahead of the road for Indian manufacturers, lying on the axis of innovation and increased production capacities, stainless steel forged fittings will open up their scope both in domestic and international markets.

Stainless steel tubes have played an essential role in a high-profile industry like automotive, aerospace, construction, and pharmaceuticals. India boasts itself as a hub that rules the world in manufacturing stainless steel tubes with flawless quality tubing solutions. Strong manufacturing infrastructure and skilled human resources, along with abundant raw materials are some of the aspects, making this country's reputation surmounting in this sector.

The high-pressure applications require Stainless Steel Tube Manufacturers In India which are prized for corrosion resistance and tensile strength as well as excellent durability. Such an excellent product needs extreme care and accurate manufacturing techniques such as seamless and welded tubing, which demand stringent requirements pertaining to the quality of the end product. The manufacturers in India have approached new technology and automation to provide better production efficiency with consistent products.

Indian government thrust area on "Make in India" initiative and infrastructure development investment has been additional fuel to growth in this stainless steel tubes industry. As expansion in the construction sector and automobile take a leap, high-grade stainless steel tubes are likely to witness long term demand pickup. In addition, call for sustainability and green economy is also driving manufacturers to work towards innovative solutions that reduce waste and enhance energy efficiency.

Many Indian stainless steel tube manufacturers are also focused on export-oriented products, catering to international markets who seek reliable and durable tubing solutions. Being in line with global quality standards and certifications has further enhanced the global footprint and long-term relations with clients globally.

Therefore, in synopsis, the growth prospects for India in respect to stainless steel tube manufacturing are vast and promising. Indian manufacturers, committed to excellence with innovative and green products, are set to become the major contender in the global market, supplying not only the Indian but also the international market.

#Stainless Steel Forged fittings#stainless steel tube manufacturers in India#Armech Alloys#Tubotech Stainless Inc

0 notes

Text

Hydraulic Fluids Market: Significance, Current Trends, and Future Outlook

The hydraulic fluids market is critical in powering machinery across various industries such as construction, manufacturing, aerospace, and automotive. These fluids enable the transmission of power in hydraulic systems by transferring force through pressurized liquid. As industrial demands evolve and sustainability takes center stage, the hydraulic fluids market is undergoing significant changes.

Hydraulic systems, which rely on pressurized fluids to generate mechanical power, have been a part of human technology for centuries. The earliest hydraulic systems can be traced back to ancient civilizations that used water as a basic hydraulic fluid to transport heavy objects and power basic machinery, such as water wheels. However, the modern concept of hydraulic fluids, as we know them today, began taking shape during the Industrial Revolution. With the rise of mechanical engines and complex machinery, there was a growing need for fluids that could facilitate smooth operations, provide lubrication, and prevent corrosion.

In the early 20th century, petroleum-based hydraulic fluids became widely used, offering superior lubrication and heat management properties compared to water-based systems. As technology advanced, the market for hydraulic fluids diversified to meet the unique needs of industries such as aerospace, automotive, and construction. Today, hydraulic fluids come in various forms, including mineral-based oils, synthetic fluids, and biodegradable options, each tailored to specific operational requirements and environmental considerations.

The global Hydraulic fluids market is valued at USD 8.7 billion in 2024 and is projected to reach USD 10.2 billion by 2029, growing at 3.2% cagr from 2024 to 2029.

Current Trends

The hydraulic fluids market is experiencing significant changes due to technological advancements, regulatory pressures, and shifting industrial priorities. One of the most prominent trends is the growing emphasis on sustainability. Environmental regulations worldwide are pushing industries to adopt eco-friendly alternatives to traditional petroleum-based fluids. This has spurred the development of biodegradable and renewable hydraulic fluids, which have a reduced environmental impact and can safely decompose without harming ecosystems. These green alternatives are gaining traction, particularly in sectors like agriculture, forestry, and marine, where environmental concerns are paramount.

Another notable trend is the rise of synthetic hydraulic fluids, which offer superior performance in extreme conditions. Synthetic fluids, made from chemically engineered base oils, provide enhanced thermal stability, oxidation resistance, and longer service life compared to their mineral-based counterparts. These fluids are particularly valuable in industries that operate in high-temperature or high-pressure environments, such as aerospace and automotive. The demand for synthetic fluids is expected to grow as industries increasingly prioritize efficiency and reduced downtime.

Additionally, the Asia-Pacific region, particularly countries like China and India, is witnessing rapid growth in the hydraulic fluids market. This can be attributed to the region’s booming construction and manufacturing industries, coupled with increasing energy consumption. As these economies continue to develop, the demand for hydraulic fluids, particularly cost-effective and high-performance thermoplastics-based insulation materials, is expected to rise.

Expert Opinions

Industry experts are optimistic about the future of the hydraulic fluids market, highlighting the importance of balancing performance with environmental sustainability. John Smith, a senior engineer at Fluid Dynamics Corp., states, “The future of hydraulic fluids lies in innovation that balances performance with environmental responsibility. As regulations become more stringent, especially in Europe and North America, industries will need to adopt biodegradable and synthetic alternatives that meet both operational needs and environmental standards.”

Practical Applications

Hydraulic fluids are indispensable across a wide range of industries. In the construction sector, hydraulic fluids power heavy machinery like excavators, loaders, and cranes. These fluids allow machines to lift, move, and operate efficiently by transferring force through the hydraulic system. In manufacturing, hydraulic systems control various operations such as pressing, molding, and assembly line movements, ensuring precision and smooth operation.

The aerospace industry relies heavily on hydraulic systems for critical functions, including controlling landing gear, wing flaps, and braking systems. These applications demand high-performance hydraulic fluids that can withstand extreme temperatures and pressures. Similarly, in the automotive industry, hydraulic fluids are used in brake systems, power steering, and suspension, ensuring the safety and functionality of vehicles.

Future Outlook

Looking ahead, the hydraulic fluids market is poised for continued growth, driven by technological advancements and a global focus on sustainability. The increasing automation of industrial processes, particularly in developing regions, will fuel demand for high-performance hydraulic systems that require advanced fluid solutions. Moreover, the transition to electric vehicles (EVs) and renewable energy infrastructure will present new opportunities for the hydraulic fluids market. EV manufacturing requires specialized hydraulic systems for battery production, while renewable energy projects like wind turbines rely on hydraulic systems for efficient operation.

The push for zero-emission industrial operations will likely accelerate innovation in the hydraulic fluids market. Companies will continue to invest in research and development to create fluids that not only enhance machinery performance but also minimize environmental impact. As industries become more conscious of their carbon footprint, the demand for biodegradable and energy-efficient hydraulic fluids is expected to grow substantially.

Download PDF Brochure :

The hydraulic fluids market plays an essential role in ensuring the smooth and efficient operation of machinery across various industries. As technological advancements and environmental concerns shape the future of industrial processes, the demand for high-performance, sustainable hydraulic fluids will continue to rise. By adopting innovative and eco-friendly fluid solutions, industries can improve operational efficiency, reduce environmental impact, and position themselves for long-term success in an increasingly competitive global market.

#hydraulic fluids market#sustainable hydraulic fluids#biodegradable fluids#synthetic hydraulic fluids#industrial machinery#aerospace hydraulics#fluid transmission

0 notes

Text

Automotive Lubricants: Key Players and Global Market Growth

The global lubricant industry is an essential component of modern industrial, automotive, and machinery sectors. Lubricants play a pivotal role in minimizing friction, preventing wear and tear, enhancing machine efficiency, and ensuring the smooth operation of engines and equipment. Over the past decade, the industry has seen dynamic changes due to advancements in technology, evolving environmental standards, and shifting consumer preferences. This blog explores key trends shaping the lubricant market, identifies major industry players, and provides an analytical conclusion on the future trajectory of the industry.

Market Trends in the Lubricant Industry

The lubricant industry is witnessing several trends that are reshaping its landscape. These include the growing demand for synthetic lubricants, the push toward bio-based and environmentally friendly products, and the increasing role of digitalization and smart lubricants. Let's delve into the major trends impacting the industry.

1. Rising Demand for Synthetic Lubricants

Synthetic lubricants are increasingly preferred due to their superior performance characteristics over traditional mineral-based lubricants. Synthetics offer greater thermal stability, longer oil drain intervals, and enhanced protection in extreme conditions such as high-temperature operations or heavy-duty machinery. As industries such as aerospace, automotive, and manufacturing demand higher performance and reduced downtime, synthetic lubricants are becoming the preferred choice.

The global market for synthetic lubricants is expected to grow at a compound annual growth rate (CAGR) of around 5% between 2024 and 2030. This is fueled by the need for efficiency in high-performance machinery and automotive systems, particularly in developed markets like North America and Europe, where strict environmental standards are encouraging the shift toward low-emission products.

2. Push Toward Bio-Based and Environmentally Friendly Lubricants

With rising environmental awareness and regulatory pressure, there is a growing emphasis on sustainability across all sectors, including the lubricant industry. Bio-based lubricants, made from renewable resources such as vegetable oils, are gaining traction as a green alternative to conventional petroleum-based lubricants. These lubricants are biodegradable and have a lower environmental footprint, making them increasingly popular, particularly in regions like Europe and North America.

Governments and regulatory bodies across the globe are introducing stringent regulations to minimize the environmental impact of industrial activities. For instance, the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation mandates the use of safer chemicals in lubricants. Such regulations are driving lubricant manufacturers to invest in R&D for developing bio-based and low-emission products.

The adoption of bio-based lubricants is especially strong in sectors like agriculture, forestry, and marine, where environmental impact is a significant concern. However, the high cost of bio-based lubricants remains a barrier to widespread adoption, especially in price-sensitive markets like Asia and Africa.

3. Growth in the Automotive Sector

The automotive industry continues to be a major consumer of lubricants, accounting for more than half of the total demand. With the global automotive market expanding, especially in emerging economies like China and India, the demand for automotive lubricants is set to grow. As the number of vehicles on the road increases, so does the need for engine oils, transmission fluids, and greases.

Electric vehicles (EVs), while reducing the need for traditional engine oils, are creating new opportunities for specialized lubricants. EVs require lubricants for components such as gearboxes, bearings, and thermal management systems, thus driving innovation in lubricant formulation. As the transition to electric mobility accelerates, manufacturers are developing fluids designed to meet the unique requirements of EVs, such as improved heat dissipation and enhanced durability.

4. Increasing Use of Smart Lubricants and IoT Integration

Digitalization is transforming various industries, and the lubricant sector is no exception. The use of smart lubricants, combined with the integration of the Internet of Things (IoT), is revolutionizing maintenance practices in industrial settings. Smart lubricants are designed to adapt to changing conditions and respond to operational needs in real-time, helping companies reduce downtime, optimize efficiency, and extend machinery life.

By integrating sensors with lubricants, industrial companies can monitor lubricant performance, viscosity, and temperature in real time. This allows for predictive maintenance, ensuring machinery operates optimally and preventing potential breakdowns. IoT-enabled lubricant systems are particularly valuable in industries like manufacturing, oil and gas, and power generation, where equipment reliability is critical.

5. Focus on Regional Expansion and Market Diversification

Leading lubricant manufacturers are focusing on expanding their regional presence to tap into high-growth markets like Asia-Pacific, Latin America, and the Middle East. These regions are experiencing rapid industrialization, urbanization, and automotive growth, creating a burgeoning demand for lubricants. Companies are strategically investing in local production facilities and distribution networks to cater to the growing needs of these markets.

At the same time, diversification into niche markets such as high-performance lubricants for aerospace, marine, and specialized industrial applications is helping companies broaden their portfolios and enhance profitability. This strategy is enabling market players to address specific customer requirements and mitigate the risk of dependence on traditional markets.

Key Market Players in the Lubricant Industry

Several global companies dominate the lubricant industry, with established brands and strong market positions. These companies are investing heavily in research and development, innovation, and sustainability to remain competitive in a rapidly evolving market.

1. Royal Dutch Shell Plc

Shell is one of the largest lubricant manufacturers globally, with a diverse portfolio of automotive, industrial, and marine lubricants. The company has a strong presence in Asia-Pacific, Europe, and North America, and holds a market share of around 12-14%. Shell’s commitment to innovation is evident in its focus on developing synthetic lubricants and low-carbon alternatives to meet the growing demand for sustainable products.

Shell’s recent investment in bio-lubricants and circular economy initiatives aligns with the industry's sustainability goals. The company is also leveraging digitalization to enhance customer experience and offer value-added services such as predictive maintenance solutions.

2. ExxonMobil Corporation

ExxonMobil is another key player, with a market share of approximately 10-12%. The company’s flagship brand, Mobil, is renowned for its high-performance synthetic lubricants, which cater to the automotive and industrial sectors. ExxonMobil is particularly strong in North America, Europe, and the Asia-Pacific region.

The company’s strategic focus on expanding its synthetic lubricant portfolio and offering advanced lubricant formulations for electric vehicles is positioning it for future growth. ExxonMobil is also investing in sustainability initiatives and has committed to reducing its carbon footprint through innovative product development.

3. BP Plc (Castrol)

BP, through its Castrol brand, holds a market share of around 8-10%. Castrol is a leader in the automotive lubricant segment, known for its high-performance engine oils and specialized products for motorsports and heavy-duty vehicles. The company’s global footprint spans Europe, North America, and Asia, where it maintains a strong presence.

BP is investing in green technologies and bio-based lubricants to meet the growing demand for environmentally friendly products. Castrol’s innovative approach to electric vehicle lubricants and its focus on developing smart lubricants for industrial applications are driving the company’s market expansion.

4. TotalEnergies SE

TotalEnergies is a leading lubricant manufacturer with a market share of approximately 7-9%. The company has a strong presence in Europe and Africa, where it supplies lubricants to the automotive, industrial, and marine sectors. TotalEnergies is committed to sustainability, and its investments in bio-based lubricants and eco-friendly product formulations are gaining traction in global markets.

The company’s focus on expanding its portfolio to include high-performance lubricants for EVs and renewable energy systems is positioning it for long-term growth in the evolving energy landscape.

5. Chevron Corporation

Chevron, with a market share of around 5-7%, is a key player in the industrial and automotive lubricant sectors. The company’s Delo brand is widely used in heavy-duty vehicles and industrial machinery. Chevron is actively investing in research and development to produce more efficient and eco-friendly lubricants, in line with global sustainability goals.

Chevron’s emphasis on expanding its synthetic lubricant offerings and enhancing its distribution network in emerging markets is expected to bolster its competitive position in the coming years.

Conclusion

The lubricant industry is undergoing significant transformation driven by technological advancements, evolving consumer preferences, and environmental regulations. Key trends such as the growing demand for synthetic and bio-based lubricants, the rise of electric vehicles, and the integration of IoT in lubricant systems are reshaping the market landscape. Leading players like Shell, ExxonMobil, BP, TotalEnergies, and Chevron are investing heavily in innovation, sustainability, and regional expansion to maintain their competitive edge. As the industry continues to evolve, the focus on balancing performance, cost-efficiency, and environmental sustainability will be crucial for market players to thrive. Companies that successfully navigate these challenges and embrace innovation are likely to lead the lubricant industry into a new era of growth and opportunity.

0 notes

Text

Oil Cooler Heat Exchanger Manufacturer & Suppliers in India

India's industrial landscape has witnessed remarkable growth, fueled by advancements in technology and an increasing demand for efficient cooling solutions. Among these solutions, oil cooler heat exchangers play a pivotal role in maintaining optimal operating temperatures for various industrial machinery and automotive applications. As the demand for these essential components grows, the spotlight shines on the leading oil cooler heat exchanger manufacturer & suppliers in India.

The Importance of Oil Cooler Heat Exchangers

Oil cooler heat exchangers are critical components in a wide range of applications, including automotive engines, hydraulic systems, and industrial machinery. They function by transferring heat from the oil to a cooling medium, usually air or water, ensuring that the oil maintains a stable temperature. This is crucial for preventing overheating, which can lead to equipment failure, reduced efficiency, and costly downtime.

In the automotive sector, oil cooler heat exchangers are indispensable for maintaining the engine oil at an optimal temperature, ensuring efficient performance and longevity of the engine. Similarly, in industrial machinery, these heat exchangers help in maintaining the hydraulic fluids at the desired temperature, thereby enhancing the operational efficiency and lifespan of the equipment.

Leading Oil Cooler Heat Exchanger Manufacturer & Suppliers in India

India boasts a number of reputable oil cooler heat exchanger manufacturer & suppliers, each known for their innovative solutions and commitment to quality. These manufacturers leverage advanced technologies and adhere to stringent quality standards to produce heat exchangers that meet the diverse needs of their clients.

XYZ Industries: A prominent name in the industry, XYZ Industries has been at the forefront of manufacturing high-performance oil cooler heat exchangers. Their products are known for their durability, efficiency, and compatibility with various industrial applications.

ABC Heat Exchangers: Specializing in customized solutions, ABC Heat Exchangers offers a wide range of oil cooler heat exchangers designed to meet specific client requirements. Their focus on innovation and quality has earned them a strong reputation in the market.

PQR Cooling Solutions: With a commitment to sustainability and energy efficiency, PQR Cooling Solutions provides advanced oil cooler heat exchangers that not only enhance performance but also contribute to energy savings. Their products are widely used in automotive and industrial applications.

Innovations and Advancements

The oil cooler heat exchanger manufacturer & suppliers in India are continuously innovating to meet the evolving demands of the market. The integration of cutting-edge materials, such as aluminum alloys and advanced composites, has significantly improved the efficiency and durability of these heat exchangers. Additionally, advancements in manufacturing techniques, including 3D printing and precision machining, have enabled the production of highly efficient and reliable heat exchangers.

Moreover, the emphasis on sustainable practices has led to the development of eco-friendly oil cooler heat exchangers. These products are designed to minimize energy consumption and reduce environmental impact, aligning with global trends towards sustainability and green manufacturing.

Conclusion

The role of oil cooler heat exchanger manufacturer & suppliers in India is indispensable in the modern industrial and automotive sectors. Their commitment to innovation, quality, and sustainability ensures that industries can rely on efficient and durable cooling solutions. As technology continues to advance, these manufacturers are poised to meet the growing demands and challenges of the market, contributing to the overall progress of India's industrial landscape.

In conclusion, the oil cooler heat exchanger manufacturer & suppliers in India are not just keeping pace with global standards but are also setting benchmarks for quality and innovation. Their efforts ensure that critical machinery operates efficiently, enhancing productivity and reducing operational costs for industries across the board.

0 notes

Text

Cleaning Up Industry: Insights into the Industrial Cleaning Chemicals Market

In the dynamic landscape of industrial operations, cleanliness and hygiene are paramount for maintaining safety, efficiency, and compliance with regulatory standards. Industrial cleaning chemicals play a crucial role in ensuring that equipment, machinery, and facilities remain free from contaminants, residues, and buildup that can compromise performance and pose health and safety risks to workers. This article explores the factors driving the growth of the industrial cleaning chemicals market and examines its significance in promoting cleanliness, productivity, and sustainability across various industrial sectors.

At the heart of the industrial cleaning chemicals market lies the need for effective, reliable, and environmentally responsible solutions for cleaning, degreasing, and sanitizing industrial equipment and surfaces. Industrial cleaning chemicals encompass a diverse range of formulations, including detergents, solvents, degreasers, disinfectants, and specialty chemicals, each tailored to specific cleaning tasks, surfaces, and contaminants. Whether it's removing grease and oil from machinery in manufacturing plants, disinfecting surfaces in food processing facilities, or degreasing equipment in automotive workshops, industrial cleaning chemicals play a critical role in maintaining operational efficiency and ensuring compliance with industry standards and regulations.

Moreover, the industrial cleaning chemicals market is driven by advancements in formulation technology, product innovation, and sustainability initiatives that enhance performance, safety, and environmental stewardship. Manufacturers of industrial cleaning chemicals invest in research and development to develop biodegradable, non-toxic, and eco-friendly formulations that minimize the use of hazardous chemicals, reduce waste generation, and mitigate environmental impact. Additionally, advancements in surfactant chemistry, enzyme technology, and microbial control enable the development of highly effective cleaning solutions that penetrate, emulsify, and remove stubborn soils, stains, and contaminants without compromising worker safety or environmental integrity.

Request the sample copy of report @ https://www.globalinsightservices.com/request-sample/GIS20144

Furthermore, the industrial cleaning chemicals market is influenced by evolving regulatory standards, industry best practices, and customer preferences that prioritize health, safety, and sustainability in cleaning operations. Regulatory agencies worldwide impose strict requirements on the use, handling, and disposal of industrial cleaning chemicals to protect human health and the environment from the adverse effects of hazardous substances. As a result, manufacturers and end-users of industrial cleaning chemicals are increasingly adopting green chemistry principles, sustainable sourcing practices, and closed-loop recycling programs to minimize environmental impact, conserve resources, and promote circular economy principles.

Additionally, the industrial cleaning chemicals market serves diverse end-user industries, including manufacturing, food and beverage, healthcare, automotive, aerospace, and hospitality, each with unique cleaning requirements and operational challenges. In manufacturing facilities, industrial cleaning chemicals are used to remove oils, lubricants, and metalworking fluids from production equipment, ensuring optimal performance and product quality. In food processing plants, cleaning and sanitation protocols are critical for preventing contamination and ensuring food safety compliance, driving demand for specialized cleaning chemicals that are safe, effective, and compatible with food contact surfaces. In healthcare facilities, stringent hygiene standards and infection control protocols require the use of hospital-grade disinfectants and sanitizers to eliminate pathogens and prevent healthcare-associated infections. In automotive workshops and service centers, industrial cleaning chemicals are essential for degreasing engines, removing brake dust, and cleaning vehicle interiors, enhancing customer satisfaction and safety.

Despite the opportunities for growth, the industrial cleaning chemicals market also faces challenges, including cost pressures, supply chain disruptions, and evolving customer expectations. Price volatility in raw materials, energy costs, and transportation expenses may impact the profitability and competitiveness of industrial cleaning chemical manufacturers and distributors, requiring prudent cost management strategies and supply chain optimization measures to maintain margins and pricing stability. Additionally, supply chain disruptions, such as natural disasters, geopolitical tensions, and global pandemics, may disrupt production, distribution, and delivery of industrial cleaning chemicals, posing challenges for manufacturers, distributors, and end-users seeking reliable and timely supply of essential cleaning products.

In conclusion, the industrial cleaning chemicals market plays a critical role in promoting cleanliness, safety, and sustainability in industrial operations worldwide. With their emphasis on performance, innovation, and environmental responsibility, industrial cleaning chemicals enable companies to maintain high standards of cleanliness, hygiene, and regulatory compliance while minimizing environmental impact and protecting human health. By understanding the factors driving the growth of the industrial cleaning chemicals market and addressing the challenges facing the industry, stakeholders can unlock opportunities to enhance operational efficiency, ensure workplace safety, and achieve sustainable growth in the years to come.

0 notes

Text

Future-Ready: Aligning Your Career Goals with B.Tech Specializations

In the rapidly evolving landscape of the 21st century, where technology and innovation drive progress, engineering remains at the forefront of shaping the future. The Bachelor of Technology (B.Tech) degree, a beacon of technical education, offers various specializations that cater to the diverse interests and career aspirations of students. Among these, B.Tech in Computer Science Engineering (CSE), Information Technology (IT), and Mechanical Engineering stand out for their relevance to current and future industry demands. Selecting the right B.Tech specialization is crucial in aligning one’s career goals with the opportunities of tomorrow, and B.Tech colleges in India are instrumental in paving the way for this alignment.

B.Tech in Computer Science Engineering (CSE) and Information Technology (IT)

B.Tech CSE and B.Tech CSE IT are among the most sought-after specializations, reflecting the digital era's growing dependency on technology. These programs equip students with the knowledge and skills to design, develop, and manage software, applications, and systems that meet the technological needs of businesses and society. With a curriculum that encompasses programming languages, data structures, algorithms, and network and database management, these specializations prepare students for a wide range of careers in the tech industry, from software development to cybersecurity.

The dynamic nature of the tech industry means that graduates must be adaptable and continually update their skills. The best B.Tech college in India for CSE IT is one that not only provides a strong foundational education but also encourages innovation, research, and practical application through projects and internships. This hands-on experience is invaluable, offering students insights into real-world challenges and the latest technological advancements.

B.Tech in Mechanical Engineering

B.Tech in Mechanical Engineering is a timeless specialization that combines the principles of engineering with physics and materials science to design, analyze, manufacture, and maintain mechanical systems. It is one of the broadest and most versatile engineering disciplines, offering opportunities across various sectors, including automotive, aerospace, energy, manufacturing, and robotics.

The curriculum for B.Tech Mechanical Engineering covers a wide range of topics, from thermodynamics and fluid mechanics to material science and control systems. With sustainability and innovation becoming increasingly important, the program also emphasizes green technologies and the development of new materials and processes. Graduates can look forward to careers in research and development, design, systems analysis, and project management, among others.

Choosing the Right B.Tech College in India

The choice of college is as crucial as the specialization itself. The best B.Tech college in India offers a robust curriculum, experienced faculty, modern facilities, and strong industry connections. These institutions provide an environment that fosters learning, innovation, and personal growth, ensuring that students are not just academically prepared but are also equipped with soft skills like teamwork, communication, and problem-solving.

Prospective students should consider factors such as the college's accreditation, faculty qualifications, placement records, research opportunities, and campus culture when making their decision. Additionally, attending college fairs, visiting campuses, and speaking with current students and alumni can provide valuable insights into what to expect.

Aligning Career Goals with B.Tech Specializations

The decision to pursue a B.Tech specialization should be informed by a combination of passion, aptitude, and market demand. Students should research the current trends and future projections in their field of interest, considering how technological advancements and societal needs might shape career opportunities. It's also important to reflect on one's strengths and interests, choosing a specialization that resonates personally and professionally.

Networking with professionals in the field, seeking mentorship, and engaging in internships and extracurricular activities related to one’s specialization can further align career goals with educational pursuits. These experiences not only enhance one’s resume but also provide a clearer understanding of the industry and potential career paths.

Conclusion

The journey to becoming future-ready through a B.Tech degree is a transformative experience that goes beyond academics. It’s about making informed decisions regarding one’s specialization and college, driven by a clear understanding of career aspirations and industry trends. B.Tech in CSE, IT, and Mechanical Engineering are just a few of the specializations that offer a gateway to exciting and rewarding careers in engineering. By choosing the right path and immersing oneself in the opportunities presented during the course, students can ensure that they are well-prepared to meet the challenges of the future head-on, equipped with the knowledge, skills, and creativity to make a significant impact in their chosen fields.

#engineering colleges in kolkata#top engineering colleges in kolkata#best engineering colleges in kolkata#top private engineering colleges in kolkata#best private engineering colleges in kolkata#private engg colleges in kolkata#top private engg colleges in kolkata

0 notes

Text

The Importance of Eco-Friendly Scrap Car Removal Mississauga

As the globe accelerates towards a greener future, the residents of Mississauga are increasingly recognizing the significance of eco-friendly car disposal methods. Sustainable scrap car services are not just a responsible choice but a necessary step in safeguarding our environment. By opting to recycle old cars, car owners in Mississauga contribute to reducing landfill waste and pollution, aligning local actions with broader global sustainability goals. This eco-conscious approach in vehicle recycling ensures that green automotive waste solutions become a staple in community practices.

Key Takeaways:

Adopting eco-friendly car disposal practices is essential for a sustainable future.

Recycling old cars reduces landfill use and pollution, benefiting the environment.

Sustainable scrap car services in Mississauga align with international eco-friendly goals.

Proper vehicle recycling aids in conserving natural resources and energy.

A commitment to green automotive waste solutions reflects community responsibility.

Understanding the Impact of Automotive Waste

The conversation about vehicle disposal is not just about making space in our garages or driveways; it's a matter of considerable environmental concern. As the awareness of sustainability grows, so does the recognition of the real-world implications of automotive waste. This section dives into the intricate details shaping the environmental discourse on scrap car removal mississauga.

The Environmental Burden of Improper Car Disposal

Improper car disposal introduces a myriad of environmental problems, from soil contamination due to leaking fluids to the release of toxins into the atmosphere. The Canadian Environmental Protection Agency's reports have raised alarms on the dangerous levels of toxic runoff that can emanate from unsustainably discarded vehicles, contaminating not only the soil but also our water systems and posing significant risks to both human health and wildlife.

Statistical Overview of Vehicle Scrap in Canada

Statistics Canada sheds light on the numbers that paint a stark picture of automotive waste. Each year, a staggering amount of vehicles reach the end of their life cycle, translating into tons of waste. Current automotive waste statistics in Canada unambiguously illustrate the growing pile of vehicle components—engines, batteries, tires, and more—that require careful and sustainable management to prevent further environmental degradation.

Challenges in Traditional Car Scrapping Methods

The issues with traditional car scrapping stem from outdated practices that fail to consider modern environmental and health standards. These methods often neglect the proper segregation and disposal of hazardous materials, leading not only to resource wastage but also to a trail of ecological damage. These pressing concerns highlight the dire need for more sustainable vehicle disposal methodologies that prioritize the planet's health.

Amidst this backdrop of challenges, there are compelling reasons to transition towards more sustainable practices in the automotive sector:

Reducing the footprint of hazardous waste

Conserving limited resources and energy

Diminishing greenhouse gas emissions

Promoting a cleaner and safer environment

Adopting responsible car disposal methods is not just beneficial—it's imperative for the health of our environment and future generations.

youtube

Scrapping Issues Sustainable Disposal Solutions

Soil and Water Contamination Enhanced Fluid Recovery Systems

Inefficient Material Recovery Advanced Material Separation

Techniques

Toxic Emissions Greenhouse Gas Control Measures

High Energy Consumption Energy-Efficient Recycling Processes

The Benefits of Choosing Green Car Recycling

Turning to green car recycling presents a myriad of advantages, both ecologically and economically. When we consider the advantages of green car recycling, we're not merely discussing the act of responsibly discarding unwanted vehicles; we're talking about a comprehensive approach to sustainability that reverberates through the entirety of our environmental ecosystem. Sustainable automotive recycling perks extend far beyond the immediate gratification of decluttering auto junkyards—they pave the way for a healthier planet.

At the core of eco-friendly vehicle disposal benefits is the significant reduction in the ecological footprint of automotive waste. Properly recycling a vehicle ensures that hazardous materials, such as lead-acid batteries and engine oils, are dealt with in a way that minimizes environmental harm. By utilizing specialist facilities and employing meticulous processes, the potential for these substances to contaminate soil and water supplies is significantly mitigated.

The conservation of resources is another critical environmental gain from vehicle recycling. It's not just about avoiding wastefulness; it's about reclaiming valuable materials and giving them new life. Through the sophisticated separation and recovery techniques employed by green car recyclers, metals, plastics, and even rubber are salvaged and repurposed. This resourcefulness leads to a substantial decrease in the need for virgin materials, which, in turn, reduces the energy required for the manufacturing of new components—thus, alleviating the pressure on our natural resources.

Furthermore, the contribution of sustainable automotive recycling to reducing greenhouse gas emissions cannot be overstated. By eliminating the need for extensive mining and processing of raw materials, we curtail the carbon footprint associated with these practices. In essence, every vehicle that goes through the recycling process instead of languishing in a landfill is a win for our atmosphere and a step towards a cooler planet.

Advantages of Green Car Recycling:

Minimizes the release of pollutants and greenhouse gases

Diminishes the dependence on landfill sites

Conserves natural resources by reducing the need for new material extraction

Eco-Friendly Vehicle Disposal Benefits:

Hazardous materials are safely disposed of or recycled

Energy consumption is significantly reduced

Contributes to the economy through the creation of green jobs

Environmental Gain from Vehicle Recycling:

Facilitates a cleaner and more sustainable environment

Helps in maintaining biodiversity by reducing habitat destruction associated with mining

Supports community health by reducing potential for contamination

Lastly, we cannot overlook the societal benefits that emanate from mindful vehicle recycling practices. Healthier communities thrive when their air and water are uncontaminated by the detritus of industrial processes. With the advancement of eco-friendly vehicle disposal methods, we ensure a planet that nurtures life rather than diminishes it, which is perhaps the most profound benefit of them all.

Recycle Your Vehicle with Scrap Car Removal Mississauga

The Process of Eco-friendly Vehicle Recycling

An eco-friendly approach to vehicle recycling involves a series of steps designed to minimize waste and reduce environmental impact. Here is the step-by-step breakdown of how your car transitions from being a non-operable vehicle to becoming a source of reusable materials:

Initial Assessment: Your vehicle's condition is assessed to determine the recyclable parts and materials.

Fluid Drainage: All hazardous fluids are safely removed and disposed of or recycled.

Part Removal: Reusable parts are dismantled and sorted for resale or remanufacture.

Material Separation: The remaining frame is processed, and materials like metal, plastic, and glass are separated.

Material Recycling: These materials are then sent to respective recycling facilities for further processing.

How Recycling Cars Preserves Natural Resources

Car recycling is much more than just crushing old cars; it presents an excellent opportunity to preserve natural resources. Here's a quick glance at the conservation impact of recycling vehicles:

Iron and Steel: Reduces the need for iron ore extraction, saving energy and reducing CO2 emissions.

Aluminum: Conserves energy as it requires less power to recycle than to produce new aluminum from bauxite.

Plastics: Limits petroleum usage for new plastic production and reduces plastic waste.

Glass: Decreases the consumption of raw materials and energy required to manufacture new glass.

The Role of Local Mississauga Services in Sustainability

Local services that facilitate Mississauga scrap car removal are integral to the sustainability efforts within our community. These services not only ensure the responsible handling and disposal of vehicles but also advance the mission to build a more sustainable and resourceful local environment. When you choose a reliable scrap car removal service in Mississauga, you're choosing a future where sustainability is a priority.

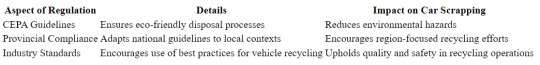

Legal and Environmental Regulations Guiding Scrap Car Removal

When it comes to the disposal of vehicles, it is not merely about getting rid of an old car but ensuring that this process is done in harmony with stringent regulations for scrap car disposal and environmental laws for vehicle recycling. Across Canada, a robust legal framework for car scrapping is established to protect our environment, spanning national to provincial levels. Understanding and adhering to these regulations is crucial for both car owners and scrap service providers, forming the backbone of compliance in automotive waste management.

The Canadian Environmental Protection Act (CEPA) stands out as one of the central pillars of environmental legislation, driving the ethical and eco-conscious recycling of vehicles. Its guidelines serve to prevent potential environmental harm that can arise from irresponsible vehicle disposal and promote the safe handling of hazardous substances contained within automotive waste.

The CEPA's rigorous standards exemplify how legislation can coalesce with industry efforts to foster a more sustainable future.

Prevention of soil and water contamination: by ensuring proper disposal of toxic vehicle fluids and batteries.

Promotion of resource conservation: through the mandated recycling of car parts and materials.

Emission reductions: by avoiding improper dismantling practices that release harmful gases.

Legal adherence also spurs a broader cultural shift towards environmental responsibility. Scrap car removal services that prioritize compliance not only contribute to a greener earth but also set an example for the industry and consumers alike. Facilitating the transition from traditional disposal methods to more sustainable practices ensures the automotive industry's alignment with Canada's environmental objectives.

As stewards of the planet, it is incumbent upon both service providers and car owners to actively engage with and uphold the legal framework for car scrapping. Doing so not only avoids legal penalties but contributes to the cultivation of a cleaner, more sustainable environment for all Canadians.

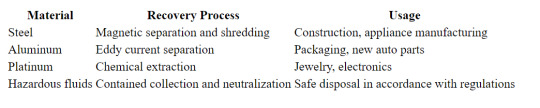

Materials Recovered in the Recycling Process

The automotive recycling industry is not just a means of disposing of unwanted vehicles; it's a hub of recycling valuable metals and ensuring sustainable materials recovery. Each vehicle brought in for recycling is a trove of materials that can be reused or disposed of in an environmentally responsible manner.

Valuable Metals and Alloys That Can Be Reused

The dismantling of a vehicle is a key procedure in recovering precious metals. It is estimated that over 14 million tonnes of steel is salvaged from scrapped cars in North America alone. These recovered metals, including steel and platinum, are then repurposed to manufacture new products, reducing the demand for virgin resources and minimizing the carbon footprint associated with metal production.

Hazardous Materials and Their Safe Disposal

Automotive recycling also plays a critical role in hazardous materials disposal. A single vehicle can contain hazardous materials such as battery acid, coolant, and brake fluid, which require careful handling. Scrap yards are committed to following stringent environmental regulations to ensure these substances do not harm the ecosystem.

Innovations in Automotive Recycling Technologies

Automotive recycling innovations have significantly improved over recent years. Advanced technologies now allow for more efficient separation and processing of different materials, which contributes to enhanced sustainable materials recovery. These processes are precise and aim to maximise the reuse of automotive components while minimising environmental impact.

Selecting the Right Service for Your Scrap Car

When it's time to retire your vehicle responsibly, selecting the right scrap car service is paramount to ensuring your car is disposed of in an eco-friendly manner. With numerous options available, focusing on a company that showcases a robust commitment to sustainability is key. Not only does this choice benefit the environment, but it also aligns with the **eco-friendly service criteria** that are becoming increasingly important for conscious consumers in Mississauga and beyond.

Criteria for Choosing Eco-Friendly Scrap Car Services

The first step in **choosing scrap car services** is to look for those that actively demonstrate environmental responsibility. Services that integrate green practices, offer transparent procedures, and prioritize the reduction of their carbon footprint are desirable. A reputable service will typically provide detailed information about their recycling process, emphasizing how they handle hazardous materials and ensure that all automotive waste is managed sustainably.

Recognizing Certifications and Environmental Standards

Certifications offer a tangible way to assess whether a scrap car service meets accepted environmental standards. Look for companies that adhere to recognized certifications such as the ISO standards for environmental management. This accreditation indicates that the service provider operates in compliance with high environmental standards and is dedicated to continuous improvement in their recycling processes.

What to Expect During the Scrap Car Pickup Process

Understanding what to anticipate when scheduling a scrap car pickup can streamline the process for car owners. Typically, the service will conduct a thorough assessment of the vehicle, complete any necessary documentation, and explain the next steps in the recycling chain. Reliable companies will also issue a certificate of destruction or recycling, giving owners the assurance that their vehicle has been disposed of according to **environmental certifications for recycling**. Knowing these **scrap car pickup expectations** can provide peace of mind that you're contributing to a greener future.

0 notes

Text

UV Curing System Companies - Heraeus (Germany) and Nordson (US) are the Leading Key Players

The UV curing system market is projected to reach USD 8.6 billion by 2026 from USD 3.6 billion in 2021; it is expected to grow at a CAGR of 18.6% from 2021 to 2026. The growth of the UV curing system market in North America is mainly driven by large-scale funded programs by the government. Moreover, the high adoption rate and technological advancements also drive the growth of the UV curing system market in North America.

The North American region is the largest market as the region is home to major players in the market such as Dymax (US), Phoseon (US), and Baldwin Technology (US). Stringent regulatory framework by agencies such as EPA (Environment Protection Agency) and the American Industrial Hygiene Association (AIHA) is playing a key role in the monitoring and commercialization of UV curing technology. The large share enjoyed by the region is due to the vast presence of various large—scale automotive and medical machinery manufacturers.

The outbreak of the novel coronavirus is expected to affect the UV curing system market, but steady recovery is expected by 2022. The expansion of the market is due to the rising demand from the semiconductor & electronics industry as well as from the medical sector. Developing countries in APAC have a vast growth potential as well as a favorable environment for product manufacturers. Therefore, the UV curing system market in APAC is expected to grow at the highest rate during the forecast period.

Growing inclination toward eco-friendly products, along with stringent regulations regarding use of green products would further fuel the adoption of UV curing systems in APAC. Furthermore, greater benefits of UV Curing systems than traditional curing systems and rising demand of UV LEDs across industries are also favoring the growth of the UV curing system market in the region.

High-growth prospects of UV curing technology in new applications and preference for UV technologies for print label and packaging due to COVID-19 are the major opportunities for the UV curing system market. On the other hand, factors such as the lack of awareness and high cost of UV curable coatings and limited depth of curing are restraining the growth of the UV curing system market. Risks related to hazardous effects of mercury present in UV mercury lamps, slowdown in production of manufacturing industries due to COVID-19 and cracking defects on UV curable coating products are few challenges that the manufacturers are facing.

Major UV Curing System companies include:

Baldwin Technology (US),

Dymax (US),

Nordson (US),

Excelitas Technologies (US),

Heraeus (Germany),

Phoseon Technology (US),